Production method and production line for measuring size of pipe diameter of sucking pipes on line

A production method and technology of a production line, applied to the production method and production line field of online measurement of the pipe diameter of straws, can solve problems such as inability to meet on-site inspections, achieve improved production efficiency and product qualification rate, wide measurement range, and fast scanning speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

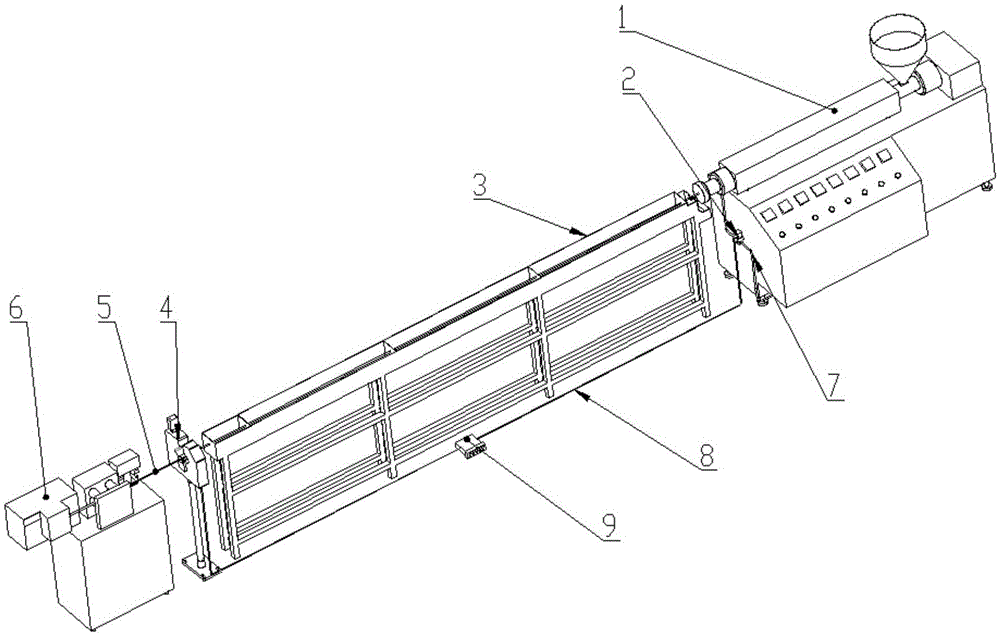

[0027] Example: see Figure 1~2 , the production method for measuring the diameter of the straw on-line provided by the present embodiment comprises the following steps:

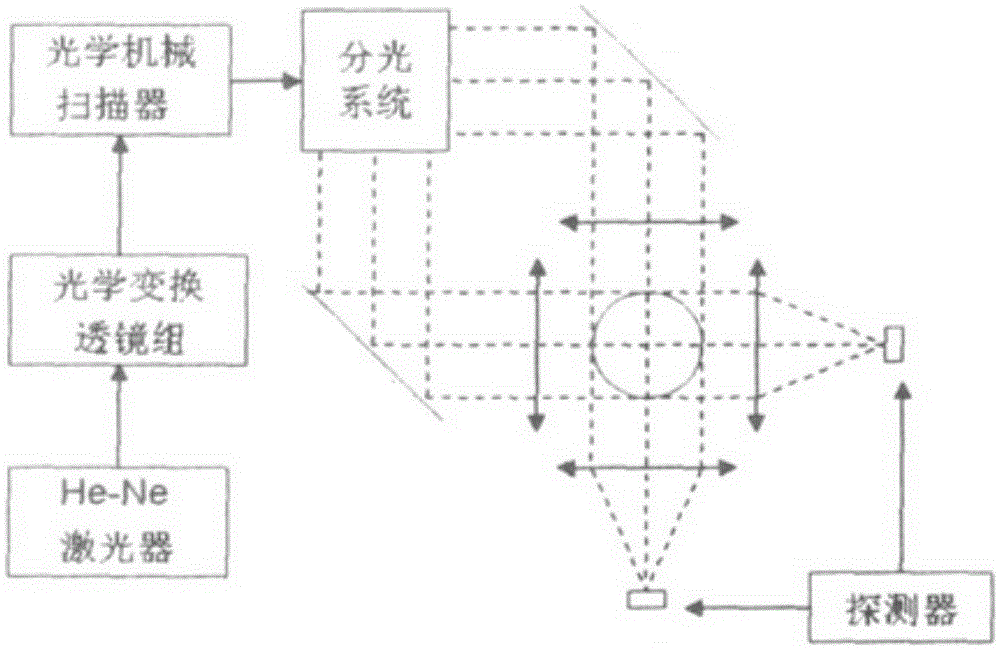

[0028] (1) An extruder 1, a cooling device 3, an electric proportional valve 2, a two-dimensional laser diameter measuring device 4, and a traction cutting machine 6 are respectively arranged, and the extruder 1, the cooling device 3, and the electric proportional valve 2 , two-dimensional laser diameter measuring device 4, and traction cutting machine 6 are arranged in sequence along the direction of the production line;

[0029] (2) A remote controller 9 is arranged between the two-dimensional laser caliper measuring device 4 and the electric proportional valve 2, for receiving the diameter value and the deviation value data output by the two-dimensional laser caliper measuring device 4, and the remote controller 9 receives the After the data is sampled and processed in real time, and the control signal i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com