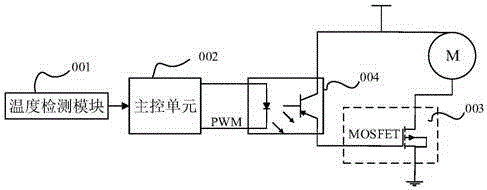

Direct current electric motor control method and device

A technology of DC motors, control methods, applied in directions such as excitation or armature current control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

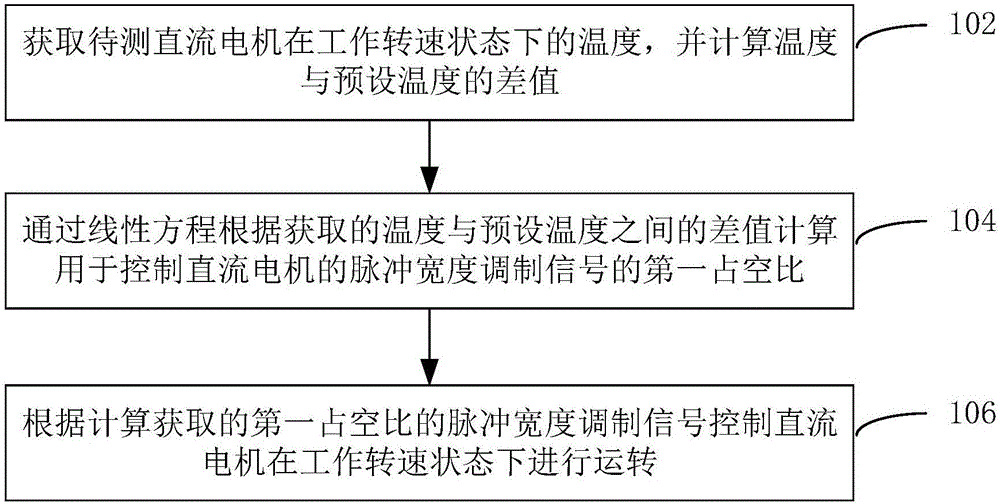

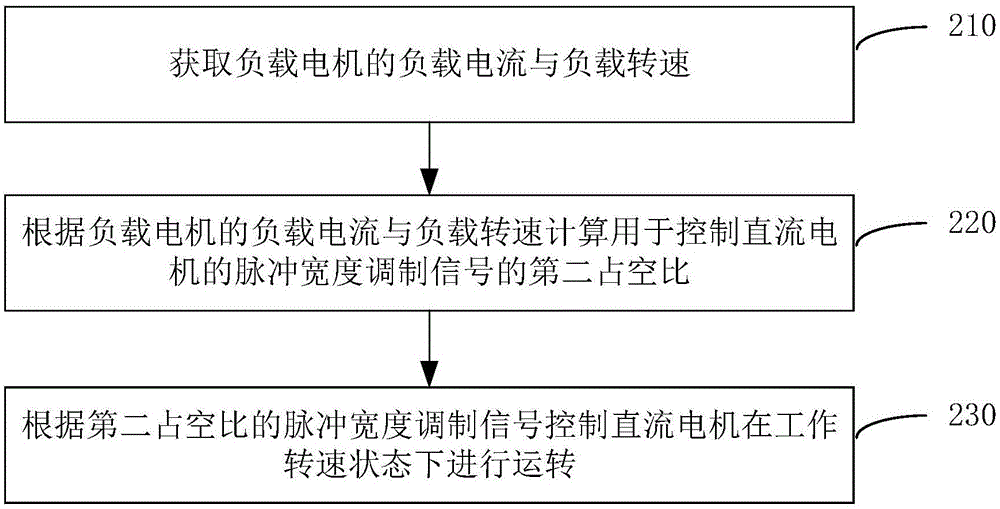

[0021] In order to make the purpose, technical solution and advantages of the present invention more clear, the method and device for controlling the DC motor of the present invention will be further described in detail below with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0022] In the prior art, common control modes of DC motors include power-on control mode, temperature switch control mode, and gear-based speed regulation control mode. Among them, power-on start is the simplest control method, that is, after starting the controller, a constant amplitude DC voltage is passed to the fan motor to make the motor run at a constant speed; for the temperature switch control method, it is Add a switch on the basis of the temperature control switch on and off, when the temperature is too low, the switch is off, the fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com