Method for preparing calcium phosphate by utilizing slag charge discharged during sodium hypophosphite preparation

A technology of calcium phosphite and sodium hypophosphite, applied in the chemical industry, can solve problems such as environmental pollution and energy consumption, and achieve the effects of less investment in equipment, solving environmental pollution, and reasonable utilization of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

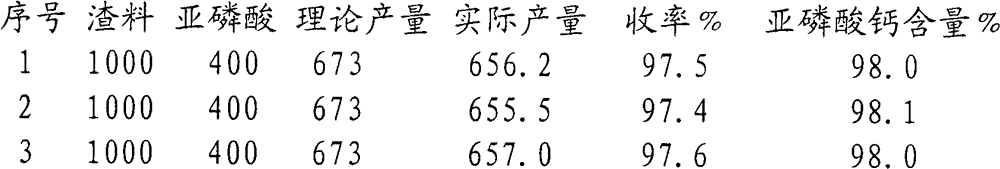

[0044] Below in conjunction with accompanying drawing 1 and attached figure 2 Examples illustrating, but not limited to, the invention are as follows:

[0045] See attached picture 1:

[0046] In Figure 1, point A calcium dihydrogen phosphite monohydrate Ca(H 2 PO 3 ) 2 ·H 2 O solid phase formation point, B point calcium phosphite monohydrate CaHPO 3 ·H 2 o

[0047]The solid phase forms a point, the point E monohydrate calcium phosphite and the monohydrate calcium phosphite co-saturated solution form a point, the curve of the saturated solubility of the line segment ME monohydrate calcium phosphite salt; the line segment DE monohydrate calcium phosphite Salt saturation solubility curve; ΔAME monohydrate calcium dihydrogen phosphite salt crystallization region, ΔEBD monohydrate calcium salt crystallization region, ΔEAB monohydrate calcium phosphite and monohydrate calcium salt crystallization of two calcium salts Area.

[0048] Below with the slag material that produce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com