Control method for steplessly adjusting operation of high power water pump or fan

A technology of stepless adjustment and control method, applied in pump control, starter of single multi-phase induction motor, mechanical equipment, etc., can solve the problems of limited maximum capacity, large one-time investment, roughness, etc., and achieve precise control of production operation. parameters, saving equipment investment, and reducing the effect of impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

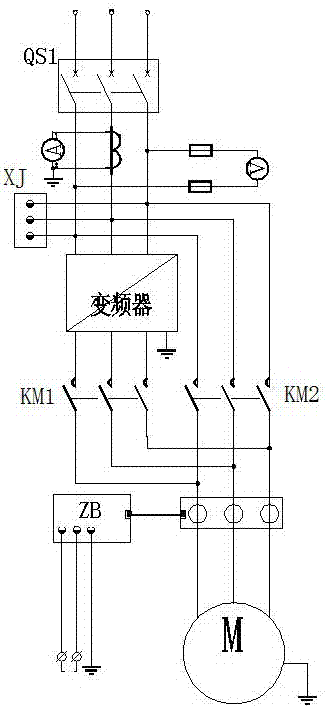

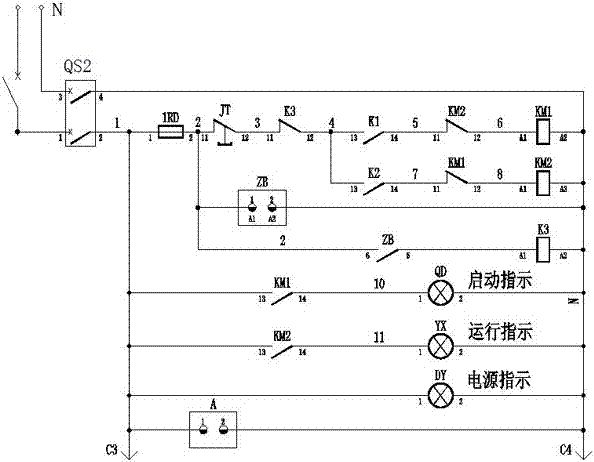

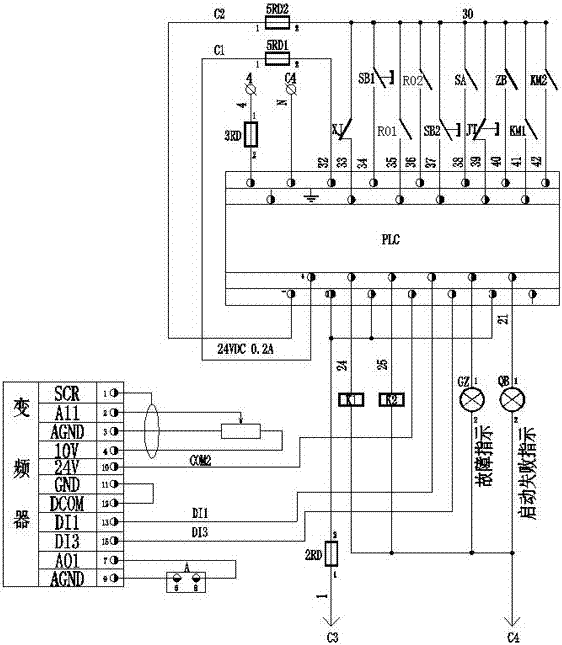

[0022] Two water pumps were used as brine pumps in the refrigeration workshop of a wellbore freezing project (models 12SH-6A and 12SH-9A, and the rated power of the motors were 280 KW and 160 KW respectively). Because the frequency converter in the original control circuit matches the 160KW motor, and for the 280KW motor, the existing method of installation needs to buy a new control cabinet.

[0023] Through research and development, the inventor has provided a control method for steplessly adjusting the operation of high-power water pumps or fans. The controller PLC CPM1A is used to control the frequency converter ACS510 160KW, and the frequency converter is used to control the motor. According to the values of the motor power and the power of the frequency converter, Manual or automatic switching control mode;

[0024] Since the power of the 280KW motor does not exceed twice the rated power of the inverter (320KW), modify the rated power of the inverter to the power of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com