Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "Reasonable separation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

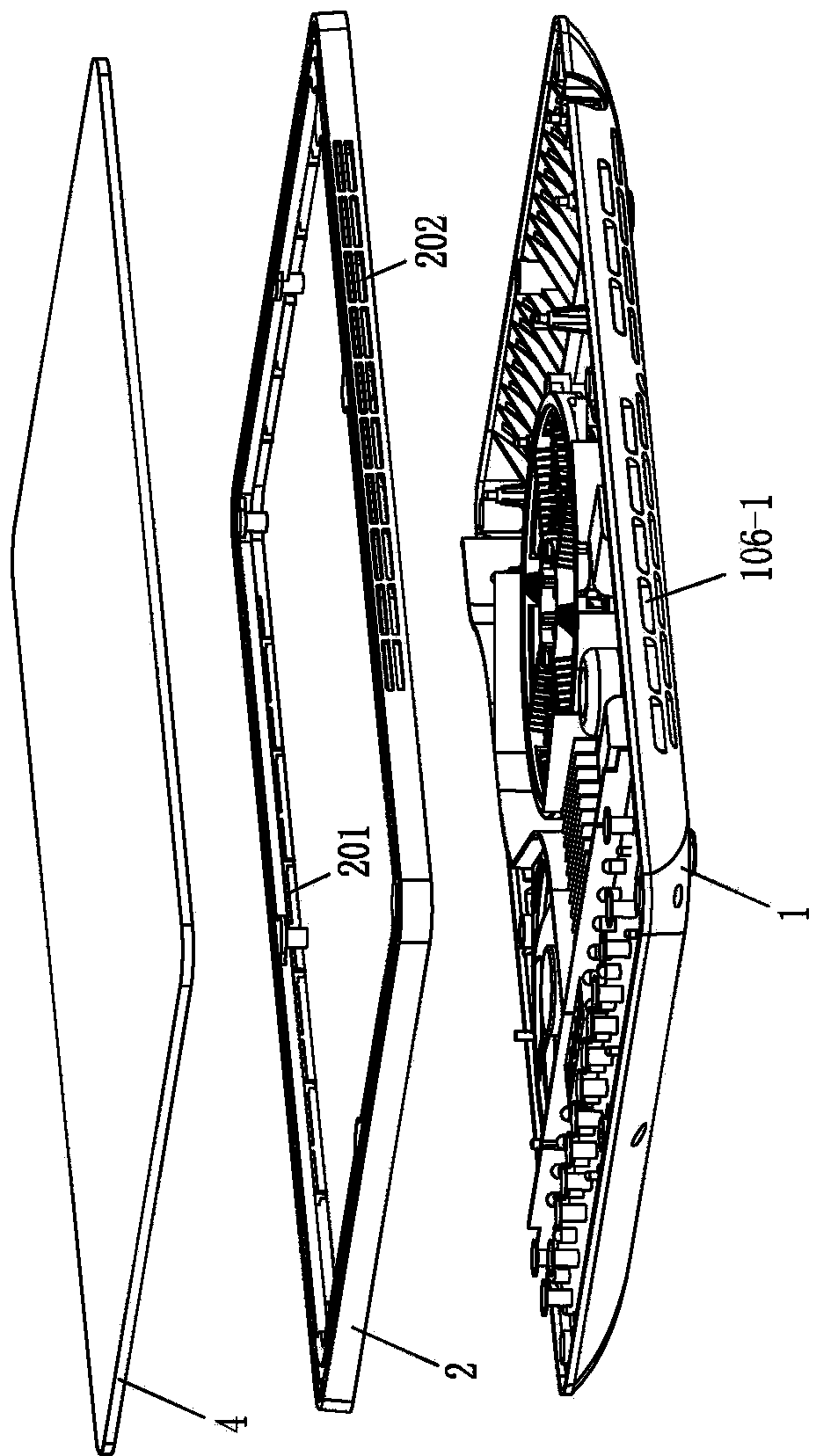

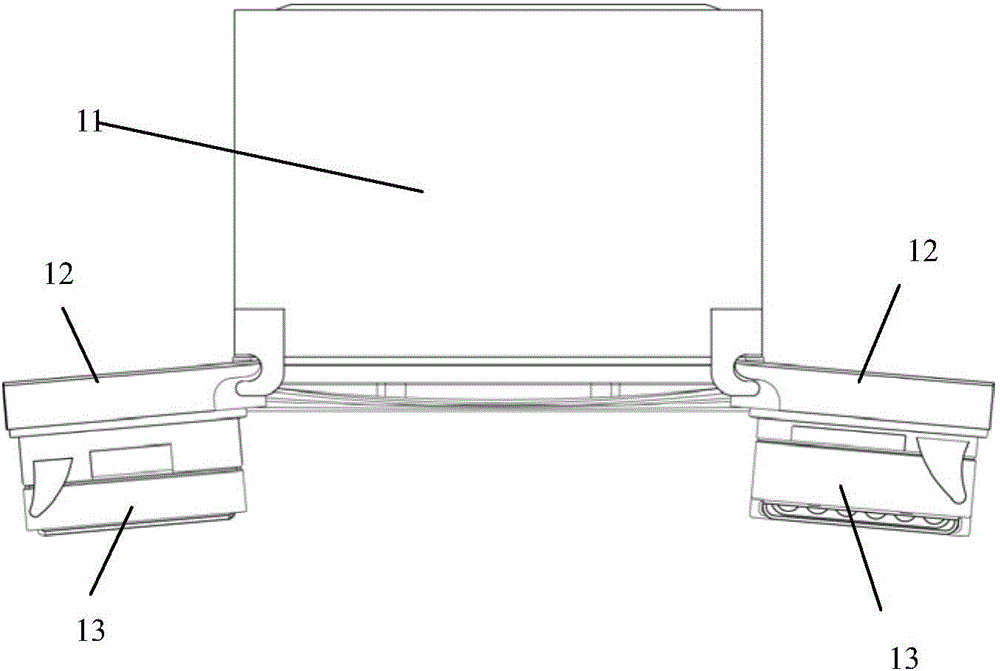

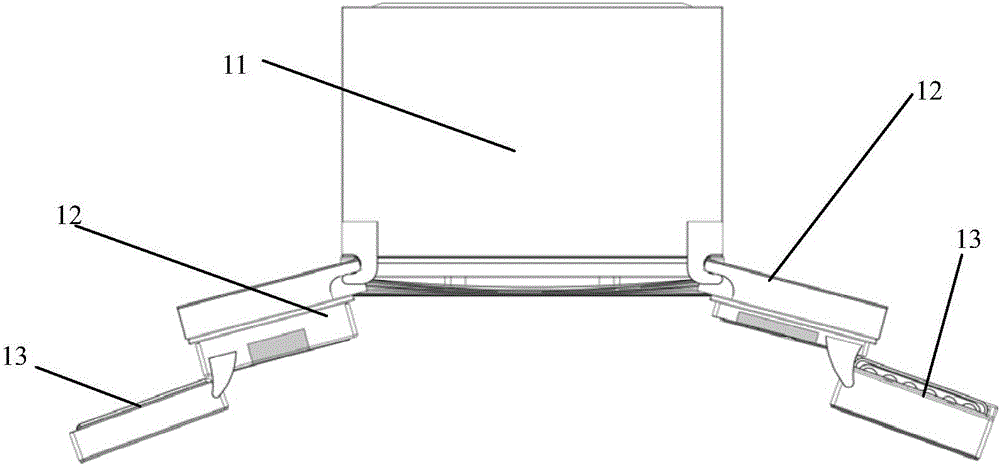

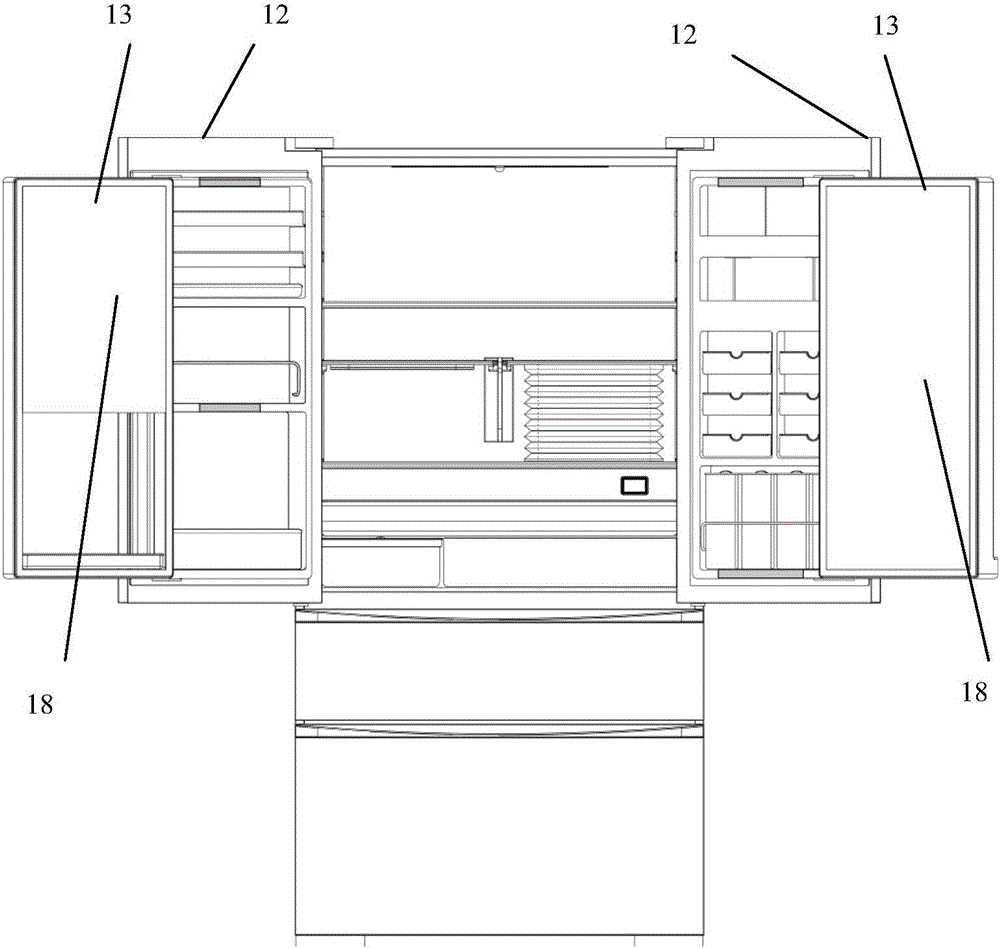

Refrigerator

ActiveCN103471311ASimple structureEasy to useLighting and heating apparatusDomestic refrigeratorsFood materialCold store

The invention relates to a refrigerator which comprises a refrigerator body. A refrigerating chamber is arranged on the upper portion of the refrigerator body, and a freezing chamber is arranged on the lower portion of the refrigerator body. A refrigerator door mounted on the refrigerator body comprises an inner door and an outer door. The inner door and the outer door form the refrigerator door which is of a double-layered door structure. When the refrigerator door is closed, the inner door is positioned in the refrigerator, the outer door facing users enables the users to open the refrigerator body, the inner door and the outer door are in rotating or sliding connection, and the outer door and the refrigerator body are in rotating connection. A plurality of special storage devices and lighting devices are arranged in the refrigerator body, the refrigerating chamber and the freezing chamber according to stored objects. The refrigerator is simple in structure and convenient to use, food can be effectively stored according to different packages or cleanliness, neatness and convenience levels of the food, the problems like scattering and odor tainting of the food or food materials are avoided, safety and convenience in storing of the food or the food materials are improved, and the refrigerator is in conformity with use habits of users.

Owner:GUANGDONG CANBO ELECTRICAL

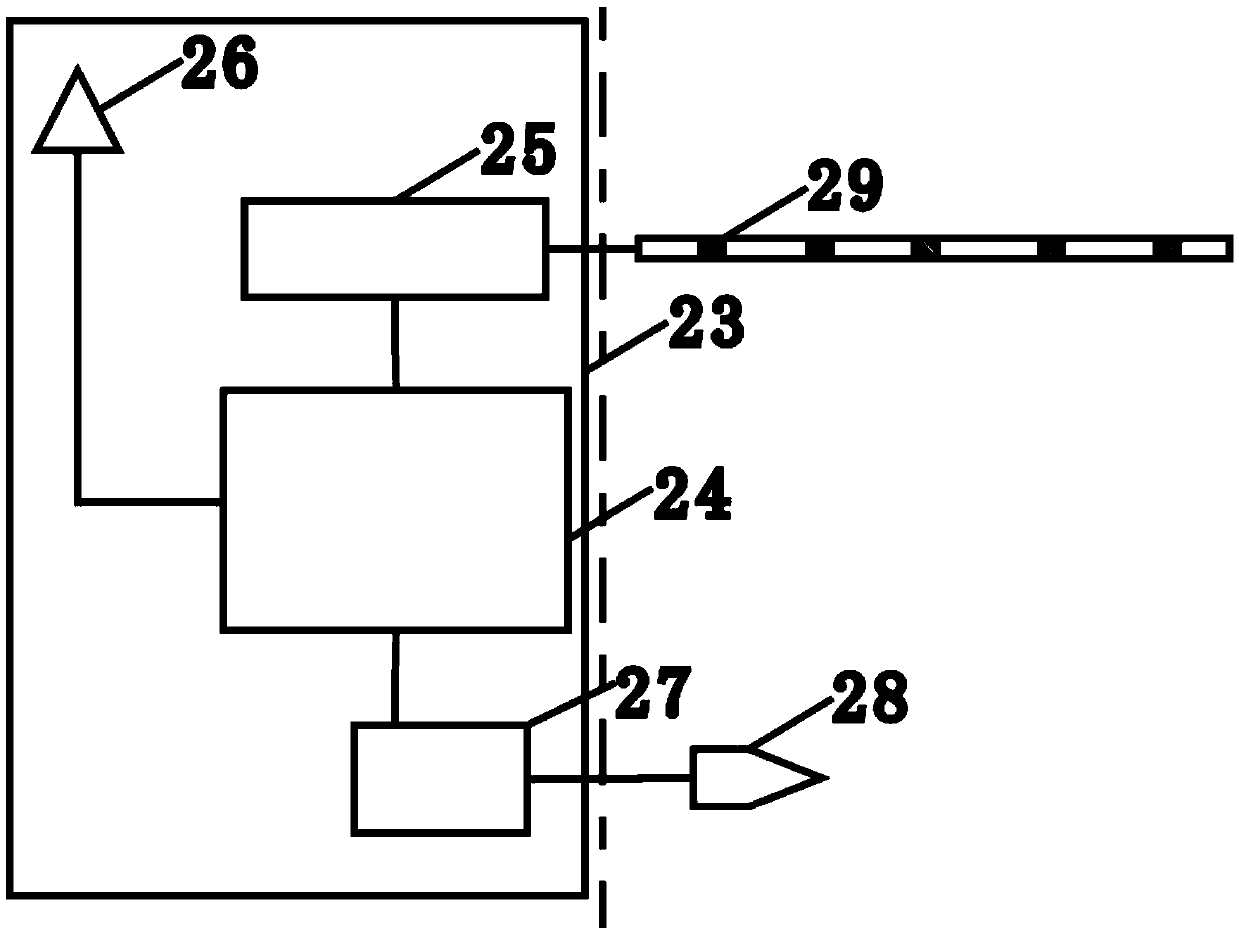

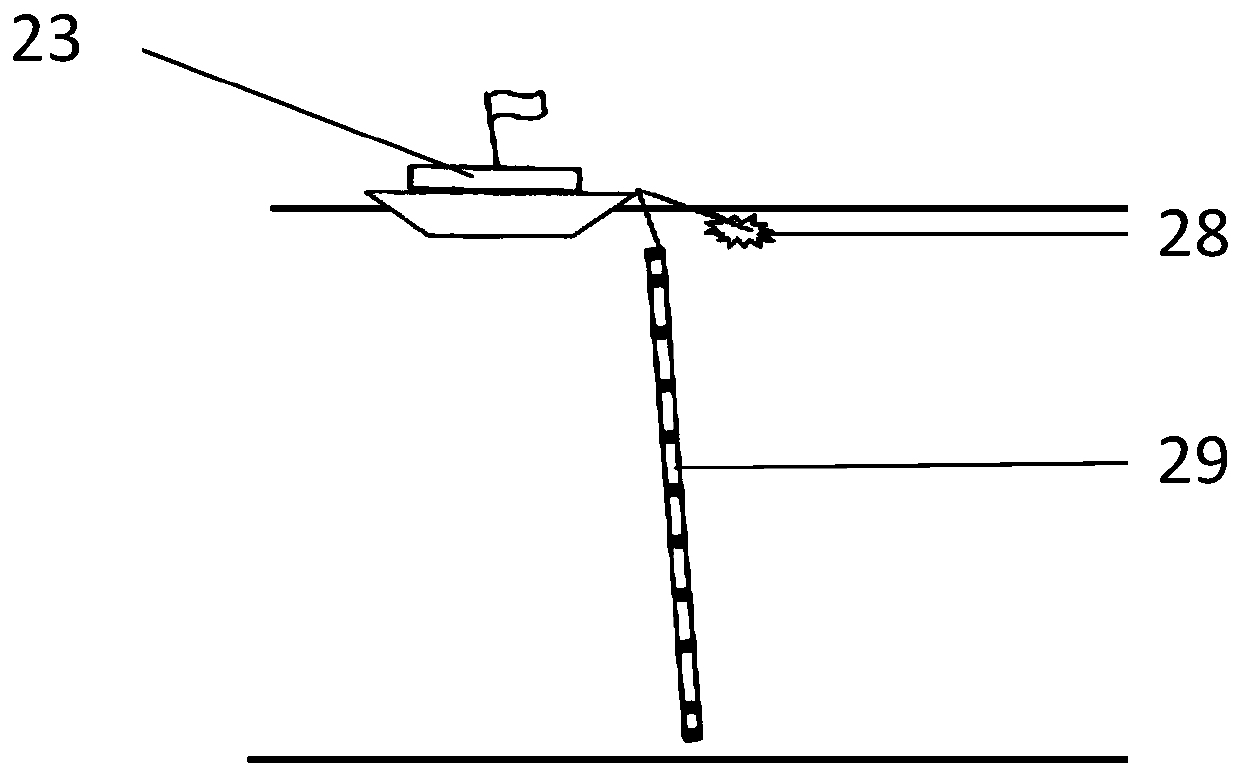

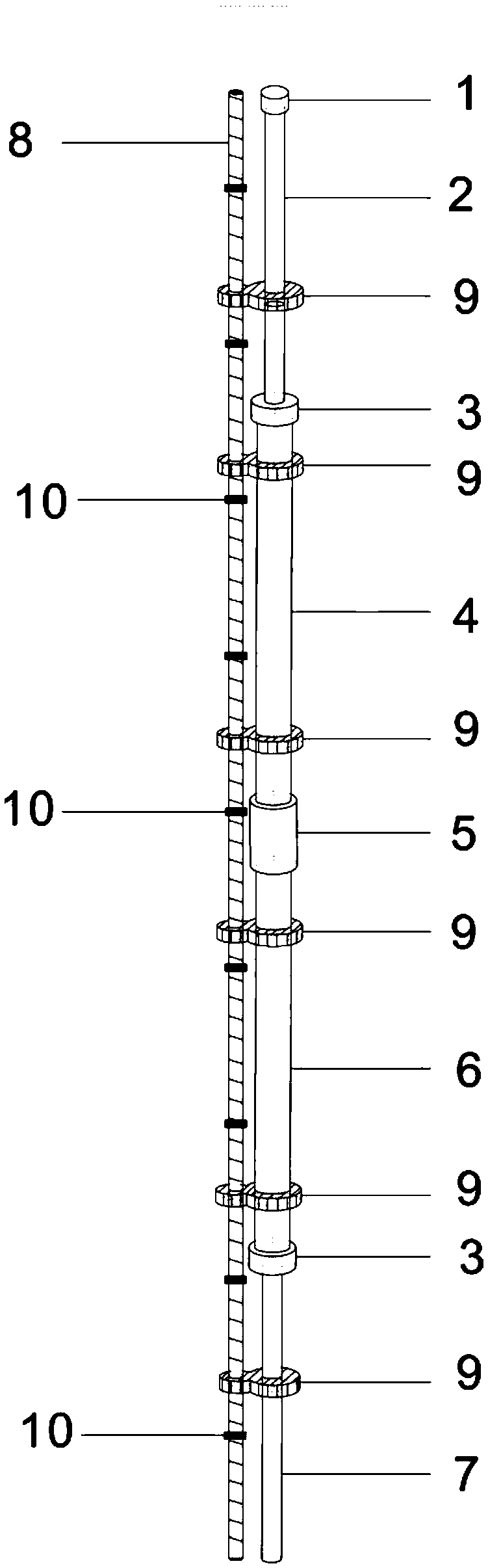

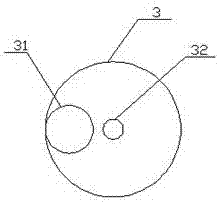

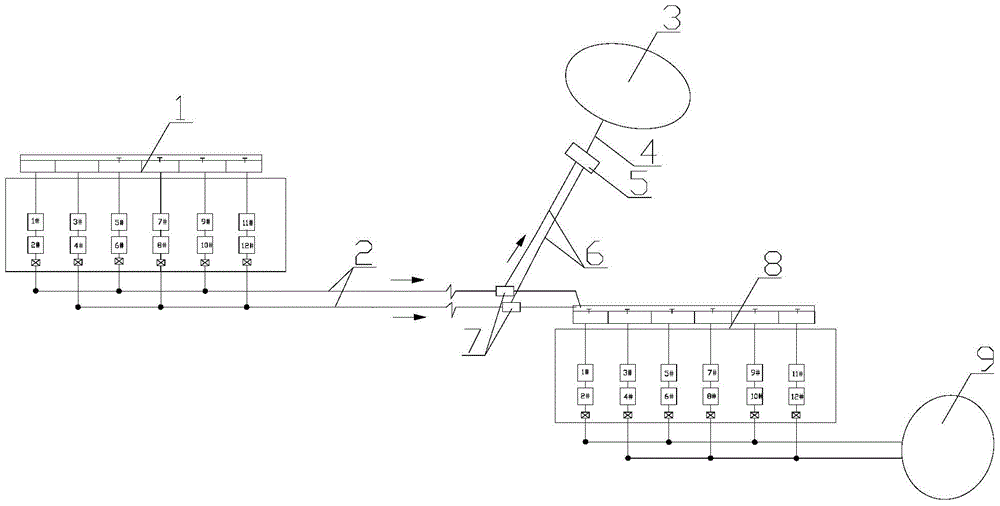

Pull-type marine seismic prospecting vertical cable data acquisition system

A pull-type marine seismic prospecting vertical cable data acquisition system comprises a working ship carrying an excitation system and a pull-type marine seismic prospecting vertical cable, the vertical cable includes an auxiliary steel cable and a cable part, the cable part includes a front connecting segment, a head working segment, a tail working segment and a tail connecting segment in sequence from top to bottom, a clinometer and a pressure sensor group are arranged between the front connecting segment and the head working segment, the head and tail working segments are provided with eight hydrophone combinations in sequence along a length direction, an extendable eight-channel digital packet is arranged between the head working segment and the tail working segment, and a clinometer and a pressure sensor group are arranged between the tail working segment and the tail connecting segment. Analog-to-digital conversion is realized on a vertical cable, thereby truly realizing digitalization of the cable; the operating depth of water is large, and when the depth of water is 1000m, the vertical cable can still work normally; the time sampling rate is high, the auxiliary steel cable is arranged outside, and reasonable separation of functions is realized; and the prospecting depth is large, and the immersion depth of the vertical cable can be controlled in real time through adjustment of the front connecting segment and the tail connecting segment.

Owner:OCEAN UNIV OF CHINA

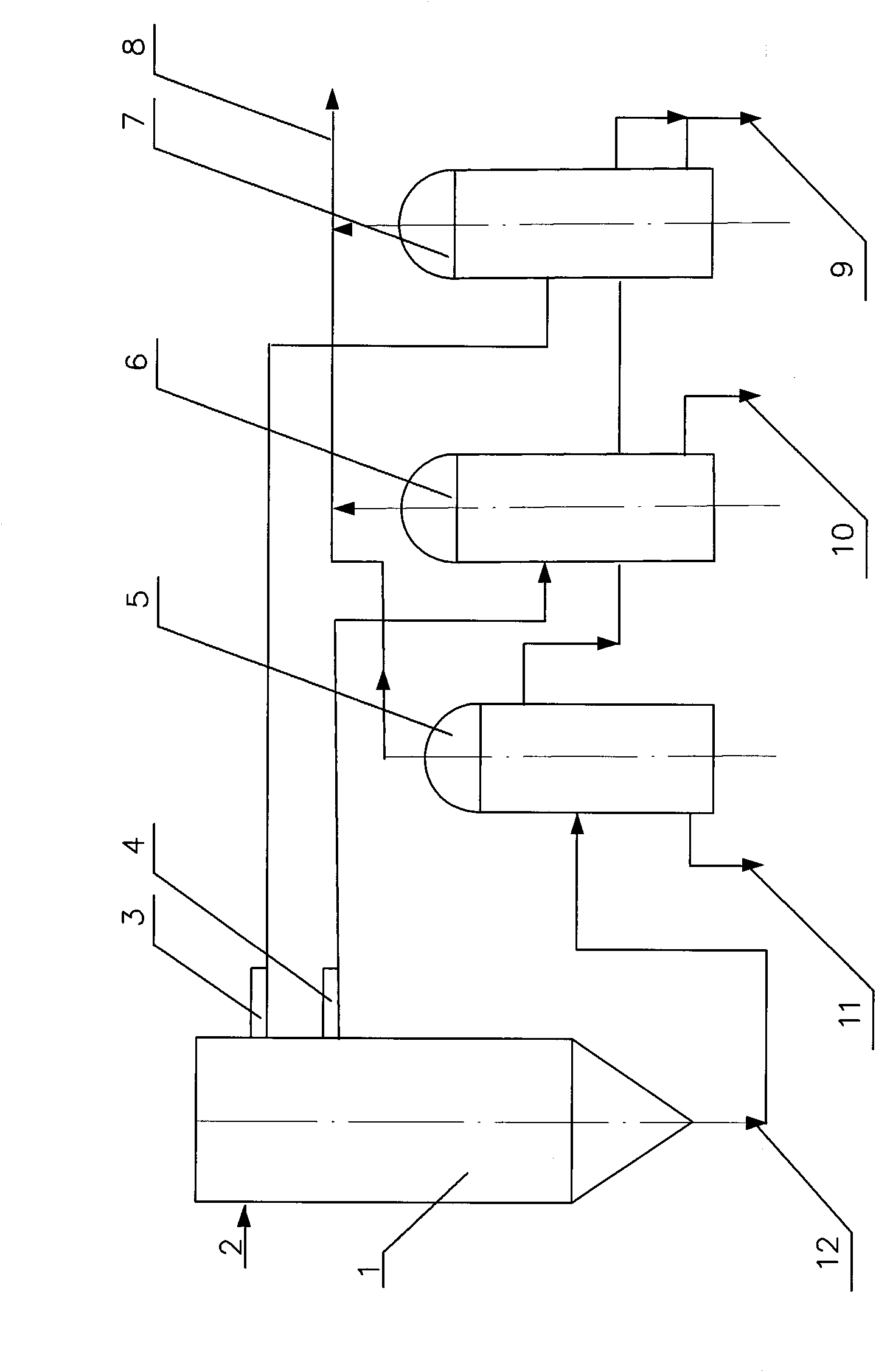

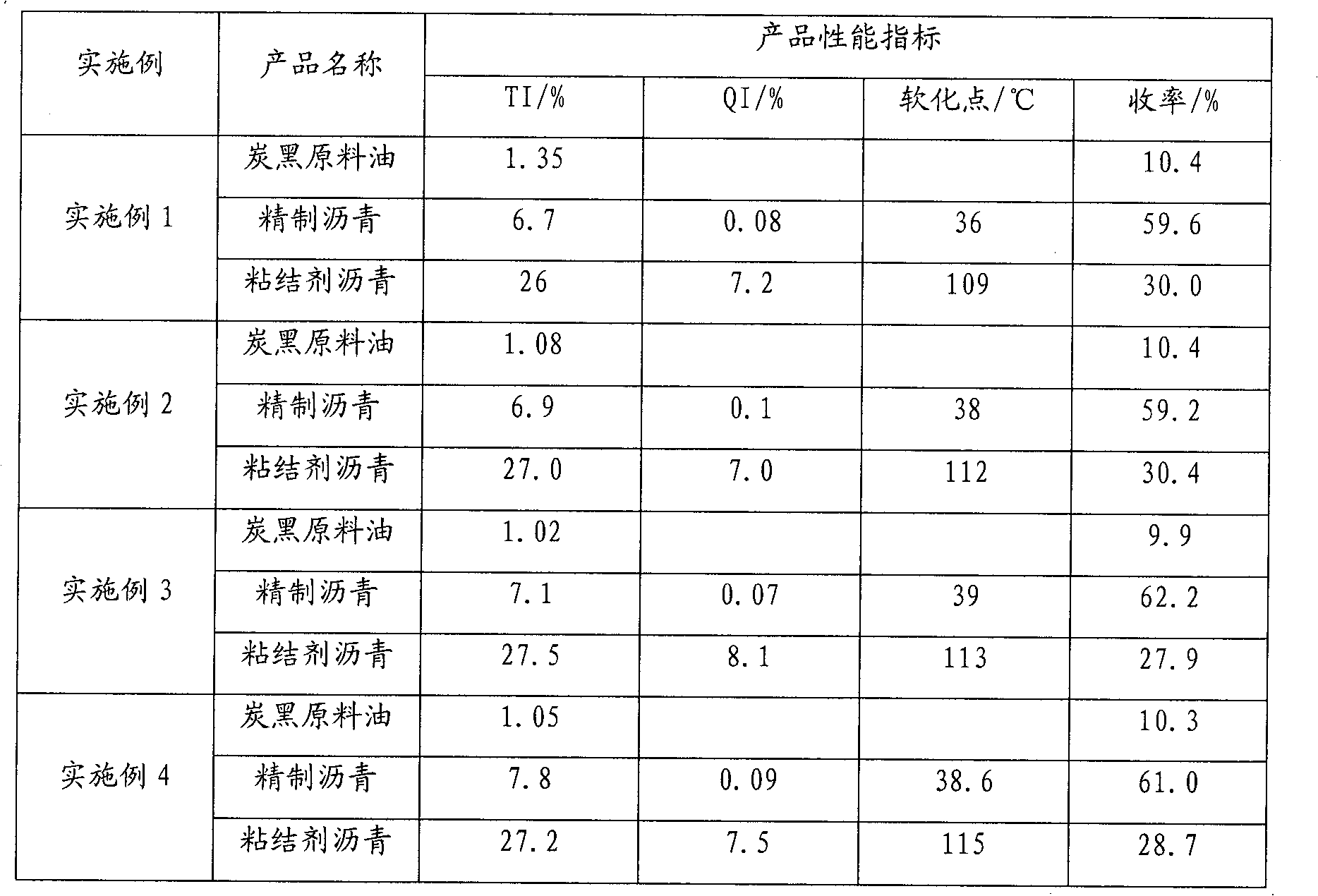

Process for co-production of high-quality carbon black raw oil, refined asphalt and binder asphalt

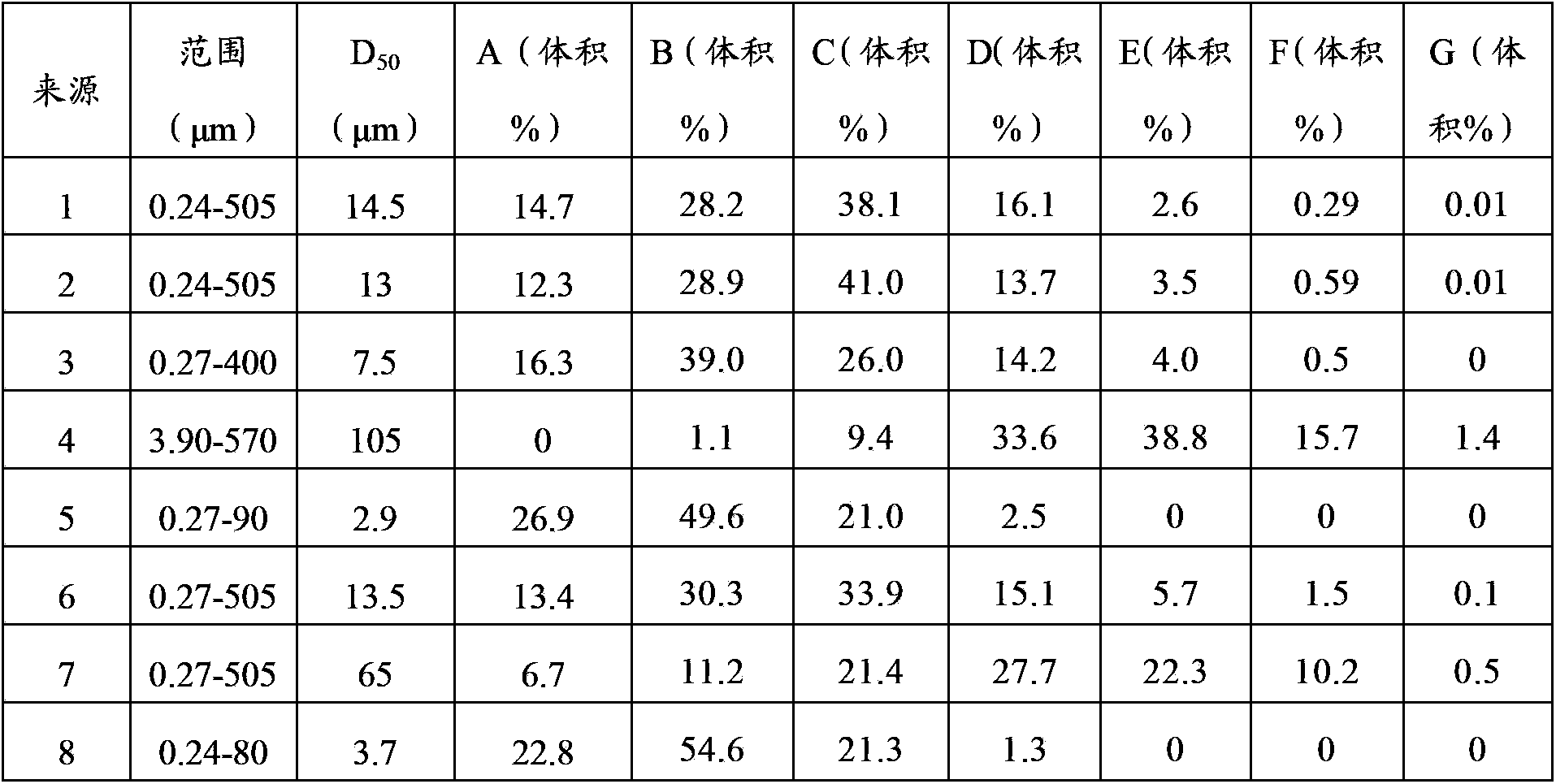

InactiveCN101798515AReduce energy consumptionLow costWorking-up pitch/asphalt/bitumen by distillationWorking-up pitch/asphalt/bitumen by selective extractionFlocculationDensity distribution

The invention relates to deep processing technology of coal-tar asphalt, in particular to the process for co-production of high-quality carbon black raw oil, refined asphalt and binder asphalt. The process comprises a step of mixing crude coal-tar asphalt and a solvent in a certain ratio and injecting the mixture into an extraction separator for separating, wherein the process comprises technical steps: mixing the crude coal-tar asphalt and the solvent in a certain ratio and injecting the mixture into the extraction separator and performing extraction, flocculation, sedimentation and separation; extracting a light phase component, a secondary light phase component and a heavy phase component from an upper position, a middle position and a lower position of the separator respectively according to a density distribution principle; and controlling the ratio between double solvents and the ratio between the double solvent and the crude coal-tar asphalt, wherein the double solvents consist of an aromatic solvent and an aliphatic solvent. The process not only can obtain the high-quality carbon black raw oil with a high additional value and prepare pure refined asphalt and carbon for needle coke and the binder asphalt for a refractory material product, and but also has no waste emitted in the overall technical process.

Owner:UNIV OF SCI & TECH LIAONING

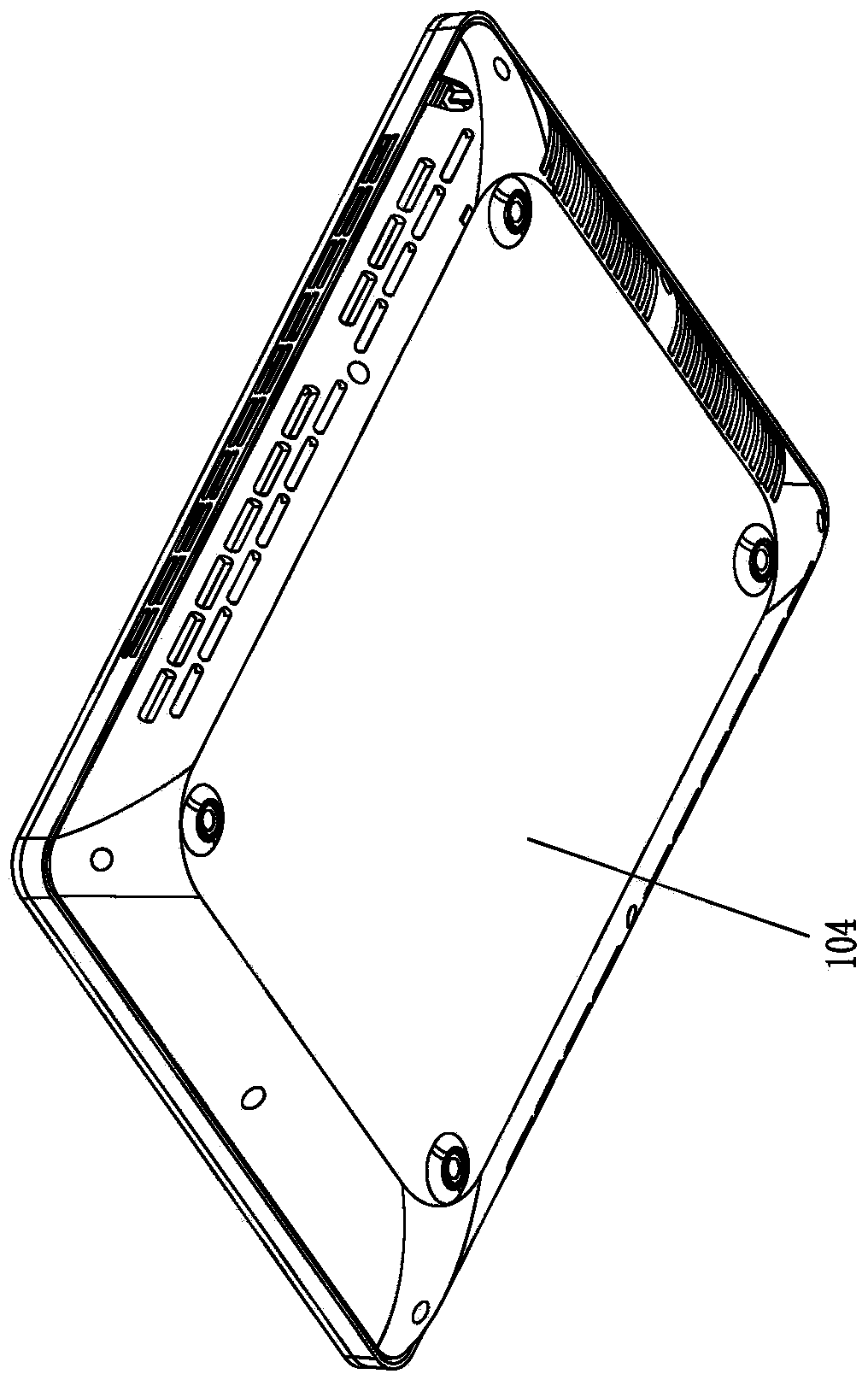

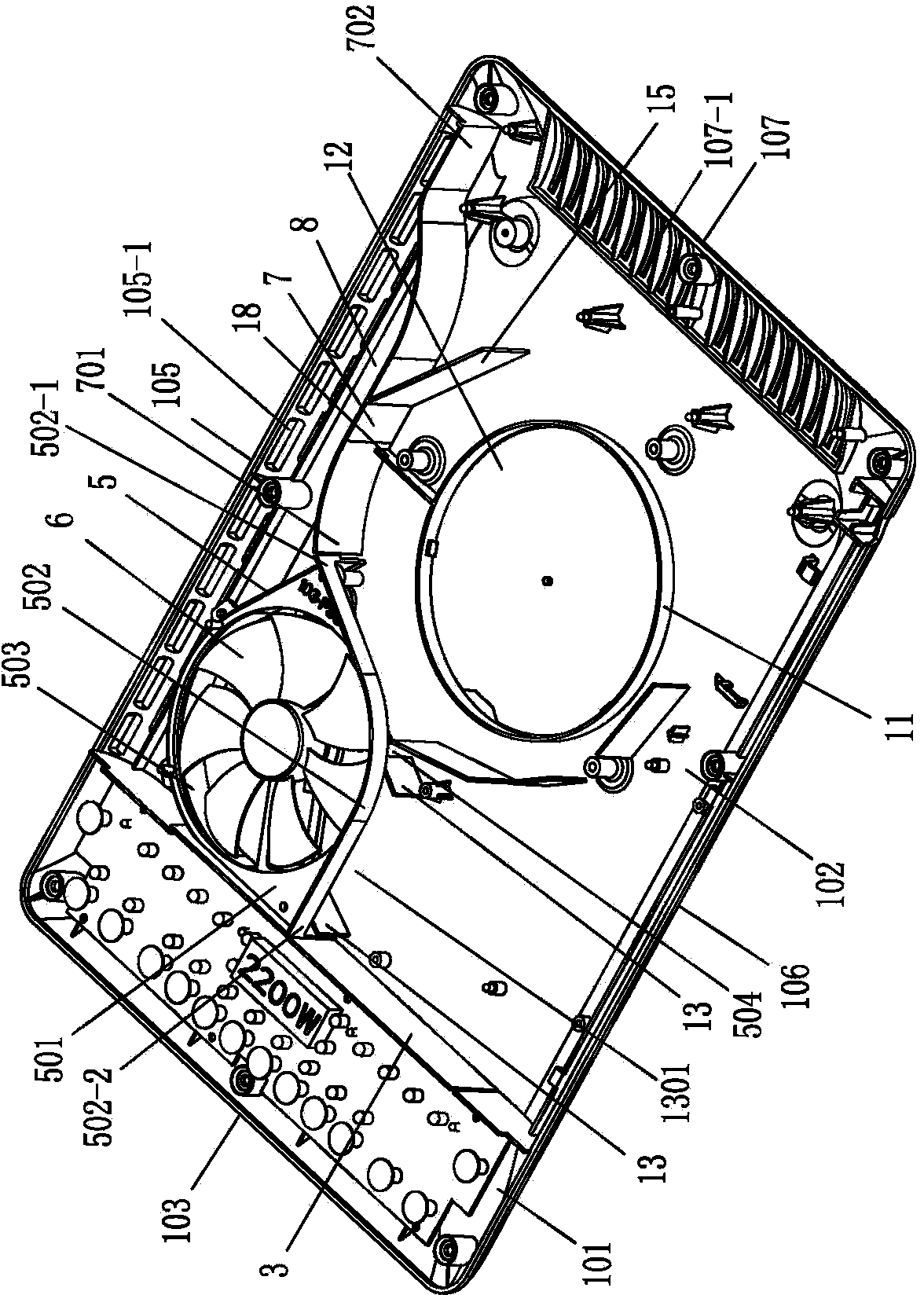

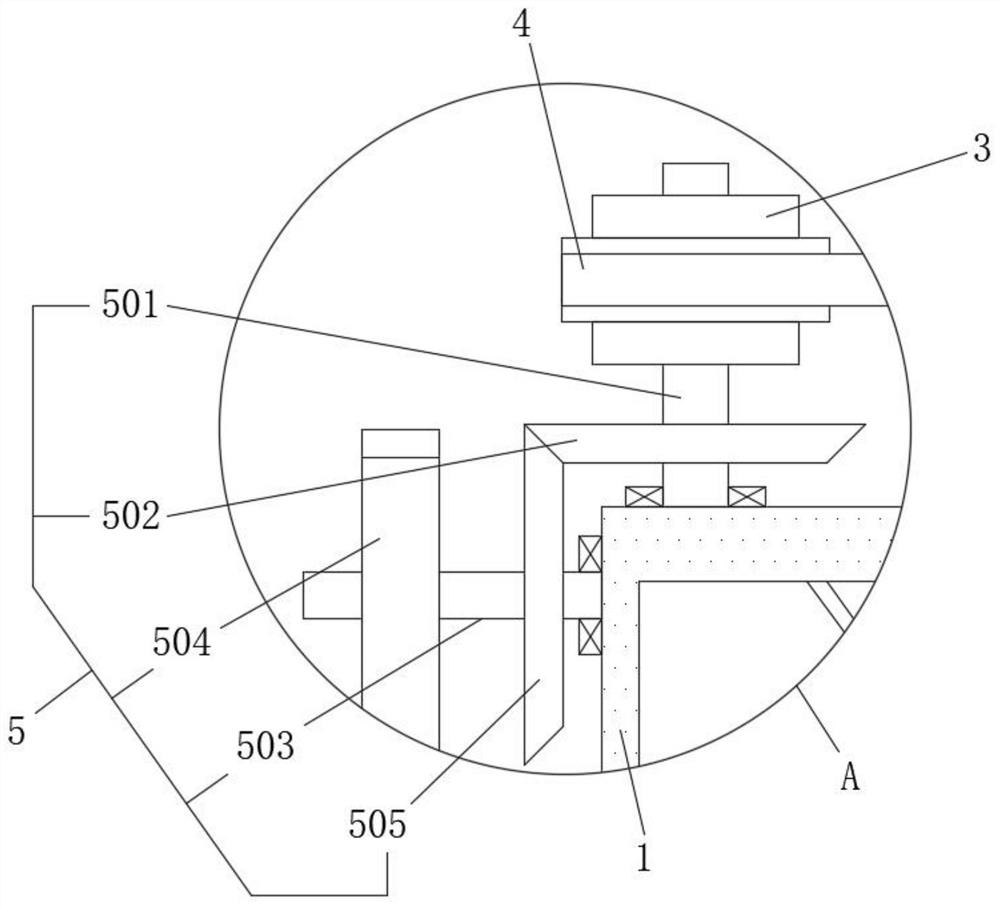

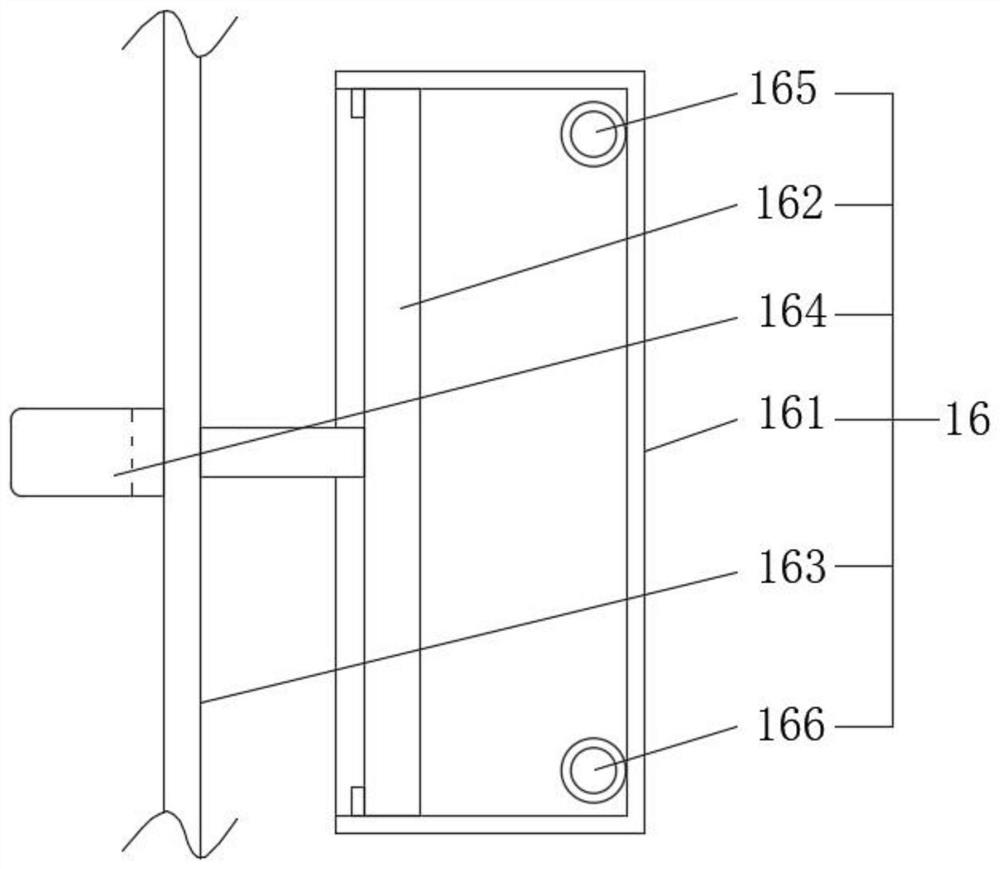

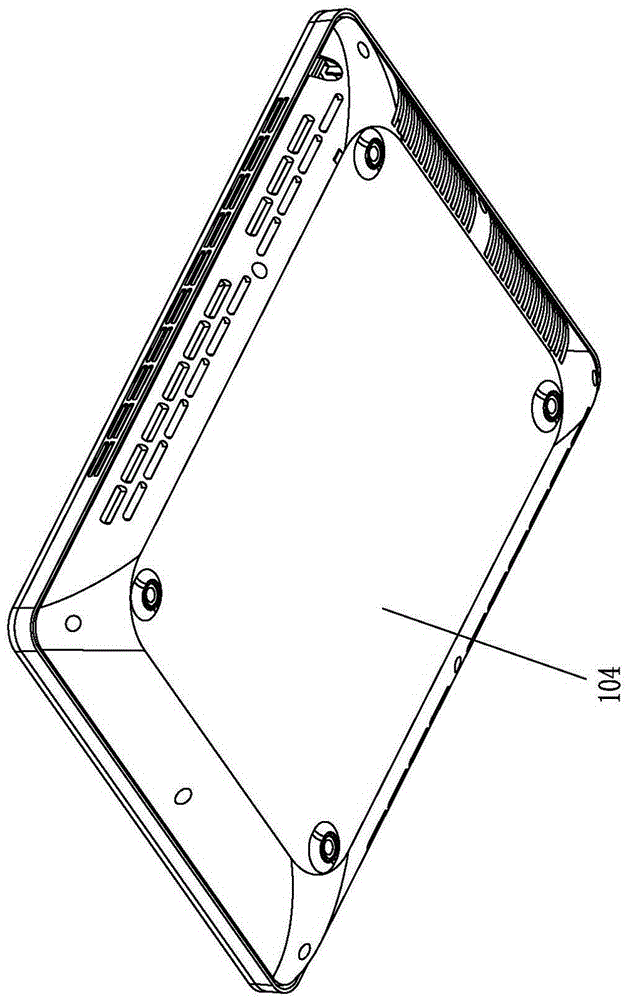

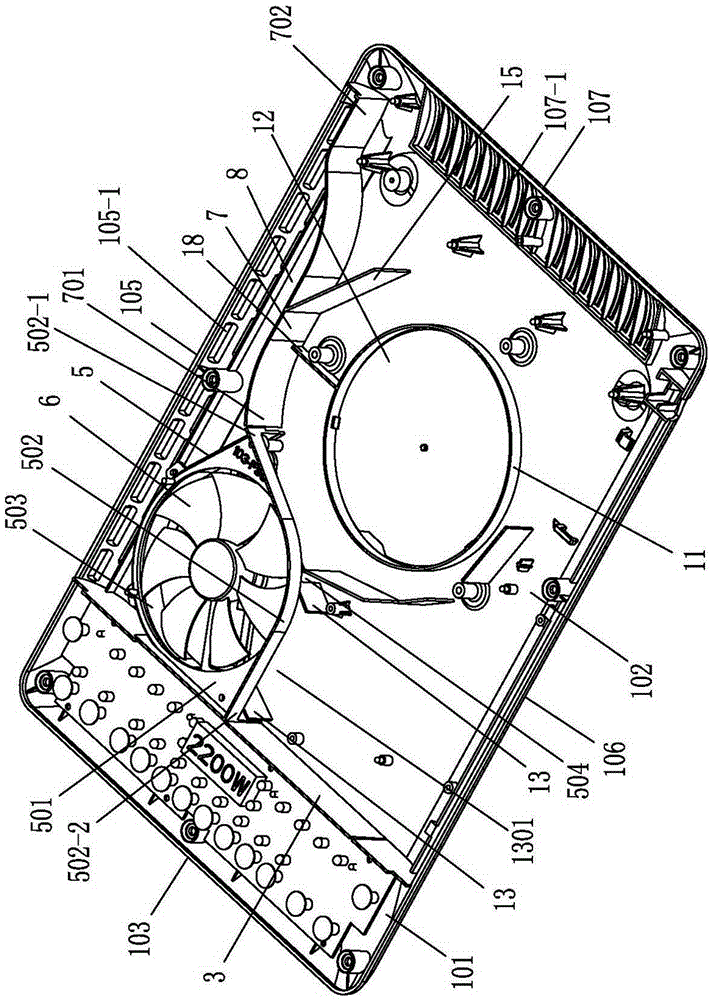

Novel induction cooker

ActiveCN103884029AReasonable structureReasonable separationDomestic stoves or rangesLighting and heating apparatusEngineeringInduction cooking

The invention relates to a novel induction cooker. The novel induction cooker is characterized in that an inner cavity of a bottom shell is divided into a control panel region and an element mounting region by a functional partition board, wherein the control panel region is arranged on the front side of the bottom shell, the bottom surface of the bottom shell is closed, a face shell is arranged on the bottom shell and is connected with a microcrystalline board, an air inlet side face and an air outlet side face are respectively formed by two side faces, corresponding to the element mounting region, of the bottom shell, a plurality of air inlets and a plurality of first exhausting holes convective with one another are correspondingly formed in the air inlet side face and the air outlet side face, and a plurality of second exhausting holes are formed in the rear side face, corresponding to the element mounting region, of the bottom shell; a cooling fan is fixed at an opposite-angle position formed by the functional partition board and the air inlet side face through an air collection box, an air inlet guiding baffle is fixed in the element mounting region adjacent to the inner sides of the air inlets, a circuit main board is fixed at the element mounting region between an air outlet of the air collection box and the first exhausting holes, and a coil panel is fixed at the element mounting region between the air outlet of the air collection box and the second exhausting holes. The novel induction cooker has the beneficial effects that the structure is simple and reasonable, an air inlet area and an air outlet are increased, and the cooling speed is high.

Owner:佛山市顺德区普发特电器实业有限公司

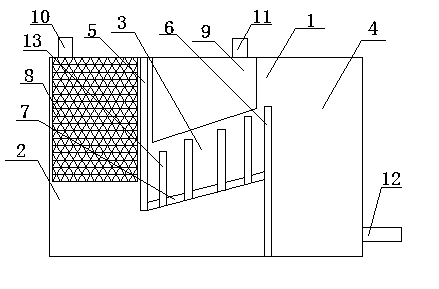

A method and equipment for treating waste gas of a hot press

ActiveCN102284220AImprove processing efficiencyWon't catch fireUsing liquid separation agentSewageWater spray

The invention relates to a method and equipment for treating waste gas of a hot press. The method comprises the following steps of: S1, injecting water into a dust absorption pipeline to ensure that gas and water are fully contacted and mixed; and S2, allowing water spray carrying waste gas to enter a water dust scrubber, collecting sewage carrying impurities, and discharging purified gas. A water injection device is arranged in the dust absorption pipeline; the dust is not stuck onto the dust absorption pipeline easily so the pipeline is prevented from being blocked and fire is avoided; the waste gas treatment efficiency is high; and the dust, and a large amount of high-temperature volatile matter of formaldehyde and transmission lubricant are collected, the collected waste gas and waterare treated further ad separated reasonably, water is recycled, and no sewage is discharged, so secondary pollution is avoided. Meanwhile, the invention also provides equipment for treating the wastegas of the hot press.

Owner:SUZHOU XIELI ENVIRONMENTAL PROTECTION EQUIP

Oil-water oil extractor

InactiveCN104140163ASimple structureEasy to assembleMultistage water/sewage treatmentOil waterSuspended solids

The invention relates to the technical field of filters and in particular relates to an oil-water extractor which comprises an oil extractor body, a deslagging zone, a separation zone, a clean water zone, a clapboard I, a clapboard II, a fixed plate, a deslagging net and a separation box, wherein the oil extractor body is internally provided with the deslagging zone, the separation zone and the clean water zone; the clapboard I is arranged between the deslagging zone and the separation zone; the clapboard II is arranged between the separation zone and the clean water zone; the fixed plate is arranged between the clapboard I and the clapboard II; the deslagging zone is internally provided with the deslagging net, the separation box is arranged in the separation zone; a liquid inlet is arranged above the deslagging zone; an oil extractor is arranged above the separation zone; a water outlet is formed at one side of the clean water zone; a corrugated pipe is arranged on the fixed plate. The oil-water extractor is simple, compact and reasonable in structure, convenient and rapid to assemble, reliable in connection and high in oil water separation efficiency, can be used for effectively and reasonably separating out precipitates and suspended solids and greatly improving the working reliability of the oil-water oil extractor, and is easy to popularize and use.

Owner:CHANGZHOU YINXING COLOR PRINTING PACKAGING

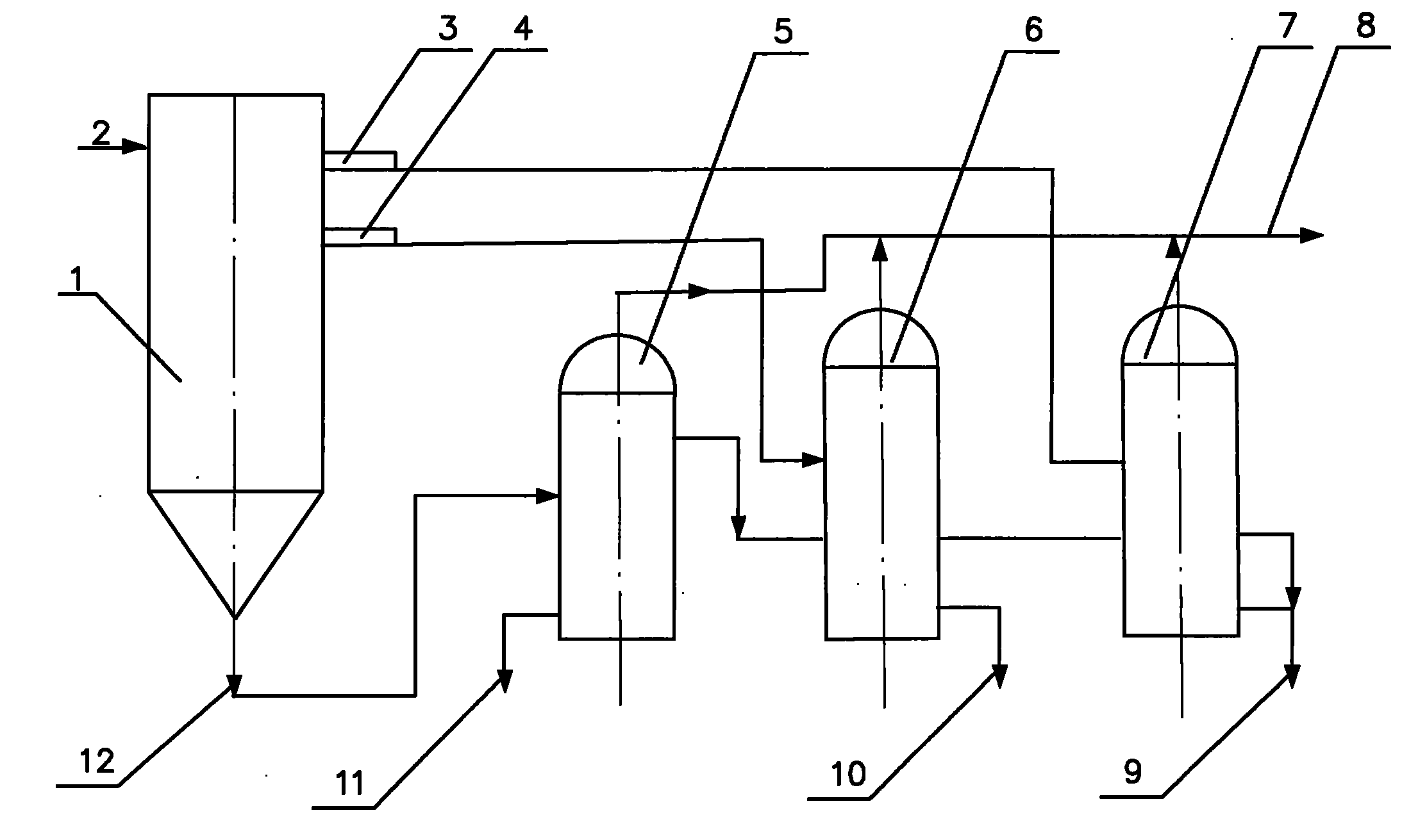

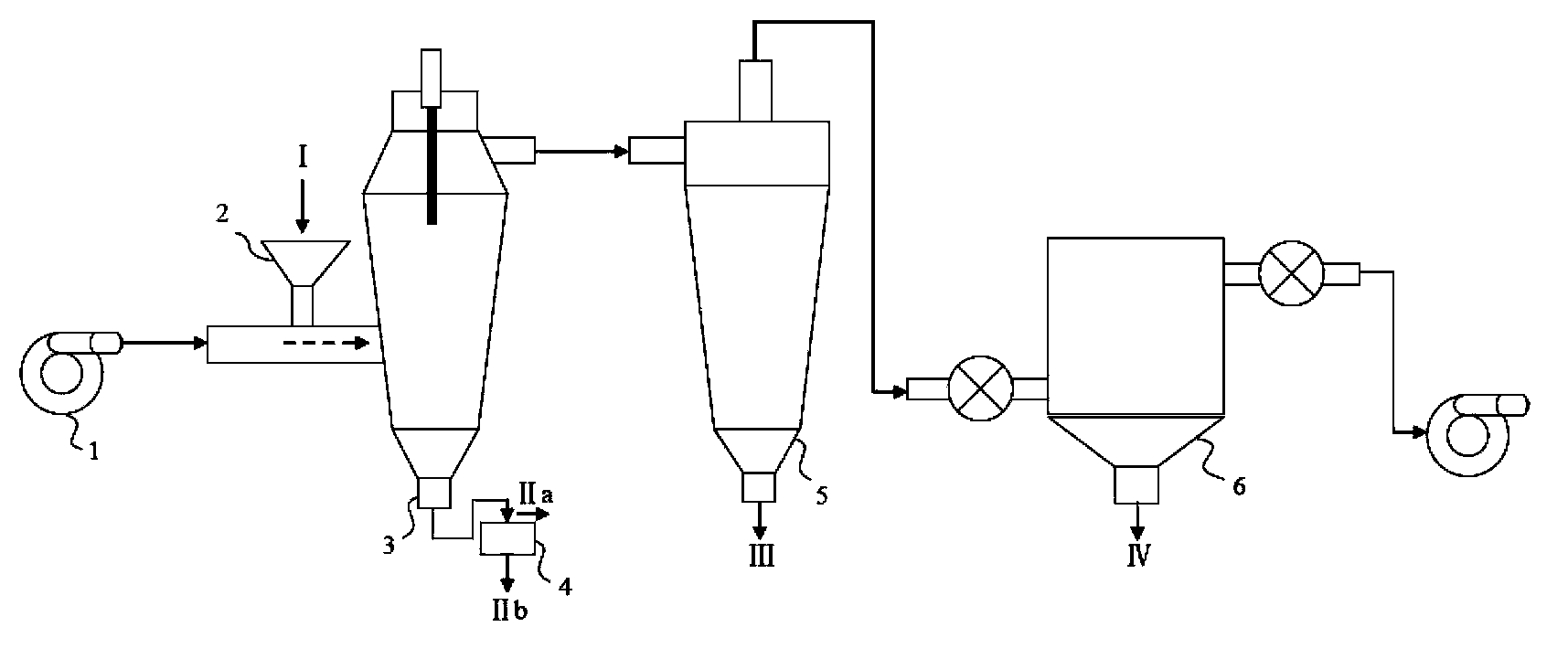

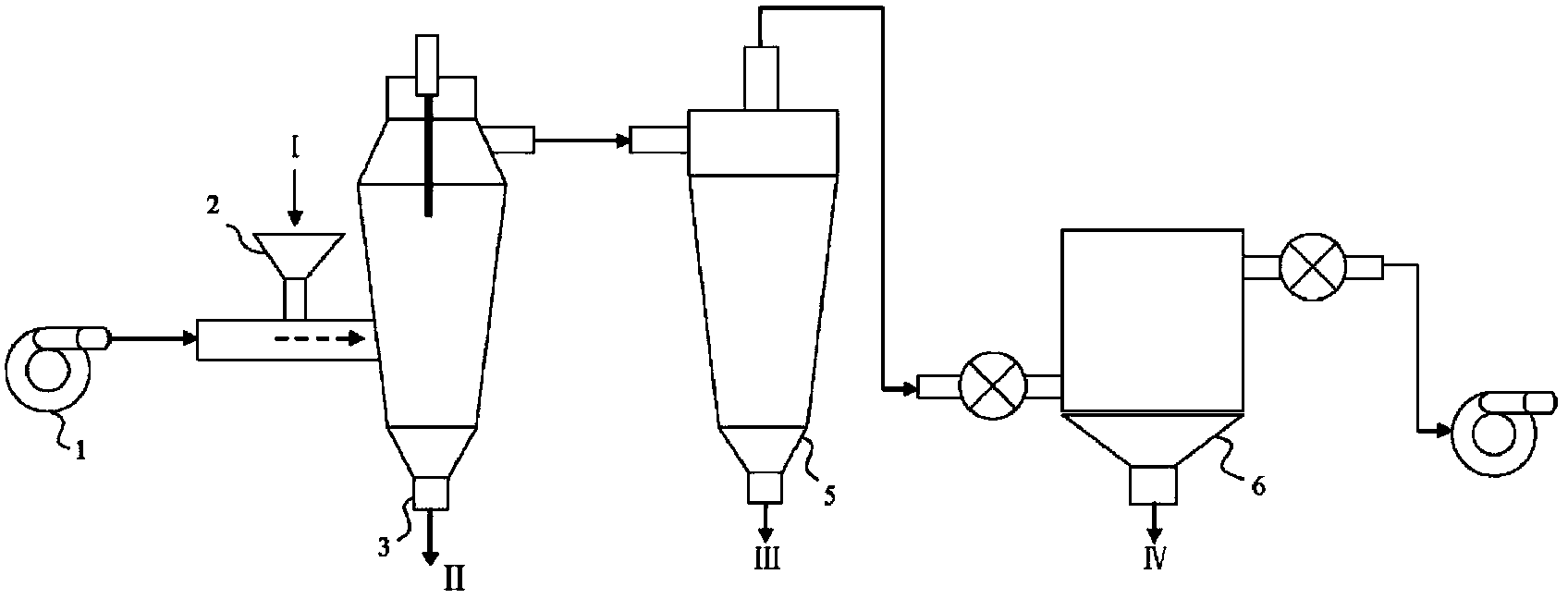

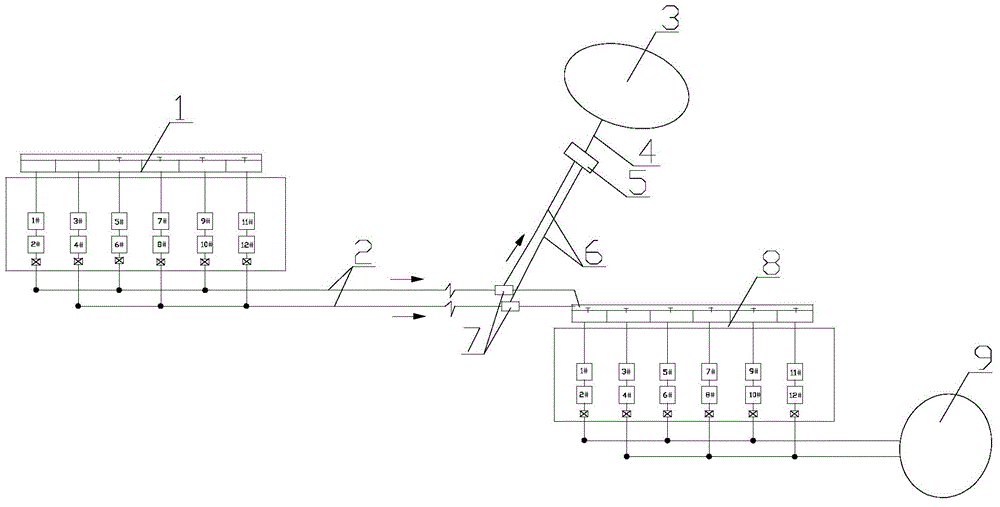

Method and system for separating powder

ActiveCN103977918AReasonable separationImprove use valueVortex flow apparatusCyclonic separationEngineering

The invention relates to a method and a system for efficiently and controllably separating powder into components with required sizes. The method comprises the following steps: (a) using at least a centrifugal separation device for centrifugal separation of the powder to obtain first level coarse dust and first level fine dust; and (b) using at least a cyclone separating device for cyclone separation of the first level fine dust to obtain second level coarse dust and second level fine dust. The system comprises a centrifugal separation unit; a cyclone separation unit; and optionally, a bag type filter unit. The method and the system can realize more reasonable separation of the powder, so that the powder has higher use value.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

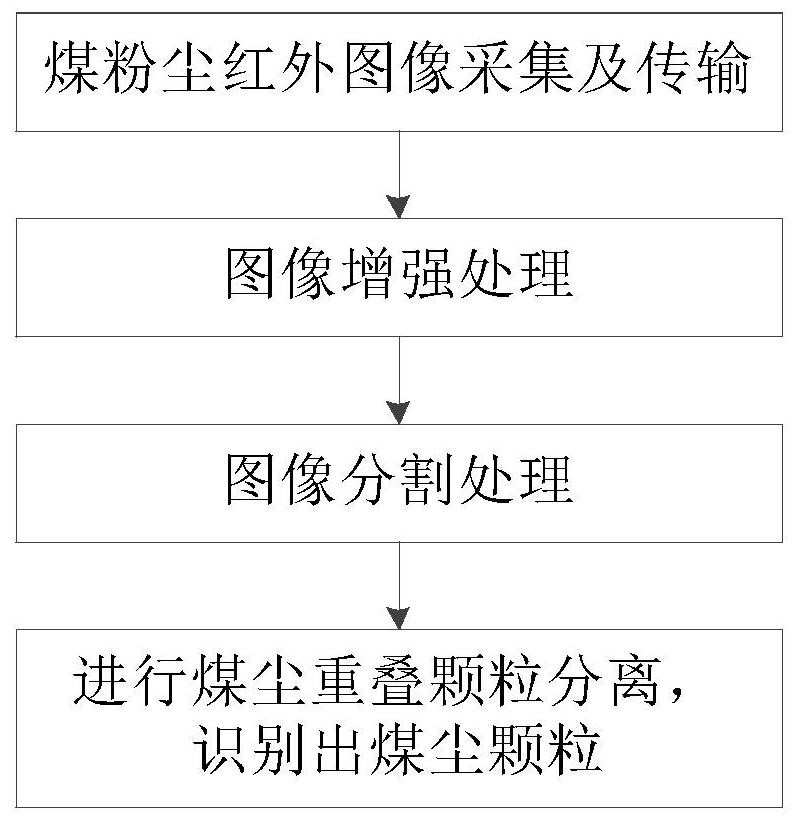

Coal dust image recognition method for underground coal mine explosion-proof detection

InactiveCN113012179AThe method steps are simpleNovel and reasonable designImage enhancementImage analysisCoal dustImage segmentation

The invention discloses a coal dust image recognition method for coal mine underground explosion-proof detection. The method comprises the following steps: 1, collecting and transmitting a coal dust infrared image; 2, image enhancement processing; 3, carrying out image segmentation processing; and 4, separating overlapped coal dust particles, and recognizing the coal dust particles. The method is simple in step, novel and reasonable in design and convenient to implement, coal dust overlapped particles can be reasonably separated out by adopting the fruit fly algorithm to separate the coal dust overlapped particles, good robustness is obtained, the recognition effect is good and stable, the speed is high, the image compatibility is extremely high, the recognition precision of the coal dust overlapped particles is improved, and the method is suitable for popularization and application. The method is good in effectiveness and robustness, high in adaptability, flexible and convenient to use, high in practicability, good in using effect and high in application and popularization value.

Owner:李韵涵

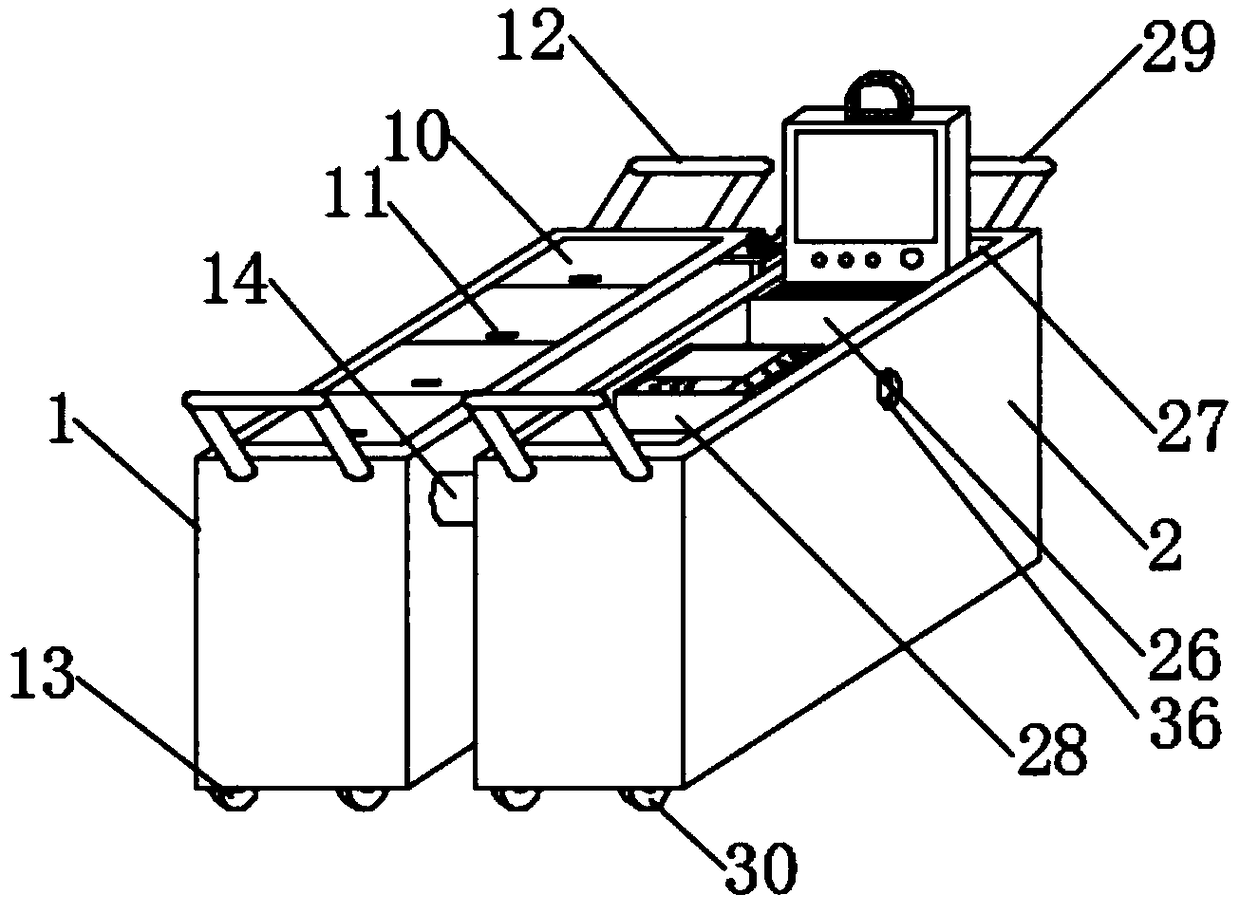

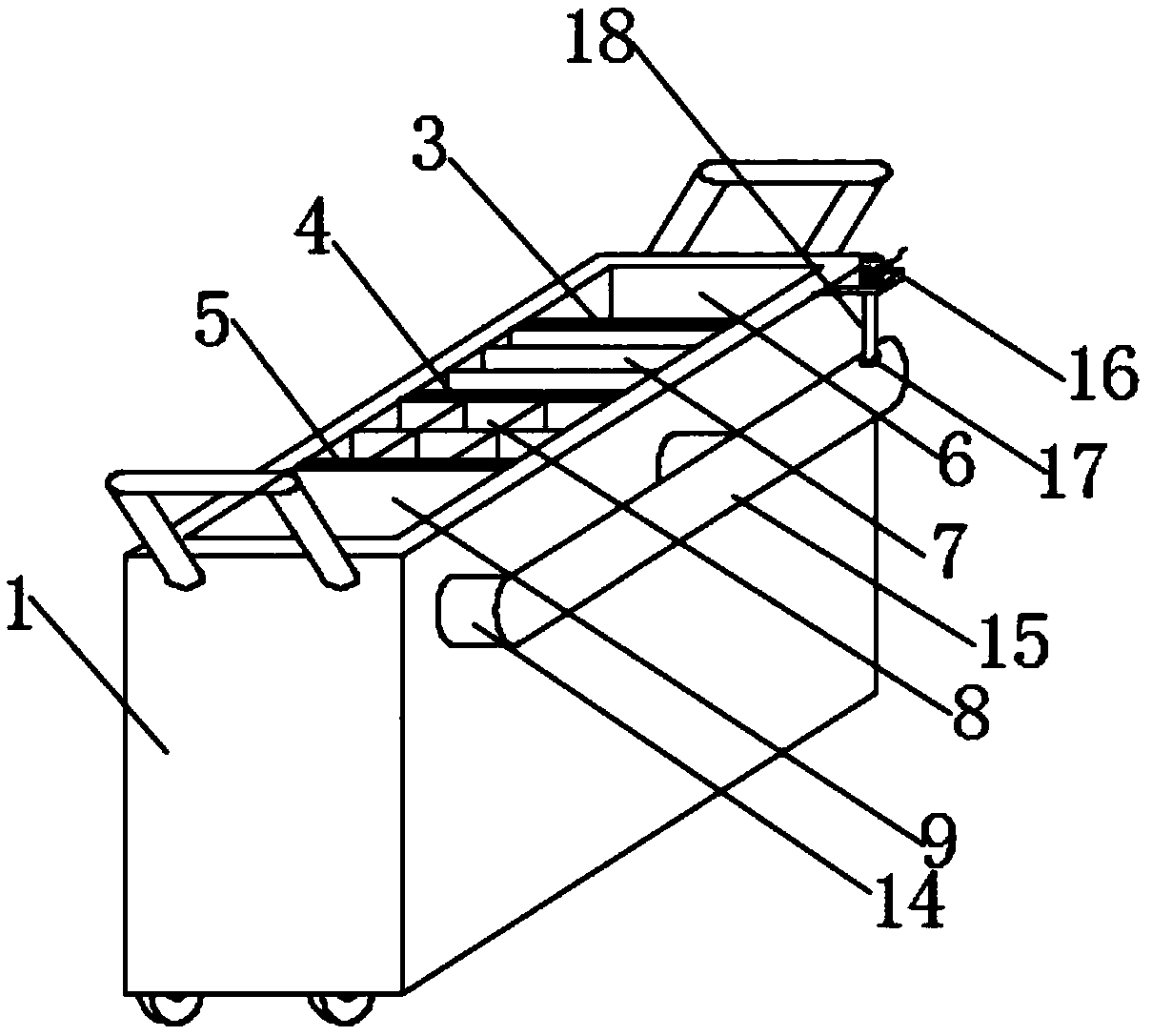

Kitchen garbage can

InactiveCN107161557AAffect health and safetyEasy to handleWaste collection and transferRefuse receptaclesSewageReducer

The invention discloses a kitchen garbage can, and relates to the field of kitchens. The kitchen garbage can comprises a can end cover, a rotary disc, a bottom disc, a connecting shaft, a speed reducer, a motor, an obstruction plate, a circular hole channel, a storage chamber, an air outlet hole with a plug, a discharging port with an end cover, a storage groove, a nitrogen storage tank, a filter net, a water pipe, a filter core, a spherical filter pipe, a can body and a cavity. According to the prepared kitchen garbage can, waste water and solid garbage in kitchen garbage can be reasonably separated, meanwhile, waste water can be well treated, and pollution to the natural environment from discharging of domestic waste water is avoided.

Owner:陈桂芳

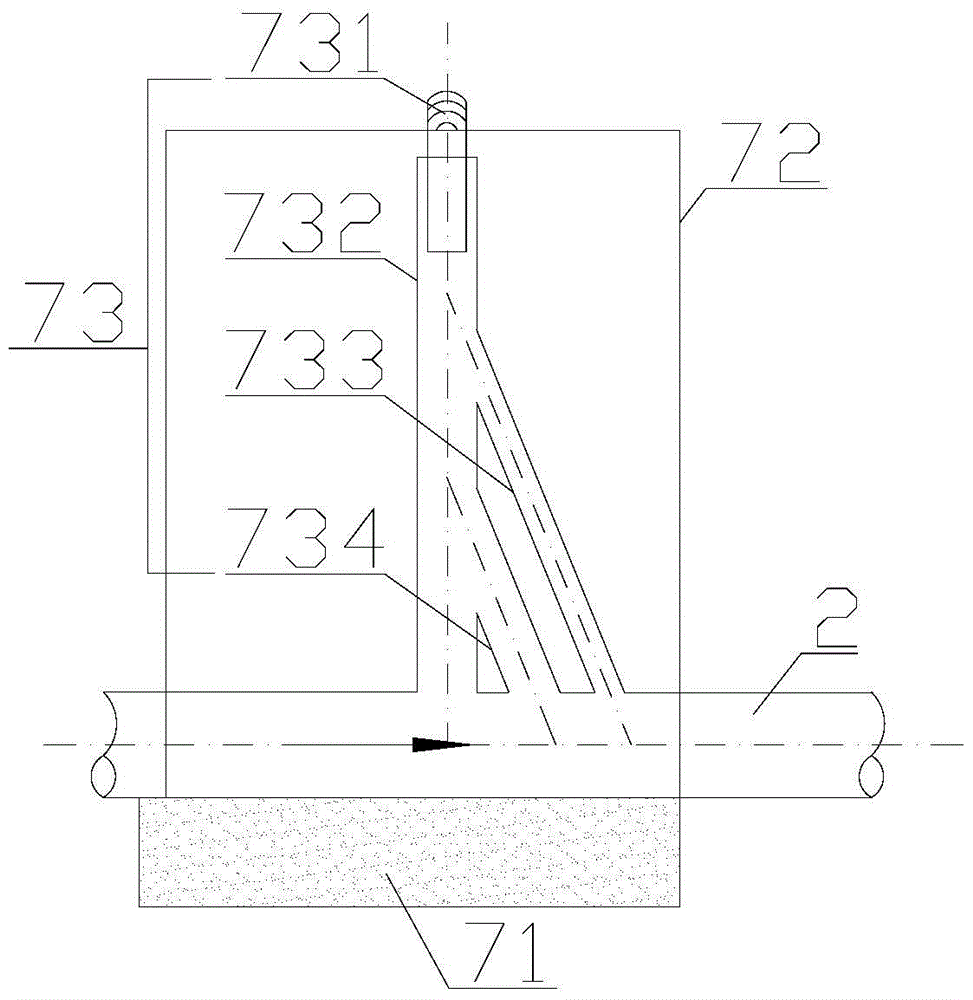

Automatic separating device for fine-sized slime in tailings conveying manifolds

ActiveCN104874472AReasonable separationDelivery normalMechanical material recoveryWet separationMining engineeringDiameter ratio

The invention discloses an automatic separating device for fine-sized slime in tailings conveying manifolds and belongs to mine tailings grading and conveying equipment. At least one guiding-out mechanism composed of a door-shaped support and a leading-out pipe is arranged on any tailings conveying manifold, each leading-out pipe is fixed on the corresponding door-shaped support and communicated with the corresponding tailings conveying manifold and a fine grain conveying pipe in a connected manner respectively, a proportion flow limiting mechanism is arranged in a horizontal pipe section at the tail of each leading-out pipe, and the middle of each fine grain conveying pipe is supported by multiple supporting frames while the head of the same extends into a mine pit. Each leading-out pipe composed of a vertical pipe, a first bypass inclined pipe, a second bypass inclined pipe and a connecting elbow is adopted, and pipe-diameter ratio and tailings slurry flow speed are designed reasonably, so that separating of fine-sized slime in the tailings conveying manifold can be realized without newly-added power, energy resources are saved, the fine-sized slime entering a tailings pond is reduced, grade matching of tailings entering the tailings pond is improved, gradient of a dry beach at a flood regulation section is increased, and safety superelevation and flood regulation height floor prevention indicators of the tailings pond are enabled to meet safety requirements.

Owner:ANHUI MASTEEL MINING RESOURCES GRP NANSHAN MINING CO LTD +1

Rice processing equipment

The invention discloses rice processing equipment, which comprise a screening frame and a second pulling plate. Fixing springs are connected to the left end and the right end of the inner wall insidethe screening frame correspondingly, a screening plate is installed in the middle of the inner wall inside the screening frame, supporting columns are arranged on the inner wall inside the screening plate, the outer wall outside the bottom of the screening frame is connected with a connecting rod, and a slideway is formed in the outer wall outside the bottom of the connecting rod, a hydraulic airrod is arranged at the right end of the outer wall outside the slideway, and a telescopic frame is installed on the outer wall outside the hydraulic air rod. According to the rice processing equipment, a connecting block, a moving shaft and an installation plate are arranged, a cleaning plate can be rotated through the action of the connecting block and the moving shaft, broken rice attached to the outer walls outside crushing gears is cleaned advantageously, unnecessary troubles caused by crushing of the crushing gear are avoided, the crushing gears can be rotated mutually through an electromotor with the type being D180M-O250030C-E, the rice is ground and crushed conveniently, and more convenient is achieved.

Owner:ZHUSHAN COUNTY PEIFENG GRAIN OIL IND TRADE

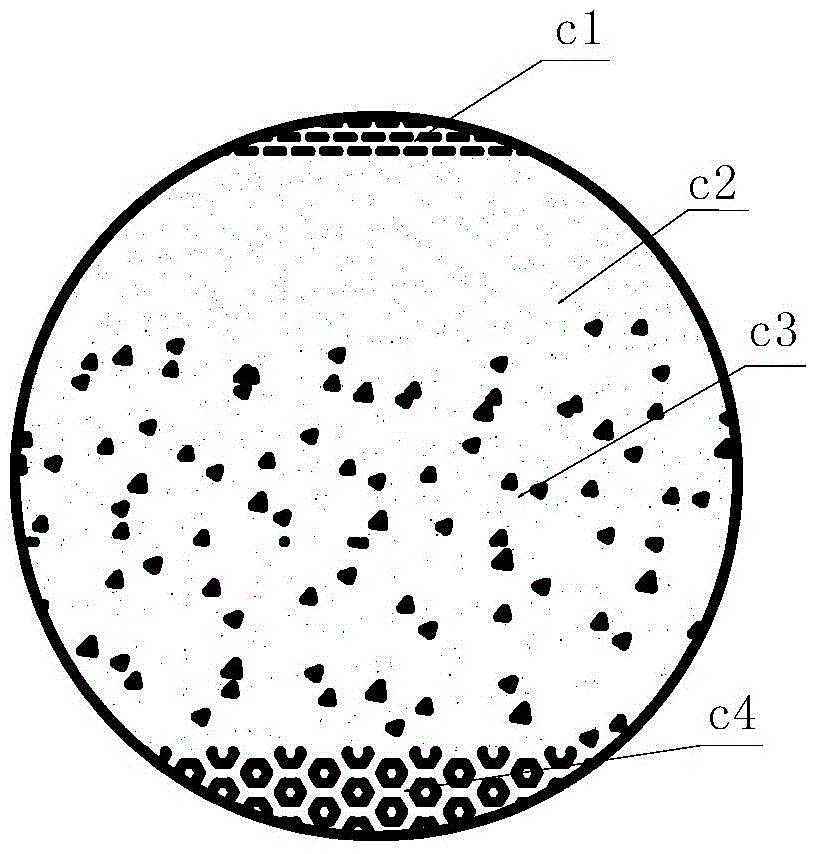

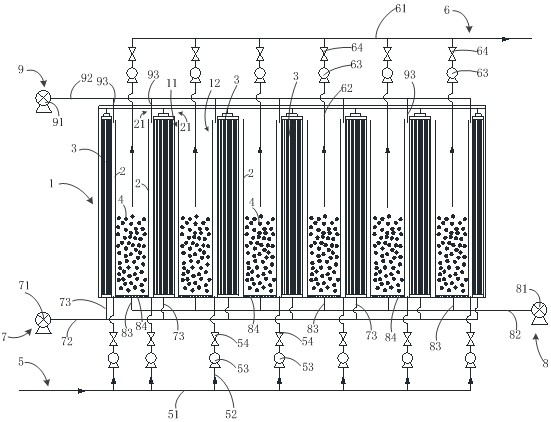

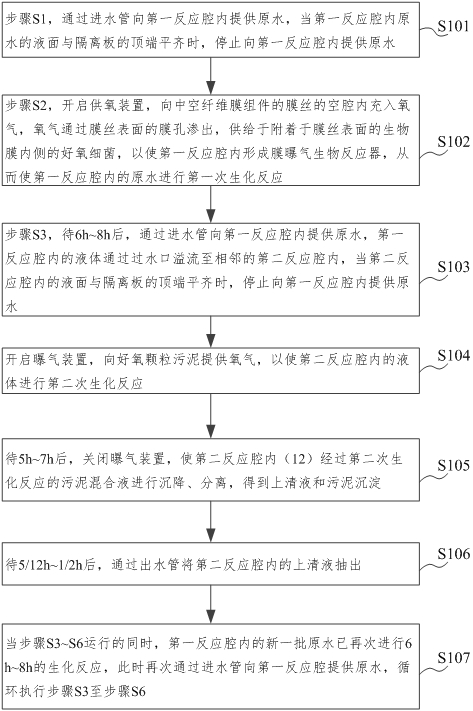

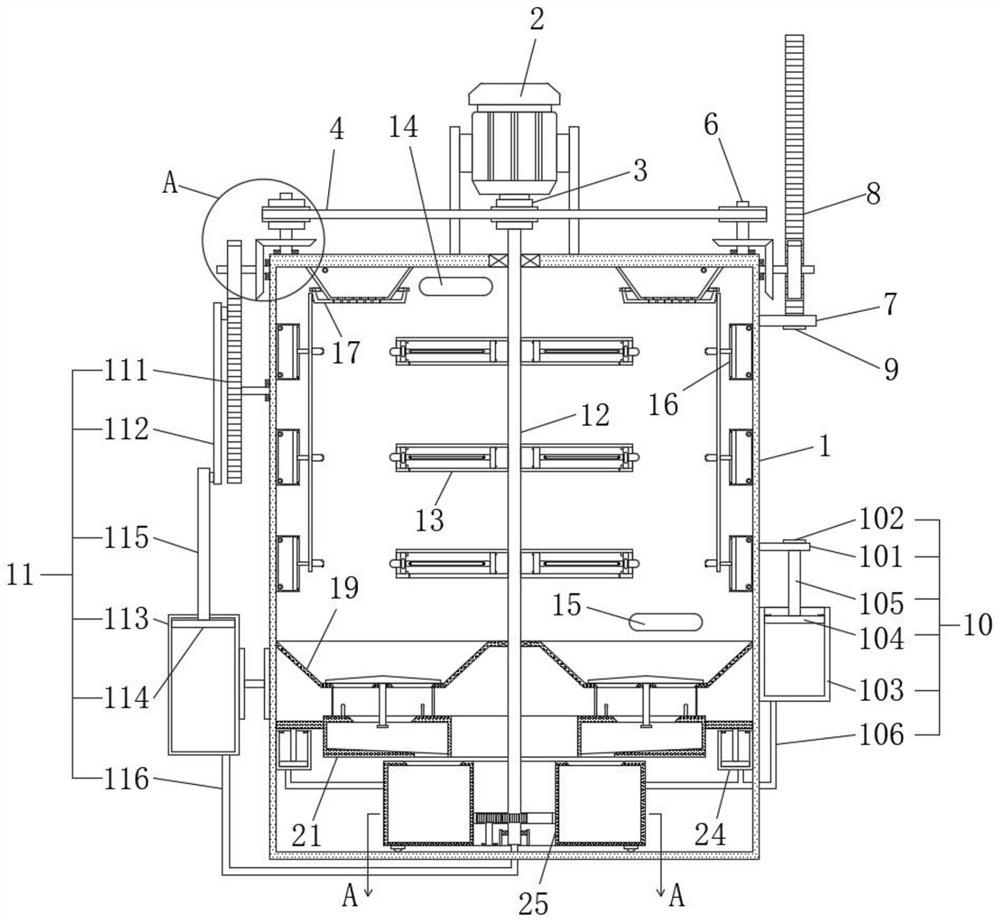

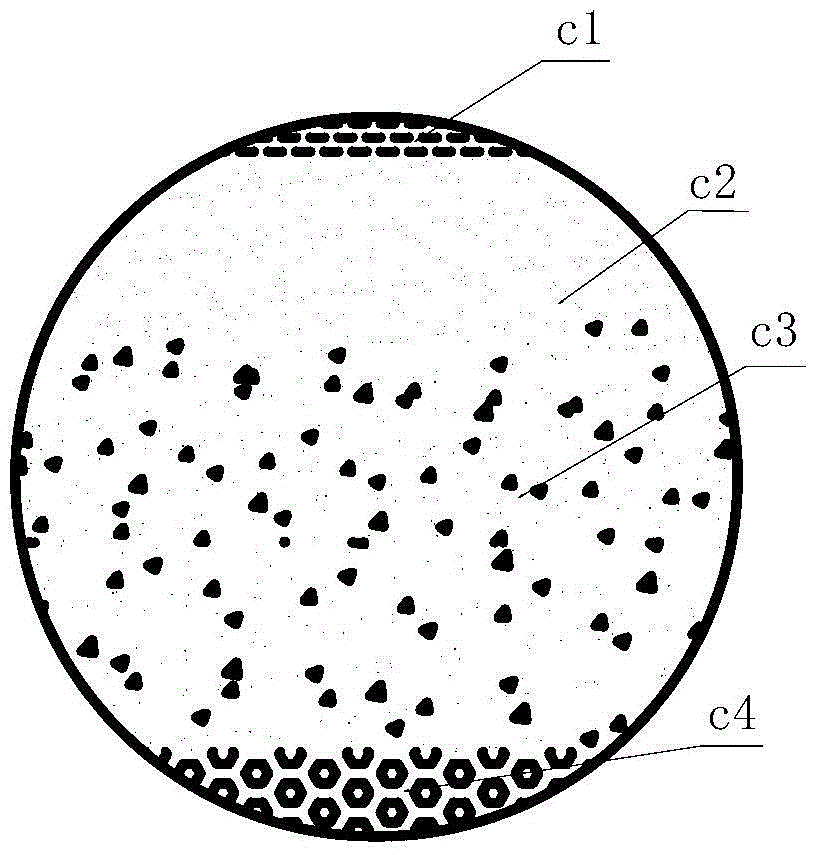

Membrane aeration bioreactor-granular sludge integrated sewage treatment device and method

ActiveCN113636639AHigh removal rateReasonable separationTreatment using aerobic processesWater aerationSludgeSewage treatment

The invention relates to a membrane aeration bioreactor-granular sludge integrated sewage treatment device and a membrane aeration bioreactor-granular sludge integrated sewage treatment method. The device comprises a reaction tank body, an isolation plate, a hollow fiber membrane module, aerobic granular sludge and a pipe gallery structure, the isolation plate is arranged in the reaction tank body and divides the reaction tank body into a first reaction cavity and a second reaction cavity, the hollow fiber membrane module is arranged in the first reaction cavity, the aerobic granular sludge is arranged in the second reaction cavity, and a water passing opening is formed between the top end of the isolation plate and the reaction tank body; the pipe gallery structure comprises a water inlet pipe, a water outlet pipe, an oxygen supply device and an aeration device, the water inlet pipe is connected into the first reaction cavity, the oxygen supply device is communicated with the hollow fiber membrane module, the water outlet pipe is internally connected above the aerobic granular sludge in the second reaction cavity, and an aeration port of the aeration device is located below the aerobic granular sludge in the second reaction cavity. The effluent turbidity is lower, the water quality is better, and a secondary sedimentation tank and a sludge backflow system do not need to be arranged.

Owner:GREENTECH ENVIRONMENTAL CO LTD

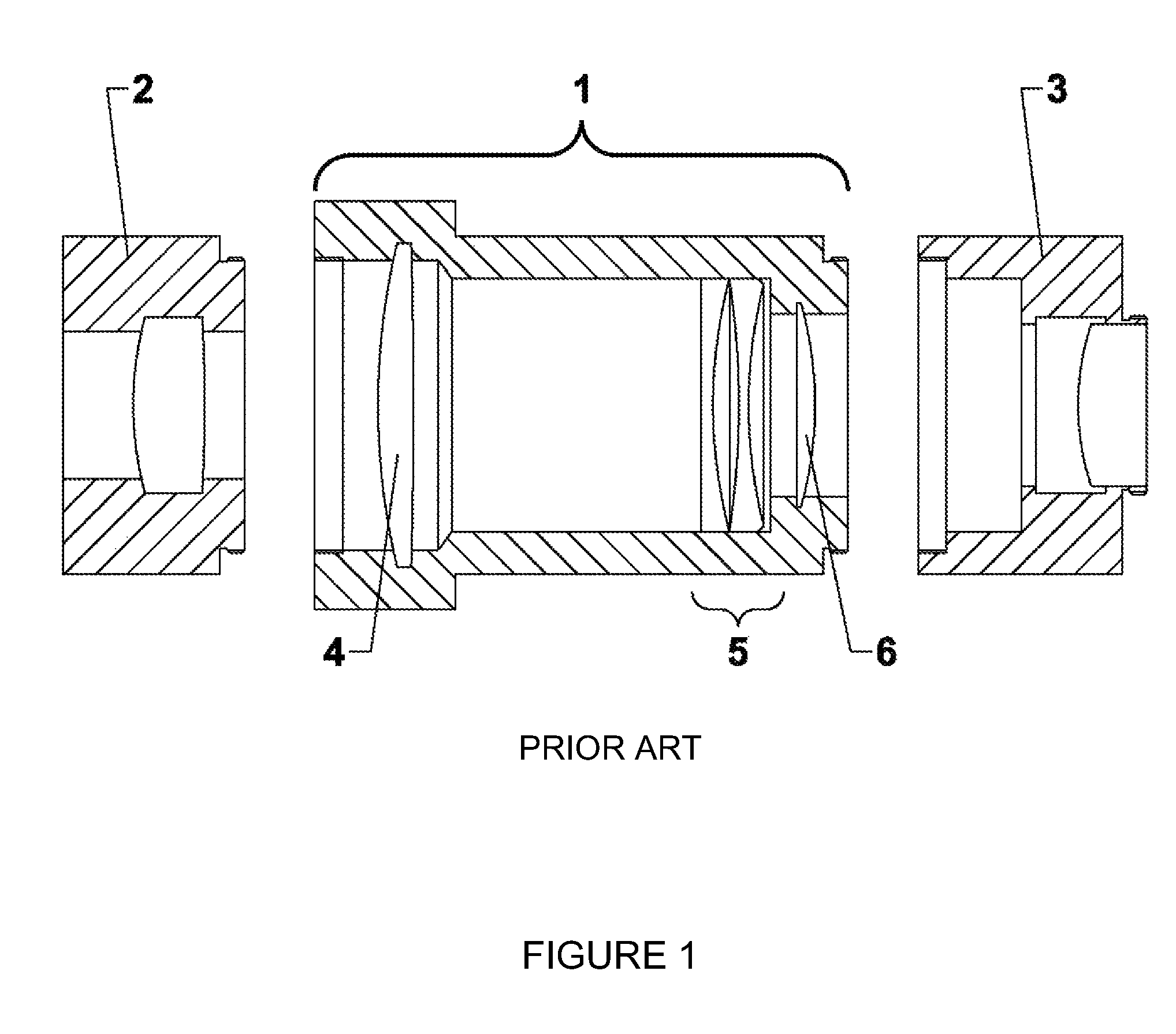

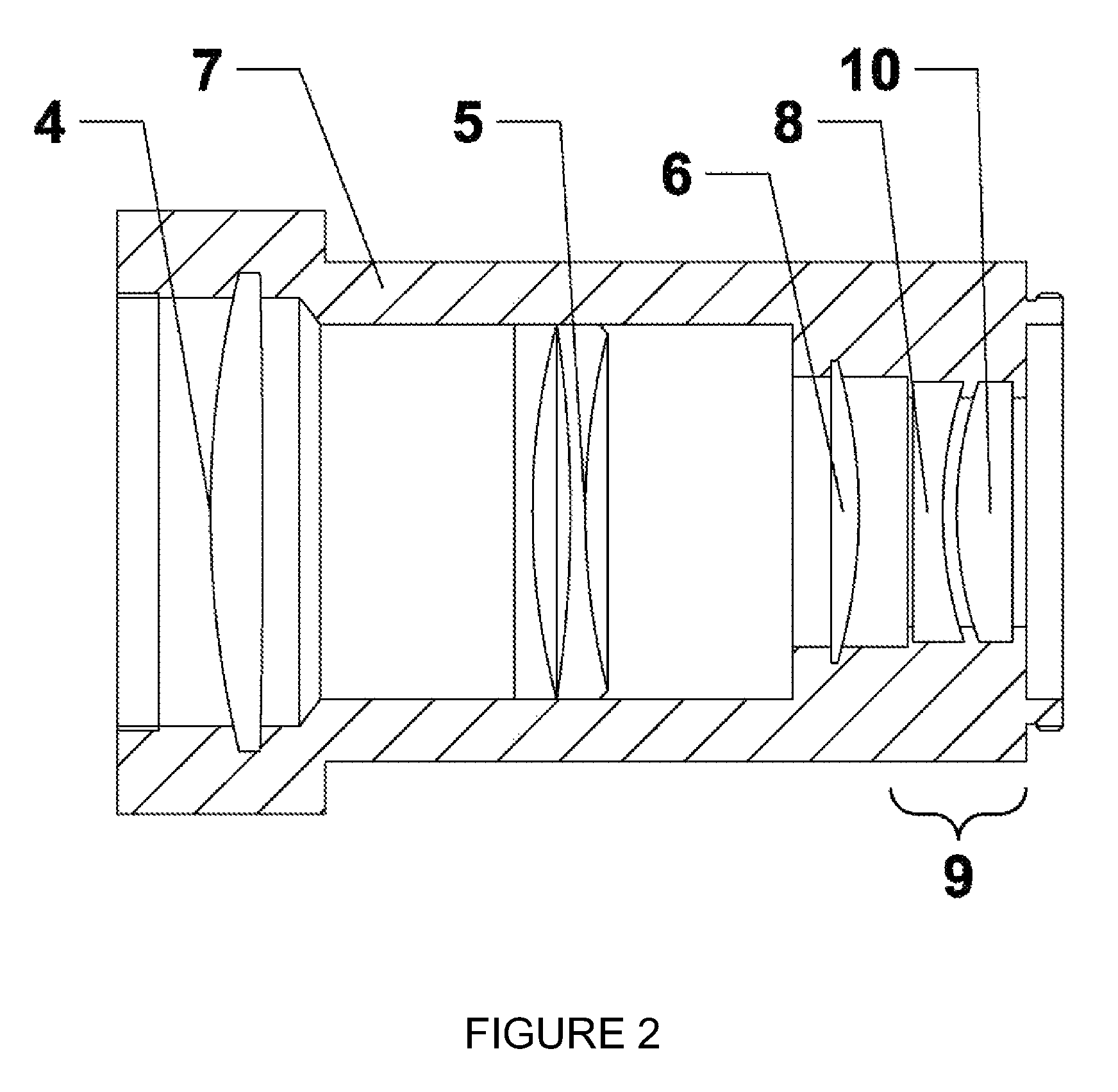

Complex modular afocal variator with spherical and chromatic aberration correction

The present invention provides a complex modular afocal variator in which a modular afocal variator is supplemented with additional optics to form a more complex, but still modular afocal variator system, that can impart internal focusing as well as active spherical and chromatic aberration corrective improvement.

Owner:INFINITY PHOTO OPTICAL

Device for degrading dye wastewater through photocatalytic oxidation

PendingCN113511766AImprove continuitySave spaceWater/sewage treatment by irradiationWater treatment compoundsPhotosensitizerCatalytic oxidation

The invention discloses a device for degrading dye wastewater through photocatalytic oxidation. The device comprises a device box, and a water inlet and a water outlet which are formed in the rear surface of the device box; a motor is mounted at the top of the device box, and the output end of the motor is connected with a one-way driving assembly; a transmission assembly is arranged on the outer side of the one-way driving assembly; and a first steering assembly and a second steering assembly are arranged on the two sides of the top of the device box correspondingly. According to the device, a plurality of steps can be met only by using one device box, so that the space is saved for a factory; meanwhile, one motor can meet a series of steps of pretreatment, precipitate precipitation, photocatalytic oxidation and photosensitizer precipitation of the dye wastewater, so that resources are greatly saved; and meanwhile, the motor does not need to be shut down, so that dye wastewater treatment continuity is high, time can be greatly saved, meanwhile, the working efficiency is effectively improved, and the national call of saving resources is responded.

Owner:ZAOZHUANG UNIV

Examination device for cardiovascular internal medicine department

InactiveCN108969262AEasy to checkConvenient careSurgical furnitureNursing accommodationMedical equipmentMedicine

The invention discloses an examination device for a cardiovascular internal medicine department in the technical field of cardiovascular medical equipment. The device comprises a first sub-body trolley, a second sub-body trolley and a first partition plate and the like, and the first sub-body trolley and the second sub-body trolley are combined by pressing down an L-shaped plate, the combination of the two trolleys facilitates the examination and nursing of a cardiovascular patient with severe condition; when the cardiovascular patient gets stable, the inserting rod is pulled out of a first jack and a second jack, and a inserting pipe and a connecting pipe are separated by pushing the second sub-body trolley, and the first sub-body trolley and the second sub-body trolley are separated, thesecond sub-body trolley is pushed and removed, an electrocardiogram monitor and a defibrillator are removed, and because for part cardiovascular diseases, after the condition is stable, only daily regular examination is needed, timely removing the electrocardiogram monitor and the defibrillator can effectively allocate resources, thereby avoiding waste of medical resources.

Owner:胡人月

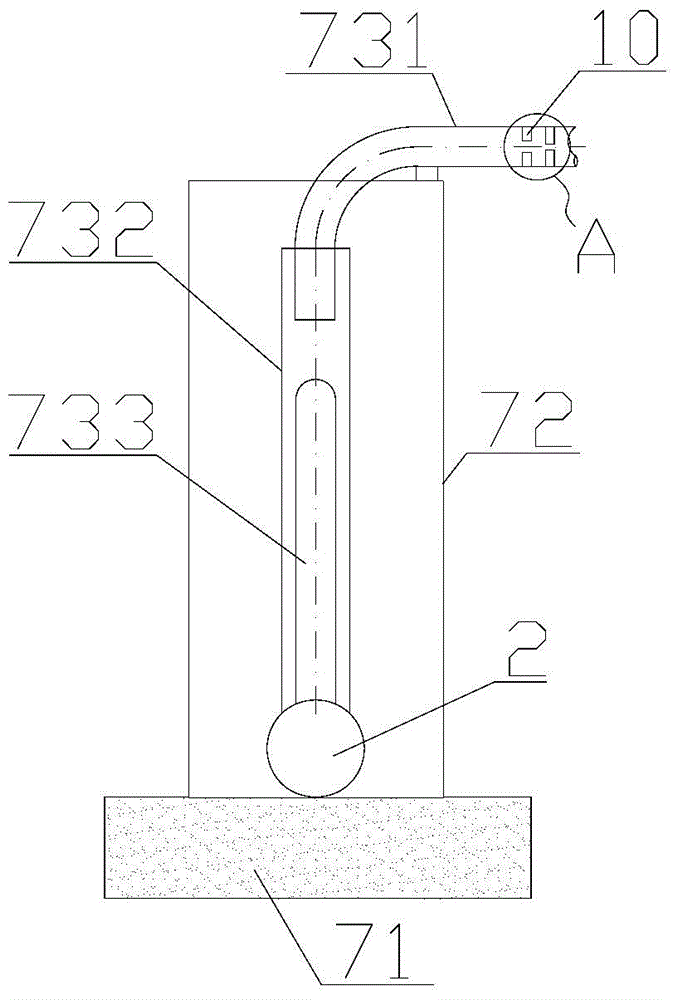

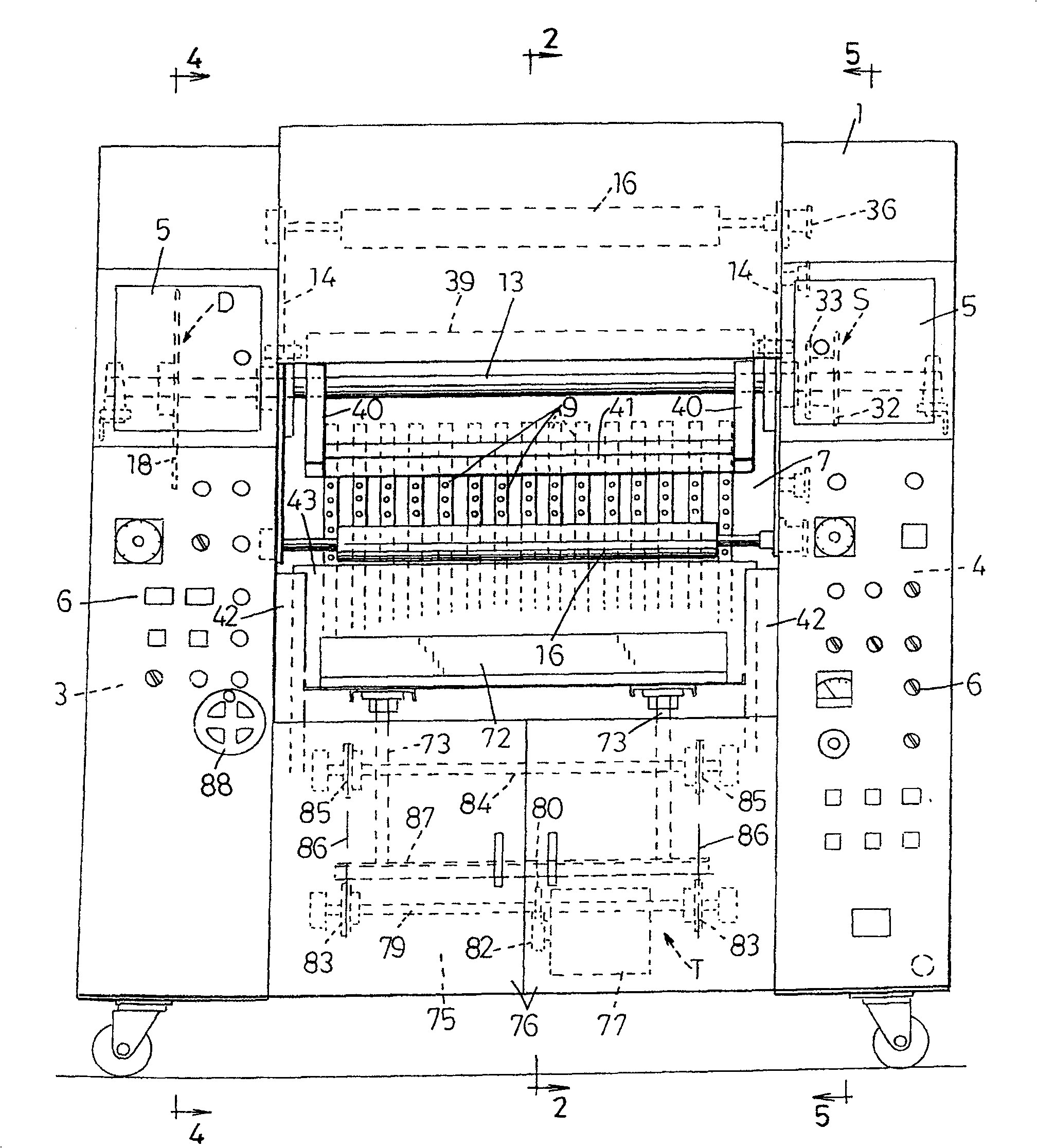

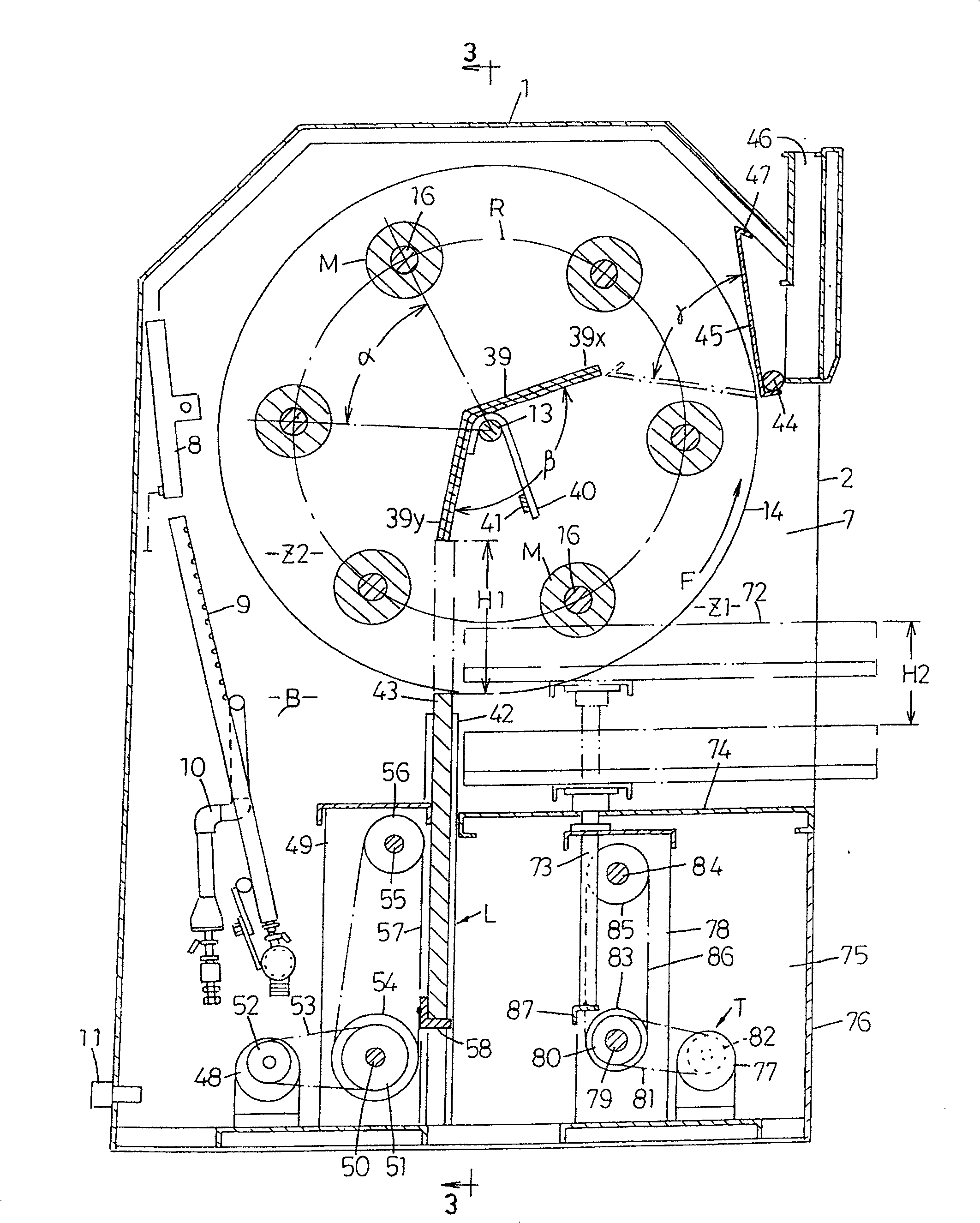

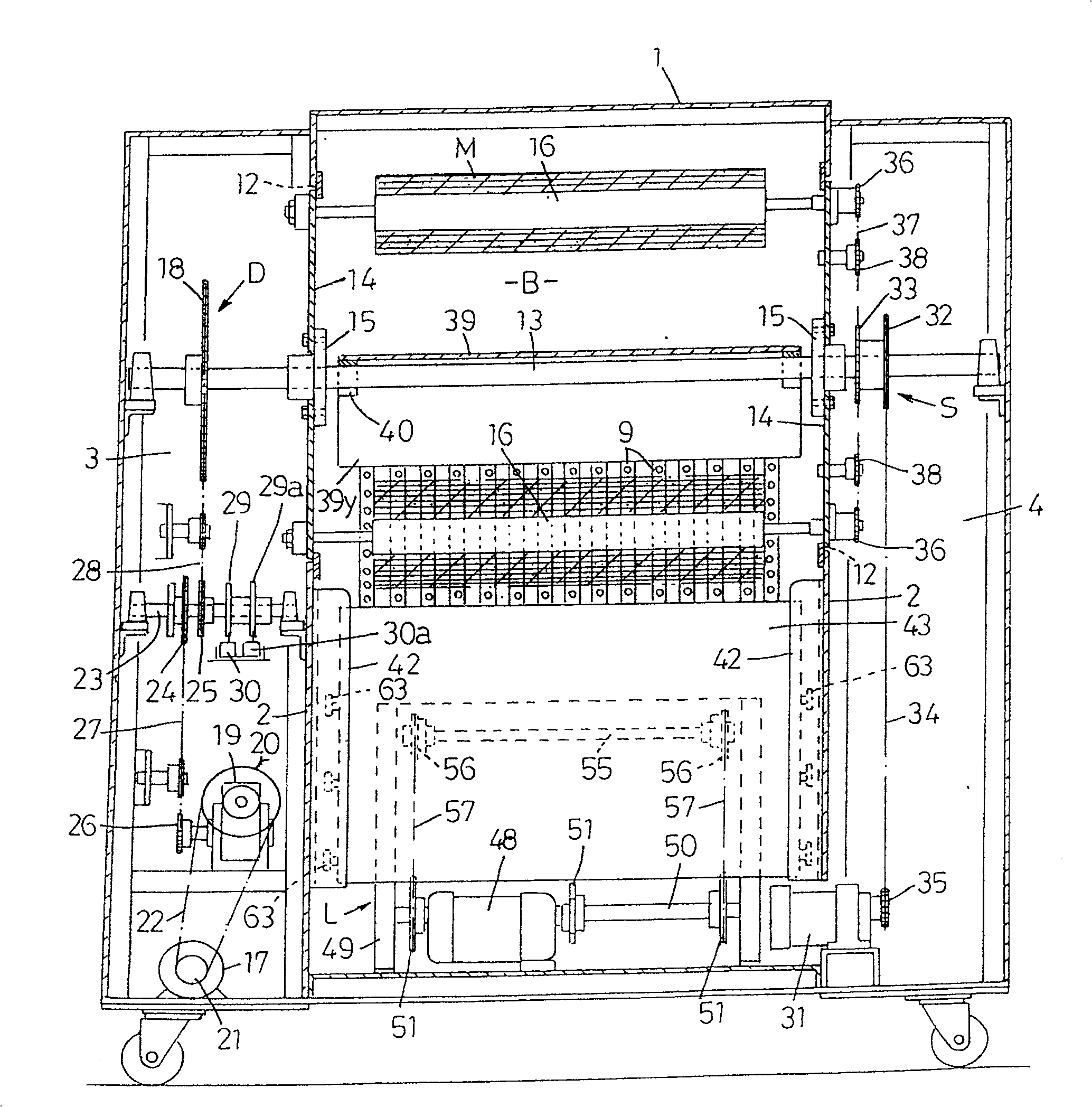

Baumkuchen annual ring cake roast

InactiveCN100539847CEase of mass productionImprove qualityCylindrical cake bakingHigh-frequency/infra-red heating bakingElectrical and Electronics engineeringEngineering

PROBLEM TO BE SOLVED: To obtain Baumkuchen having a rich expansion degree and a rich wet touch in a high quality baked state. SOLUTION: This Baumkuchen-baking machine is characterized by disposing the first, second dividing shutters (43), (45) for dividing a baking oven (B) into an entrance side dough-coating zone (Z1) having a dough dish (72) existing therein and an inner deep side dough-baking zone (Z2) having gas burners (8), (9) of heating sources existing therein, moving forward or backward a first and second dividing shutters (43), (45) to shut off the revolution movement locus (R) of rolling pins (16) synchronously with the intermittent rotation driving of a rotation drum (14), closing the dough-baking zone (Z2) to prevent the release of heat from the dough-baking zone during the temporary stop of the rotation drum (14), and opening the dough-baking zone (Z2) in a state communicating with the side dough-coating zone (Z1) during the rotation of the rotation drum (14).

Owner:株式会社 不二商会

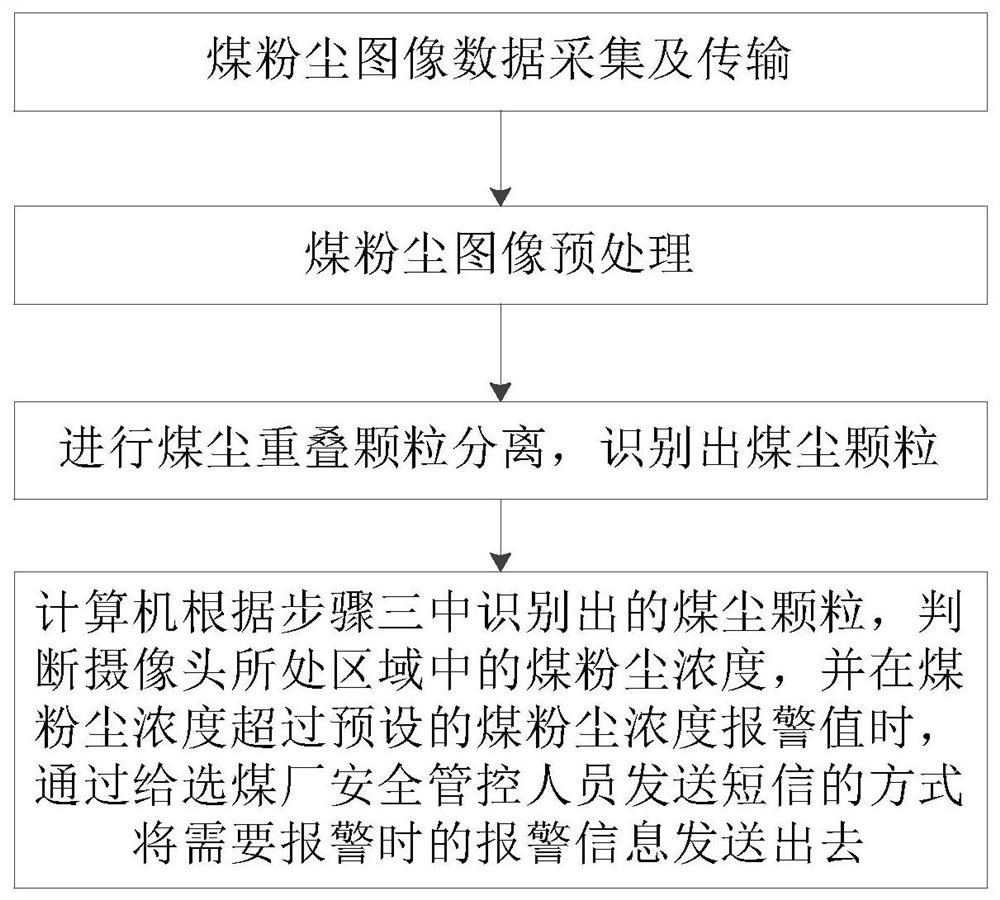

Visual information-based early warning method for coal dust explosion of coal preparation plant

PendingCN113011229AThe method steps are simpleNovel and reasonable designCharacter and pattern recognitionArtificial lifeAlarm messageCoal dust

The invention discloses a coal preparation plant coal dust explosion early warning method based on visual information. The method comprises the following steps: 1, collecting and transmitting coal dust image data; 2, preprocessing the coal dust image; 3, separating overlapped coal dust particles, and recognizing the coal dust particles; fourthly, the computer judges the coal dust concentration in the area where the camera is located according to the coal dust particles recognized in the third step, and when the coal dust concentration exceeds a preset coal dust concentration alarm value, alarm information when an alarm is needed is sent out in the mode that a short message is sent to safety management and control personnel of the coal preparation plant. The method is simple in step, novel and reasonable in design, convenient to implement, capable of reasonably separating out coal dust overlapped particles, good in robustness, capable of effectively detecting the coal dust concentration, high in practicability, capable of being well applied to coal dust explosion early warning of a coal preparation plant, good in using effect and convenient to use and popularize.

Owner:李韵涵

a refrigerator

InactiveCN103471311BSimple structureEasy to useLighting and heating apparatusDomestic refrigeratorsFood materialCold store

The invention relates to a refrigerator which comprises a refrigerator body. A refrigerating chamber is arranged on the upper portion of the refrigerator body, and a freezing chamber is arranged on the lower portion of the refrigerator body. A refrigerator door mounted on the refrigerator body comprises an inner door and an outer door. The inner door and the outer door form the refrigerator door which is of a double-layered door structure. When the refrigerator door is closed, the inner door is positioned in the refrigerator, the outer door facing users enables the users to open the refrigerator body, the inner door and the outer door are in rotating or sliding connection, and the outer door and the refrigerator body are in rotating connection. A plurality of special storage devices and lighting devices are arranged in the refrigerator body, the refrigerating chamber and the freezing chamber according to stored objects. The refrigerator is simple in structure and convenient to use, food can be effectively stored according to different packages or cleanliness, neatness and convenience levels of the food, the problems like scattering and odor tainting of the food or food materials are avoided, safety and convenience in storing of the food or the food materials are improved, and the refrigerator is in conformity with use habits of users.

Owner:GUANGDONG CANBO ELECTRICAL

Sludge flushing and filtering device

InactiveCN109675352AEasy to recycleReasonable separationSludge treatmentSpecific water treatment objectivesSludgeWater pipe

The invention discloses a sludge flushing and filtering device. The sludge flushing and filtering device is provided with a filtering cylinder provided with a sludge inlet, a spraying head is arrangedin the filtering cylinder, a water inlet pipe is arranged at the upper end of the spraying head, a sieving plate is arranged in the filtering cylinder, fine meshes are formed in the sieving plate, awater outlet is formed in the lower side of the filtering cylinder, and a recycling tank is arranged next to the water outlet. The spraying head is arranged in the filtering device, thus sludge can bediluted, impurities and the sludge can be reasonably separated, and the sludge can be recycled more conveniently; the sieving plate is arranged in the filtering cylinder, thus the sludge can be further filtered; and the recycling tank is arranged next to the water outlet, and thus the sludge can be recycled more conveniently.

Owner:江苏江澄环保设备工程有限公司

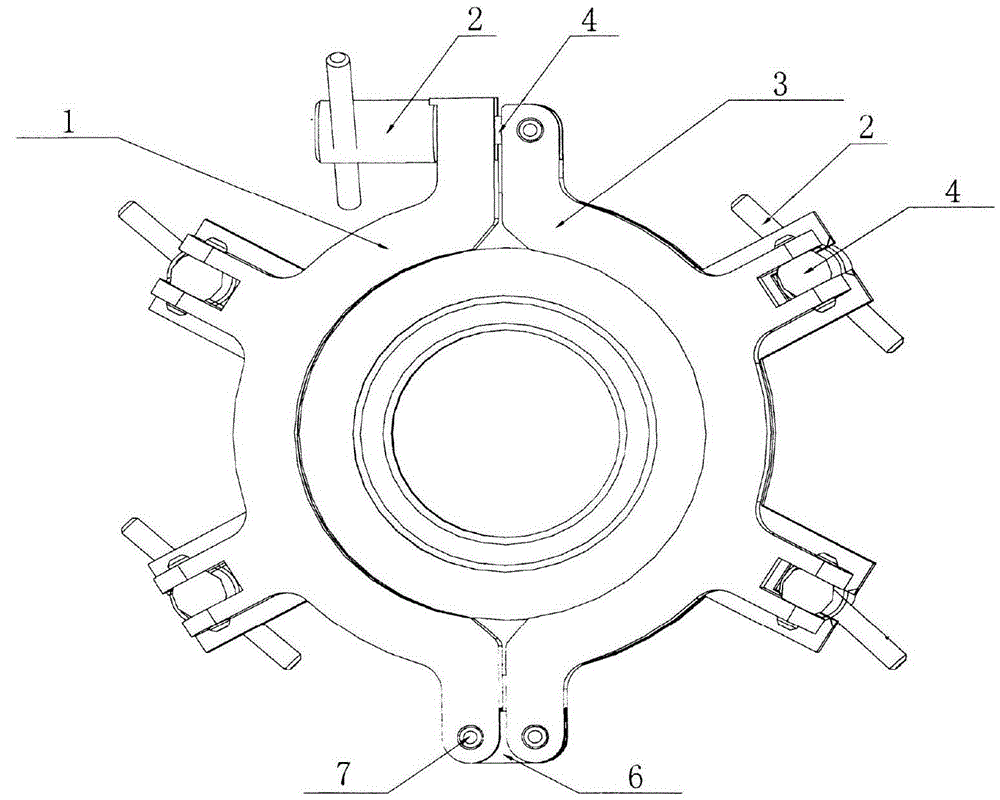

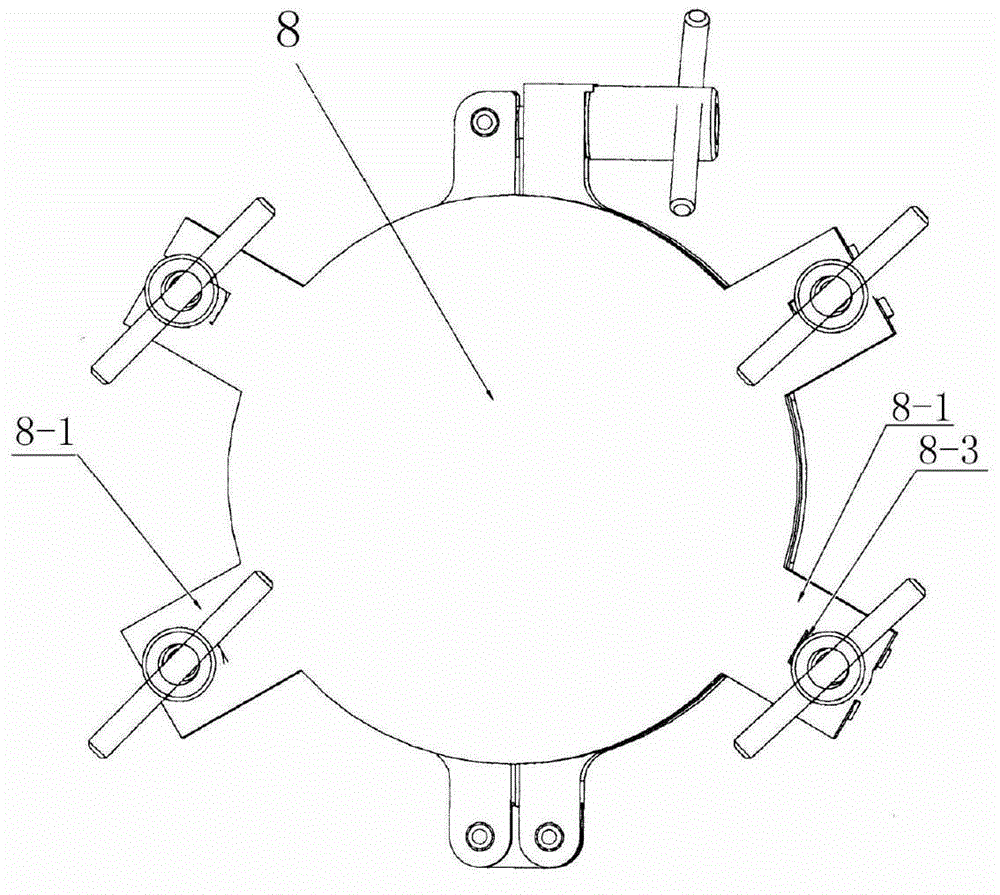

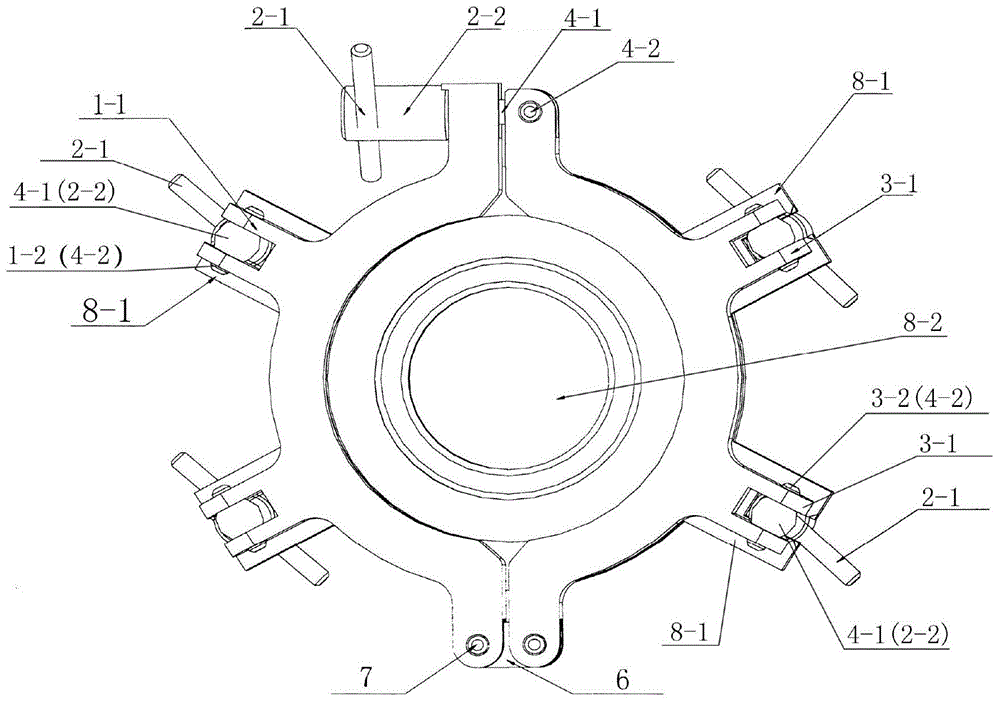

Air-pressing tool fixture and application thereof

InactiveCN104907961ASimple structureEven by forceWork holdersStrength propertiesSoftware engineeringAtmospheric pressure

The invention relates to an air-pressing tool fixture and an application thereof. The air-pressing tool fixture is composed of a left support plate, a right support plate and a retaining cap; one end of the left support plate and one end of the right support plate are fixed with the retaining cap through connecting bolts, and the other end of the left support plate and the other end of the right support plate are connected with each other through matching of a handle nut and a handle bolt, the left support plate is provided with multiple connecting portions I, the right support is provided with multiple connecting portions II, the retaining cap is provided with connecting portions III corresponding to the connecting portions I and the connecting portions II, and the connecting portions I and the connecting portions II are connected with the connecting portions III through matching of handle nuts and handle bolts respectively. An annular part positioning portion is arranged in the middle of the retaining cap. According to the air-pressing tool fixture and the application thereof, the tool weight is light, the structure is simpler, operation and use are convenient, and the sealing performance can be guaranteed.

Owner:SHENYANG AIRCRAFT CORP

A new type of induction cooker

ActiveCN103884029BReasonable structureReasonable separationDomestic stoves or rangesLighting and heating apparatusEngineeringCooker

Owner:佛山市顺德区普发特电器实业有限公司

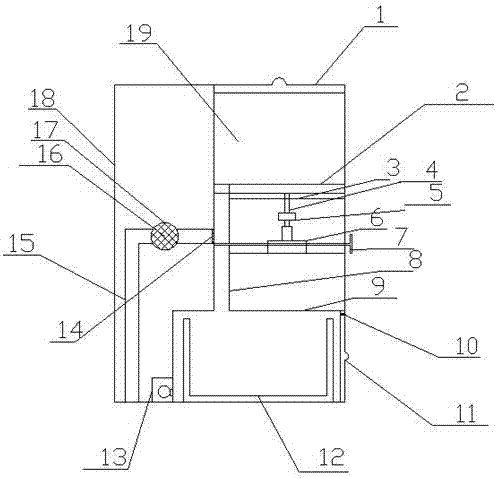

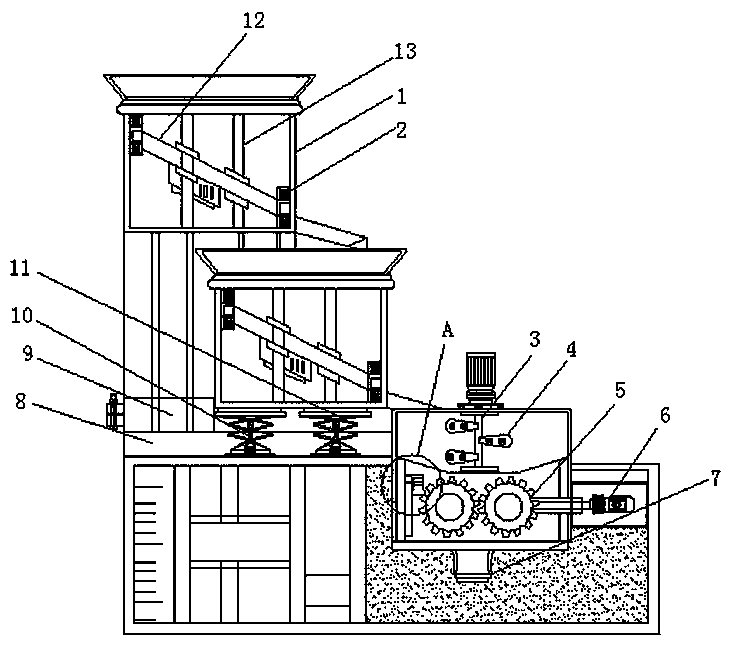

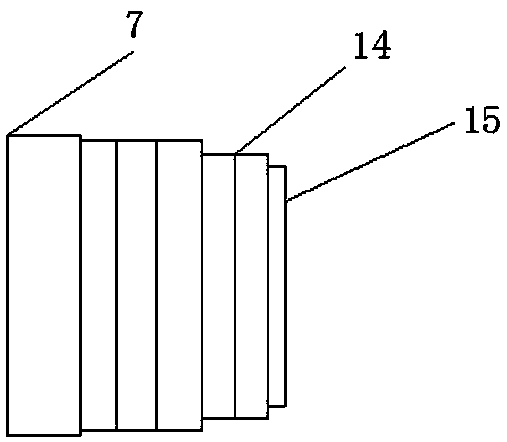

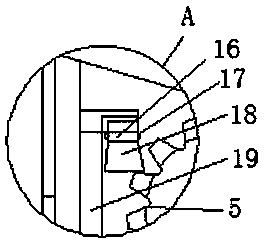

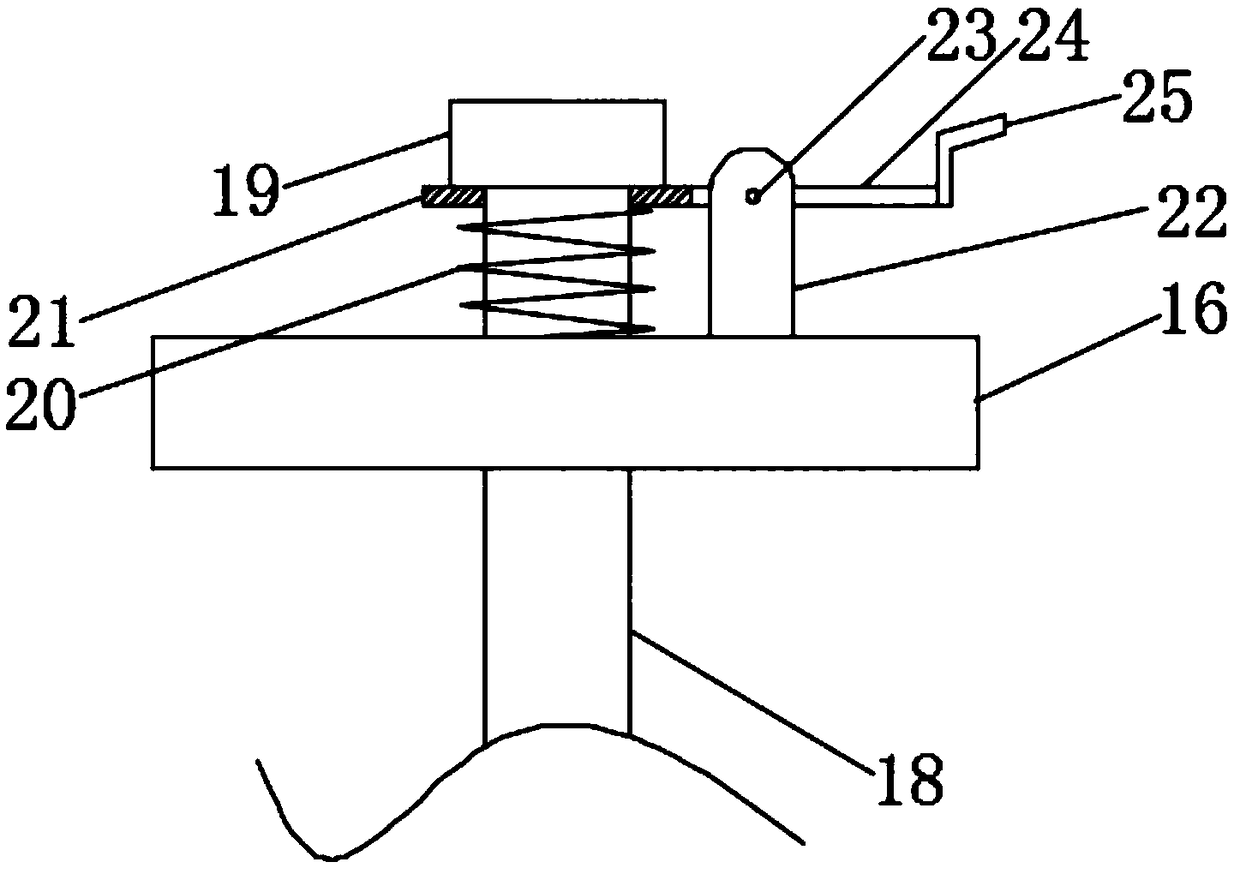

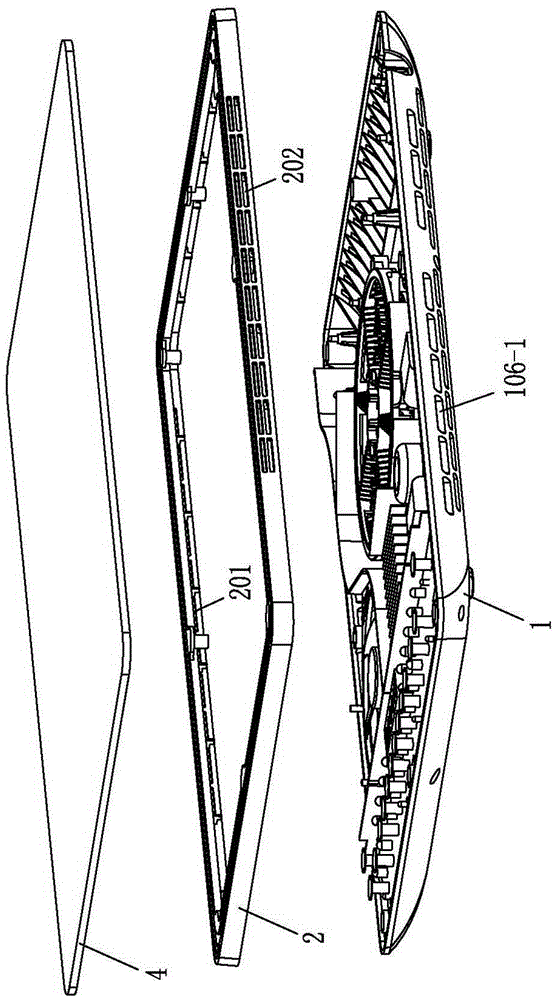

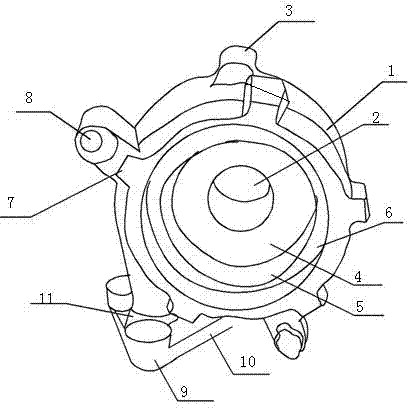

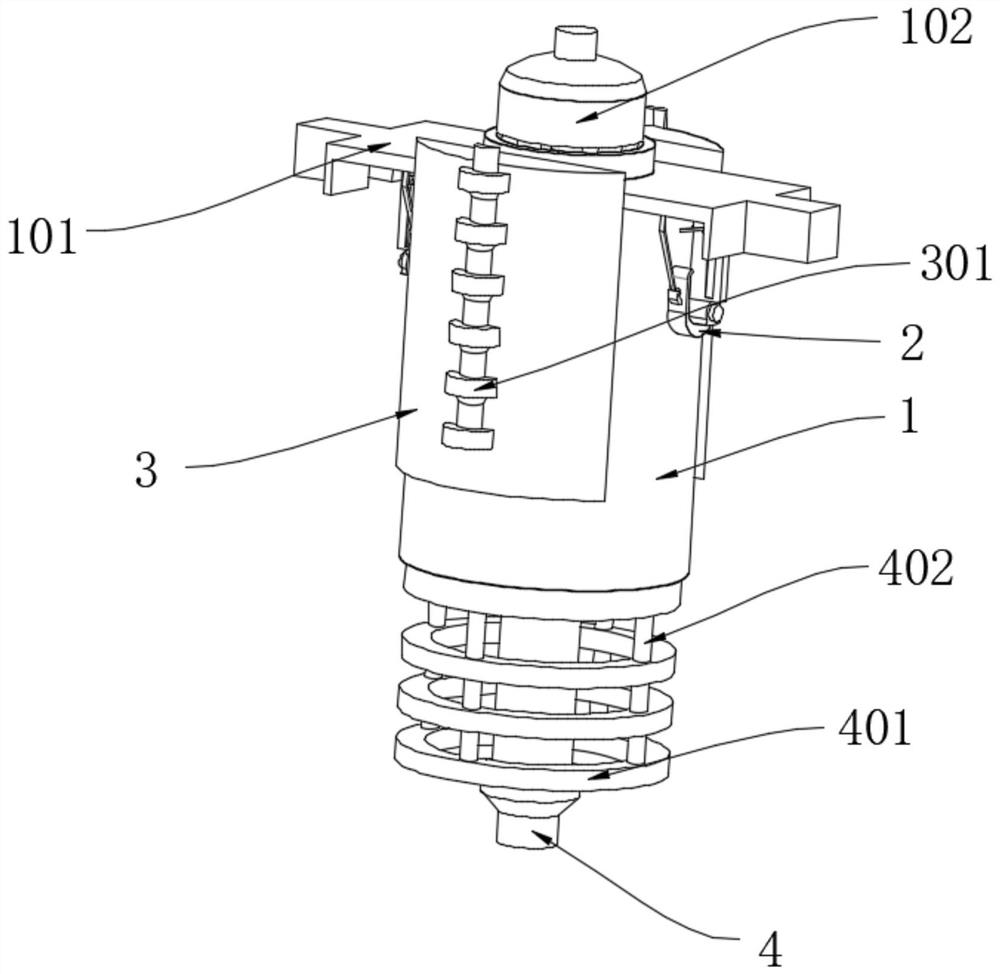

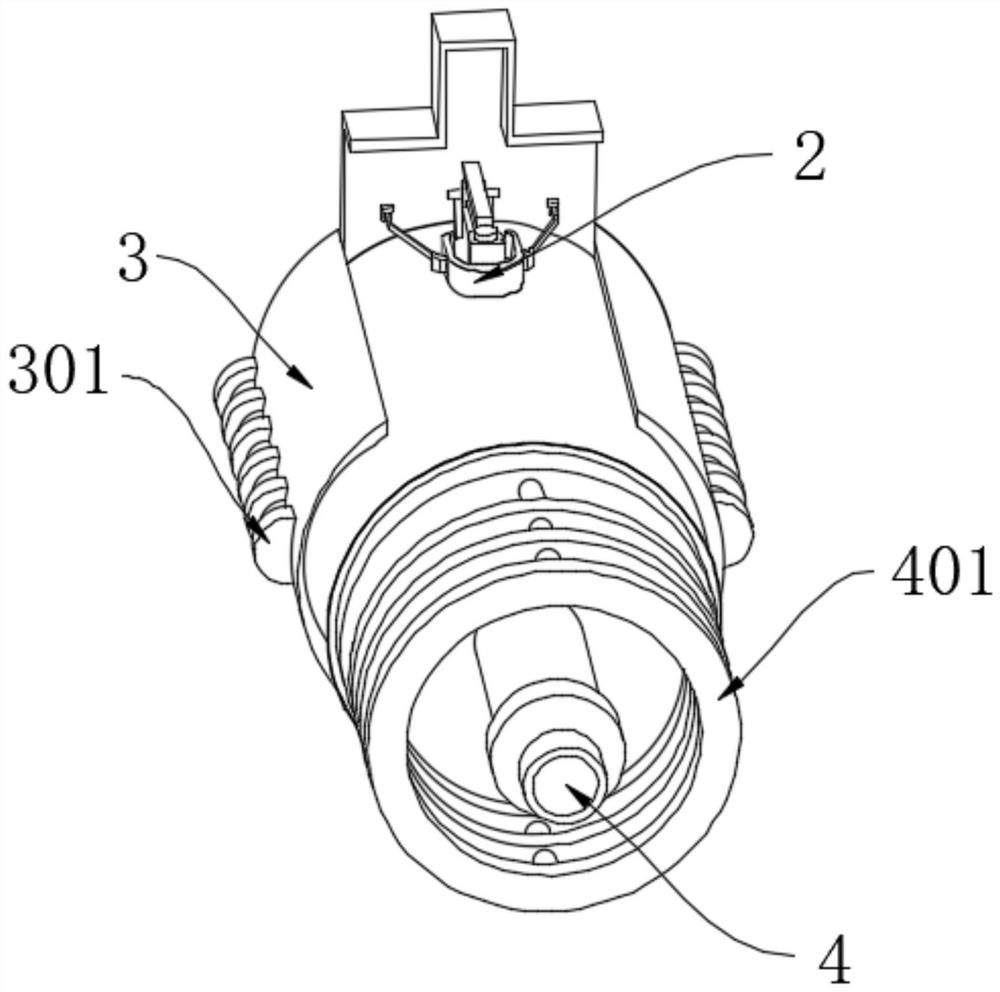

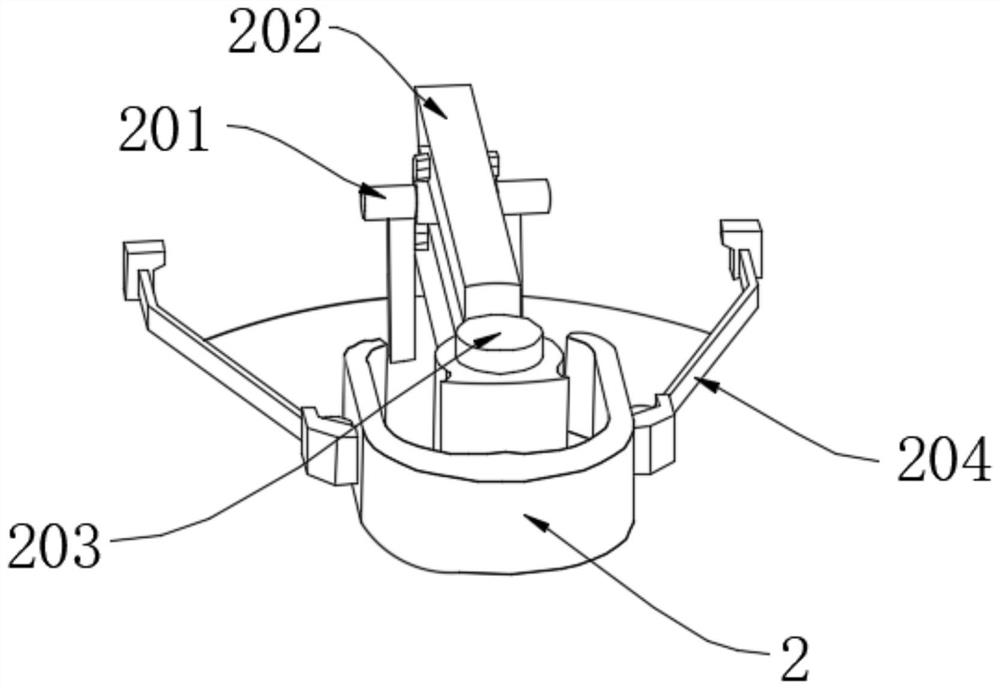

Marine motor fixing device

InactiveCN106936244AReasonable separationSimple structural designSupports/enclosures/casingsEngineeringMotor shaft

The invention discloses a marine motor fixing device, which comprises a fixing device body (1), the fixing device body (1) is provided with a motor shaft positioning hole (2), a support seat and the fixing device body (1) extending outward The clamping piece (3) on the motor shaft positioning hole (2) is provided with a first reinforcement ring (4), a second reinforcement ring (5) and a reinforcement boss (6) in sequence from the inside to the outside, and the reinforcement A lead frame (7) is extended from the boss (6), and a lead hole (8) is provided on the lead frame (7). The invention has a simple structural design, is suitable for large-scale industrial production, and can rationally separate traction wires while stably installing, thereby avoiding safety accidents.

Owner:马卫华

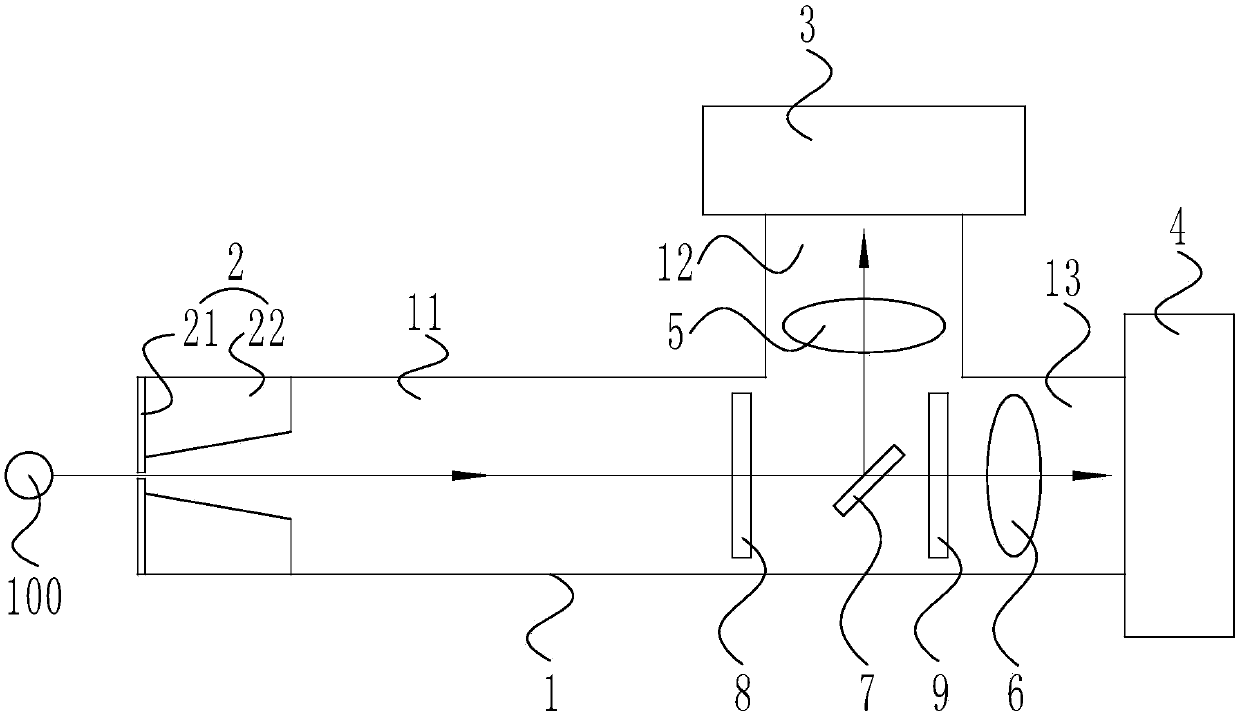

Neutron and X-ray double-spectrum imaging camera

PendingCN107748170ANovel structureEasy to implementMaterial analysis by transmitting radiationPhysicsCompound imaging

The invention discloses a neutron and X-ray double-spectrum imaging camera. The neutron and X-ray double-spectrum imaging camera comprises a flight pipe, the flight pipe comprises a main part, and a first branch part and a second branch part communicated with the main part, wherein the main part and the second branch part are coaxially arranged, and axis of the first branch part and the axis of the second branch part have an included angle; a composite imaging assembly, a first optical image sensor and a second optical image sensor are respectively arranged at outside of the main part, the first branch part and the second branch part, an optical element, a X-ray scintillator and a neutron scintillator are arranged in the flight pipe, wherein the X-ray scintillator is positioned at a frontpart of the optical element, and the neutron scintillator is positioned at a rear part of the optical element. By employing the above structure, two spectrum segment images of neutron radiation and X-ray radiation emitted by a certain radiation source direction can be recorded, an X-ray signal and a neutron radiation signal are separated in a reasonable mode, and a signal to noise ratio of the images is high.

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

Method and equipment for treating waste gas of hot press

ActiveCN102284220BImprove processing efficiencyWon't catch fireUsing liquid separation agentSewageWater spray

Owner:SUZHOU XIELI ENVIRONMENTAL PROTECTION EQUIP

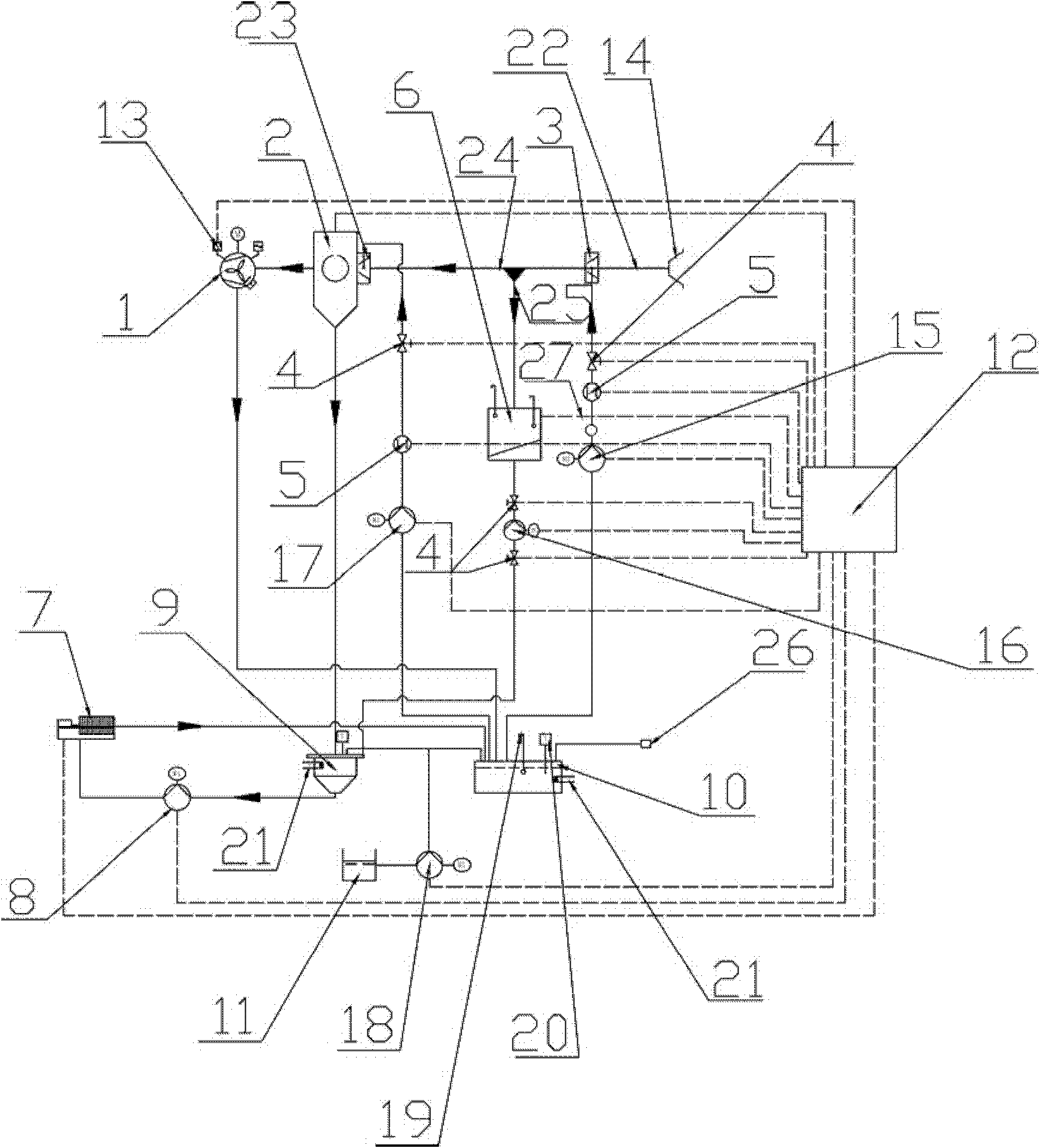

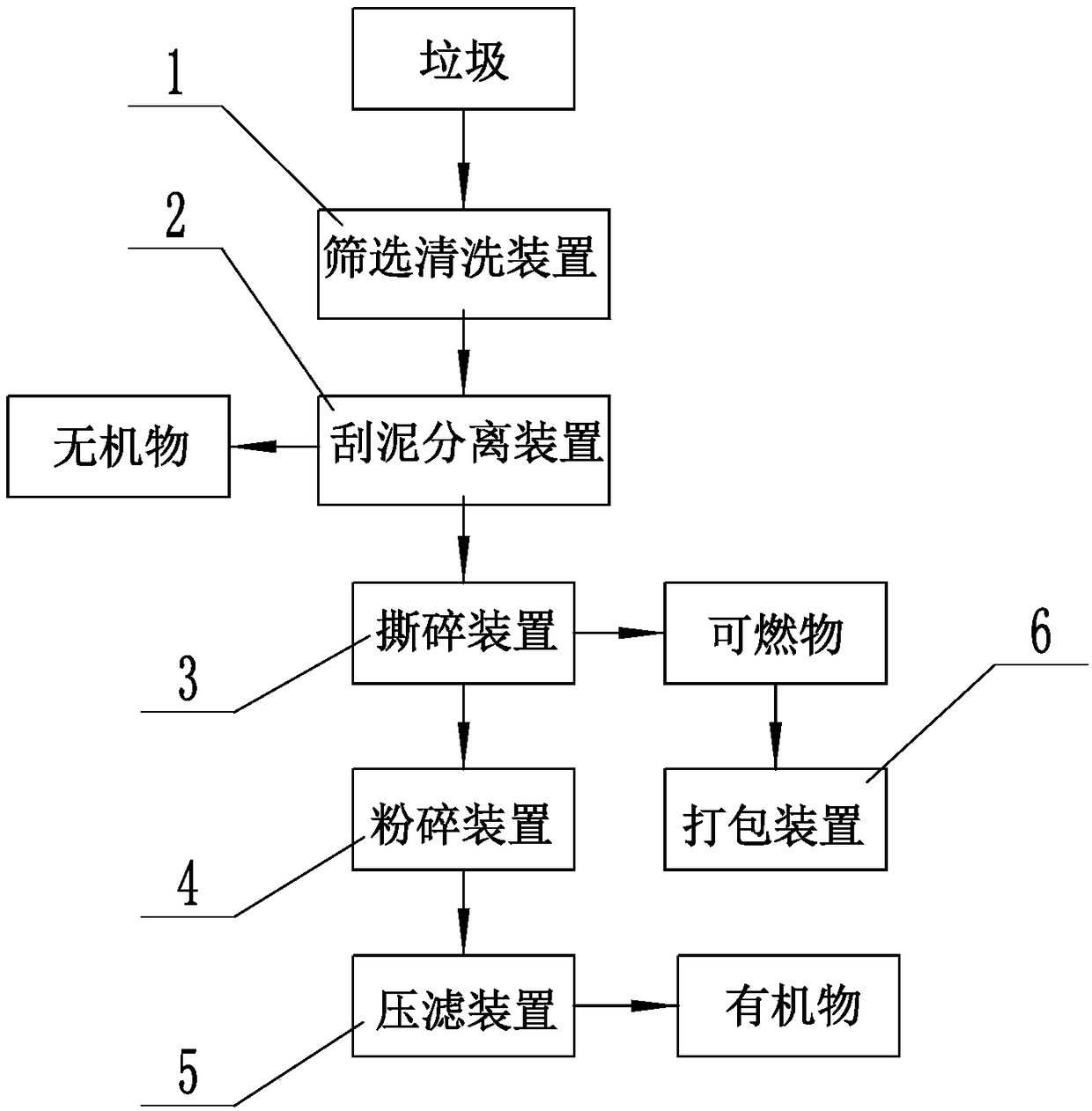

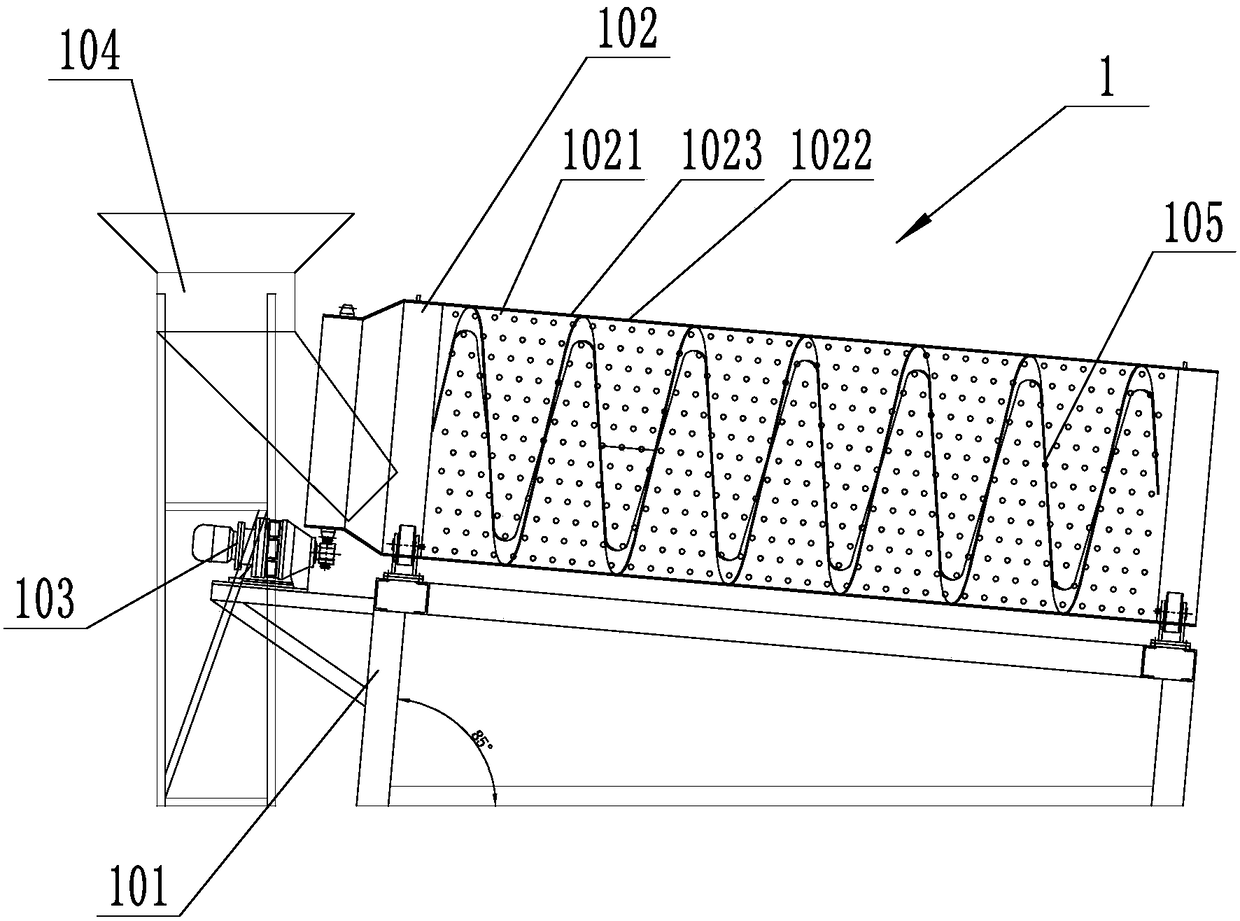

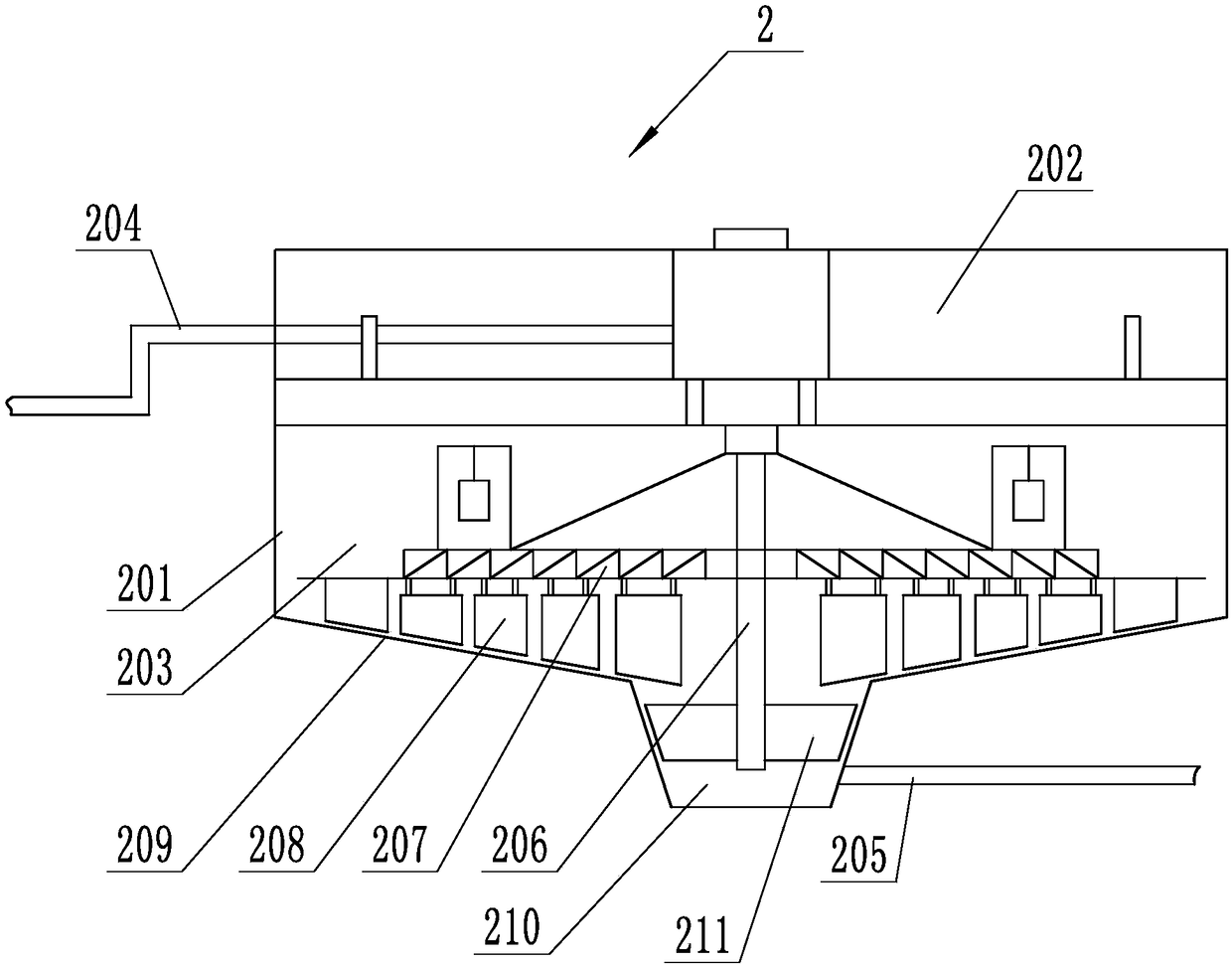

a garbage disposal system

ActiveCN106345790BReasonable separationReliable Separation ProcessingSievingScreeningLitterTherapeutic effect

The invention relates to a garbage treatment system. The garbage treatment system comprises a screening and cleaning device, a mud scraping and separating device, a shredding device, a smashing device, a filter pressing device and a packing device, wherein the mud scraping and separating device separates inorganic matters from organic matters; after the organic matters are shredded through the shredding device, combustible matters are separated; the combustible matters are packed through the packing device; and after the combustible matters are separated from the organic matters, the organic matters are treated by the smashing device and the filter pressing device to form organic matter filter cakes. By the garbage treatment system, garbage can be reasonably and reliably separated, secondary pollution does not exist after the garbage is treated, a treatment process is simple, treatment effect is good, and efficiency is high.

Owner:WUXI JINYUAN SLUDGE DISPOSAL NEW FUEL TECH

Automatic separation device for medium and fine-grained sludge in tailings conveying main pipe

ActiveCN104874472BReasonable separationDelivery normalMechanical material recoveryWet separationMining engineeringDiameter ratio

The invention discloses an automatic separating device for fine-sized slime in tailings conveying manifolds and belongs to mine tailings grading and conveying equipment. At least one guiding-out mechanism composed of a door-shaped support and a leading-out pipe is arranged on any tailings conveying manifold, each leading-out pipe is fixed on the corresponding door-shaped support and communicated with the corresponding tailings conveying manifold and a fine grain conveying pipe in a connected manner respectively, a proportion flow limiting mechanism is arranged in a horizontal pipe section at the tail of each leading-out pipe, and the middle of each fine grain conveying pipe is supported by multiple supporting frames while the head of the same extends into a mine pit. Each leading-out pipe composed of a vertical pipe, a first bypass inclined pipe, a second bypass inclined pipe and a connecting elbow is adopted, and pipe-diameter ratio and tailings slurry flow speed are designed reasonably, so that separating of fine-sized slime in the tailings conveying manifold can be realized without newly-added power, energy resources are saved, the fine-sized slime entering a tailings pond is reduced, grade matching of tailings entering the tailings pond is improved, gradient of a dry beach at a flood regulation section is increased, and safety superelevation and flood regulation height floor prevention indicators of the tailings pond are enabled to meet safety requirements.

Owner:ANHUI MASTEEL MINING RESOURCES GRP NANSHAN MINING CO LTD +1

Equipment for conveniently extracting and preparing adipose-derived stem cell exosome and extraction process

PendingCN113832003AAvoid damageQuantity averageBioreactor/fermenter combinationsCell dissociation methodsExosomeBiology

The invention relates to the technical field of cell preparation, and provides equipment convenient for extracting and preparing adipose-derived stem cell exosomes and an extraction technology. The equipment comprises a separation adjusting frame, an extraction head and a separation frame, the separation adjusting frame comprises a pushing block, and rotating wheels used for adjusting the descending position are movably connected to the two sides of the pushing block; a central rotating rod is movably connected to the side, away from the rotating wheel, of the pushing block, and sliding connecting rods used for adjusting pressure are arranged on the two sides of the central rotating rod correspondingly. According to the equipment for conveniently extracting and preparing adipose-derived stem cell exosome and the extraction process, collected materials are stacked to extrude the air bag frame, so that the air bag frame drives the clamping plate frame and the stabilizing frame through the air column to be tightly buckled and separated into the groove of the rotating block, the rotating stabilizing force in the air bag frame is increased, and the separated precipitate is adipose-derived stem cell exosome, so that the separation stability of the key substance liquid is improved, and the collection efficiency of the adipose-derived stem cell exosome is improved.

Owner:上海芙普瑞生物科技有限公司

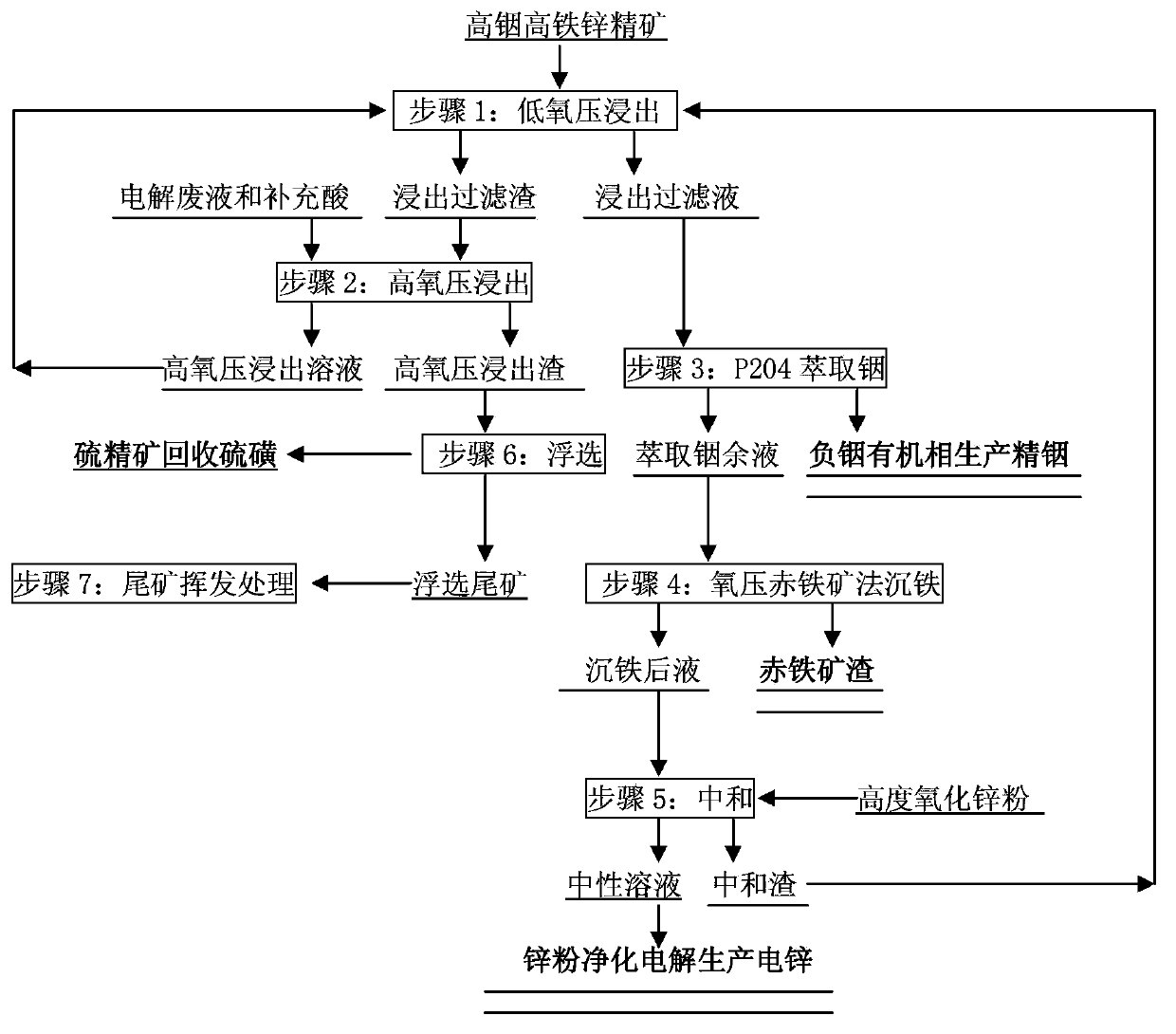

Treatment method of high-indium high-iron zinc concentrate

The invention relates to a treatment method of high-indium high-iron zinc concentrate, which comprises the following steps: carrying out two-section acidic reflux oxygen pressure leaching, including low-oxygen-pressure leaching and high-oxygen-pressure leaching, on zinc concentrate which contains 0.07-0.25% of indium In, 14-25% of iron and 40-50% of zinc; directly extracting indium from the low-oxygen-pressure leaching solution; precipitating iron from the solution after indium extraction by an oxygen pressure hematite process, thereby producing hematite slag containing 55-65% of iron; neutralizing the solution after iron precipitation with zinc oxide; carrying out zinc dust purification electrolysis on the neutralized solution to produce electric zinc; returning the neutralized slag to the low-oxygen-pressure leaching; and separating sulfur concentrate and flotation tailings from the high-oxygen-pressure leaching slag by a flotation process, recovering sulfur from the sulfur, and sending the flotation tailings into a fuming furnace to carry out reduction volatilization treatment. The invention can effectively separate iron, zinc and indium in the zinc concentrate, enhance the smelting recovery rate of zinc and indium, recycle iron in the zinc concentrate as a resource, and fundamentally avoid producing low-concentration sulfur dioxide, thereby effectively protecting the environment.

Owner:LAIBIN CHINA TIN SMELTING

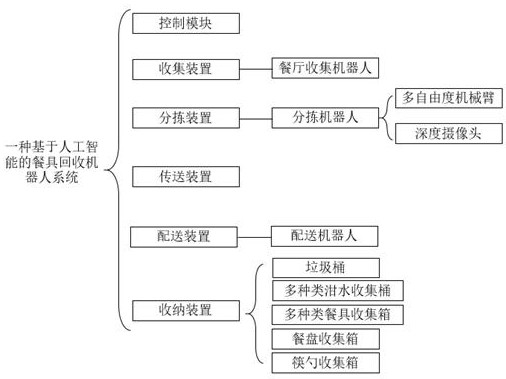

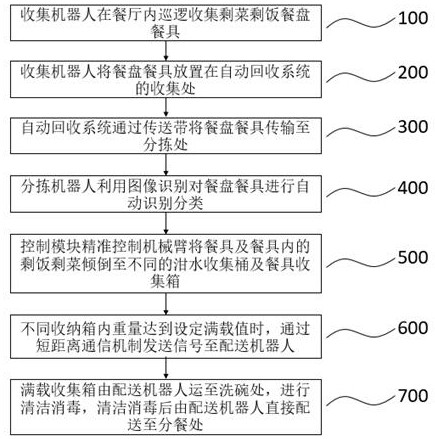

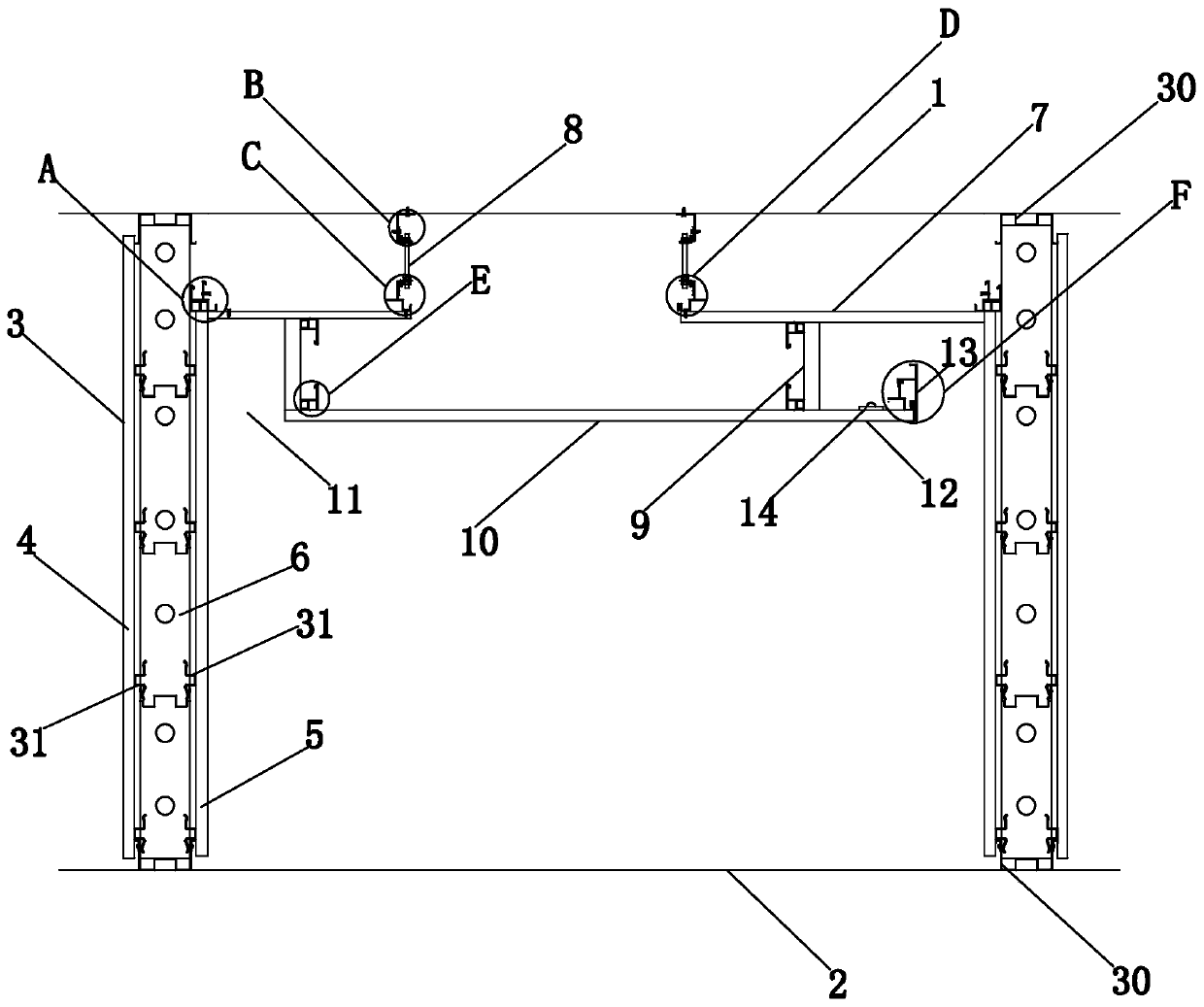

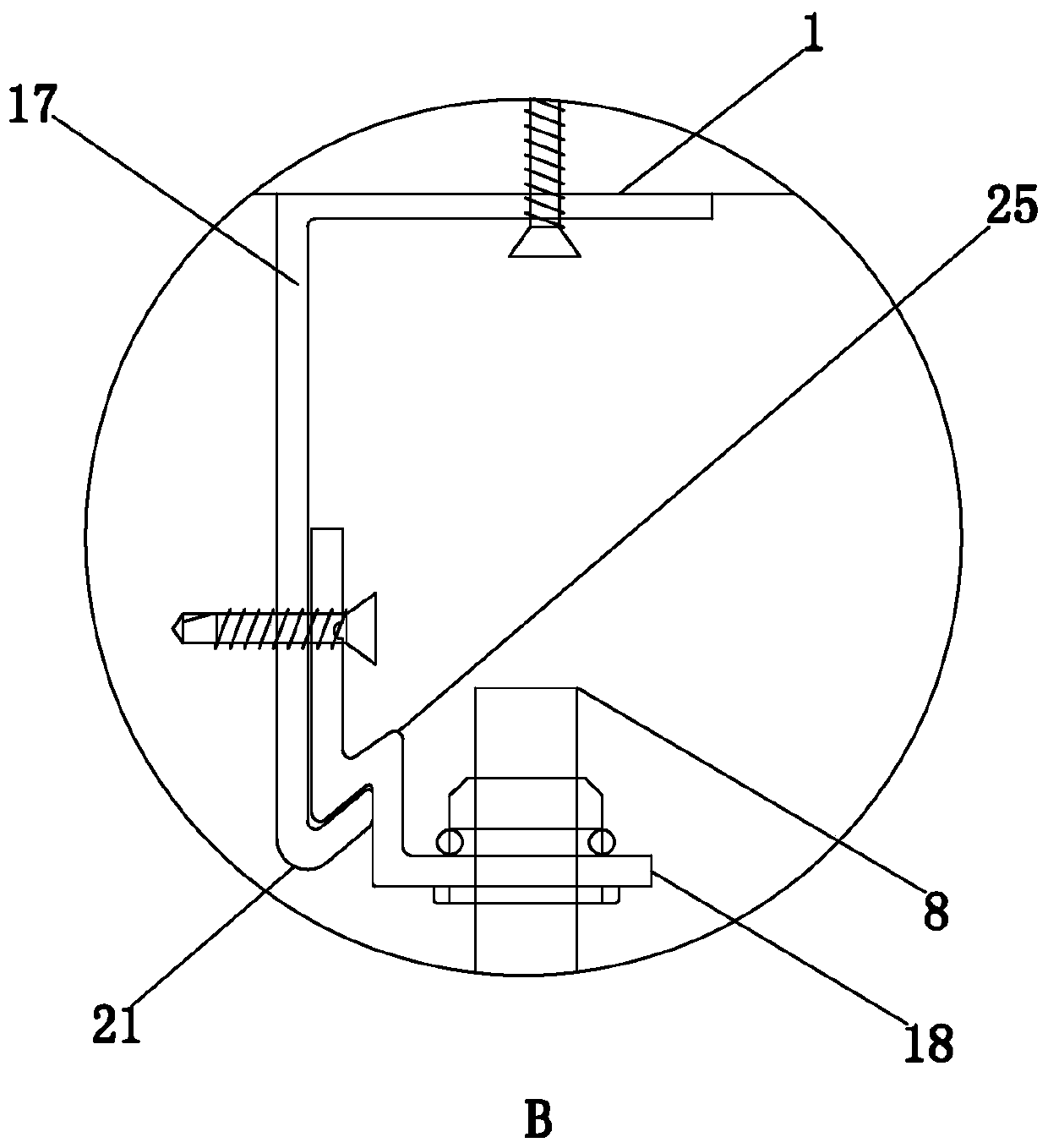

Tableware recycling robot system based on artificial intelligence

PendingCN114101103AReasonable separationImprove sanitationBottle emptyingSortingControl engineeringIndustrial engineering

The invention provides a tableware recycling robot system based on artificial intelligence. The system comprises a control module, a collecting device, a sorting device, a conveying device, a distribution device and a storage device, the sorting device comprises a multi-degree-of-freedom mechanical arm and a depth camera, the conveying device comprises a conveyor, a conveying belt and a conveying track, and the distribution device is a distribution robot; the storage device comprises a garbage can, a multi-type swill collecting barrel, a multi-type tableware collecting box, a dinner plate collecting box and a chopstick and spoon collecting box.

Owner:山东新一代信息产业技术研究院有限公司

Fabricated partition wall ceiling structure

PendingCN110306714AAvoid pollutionAvoid the problem of cross-construction mutual interferenceCeilingsFloor slabKeel

The invention discloses a fabricated partition wall ceiling structure. The fabricated partition wall ceiling structure comprises a roof and a floor. Fabricated partition walls are connected between the two sides of the roof and the floor. Each fabricated partition wall comprises an outer wall board, an inner wall board and a keel framework arranged between the outer wall board and the inner wall board. A composite ceiling is arranged between the upper ends of the pair of inner wall boards. The composite wall ceiling comprises a pair of first-stage ceiling edge plates, a pair of horizontal screws, a pair of necking-down vertical plates, and a pair of secondary ceiling plates. The fabricated partition wall ceiling structure is novel in design and stable and firm in structure, all componentsare combined ingeniously, the indoor space is reasonably partitioned, the multi-stage ceiling structure is perfect, and rich shapes and variable functions can be achieved through expansion and extension.

Owner:艺墙之格建筑发展(上海)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com