Magnetorheological Pressure Control Valve

A pressure control and magnetorheological technology, applied in the direction of lift valve, valve details, valve device, etc., can solve the problems of small movement of the valve core, affecting the control valve, poor product consistency, etc., to achieve a large pressure control range, reduce coil Effects of heat generation, flexible spool size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

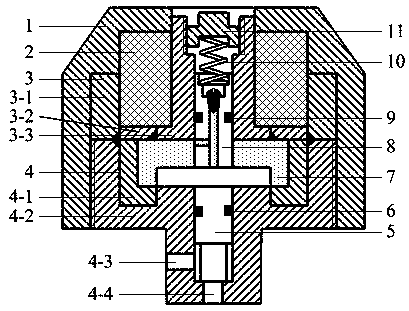

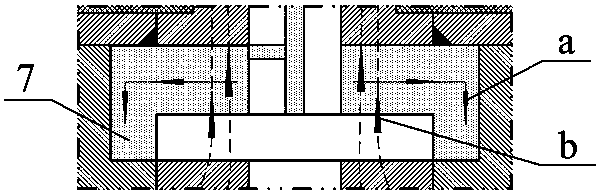

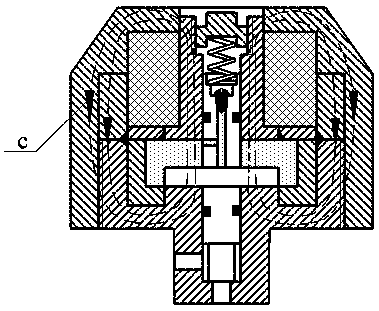

[0014] attached by figure 1 As shown: the magnetorheological pressure control valve includes: a valve cover 1, a coil assembly 2 composed of a coil and a magnetic isolation jacket, an upper valve body 3, a lower valve body 4, a lower valve core 5, and a magneto-rheological fluid inside. Working chamber 7, upper spool 8, return spring 10, adjusting nut 11 and multiple rubber sealing rings (6, 9). The bonnet is a magnetic material, and the bonnet 1 and the lower valve body 4 are threadedly connected to the upper and outer sides of the lower valve body 4; the lower valve body 4 is magnetically guided by the lower valve body magnetic isolation ring 4-1 and the lower valve body The main body 4-2 is welded, the lower valve body 4 and the upper valve body 3 are welded on the lower side of the upper valve body 3, the upper valve body 3 is composed of the upper valve outer magnetic guide ring 3-1, the upper valve body magnetic isolation ring 3- 2 and the magnetic guide ring 3-3 in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com