Automatic glue coating and sand planting machine for sand cap pipe and working method

A technology of gluing and capping, which can be used in manufacturing tools, metal processing equipment, grinding devices, etc., and can solve problems such as artificial gluing and sand planting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

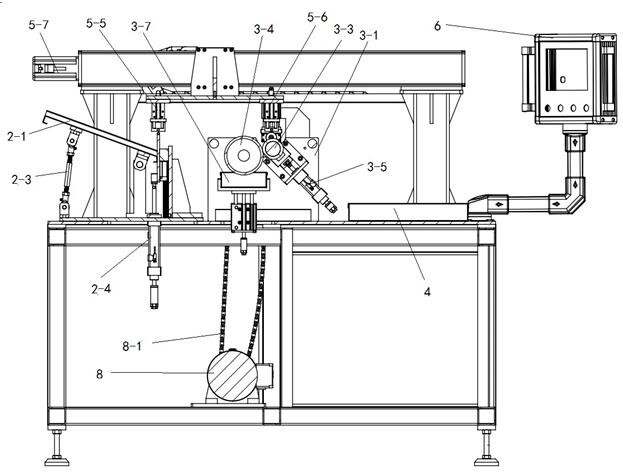

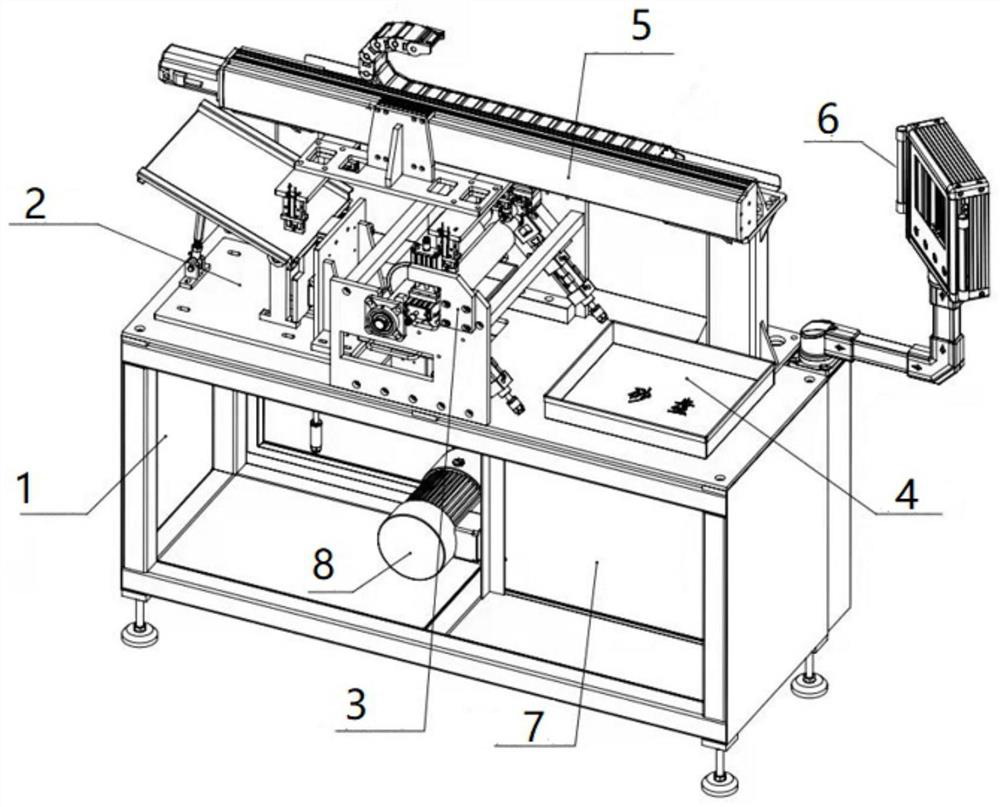

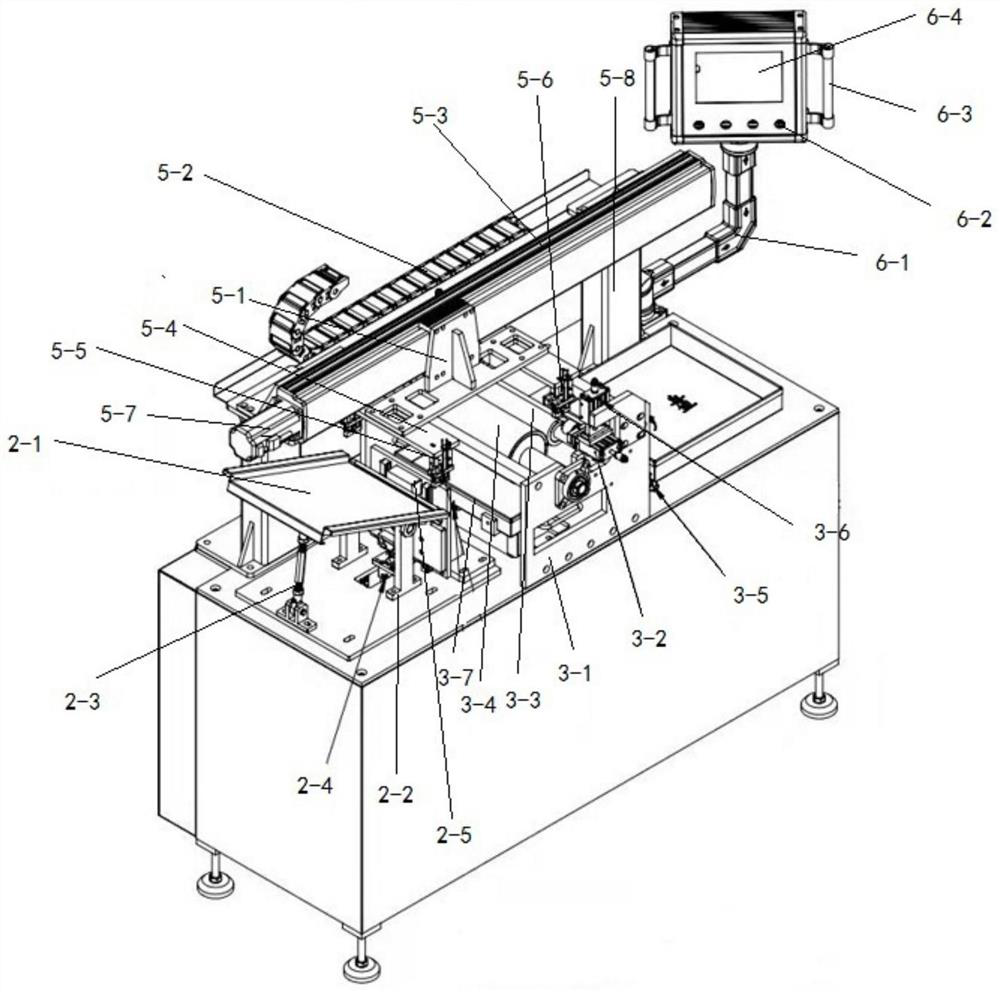

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments:

[0022] The invention provides an automatic sand cap pipe glue coating and sand planting machine and a working method. By arranging equipment with a frame, a feeding unit, a glue coating unit, a sand tray, an operation unit and a console, by placing a waiting unit on the feeding unit To process the sand cap tube, the manipulator set on the operation unit grabs the sand cap tube to the gluing unit on the rear side. The manipulator grabs it and places it in the sand pan, the sand cap tube evenly sticks the sand on the outer surface of the sand pan, and then the operation unit places the sand cap tube on the conveyor belt of the next process, and repeats the above process to complete the sand cap tube The automatic processing of glue and sand planting can solve the problem that traditional sand cap pipe processing requires manual glue and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com