A new type of induction cooker

An induction cooker, a new type of technology, applied in the field of induction cooker, can solve the problems of easy failure, burnout of coil disks and circuit board components, long residence time, etc., and achieve the effects of improving heat dissipation and exhaust speed, prolonging service life, and increasing cold air flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

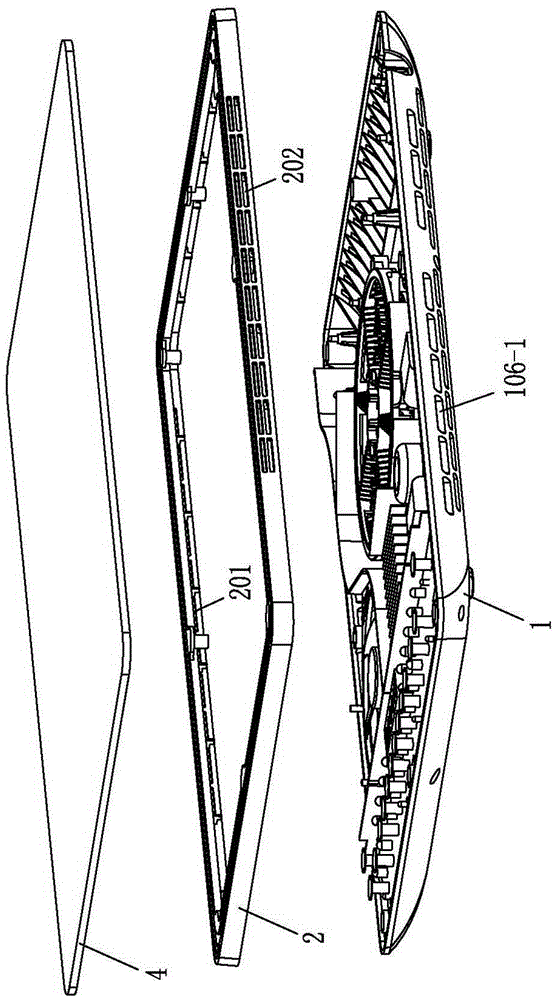

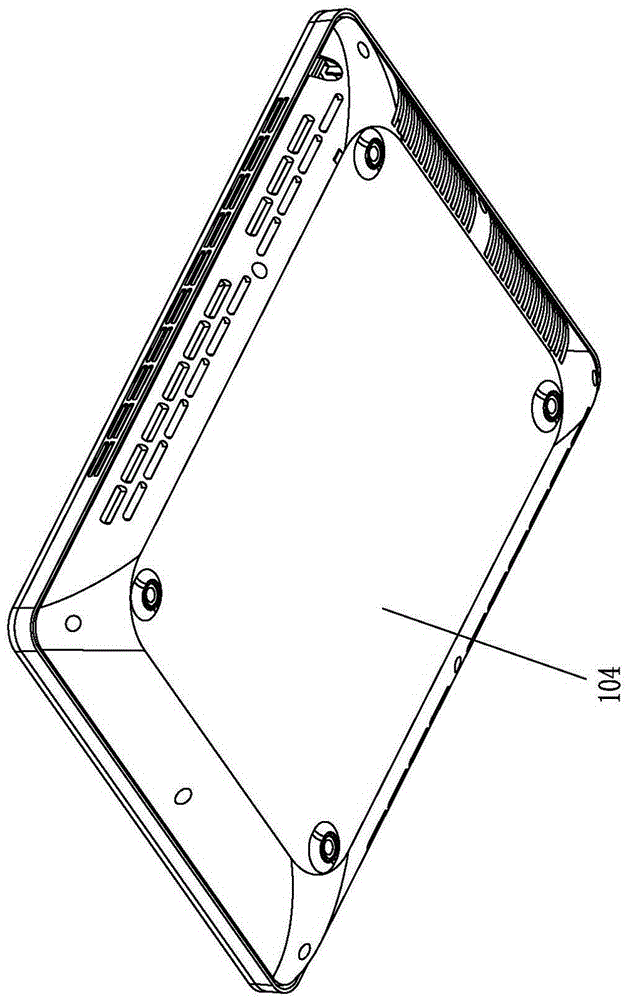

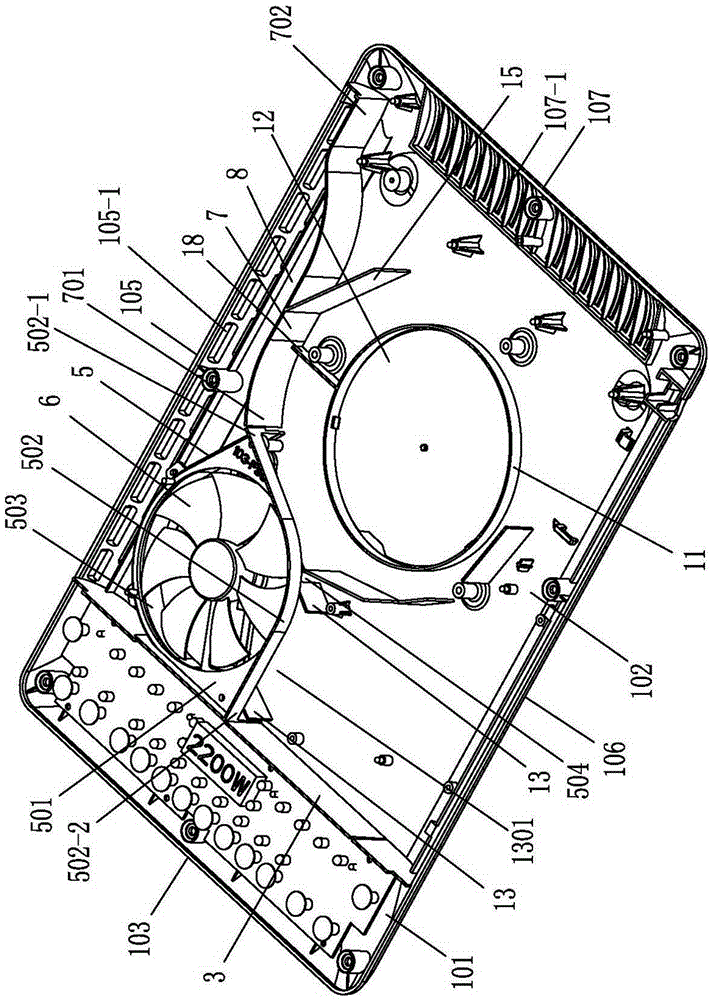

[0033] Such as Figure 1 to Figure 6 As shown, a new type of induction cooker includes a bottom shell 1 and a surface shell 2. The inner cavity of the bottom shell 1 is divided into a control panel area 101 and a component installation area 102 by a functional partition plate 3. The control panel area 101 is arranged on the bottom shell 1. The front side 103 and the bottom surface 104 of the bottom case 1 are airtight, forming a hidden heat dissipation fan structure. The face case 2 is covered on the bottom case 1, and the face case 2 is connected with a microcrystalline plate 4. It is characterized in that the element The two sides of the bottom case 1 corresponding to the installation area 102 respectively form an air intake side 105 and an exhaust side 106, and the air intake side 105 and the exhaust side 106 are correspondingly provided with a plura...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com