Ultra-fast and ultra-thin balanced type electric heating machine

An electric heater, ultra-thin technology, applied in heating methods, household heating, lighting and heating equipment, etc., can solve the problems of difficult control of surface temperature rise, increased assembly costs of workers, and insufficient power requirements. Promote the economic development of the whole land, save the installation cost and additional material cost, the effect of uniform power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

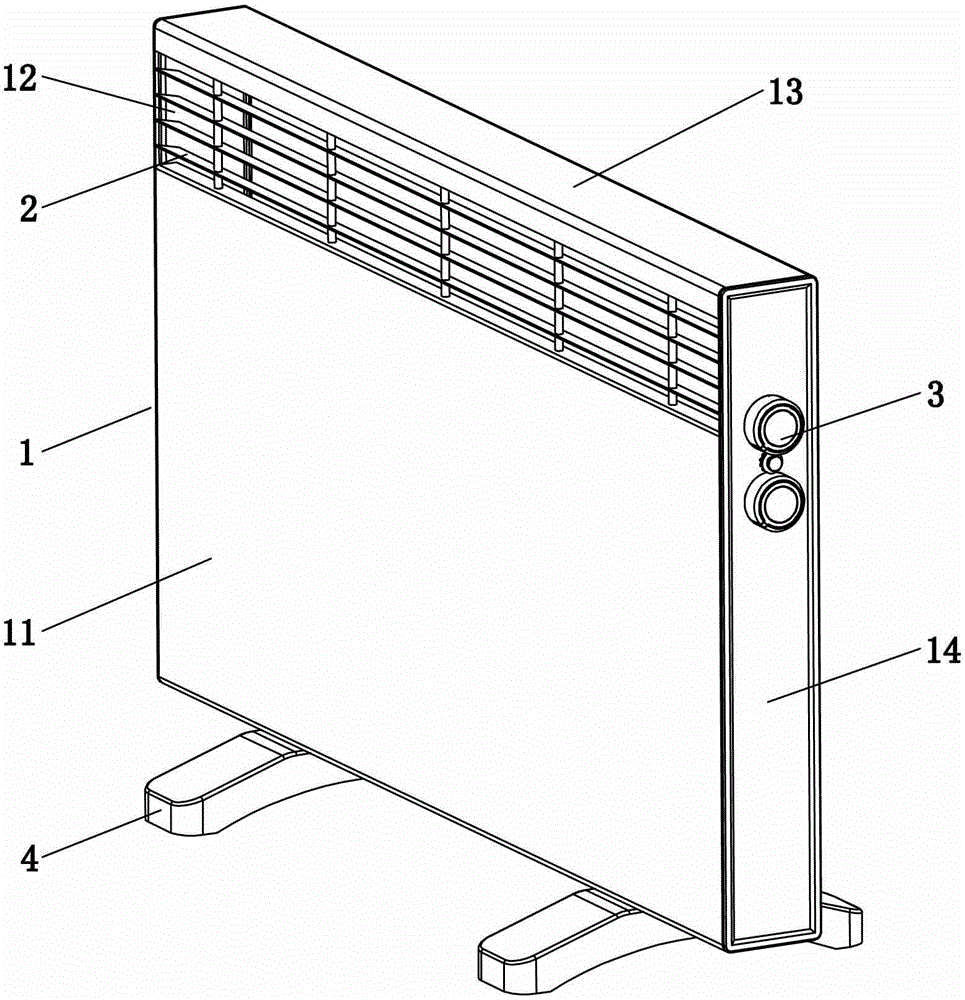

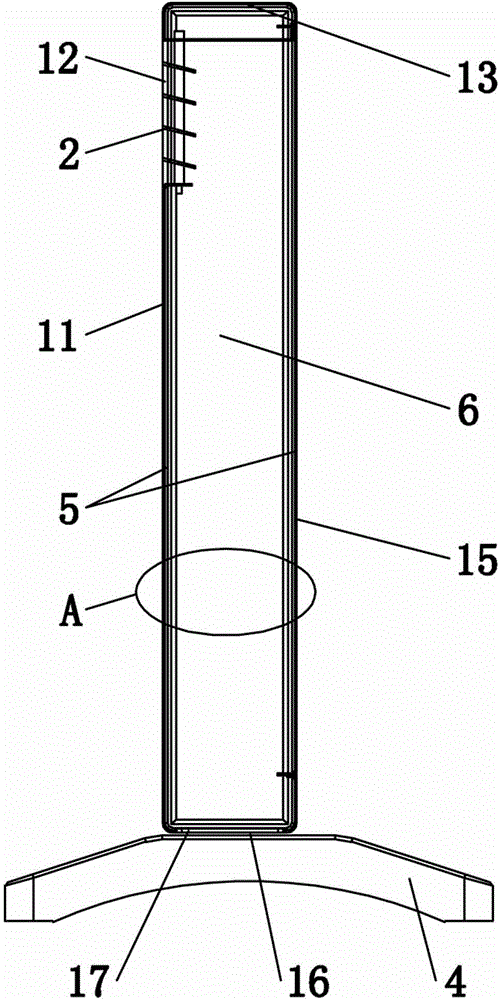

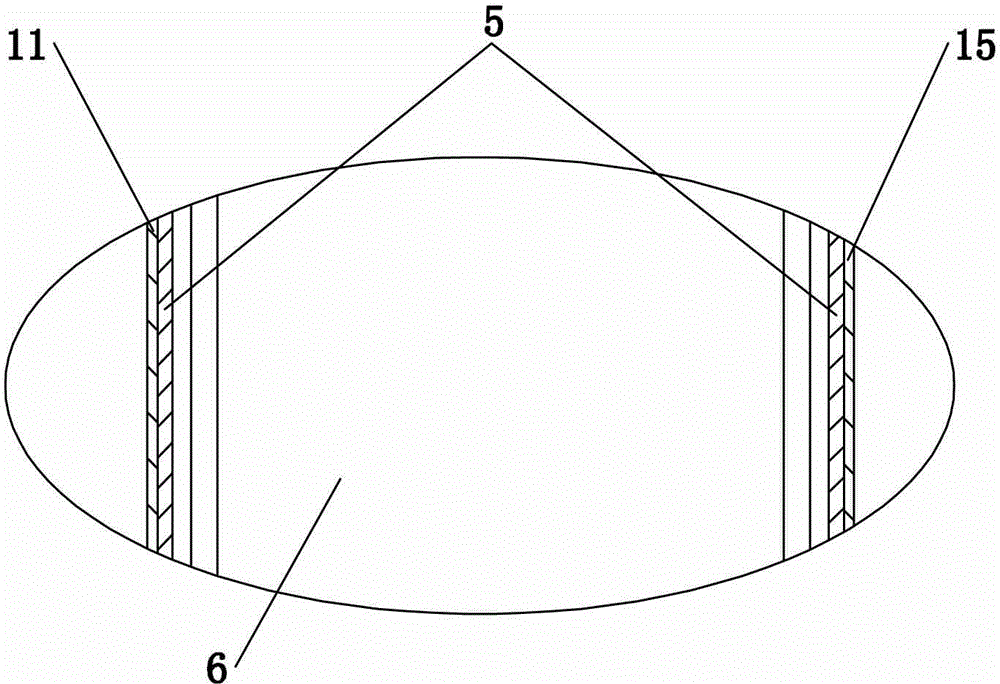

[0029] see Figure 1 to Figure 4 As shown, an extremely fast ultra-thin counterbalanced electric heater includes a casing 1, a heating body and an electrical control system component 3. A convection channel 6 is formed inside the casing 1, and the casing 1 corresponds to the upper and lower sides of the convection channel 6. Air outlets 12 and air inlets 17 are respectively provided at the two ends, and the heating body is the film heating element 5, which is arranged inside the convection channel 6 and is electrically connected with the electrical control system component 3.

[0030] Described shell 1 is the box structure of rectangle, and it is made of left shell, right shell 14, front shell 11, rear shell 15, top shell 13 and lower shell 16, left shell, right shell 14. The front casing 11, the rear casing 15, the top casing 13 and the lower casing 16 join...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com