Impeller type feeder

A feeder and impeller-type technology, applied in the field of impeller-type feeders, can solve problems such as system failures and material jams

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with accompanying drawing.

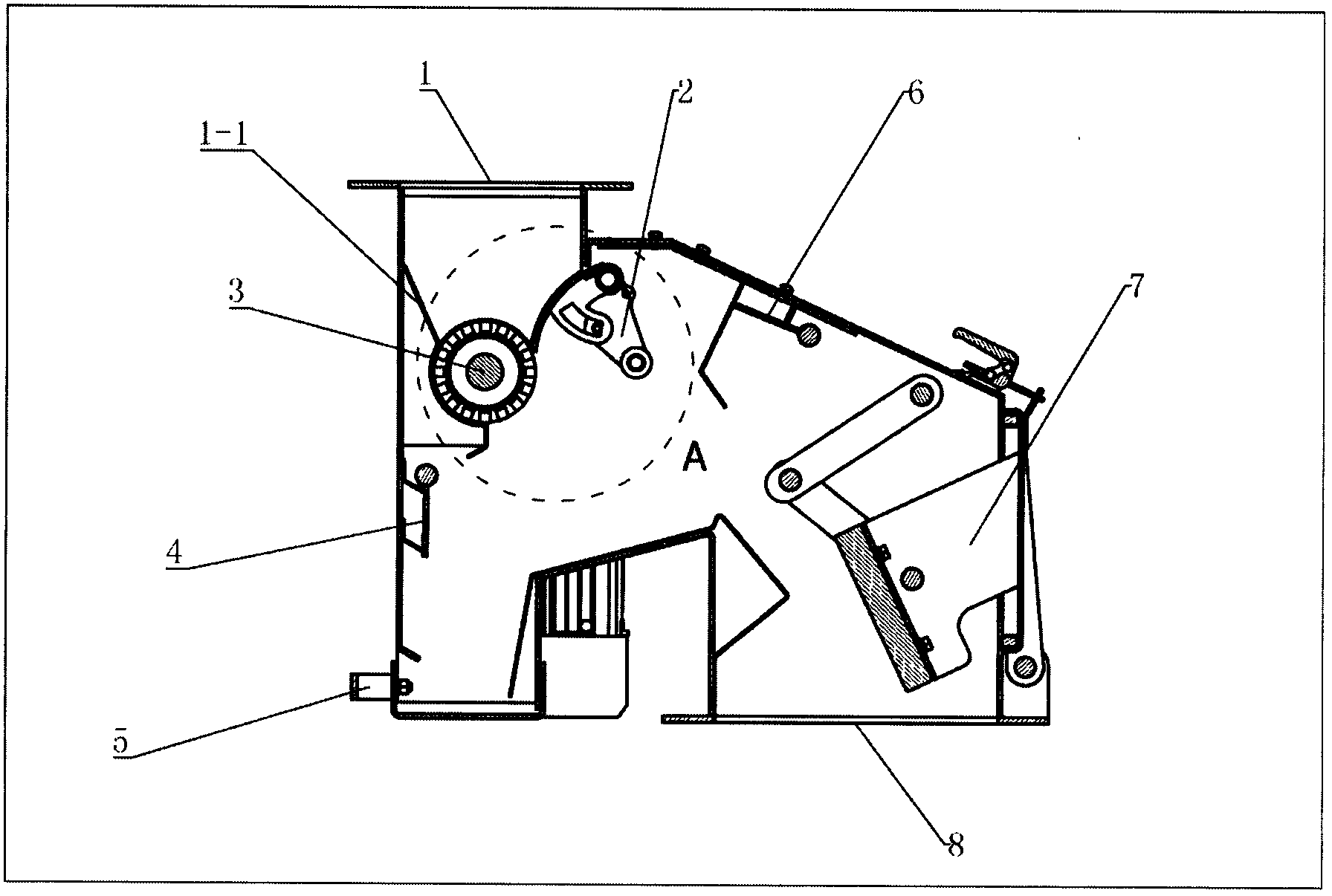

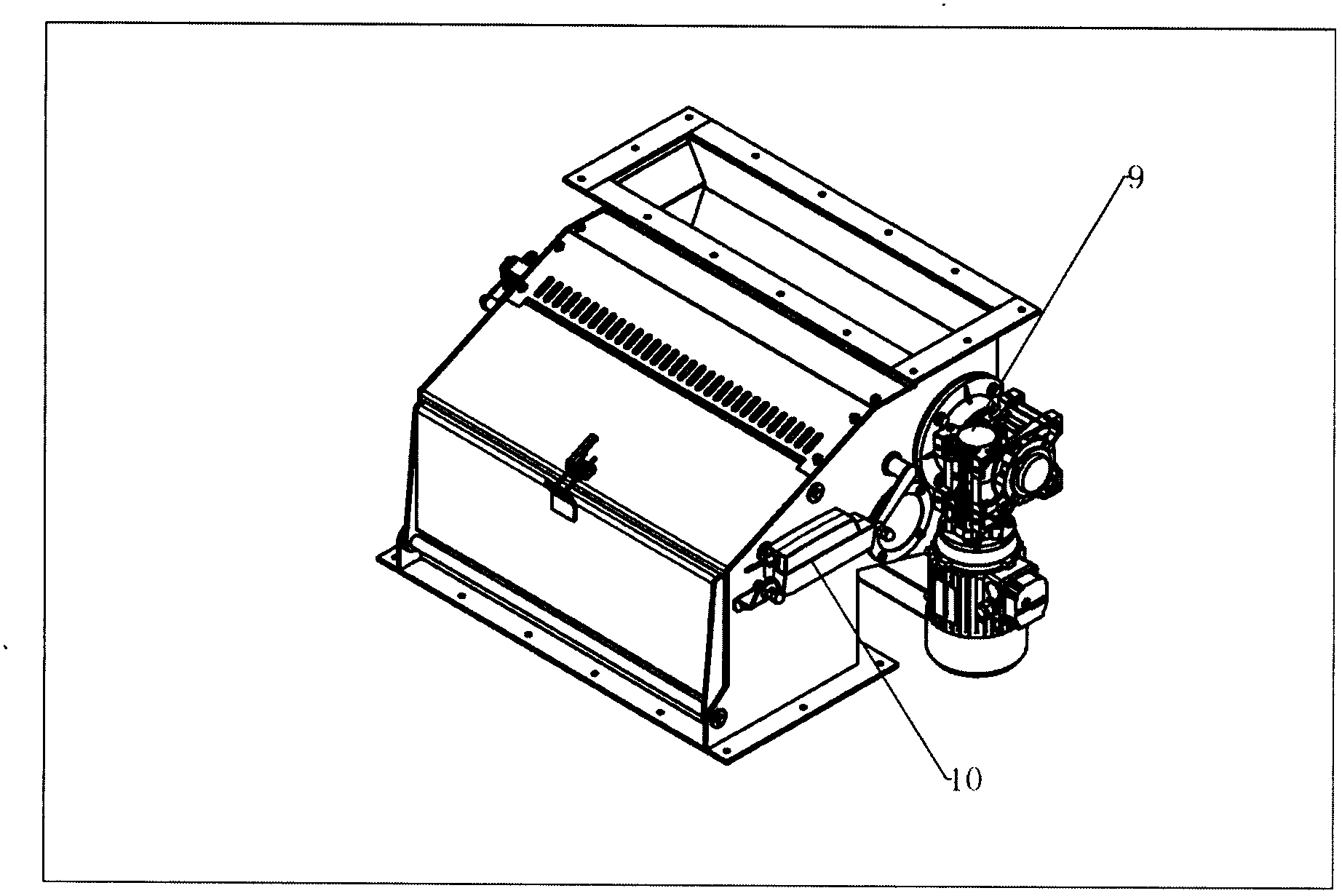

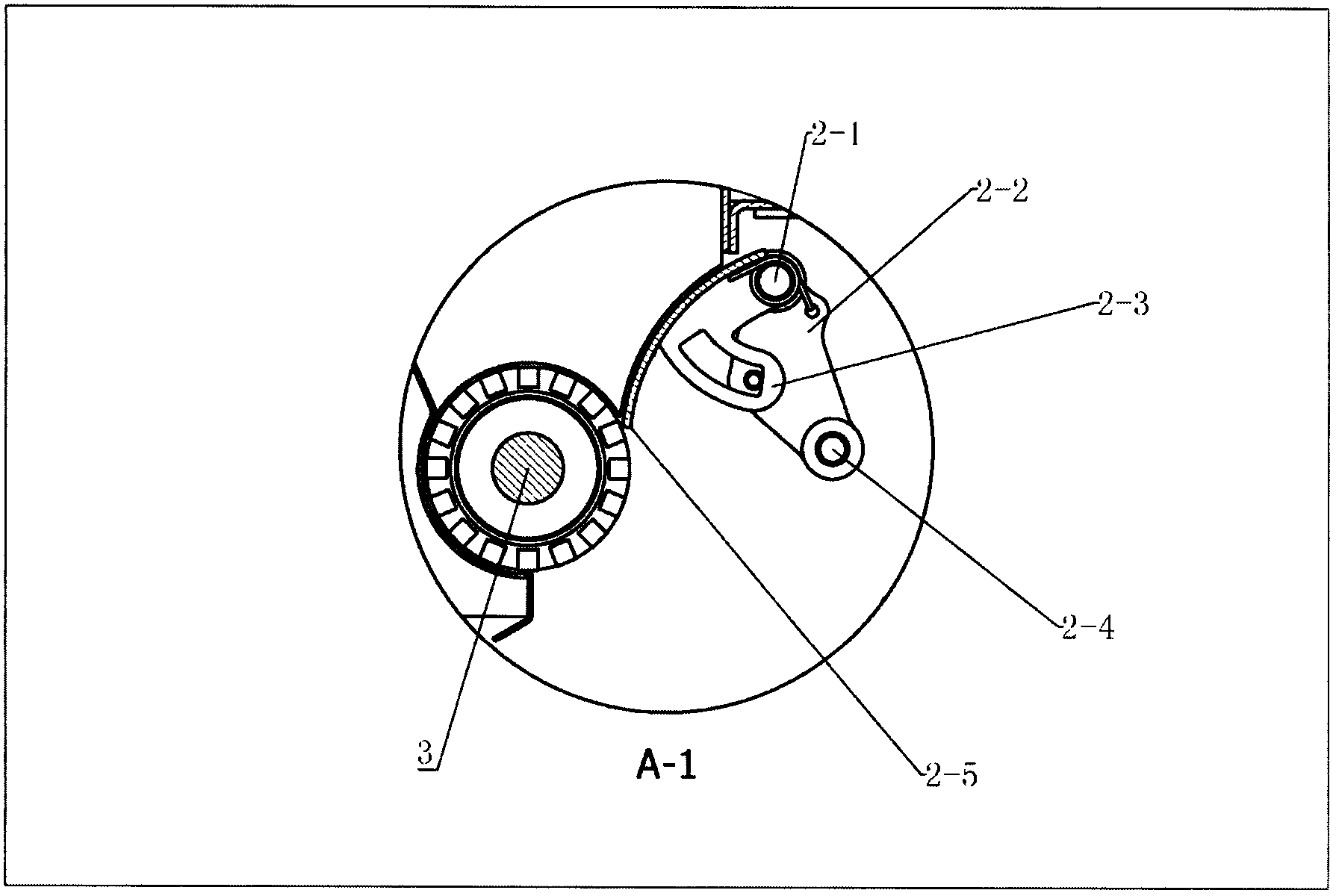

[0011] exist figure 1 , figure 2 Among them, this embodiment includes a housing (1), a left material guide plate (1-1), an adjustable right material guide plate (2), an impeller (3), an air supplement door (4), a miscellaneous drawer (5), Upper supplement air door (6), magnetic separation device (7), discharge port (8), variable speed motor (9). Wherein the adjustable right material guide plate (2) is composed of a torsion spring mechanism (2-1), a flap adjusting plate (2-2), a flap positioning plate (2-3), a flap rotating shaft (2-4), a flap Plate (2-5), push rod (10) etc. are formed. When feeding, the variable speed motor (9) drives the impeller (3) to rotate to throw the material to feed, and the different specific gravity and particle size correspond to different throwing distances to achieve the effect of removing impurities. The feeding amount is realized by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com