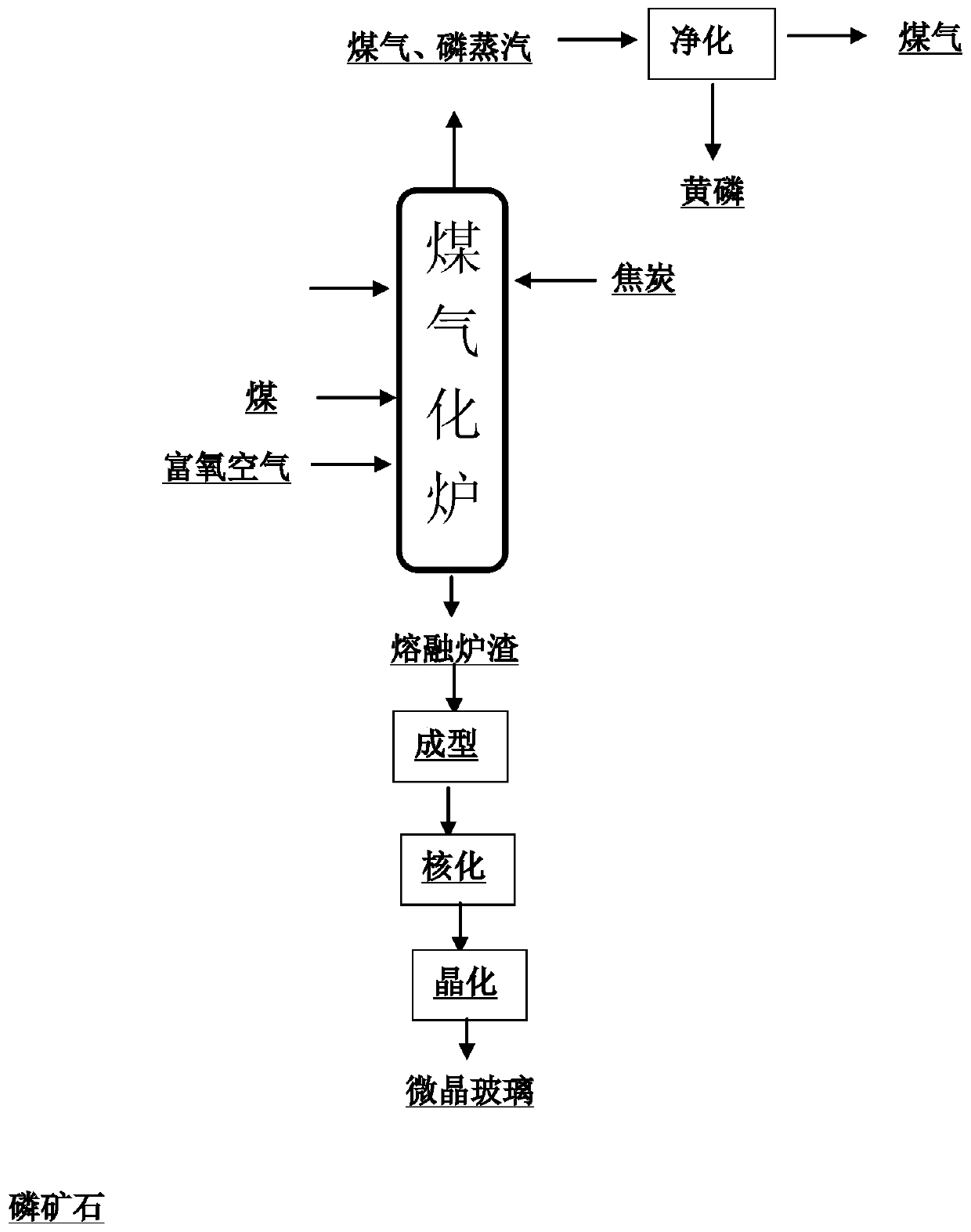

Coal gas-yellow phosphorus-building material co-production integrated method

A technology of coal gasification and yellow phosphorus, applied in the chemical industry, climate sustainability, sustainable manufacturing/processing, etc., to achieve the effects of reasonable comprehensive utilization of resources, reduced product energy consumption, and high equipment productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

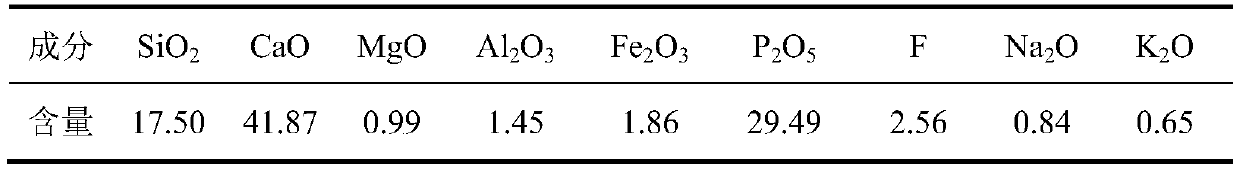

[0041] Example 1: Take 100 g of phosphate rock powder, weigh 13.1 g of coke according to the coke excess coefficient of 1.05, the total amount of the two acidic substances is 20.35 g, and the alkaline substance is 43.50 g. Every 100g of coal ash contains 82.07g of alkaline substances and 11.09g of acidic substances. If the acidity value of the slag is set to 1.2, 46.32g of coal ash needs to be added.

[0042] After the above materials are mixed, put them into a graphite crucible, put them into a quartz tube with a seal and an air outlet, use CO to discharge the air, then raise the temperature to 1500°C and keep it warm for 30 minutes. After melting for 3 hours, the temperature was raised to 900°C for crystallization for 1 hour, then the power was turned off and the furnace door was slightly opened, and the furnace was cooled down to 100°C before being taken out, and the natural environment was lowered to room temperature for data analysis.

[0043] After testing, the compressi...

Embodiment 2

[0044] Example 2: Take 100 g of phosphate rock powder, weigh 13.1 g of coke according to the coke excess coefficient of 1.05, the total amount of the two acidic substances is 20.35 g, and the alkaline substance is 43.50 g. Every 100g of coal ash contains 82.07g of alkaline substances and 11.09g of acidic substances. If the acidity value of the slag is set to 1.5, 68.61g of coal ash needs to be added.

[0045] After the above materials are mixed, put them into a graphite crucible, put them into a quartz tube with a seal and an air outlet, use CO to discharge the air, then raise the temperature to 1550°C and keep it for 25 minutes. , and then heated up to 800°C for crystallization for 1.5 hours, then cut off the power and slightly opened the furnace door, and took it out after the furnace cooled down to 100°C, and the natural environment dropped to room temperature for data analysis.

[0046] After testing, the compressive strength of the glass-ceramic is 589MPa, the Mohs hardne...

Embodiment 3

[0047] Example 3: Take 100 g of phosphate rock powder, weigh 13.1 g of coke according to the coke excess coefficient of 1.05, the total amount of the two acidic substances is 20.35 g, and the alkaline substance is 43.50 g. Every 100g of coal ash contains 82.07g of alkaline substances and 11.09g of acidic substances. If the acidity value of the slag is set to 1.8, 93.30g of coal ash needs to be added.

[0048] After the above materials are mixed, put them into a graphite crucible, put them into a quartz tube with a seal and an air outlet, use CO to discharge the air, then raise the temperature to 1600°C and keep it for 20 minutes. After melting for 3 hours, the temperature was raised to 850°C for 2 hours of crystallization, and then the power was turned off and the furnace door was slightly opened. After the furnace was cooled to 100°C, it was taken out, and the natural environment was lowered to room temperature for data analysis.

[0049] After testing, the compressive streng...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com