Slide valve type hydraulic valve with differential motion function

A hydraulic valve and function technology, applied in the direction of fluid pressure actuation device, servo motor assembly, mechanical equipment, etc., can solve the problems of increasing product cost and product failure rate, unable to achieve stepless flow control, complex valve body structure, etc. To achieve the effect of less overall structural changes, easy implementation, and lower product costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

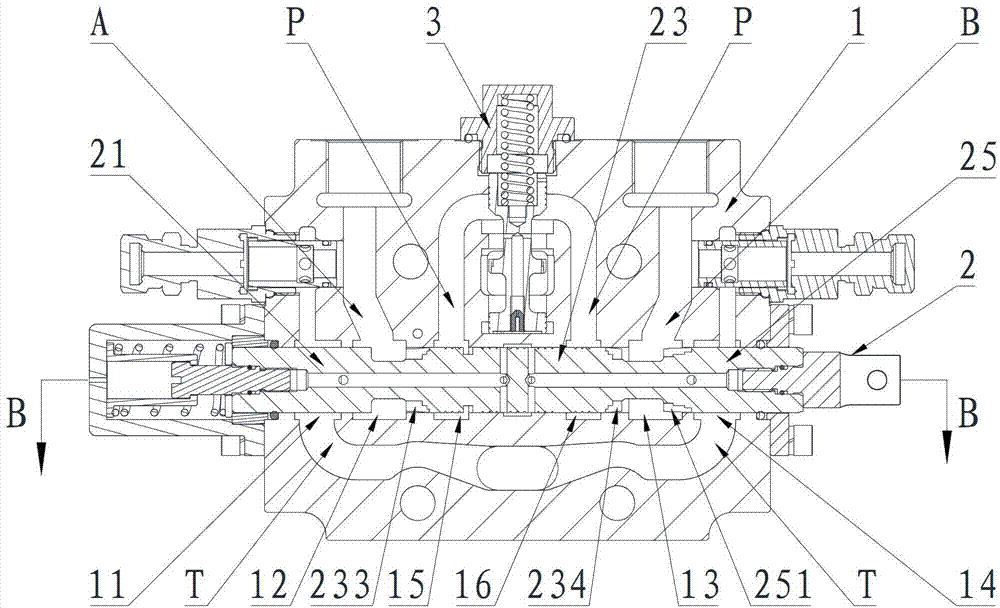

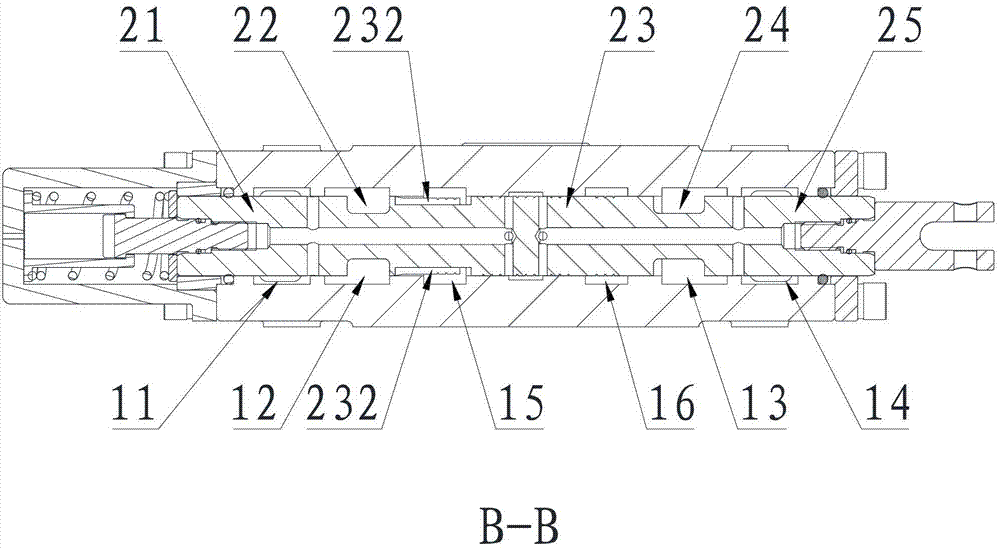

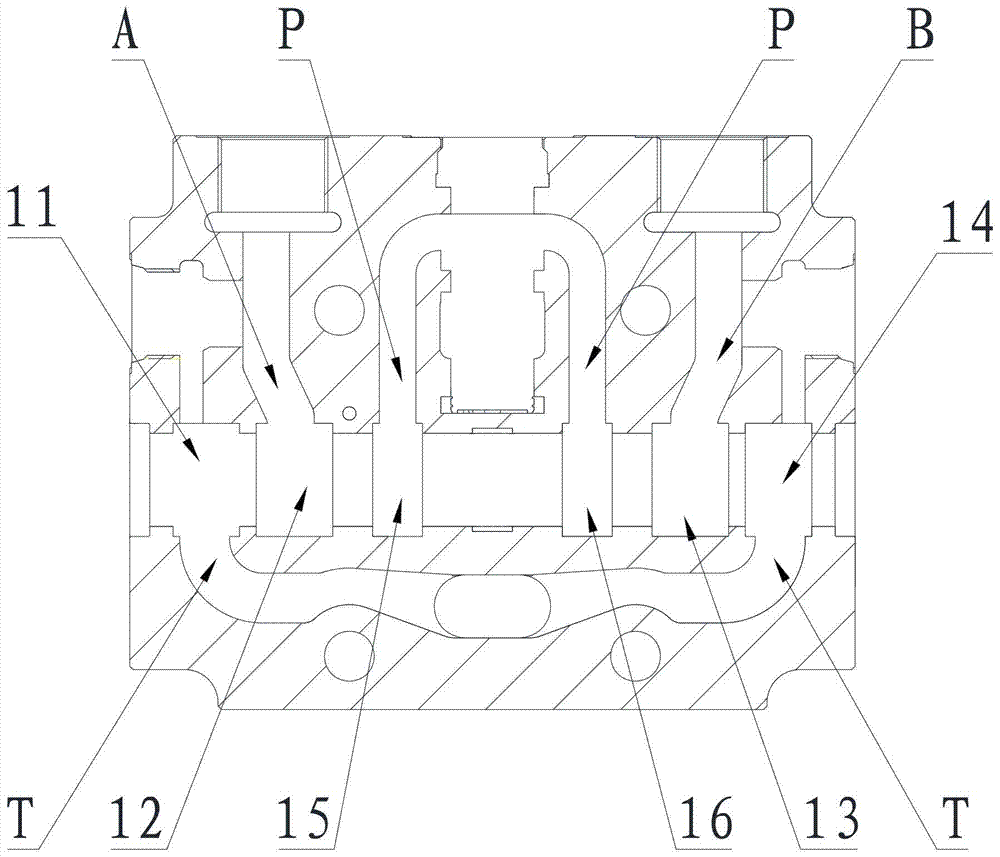

[0032] Figure 1 to Figure 5 That is the relevant drawings of this embodiment, as shown in the figure, the slide valve hydraulic valve with differential function described in this embodiment includes a valve body 1 and a valve core 2 arranged in the hole of the valve body 1, The first undercut groove 11, the second undercut groove 12, the fifth undercut groove 15, the sixth undercut groove 16, the third undercut groove 13 and the fourth undercut groove are sequentially arranged in the hole of the valve body 1. 14, the first undercut groove 11 and the fourth undercut groove 14 communicate with the oil return port T, the second undercut groove 12 and the third undercut groove 13 communicate with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com