Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Realize stepless control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

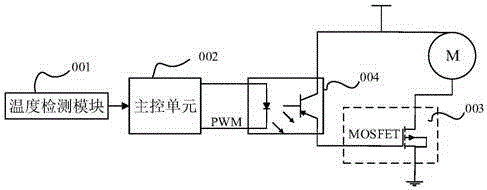

DC fan motor control circuit and control method of using same

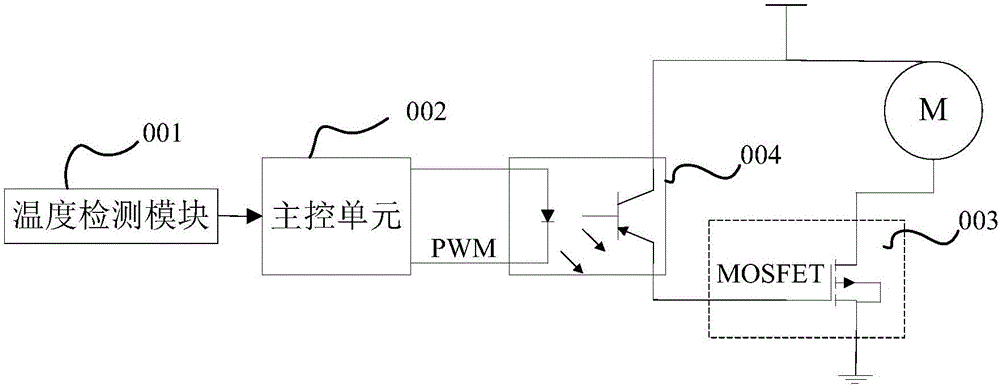

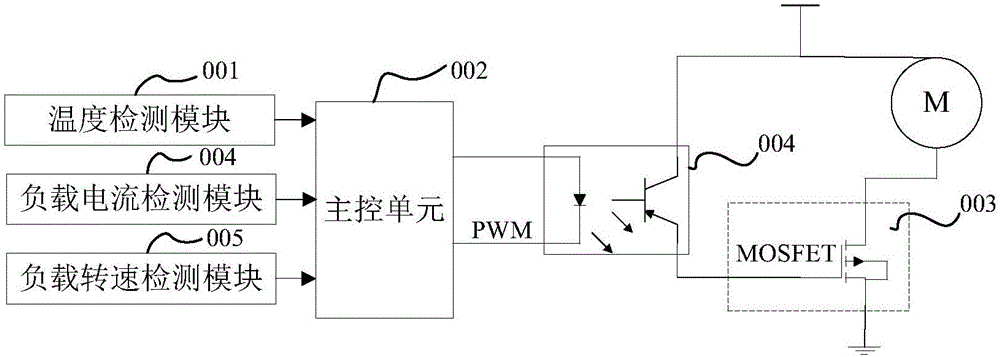

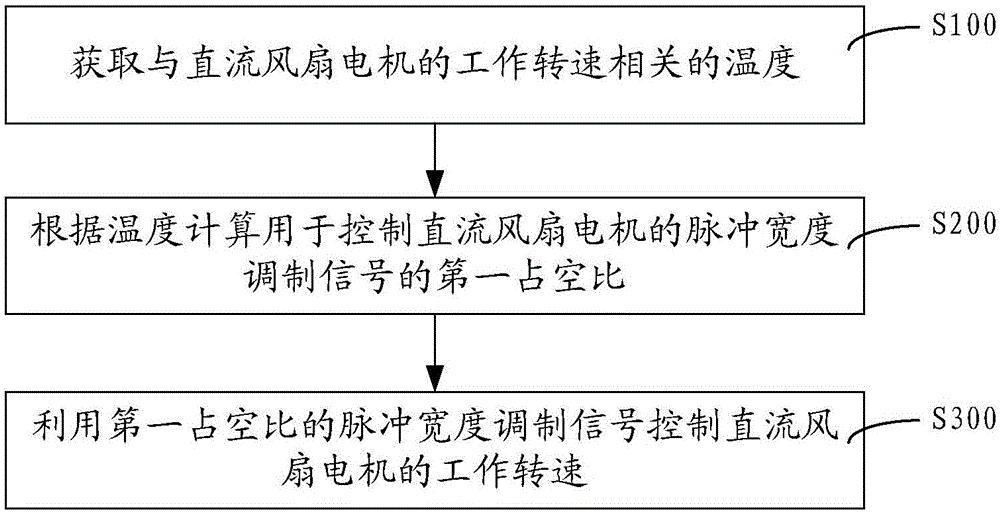

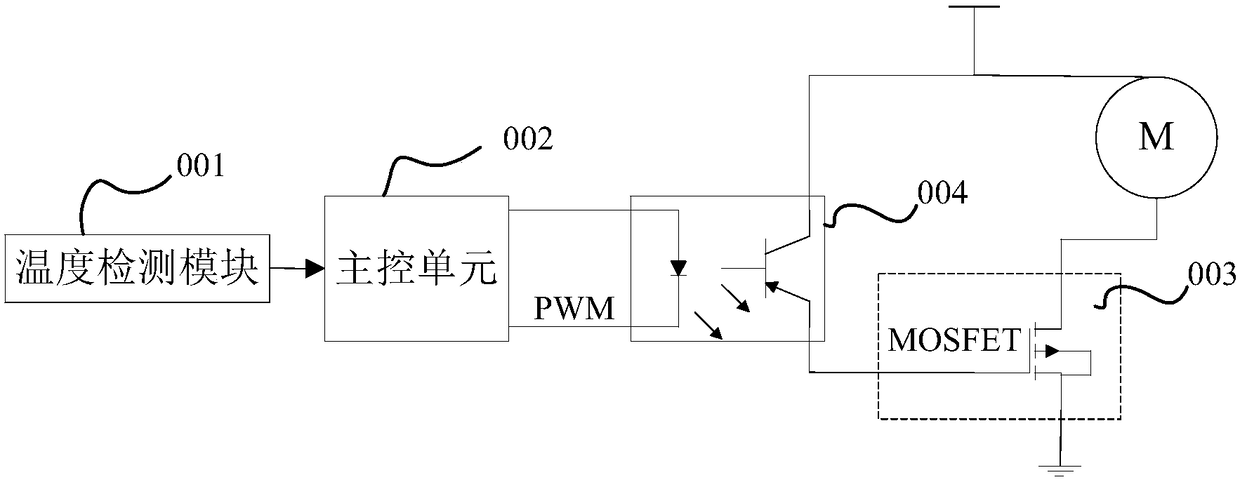

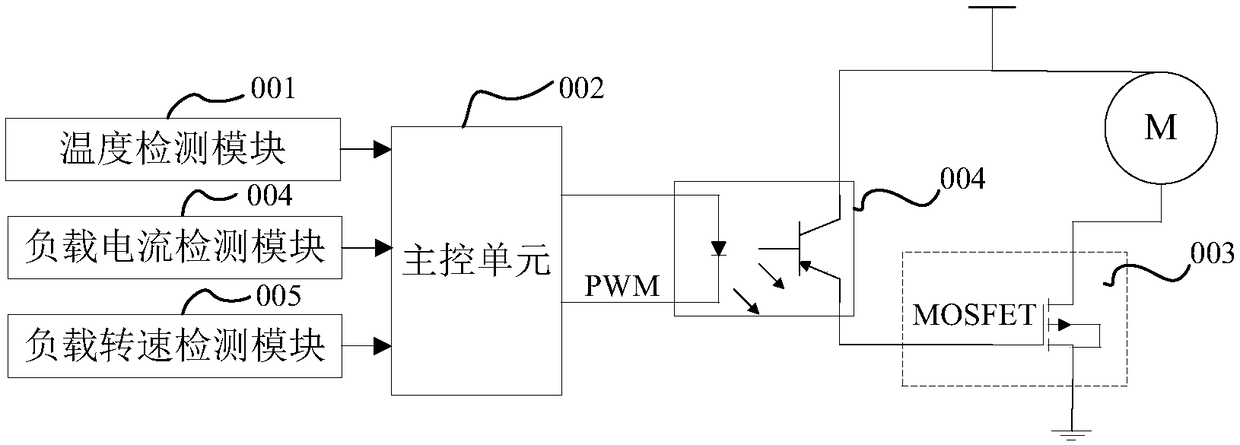

The invention discloses a DC fan motor control circuit and a control method of using the same. The control circuit comprises a temperature detection module, a master control unit and a voltage control module, wherein the temperature detection module is used for detecting a temperature related to a working speed of a DC fan motor and forming a temperature signal; the master control unit is connected with the temperature detection module and is used for receiving a temperature signal output by the temperature detection module and outputting a pulse width modulation signal with a corresponding duty ratio according to the temperature signal; and the voltage control module is electrically connected with the DC fan motor and is used for controlling the voltage of the DC fan motor according to the duty ratio of the pulse width modulation signal. The pulse width modulation signal is introduced and the duty ratio of the pulse width modulation signal is controlled to change according to a temperature change, so that high-accuracy adjustment is carried out on the rotating speed of the DC fan motor through the pulse width modulation signal.

Owner:GREE ELECTRIC APPLIANCES INC OF ZHUHAI

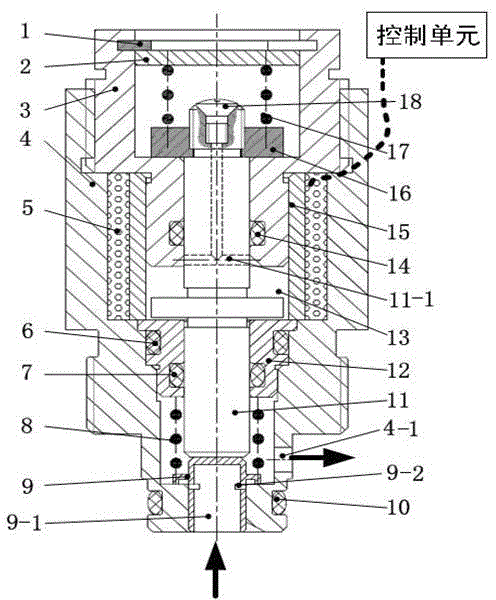

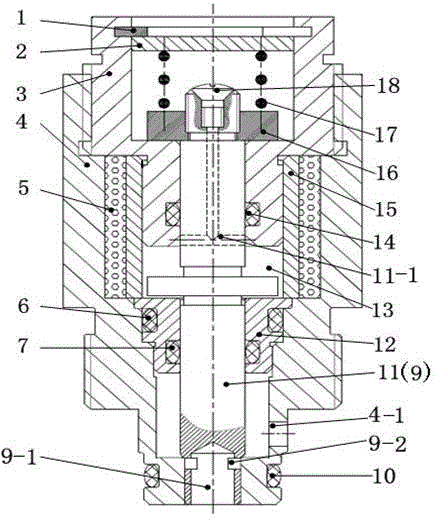

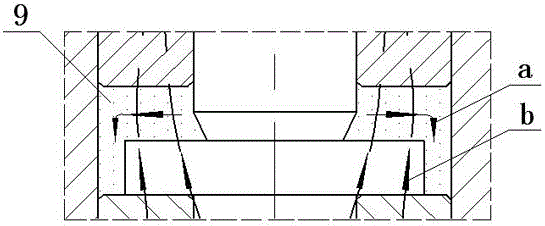

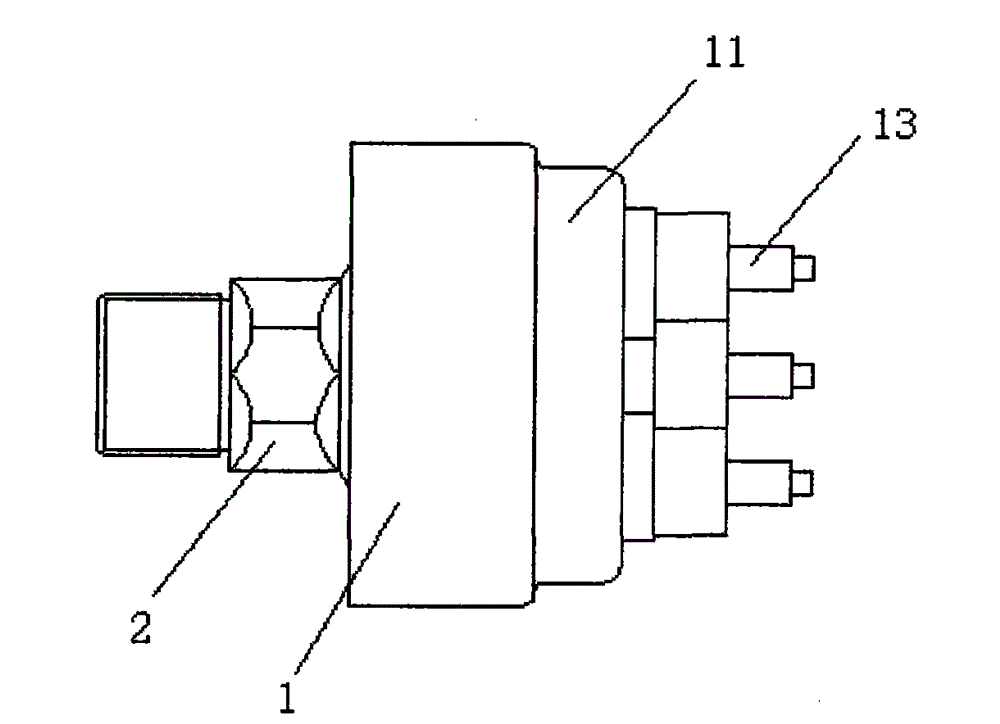

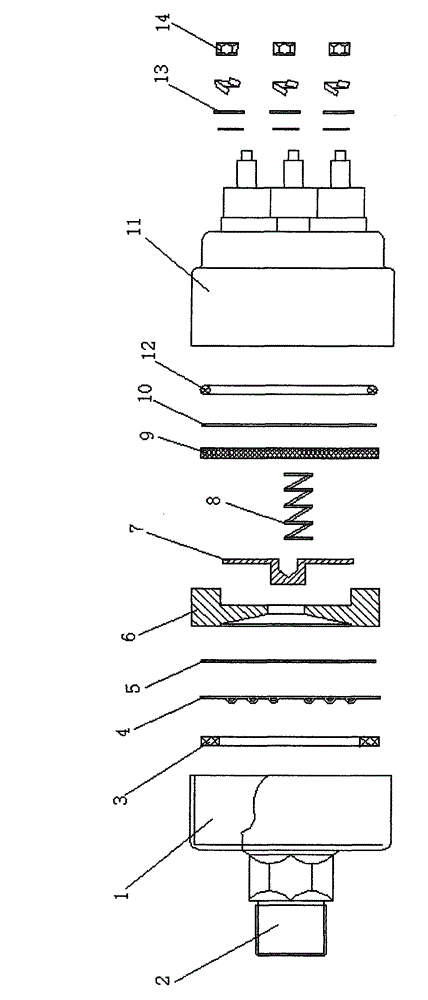

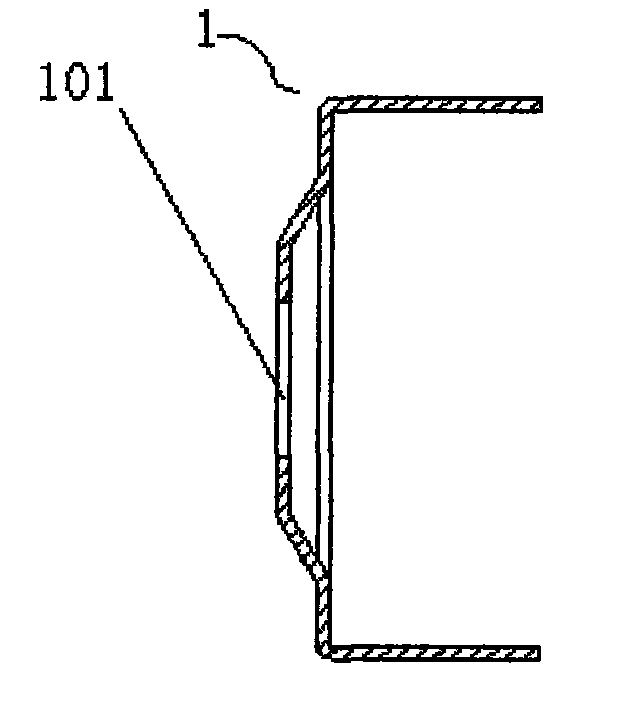

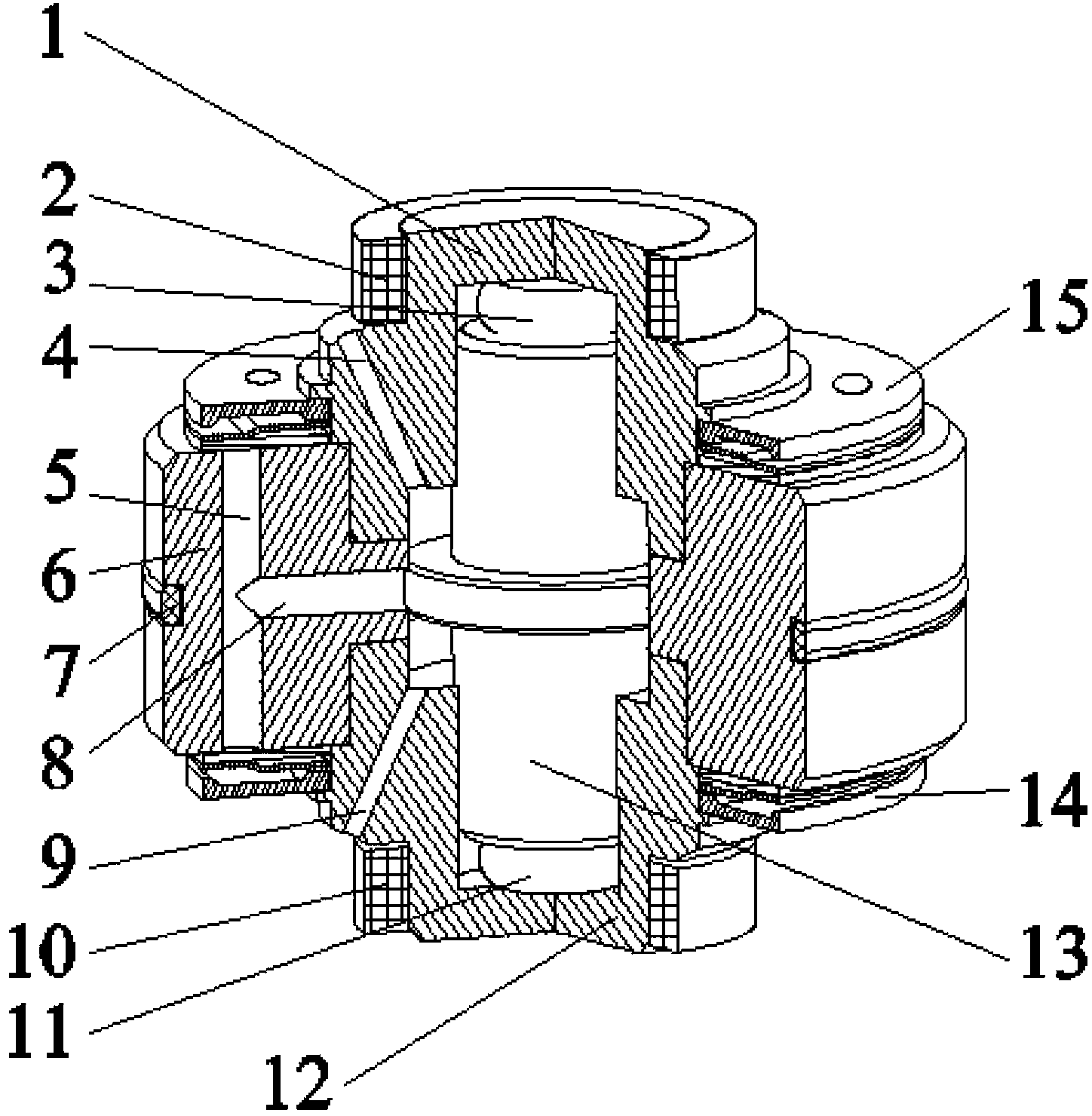

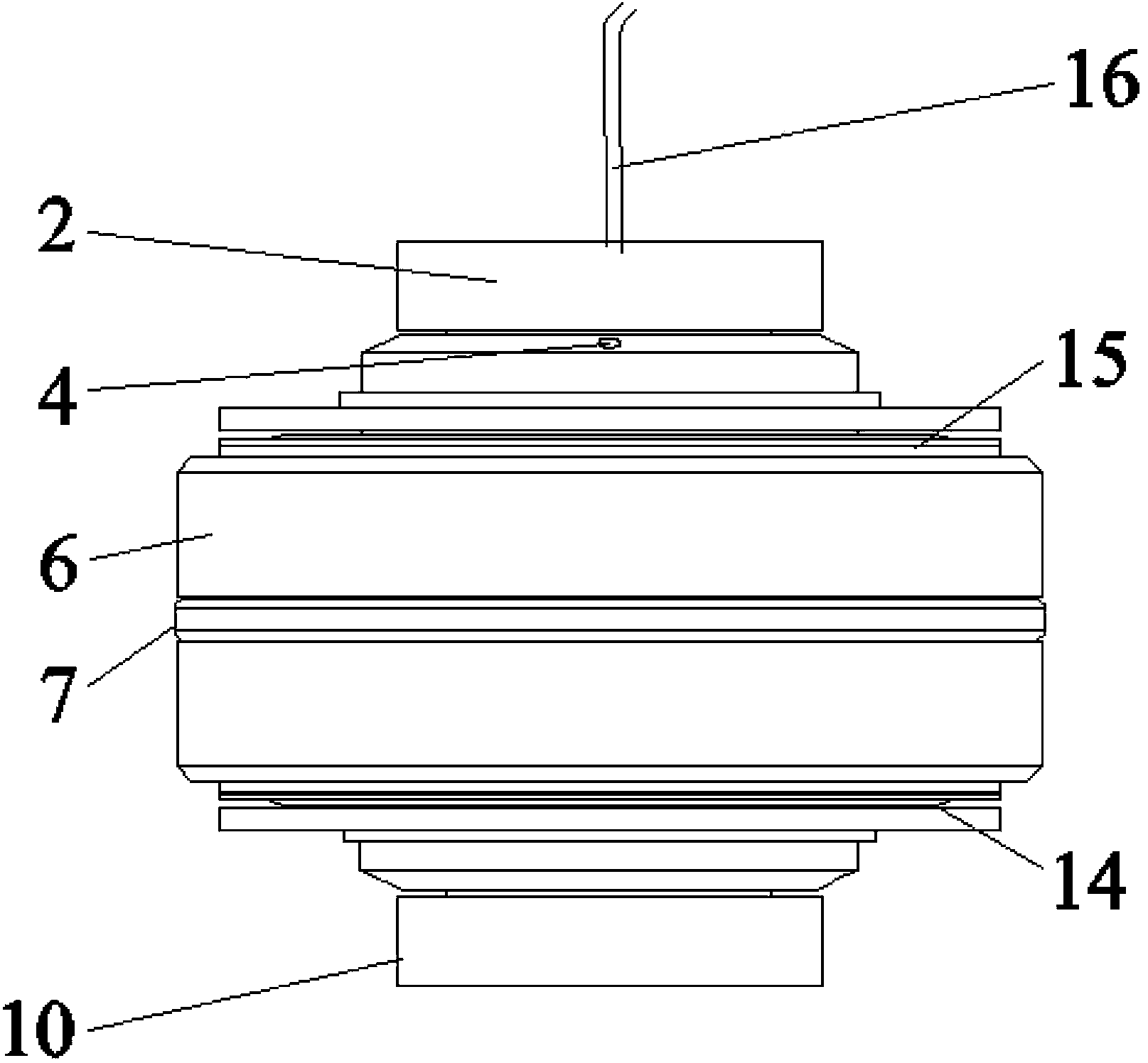

Oil pressure warning sensor for pressure sensitive capacitor

InactiveCN101793179AHigh precisionImprove stabilitySafety devices for pressure lubricationFluid pressure measurement using capacitance variationCapacitanceControl circuit

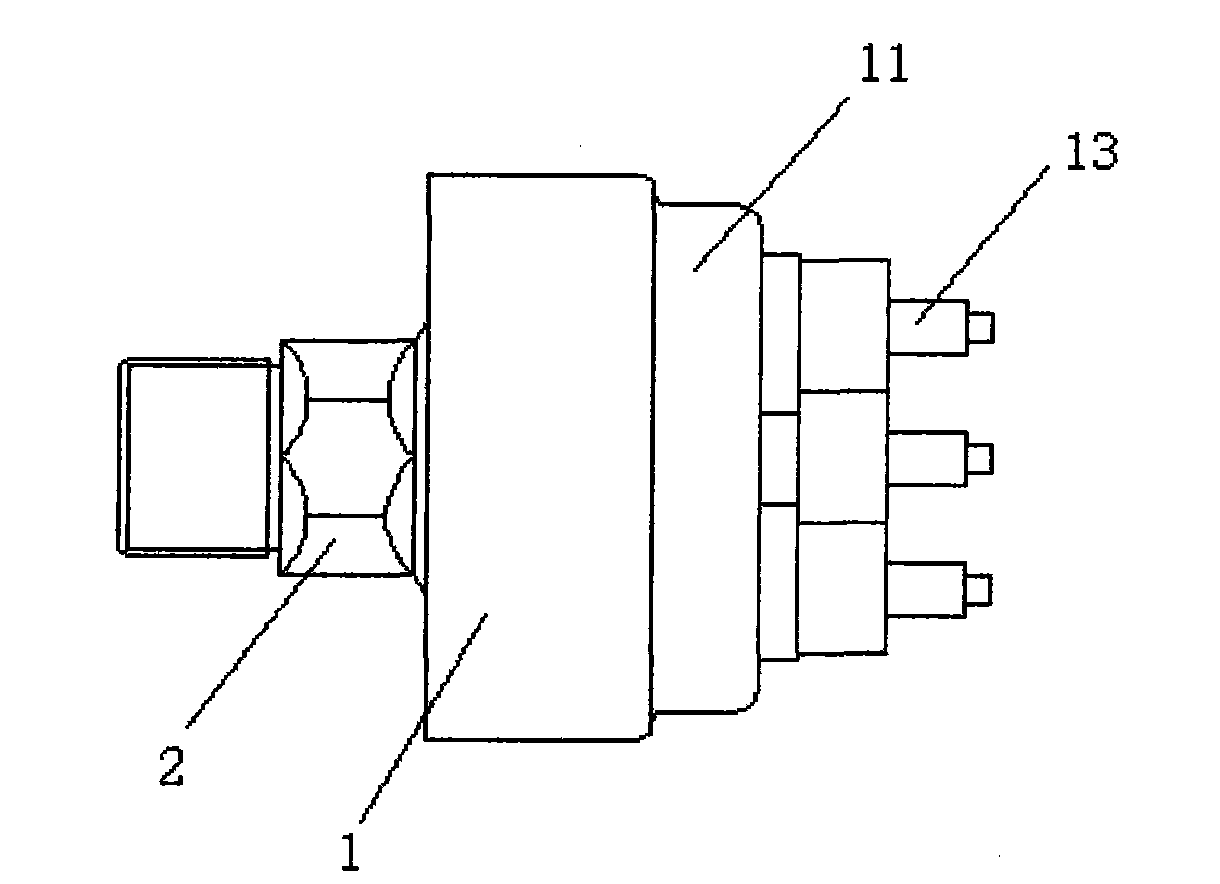

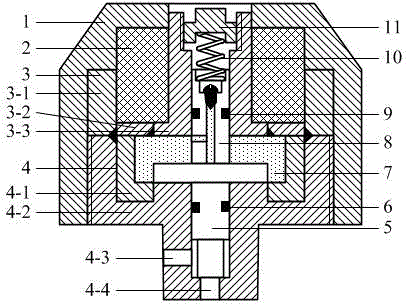

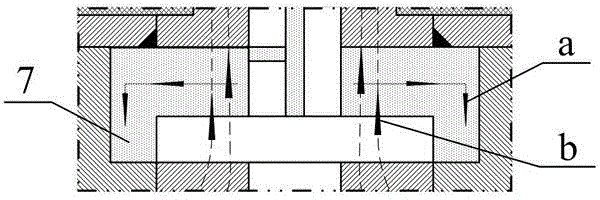

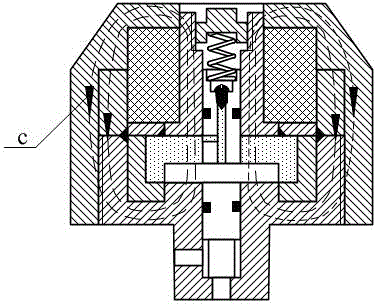

An oil pressure warning sensor for a pressure sensitive capacitor relates to a sensor, which comprises a telescoping oil tank main element, an oil tank telescoping component arranged in the telescoping oil tank main element, and a casing cooperating with the telescoping oil tank main element to close the oil tank telescoping component in the telescoping oil tank main element, wherein the telescoping oil tank main element comprises an iron-bottomed bowl and screws in sealed fit with through holes reserved at the bottom of the iron-bottomed bowl; the oil tank telescoping component comprises a sealing washer, a waveform return spring plate, a knurled spring plate, a sliding sleeve, a movable electrode plate, a return spring, a double-sided circuit board and a circuit board retaining snap ring, which are arranged in the iron-bottomed bowl in turn; a fixed electrode plate is arranged on one side, close to the movable electrode plate, of the double-sided circuit board; the movable electrodeplate and the fixed electrode plate form a capacitor with variable capacitance; upon receiving the pressure from the engine oil, the waveform return spring leaf and the knurled spring leaf deform anddrive the movable electrode plate to compress and deform the return spring so as to change the distance between the movable electrode plate and the fixed electrode plate to change the capacitance of the capacitor; and the oil pressure warning sensor for the pressure sensitive capacitor is further provided with a control circuit connected with the capacitor and used for converting the variation ofoil pressure into an electrical signal and transmitting the electric signal to an oil instrument.

Owner:李科明

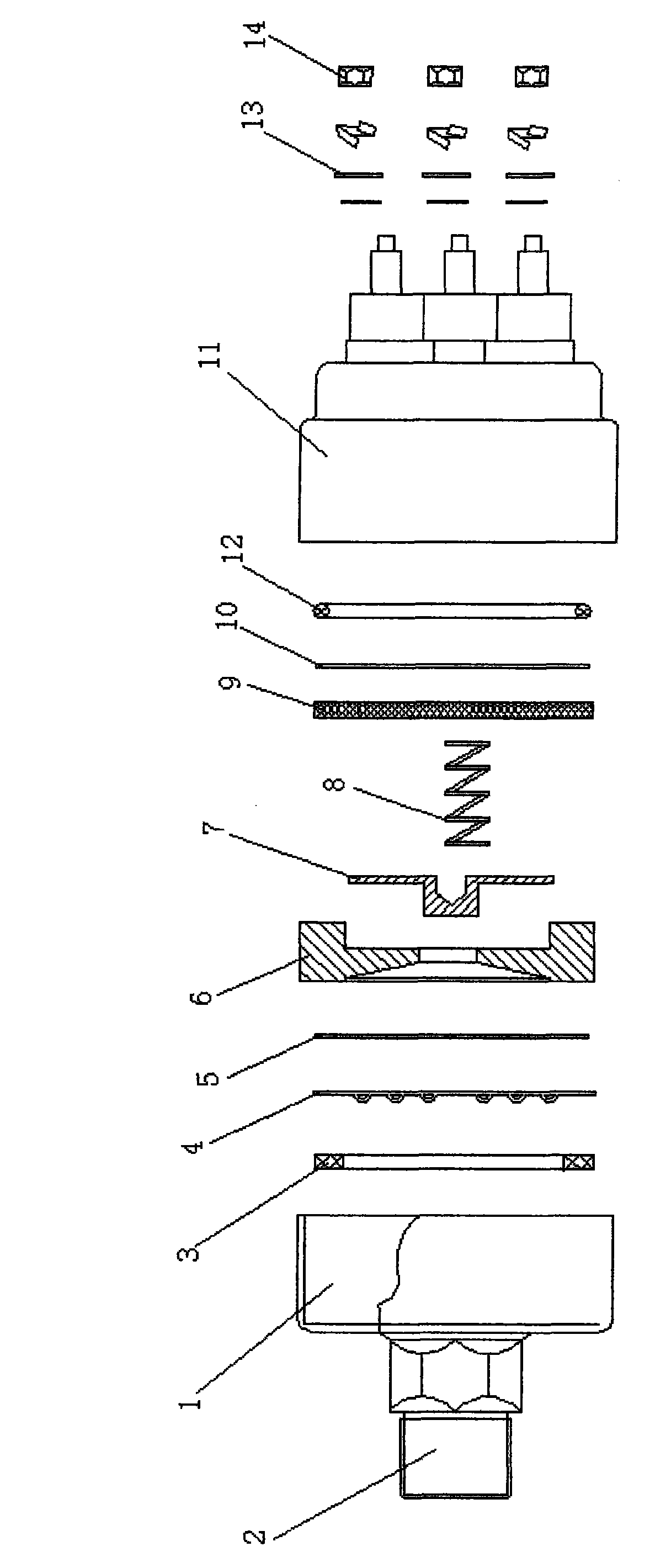

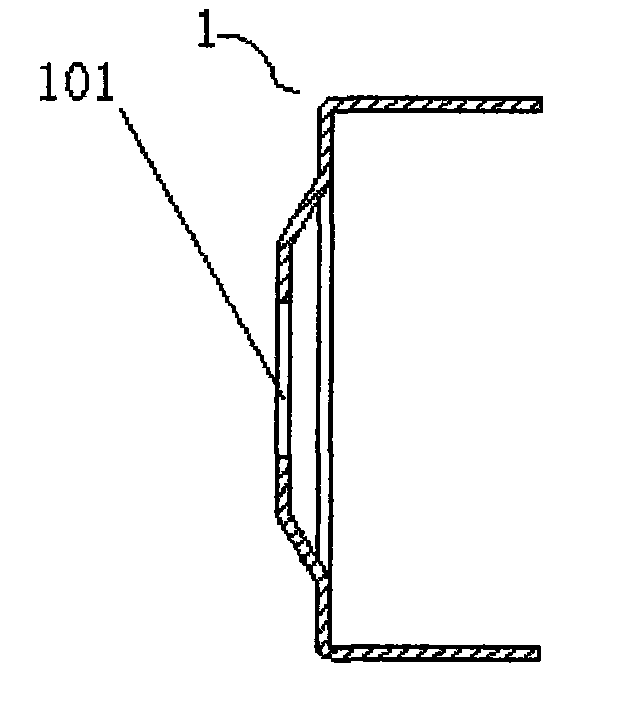

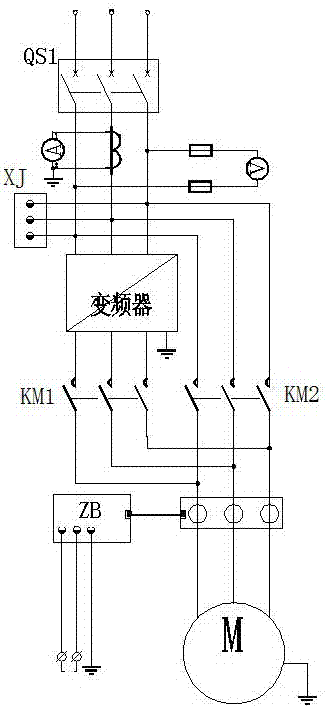

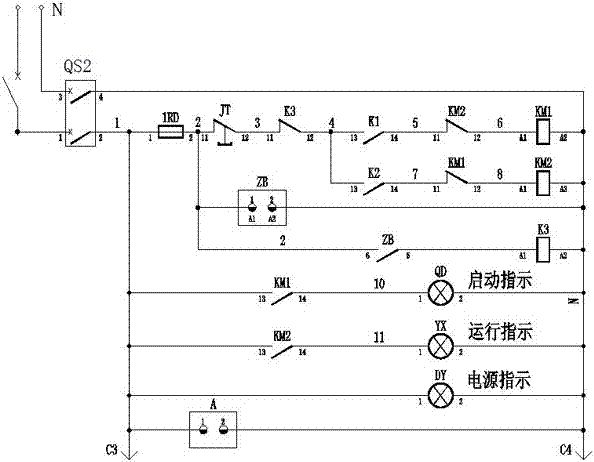

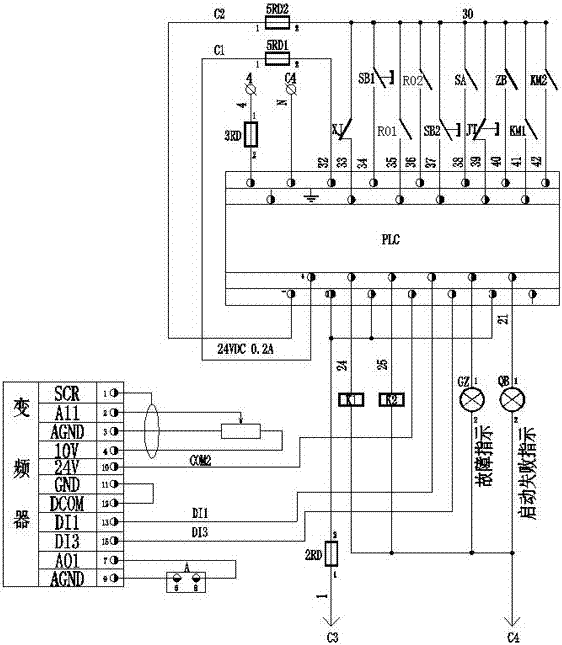

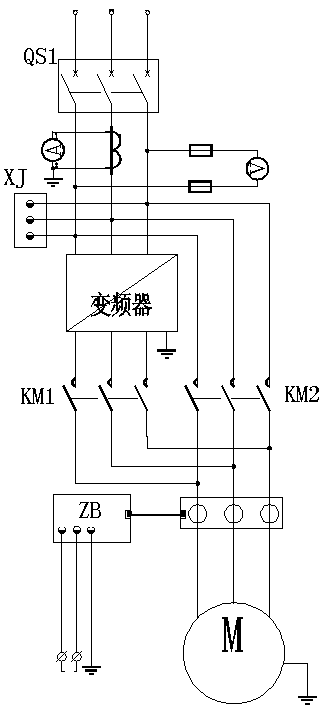

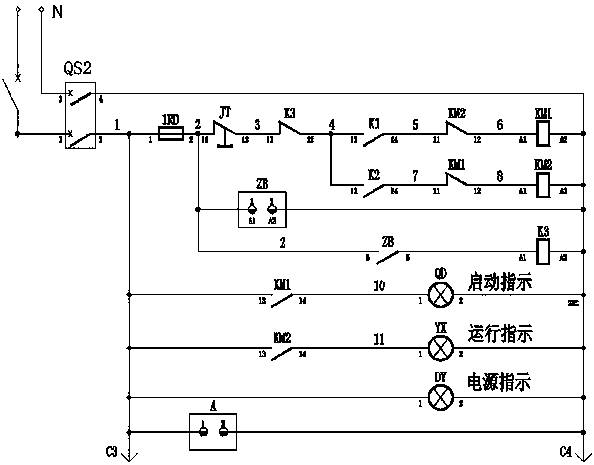

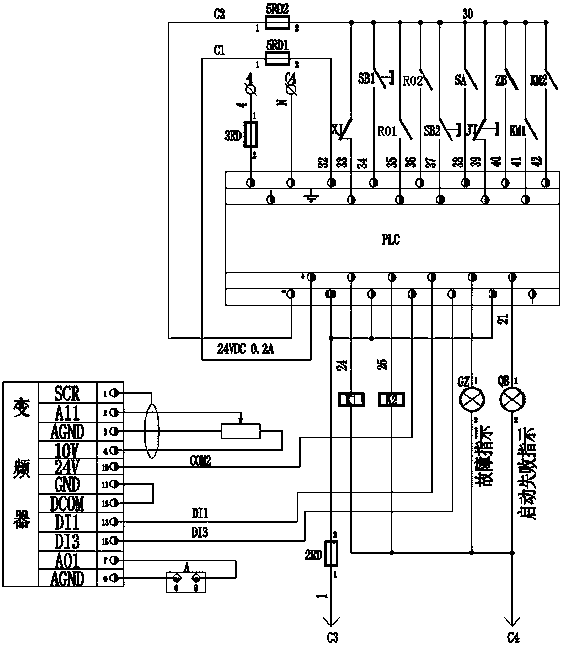

Control method for steplessly adjusting operation of high power water pump or fan

ActiveCN106979148ARealize stepless controlMeet the requirements of full load operationPump controlPositive-displacement liquid enginesImpellerAir volume

The invention discloses a control method for steplessly adjusting operation of a high power water pump or a fan. A controller controls a frequency converter, and the frequency converter controls a motor; and controlled working modes are manually or automatically switched according to values of the power of the motor and the power of the frequency converter. According to the control method disclosed by the invention, the frequency converter with the capacity which is 1 / 2 of the capacity of the motor is adopted to control the motor of the pump or the fan to be started, so as to realize stepless control over the rated flow of about 0 to 80 percent, and the full-load operation requirement under a special condition is met. The low capacity frequency converter controls the high power motor, thus reducing the surplus of use of the frequency converter, saving energy and decreasing the equipment investment; impact on a power grid is reduced; meanwhile, the impact influence on a water pump impeller, a pump shaft and a bearing can be reduced to the maximum extent, the service lives of equipment and valves are prolonged, and the maintenance cost of equipment pipes is saved; by stepless adjustment of the water amount and the air volume, production operation parameters can be precisely controlled, and the engineering requirement can be met; and multiple interfaces can be connected with a computer and a network to realize intelligent control.

Owner:CHINA COAL SPECIAL DRILLING ENG +1

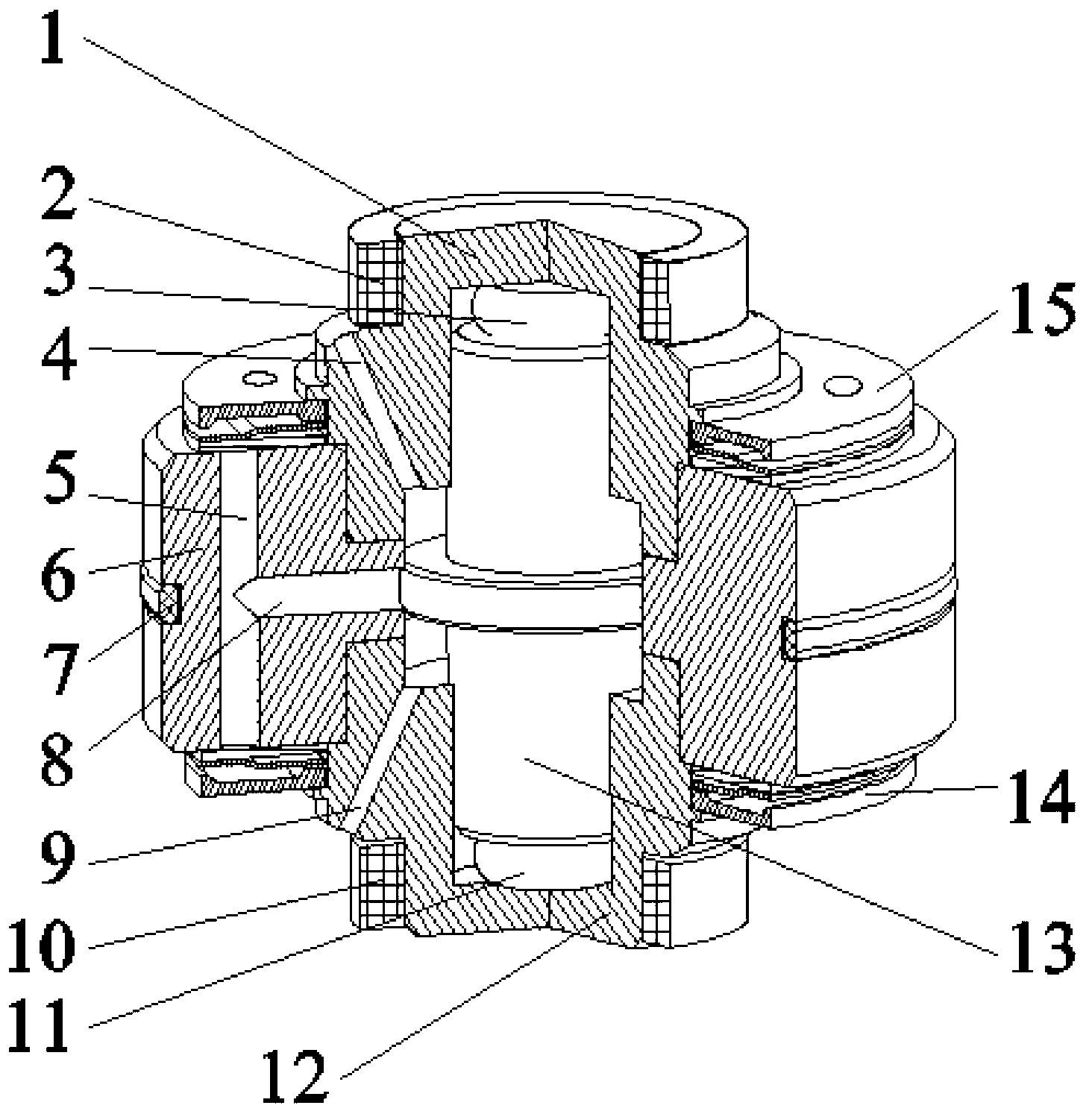

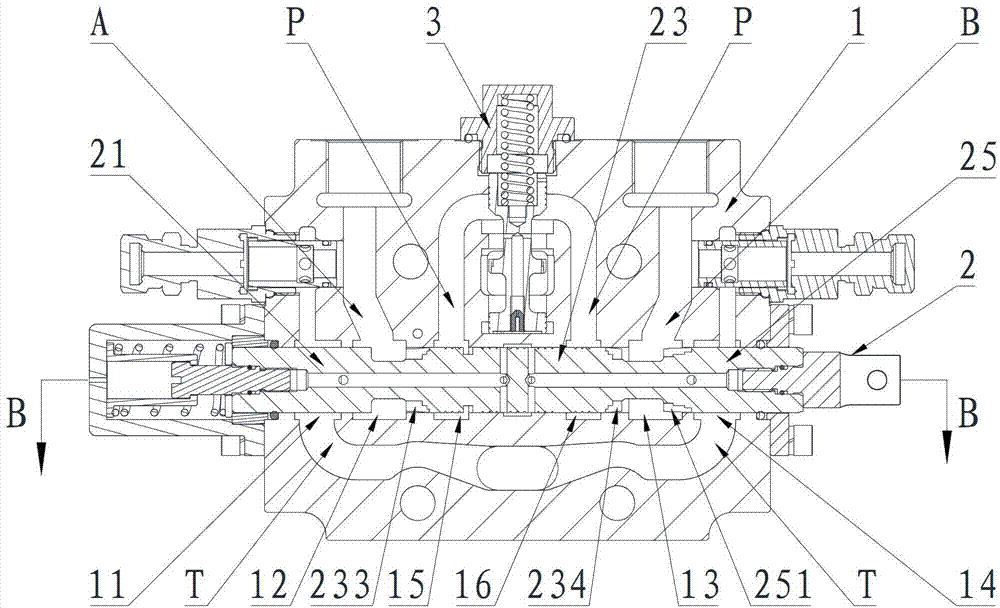

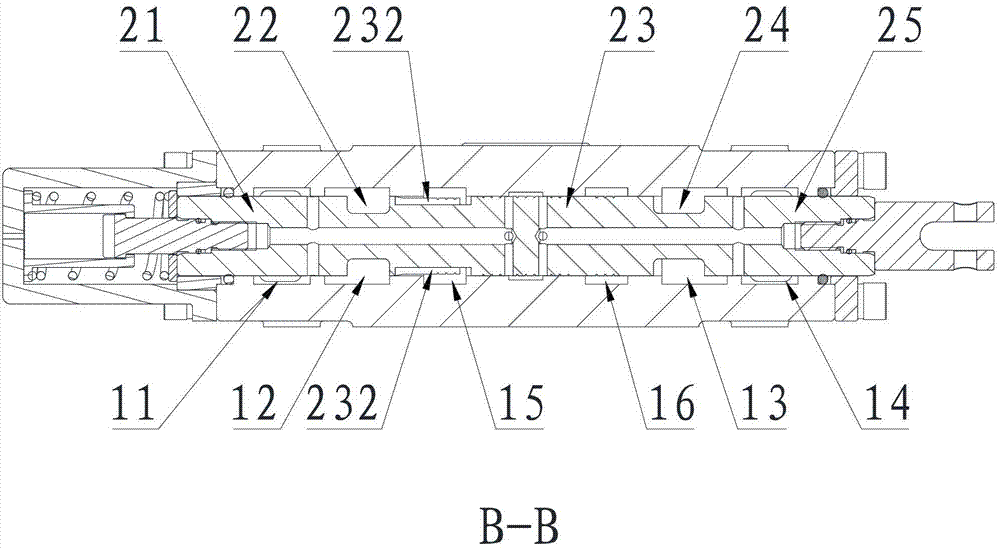

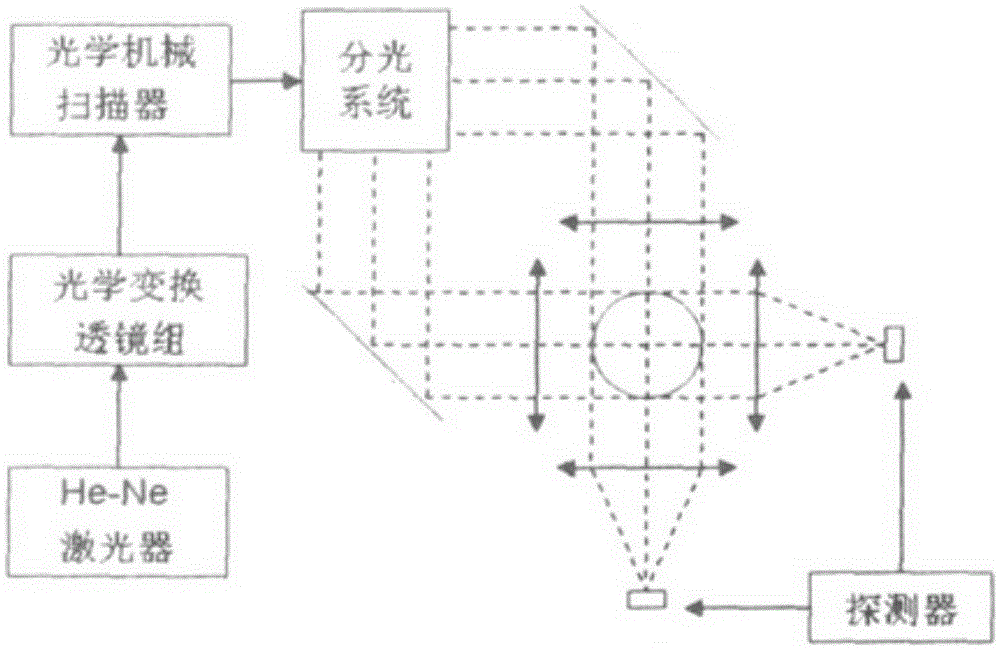

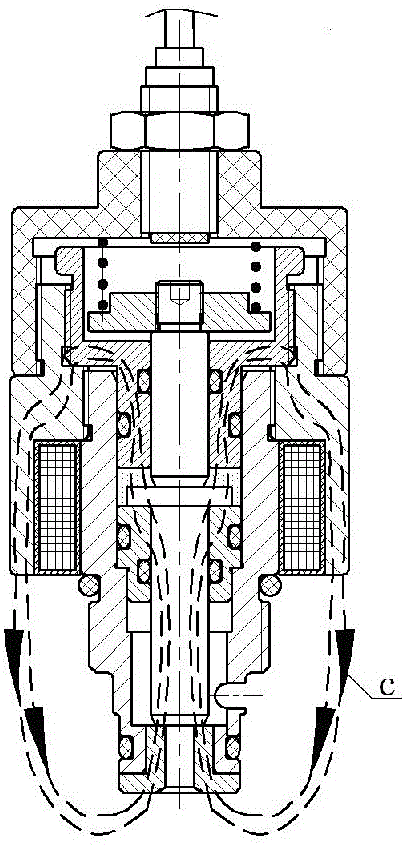

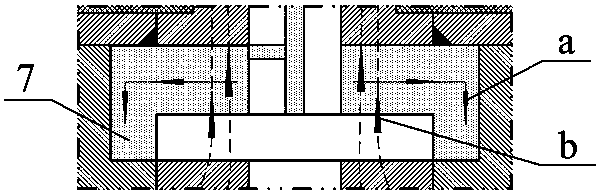

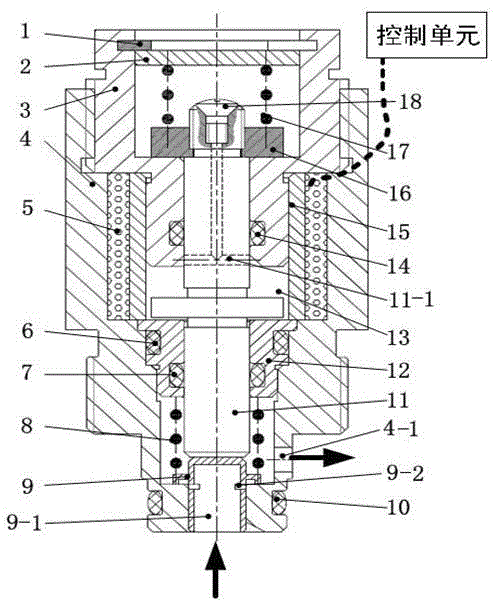

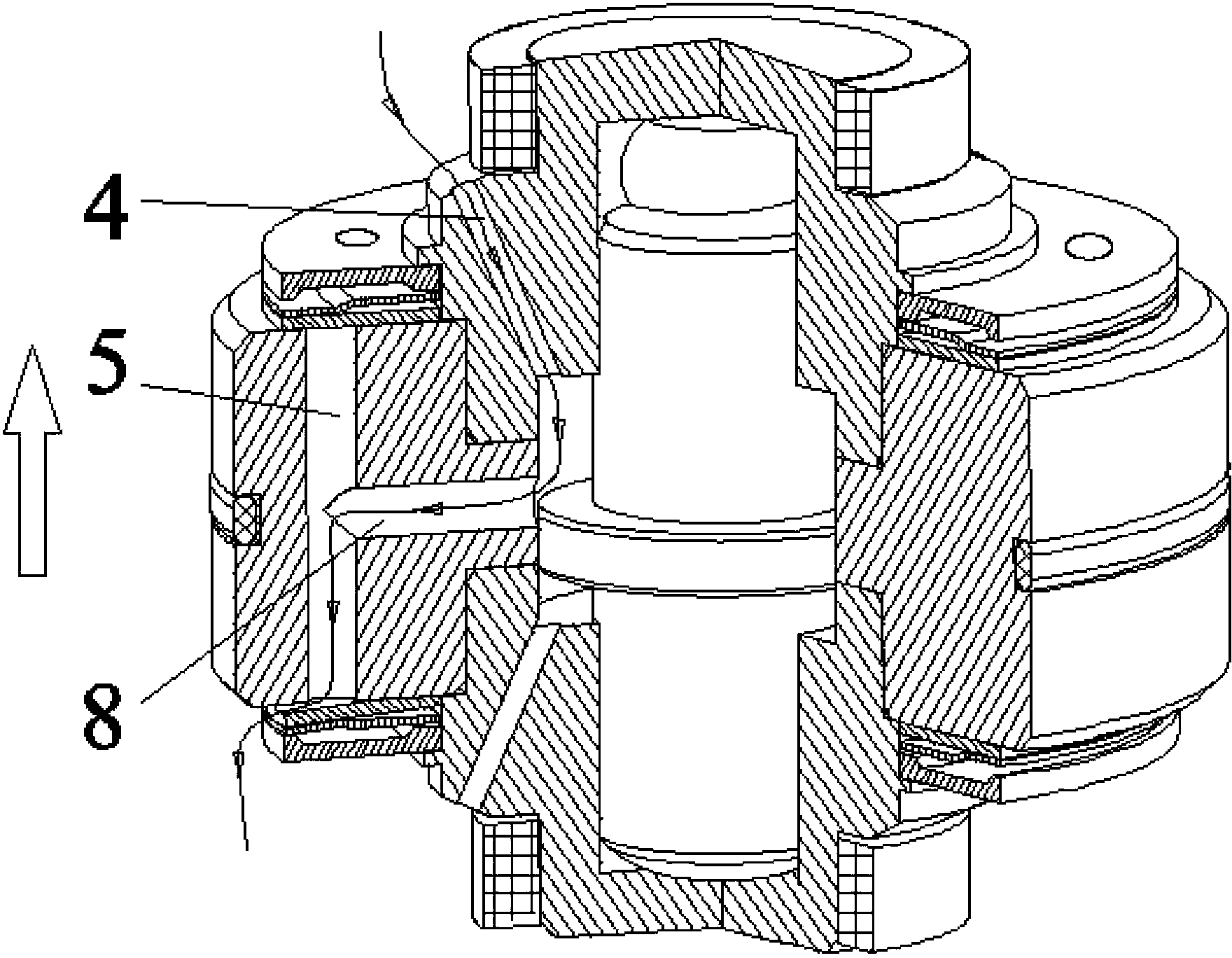

Magnetorheological flow control valve

ActiveCN103148257AEasy to controlQuick response to yield strength changeOperating means/releasing devices for valvesMagnetic currentMagnetorheological fluid

The invention relates to a flow control valve, in particular to a magnetorheological flow control valve which realizes flow control through the opening degree of the control valve. The flow control valve comprises a jump ring, an upper end cover, an upper valve body, a lower valve body, a coil, a lower thrust spring, a valve core, a thrust shaft, an inner valve body, a working cavity, a magnetic isolation sleeve, a spring seat, an upper thrust spring, a seal bolt and a plurality of rubber seal rings; and according to the magnetorheological flow control valve, the shifting position of the valve core is controlled through a technical method in which the magnetic field intensity which acts on magnetorheological fluid in the working cavity formed between the magnetic isolation sleeve and the upper valve body is controlled, so that the magnetorheological fluid yield strength is affected and the action force of magnetorheological fluid to the thrust shaft is controlled, so that different circulation areas are obtained and the the control over the fluid flow is realized.

Owner:JILIN UNIV

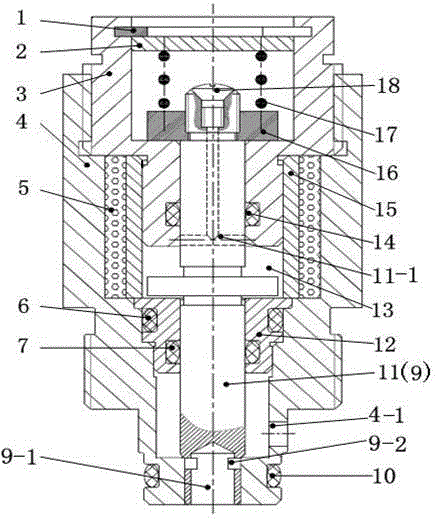

Double-acting magneto-rheological pressure and flow control valve

ActiveCN103267159AControl flowEasy to controlOperating means/releasing devices for valvesEngineeringMagneto rheological

The invention discloses a double-acting magneto-rheological pressure and flow control valve which comprises an upper end cover and a lower end cover. The upper end cover and the lower end cover are arranged in a longitudinal symmetry manner, and a thrust shaft is slidably connected into a cavity formed between the upper end cover and the lower end cover; two cavities are formed in rooms among two ends of the thrust shaft, the upper end cover and the lower end cover, and an upper flow control cavity and a lower flow control cavity are respectively mounted in the two cavities; the upper end cover is fixed to the lower end cover by a piston, an upper auxiliary damping hole and a lower auxiliary damping hole are respectively machined on the upper end cover and the lower end cover, and an auxiliary channel which is communicated with the damping holes is arranged in an inner ring of the piston; and the opening of the auxiliary channel is determined by the sliding stroke of the thrust shaft. The double-acting magneto-rheological pressure and flow control valve has the advantages of high response speed and extremely wide bearing pressure range owing to fast yield strength variation response and wide range of magneto-rheological fluid. Besides, the double-acting magneto-rheological pressure and flow control valve is simple and compact in structure, convenient to manufacture and high in portability, and can be connected into an electronic control unit, so that a bidirectional flow can be intelligently and steplessly controlled.

Owner:JILIN UNIV

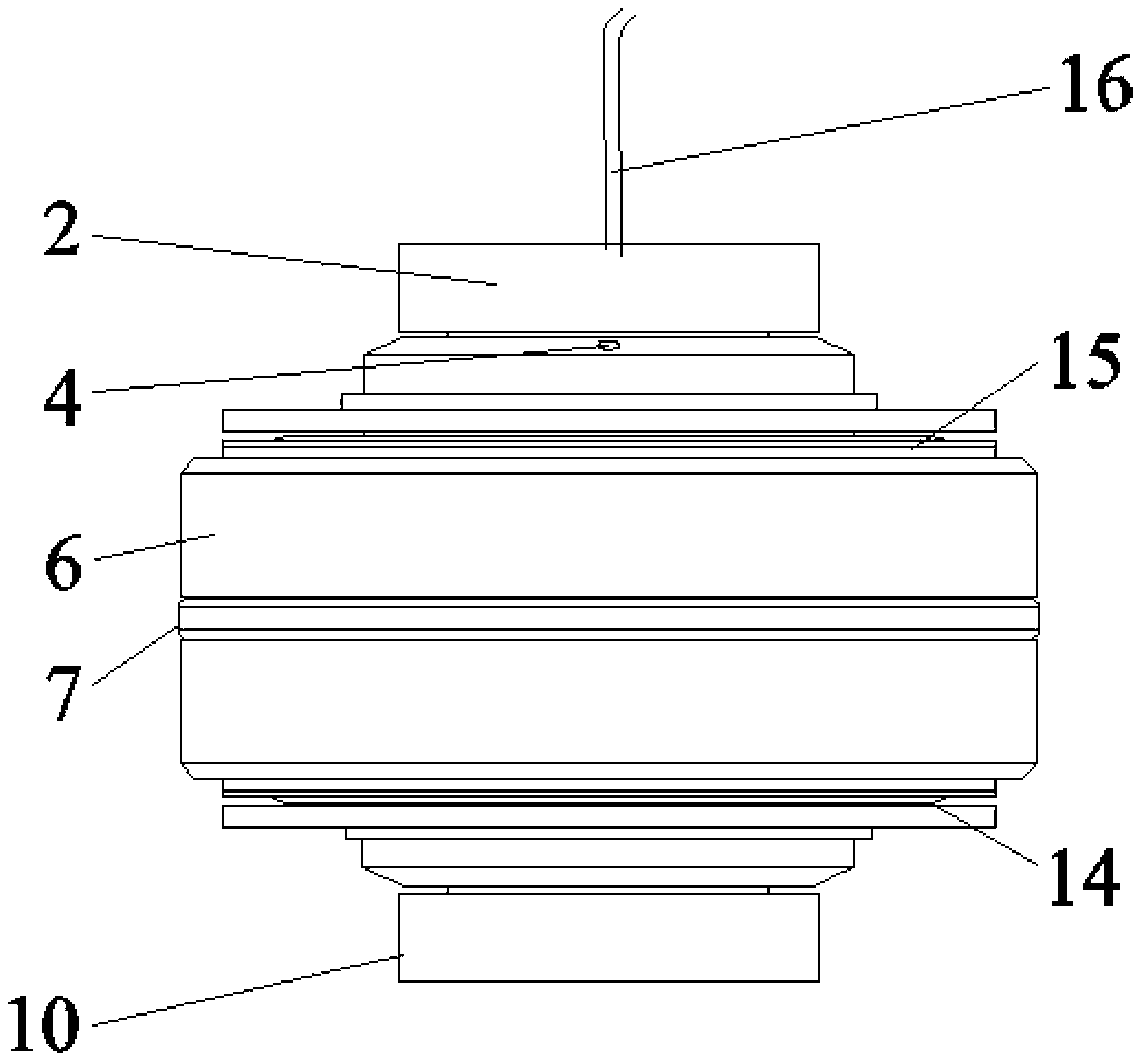

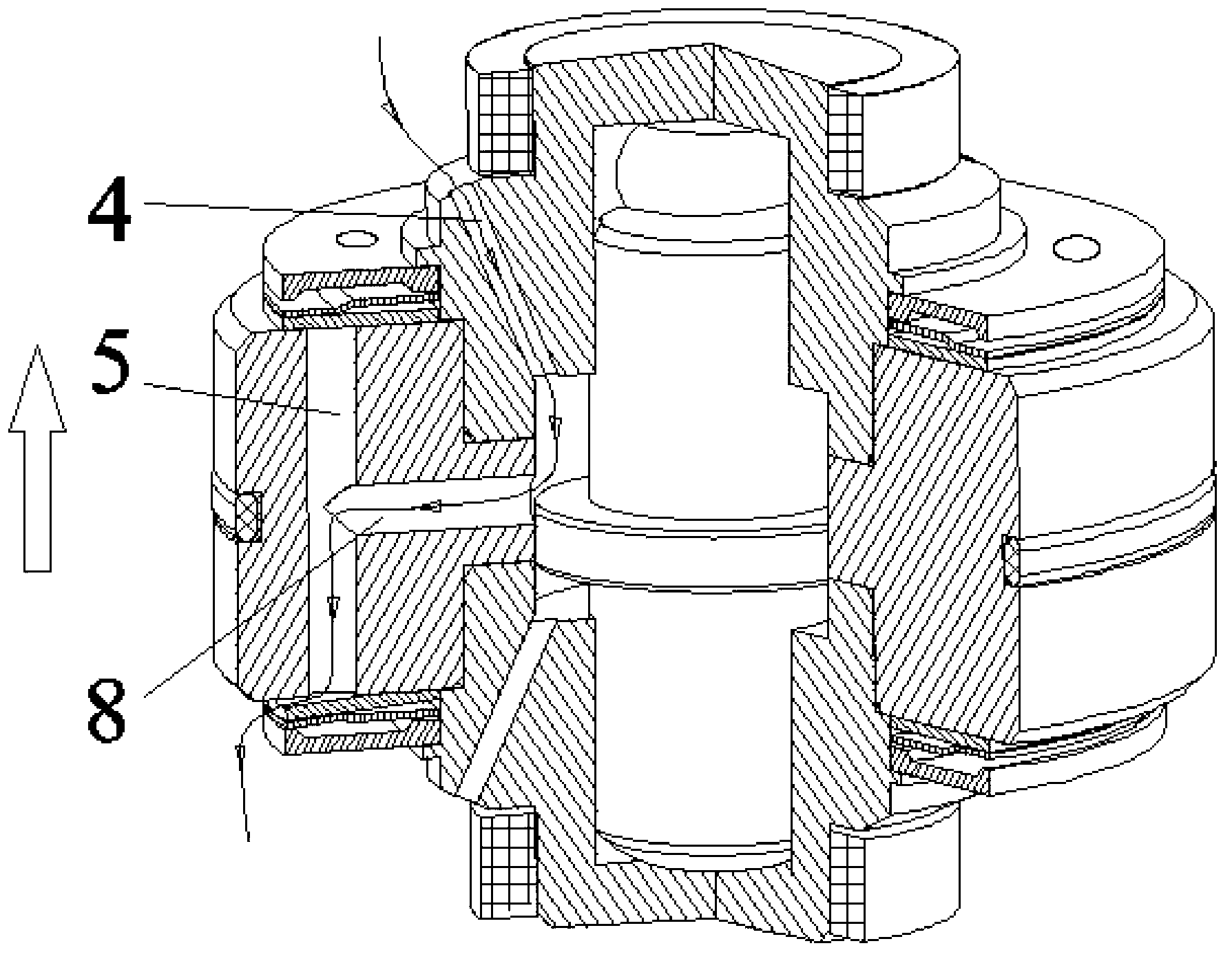

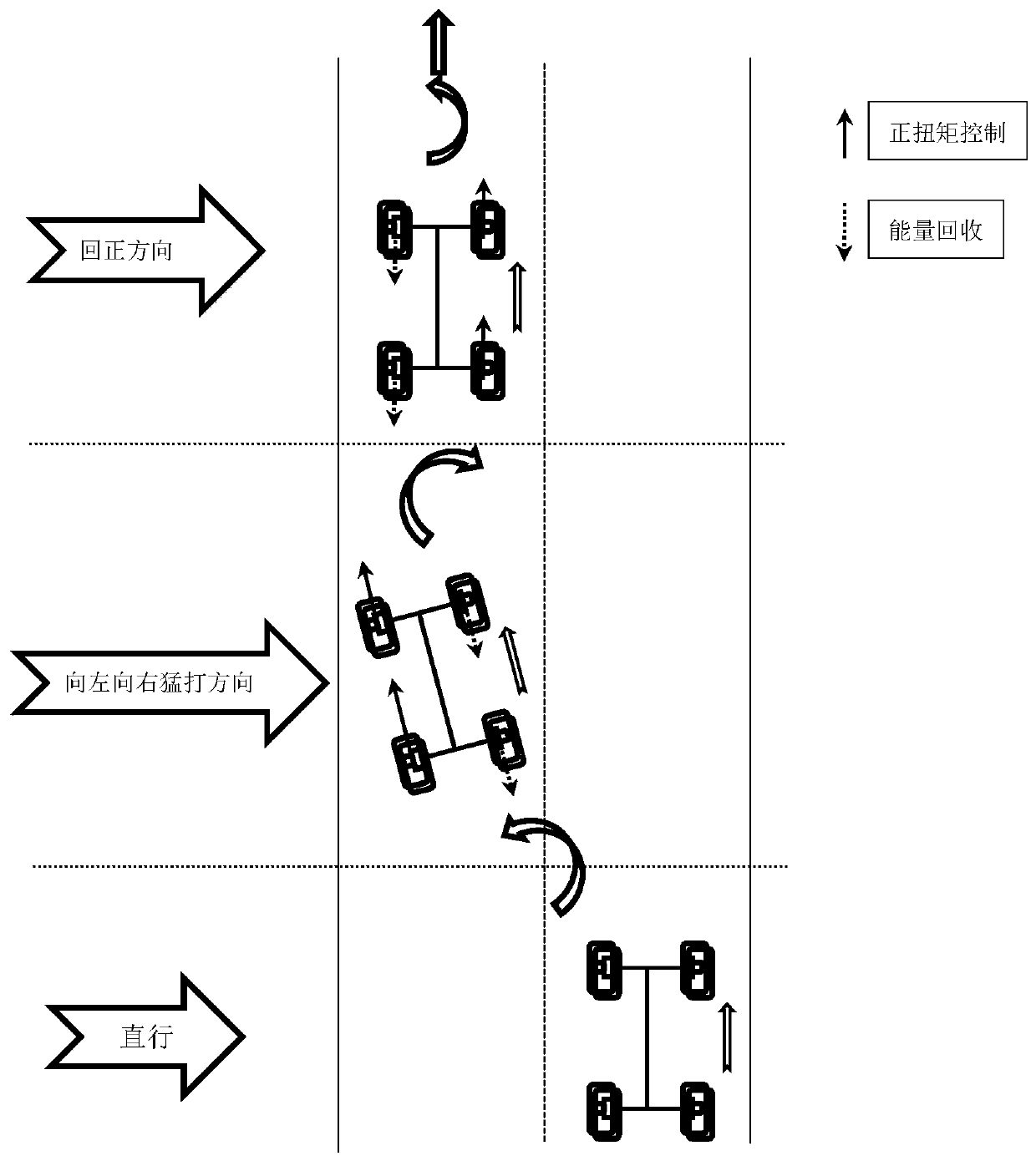

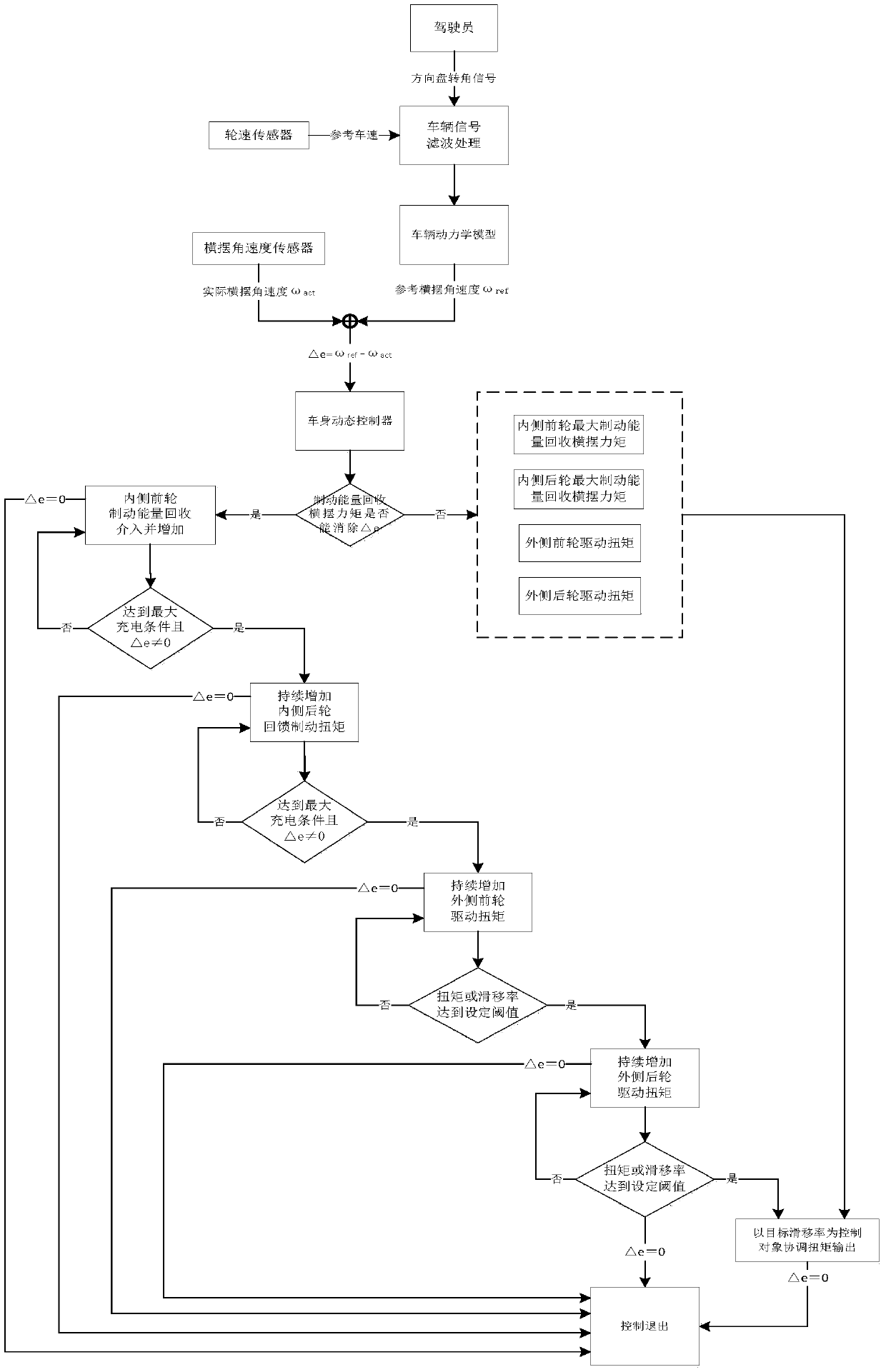

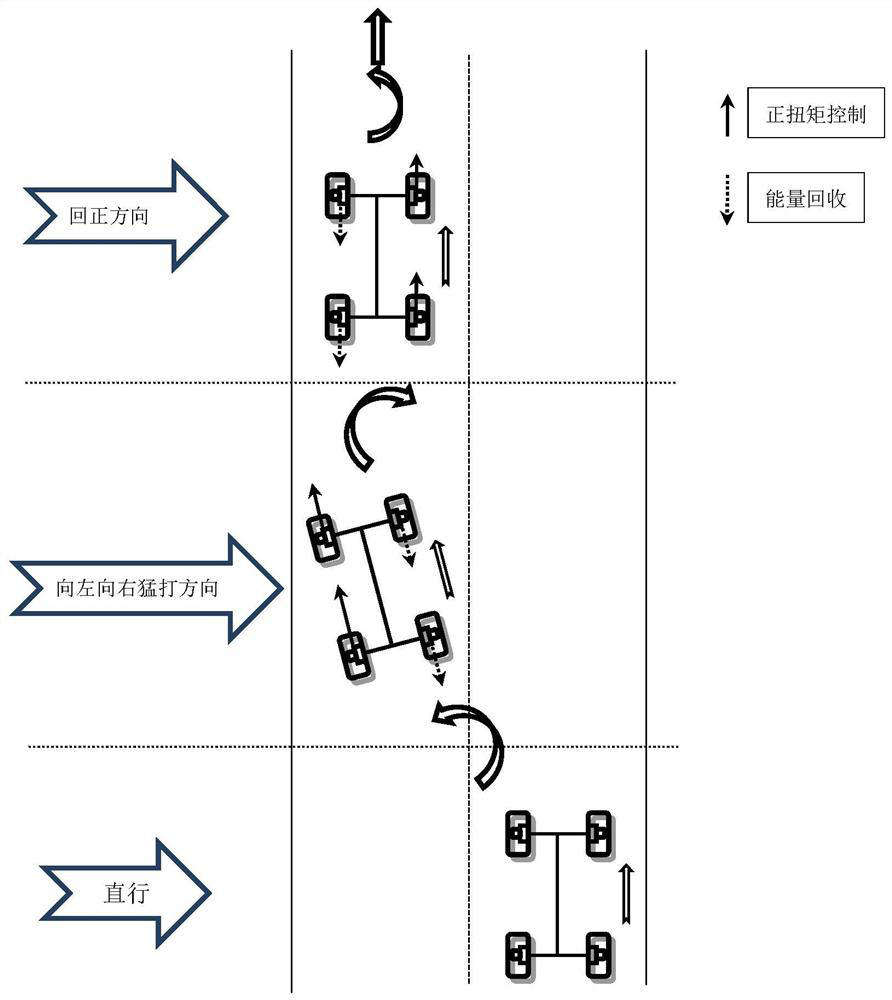

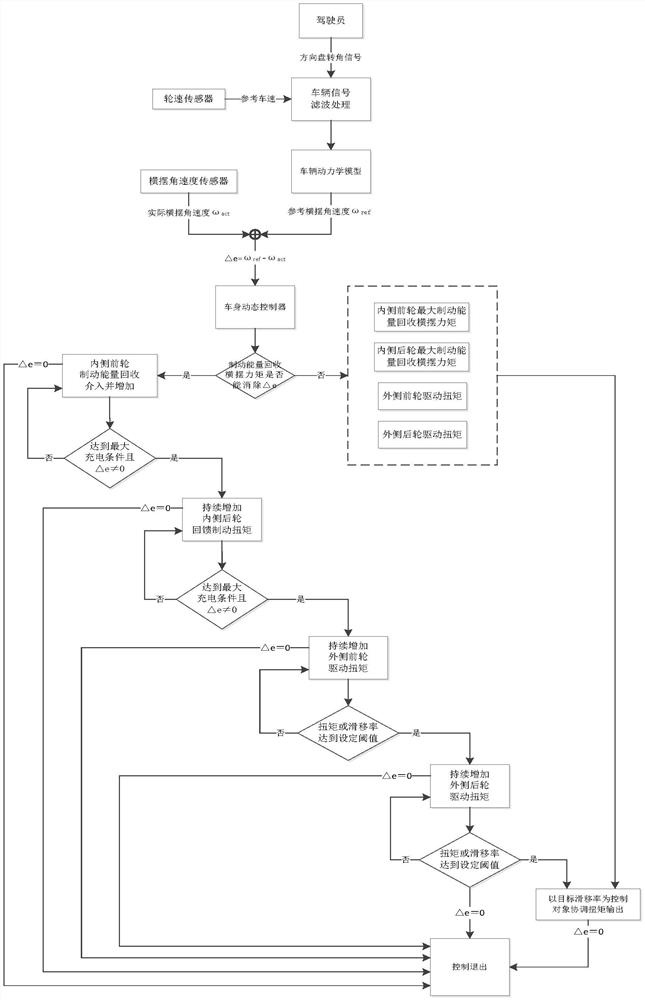

Four-wheel drive electric automobile steering stability control method

ActiveCN110254420AEliminate deviations in motion stateImprove stabilityElectrodynamic brake systemsEnergy recoveryControl theory

The invention discloses a four-wheel drive electric automobile steering stability control method. When a vehicle is judged to be turned, the yaw moment offset is calculated; and when it is judged that the steering is insufficient, inner-side front wheels and rear wheels inside are controlled to perform braking energy recovery to generate a yaw moment; if the braking yaw moment is larger than or equal to the yaw moment offset, the inner-side front wheels are controlled to perform braking energy recovery, and when the maximum charging condition of the inner-side front wheel energy is reached, the inner-side rear wheels are controlled to perform braking energy recovery until the yaw moment offset is eliminated; and if the braking yaw moment is smaller than the yaw moment offset, the inner-side front and rear wheel brake energy is controlled to recover and increase the outer side front, the rear wheels drive the torque, and the target slip rate is used as a control object to coordinate the output of the torque, and the deflection amount of the yaw moment is eliminated; and when it is judged that the steering is over, the front wheels and the rear wheels outside are controlled to perform braking energy recovery, and the control strategy and the steering insufficiency are the same. Torque control can be performed on each wheel, and stability and robustness of control are improved.

Owner:清华大学苏州汽车研究院(吴江)

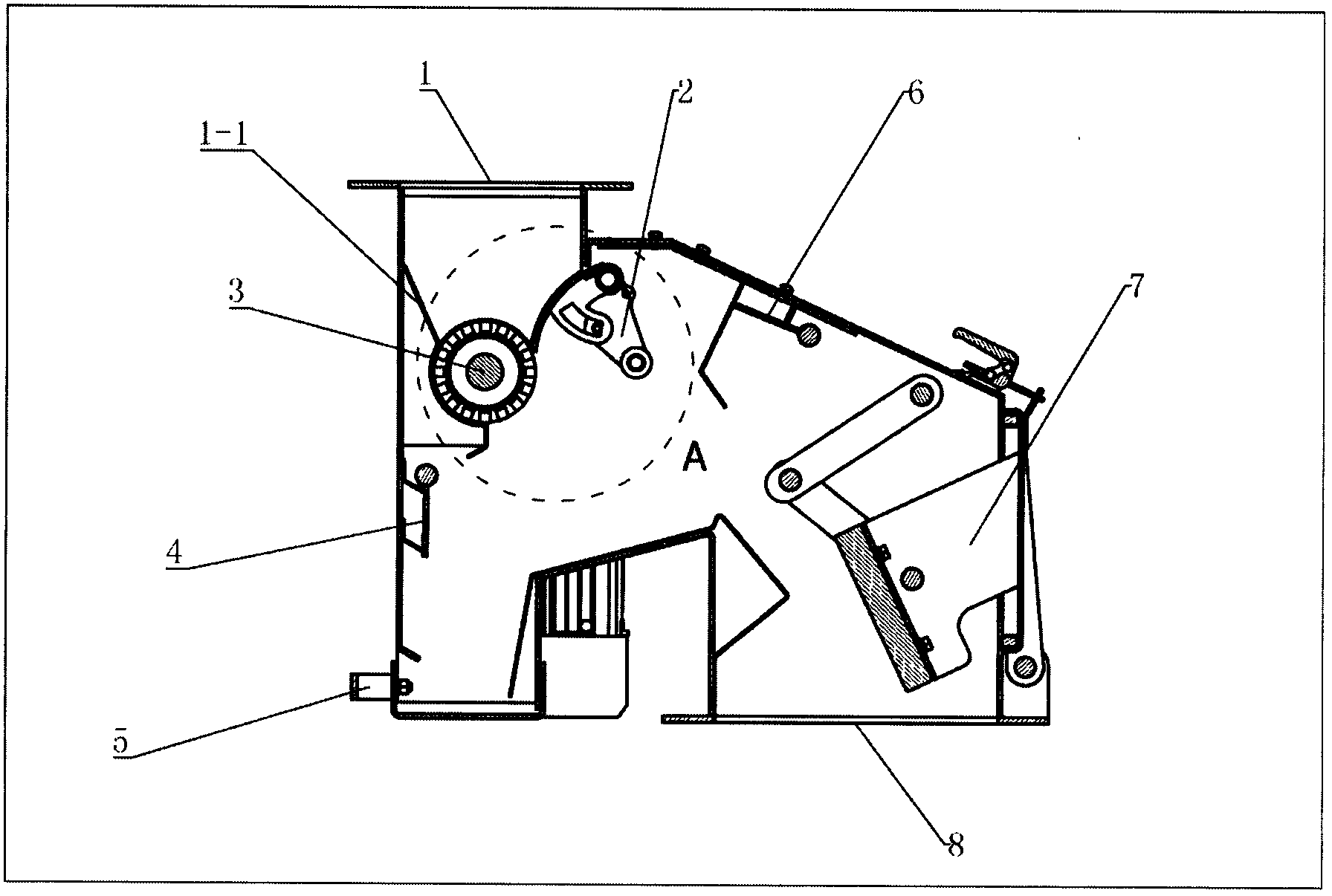

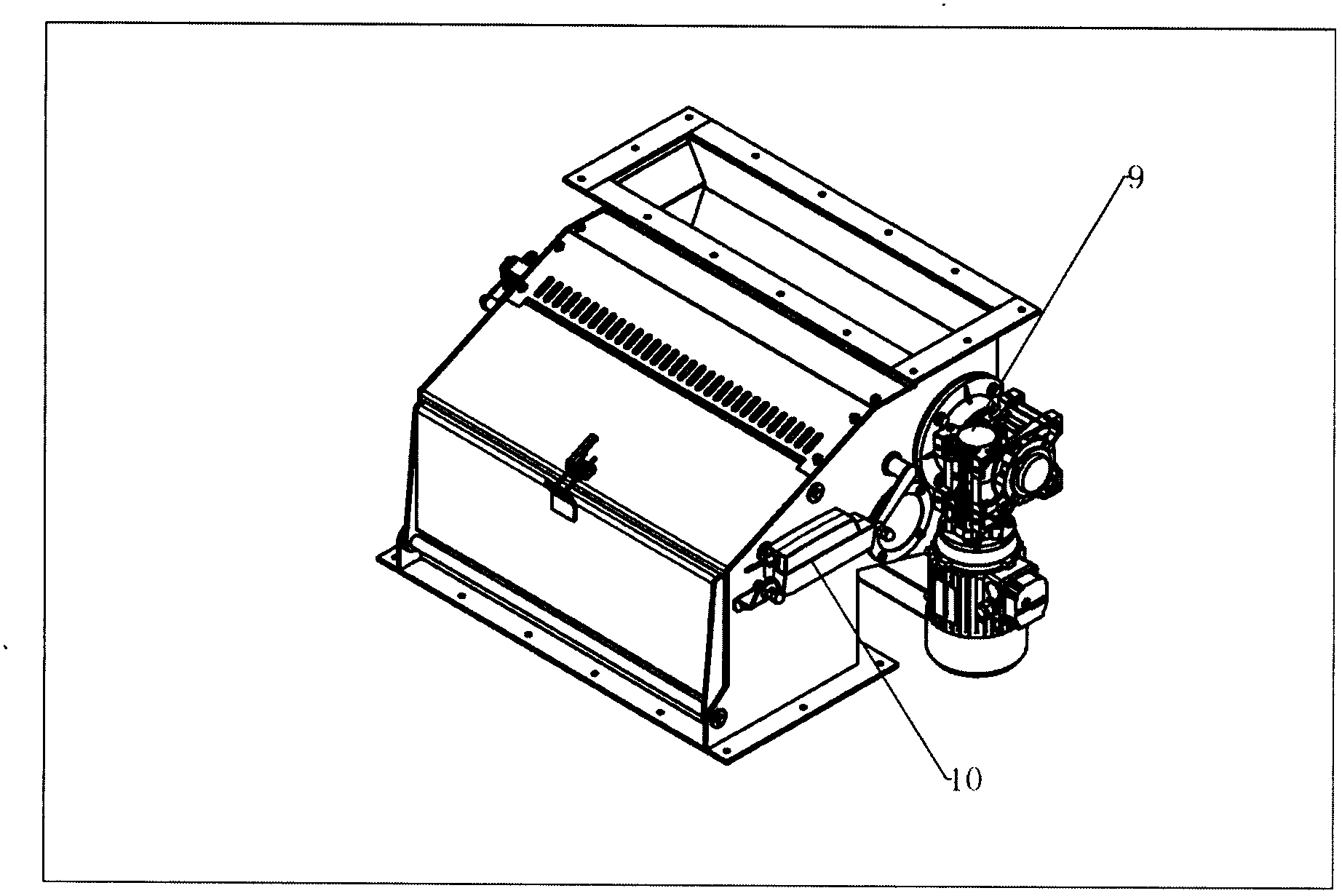

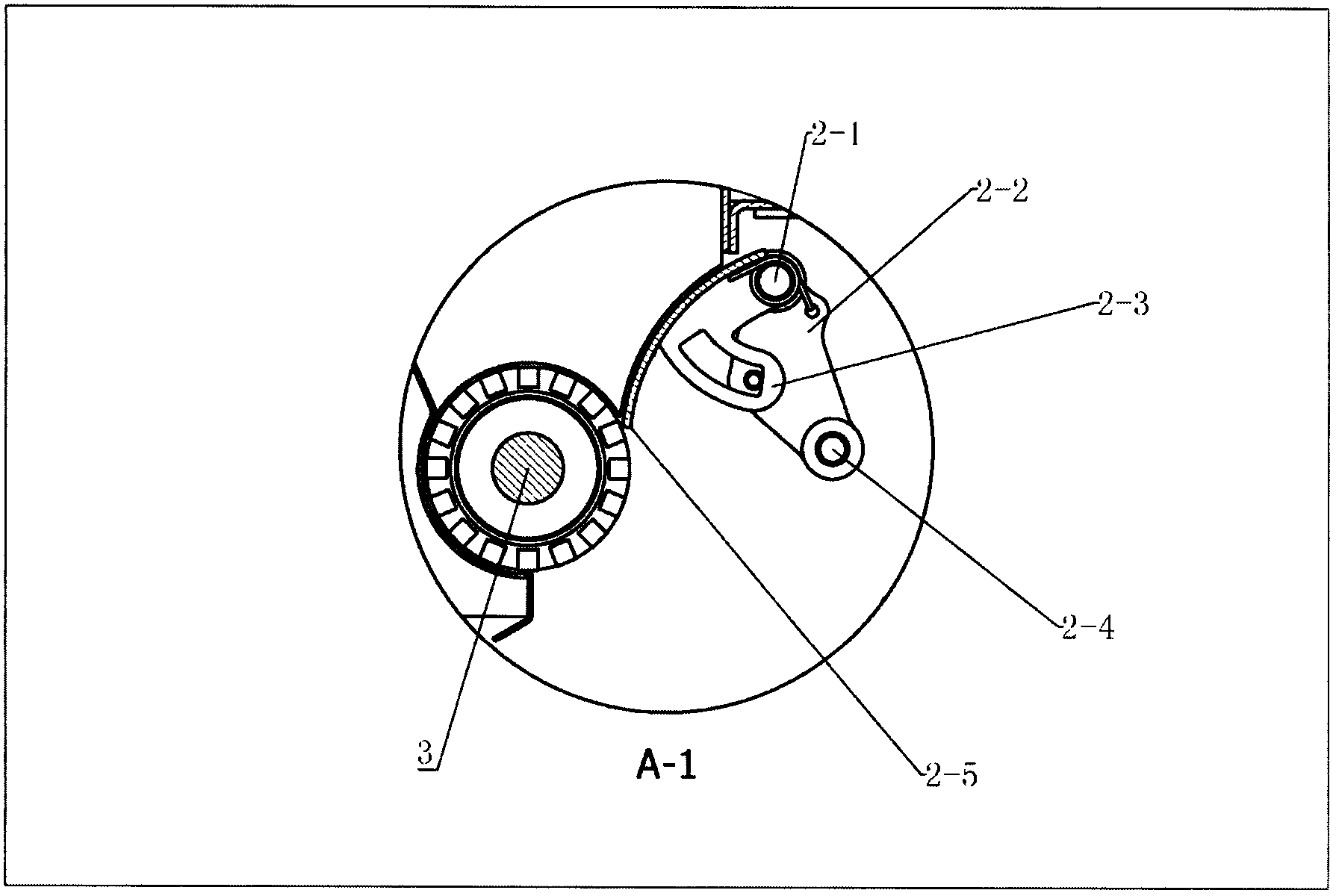

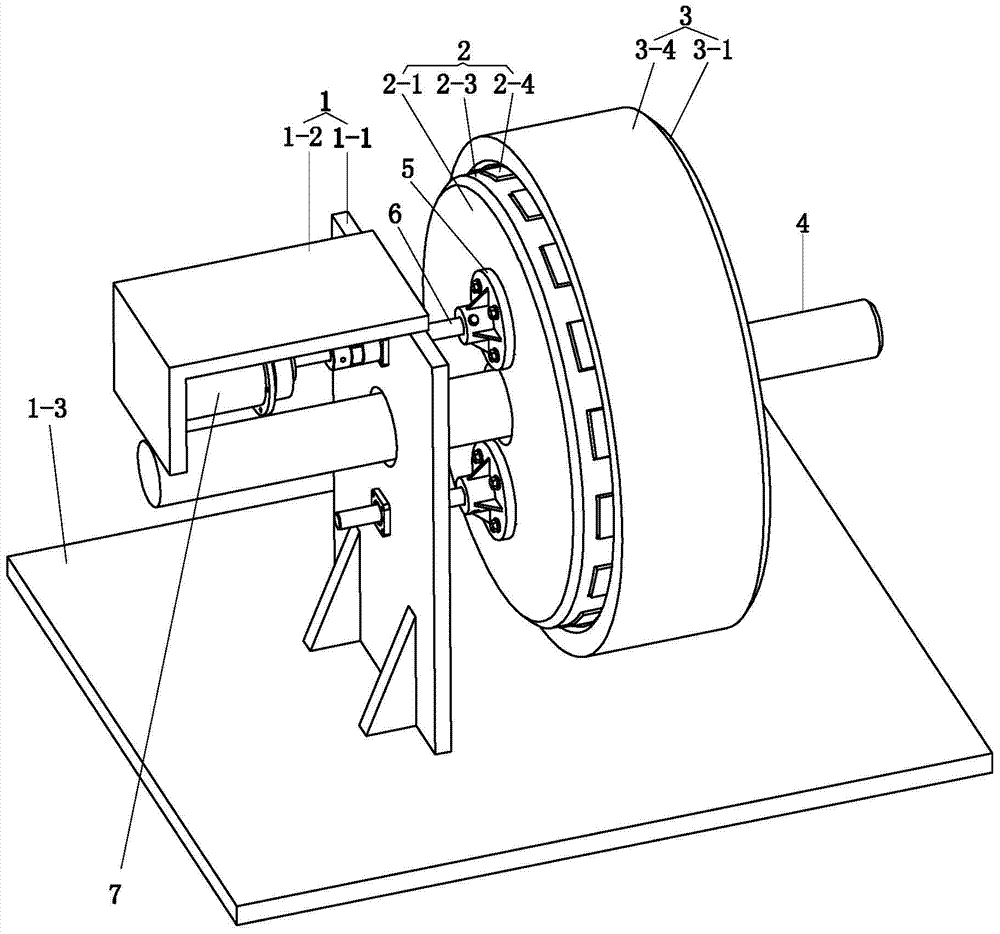

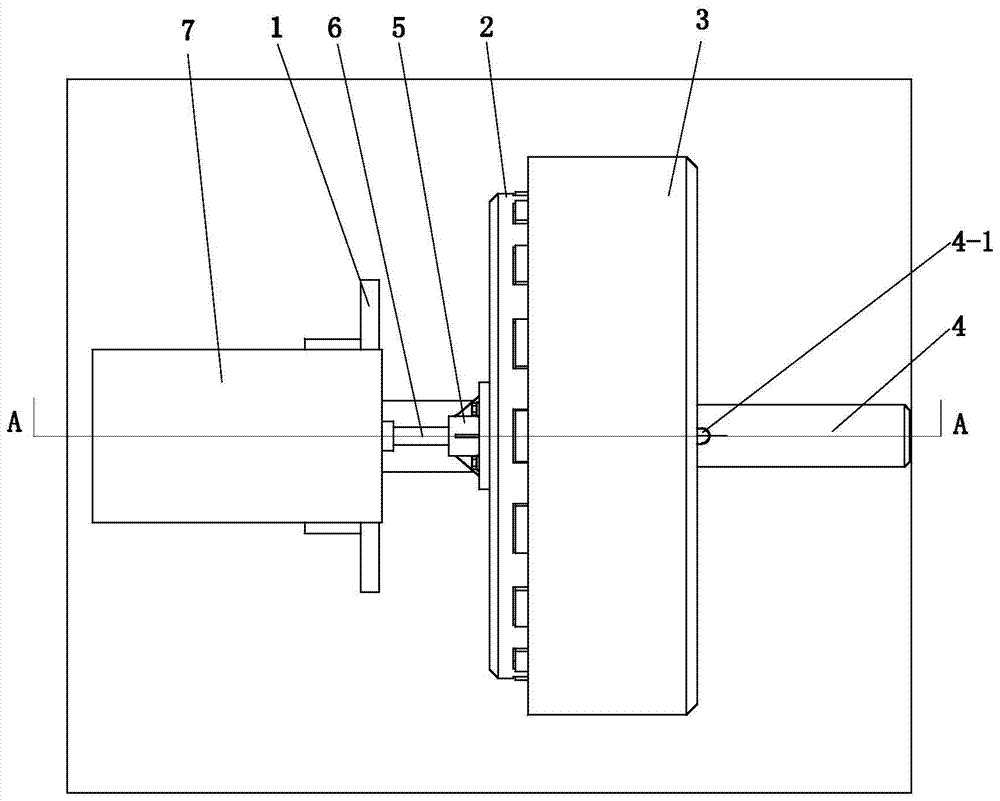

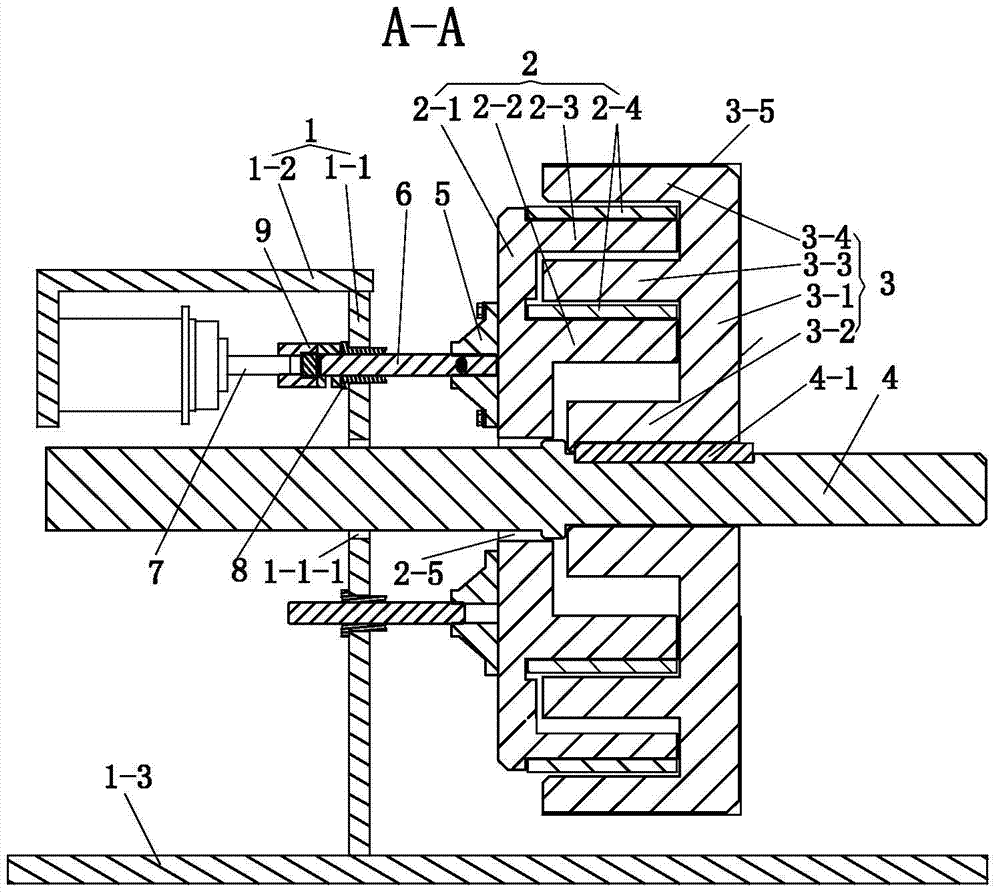

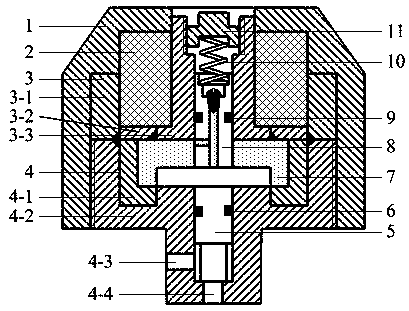

Impeller type feeder

InactiveCN103803255ARealize stepless controlSatisfies the requirements of large particles with comparable widthRotary conveyorsImpellerChemical industry

The invention relates to an impeller type feeder used in the fields such as grain, feed, food, chemical industry, medicine and fertilizer. The impeller type feeder has the functions of adjusting a feeding quantity in a stepless mode, removing impurities and preventing blockage. The impeller type feeder is designed with a special adjustable right guide plate (2), when chunk materials enter the feeder, large particles can smoothly enter as a turnover plate (2-5) is stressed to rotate backwards, after the large particles enter, the turnover plate (2-5) is automatically reset to the normal position under the action of an torsion spring mechanism (2-1), the impeller type feeder is suitable for the feeding demands of large-particle materials with higher hardness under different feeding flow conditions, and the materials cannot be blocked under the conditions of smaller flow and large size particularly.

Owner:上海春谷机械制造有限公司

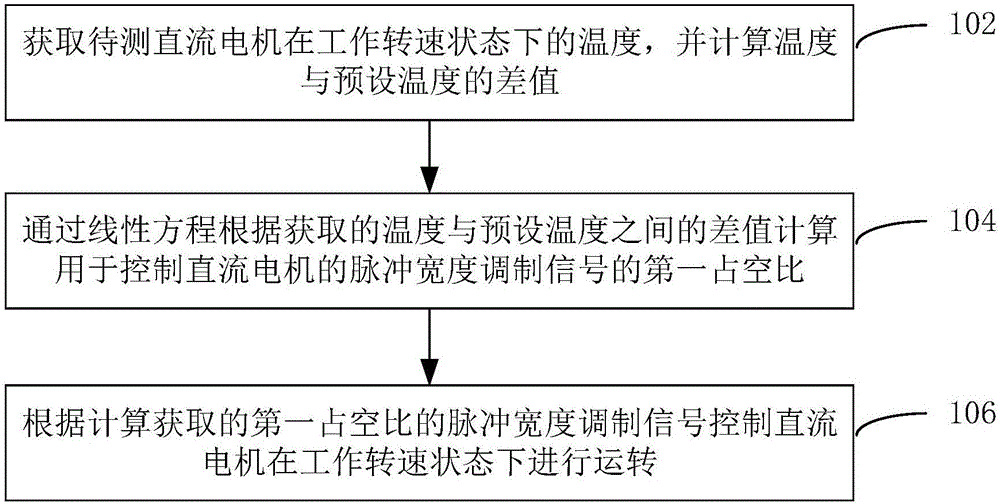

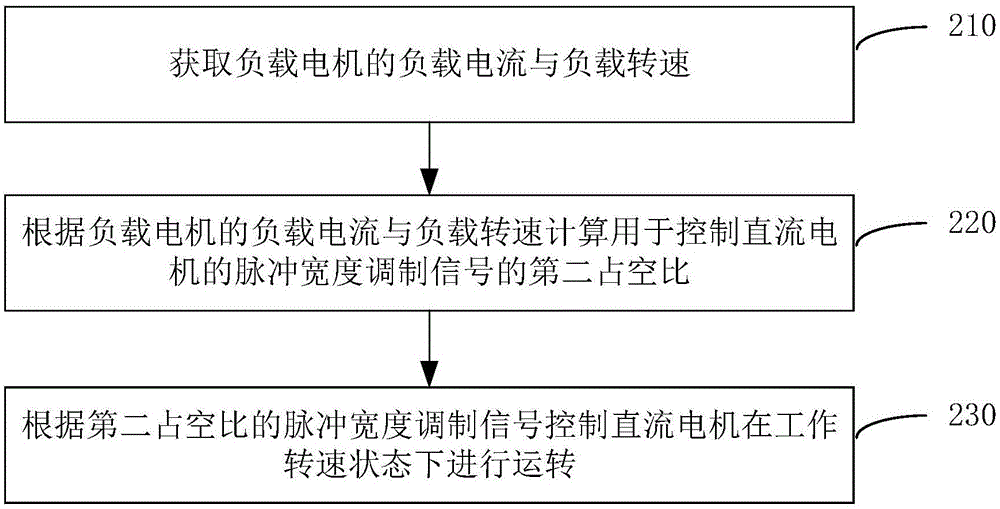

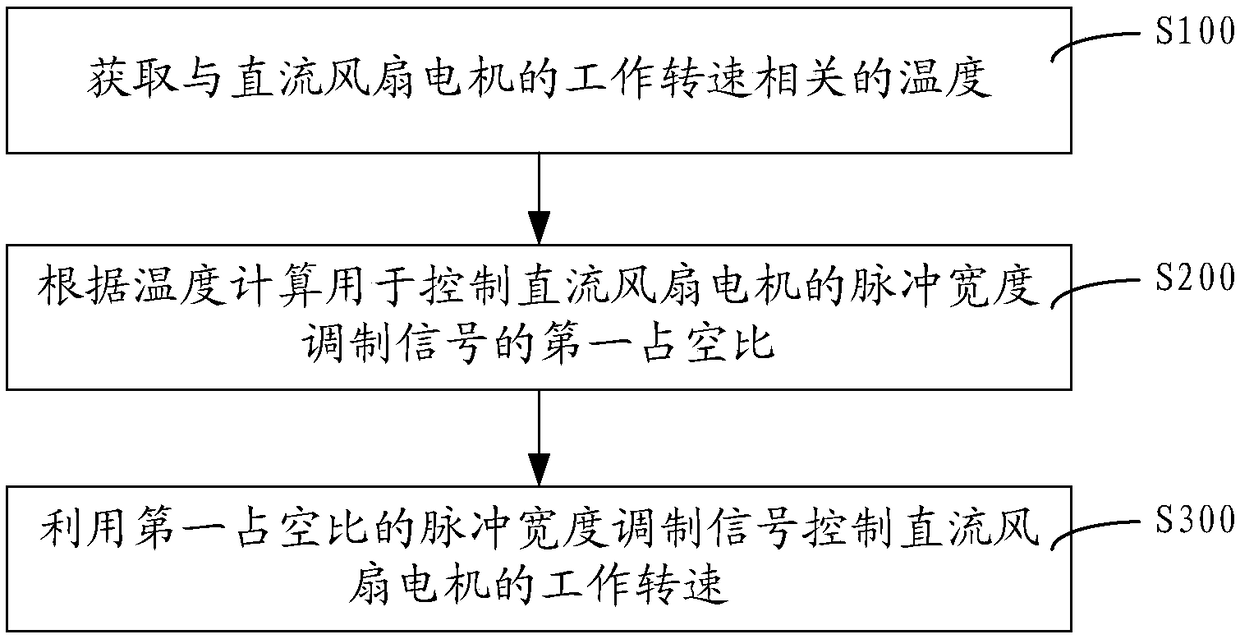

Direct current electric motor control method and device

InactiveCN106253770ARealize stepless controlField or armature current controlControl mannerEngineering

The invention discloses a method and device for controlling a DC motor, wherein the method includes the following steps: obtaining the temperature of the DC motor to be measured at a working speed state, and calculating the difference between the temperature and the preset temperature; The difference between the temperature and the preset temperature is used to calculate the first duty cycle of the pulse width modulation signal used to control the DC motor; the pulse width modulation signal of the first duty cycle obtained according to the calculation is used to control the DC motor in the working speed state run. Since the first duty cycle of the pulse width modulation signal can be accurately adjusted according to the temperature reference factor, the rotational speed of the DC motor can be adjusted with high precision through the pulse width modulation signal. Compared with the control method of dividing the detected temperature into intervals and controlling the operation of the DC motor in different gears in the traditional technology, it realizes the stepless control of the DC motor control.

Owner:刘华英

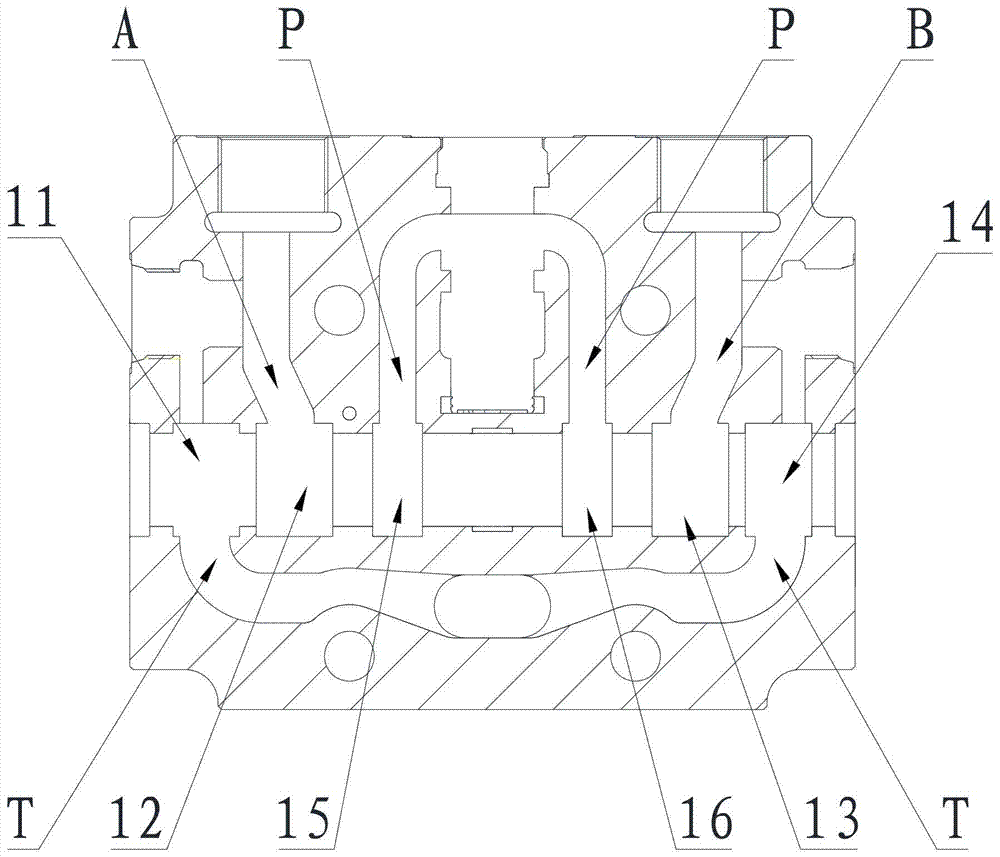

Slide valve type hydraulic valve with differential motion function

The invention provides a slide value type hydraulic valve with a differential motion function. The slide value type hydraulic valve comprises a valve body and a valve element which is arranged in a valve body hole; a first undercutting groove, a second undercutting groove, an oil inlet undercutting groove, a third undercutting groove and a fourth undercutting groove are arranged in the valve body hole in sequence, wherein the first undercutting groove and the fourth undercutting groove are communicated with an oil return opening, the second undercutting groove and the third undercutting groove are communicated with a working oil port respectively, and an oil inlet undercutting groove is communicated with an oil inlet; the valve element comprises a left circular bead, a left shaft neck, a middle circular bead, a right shaft neck and a right circular bead from left to right; a circular groove, a first valve port and a second valve port are arranged on the excircle of the left part of the middle circular bead, wherein the first valve port and the second valve port are not communicated with each other; a third valve port and a fourth valve port which are communicated with the right shaft neck are arranged on the excircle of the right part of the middle circular bead and the excircle of the left part of the right circular bead respectively. The slide value type hydraulic valve realizes differential motion function through improving the structure of a main valve element of the hydraulic valve, the integral structure is changed little, so as to reduce the product cost and failure rate of the product; the differential motion function is realized, and stepless control of flow can be realized at the same time.

Owner:SANY HEAVY IND CO LTD (CN)

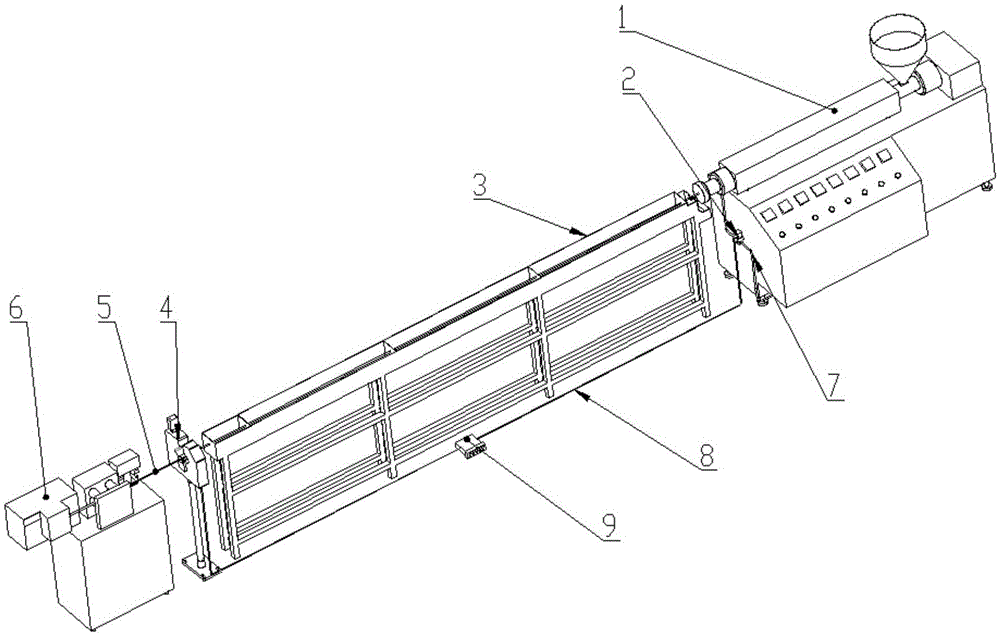

Production method and production line for measuring size of pipe diameter of sucking pipes on line

InactiveCN105109018ARealize non-contact caliper measurementEasy to controlTubular articlesProduction lineControl signal

The invention discloses a production line for measuring size of pipe diameter of sucking pipes on line. The production line comprises an extruder, a cooling device, an electric proportional valve, a two-dimensional laser diameter measuring device and a traction cutter which are arranged in sequence along the direction of the production line, wherein a remote controller is arranged between the two-dimensional laser diameter measuring device and the electric proportional valve and is used for receiving data of diameter values and deviation values output by the two-dimensional laser diameter measuring device; the remote controller is used for sampling in time after receiving the data, sending control signals to the electric proportional valve and controlling the electric proportional valve to correct the deviation values and maintain the consistency of line diameter. The invention also discloses a production method for measuring size of the pipe diameter of the sucking pipes on line. The production line and the production method are capable of carrying out two-dimensional detection on the sucking pipes on line; the laser scanning technique is adopted; the production line and the production method have the advantages of non-contact measurement, wide measurement range, high scanning speed, high measurement accuracy and stable performance.

Owner:楼仲平

Magnetorheological Pressure Control Valve

ActiveCN103591363BControl yield strengthControl forceOperating means/releasing devices for valvesSpringsMagnetorheological fluidSystem pressure

The invention relates to a pressure control valve, in particular to a magnetorheological pressure control valve for achieving hydraulic system pressure control through a force required to start the control valve. The pressure control valve comprises an inner valve body, a valve core, a blanking cap, a main valve body, a working chamber containing magnetorheological fluid, a coil assembly composed of a coil and a magnet separation jacket, an outer valve body, an upper valve body, a thrust shaft, a spring seat, a reset spring, an end cap, a travel switch sensor and a plurality of rubber seal rings. The magnetorheological pressure control valve is simple in structure, convenient to manufacture, high in energy efficiency and quick in pressure response and stepless and intelligent control of system pressure can be achieved.

Owner:浙江孔辉汽车科技有限公司

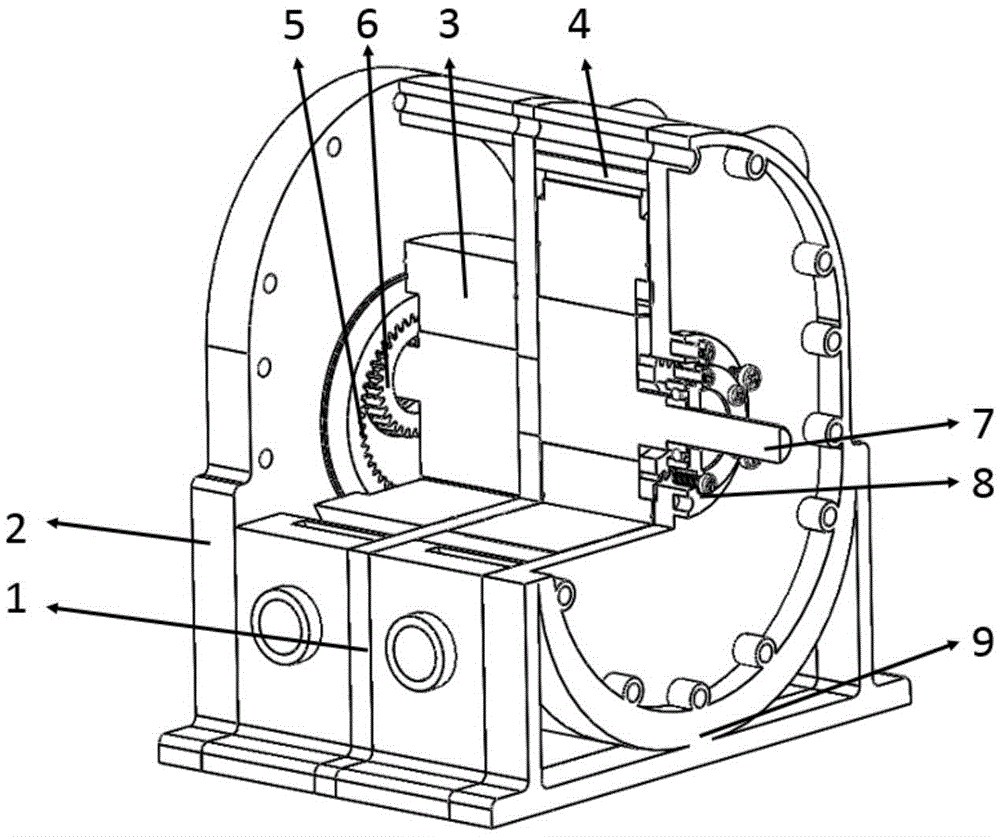

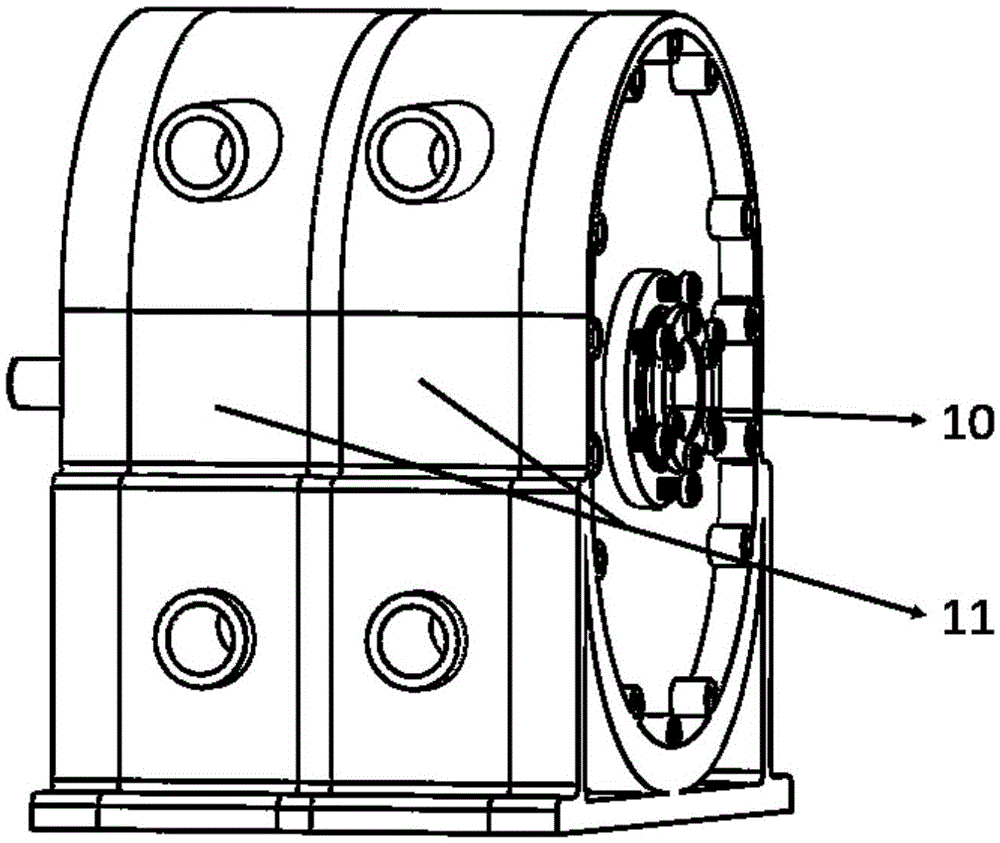

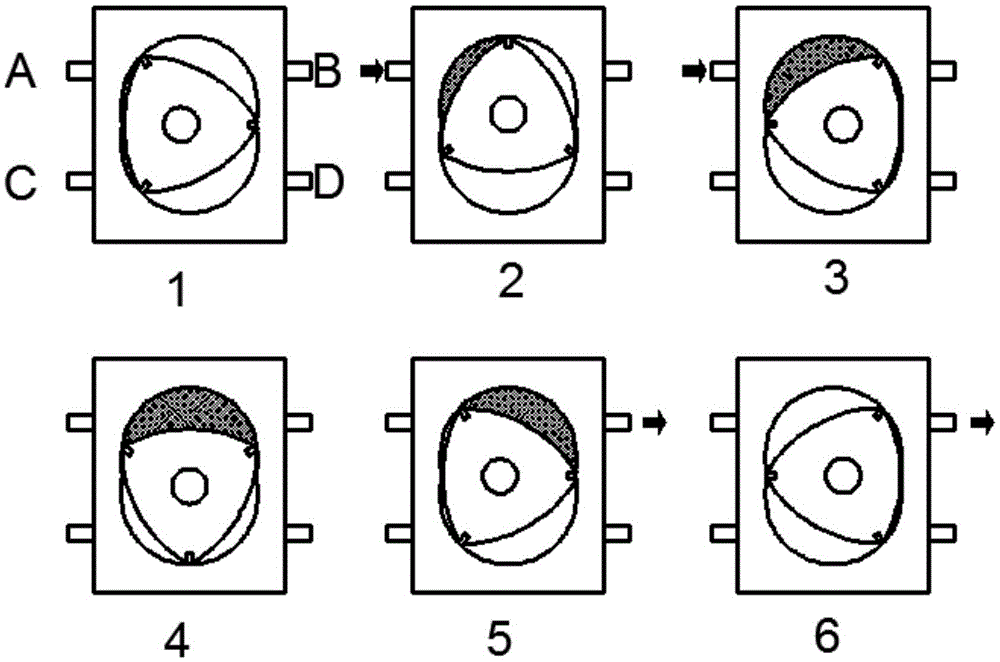

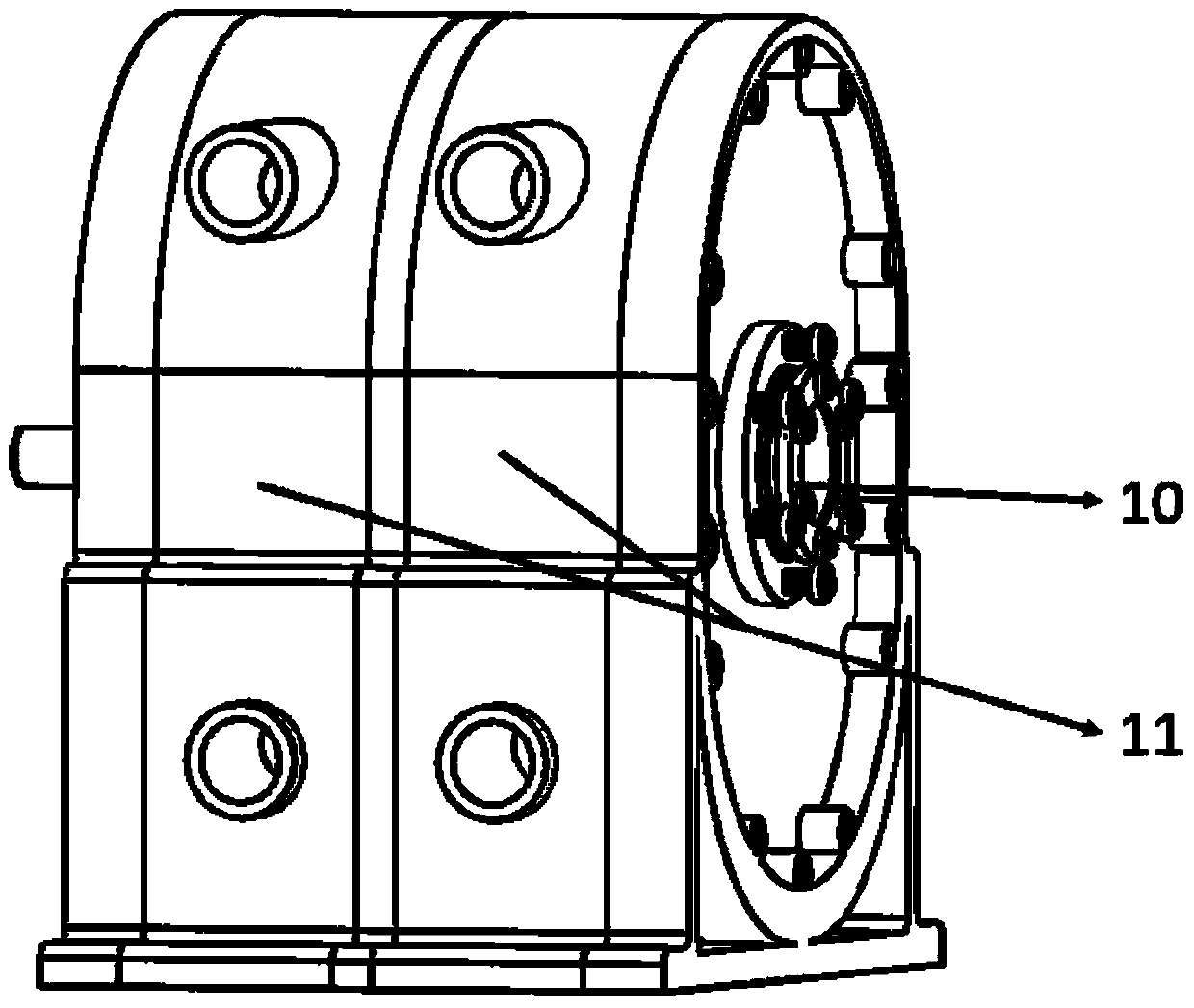

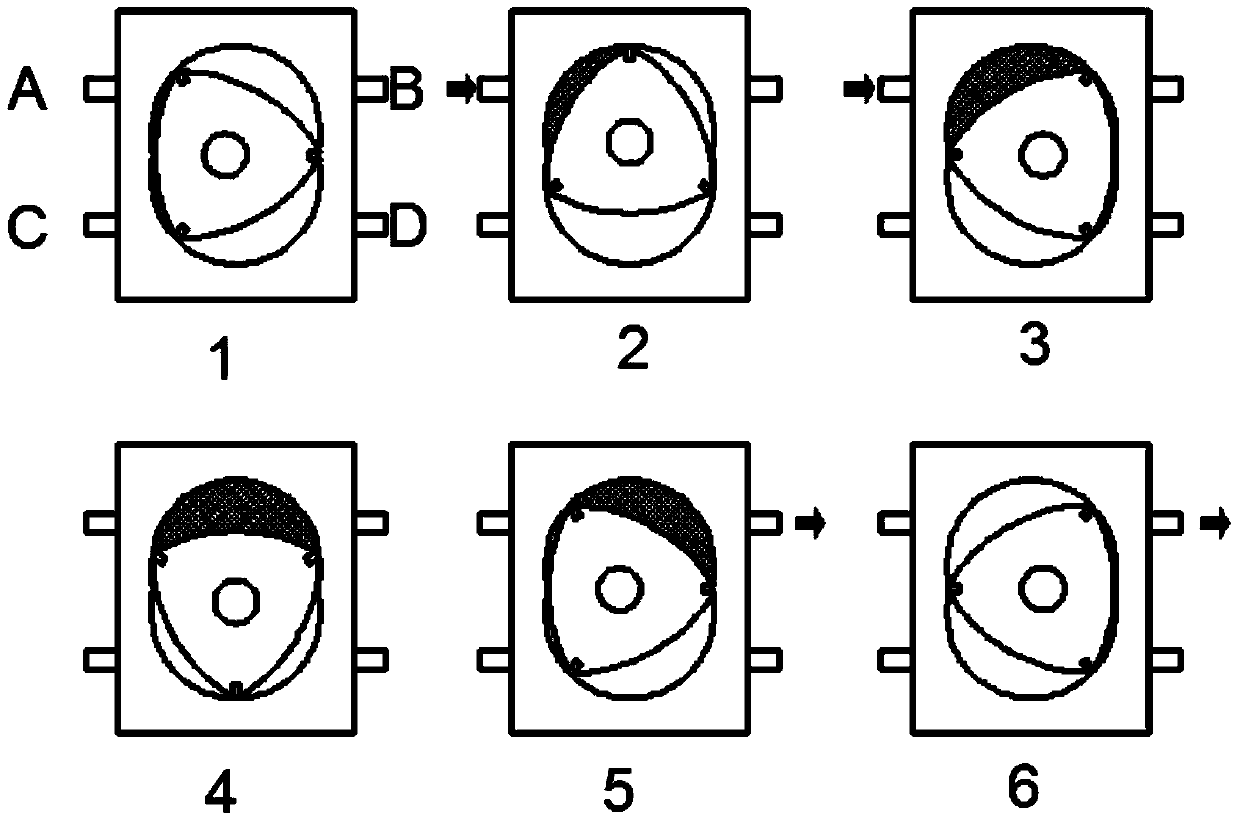

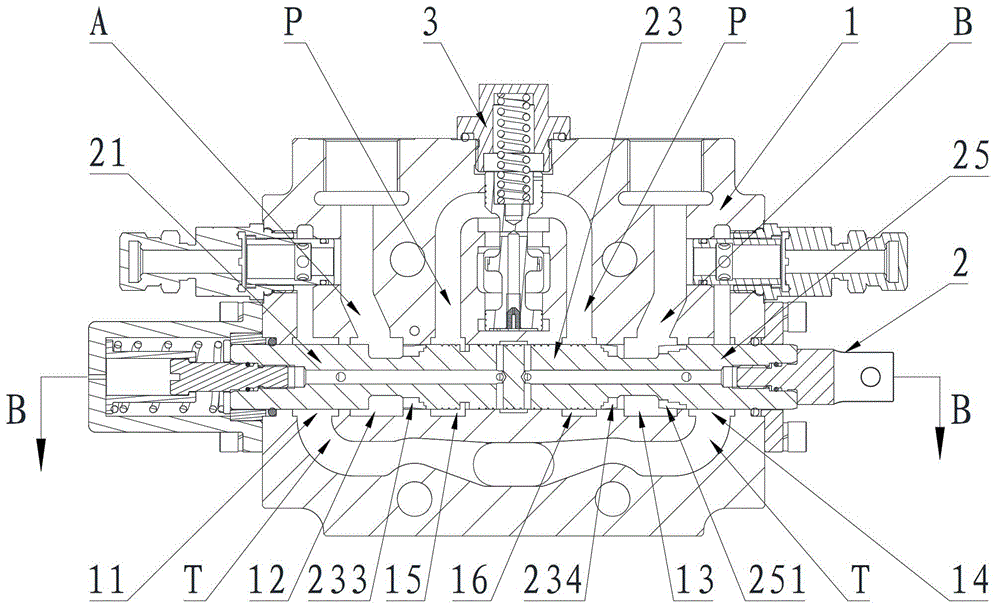

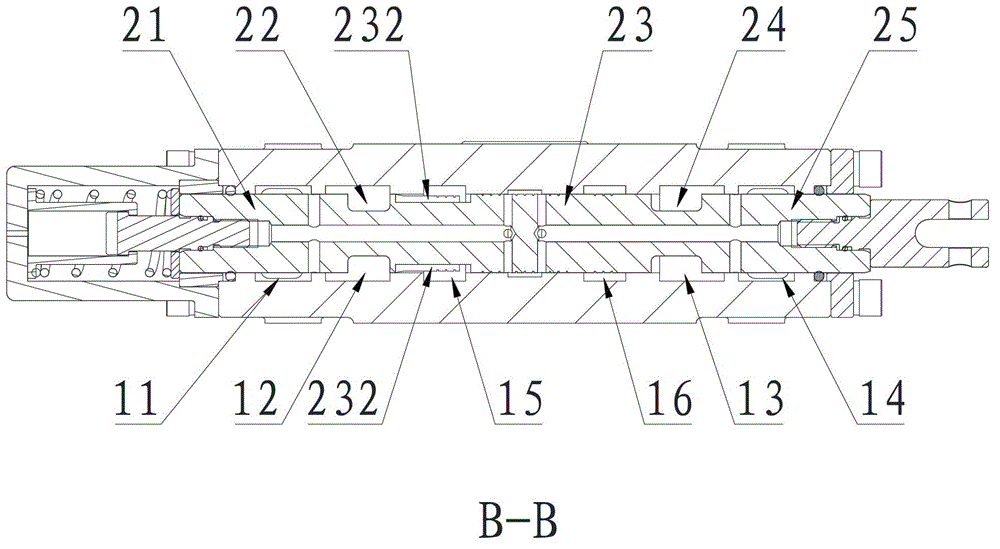

Double-cylinder eccentric rotary pump

ActiveCN106014974AHigh liftEasy maintenanceRotary piston pumpsRotary/oscillating piston combinationsRotary pumpEngineering

The invention discloses a double-cylinder eccentric rotary pump. The double-cylinder eccentric rotary pump comprises a first cylinder body and a second cylinder body. The first cylinder body and the second cylinder body are each internally provided with a cavity. The outer end surface of the first cylinder body and the outer end surface of the second cylinder body are each provided with inlets and outlets. The cavity of the first cylinder body and the cavity of the second cylinder body are internally provided with a first rotor and a second rotor correspondingly. Working cavities are formed between the side surface of the first rotor and the cavity of the first cylinder body as well as between the side surface of the second rotor and the cavity of the second cylinder body correspondingly. The first rotor and the second rotor are installed on a first eccentric part and a second eccentric part of the same crankshaft in a sleeving mode correspondingly so that the working cavities can be increased or decreased and the inlets can communicate with the outlets. The first rotor is in clearance fit with the crankshaft, and the second rotor is in clearance fit with the crankshaft. Fixed gears are fixed to the first cylinder body and the second cylinder body. Teeth or gear rings matched with the fixed gears are arranged in the middle of the first rotor and the middle of the second rotor. The double-cylinder eccentric rotary pump is high in efficiency, user-friendly, convenient to transport, easy to maintain and capable of achieving real-time monitoring and stepless speed adjusting.

Owner:SHANDONG UNIV

Oil pressure warning sensor for pressure sensitive capacitor

InactiveCN101793179BHigh precisionImprove stabilitySafety devices for pressure lubricationFluid pressure measurement using capacitance variationCapacitanceControl circuit

An oil pressure warning sensor for a pressure sensitive capacitor relates to a sensor, which comprises a telescoping oil tank main element, an oil tank telescoping component arranged in the telescoping oil tank main element, and a casing cooperating with the telescoping oil tank main element to close the oil tank telescoping component in the telescoping oil tank main element, wherein the telescoping oil tank main element comprises an iron-bottomed bowl and screws in sealed fit with through holes reserved at the bottom of the iron-bottomed bowl; the oil tank telescoping component comprises a sealing washer, a waveform return spring plate, a knurled spring plate, a sliding sleeve, a movable electrode plate, a return spring, a double-sided circuit board and a circuit board retaining snap ring, which are arranged in the iron-bottomed bowl in turn; a fixed electrode plate is arranged on one side, close to the movable electrode plate, of the double-sided circuit board; the movable electrode plate and the fixed electrode plate form a capacitor with variable capacitance; upon receiving the pressure from the engine oil, the waveform return spring leaf and the knurled spring leaf deform and drive the movable electrode plate to compress and deform the return spring so as to change the distance between the movable electrode plate and the fixed electrode plate to change the capacitance of the capacitor; and the oil pressure warning sensor for the pressure sensitive capacitor is further provided with a control circuit connected with the capacitor and used for converting the variation of oil pressure into an electrical signal and transmitting the electric signal to an oil instrument.

Owner:李科明

Magnetorheological pressure control valve

ActiveCN105715802AReduce the impactImprove cooling effectOperating means/releasing devices for valvesSpringsCircular discMagnetorheological fluid

The invention relates to a magnetorheological pressure control valve. The magnetorheological pressure control valve comprises a valve cover, a coil assembly 2, an upper valve body, a lower valve body, a lower valve core, a first rubber seal ring, a second rubber seal ring, a work cavity, an upper valve core, a reset spring and an adjusting nut. The valve cover is fixedly connected to the upper outer side of the lower valve body. The adjusting nut is connected to the inner side of the upper valve body. The reset spring in the compressed state is arranged under the adjusting nut. The lower portion of the reset spring presses on the upper valve core. The upper valve core is arranged in the upper valve body. The lower portion of the upper valve core presses at the upper end of a disk on the lower valve core. The lower valve core is arranged in the lower valve body. The lower portion of the lower valve core presses on the upper side of an oil inlet of the lower valve body. The work cavity is formed between the upper valve body and the lower valve body. The coil assembly is arranged in a groove of the upper valve body. The upper side of the coil assembly makes contact with the inner side of the valve cover. According to the magnetorheological pressure control valve, the coil assembly is arranged on the upper side of the work cavity and far away from magnetorheological fluid, so that the influence of heating of an electromagnetic coil on the magnetorheological fluid is smaller, and the heat dissipation effect of the magnetorheological fluid is better.

Owner:浙江孔辉汽车科技有限公司

A double-cylinder eccentric rotary pump

ActiveCN106014974BHigh liftEasy maintenanceRotary piston pumpsRotary/oscillating piston combinationsRotary pumpCylinder block

The invention discloses a double-cylinder eccentric rotary pump. The double-cylinder eccentric rotary pump comprises a first cylinder body and a second cylinder body. The first cylinder body and the second cylinder body are each internally provided with a cavity. The outer end surface of the first cylinder body and the outer end surface of the second cylinder body are each provided with inlets and outlets. The cavity of the first cylinder body and the cavity of the second cylinder body are internally provided with a first rotor and a second rotor correspondingly. Working cavities are formed between the side surface of the first rotor and the cavity of the first cylinder body as well as between the side surface of the second rotor and the cavity of the second cylinder body correspondingly. The first rotor and the second rotor are installed on a first eccentric part and a second eccentric part of the same crankshaft in a sleeving mode correspondingly so that the working cavities can be increased or decreased and the inlets can communicate with the outlets. The first rotor is in clearance fit with the crankshaft, and the second rotor is in clearance fit with the crankshaft. Fixed gears are fixed to the first cylinder body and the second cylinder body. Teeth or gear rings matched with the fixed gears are arranged in the middle of the first rotor and the middle of the second rotor. The double-cylinder eccentric rotary pump is high in efficiency, user-friendly, convenient to transport, easy to maintain and capable of achieving real-time monitoring and stepless speed adjusting.

Owner:SHANDONG UNIV

Slide valve type hydraulic valve with differential motion function

ActiveCN102889257BDifferential function realizationLow costServomotor componentsFailure rateEngineering

The invention provides a slide value type hydraulic valve with a differential motion function. The slide value type hydraulic valve comprises a valve body and a valve element which is arranged in a valve body hole; a first undercutting groove, a second undercutting groove, an oil inlet undercutting groove, a third undercutting groove and a fourth undercutting groove are arranged in the valve body hole in sequence, wherein the first undercutting groove and the fourth undercutting groove are communicated with an oil return opening, the second undercutting groove and the third undercutting groove are communicated with a working oil port respectively, and an oil inlet undercutting groove is communicated with an oil inlet; the valve element comprises a left circular bead, a left shaft neck, a middle circular bead, a right shaft neck and a right circular bead from left to right; a circular groove, a first valve port and a second valve port are arranged on the excircle of the left part of the middle circular bead, wherein the first valve port and the second valve port are not communicated with each other; a third valve port and a fourth valve port which are communicated with the right shaft neck are arranged on the excircle of the right part of the middle circular bead and the excircle of the left part of the right circular bead respectively. The slide value type hydraulic valve realizes differential motion function through improving the structure of a main valve element of the hydraulic valve, the integral structure is changed little, so as to reduce the product cost and failure rate of the product; the differential motion function is realized, and stepless control of flow can be realized at the same time.

Owner:SANY HEAVY IND CO LTD (CN)

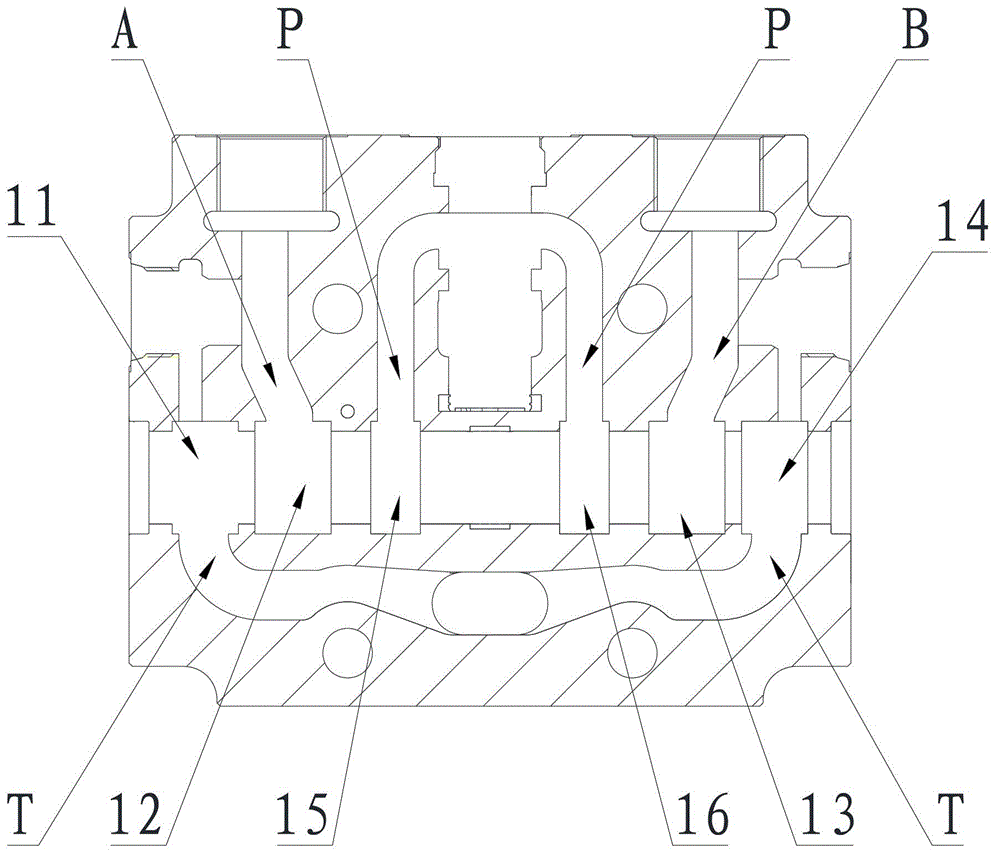

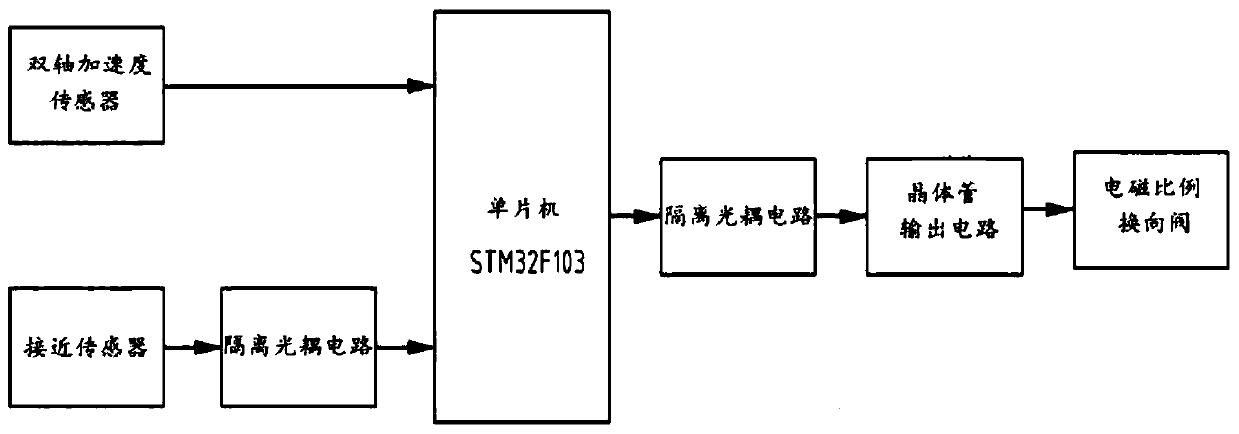

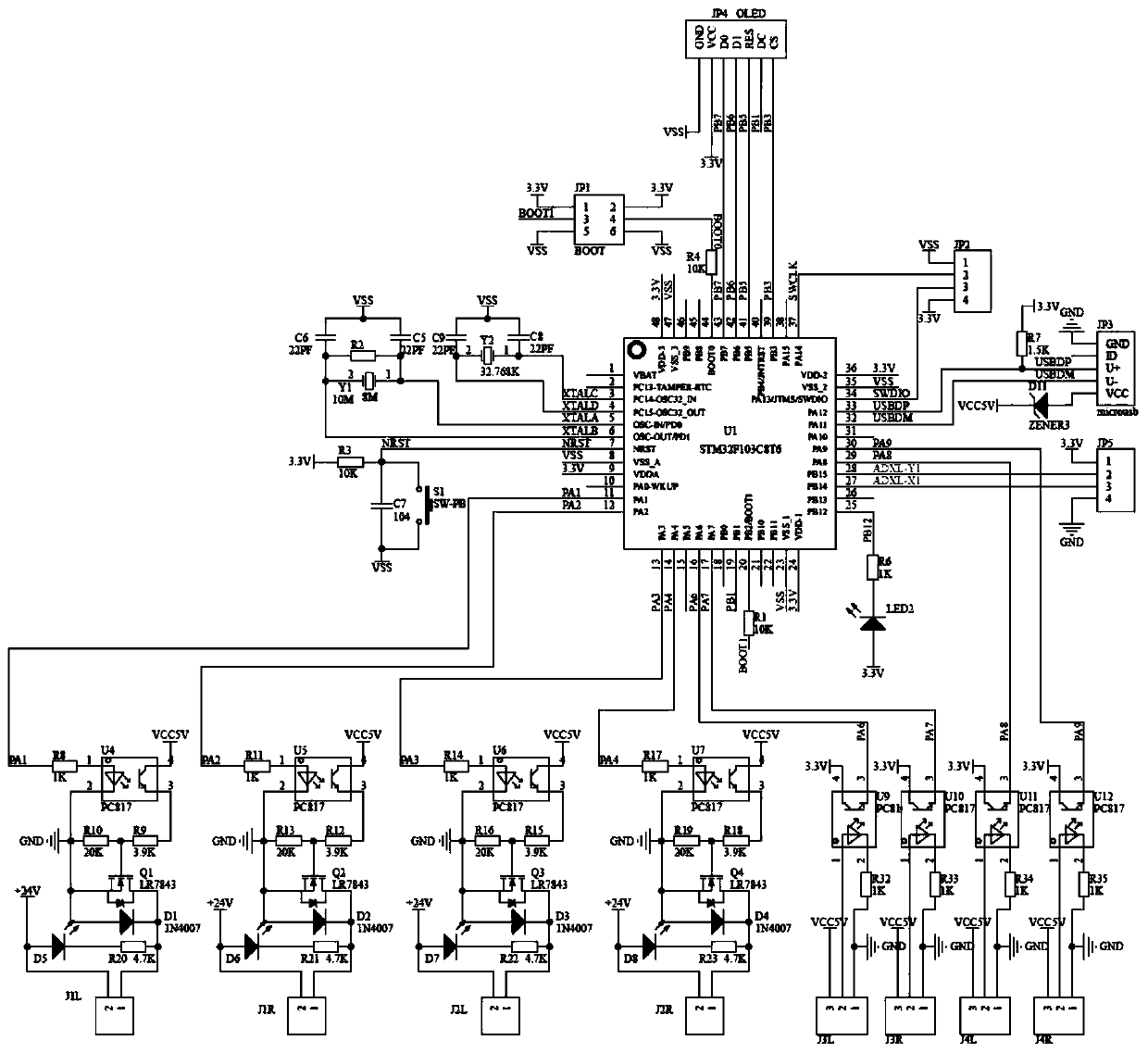

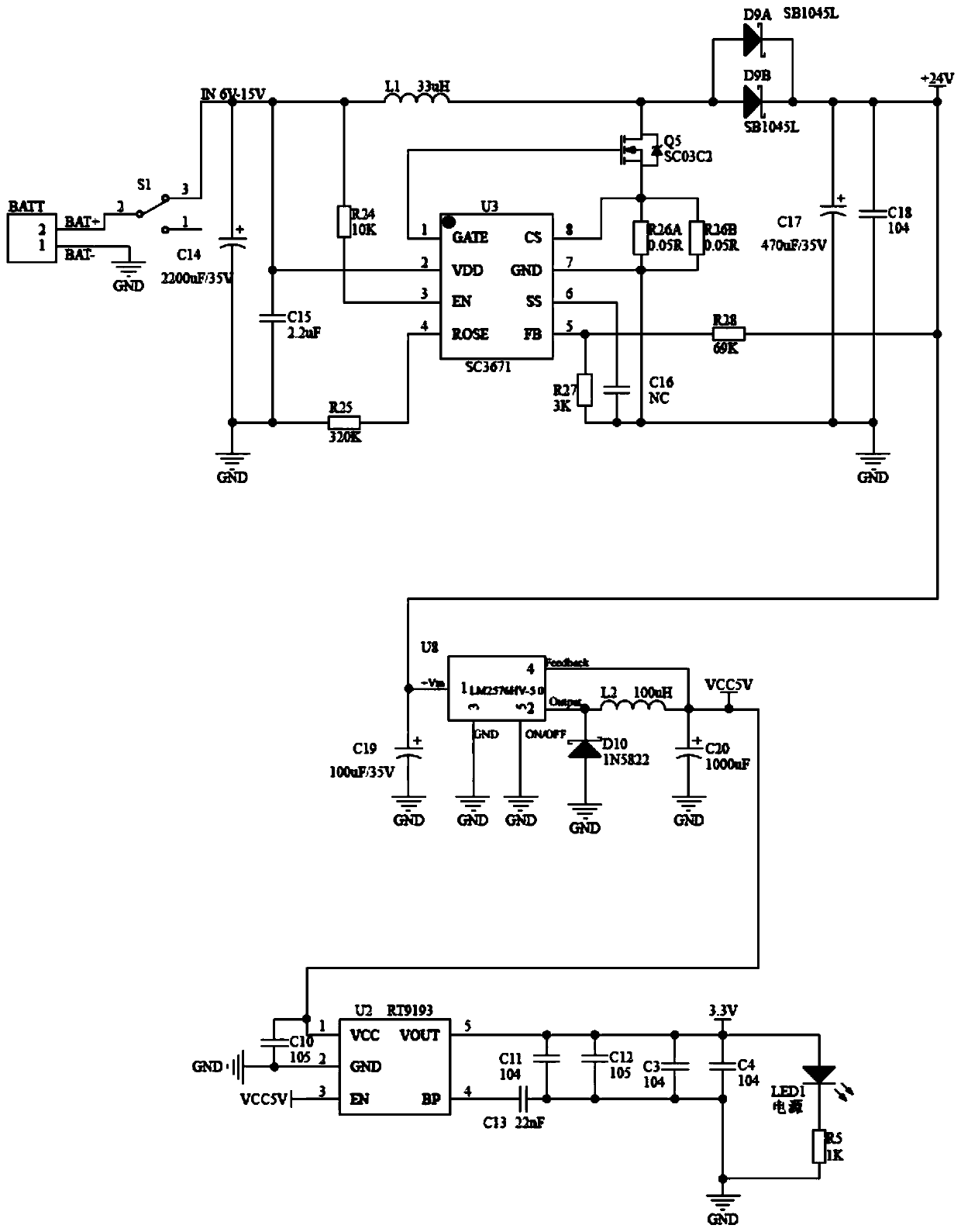

Automatic leveling control system for carrying platform of tracked carrier

PendingCN110908390AReduce mistakesReduce safety incidentsAttitude controlTotal factory controlSystems engineeringControl system

Owner:CHANGAN UNIV

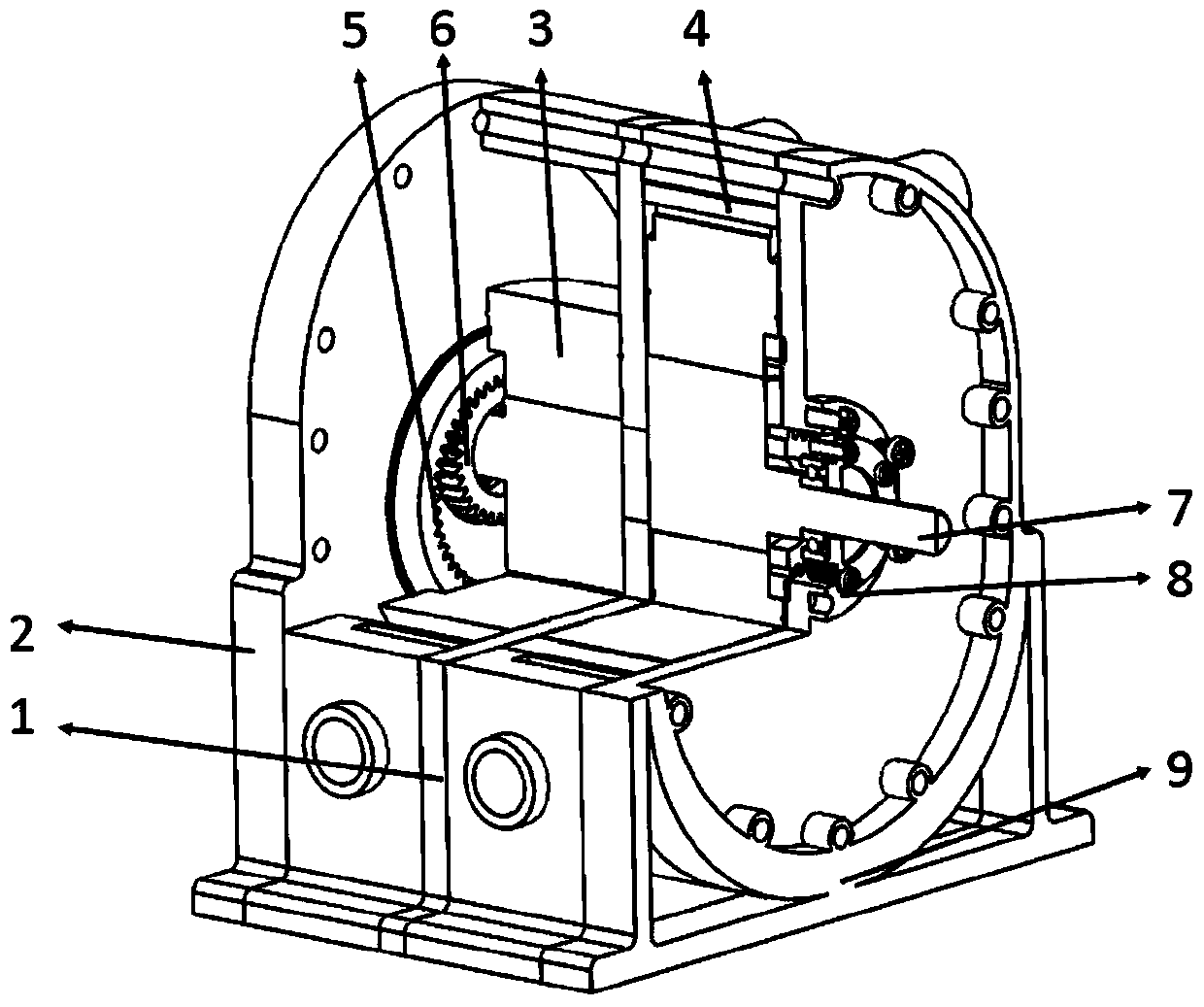

Permanent magnet retarder

ActiveCN104617743BRealize stepless controlImprove job stabilityPermanent-magnet clutches/brakesBrake torqueDrive shaft

Owner:JIANGSU UNIV OF TECH

Magnetorheological Pressure Control Valve

ActiveCN105715802BImprove cooling effectReduce the number of turnsOperating means/releasing devices for valvesSpringsMagnetorheological fluidCooling effect

The invention relates to a magnetorheological pressure control valve. The control valve includes a valve cover, a coil assembly 2, an upper valve body, a lower valve body, a lower valve core, the first and second rubber sealing rings, a working chamber, an upper valve, a return spring, an adjusting nut, and the valve cover is fixed to the lower valve body. Connected to the upper and outer sides of the lower valve body; the upper valve body and the adjustment nut are connected to the inner side of the upper valve body, and a return spring in a compressed state is provided under the adjustment nut, and the lower part of the return spring is pressed above the upper valve core, and the upper valve core is set on the Inside the upper valve body; the lower part of the upper valve core presses the upper end of the disc above the lower valve core, the lower valve core is set in the lower valve body, and the lower part of the lower valve core presses on the upper side of the oil inlet of the lower valve body; the upper valve body and A working chamber is formed between the lower valve bodies, the coil assembly is arranged in the groove of the upper valve body, and the upper side of the coil assembly is in contact with the inner side of the valve cover. In the present invention, the coil assembly is arranged on the upper side of the working chamber, away from the magneto-rheological fluid, so that the influence of the heating of the electromagnetic coil on the magnetorheological fluid is smaller, and the heat dissipation effect of the magnetorheological fluid is better.

Owner:浙江孔辉汽车科技有限公司

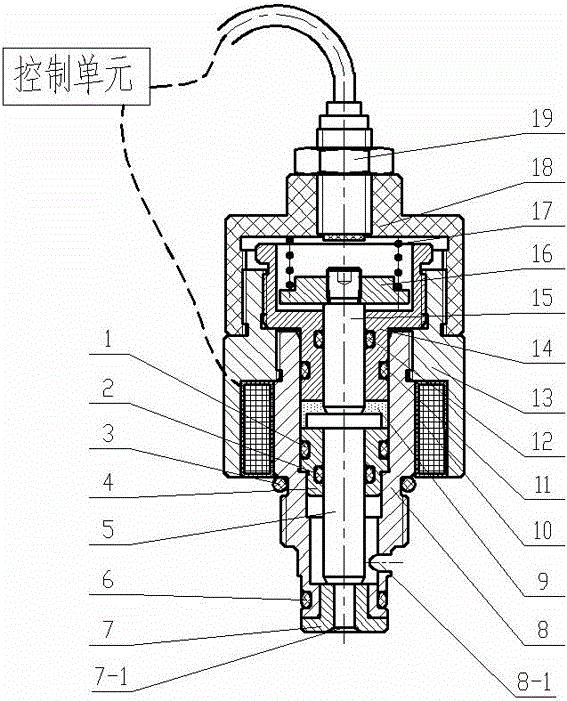

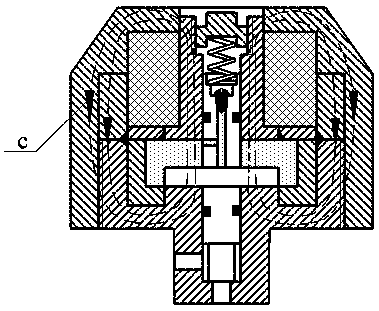

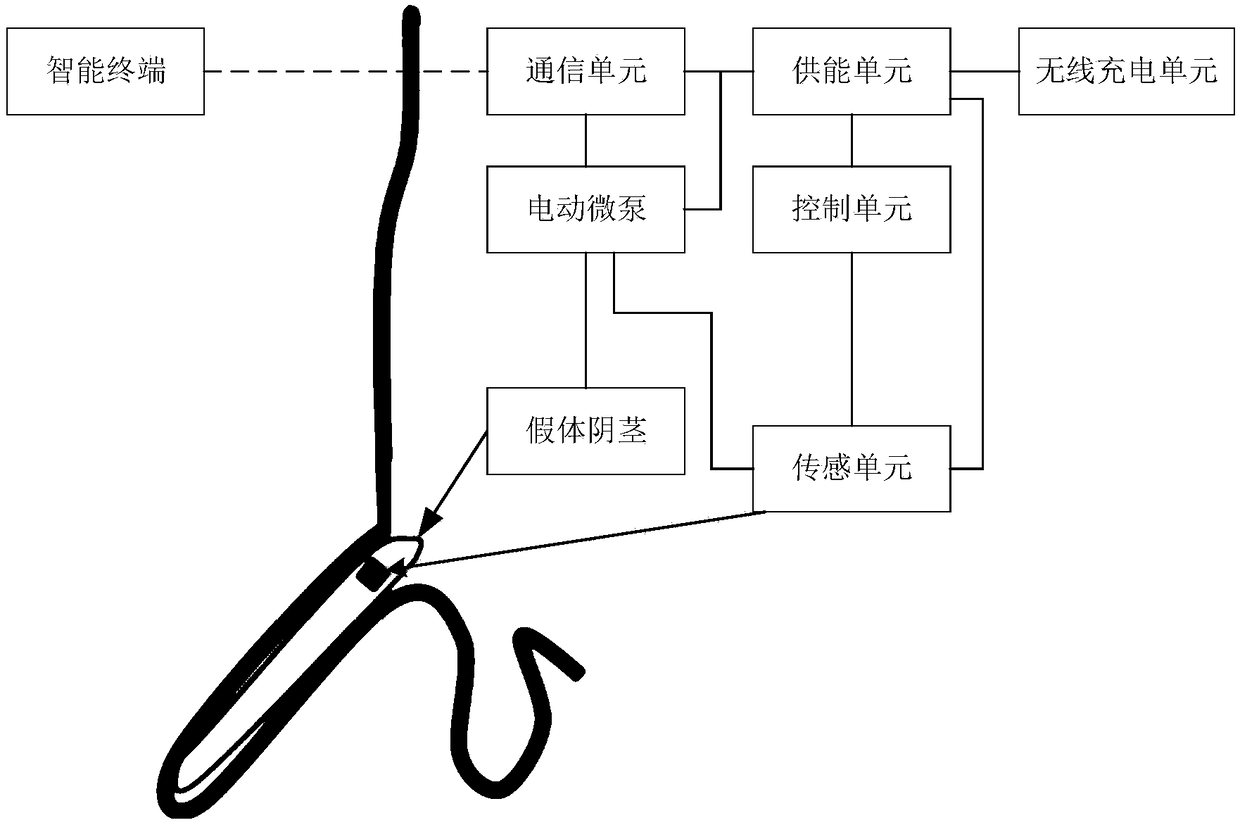

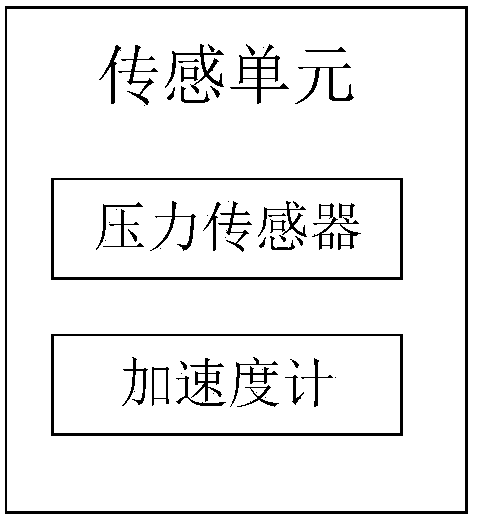

A prosthetic penis controlled using an electric micropump

ActiveCN106038031BErection achievedRealize weakPenis support devicesNon-surgical orthopedic devicesCommunication unitPenile Tumescence

The invention discloses a prosthetic penis controlled by a micro electric pump. The prosthetic penis comprises a penis prosthesis which can be implanted in a penis, a communication unit, a control unit and a sensing unit, wherein the penis prosthesis comprises a penis prosthesis main body, a liquid storage bag and the micro electric pump; the communication unit and the sensing unit are connected to the control unit; the control unit is connected to the micro electric pump; the micro electric pump and the liquid storage bag are communicated; the communication unit is used for receiving an erection order which is distributed by an intelligent terminal; the control unit is used for controlling the micro electric pump to press liquid in the liquid storage bag into the penis prosthesis main body, so that erection of the penis prosthesis is achieved; the sensing unit is used for detecting an ejaculation process of the penis prosthesis; and after the control unit detects the ejaculation process by virtue of the sensing unit, the control unit is additionally used for controlling the micro electric pump to pump the liquid in the penis prosthesis main body back into the liquid storage bag, so that the penis prosthesis becomes soft.

Owner:TONGJI HOSPITAL ATTACHED TO TONGJI MEDICAL COLLEGE HUAZHONG SCI TECH

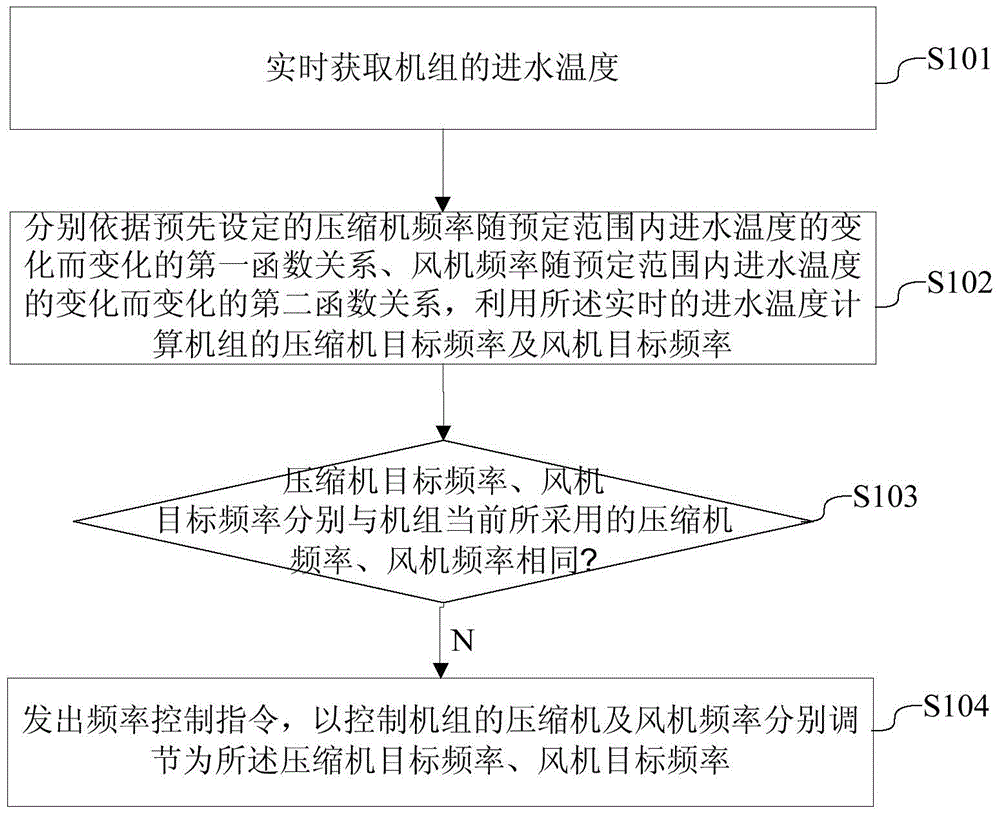

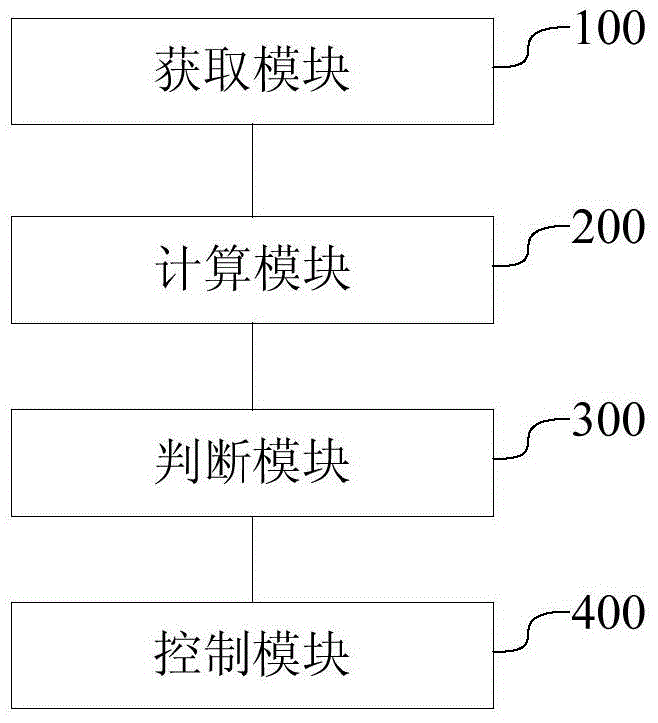

A frequency control method and system

ActiveCN104329777BImprove stabilityImprove reliabilityMechanical apparatusSpace heating and ventilation safety systemsEngineeringWater temperature

The invention discloses a frequency control method and system. The method comprises the following steps: acquiring the water inlet temperature of a unit in real time, and calculating the compressor target frequency and the fan target frequency of the unit based on a preset function relation among the compressor frequency, the fan frequency and the water inlet temperature respectively; subsequently performing corresponding adjustment on the compressor frequency and the fan frequency according to the calculated target frequency values. Through preset research and setting of the function relation between the frequency of the unit and the water inlet temperature, reasonable matching of the frequency adjustment of the unit and the change of the water inlet temperature is realized, the unit can always correspond to an appropriate frequency value at different water inlet temperatures, the problem of great frequency difference in case of cross-regional change of the water inlet temperature and the problem that the frequency does not change along with the change of the water inlet temperature in case of non-cross-regional change in the conventional sectional control way are solved, reasonable adjustment of the frequency of the unit is realized, optimal energy efficiency of the unit can be brought into full play in real time, and the running stability and reliability of the unit are enhanced.

Owner:GREE ELECTRIC APPLIANCES INC

Discharging valve

InactiveCN111810656ARealize stepless controlGuarantee continuous and stable operationOperating means/releasing devices for valvesLift valveEngineeringStructural engineering

The invention discloses a discharging valve. The discharging valve comprises a valve body; two adjusting assemblies which are diagonally arranged are arranged on the valve body, each adjusting assembly comprises a valve plate, a first hinge support, a second hinge support, an electric cylinder, a base and a third hinge support, the first hinge supports are fixed to the inner wall of the valve body, the valve plates are arranged in the valve body, the upper ends of the valve plates are rotationally arranged in the first hinge supports, the second hinge supports are fixed to the outer sides of the lower ends of the valve plates, the bases are arranged outside the valve body, the third hinge supports are fixed to the upper sides of the bases, the electric cylinders are arranged on the side face of the valve body in a penetrating mode, the telescopic ends of the electric cylinders are rotationally connected into the second hinge supports, and the fixed ends of the electric cylinders are rotationally connected into the third hinge supports. According to the discharging valve, stepless control over the opening degree of the valve is achieved, the material flow can be adjusted in real time according to needs, the opening degree of the valve can be adjusted according to the discharging amount of follow-up equipment such as a vertical mill or a roller press so as to adjust the discharging amount, continuous and stable operation of the whole preparation process is guaranteed, and then the production efficiency is improved.

Owner:NANJING KISEN INT ENG

Magnetorheological Flow Control Valve

ActiveCN103148257BEasy to controlQuick response to yield strength changeOperating means/releasing devices for valvesMagnetorheological fluidEngineering

The invention relates to a flow control valve, in particular to a magnetorheological flow control valve which realizes flow control through the opening degree of the control valve. The flow control valve comprises a jump ring, an upper end cover, an upper valve body, a lower valve body, a coil, a lower thrust spring, a valve core, a thrust shaft, an inner valve body, a working cavity, a magnetic isolation sleeve, a spring seat, an upper thrust spring, a seal bolt and a plurality of rubber seal rings; and according to the magnetorheological flow control valve, the shifting position of the valve core is controlled through a technical method in which the magnetic field intensity which acts on magnetorheological fluid in the working cavity formed between the magnetic isolation sleeve and the upper valve body is controlled, so that the magnetorheological fluid yield strength is affected and the action force of magnetorheological fluid to the thrust shaft is controlled, so that different circulation areas are obtained and the the control over the fluid flow is realized.

Owner:JILIN UNIV

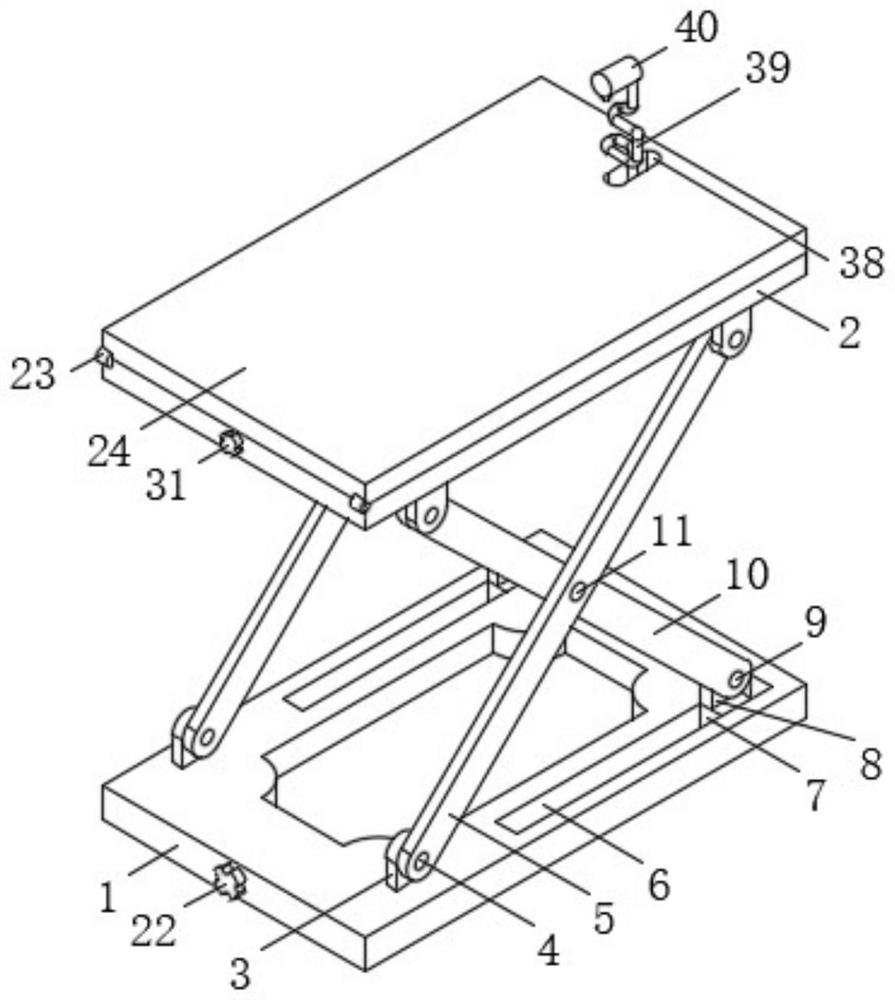

Portable hand drawing supporting device based on artistic design

InactiveCN112754150AExpand your knowledgeImprove learning efficiencyProjectorsFoldable tablesEngineeringSchool supplies

The invention discloses a portable hand drawing supporting device based on artistic design, and belongs to the technical field of school supplies, the portable hand drawing supporting device comprises a first supporting seat, a second supporting seat is arranged above the first supporting seat, and first sliding connecting grooves are formed in the opposite surfaces of the second supporting seat and the first supporting seat. According to the invention, through mutual cooperation of the designed structures such as a first threaded rod, a first threaded cylinder, a projector storage groove, a goose-shaped pipe, a projector, a torsion spring, a reducing sleeve and an elastic clamping piece, in the using process, a hand drawing student can project some line drawing methods on a drawing through the projector; the knowledge field of hand-painted students is expanded, learning and working efficiency is improved, entertainment is increased, the hand-painted students can adjust the inclination and height of the supporting panel suitable for themselves according to needs to conduct more healthy and comfortable learning work, clamping and fixing of a template sample can be achieved through opening and closing actions of the elastic clamping pieces, and the stability of the template sample is ensured.

Owner:杭州佑觞贸易有限公司

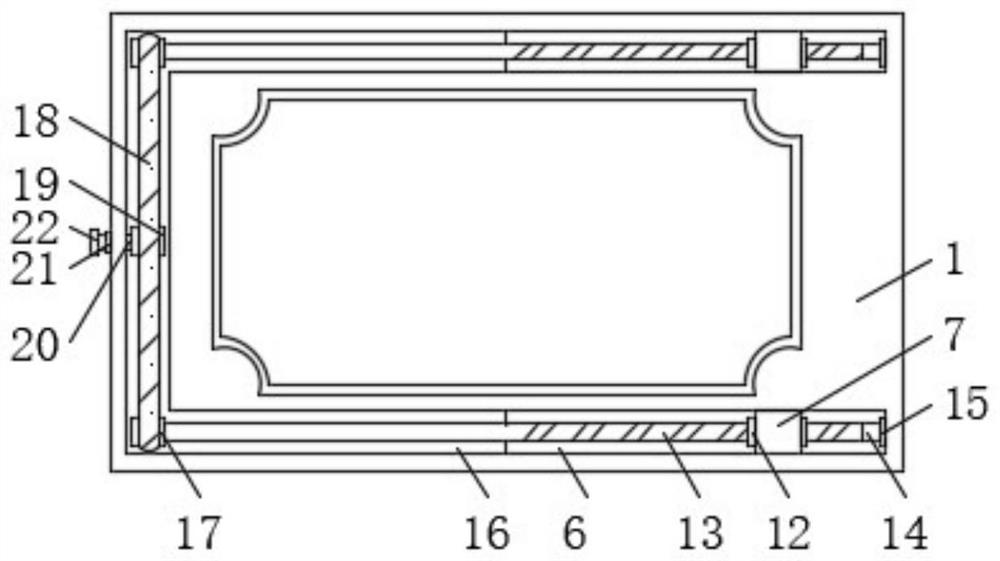

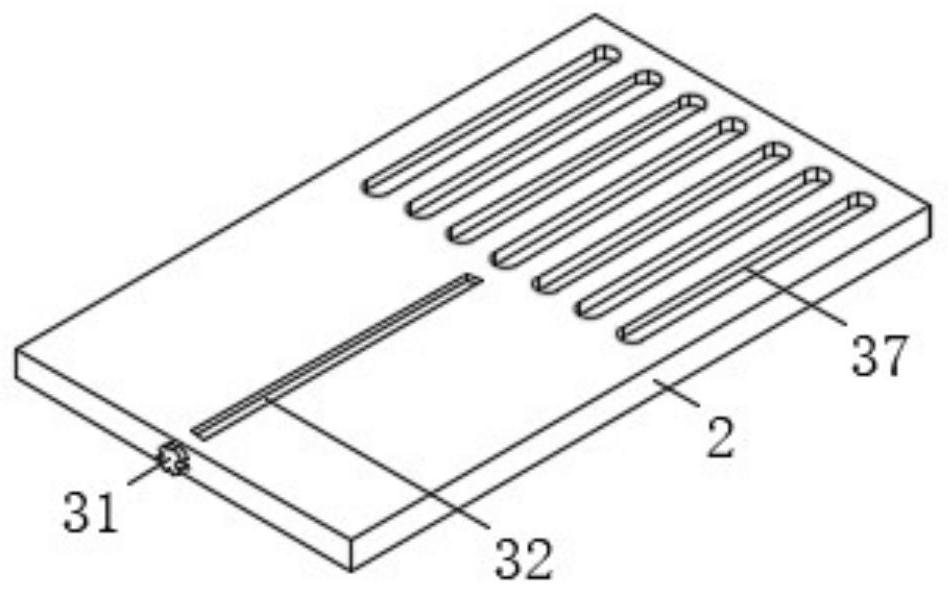

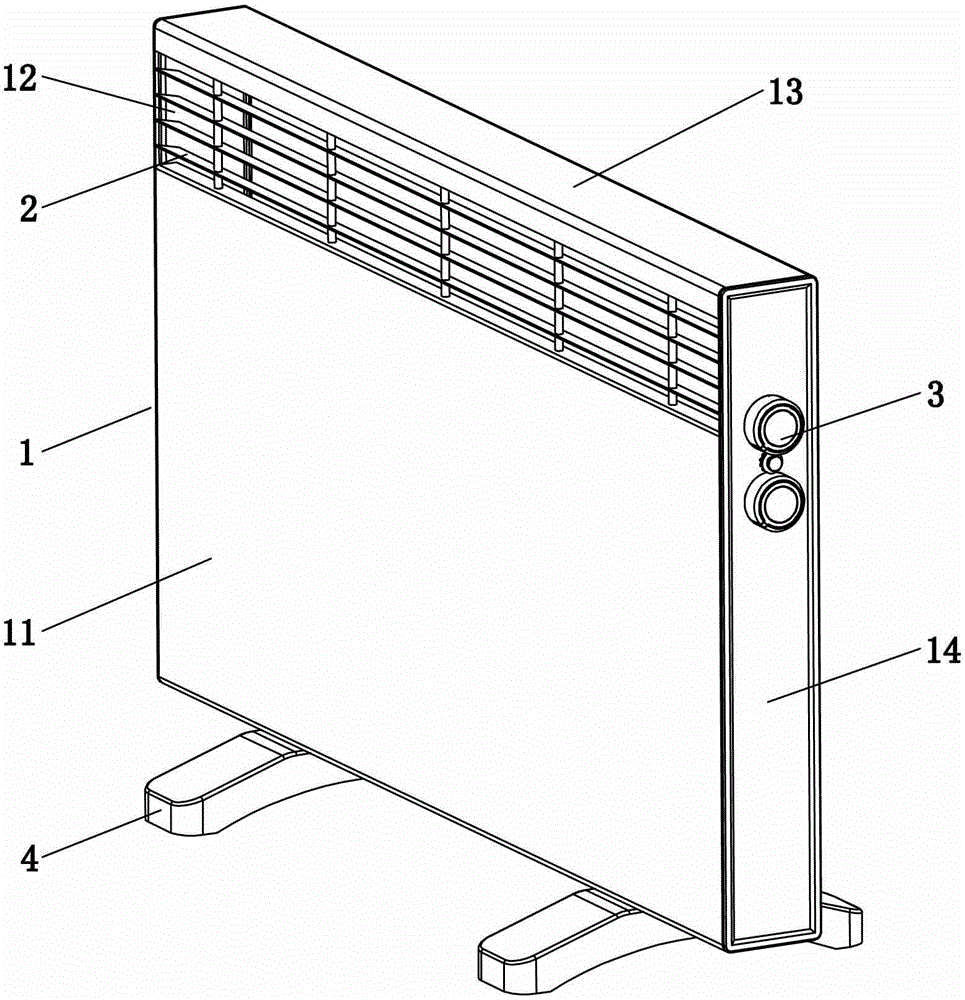

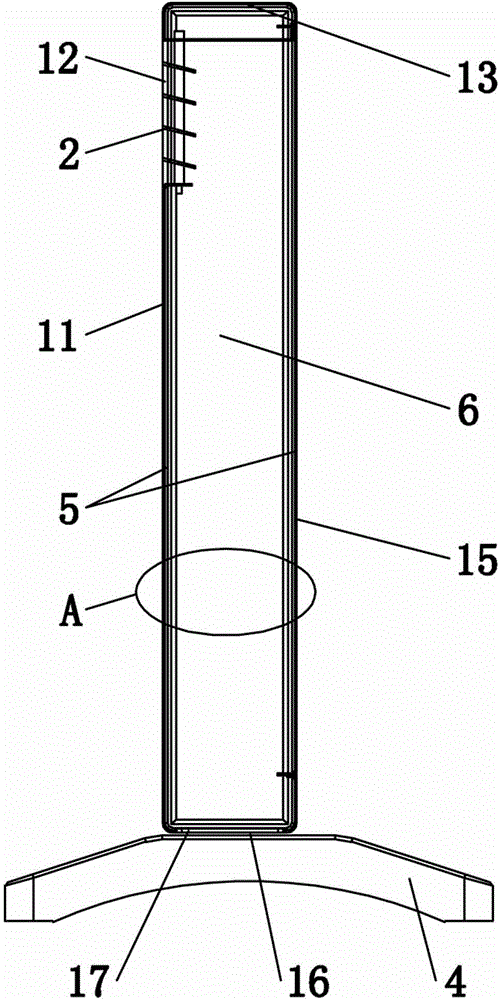

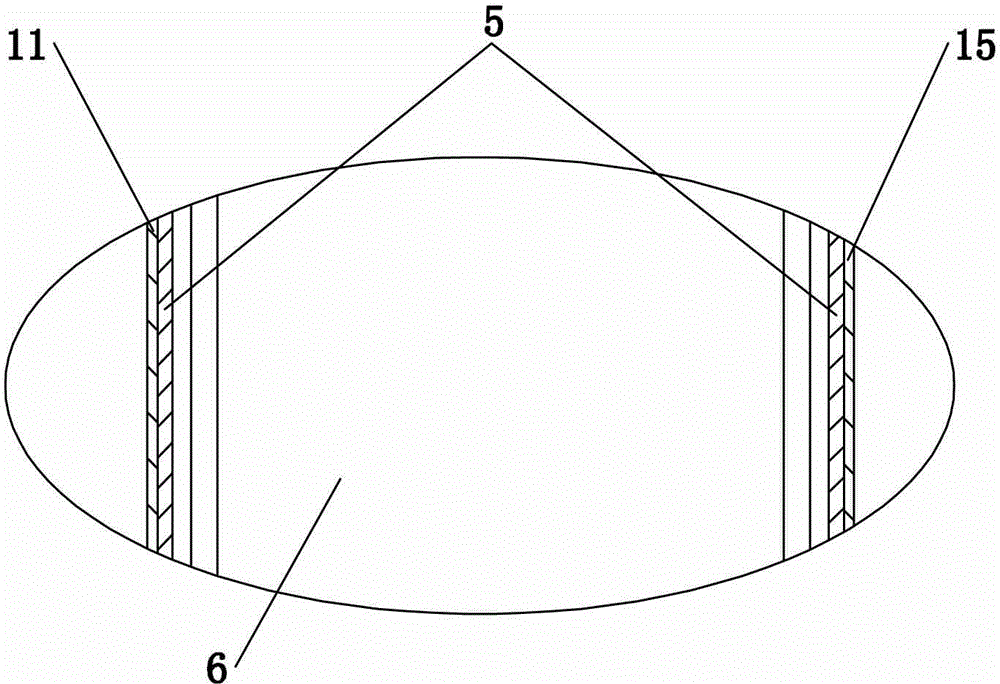

Ultra-fast and ultra-thin balanced type electric heating machine

InactiveCN104697030AReduce volumePhysically fastLighting and heating apparatusCentral heating systemCombined useWorking temperature

The invention relates to an ultra-fast and ultra-thin balanced type electric heating machine. The ultra-fast and ultra-thin balanced type electric heating machine comprises a casing, a main heating body and an electrical control system assembly, wherein a convection channel is formed in the casing; an air inlet and an air outlet are formed in an upper end and a lower end, corresponding to the convection channel, of the casing respectively; the main heating body is a film covered heating body which is arranged on the inner side of the convection channel and electrically connected with the electrical control system assembly. According to the ultra-fast and ultra-thin balanced type electric heating machine, the temperature increase speed is high, the increased temperature is stable, heating power in each position of the film covered heating body is uniform and consistent, the heating machine is not influenced by various outside environments, and natural type up-and-down convection heat dissipation is combined, so that the fast heat transfer effect is achieved; further, the ultra-fast and ultra-thin balanced type electric heating machine is stable in structure and reliable, and unnecessary mounting cost and additional material cost are saved by means of the film covered heating body; compared with the prior art, the ultra-fast and ultra-thin balanced type electric heating machine has the advantages of simple structure, convenience in use, high working temperature increase speed, simplification in mounting, cost reduction and the like.

Owner:FUJIAN ALLEN ELECTRONICS

DC fan motor control circuit and its control method

ActiveCN106253769BRealize stepless controlField or armature current controlMotor controlControl circuit

The invention discloses a DC fan motor control circuit and a control method of using the same. The control circuit comprises a temperature detection module, a master control unit and a voltage control module, wherein the temperature detection module is used for detecting a temperature related to a working speed of a DC fan motor and forming a temperature signal; the master control unit is connected with the temperature detection module and is used for receiving a temperature signal output by the temperature detection module and outputting a pulse width modulation signal with a corresponding duty ratio according to the temperature signal; and the voltage control module is electrically connected with the DC fan motor and is used for controlling the voltage of the DC fan motor according to the duty ratio of the pulse width modulation signal. The pulse width modulation signal is introduced and the duty ratio of the pulse width modulation signal is controlled to change according to a temperature change, so that high-accuracy adjustment is carried out on the rotating speed of the DC fan motor through the pulse width modulation signal.

Owner:GREE ELECTRIC APPLIANCES INC

A control method for steplessly adjusting the operation of high-power water pumps or fans

ActiveCN106979148BRealize stepless controlMeet the requirements of full load operationPump controlPositive-displacement liquid enginesFrequency changerImpeller

The invention discloses a control method for steplessly adjusting operation of a high power water pump or a fan. A controller controls a frequency converter, and the frequency converter controls a motor; and controlled working modes are manually or automatically switched according to values of the power of the motor and the power of the frequency converter. According to the control method disclosed by the invention, the frequency converter with the capacity which is 1 / 2 of the capacity of the motor is adopted to control the motor of the pump or the fan to be started, so as to realize stepless control over the rated flow of about 0 to 80 percent, and the full-load operation requirement under a special condition is met. The low capacity frequency converter controls the high power motor, thus reducing the surplus of use of the frequency converter, saving energy and decreasing the equipment investment; impact on a power grid is reduced; meanwhile, the impact influence on a water pump impeller, a pump shaft and a bearing can be reduced to the maximum extent, the service lives of equipment and valves are prolonged, and the maintenance cost of equipment pipes is saved; by stepless adjustment of the water amount and the air volume, production operation parameters can be precisely controlled, and the engineering requirement can be met; and multiple interfaces can be connected with a computer and a network to realize intelligent control.

Owner:CHINA COAL SPECIAL DRILLING ENG +1

Double-acting magneto-rheological pressure and flow control valve

ActiveCN103267159BControl flowEasy to controlOperating means/releasing devices for valvesEngineeringMagneto rheological

The invention discloses a double-acting magneto-rheological pressure and flow control valve which comprises an upper end cover and a lower end cover. The upper end cover and the lower end cover are arranged in a longitudinal symmetry manner, and a thrust shaft is slidably connected into a cavity formed between the upper end cover and the lower end cover; two cavities are formed in rooms among two ends of the thrust shaft, the upper end cover and the lower end cover, and an upper flow control cavity and a lower flow control cavity are respectively mounted in the two cavities; the upper end cover is fixed to the lower end cover by a piston, an upper auxiliary damping hole and a lower auxiliary damping hole are respectively machined on the upper end cover and the lower end cover, and an auxiliary channel which is communicated with the damping holes is arranged in an inner ring of the piston; and the opening of the auxiliary channel is determined by the sliding stroke of the thrust shaft. The double-acting magneto-rheological pressure and flow control valve has the advantages of high response speed and extremely wide bearing pressure range owing to fast yield strength variation response and wide range of magneto-rheological fluid. Besides, the double-acting magneto-rheological pressure and flow control valve is simple and compact in structure, convenient to manufacture and high in portability, and can be connected into an electronic control unit, so that a bidirectional flow can be intelligently and steplessly controlled.

Owner:JILIN UNIV

Steering stability control method for four-wheel drive electric vehicle

ActiveCN110254420BEliminate deviations in motion stateImprove stabilityElectrodynamic brake systemsStabilization controlEnergy recovery

The invention discloses a four-wheel drive electric automobile steering stability control method. When a vehicle is judged to be turned, the yaw moment offset is calculated; and when it is judged that the steering is insufficient, inner-side front wheels and rear wheels inside are controlled to perform braking energy recovery to generate a yaw moment; if the braking yaw moment is larger than or equal to the yaw moment offset, the inner-side front wheels are controlled to perform braking energy recovery, and when the maximum charging condition of the inner-side front wheel energy is reached, the inner-side rear wheels are controlled to perform braking energy recovery until the yaw moment offset is eliminated; and if the braking yaw moment is smaller than the yaw moment offset, the inner-side front and rear wheel brake energy is controlled to recover and increase the outer side front, the rear wheels drive the torque, and the target slip rate is used as a control object to coordinate the output of the torque, and the deflection amount of the yaw moment is eliminated; and when it is judged that the steering is over, the front wheels and the rear wheels outside are controlled to perform braking energy recovery, and the control strategy and the steering insufficiency are the same. Torque control can be performed on each wheel, and stability and robustness of control are improved.

Owner:清华大学苏州汽车研究院(吴江)

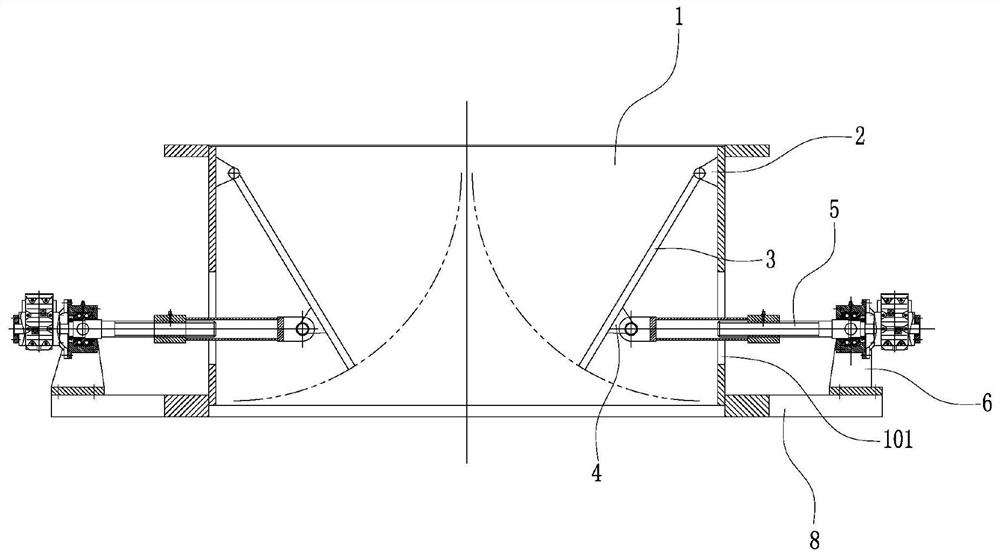

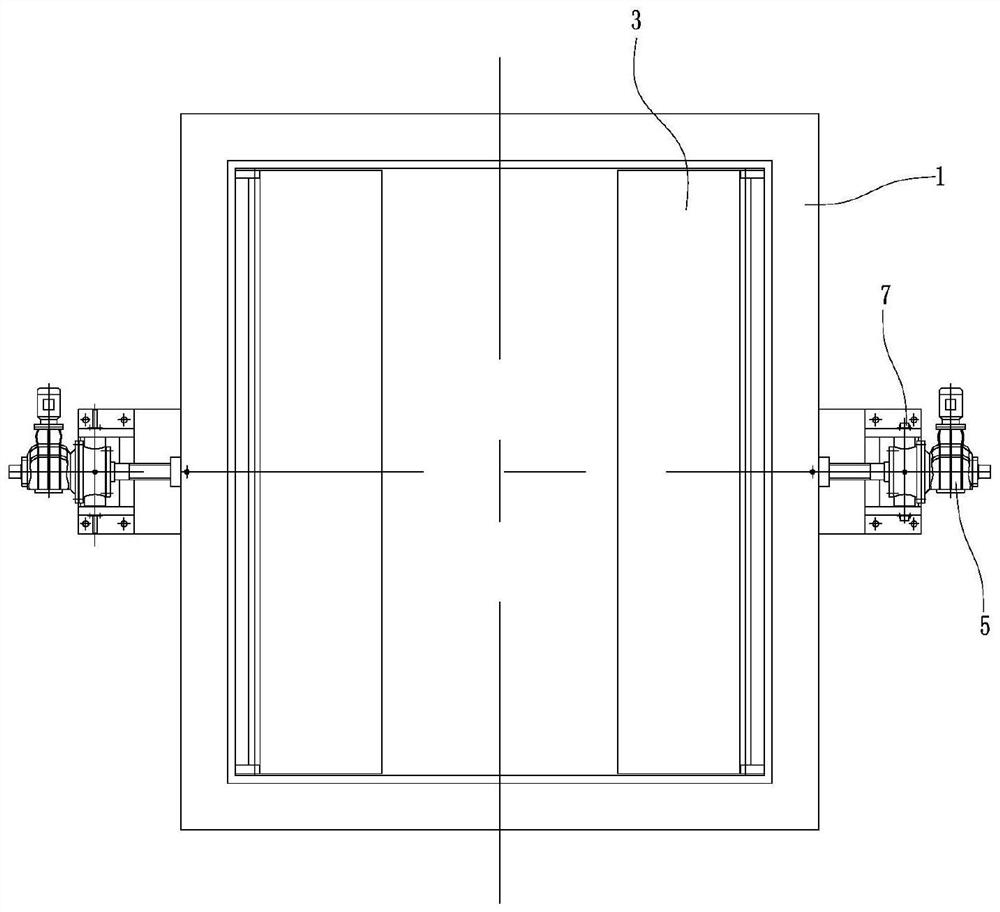

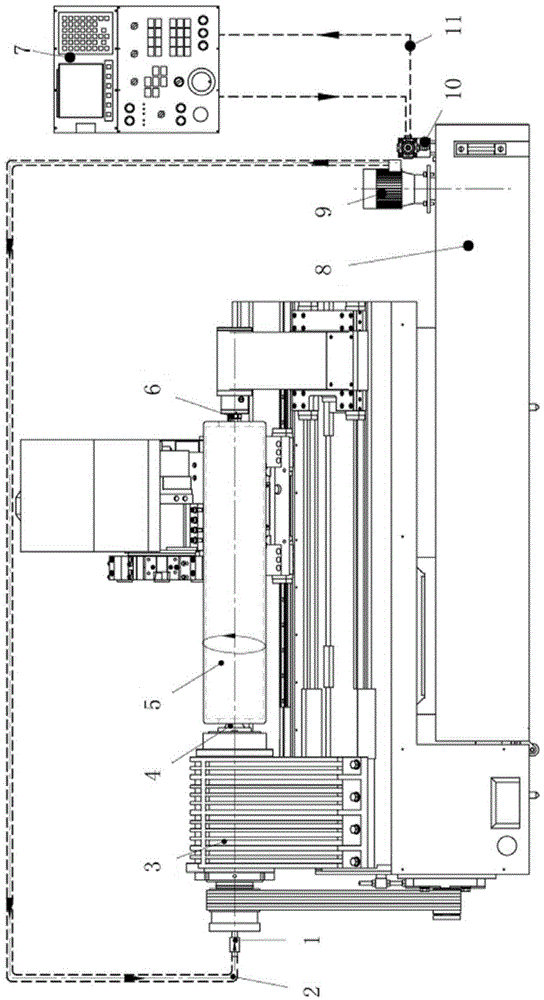

Vibration preventing device for plate roller outer circle machining

InactiveCN106694908AGuaranteed stabilityImprove shock absorptionTurning machinesMaintainance and safety accessoriesControl signalWater storage tank

The invention relates to a vibration preventing device for plate roller outer circle machining. The vibration preventing device is connected with a plate roller arranged on a main machine and used for vibration reducing in the plate roller machining process. The vibration preventing device comprises a water storage tank, an automatic water feeding circulation pump, a proportional flow controller, a vibration sensor and an upper computer. One end of the automatic water feeding circulation pump is connected with the water storage tank, and the other end of the automatic water feeding circulation pump is connected with the plate roller on the main machine through a pipeline. The vibration sensor, the upper computer, the proportional flow controller and the automatic water feeding circulation pump are sequentially connected, and the vibration sensor is arranged on the main machine. The upper computer calculates the water amount for vibration reducing according to plate roller parameters and sends control signals to the proportional flow controller, the proportional flow controller controls the automatic water feeding circulation pump to start to inject water into the plate roller, the vibration sensor feeds real-time vibration signals back to the upper computer, and the upper computer conducts stepless control over the automatic water feeding circulation pump through the proportional flow controller according to the real-time vibration signals. Compared with the prior art, the vibration preventing device has the beneficial effects that the vibration reducing effect is good, and the product quality is improved.

Owner:SHANXI YUNCHENG PLATE MAKING GRP SHANGHAI ENTERPRISE DEV CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com