Multi-robot coordination control device and method

A coordinated control and multi-robot technology, applied in the direction of program-controlled manipulators, manipulators, manufacturing tools, etc., can solve the problems that are difficult to meet the diversification of industrial production line products, increase wiring and wiring work, reduce system reliability, etc., to achieve extended production performance , the use of less wiring harness, the effect of improving flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

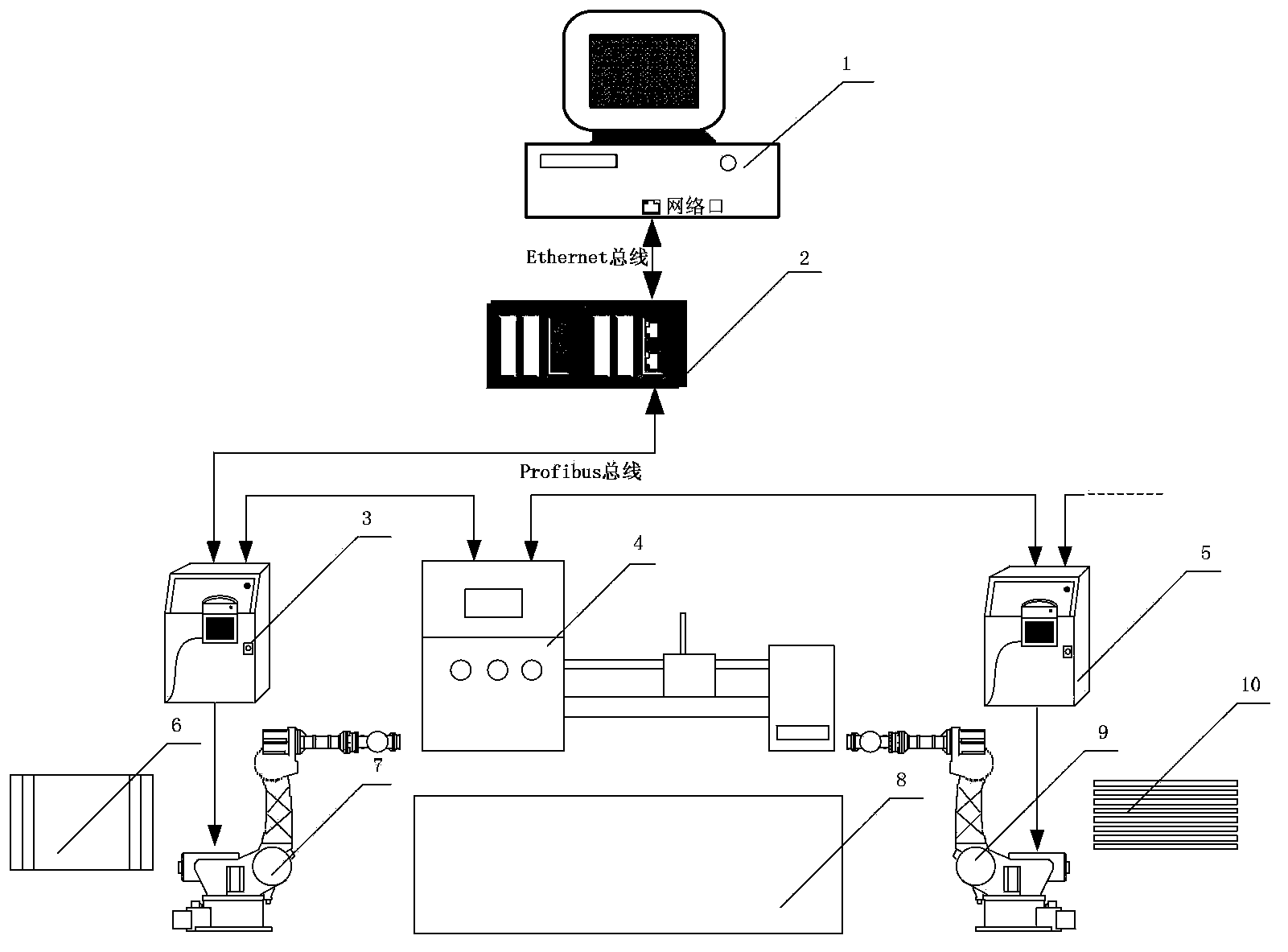

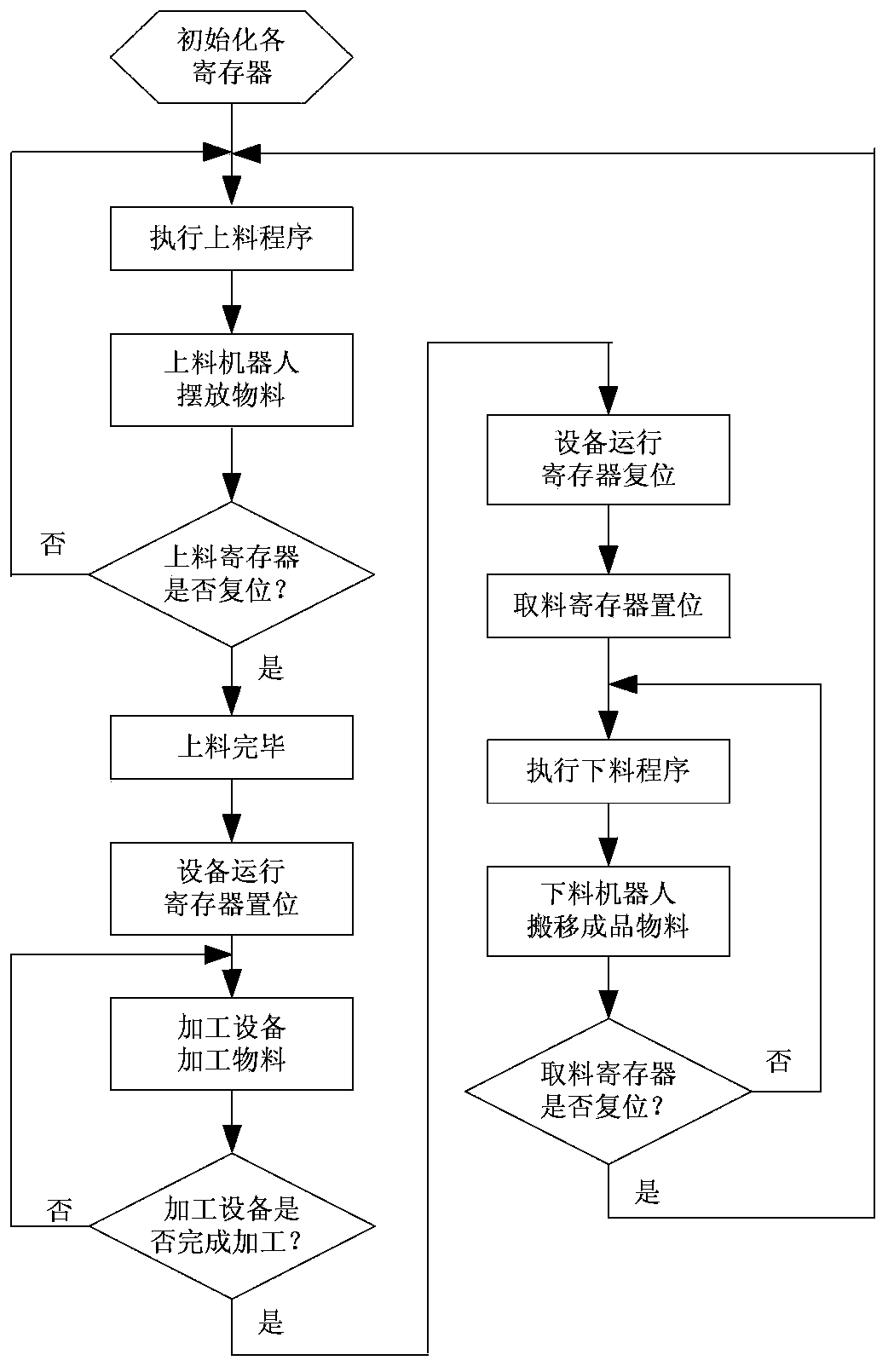

[0043] according to figure 1 , taking the system with two robots and one processing equipment as an example to illustrate the system operation process:

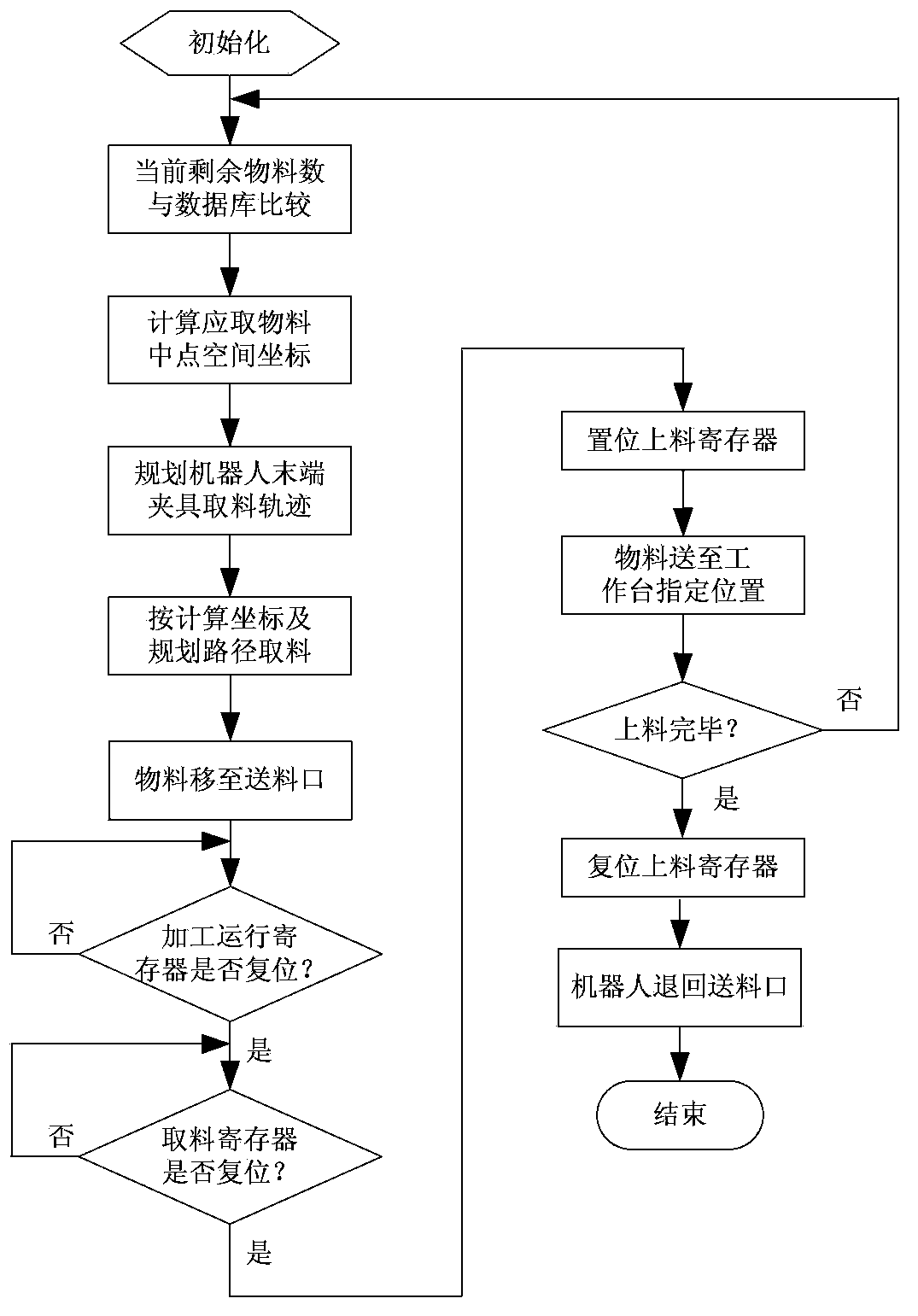

[0044] In the motion controller 2, the loading register, processing operation register and retrieving register respectively store the station status of the robot and the processing equipment, so as to fully coordinate the actions of each equipment. The operation process of the feeding robot 7 is divided into a material retrieving action and a material discharging action. The retrieving process automatically calculates the grabbing position according to the reduction of materials in the material stacking area. After grabbing, according to the preset trajectory, the material is lifted to a specific position next to the workbench. After the processing equipment is finished, the material is discharged, and the material is placed at a specific position on the workbench. The specific process is as follows:

[0045]When the device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com