Vibration preventing device for plate roller outer circle machining

A technology of anti-vibration device and plate roller, which is applied in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., to achieve the effects of processing quality assurance, reducing labor intensity and improving processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. This embodiment is carried out on the premise of the technical solution of the present invention, and detailed implementation and specific operation process are given, but the protection scope of the present invention is not limited to the following embodiments.

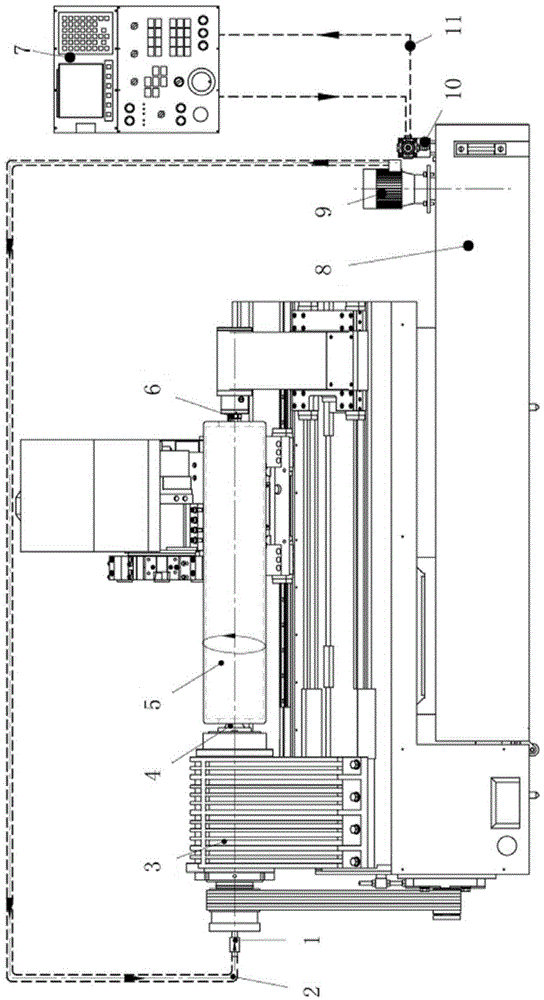

[0026] Such as figure 1 As shown, this embodiment provides an anti-vibration device for the processing of the outer circle of the plate roll, which is connected with the plate roll 5 installed on the host machine 3, and used for shock absorption during the process of the plate roll 5, including a water storage tank 8, automatic loading Water circulation pump 9, proportional flow controller 10, vibration sensor and host computer 7, one end of automatic water supply circulation pump 9 is connected to water storage tank 8, and the other end is connected to plate roller 5 on the main mach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com