Process for co-production of high-quality carbon black raw oil, refined asphalt and binder asphalt

A technology for binder asphalt and refined asphalt, which is used in the processing of tar asphalt/petroleum asphalt/natural asphalt by distillation, and the processing of tar asphalt/petroleum asphalt/natural asphalt by selective extraction, etc. It can solve the problem of unreasonable molecular weight distribution of refined asphalt. , affecting the quality of downstream products of refined asphalt, etc., to achieve the effect of low cost, simple operation and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

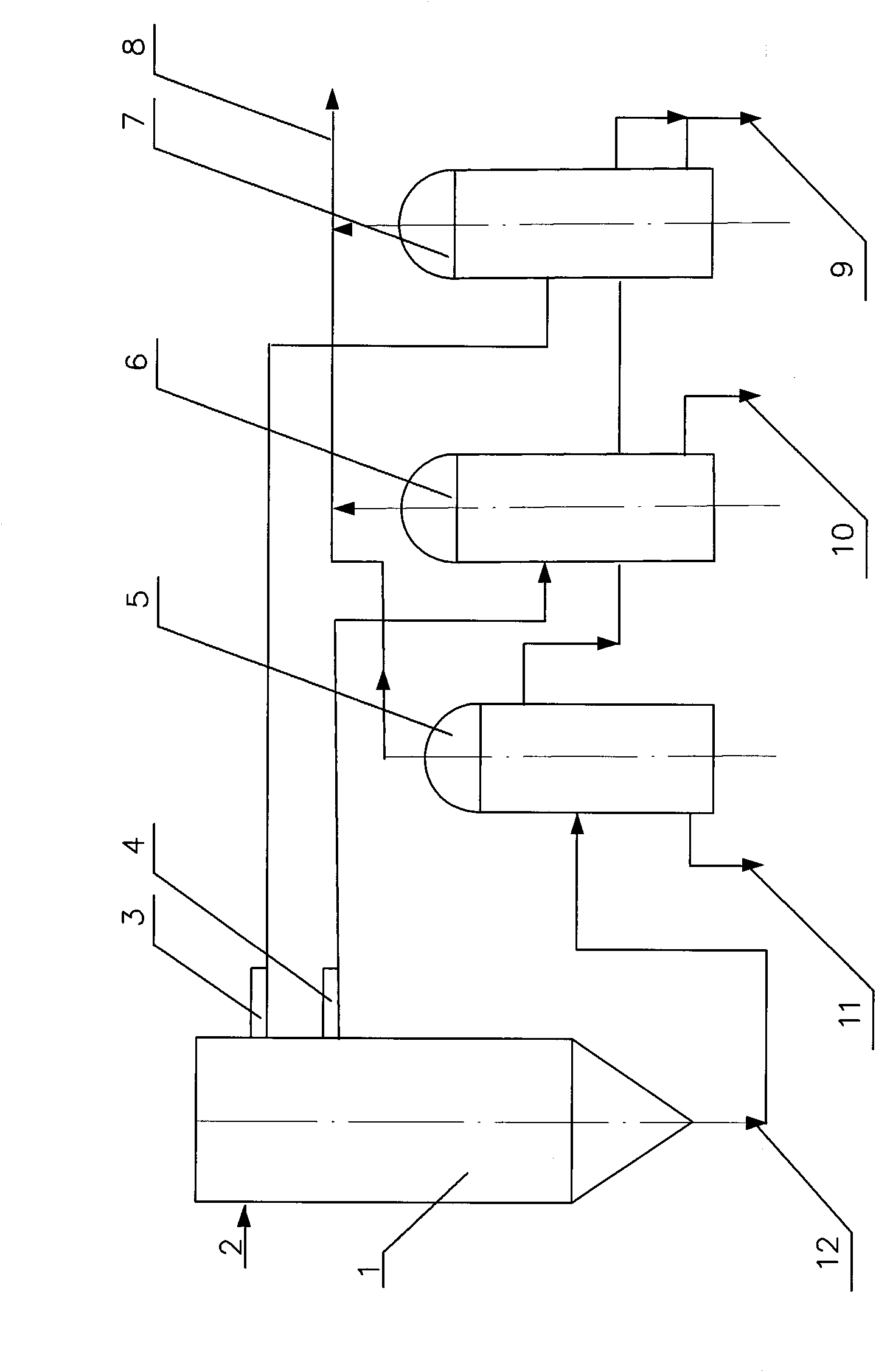

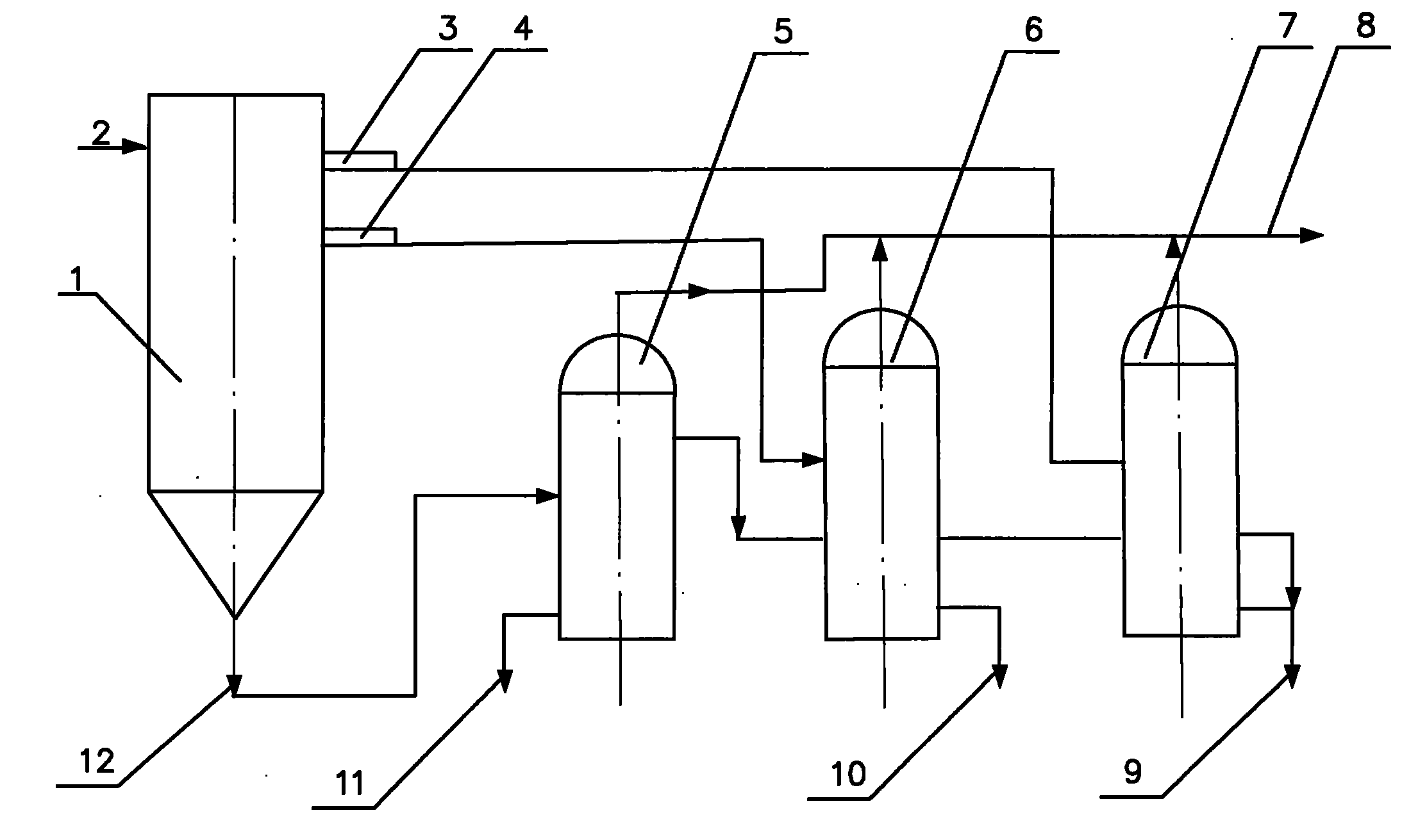

Method used

Image

Examples

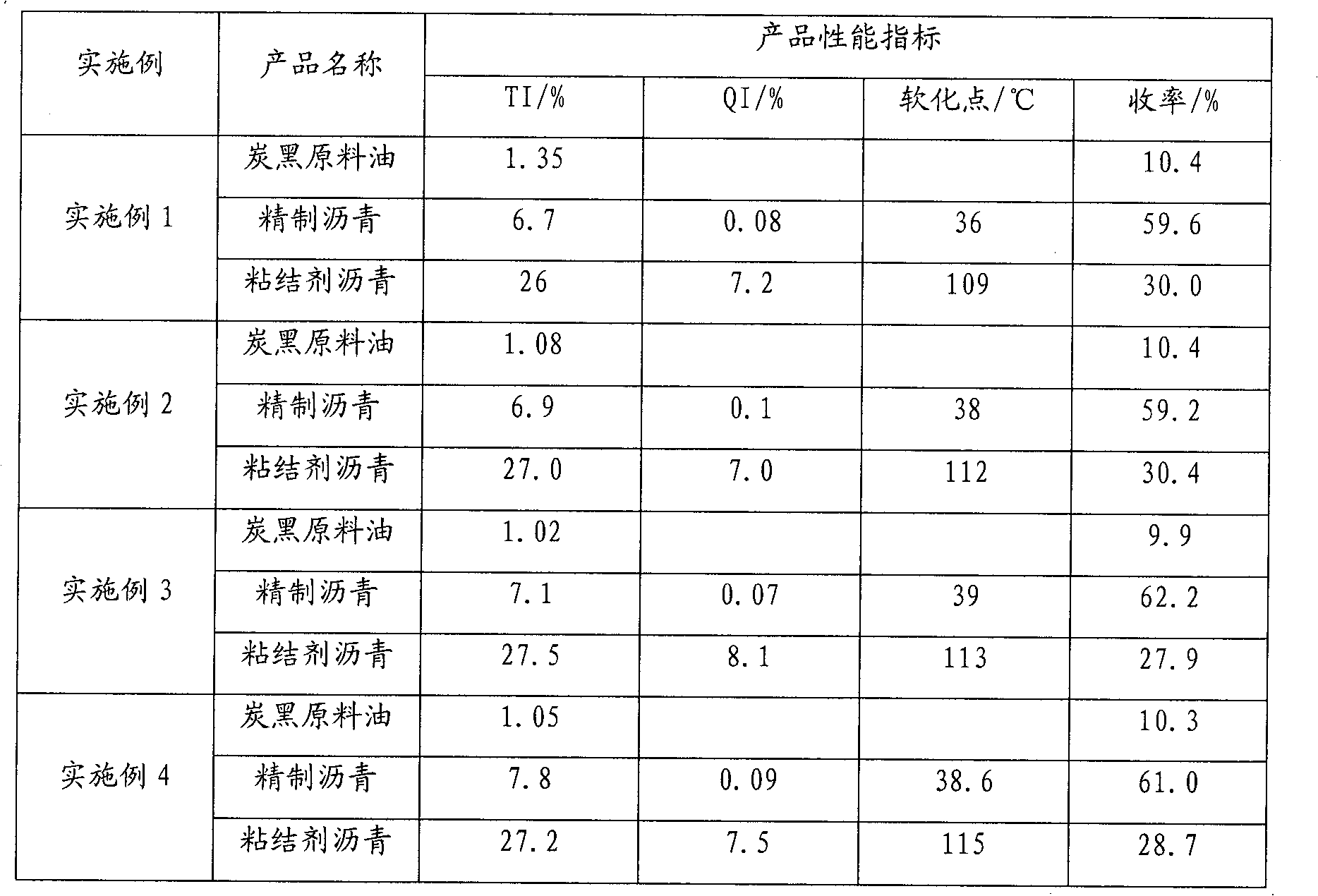

Embodiment 1

[0035] Described aromatic solvent is heavy benzene solvent oil, and described aliphatic solvent is wax oil, and the mass ratio of described heavy benzene solvent oil and wax oil is 1: 1, and described dual solvent and crude coal tar The asphalt is mixed according to the mass ratio of 0.65:1 and then injected into the extraction separator. The sedimentation separation temperature is controlled at 135°C and the sedimentation velocity is controlled at 126mm / h for extraction, flocculation and sedimentation separation. , different position controls to take out the light phase component mass ratio 5t%, next light phase component mass ratio 65%, heavy phase component mass ratio 30%, three kinds of components are separated through rectification, control rectification column under normal pressure When the tower top temperature is 280°C and the side line temperature of the heavy phase rectification tower is 295°C, after removing the solvent, the yield of carbon black raw material oil is ...

Embodiment 2

[0037] Described aromatic solvent is heavy benzene solvent oil, and described aliphatic solvent is wax oil, and the mass ratio of described heavy benzene solvent oil and wax oil is 1: 1, is formulated into double solvent, and described double Solvent and crude coal tar pitch were mixed at a mass ratio of 0.8:1 and then injected into the extraction separator. The sedimentation temperature was controlled at 135°C and the sedimentation velocity was controlled at 178mm / h for extraction, flocculation, and sedimentation. According to the principle of density distribution, From the upper, middle and lower positions of the separator, the mass ratio of light phase components is 6%, the mass ratio of sub-light phase components is 63%, and the mass ratio of heavy phase components is 31%. Each component is separated and removed by rectification. Solvent, the temperature of the top of the rectification tower is controlled at 280°C under normal pressure, and the side line temperature of the ...

Embodiment 3

[0039] Described aromatic solvent is washing oil, and described aliphatic solvent is wax oil, and the mass ratio of described washing oil and wax oil is 1.1: 1, and described double solvent and crude coal tar pitch are mixed by 1.1: The mass ratio of 1 is mixed and injected into the extraction separator. The temperature of sedimentation and separation is controlled at 135°C, and the sedimentation velocity is controlled at 182mm / h for extraction and flocculation separation. According to the principle of density distribution, the separation is controlled from the upper, middle and lower positions of the separator. Take out 7% of the light phase component mass ratio, 67% of the next light phase component mass ratio, and 26% of the heavy phase component mass ratio, and carry out rectification and separation of the three components obtained, and control the rectification column under normal pressure. The top temperature is 280°C, the side line temperature of the heavy phase rectific...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com