Method and system for separating powder

A powder and cyclone separation technology, applied in the direction of the cyclone device, etc., can solve the problems of fine powder separation and entrainment at a high rate, and achieve the effect of high use value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

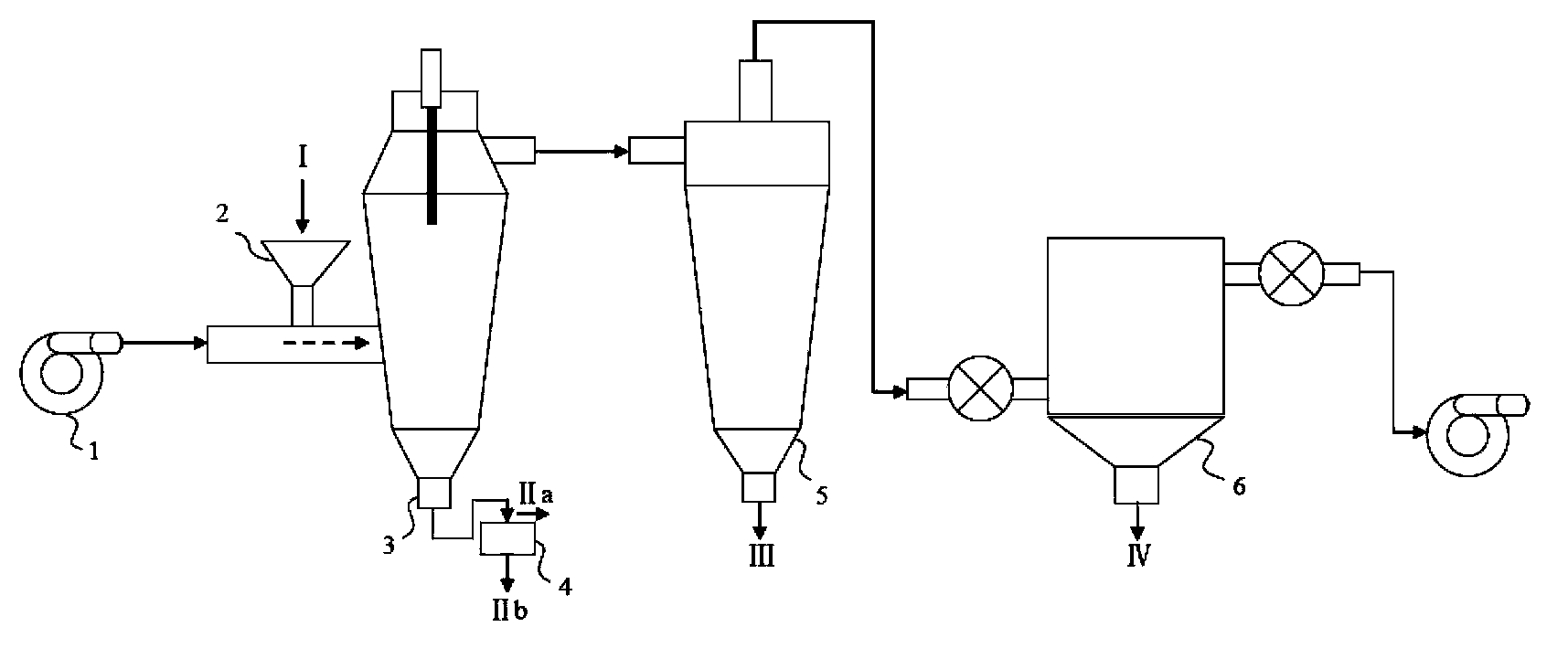

[0096] Fly ash is obtained from the thermal power plant of Beijing Guohua Electric Power Company and can meet our product 3 classification. Pass the fly ash through figure 1 The equipment shown is separated, wherein with the help of the blower 1 and the screw feeder 2, the fly ash enters the centrifugal separator 3 with a diameter of 0.2m from the port 1, and the radius of the centrifugal classifying impeller of the centrifugal separator 3 is about 0.15m . The centrifugal speed is set at 2900rpm (the peripheral tangential velocity of the centrifugal classification impeller is about 45.5m / s). The first-stage fine ash discharged from the fine ash outlet above the centrifugal separator enters the cyclone separator 5 for separation, and the apparent cross-sectional gas velocity ν of the cyclone separator 0 is 4.5m / s, the inlet gas velocity is 16m / s, the diameter D is 0.2m, and the inlet area A is 0.008m 2 (πD 2 / 4A=3.9), height H is 0.9m (H / D=4.5), exhaust pipe diameter d r i...

Embodiment 2

[0113] Fly ash is obtained from the thermal power plant of Beijing Guohua Power Company, which is the same as that in Example 1. Pass the fly ash through figure 1 The equipment shown is separated, wherein the fly ash enters the centrifugal separator 3 with a diameter of 0.2m from the port 1 through the blower 1 and the screw feeder 2, and the centrifugal speed of the centrifugal separator is set to 500rpm (centrifugal classification impeller peripheral cut The direction speed is about 7.9m / s). The first-stage fine ash discharged from the fine ash outlet above the centrifugal separator enters the cyclone separator 5 for separation, and the apparent cross-sectional gas velocity ν of the cyclone separator 0 is 2.5m / s, the inlet gas velocity is 12m / s, the diameter D is 0.2m, and the inlet area A is 0.008m 2 , the height H is 0.9m, and the diameter of the exhaust pipe is d r It is 0.08m. The second stage of coarse ash is obtained from the coarse ash discharge port III below the...

Embodiment 3

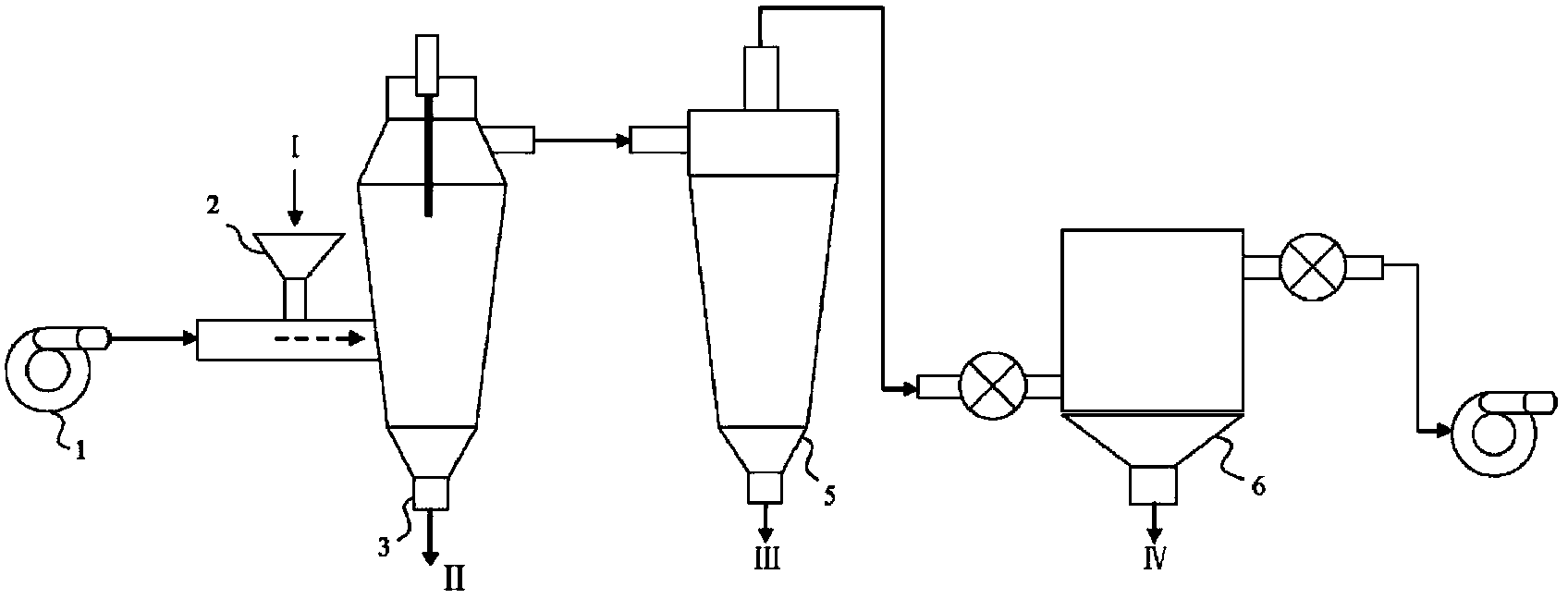

[0129] The fly ash of same source as embodiment 1 is passed through figure 2 The system shown is separated. Operate under the same conditions as in Example 1, the difference is figure 2 The system does not include a screen separation unit.

[0130] The 3 products resulting from this isolation are listed below. Product 1 (second stage fine ash) was collected from Port IV. Product 2 (secondary coarse ash) was collected from Port III. Product 3 (primary coarse ash) was collected from Port II. The weight percent of each product is listed below.

[0131] - Product 1:D 50 0.8μm, about 2%;

[0132] - Product 2:D 50 1.3μm, about 14%;

[0133] - Product 3:D 50 It is 33 μm, about 84%.

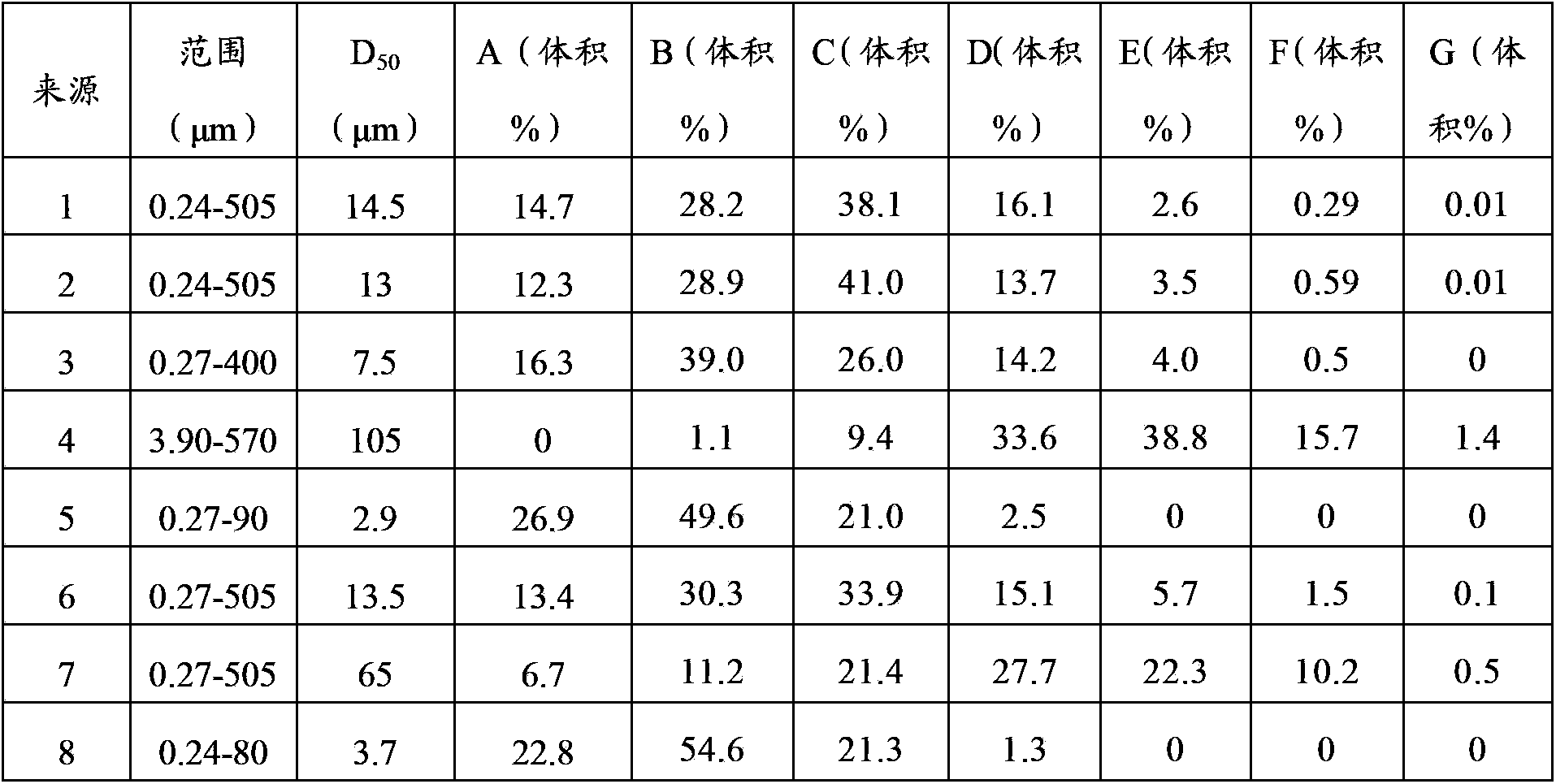

[0134] The composition of each product is listed in Table 4 below.

[0135] - Product 1 consists of 63% Fraction A and 37% Fraction B;

[0136] - Product 2 consists of 43% Fraction A and 57% Fraction B;

[0137] - Product 3 consists of 9% Fraction A, 16% Fraction B, 51% Fraction C (or 76%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com