Device for degrading dye wastewater through photocatalytic oxidation

A technology for photocatalytic oxidation and dye wastewater, which is applied in special compound water treatment, light water/sewage treatment, textile industry wastewater treatment, etc. It can solve the problems of waste of resources, cumbersome treatment steps, and no improvement in efficiency, so as to improve work efficiency , Strong continuity, space-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Next, the technical solutions in the embodiments of the present invention will be described in connection with the drawings of the embodiments of the present invention, and it is understood that the described embodiments are merely the embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art are in the range of the present invention without making creative labor premise.

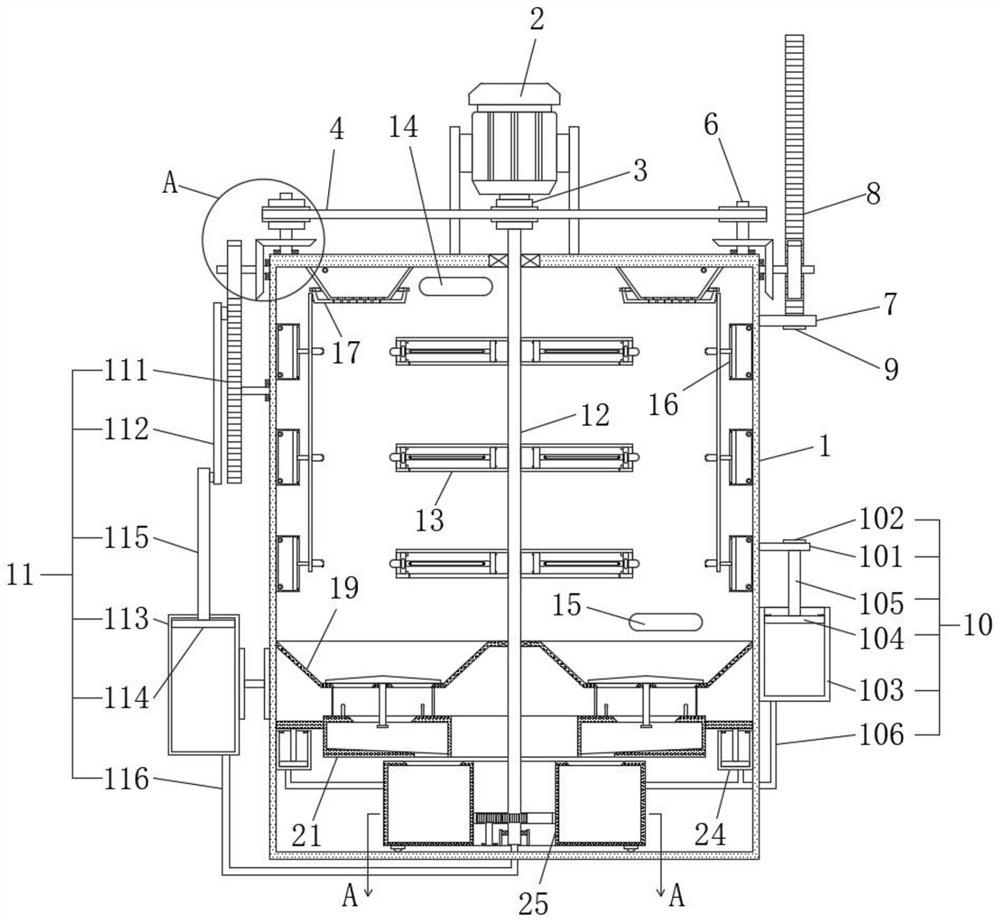

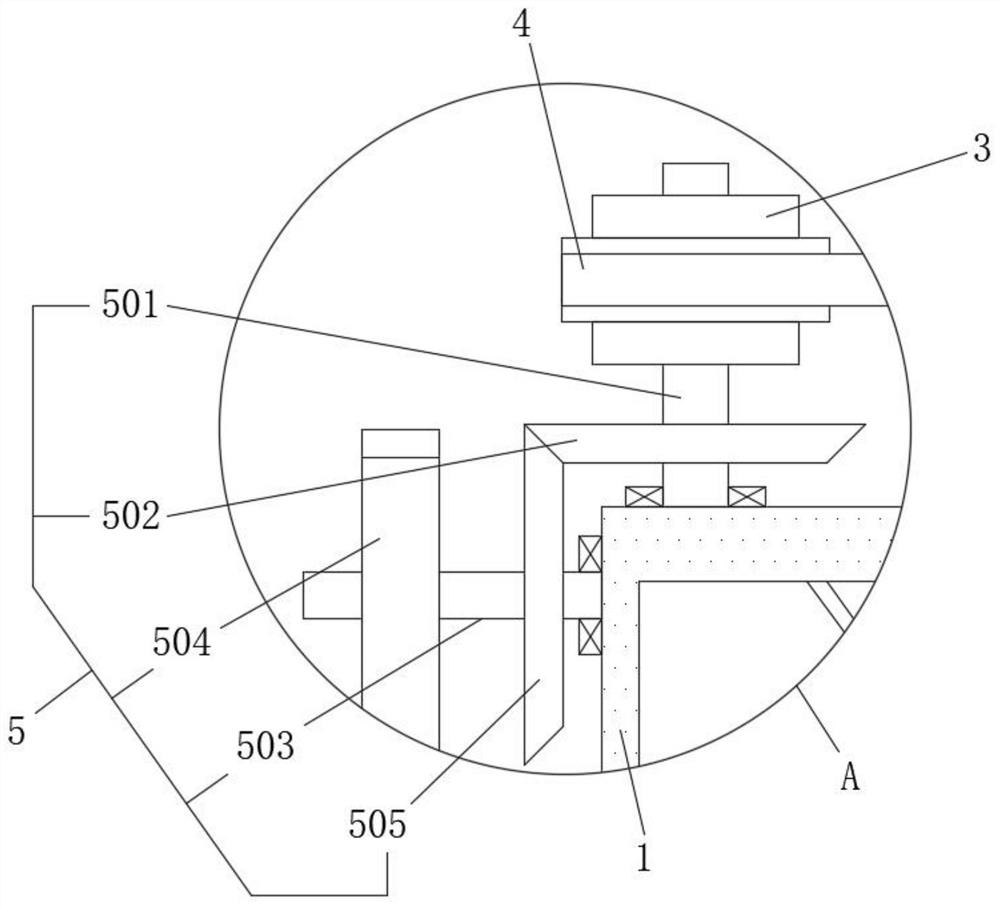

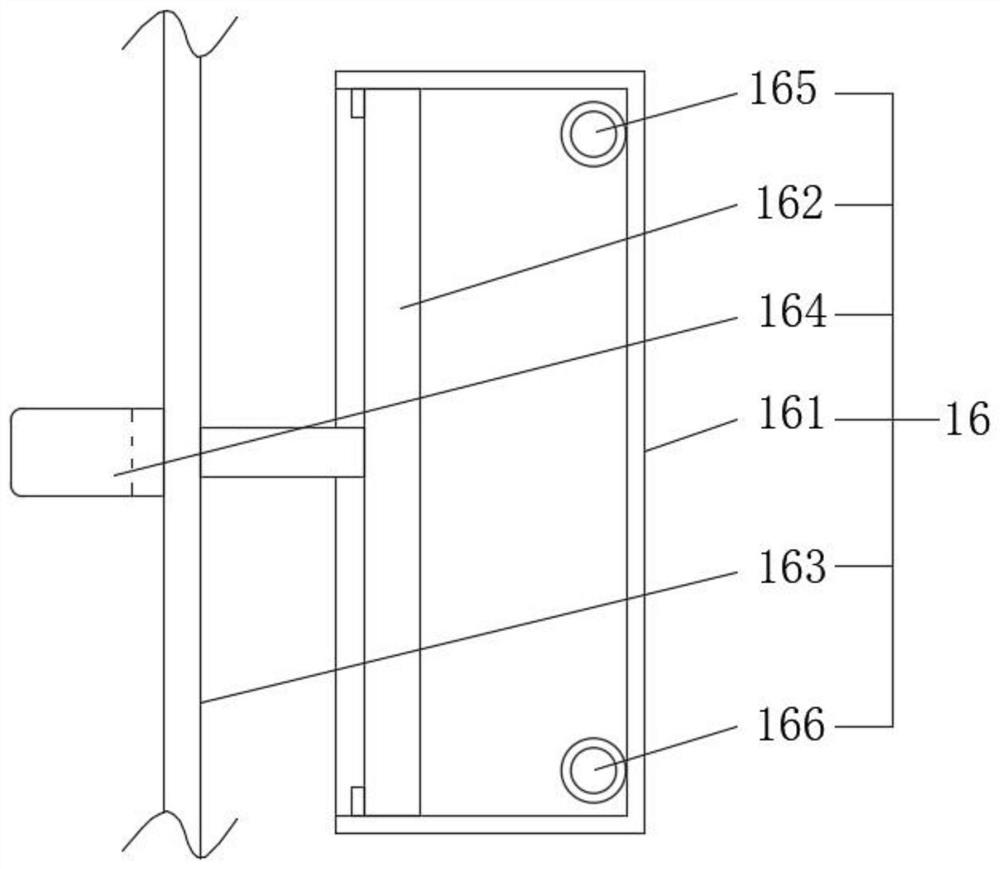

[0031] See Figure 1-8 One embodiment of the present invention is: a device for photocatalytic oxidation degradation of dye wastewater, including the cylinder 1 and the inlet 14 and the water opening 15 of the rear surface of the device box 1, and a motor is mounted on top of the device tank 1. 2, and the output of the motor 2 is connected to the unidirectional drive assembly 3, and the outer side of the one-way drive assembly 3 is provided with the transmission assembly 4, and b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com