Oil pressure warning sensor for pressure sensitive capacitor

A technology of oil pressure and pressure-sensitive capacitance, which is used in fluid pressure measurement using capacitance change, pressure-lubricated safety devices, etc., can solve the problems of easy oxidation, difficult control of levers, short service life, etc., and achieves good stability. , stable performance, high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

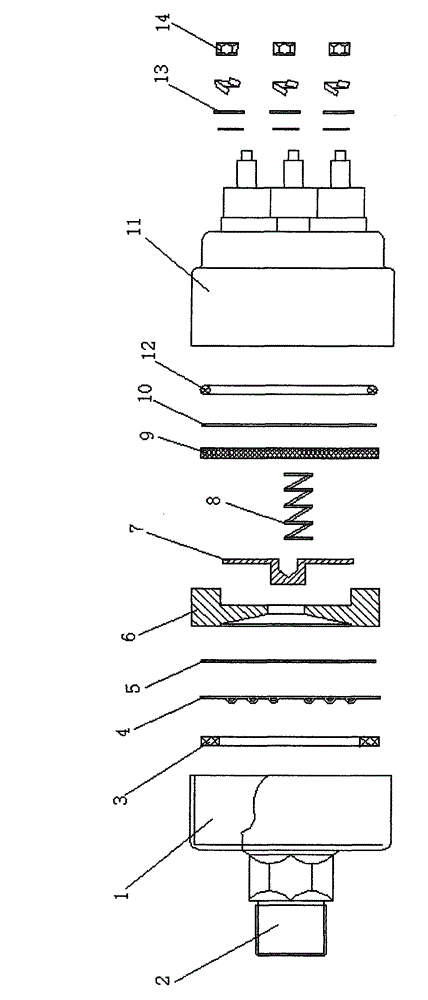

[0025] The utility model piezocapacitor oil pressure alarm sensor will be further described below in conjunction with the accompanying drawings and embodiments.

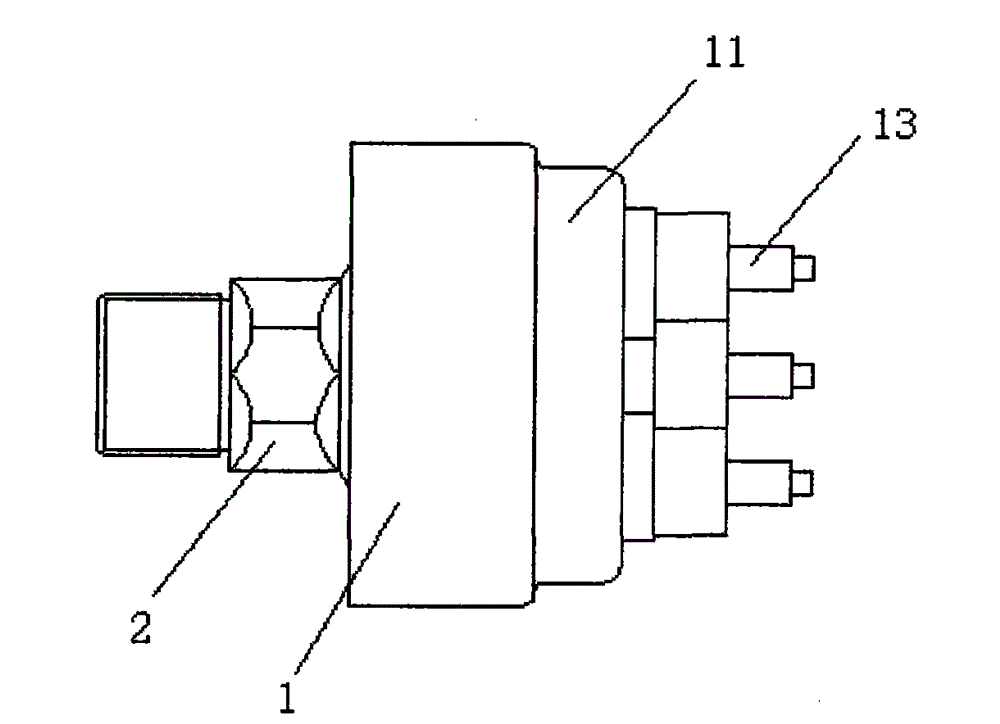

[0026] Please refer to Figure 1 to Figure 8 As shown, the utility model piezocapacitor oil pressure alarm sensor includes: a telescopic oil tank main part, an oil tank telescopic assembly arranged in the telescopic oil tank main part, and the oil tank telescopic assembly sealed in the telescopic oil tank main part in cooperation with the telescopic oil tank main part. The housing 11 in the oil tank main part.

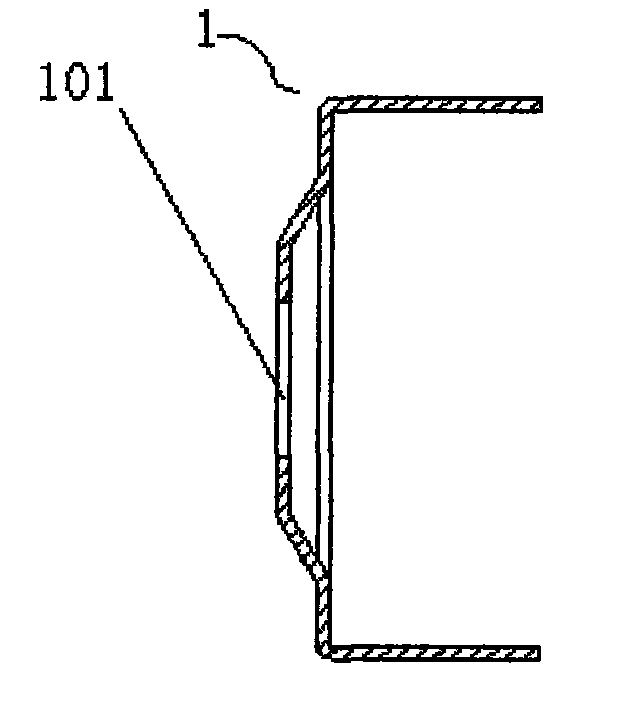

[0027] The main part of the telescopic oil tank includes a bowl-shaped iron bottom bowl 1 with a through hole 101 at the bottom and a screw 2 matching the through hole at the bottom of the iron bottom bowl 1. The screw 2 is connected to the edge of the through hole 101 of the iron bottom bowl. In order to seal the fit, the iron bottom bowl 1 and the screw 2 are directly riveted first, and then the riveting j...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com