Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Realize processing and production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

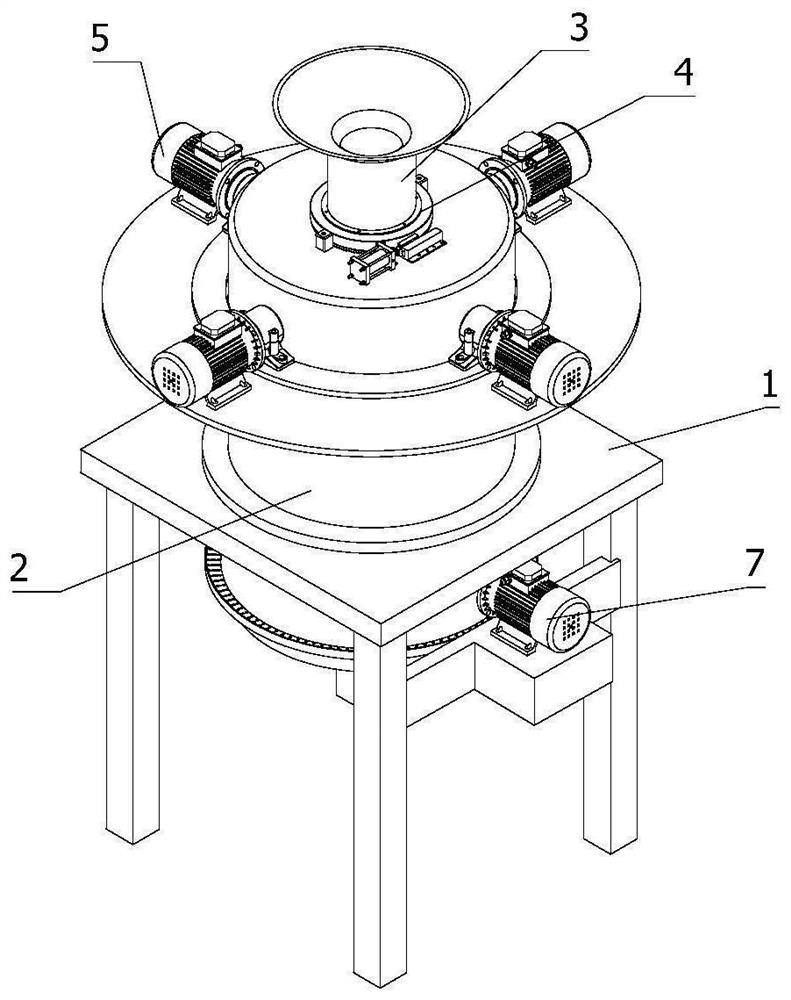

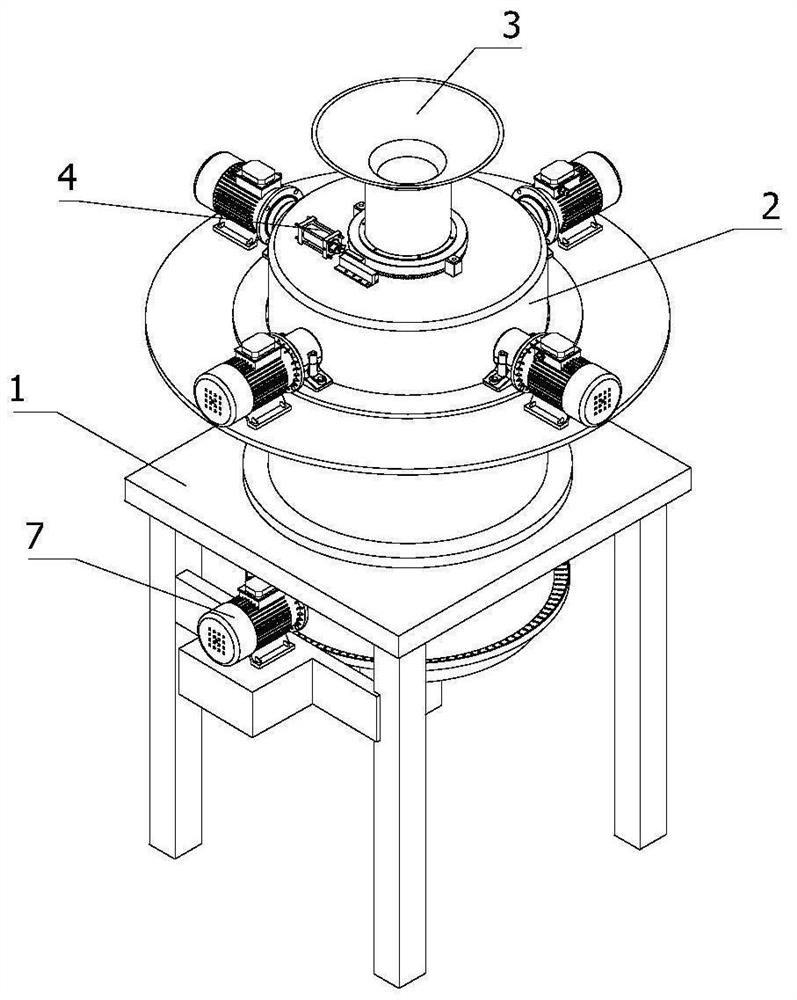

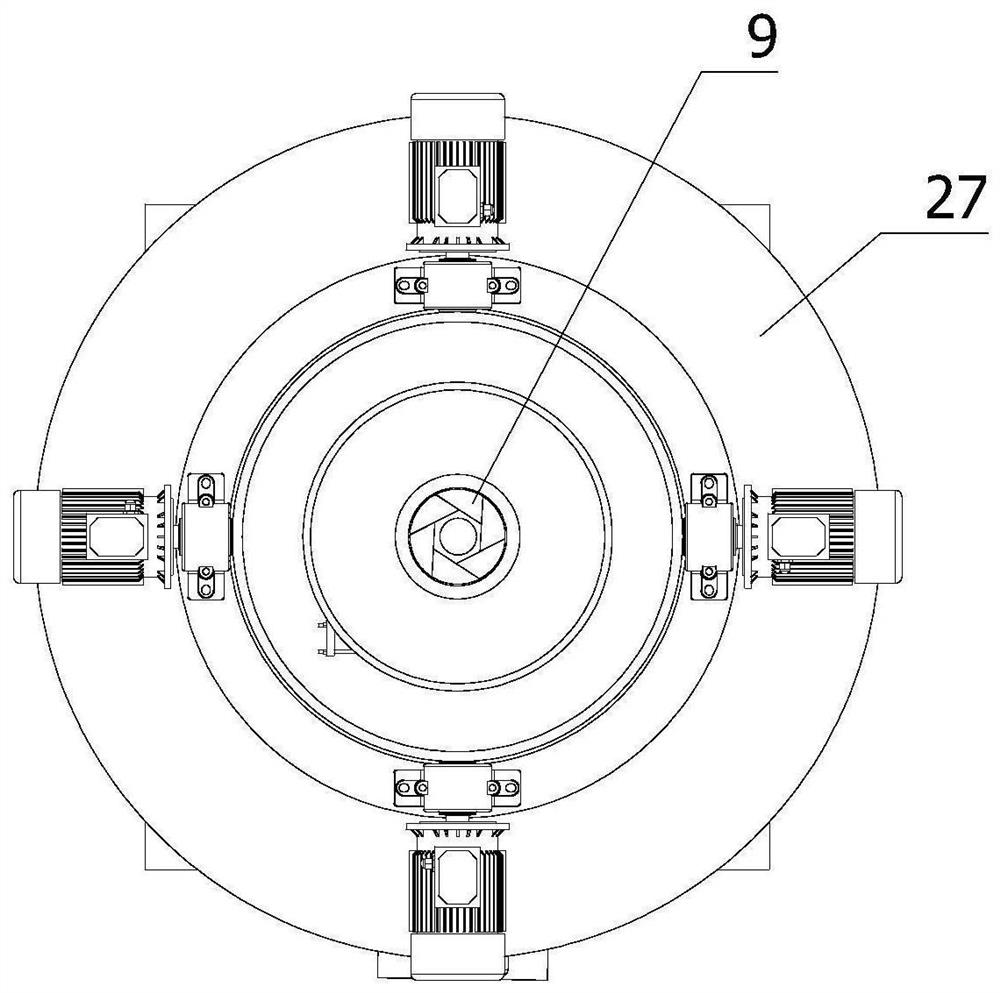

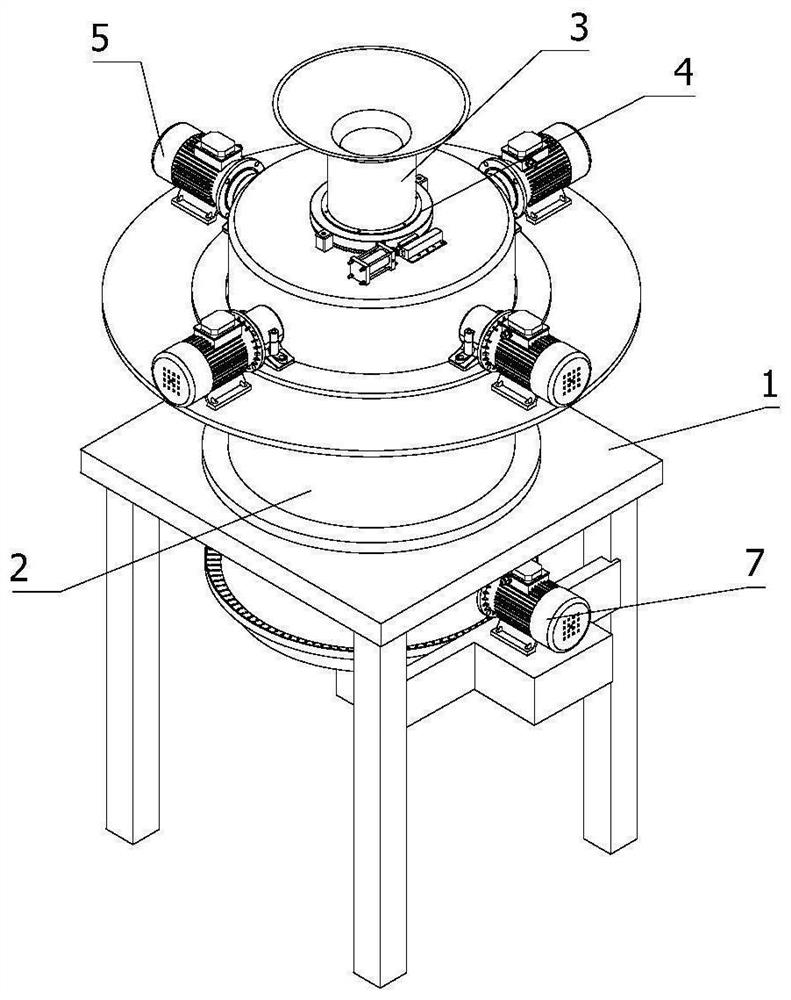

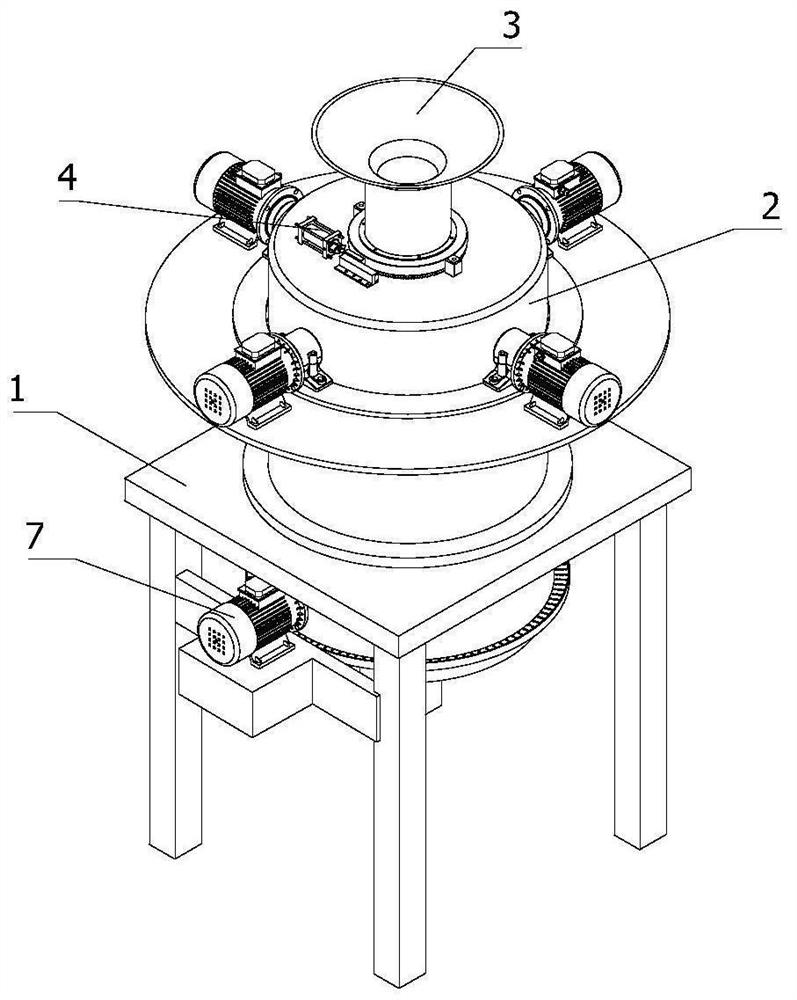

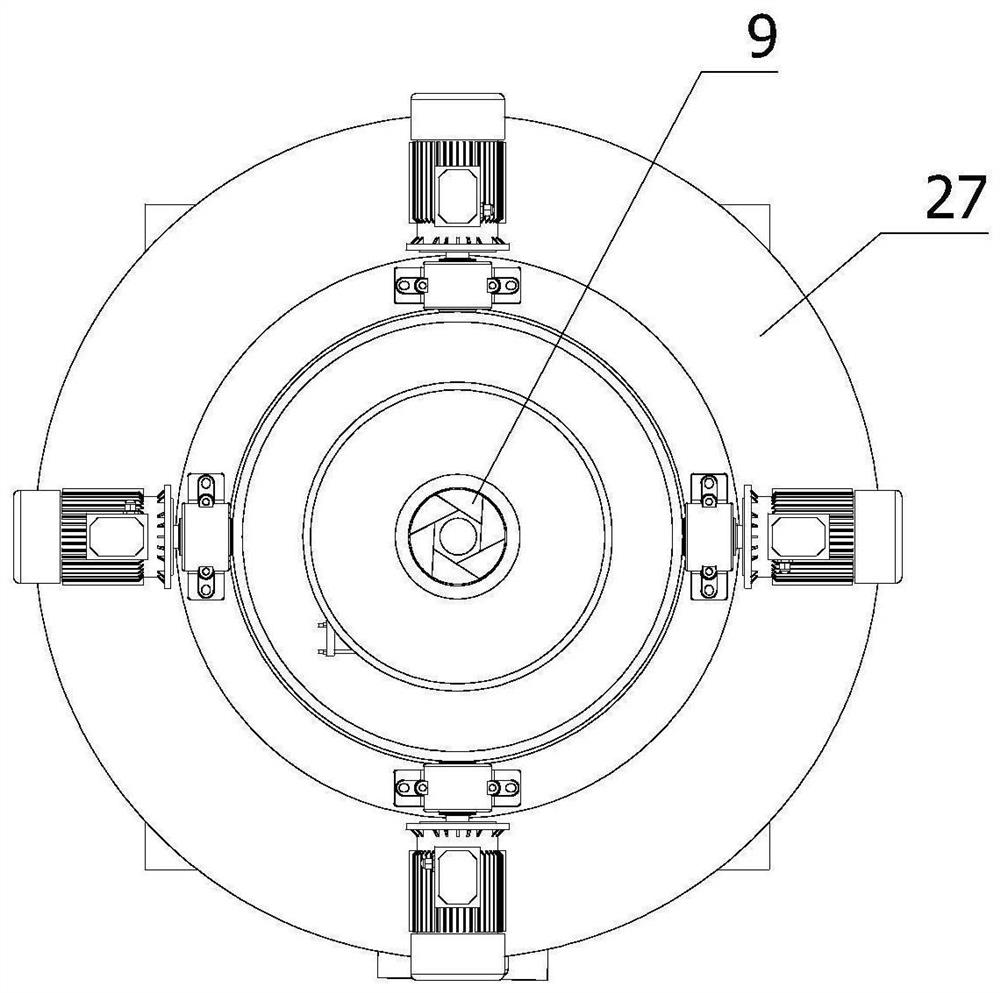

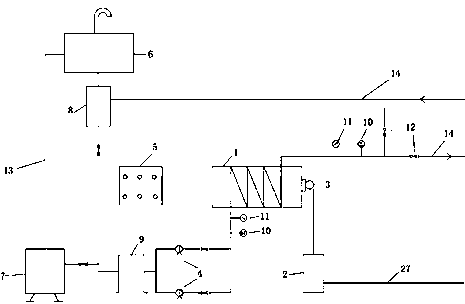

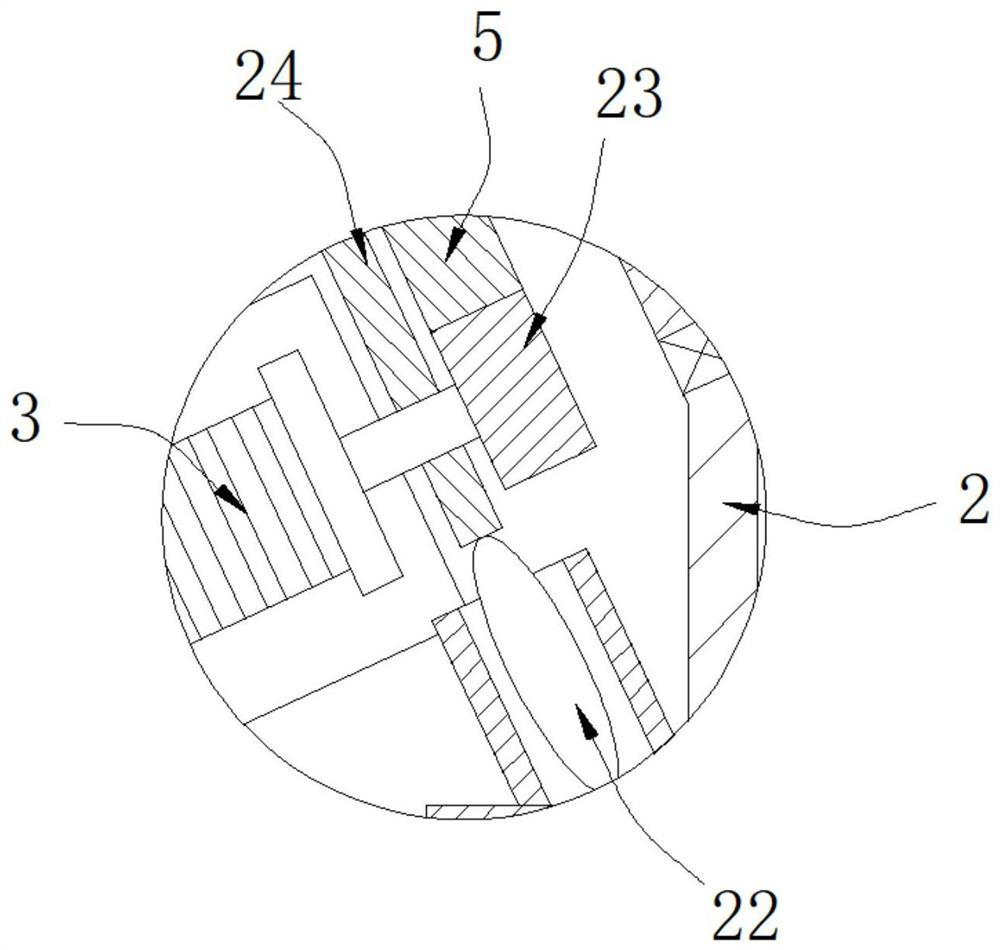

Superfine grinding system for producing cement

ActiveCN111632726ARealize processing and productionImprove processing efficiencyGrain treatmentsGear wheelProcess engineering

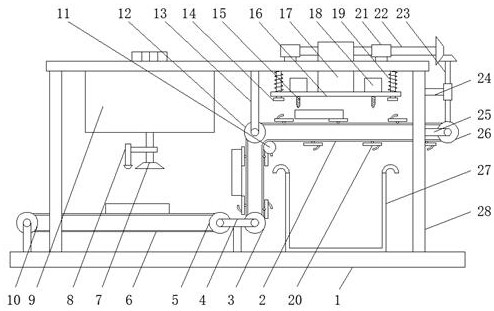

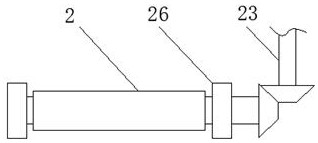

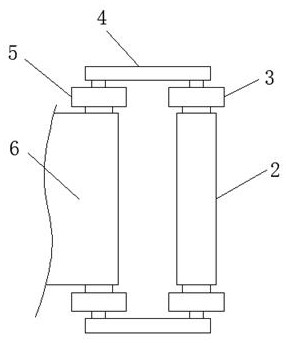

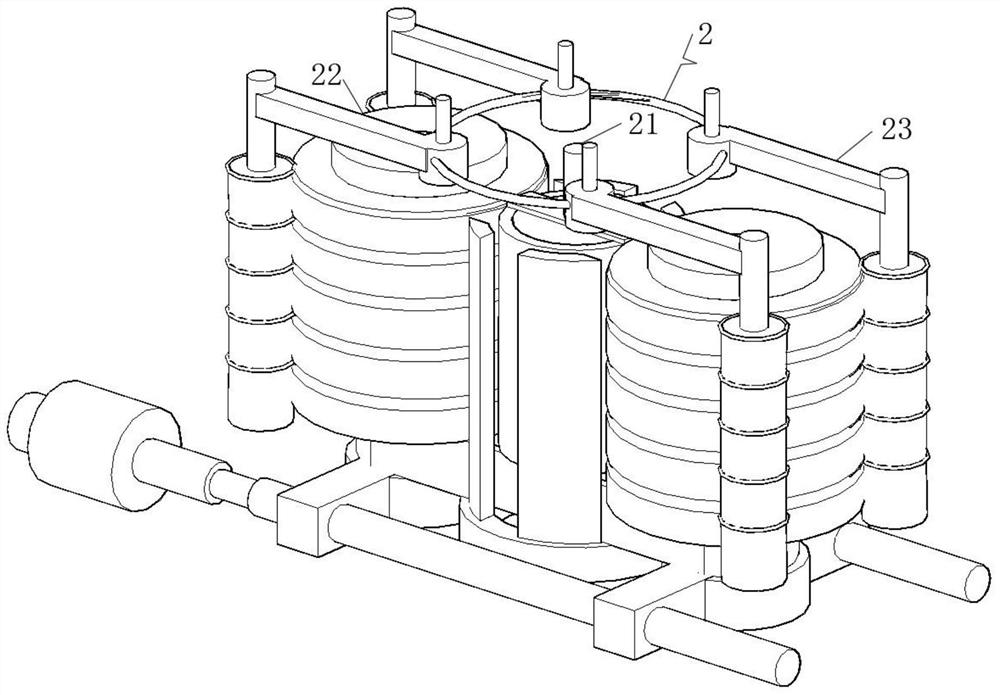

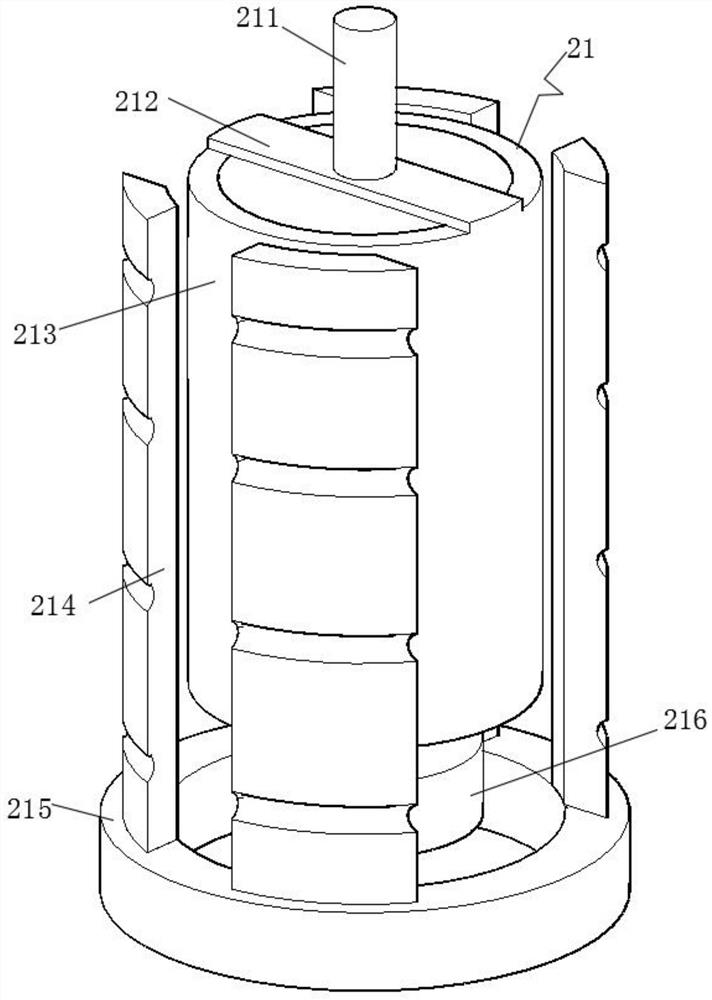

The invention relates to the field of cement producing and processing, in particular to a superfine grinding system for producing cement. The superfine grinding system comprises a supporting frame anda grinding barrel, wherein the grinding barrel is sequentially provided with a feeding channel, a shutter mechanism, four groups of coarse grinding and breaking mechanisms, a fine grinding mechanism,a reversal grinding and driving mechanism and a discharging groove from top to bottom; the shutter mechanism comprises a plurality of moving plates which can be opened and closed; the coarse grindingand breaking mechanisms comprise grinding rollers capable of rotating; a screening plate is horizontally arranged between the coarse grinding and breaking mechanisms and the fine grinding mechanism;a base is horizontally and fixedly arranged below the supporting seat; the reversal grinding and driving mechanism comprises a driving gear capable of rotating and a transmission rod; and a funnel blanking frame is arranged at the top end of the feeding channel. According to the superfine grinding system for producing the cement, disclosed by the invention, a series of operations such as feeding,heating, breaking and superfine grinding can be realized through the grinding barrel, so that production procedures are reduced, the working efficiency is greatly improved, the labor intensity is reduced and the production cost is also reduced.

Owner:澄迈华盛天涯水泥有限公司

Novel firecracker sealing agent

The invention discloses a novel firecracker sealing agent, which is prepared by uniformly stirring and mixing the following three raw materials in percentage by weight: 20 to 40 percent of portland cement, 60 to 80 percent of powdery stone and hardening agent, wherein the addition of the hardening agent is 3 to 5 percent of the weight of the portland cement. The sealing agent not only reduces preparation cost, but also improves curing strength and greatly shortens curing time of the sealing agent because the portland cement and the powdery stone with wide sources and low price are used as main raw materials for preparing the firecracker sealing agent and a small amount of hardening agent is added into the raw materials. The curing time is between 6 and 12 hours and is shortened by 4 folds than that of the conventional firecracker sealing agent to make all the working procedures for manufacturing firecrackers achieve level production. Thus, the production efficiency of the firecrackers is improved, the production cost of the firecrackers is reduced and the processing and production of mass firecrackers are realized.

Owner:吴家福

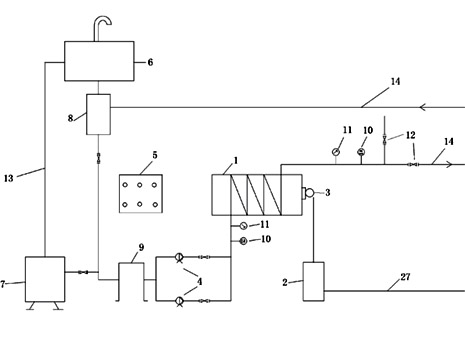

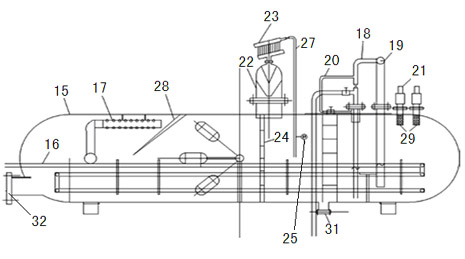

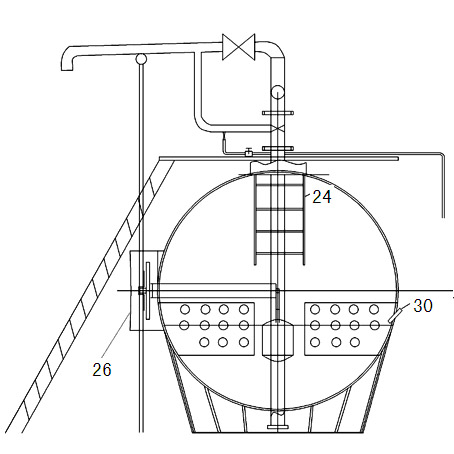

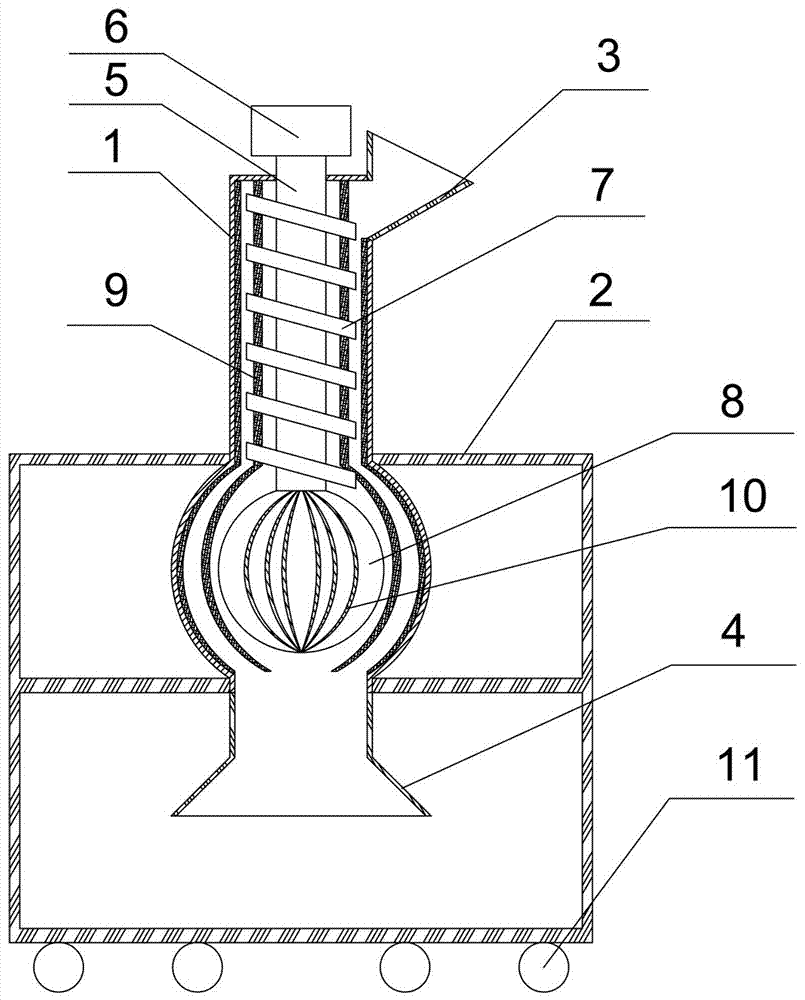

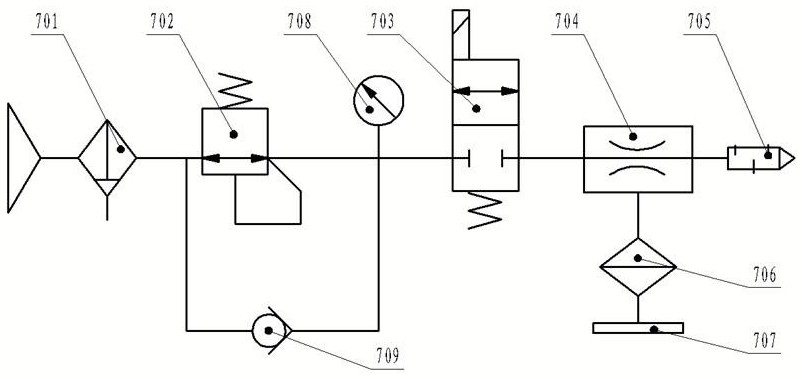

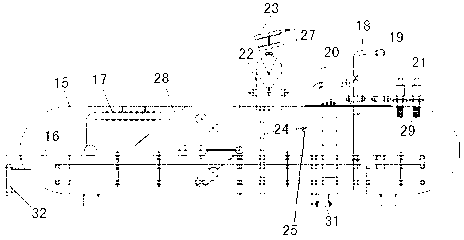

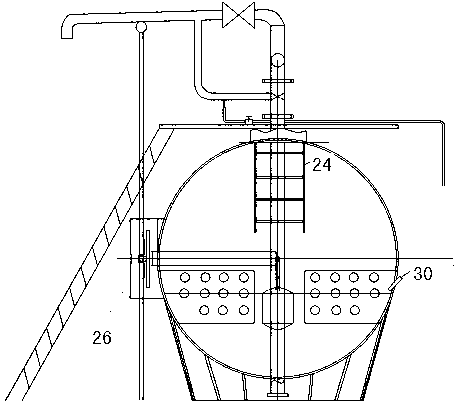

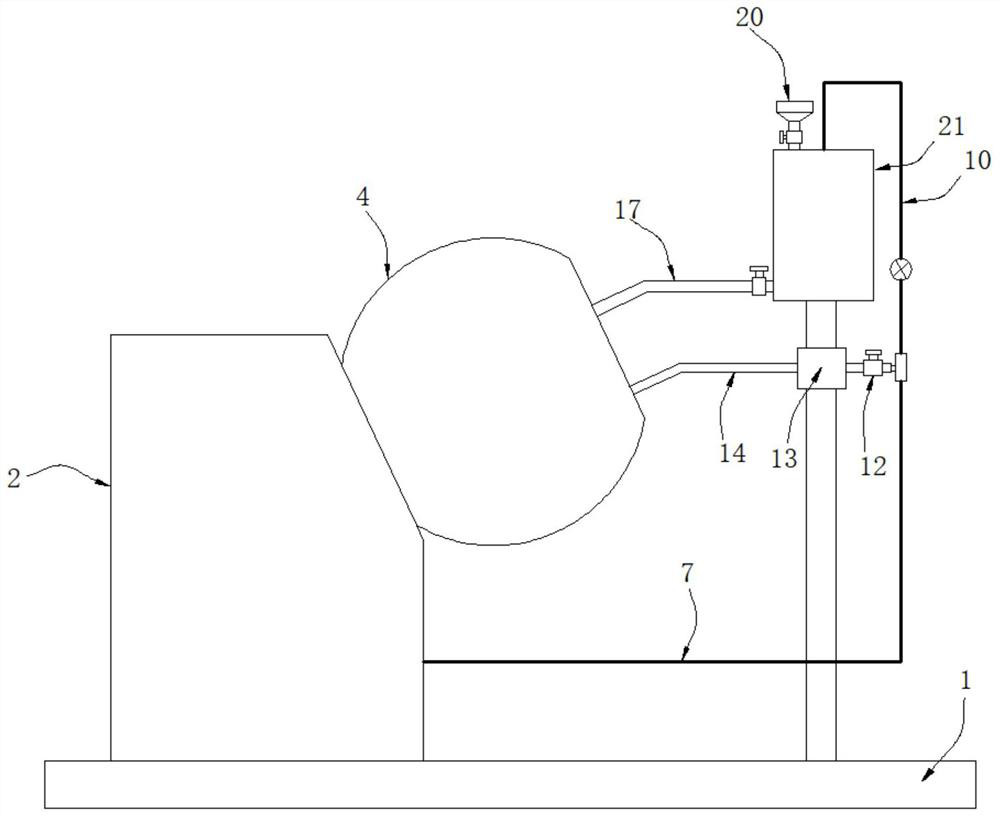

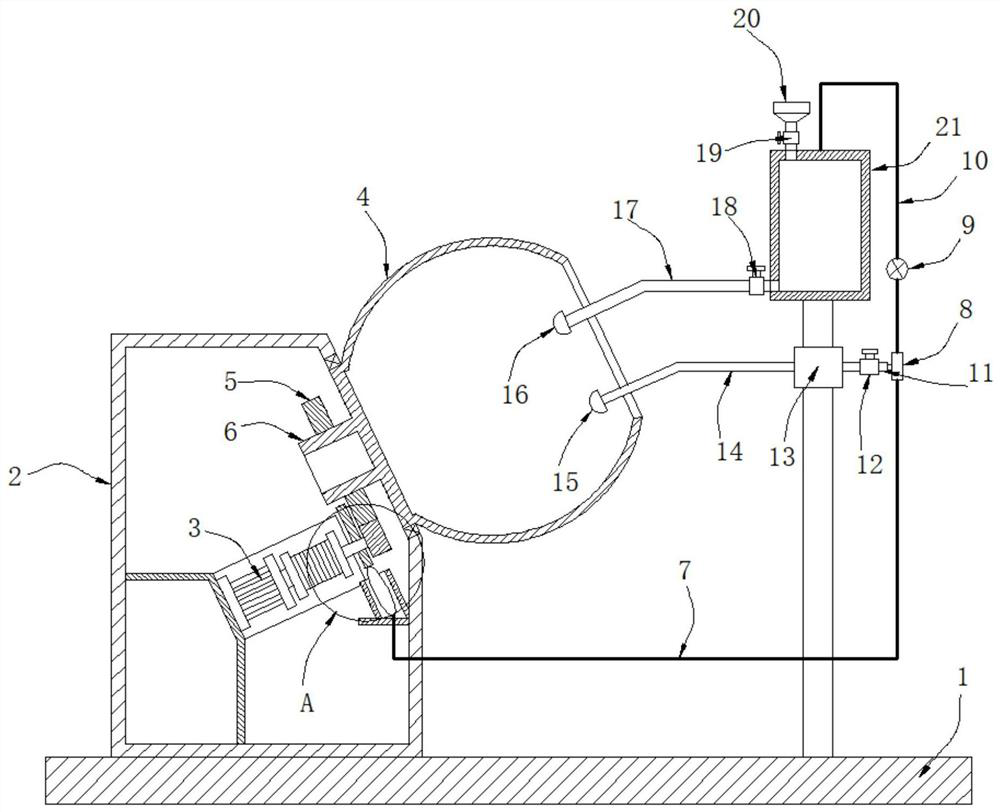

Single-well split-type heating multifunctional storage tank device

InactiveCN102582977AEasy to separateFlexible layoutLarge containersTank wagonsSpecial designStorage tank

The invention relates to a single-well split-type heating multifunctional storage tank device. The technical scheme of the invention is as follows: the single-well split-type heating multifunctional storage tank device mainly comprises a heating furnace unit and a storage tank unit which are connected by medium circulation pipes and a natural gas pipeline, a safe distance is arranged between the heating furnace unit and the storage tank unit, a heating coil pipe outlet in a furnace body of the heating furnace unit is in a double-flow manner, one path of the two flows is connected with a heat exchange coil pipe in a storage tank through a high-temperature gate valve, and the other path of the two flows is connected with a well shaft lifting heating circulating system through the high-temperature gate valve. The single-well split-type heating multifunctional storage tank device disclosed by the invention has the advantages that the heating furnace unit and the storage tank unite are designed to be of a split structure so that a potential safety hazard in the production process is eliminated, and requirements on discharging oil and water and cleaning pipes by utilizing self oil-gas pressure in the storage tank are met; in addition, the heat exchange coil pipe in the storage tank unit can be flexibly arranged so that heat exchange area is enlarged, crude oil in the storage tank isheated uniformly, a low-temperature area of the crude oil in the storage tank is reduced and the heating time is shortened; in addition, due to a special design of a Y-shaped oil inlet separation pipe, the oil-gas separation effect is improved.

Owner:SHENGLI OILFIELD SANLI GASOLINEEUM TECH DEV

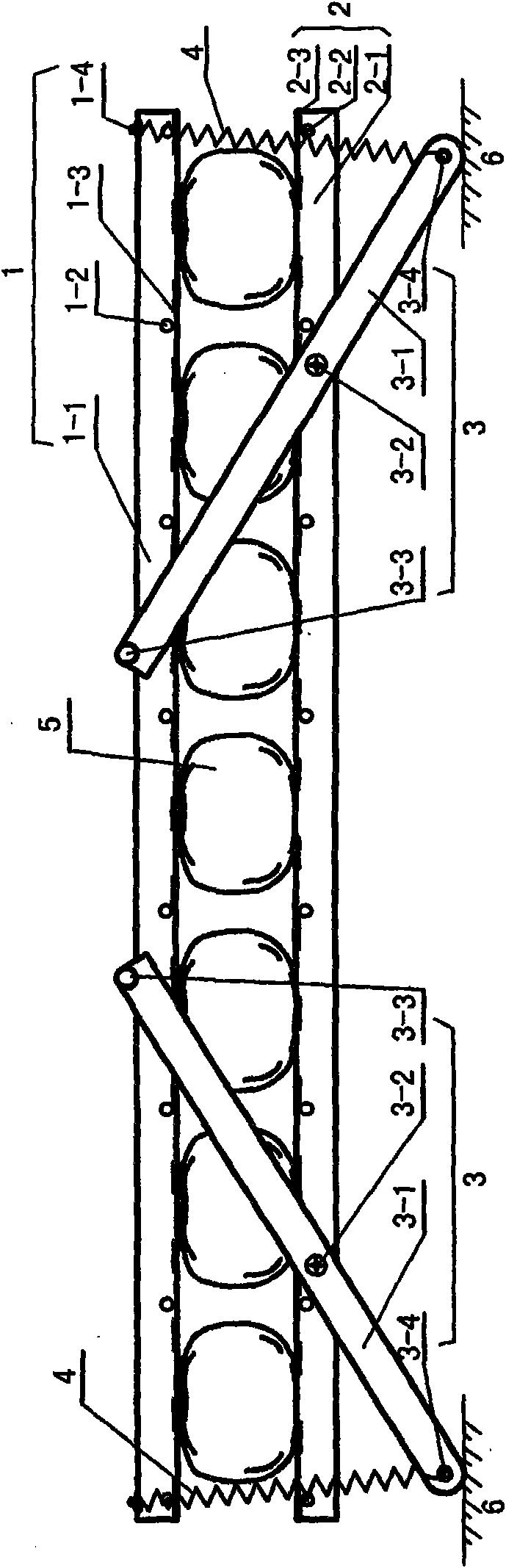

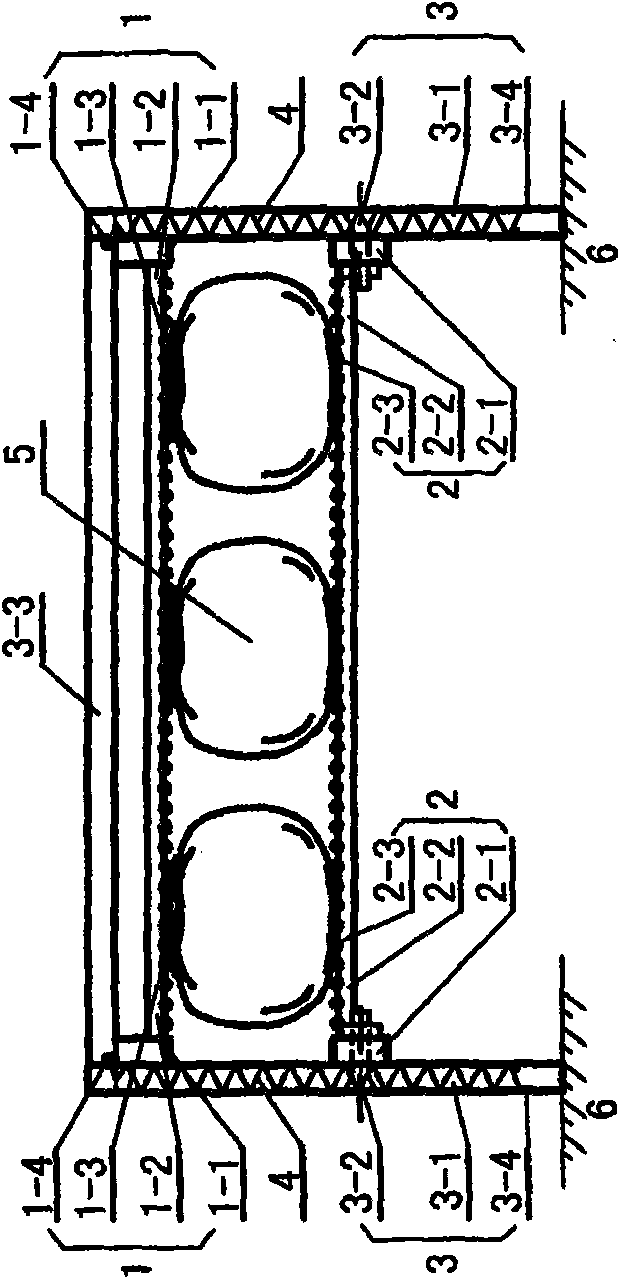

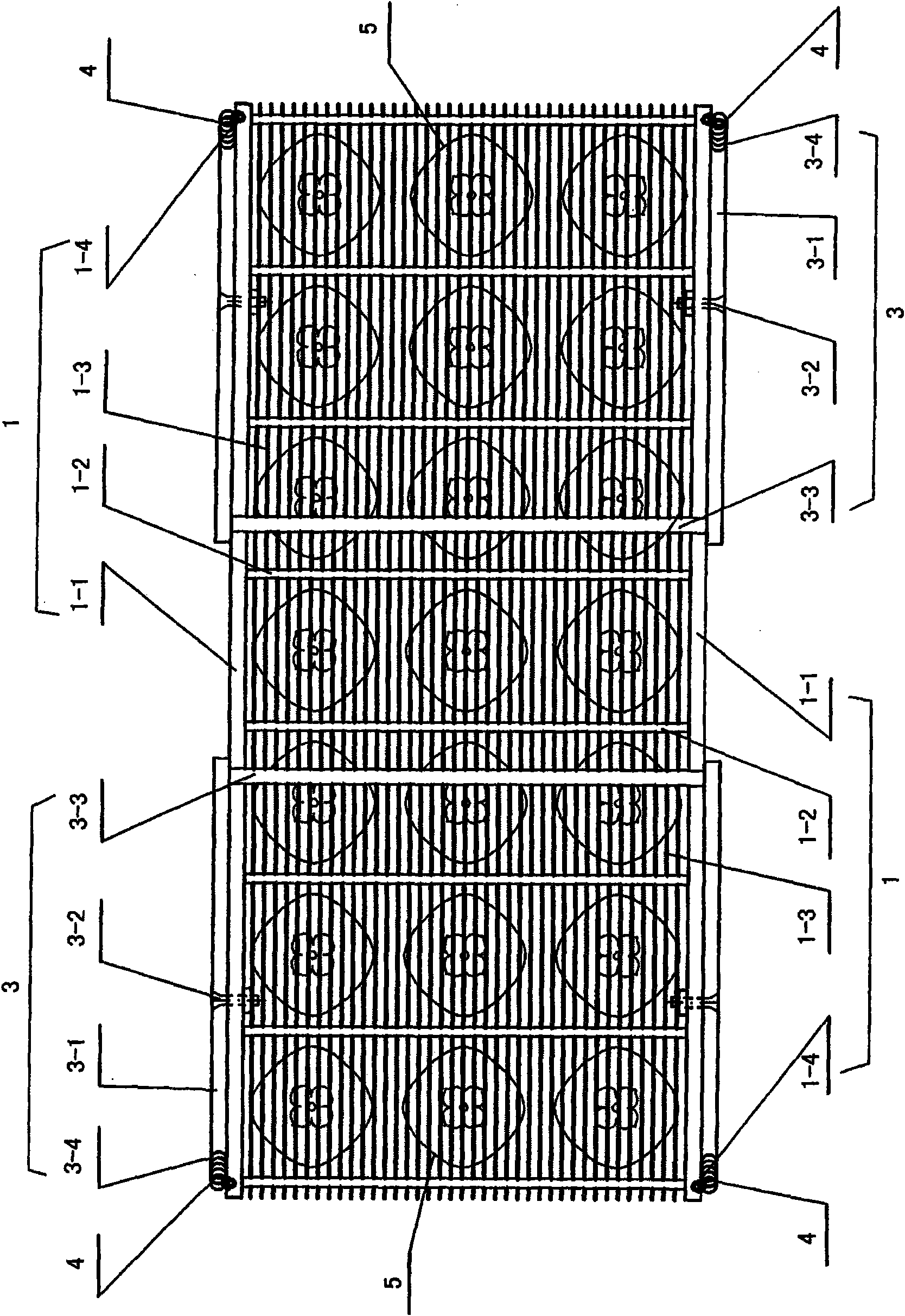

Vibration production method for dried persimmons with clamp and clamp thereof

InactiveCN101647544AReduce labor intensityIncrease productivityFood preparationFood treatmentFlavorEngineering

The invention relates to a vibration production method for dried persimmons with a clamp and a clamp thereof, belonging to the technical field of processing and production of fruits. The method comprises the following steps: putting peeled persimmons in a clamp; during drying or airing, providing vibration force to the clamp and the persimmons to accelerate the drying of the persimmons and form the dried persimmons by clamping so as to overcome the defect that the traditional production needs manual kneading. The method maintains the specific flavor of the dried persimmons, has the advantagesof high quality and high grade, can meet the requirements for industrial automatic processing and production, and is a technical innovation for processing dried persimmons. The clamp comprises an upper clamping screen plate, a lower clamping screen plate, pressure supporting legs, springs and the like. The clamp has the ingenious structural principle and can clamp the persimmons under the lever action of the clamp and the gravity of the persimmons; and the gravity, the elasticity, the vibration force and the like which are added can strengthen the clamping on the persimmons. The clamp has theadvantages of simple structure, convenient operation, reliable performance and durability and conforms to the requirements for industrial mass production. When being matched with special equipment, the clamp can produce dried persimmons having regular and beautiful appearance, favorable color and high quality.

Owner:GUANGXI POLYTECHNIC

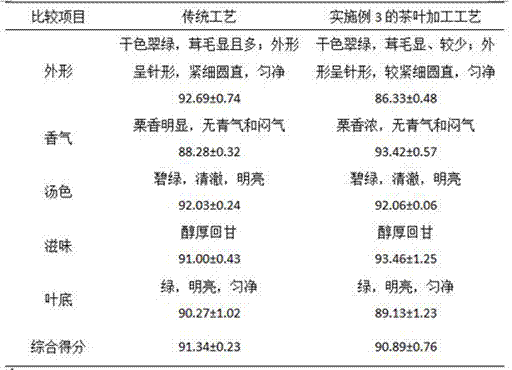

Tea processing process

InactiveCN107372881AIncrease productivityMaintain traditional qualityPre-extraction tea treatmentMechanical equipmentEngineering

The invention provides a tea processing process, which comprises the following steps of fresh leaf spreading and placing, enzyme deactivation by a roller enzyme deactivation machine, twisting by a twisting machine, shaping by a carding machine, and pekoe extraction and fragrance enhance by a bottle type dry stir-frying machine. A drying machine is used for drying before the shaping. Modern processing mechanical equipment is introduced; the production efficiency of Xinyangmaojian tea is improved; the production efficiency is 3 to 7 times of that of a conventional process; the production cost is reduced; the mass processing and production is realized; the conventional quality of the Xinyangmaojian tea is maintained; through the drying step before the shaping, the water content of the tea before the shaping is controlled; the round and straight appearance of the dry tea can be promoted; the bending degree is reduced; the damage on a great amount of chlorophyll in the high-temperature damp and hot environment is avoided; meanwhile, the quality of the tea is effectively improved.

Owner:XINYANG NORMAL UNIVERSITY

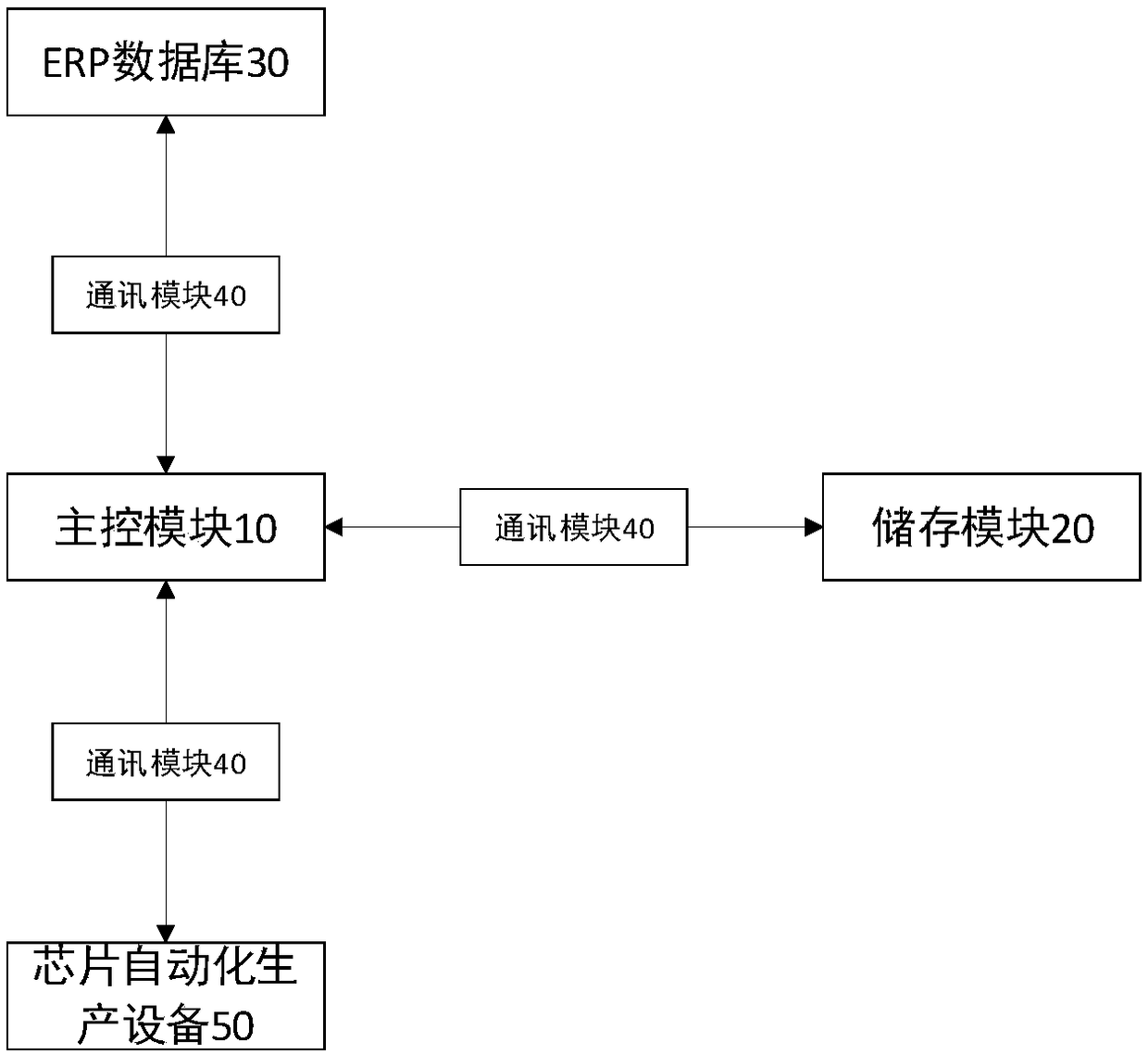

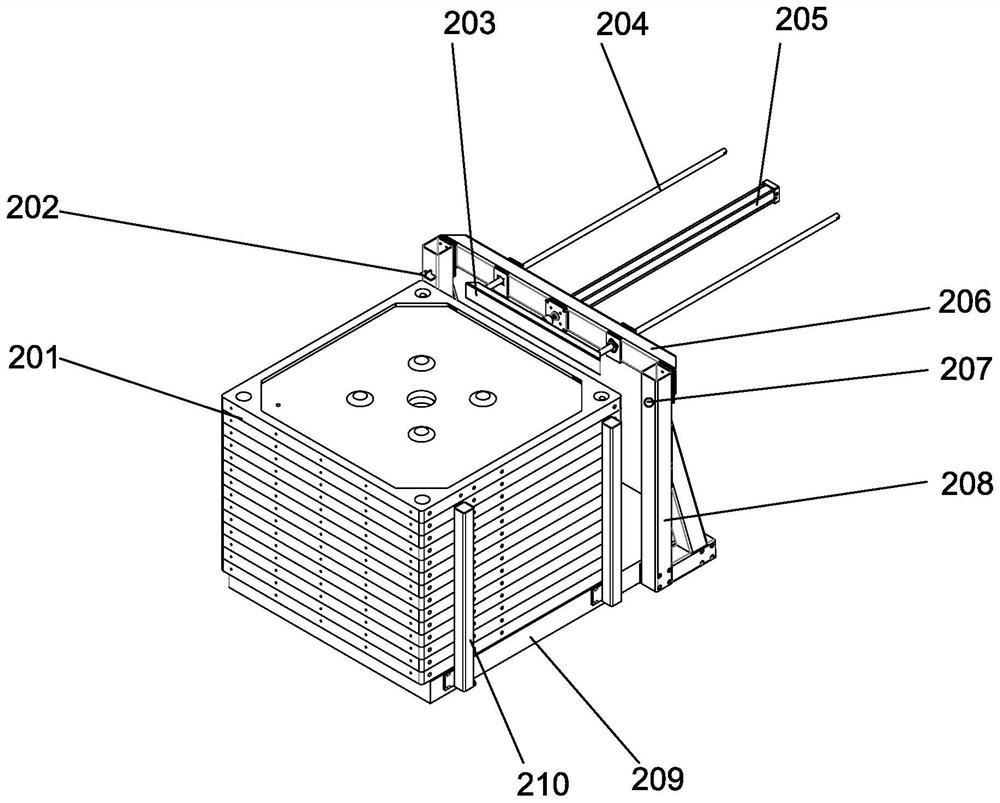

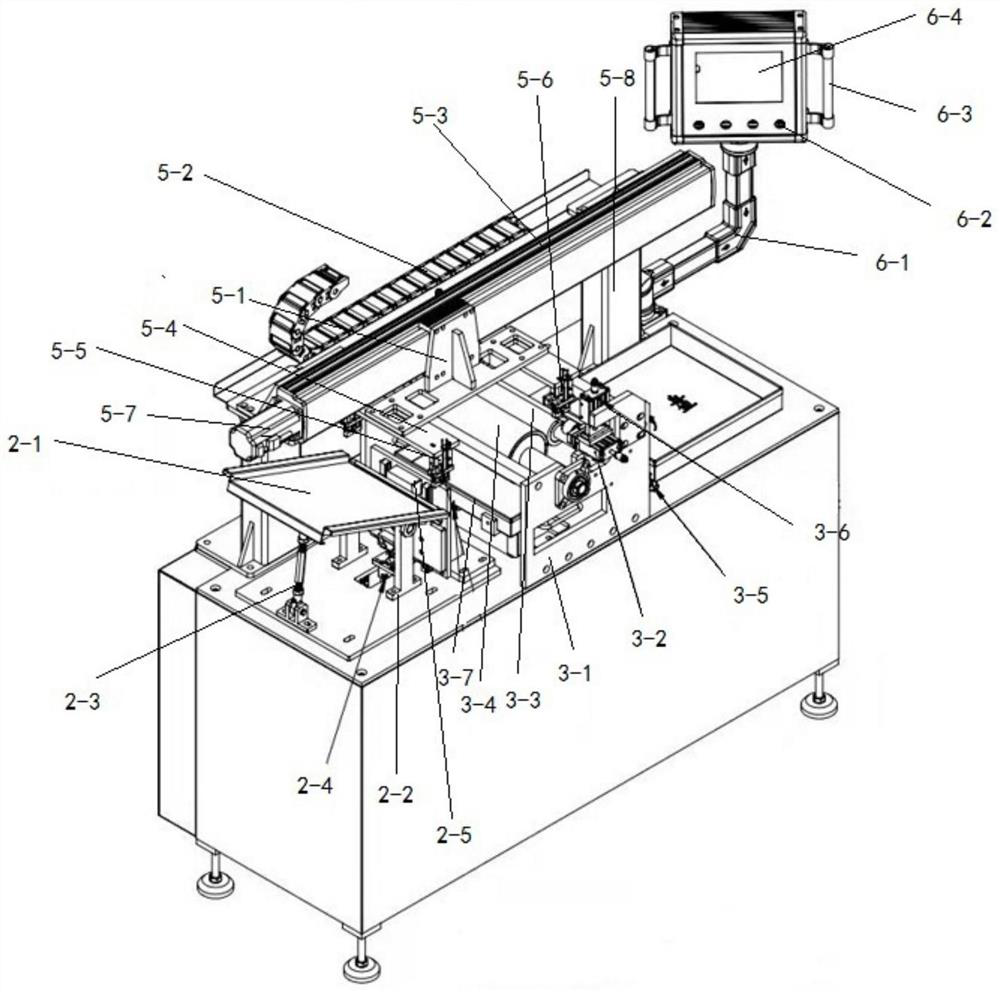

Automatic chip production equipment, system and method

PendingCN108447806AImprove production inefficiencyIncrease productivitySemiconductor/solid-state device manufacturingCode moduleVisual detection

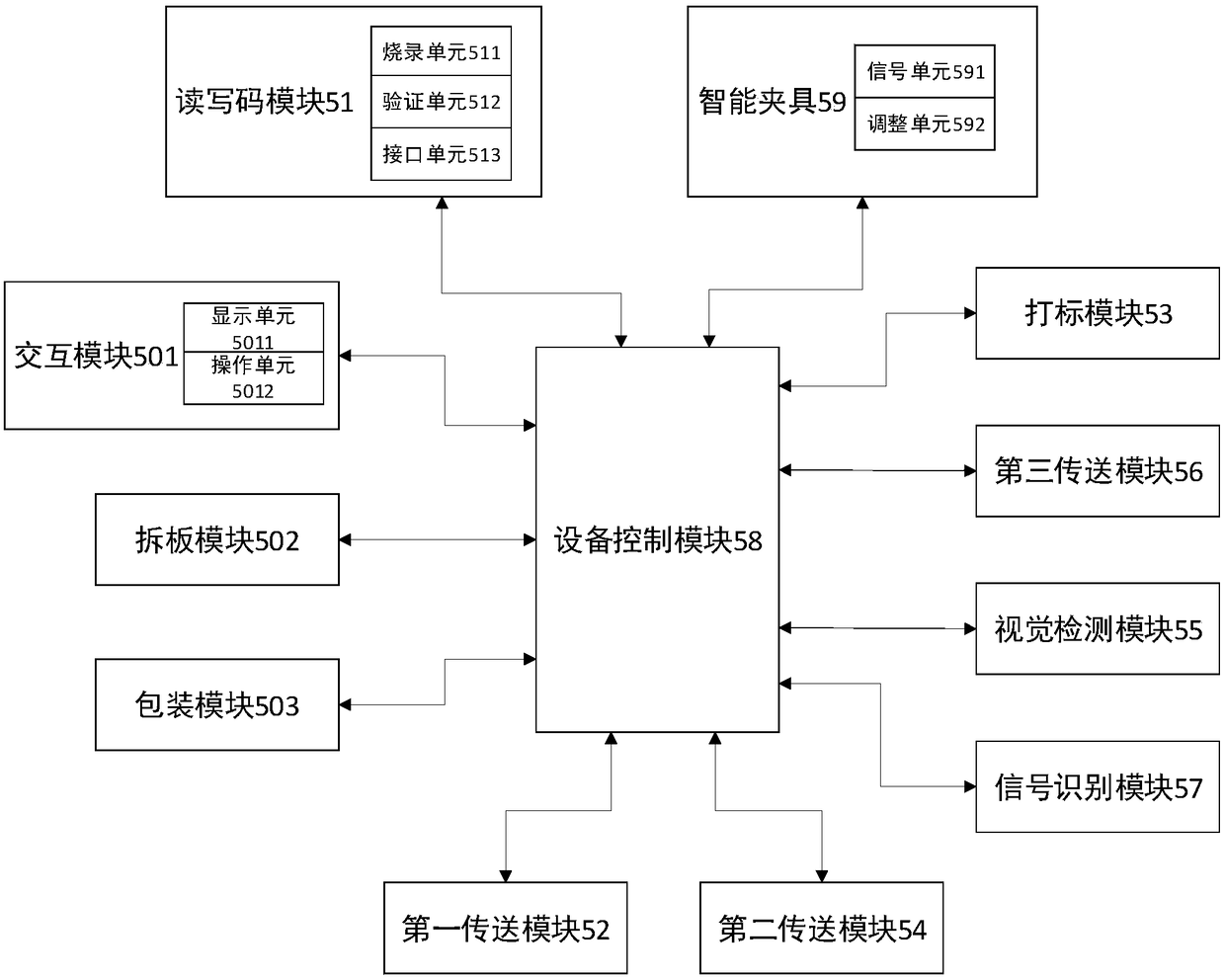

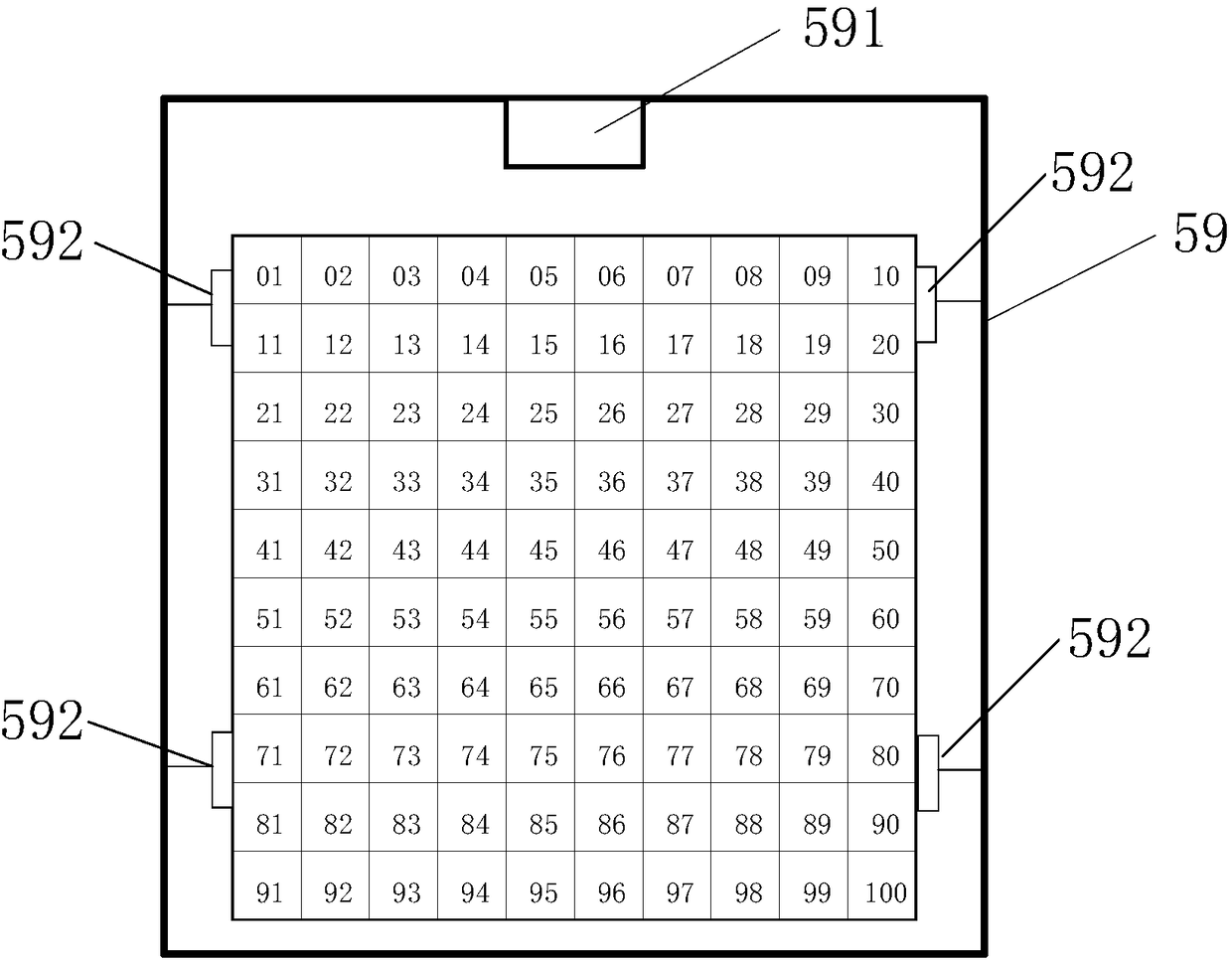

The invention discloses an automatic chip protection system. The automatic chip protection system comprises a master control module, a storage module, an ERP database, a communication module and automatic chip production equipment, wherein the automatic chip production equipment comprises an equipment control module and a reading-writing code module, a first transmission module, a marking module,a second transmission module, a visual detection module, a third transmission module, a signal identification module and an intelligent fixture which are in communication connection with the equipmentcontrol module, the equipment control module is in communication connection with the master control module and the storage module by the communication module, communication connection between the master control module and the ERP database is achieved by the communication module, the automatic chip production equipment is used for automatically producing and processing a chip under the control ofthe master control module, the production efficiency and the yield of the chip are improved.

Owner:HANGZHOU CHIPJET TECH

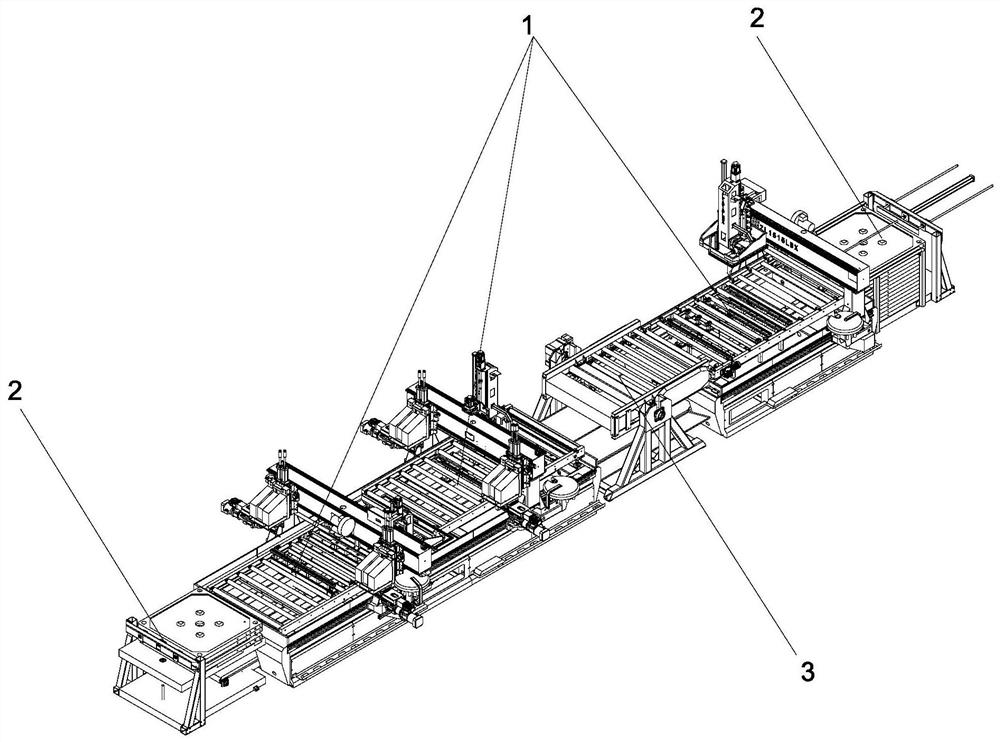

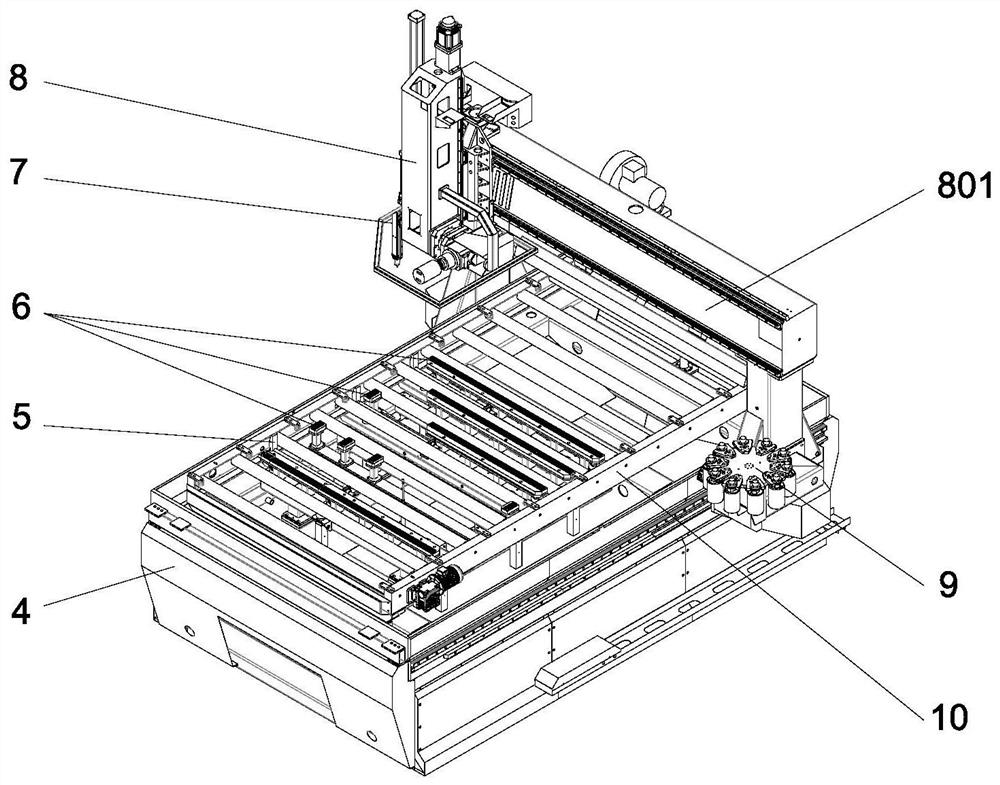

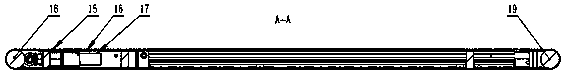

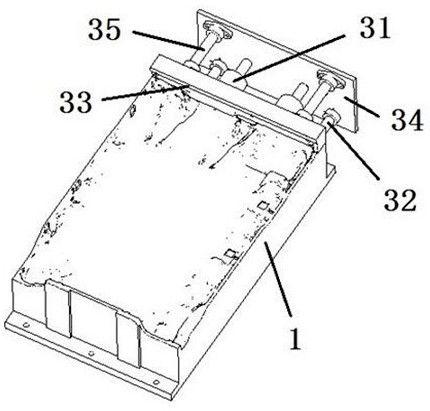

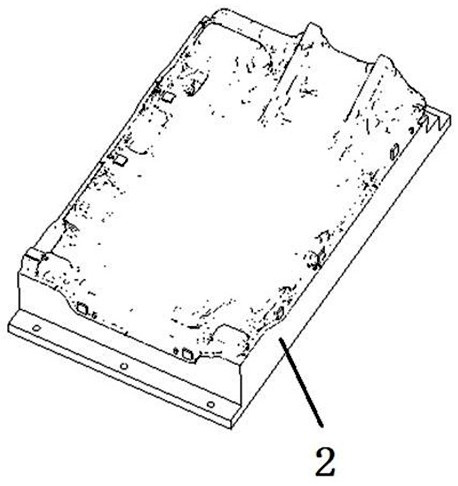

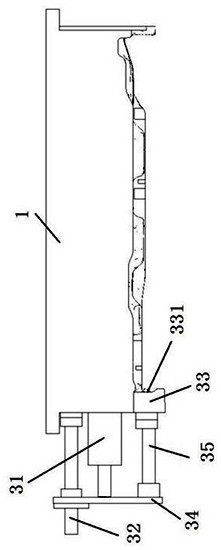

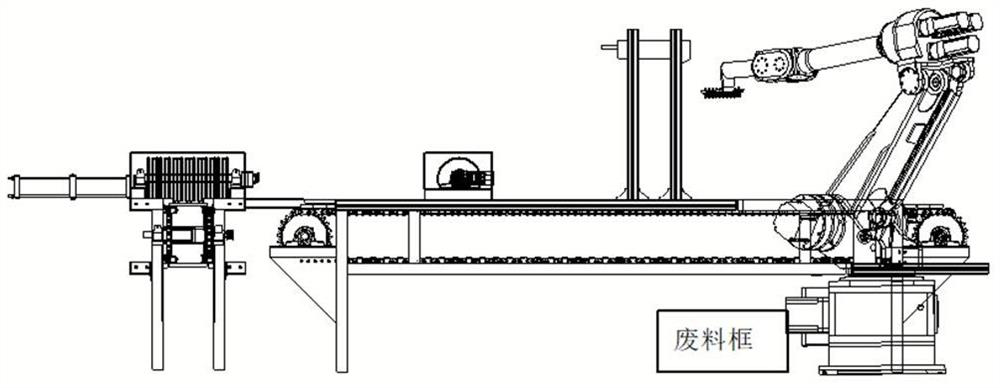

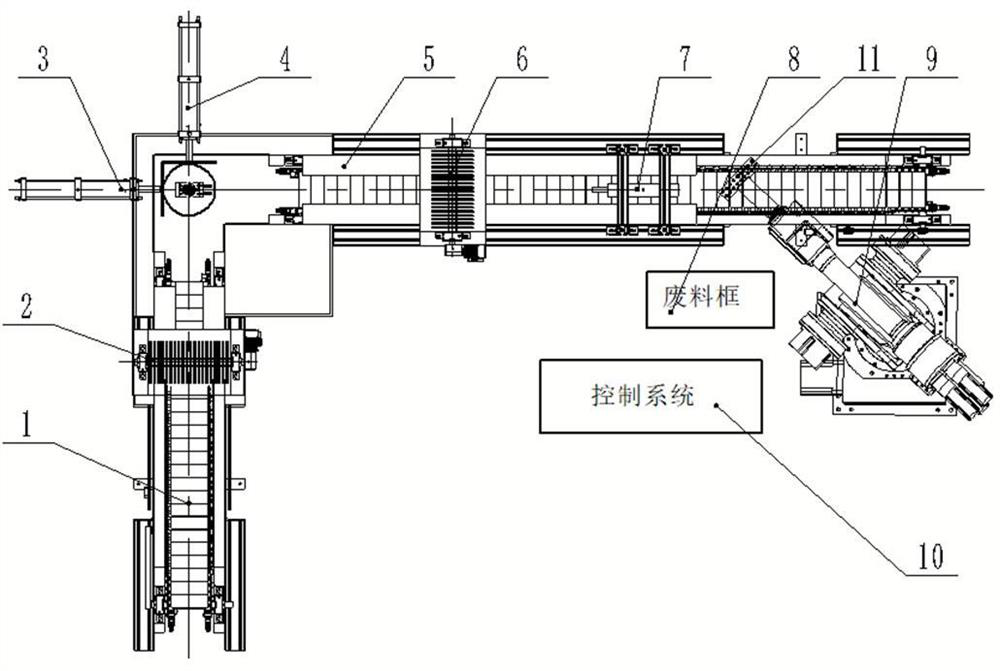

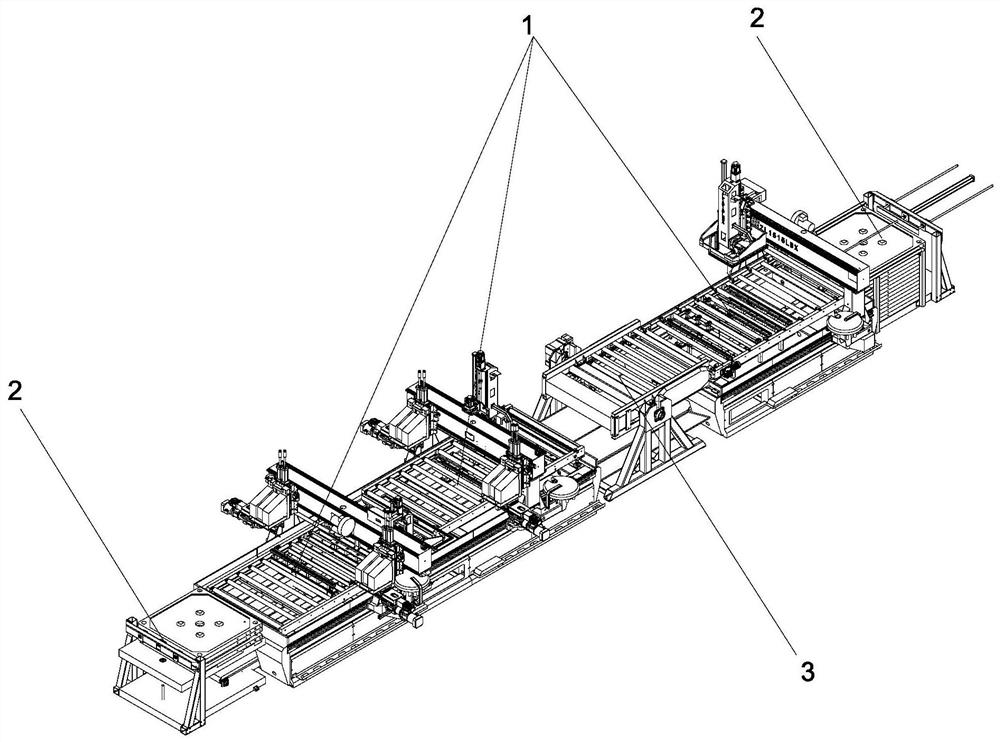

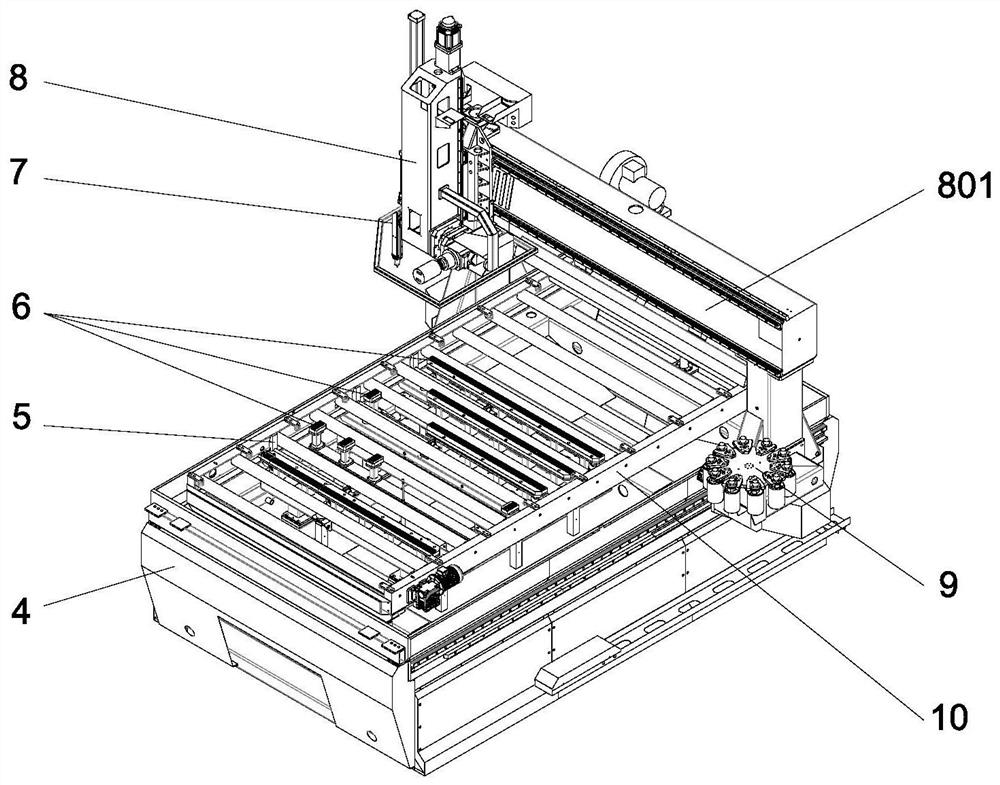

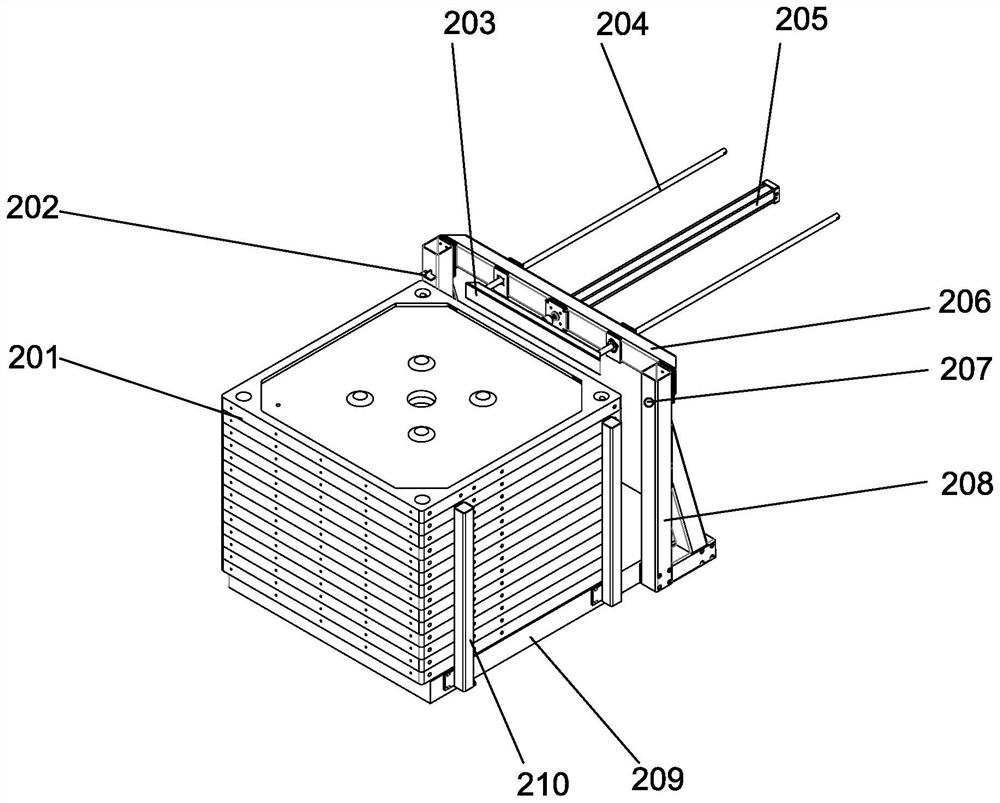

Full-automatic filter plate processing production line

ActiveCN112428340ARealize processing and productionRealize automatic feeding processMetal working apparatusWater filterProcess engineering

The invention relates to the field of processing of filter plates of water filters, in particular to a full-automatic filter plate processing production line which comprises a plurality of processingcenters, each processing center comprises a conveying mechanism used for conveying a filter plate workpiece, an adsorption device used for fixing the filter plate workpiece, a processing mechanism used for processing, a positioning device used for positioning the workpiece, a processing tool magazine used for storing processing tools, a workpiece measuring device used for measuring the size of theworkpiece, a base table used for mounting and fixing the devices, and a control device used for controlling the devices; and an overturning mechanism used for converting the processing face of the workpiece is further arranged between the two processing centers. Full-automatic filter plate production can be achieved.

Owner:济南快克广宣数控机械有限公司

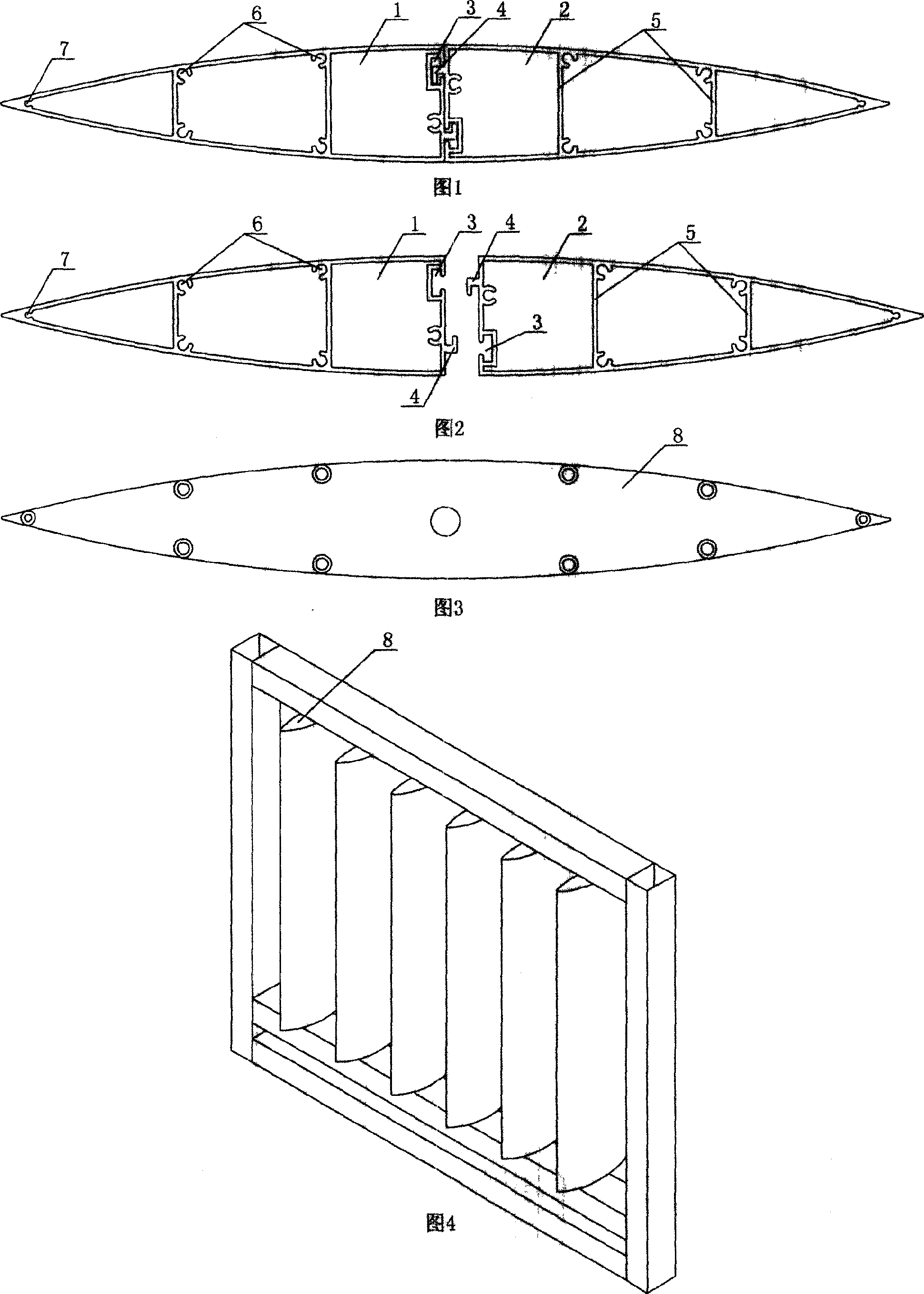

Super large cross-sectional aluminum alloy beancurd leaf

InactiveCN101012729ARealize processing and productionEasy to assembleVentilation arrangementLight protection screensMaterials scienceAluminium alloy

The invention provides an aluminum alloy louver with ultra-large section, which is provided with simple structure and durability, which comprises left and right half leafs. Left and right half leafs are connected with each other by inserted-connected or buckled-connected structure. The buckled-connected structure is that C-shape notch and L-shape hook strip buckled with each other are formed on corresponding side faces of left and right half leafs. Thereinto, there are reinforced ribs in inner cavities of left and right half leafs. End covers are fixed on two side end faces of aluminum alloy louver. After the technology project is adopted, manufacture and production of aluminum alloy louver with ultra-large section can be realized. The assembly of right and left louvers is simple and easy. The product is durable.

Owner:曹湛斌

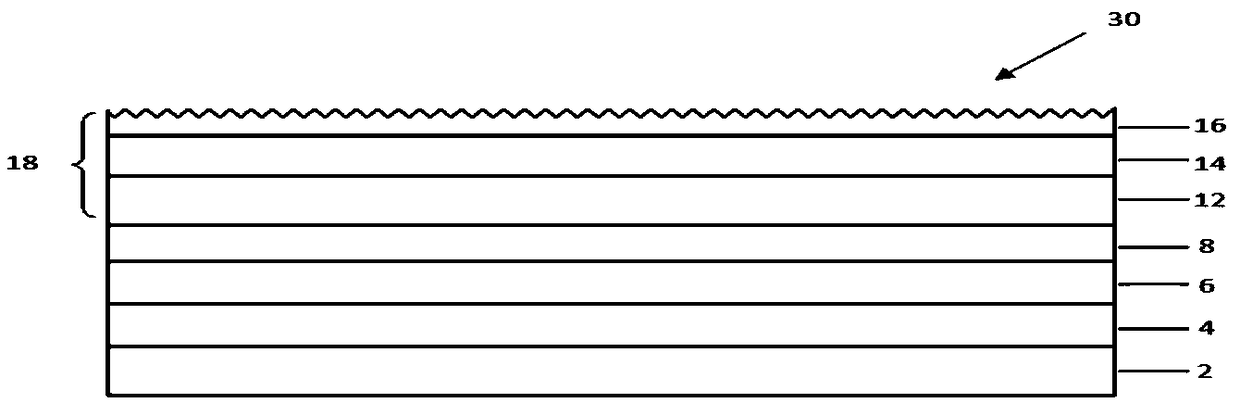

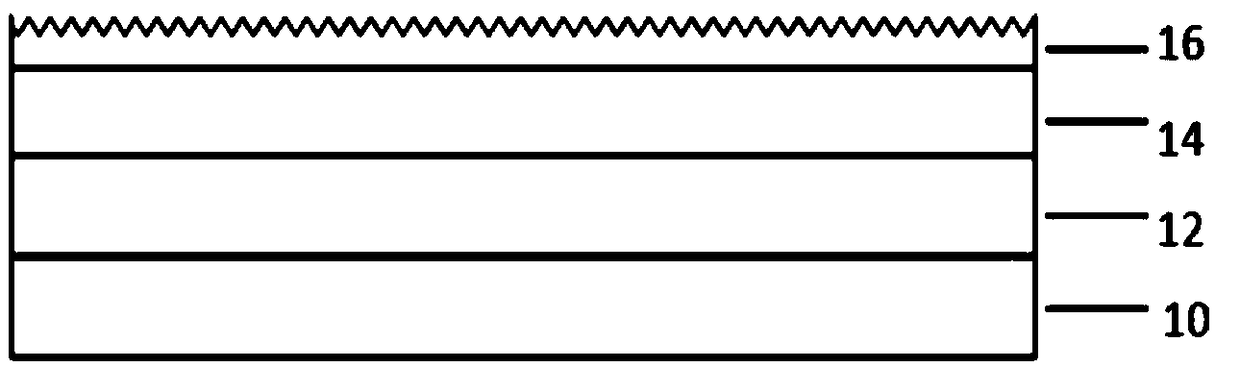

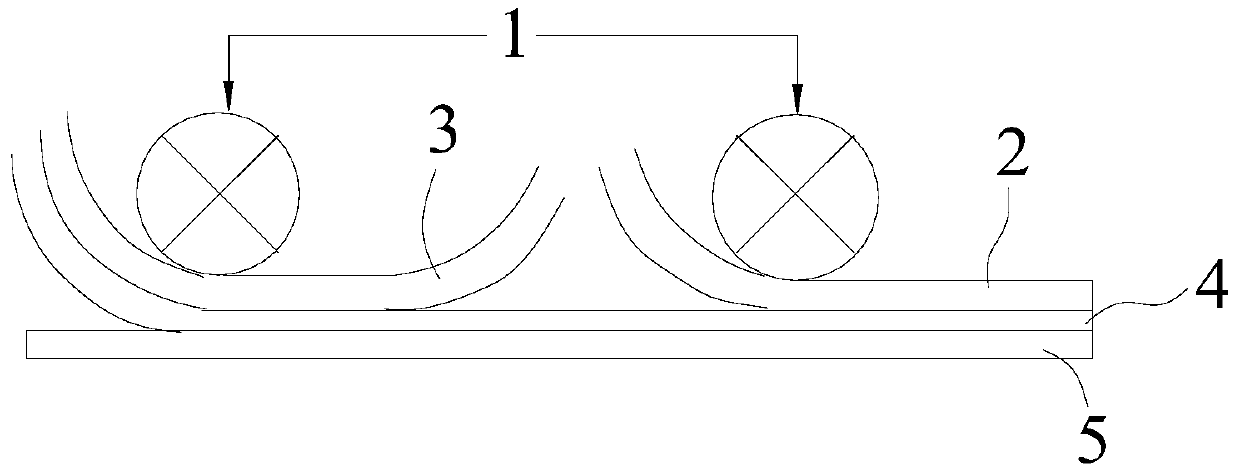

Light extraction film for OLED illumination device and manufacturing method thereof

InactiveCN108899435AFacilitates changing the direction of transmissionReduce glare effectsMaterial nanotechnologySolid-state devicesTectorial membraneNanoparticle

The present invention relates to a light extraction film for an OLED illumination device. The light extraction film is composed of a supporter; a low-refractive-index adhesive layer and a protective film which are disposed on a side of the supporter; and a high-refractive-index uneven coating disposed on the other side of the supporter. The main components of the low-refractive-index adhesive layer comprise 60 to 70 parts of resin, 17 to 27 parts of first diluent, 10 to 15 parts of nanoparticles, and 2 to 5 parts of bridging agent and curing agent. The main components of the uneven coating comprise 50 to 55 parts of film-forming resin, 10 to 14 parts of the second diluent, 15 to 20 parts of nanoparticle material, 8 to 15 parts of polymer microspheres, and 2 to 5 parts of curing agent. Thelight extraction film can be directly attached to the light-emitting surface of the OLED illumination device, and increases a light extraction rate to about 80%. The light extraction film also has ananti-dazzle effect and a function of equalizing the light of a light-emitting device. The light extraction film can be manufactured by a roller-to-roller wet coating method, and is convenient to produce and low in cost.

Owner:CHINA LUCKY FILM CORP

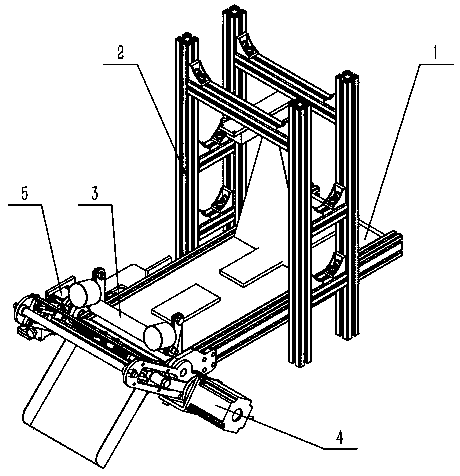

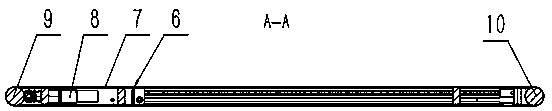

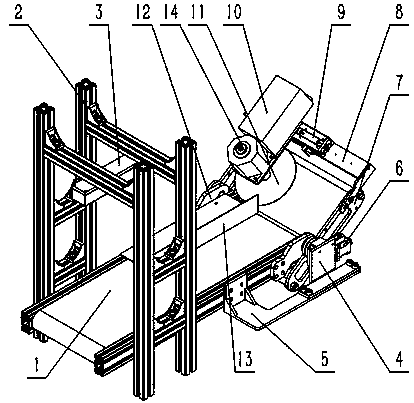

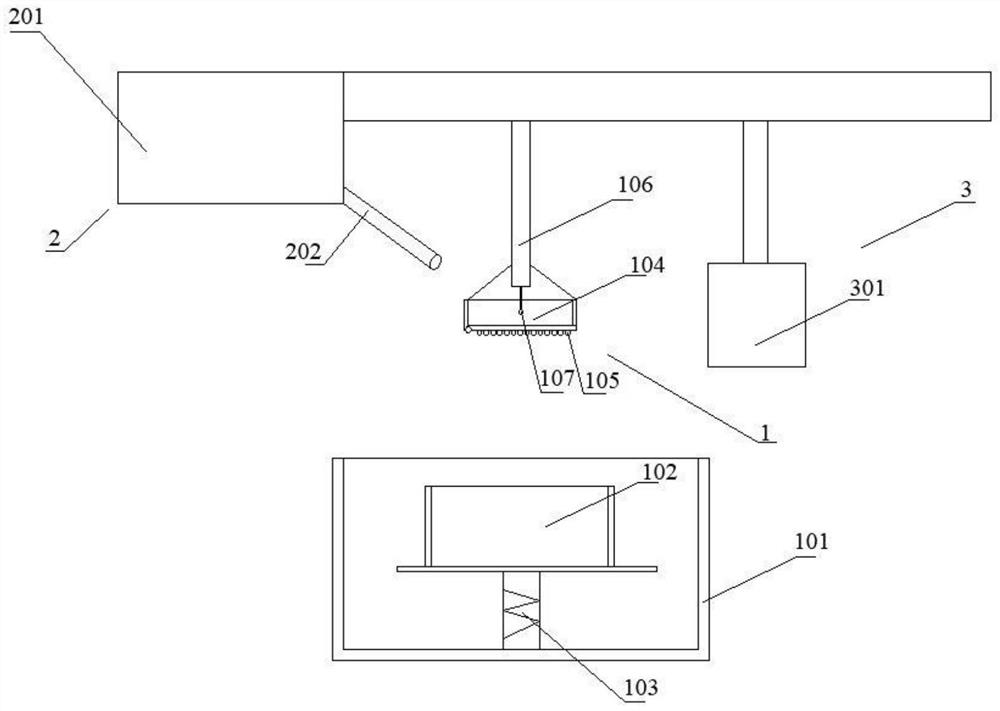

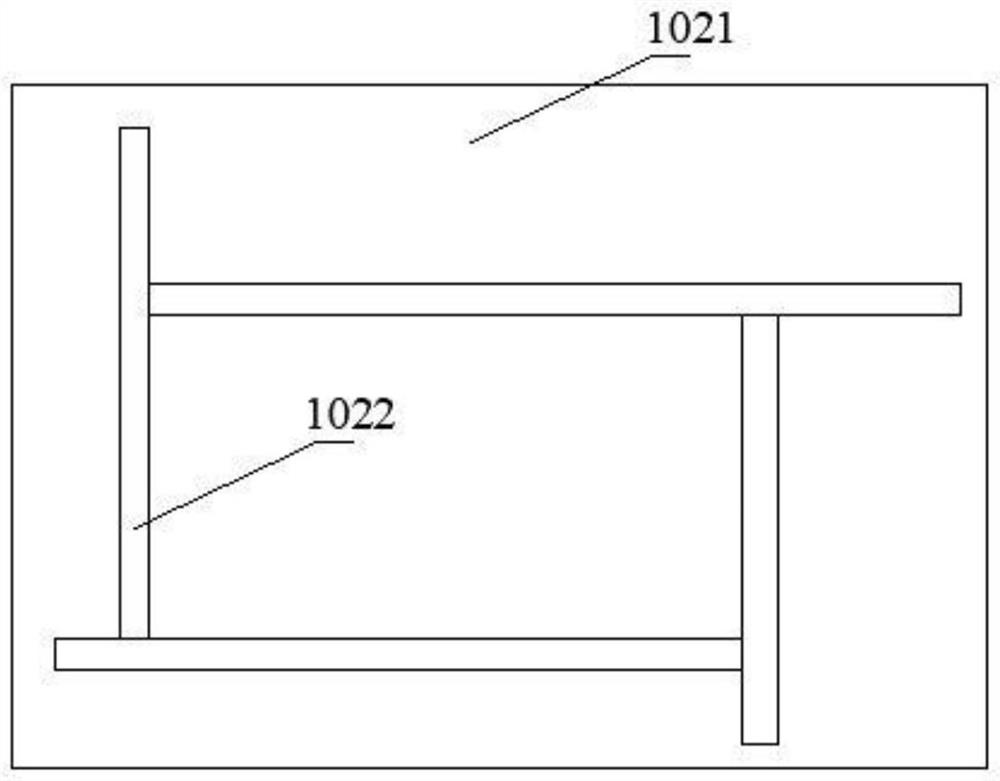

Intelligent device for squid slice and slicing method

InactiveCN109805069ARealize automatic cutting functionRealize processing and productionFish processingData processing systemEngineering

The invention discloses an intelligent device for squid slice and a slicing method. The intelligent device provided by the invention mainly comprises a belt conveying mechanism, a 3D scanning system,a fixed pressing mechanism, a cutting and angle adjusting mechanism. The belt conveying mechanism is used for conveying a squid, and the 3D scanning system is used for scanning and imaging of the squid during the conveying of the belt conveying mechanism, and a data processing system is used for controlling the conveying distance of the belt conveying mechanism and the cutting angle of the cuttingand angle adjusting mechanism, the fixed pressing mechanism is used for fixing and pressing the squid during cutting, and the cutting and angle adjusting mechanism is configured to receive a controlcommand issued by the data processing system, and to perform fixed-weight and fixed-shape cutting on the squid on a cutting station. The device in the invention can realize the automatic cutting function of the squid with fixed weight and fixed shape, solve the problems of low manual cutting efficiency and low cost rate, and realize the automatic and intelligent processing and production of squids.

Owner:OCEAN RES CENT OF ZHOUSHAN ZHEJIANG UNIV +1

Squid slice intelligent production device and method

PendingCN109805067ARealize automatic cutting functionRealize processing and productionFish processingMechanical engineering3d scanning

The invention discloses a squid slice intelligent production device and method. The intelligent production device provided by the invention mainly comprises a belt conveying mechanism, a 3D scanning system, a circular knife cutting and angle adjusting mechanism. The belt conveying mechanism is used for conveying a squid, and the 3D scanning system is used for scanning and imaging of the squid during the conveying of the belt conveying mechanism, and a data processing system is used for controlling the conveying distance of the belt conveying mechanism and the cutting angle of the circular knife cutting and angle adjusting mechanism, and the circular knife cutting and angle adjusting mechanism is configured to receive a control command issued by the data processing system, and to perform fixed-weight fixed-shape cutting on the squid on a cutting station. The device in the invention can realize the automatic cutting function of the squid with fixed weight and fixed shape, solve the problems of low manual cutting efficiency and low cost rate, and realize the automatic and intelligent processing and production of squids.

Owner:浙江大洋兴和食品有限公司 +1

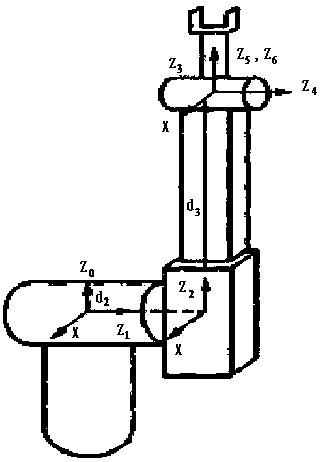

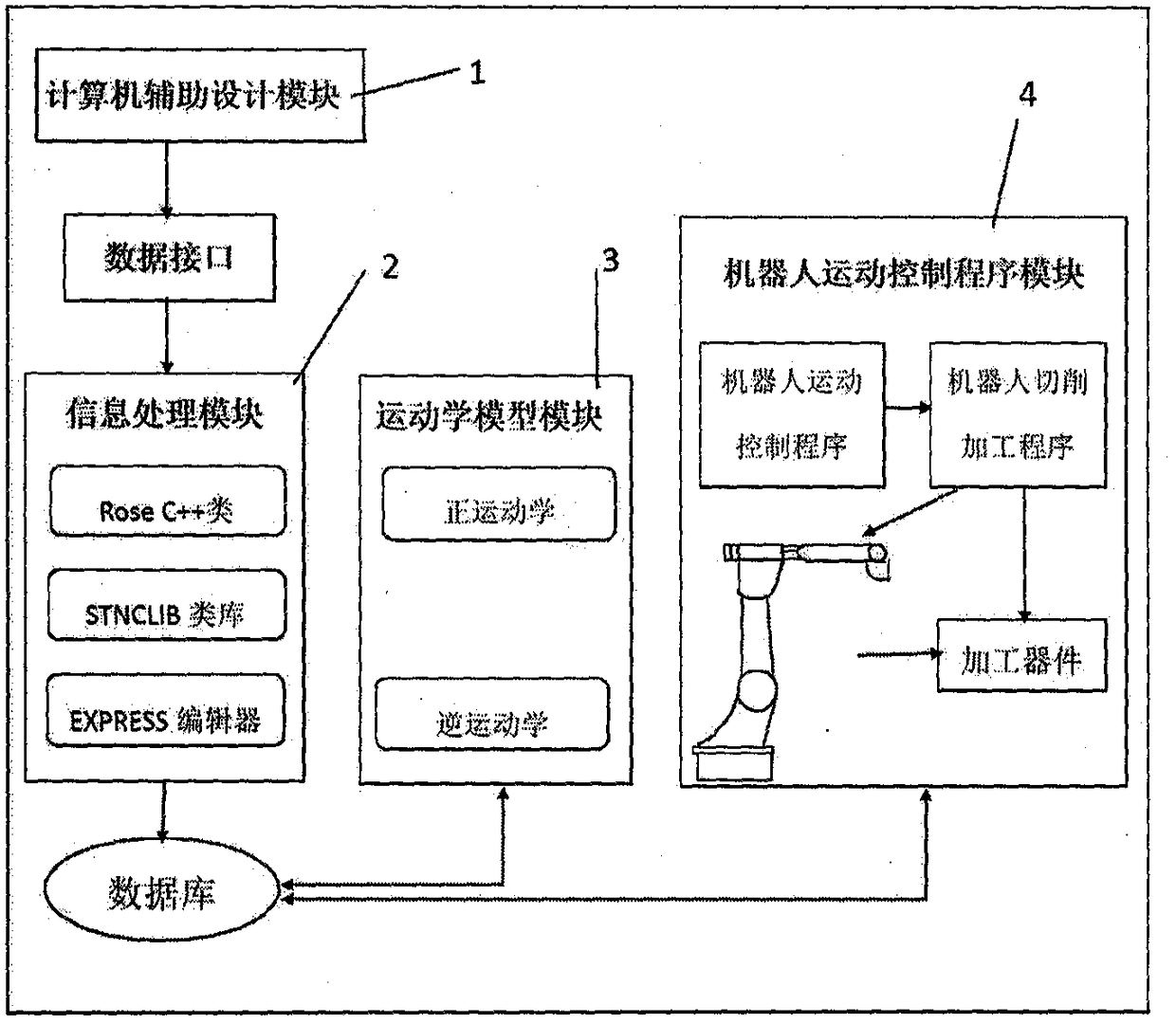

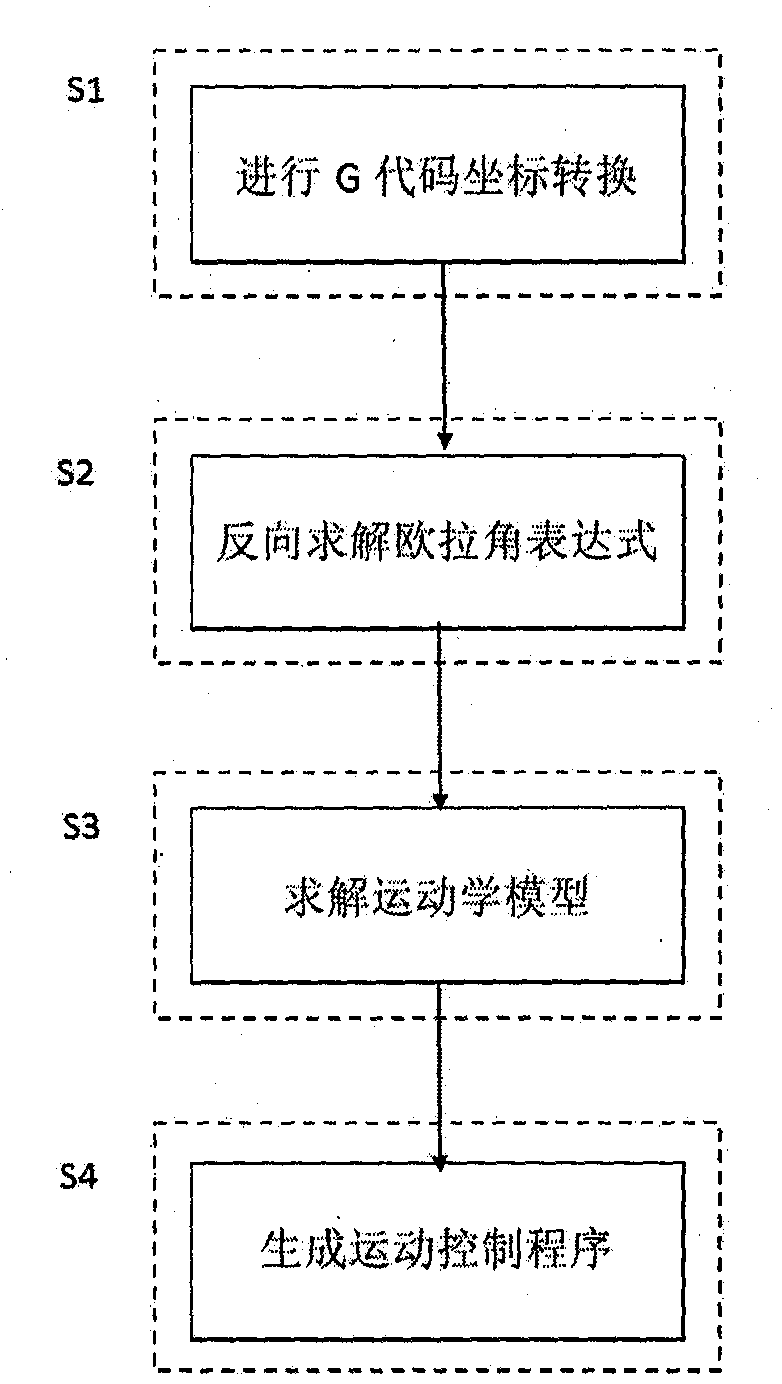

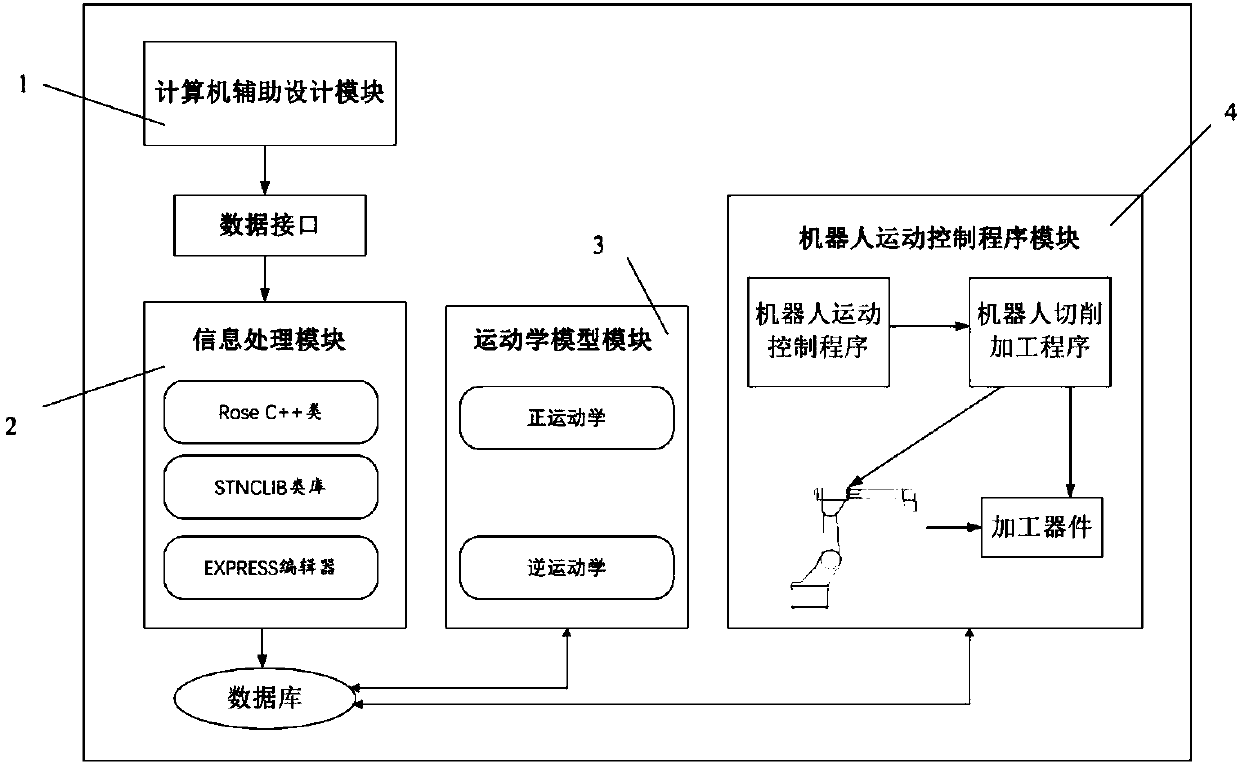

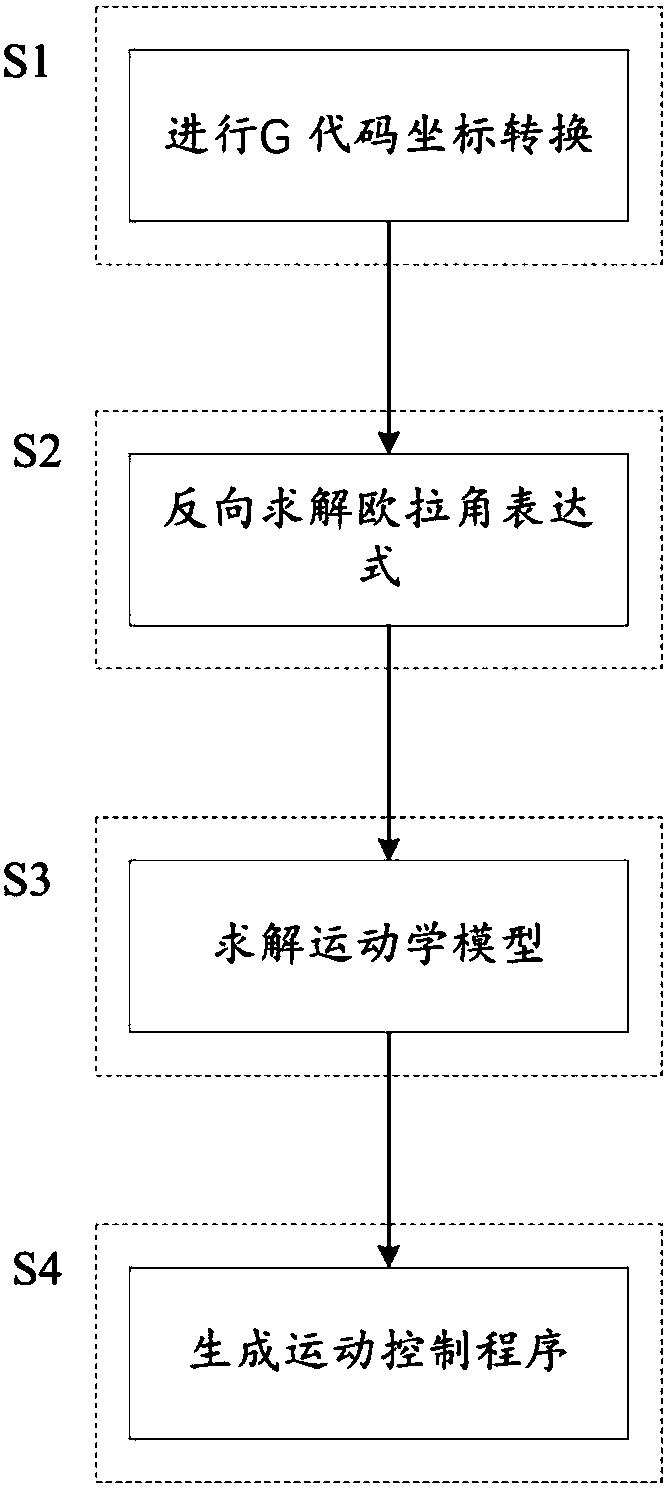

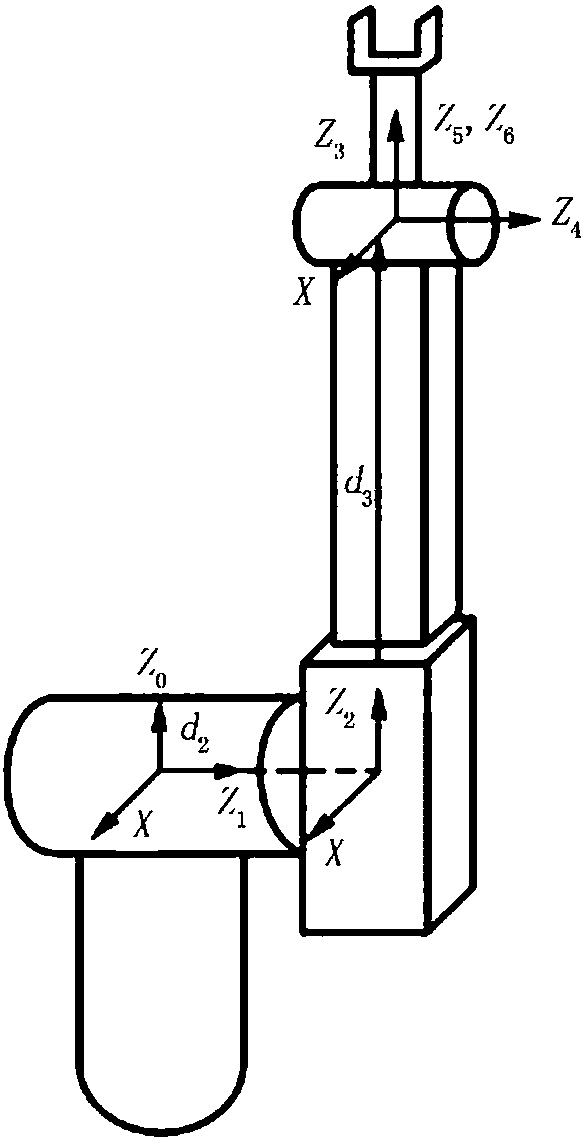

Agricultural processing robot system and control method thereof

InactiveCN108205293ARealize processing and productionProgramme controlComputer controlProcessing InstructionInformation processing

The invention discloses an agricultural processing robot system and a control method thereof. The system comprises a computer-aided design module, an information processing module, a motion model module and a robot motion control program module. The computer-aided design module is responsible for designing CAD dimension requirements of parts and generating coordinate files base on process requirements. The information processing module is used for completing acquisition of specific control information in production and processing procedures. The motion model module is used for establishing a motion model of a cutting processing robot and analyzing forward and inverse kinematics characteristics. The robot motion control program module is responsible for planning and designing a cutting processing program and generating a motion control program automatically. According to the invention, the processing instruction of the robot motion control program can be generated automatically and thusthe robot end is driven directly to perform a cutting tool motion, thereby realizing processing production of parts.

Owner:GUANGDONG POLYTECHNIC NORMAL UNIV

Ultra-high molecular weight polyethylene modification ternary system being easy to produce and process

The invention discloses an ultra-high molecular weight polyethylene modification ternary system being easy to produce and process. The modification ternary system comprises the following raw materials in percentage by weight: more than 50% and less than 100% of nascent UHMWPE (ultra-high molecular weight polyethylene), more than 0 and less than 50% of self-plasticizer controlled degradation ultra-high molecular weight polyethylene and more than 0 and less than 50% of external plasticizer; the self-plasticizer controlled degradation ultra-high molecular weight polyethylene and the external plasticizer are adopted for simultaneously modifying the nascent UHMWPE. In the modification ternary system, the controlled degradation ultra-high molecular weight polyethylene can better keep the excellent performances of the nascent UHMWPE, and the controlled degradation ultra-high molecular weight polyethylene can be simultaneously interlaced between molecules of the nascent UHMWPE to play a disentanglement role; by adding the external plasticizer, the bonding effect between macromolecules of the nascent UHMWPE can be improved or the lubricating effect between the UHMWPE and a processing device can be increased.

Owner:CHONGQING UNIV OF TECH

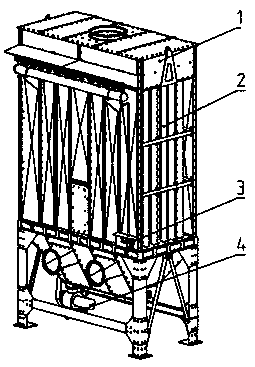

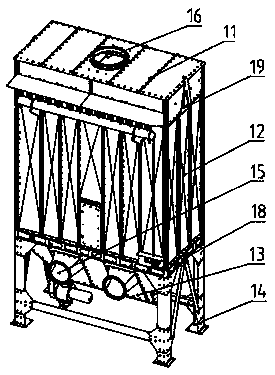

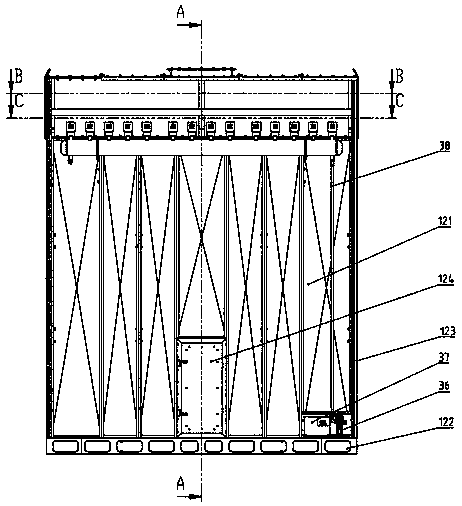

Pure-bolt-connection pulse bag type dust collector

InactiveCN110841380AAvoid pollutionEliminate all the disadvantages caused by weldingCombination devicesDispersed particle filtrationBaghouseEnvironmental engineering

The invention belongs to the technical field of protection devices, and specifically relates to a pure-bolt-connection pulse bag type dust collector, which comprises a frame shell, a filtering bag assembly, a blowing and ash removal device and an ash discharge device, wherein the filtering bag assembly and the ash discharge device are arranged in the frame shell, the blowing and ash removal deviceis arranged below the outer side, the filtering bag assembly arranged in a lower box body is used for supporting filtering bags, the filtering bags are tensioned and kept in a certain shape in the filtering and ash removal state so as to prevent the filtering bags from being folded and damaged, the blowing and ash removal device is used for removing accumulated ash on the surface of a cloth bag,and the ash discharge device is used for achieving mechanical ash discharge. According to the invention, all parts of the equipment are made of galvanized materials, and the whole structure does not adopt welding, so that all defects caused by welding are eliminated, the paint spraying procedure is thoroughly removed, and the environmental pollution caused by paint spraying is avoided; and the filtered gas is concentrated towards the center of the airflow partition plate, so the phenomenon that no gas penetrates through the filtering bag on the edge is avoided so as to improve the utilizationrate of the filtering bag to the maximum degree and effectively improve the dust removal efficiency of the equipment.

Owner:酒泉市汉鑫科技有限公司

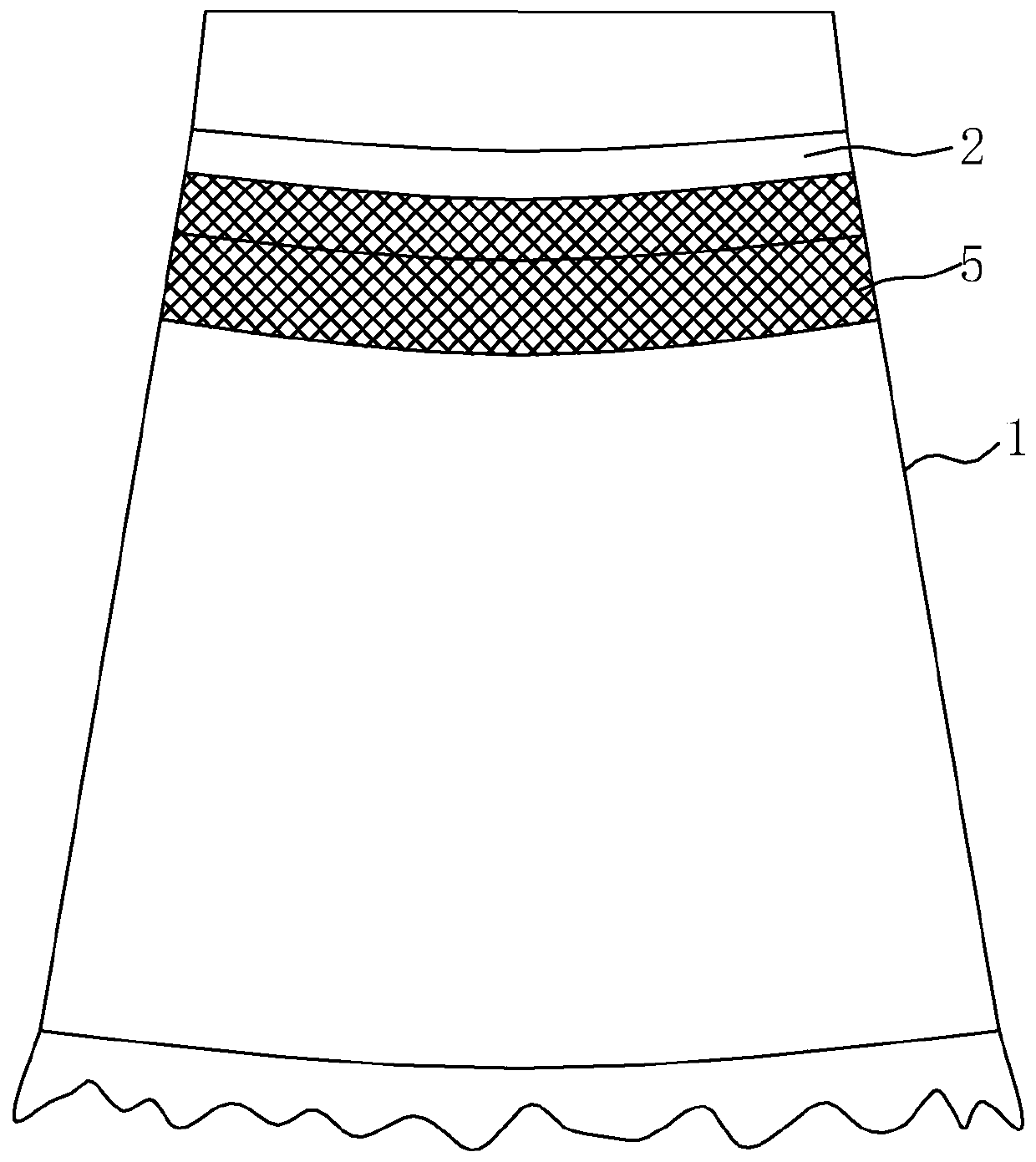

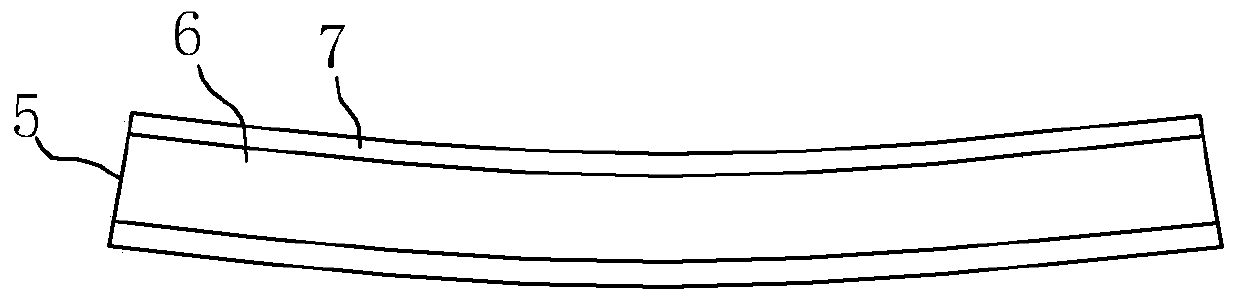

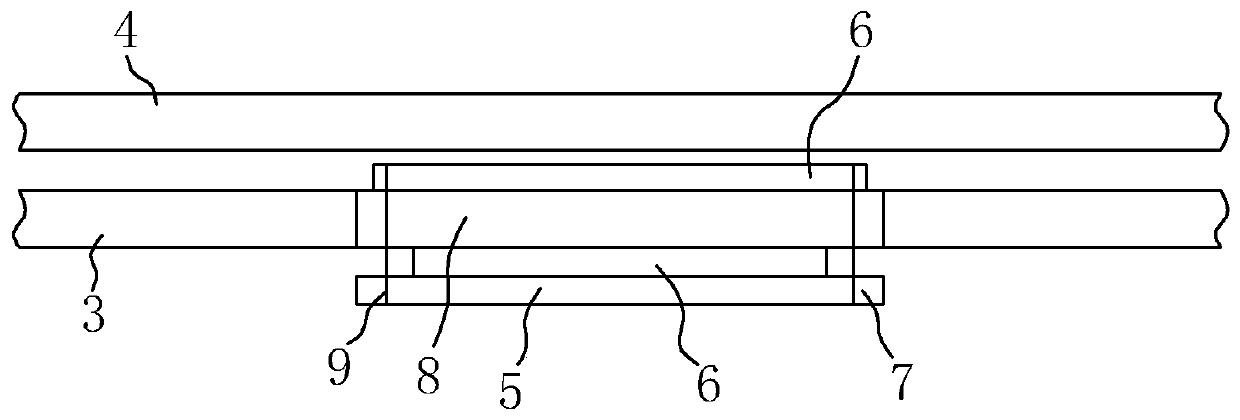

Abdomen-binding lower garment and manufacturing process thereof

PendingCN110214990AImprove concealmentPlay a corset effectTrousersSkirtsPulp and paper industryAbdomen

The invention discloses an abdomen-binding lower garment and a manufacturing process of the abdomen-binding lower garment. The abdomen-binding lower garment comprises a lower garment body, the lower garment body comprises a wrapping part wrapping the lower abdomen, and an abdomen-binding belt is arranged at the wrapping part of the lower garment body. The abdomen-binding belt is arranged at the wrapping part, corresponding to the lower abdomen, of the lower garment, the abdomen-binding belt can play a good abdomen-binding role, so that the phenomenon that the integral wearing aesthetic sense of the lower garment is influenced due to the prominent lower abdomen is avoided, the wearing trouble brought by the prominent lower abdomen during wearing of people in the prior art can be effectivelysolved, meanwhile, the abdomen-binding belt is arranged at the inner side of the lower garment body, so that no influences are caused to the integral appearance of the lower garment, in addition, during the manufacturing process, the suitable abdomen-binding belt can be obtained through cutting according to the actual demand, after the abdomen-binding strip is subjected to shaping and fixing of an adhering liner, the follow-up operation of sewing and fixing the abdomen-binding belt to the lower garment body is facilitated, the manufacturing process is simple, and the manufacturing efficiencyis high.

Owner:云创设计(深圳)集团有限公司

Agricultural robot system and control method

InactiveCN109901517ARealize processing and productionProgramme controlComputer controlInformation processingComputer Aided Design

The invention discloses an agricultural robot system and a control method. The system comprises a computer aided design module, an information processing module, a motion model module, and a robot motion control program module; the computer aided design module is responsible for designing a parts CAD size requirement, and generating a coordinate file according to the process requirement; the information processing module is used for accomplishing the acquisition of specific control information in the production and process; the motion model module is used for establishing a cutting processingrobot motion model, and analyzing the positive and inverse kinematics characteristics; and the robot motion control program module is responsible for planning the program for designing the cutting processing, and automatically generating a motion control program.

Owner:广州映博智能科技有限公司

A superfine grinding system for cement production

ActiveCN111632726BRealize processing and productionImprove processing efficiencyGrain treatmentsGear wheelProcess engineering

The invention relates to the field of cement production and processing, in particular to an ultra-fine grinding system for cement production, which includes a support frame and a grinding barrel, and the grinding barrel is sequentially provided with a feeding channel, a shutter mechanism, and four sets of coarse grinders from top to bottom. The crushing mechanism, the fine grinding mechanism, the reverse grinding drive mechanism and the feeding trough, the shutter mechanism includes several movable plates that can be opened and closed, the coarse grinding and crushing mechanism includes grinding rollers that can rotate, the coarse grinding and crushing mechanism and the fine grinding mechanism A screening plate is installed horizontally between the grinding mechanisms, a base is fixed horizontally under the supporting base, the reverse grinding driving mechanism includes a rotatable driving gear and a transmission rod, and a funnel blanking rack is provided at the top of the feeding channel. The shown ultrafine grinding system for cement production can perform a series of operations such as feeding, heating, crushing, and ultrafine grinding through the grinding barrel, which reduces the production process, greatly improves work efficiency, and reduces manual labor intensity. Reduced production costs.

Owner:澄迈华盛天涯水泥有限公司

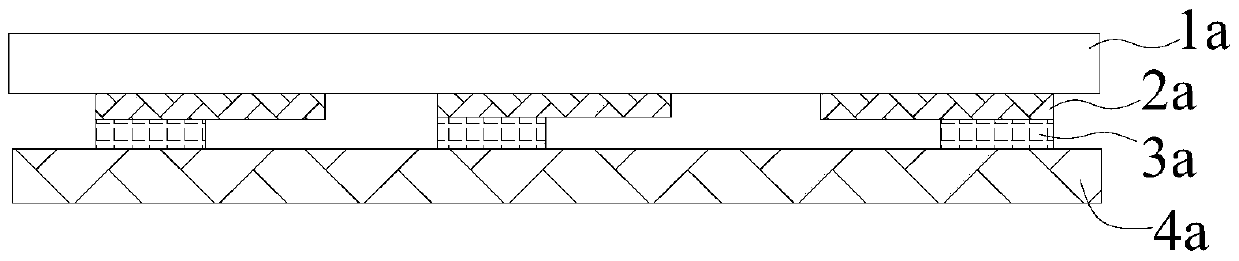

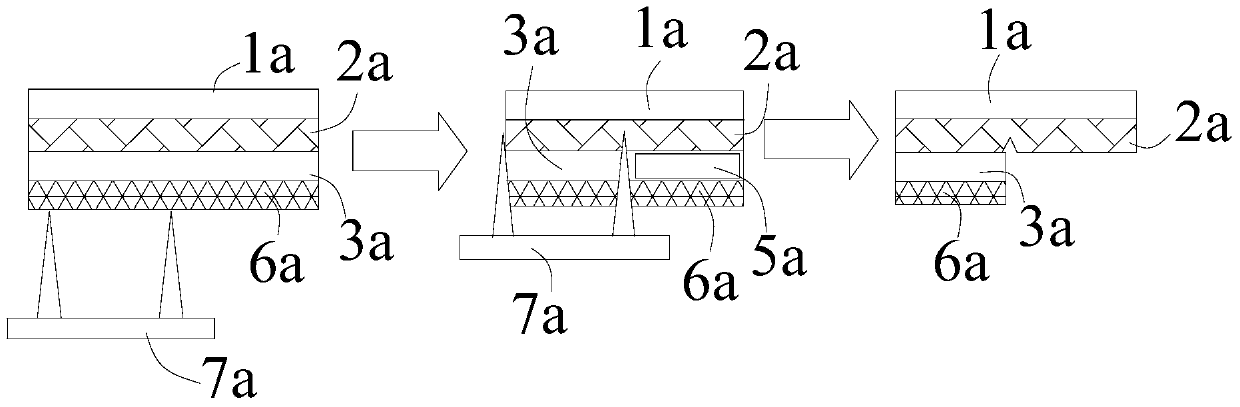

A kind of 3D shaping device and production method of non-woven fabric for automobile seat foam

The invention relates to the technical field of non-woven fabrics, in particular to a 3D sizing device and production method for non-woven fabrics for foaming automobile seats. The non-woven fabric 3D sizing device for automobile seat foaming comprises: an upper mold, a lower mold and a negative angle side pressure mold device; a plurality of concave structures are distributed on one side of the upper mold; There are multiple convex structures distributed on one side of the lower mold; the negative angle side pressure mold device is connected to one side of the upper mold and the lower mold, and mainly includes: a telescopic unit, a guide rod, and a negative angle pressing block , moving plates and connecting rods. The invention solves the problems that the existing non-woven fabric has a low degree of fit with the mold and cannot produce negative angles.

Owner:天津三和泰奥汽车部件有限公司

Production system for producing high-strength composite landscape wallboard

InactiveCN112720868ARealize processing and productionAvoid bouncingSpraying apparatusWorking accessoriesFixed frameIndustrial engineering

The invention discloses a production system for producing a high-strength composite landscape wallboard. The production system comprises a base, a frame is fixedly connected to the top of the base, fixing frames which are symmetrically distributed front and back are fixedly connected to the top of the base, and the sides, close to each other, of the two fixing frames are rotationally connected with one ends of first conveying rollers correspondingly; the sides, close to each other, of the two fixing frames are rotationally connected with one ends of second conveying rollers correspondingly, the left side of the top of the base is rotationally connected with a third conveying roller, the outer sides of the third conveying roller and the second conveying rollers are sleeved with a second conveying belt, and the inner top wall of the frame is fixedly connected with a paint storage box; and the bottom of the paint storage box is fixedly connected with a paint spraying head. The production system is novel in design, ingenious in conception, capable of achieving streamlined processing and production of landscape wallboards, capable of greatly reducing the labor amount of workers, easy to use, high in practicability and suitable for wide popularization.

Owner:安徽华铁高新技术有限公司

UHMWPE modified ternary system that is easy to produce and process

Owner:CHONGQING UNIV OF TECH

Precious metal electrolysis recovery system

PendingCN111910216ARealize the driving operationTo achieve the purpose of electrolysisPhotography auxillary processesElectrolysis componentsElectrolysisMetallurgy

The invention relates to the technical field of precious metal electrolysis equipment, in particular to a precious metal electrolysis recovery system which comprises a recovery system body. The innerend of the recovery system body comprises a treatment device and a communication device, the communication device is arranged at the upper portion of the center of the inner end of the recovery systembody, and the treatment device penetrates through the center of the inner end of the communication device and is fixedly connected with the inner end of the communication device. According to the precious metal electrolysis recovery system, through the arrangement of the treatment device, the purpose of inner-end electrolysis treatment is achieved.

Owner:戚紫宣

Fish slice processing and intelligent sorting integrated device and method

ActiveCN111034774BFully automatedRealize processing and productionFish sortingCephalopods processingBiologyMechanical engineering

The invention relates to an integrated device and method for fish slice processing and intelligent sorting. The invention comprises a fish body longitudinal sprocket conveying mechanism, a fish body transverse sprocket conveying mechanism, a cutting knife row, a propulsion mechanism, a one-side leveling mechanism, a 3D scanning system and a fish body scrap selection and sorting mechanism. Both the fish body longitudinal sprocket conveying mechanism and the fish body transverse sprocket conveying mechanism are arranged with cutting blades, and the 3D scanning system is located on the fish body transverse sprocket conveying mechanism for scanning the fish body after cutting; The fish body leftovers selection and sorting mechanism is used to sort the cut fish bodies, and distinguish qualified fish bodies and fish body leftovers. The invention can realize the automatic cutting of fish body shape and automatic sorting function of cut fish body products, solve the existing problems of low efficiency of manual cutting, low cost rate, difficulty in sorting fish body products after cutting, etc., and realize Automatic and intelligent processing and production of fish body.

Owner:ZHEJIANG UNIV

A kind of processing method of adhesive product

ActiveCN105273647BAvoid it happening againRealize processing and productionFilm/foil adhesives without carriersMetal working apparatusComposite filmPunching

The invention discloses a processing method of an adhesive product, which comprises the following steps: (1) compounding double-sided adhesive on the surface of a first release film; (2) forming the double-sided adhesive, using the double-sided adhesive to die-cut into shape The tool punches out the shape of the double-sided adhesive and punches out the set hole, removes the double-sided adhesive waste, and obtains the formed double-sided adhesive; (3) The release film is formed, and the release film and the protective film are sequentially compounded on the surface of the formed double-sided adhesive , use the release film die-cutting tool set to punch out the shape of the release film to obtain a formed release film, remove the waste of the release film and the first release film, and obtain a semi-finished adhesive product. This processing technology uses double-sided adhesive and release film to form separately, so that the double-sided adhesive is not half-cut on the release film, thus avoiding the generation of half-cut knife marks on the release film, and then realizing the processing of adhesive products without knife marks Production.

Owner:SUZHOU DAXIANG NEW MATERIAL

Single-well split-type heating multifunctional storage tank device

The invention relates to a single-well split-type heating multifunctional storage tank device. The technical scheme of the invention is as follows: the single-well split-type heating multifunctional storage tank device mainly comprises a heating furnace unit and a storage tank unit which are connected by medium circulation pipes and a natural gas pipeline, a safe distance is arranged between the heating furnace unit and the storage tank unit, a heating coil pipe outlet in a furnace body of the heating furnace unit is in a double-flow manner, one path of the two flows is connected with a heat exchange coil pipe in a storage tank through a high-temperature gate valve, and the other path of the two flows is connected with a well shaft lifting heating circulating system through the high-temperature gate valve. The single-well split-type heating multifunctional storage tank device disclosed by the invention has the advantages that the heating furnace unit and the storage tank unite are designed to be of a split structure so that a potential safety hazard in the production process is eliminated, and requirements on discharging oil and water and cleaning pipes by utilizing self oil-gas pressure in the storage tank are met; in addition, the heat exchange coil pipe in the storage tank unit can be flexibly arranged so that heat exchange area is enlarged, crude oil in the storage tank is heated uniformly, a low-temperature area of the crude oil in the storage tank is reduced and the heating time is shortened; in addition, due to a special design of a Y-shaped oil inlet separation pipe, the oil-gas separation effect is improved.

Owner:SHENGLI OILFIELD SANLI GASOLINEEUM TECH DEV

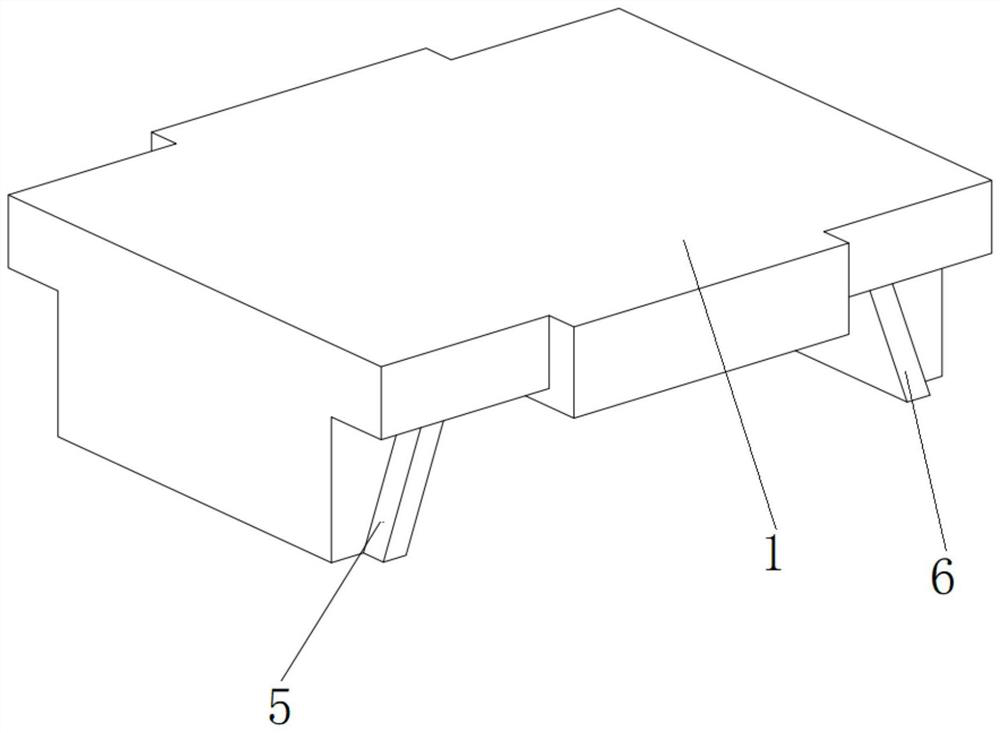

3D curved glass forming mold and forming method thereof

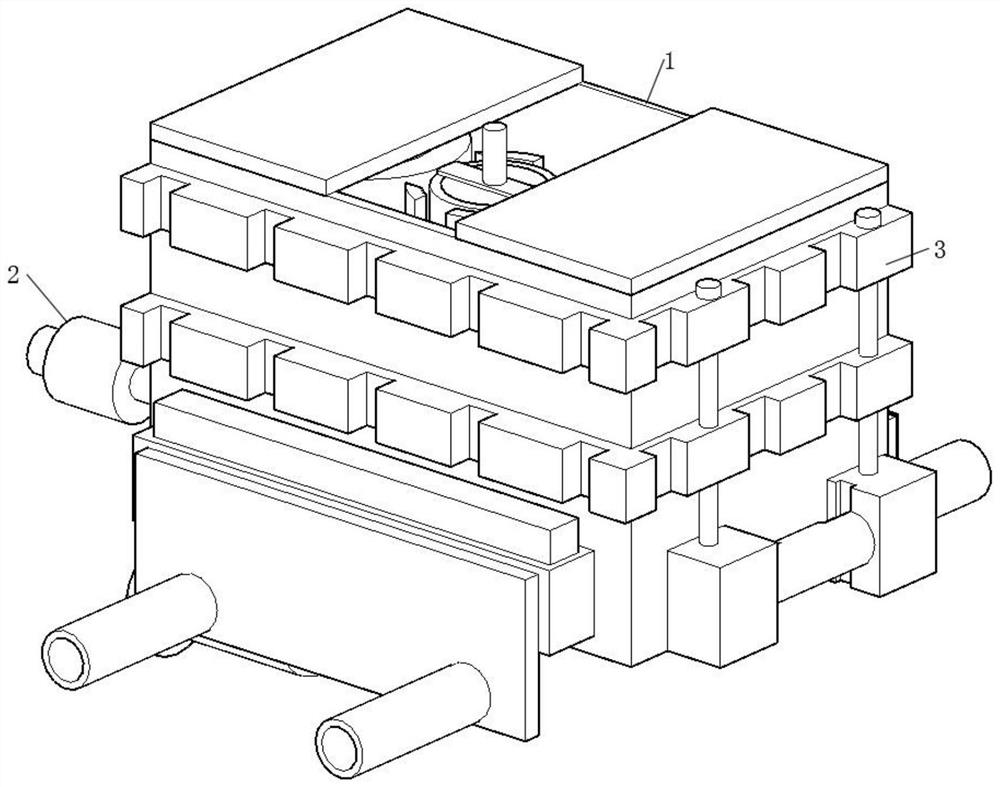

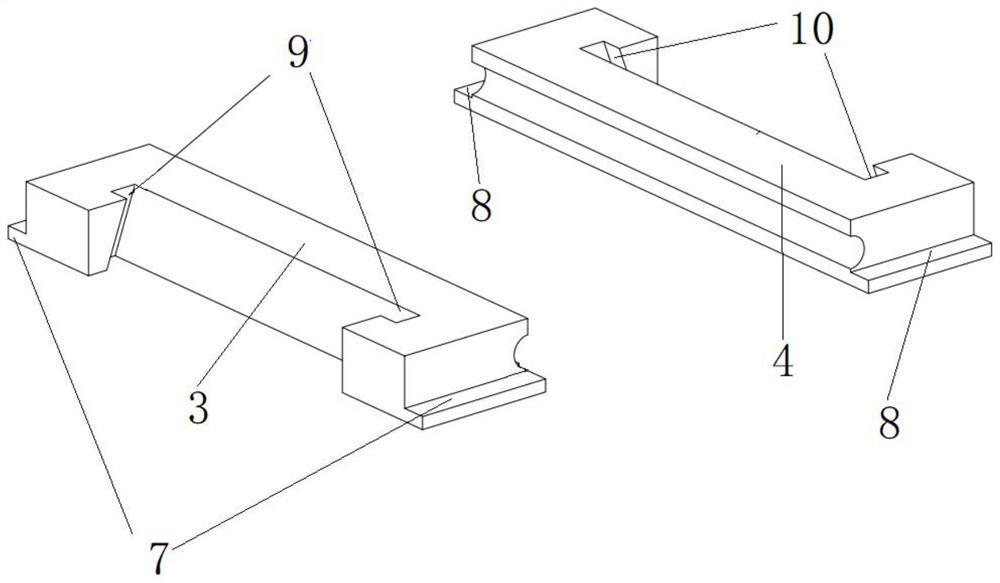

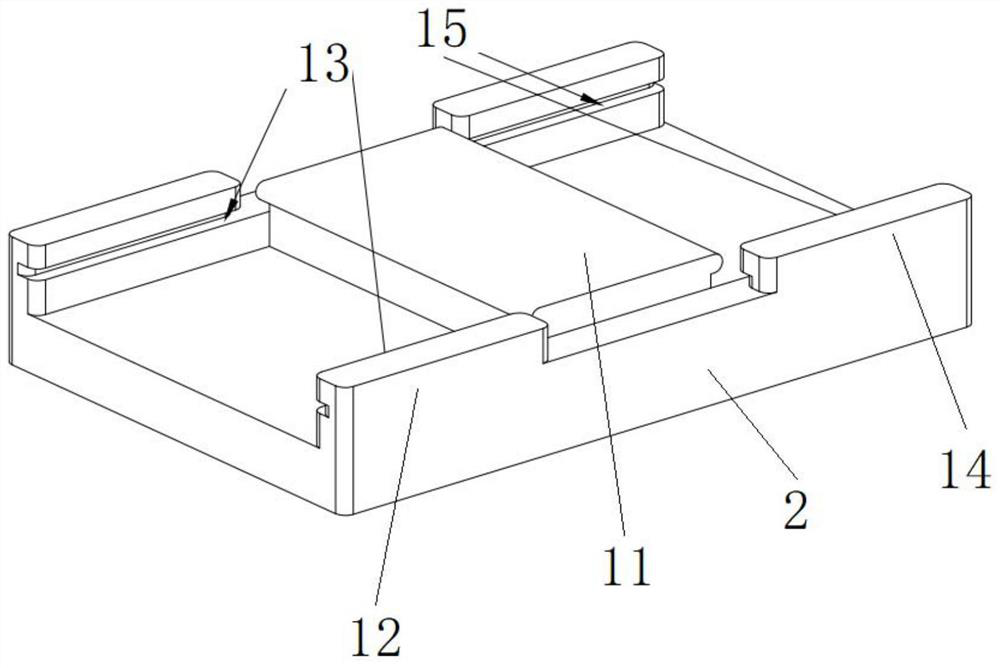

PendingCN114133132ALinkage design structure is simpleControl accuracy does not affectGlass reforming apparatusDisplay deviceEngineering

The invention provides a 3D curved glass forming mold applied to the technical field of electronic display devices, and further relates to a 3D curved glass forming method, an upper mold (1) of the 3D curved glass forming mold is provided with an inclined boss I (5) and an inclined boss II (6), a movable sliding block I (3) is provided with a flat boss I (7), a movable sliding block II (4) is provided with a flat boss II (8), and the inclined boss I (5) and the inclined boss II (6) are arranged on the upper mold (1). The movable sliding block I (3) is provided with two inclined sliding grooves I (9), the movable sliding block II (4) is provided with an inclined sliding groove II (10), the lower mold (2) is provided with a glass molding part (11), the lower mold (2) is provided with a smooth sliding groove I (13), and the lower mold (2) is provided with a smooth sliding groove II (15). The hot bending forming of special-shaped, complex-structure or concave 3D curved glass products is conveniently and quickly realized, the problems of distortion, poor flatness and poor profile tolerance of a forming area in the forming process are solved, and the production efficiency is improved.

Owner:WUHU TOKEN SCI

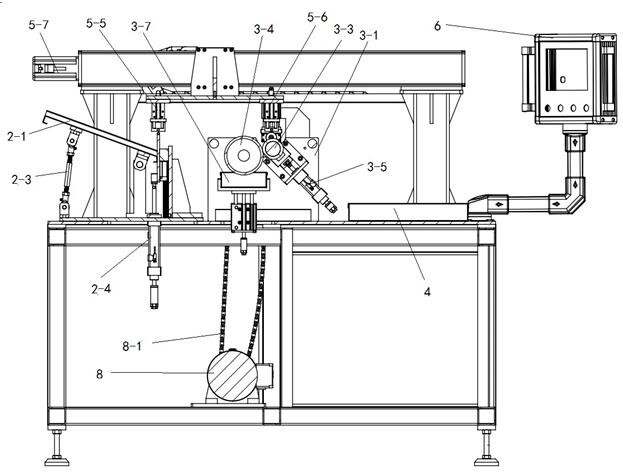

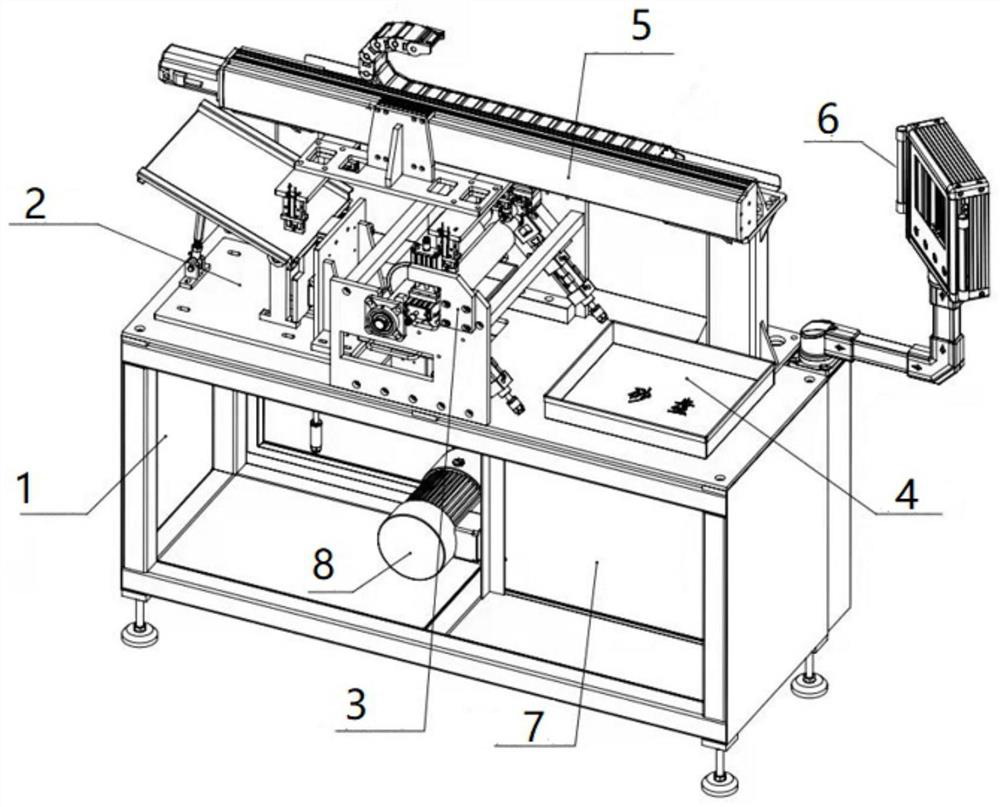

Automatic glue coating and sand planting machine for sand cap pipe and working method

ActiveCN114714267AMeet the needs of machiningApply glue evenlyGrinding devicesAgriculture gas emission reductionAgricultural engineeringElectrical control

According to the automatic sand cap pipe gluing and sand planting machine, a feeding unit is arranged at the left front end of a rack, a gluing unit is arranged on the right side of the feeding unit, a sand tray is arranged on the right side of the gluing unit, an operation unit is arranged on the rear side of the feeding unit, the rear side of the gluing unit and the rear side of the sand tray, and a sliding rail, a sliding frame and a mechanical arm are arranged on the operation unit. A control table is arranged on the right rear side of the rack, a motor and an electric control box are arranged in the rack, a to-be-machined sand cap pipe is placed on the feeding unit, the sand cap pipe is grabbed to the gluing unit on the rear side through a mechanical arm arranged on the operation unit, the outer surface of the sand cap pipe is evenly coated with glue through the coating unit, and the sand cap pipe is coated with sand. And the glued sand cap pipe is grabbed by a manipulator on the operation unit and placed in a sand tray, the outer surface of the sand cap pipe is uniformly adhered with sand grains in the sand tray, then the sand cap pipe is placed on the conveyor belt of the next procedure by the operation unit, and the process is repeated to finish the automatic gluing and sand planting processing work of the sand cap pipe.

Owner:YANCHENG XIEHE MACHINERY

Automatic filter plate processing production line

ActiveCN112428340BRealize processing and productionRealize automatic feeding processMetal working apparatusWater filterProcess engineering

Owner:济南快克广宣数控机械有限公司

Compression system for wooden door processing

ActiveCN114083635ASolve quality problemsSolve the problem of serious waste of materialsWood compressionCompression moldingStructural engineering

The invention relates to the technical field of wooden door compression production, in particular to a compression system for wooden door processing. The system comprises an arrangement assembly, a feeding assembly and a pressing assembly. The arrangement assembly is used for adjusting the to-be-compressed materials to a proper angle; the pressing assembly is used for conducting compression forming on the to-be-compressed materials; the feeding assembly is used for conveying the to-be-compressed materials into the arrangement assembly; and the arrangement assembly comprises a forming box and an adjusting mechanism which are movably connected, wherein a containing disc is arranged in the forming box, an automatic lifting assembly is arranged between the containing disc and the bottom of the forming box, and the adjusting mechanism is arranged above the containing disc. The problems of substandard product quality and serious material waste caused by poor compression effect in the prior art are solved.

Owner:四川兴事发木业有限公司

Manufacturing method of multilayer printed circuit board with embedded magnetic core power supply module

PendingCN112788870ARealize processing and productionMeet special needsPrinted circuit aspectsCircuit board tools positioningHigh densityMiniaturization

The invention provides a manufacturing method of a multilayer printed circuit board with a magnetic core-embedded power module. The method includes the following steps: substrate cutting, hole drilling and finishing, CNC groove milling, inner layer circuit, inner layer etching, embedded core pressing, etching copper reduction, X-RAY targeting, embedded core drilling, embedded core degumming, through hole drilling, electroless plating copper electroplating, outer layer circuit, L2 and L3 layer circuit, inner layer etching, browning, total pressing, outer layer drilling, electroless plating copper electroplating, outer layer circuit, pattern electroplating, half-hole milling T surface etching, B surface etching, outer layer detection, and solder resist printing. Research, development and production of the multilayer printed board with the embedded magnetic core are realized, the inductor is embedded in the printed board, the surface area of the printed board is greatly reduced, other components can be arranged more reasonably due to the saved area, and a good solution is provided for high density and miniaturization of a power supply module.

Owner:HUIZHOU ZHONGJING ELECTRONICS TECH CO LTD

Production device and production method of salbutamol capsule for treating respiratory diseases

PendingCN113350184AEasy to dryRealize processing and productionOrganic active ingredientsCapsule deliveryBiotechnologyDisease

The invention belongs to the technical field of salbutamol capsule production, and particularly relates to a production device and production method of a salbutamol capsule for treating respiratory diseases. The production device comprises a base, the top of the base is provided with a shell, the outer wall of the shell is rotatably provided with a coating pan, and the coating pan is driven by a driving motor to rotate; a stand column is further arranged at the top of the base, a liquid storage tank is fixed to the upper end of the stand column, a liquid outlet pipe is connected to the bottom of the liquid storage tank, a nozzle is installed at the tail end of the liquid outlet pipe, and the nozzle is arranged in the coating pan; a cam is further installed at the output end of the driving motor, a balloon is arranged on one side of the cam, and the balloon communicates with the top of the liquid storage tank through a pipeline; and the coating pan is driven by the driving motor to rotate at the same time, and the higher the rotating speed of the coating pan is, the more gas is generated, so that more slurry coating agents and more hot gas can be extruded.

Owner:南京望知星医药科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com