Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

73results about How to "Realize automatic pressure relief" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

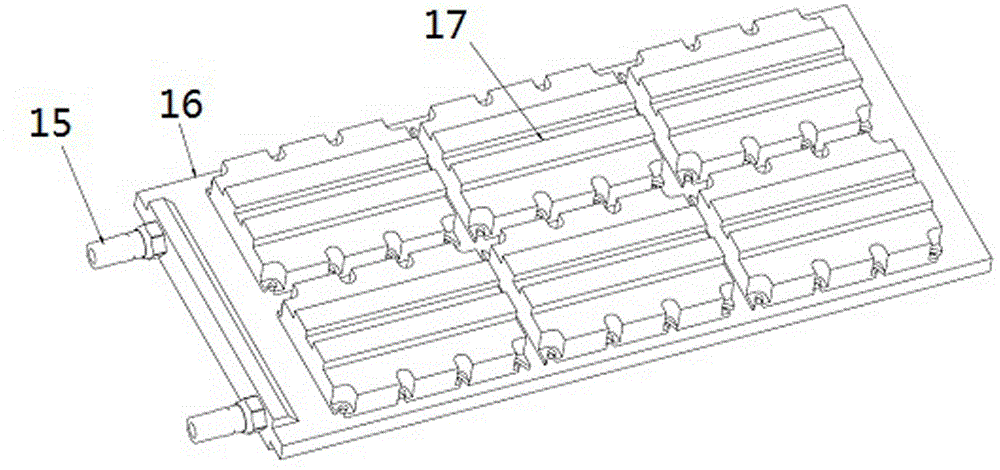

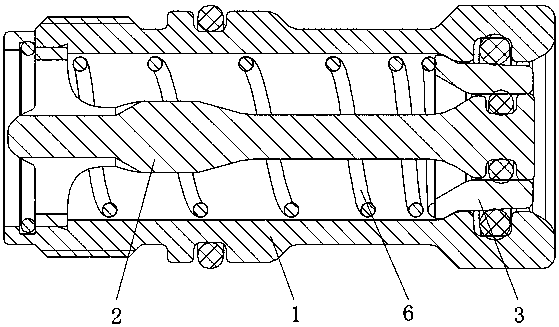

Radiator

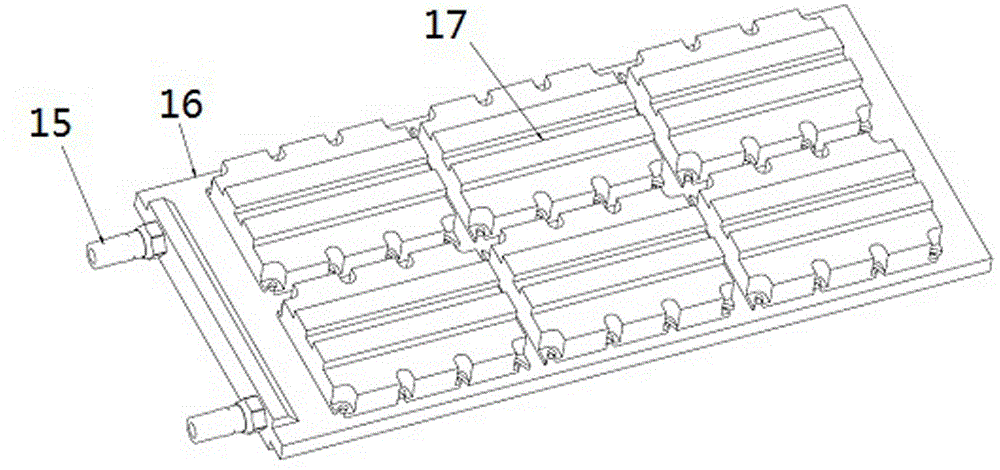

ActiveCN104567521AUnprepared to crushRealize automatic pressure reliefHeat exchanger casingsCouplingsCold plateAtmosphere

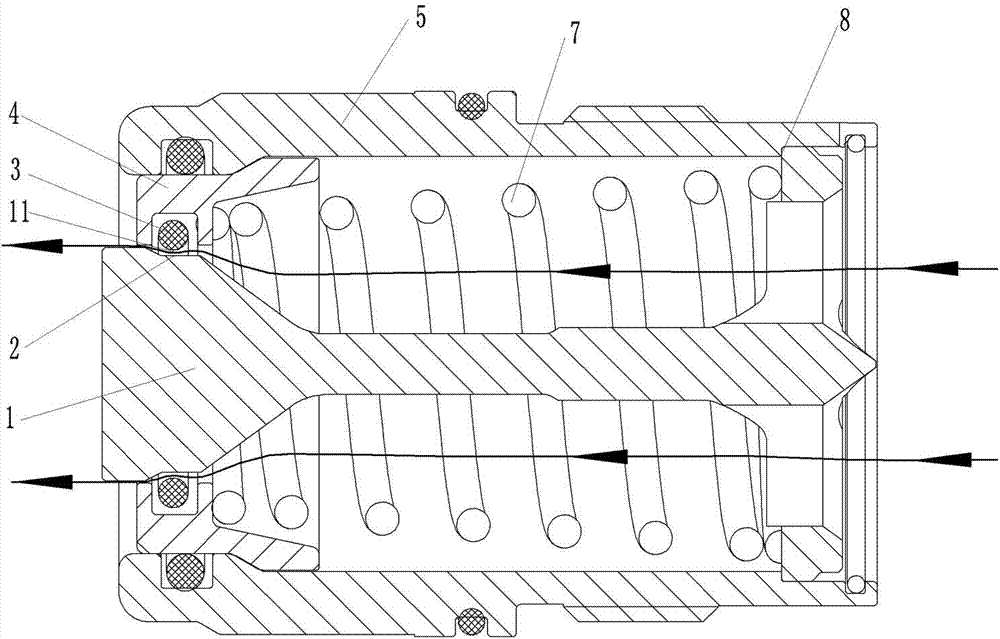

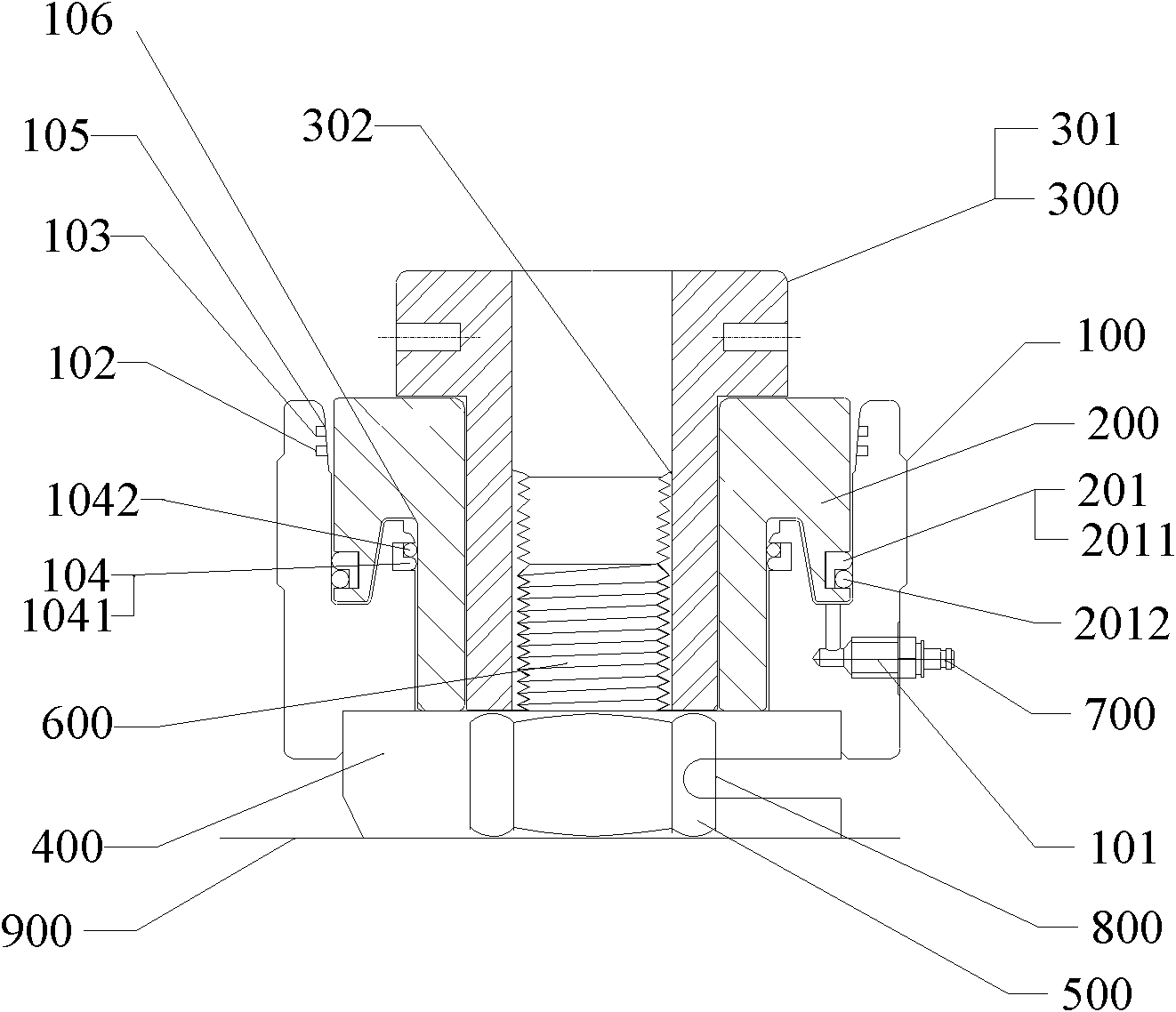

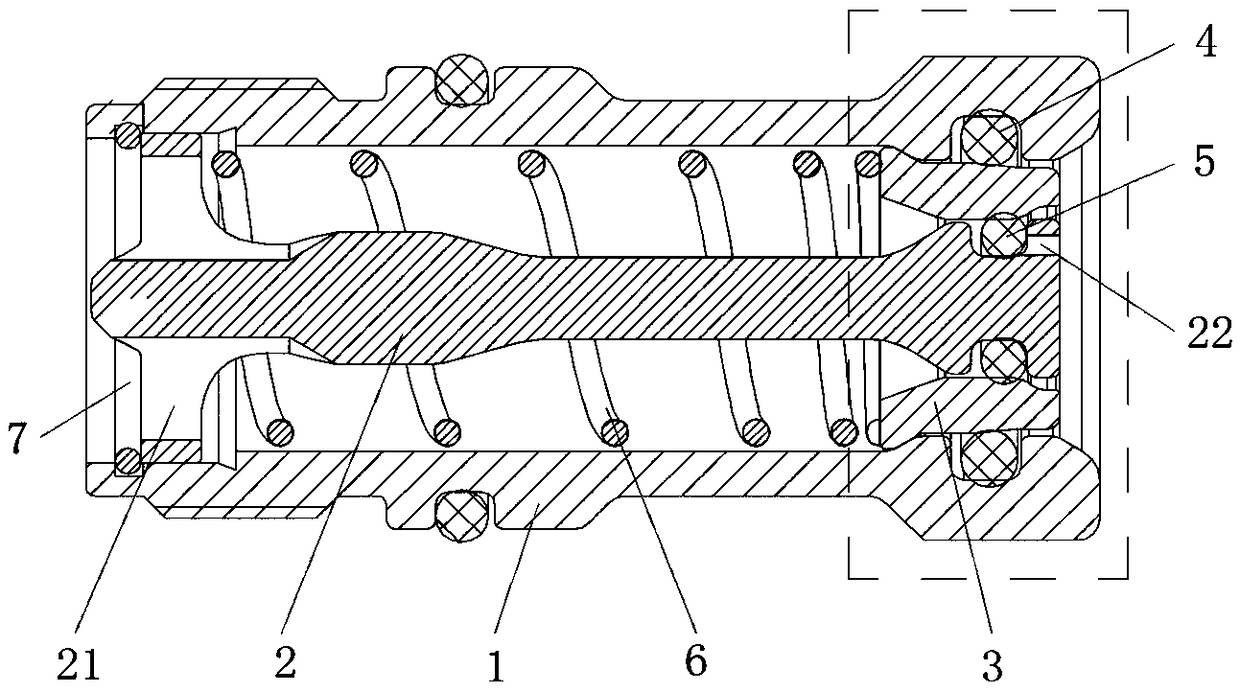

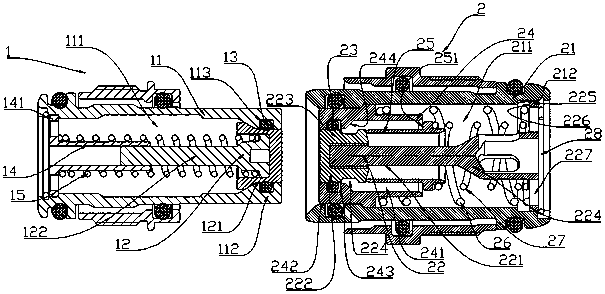

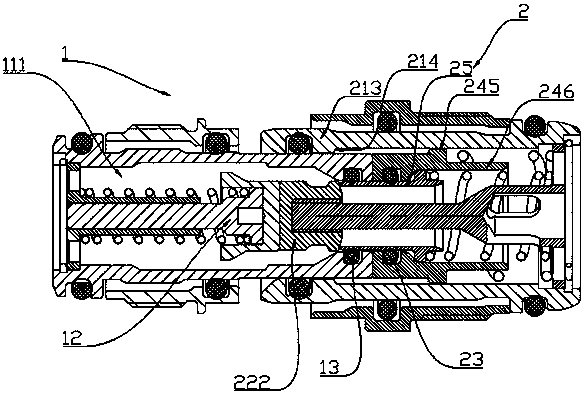

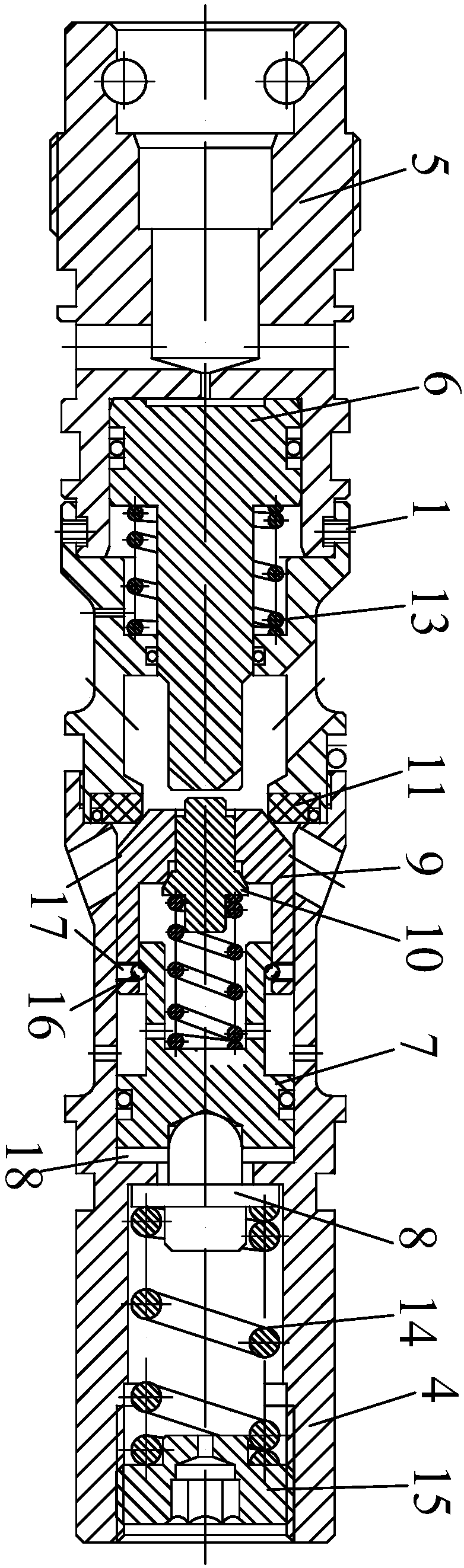

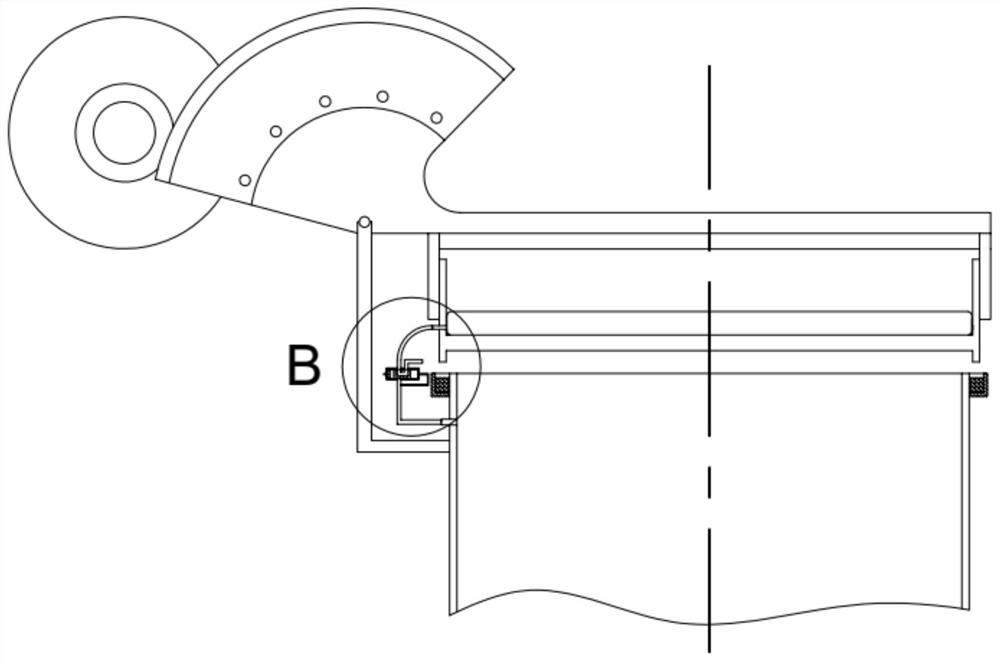

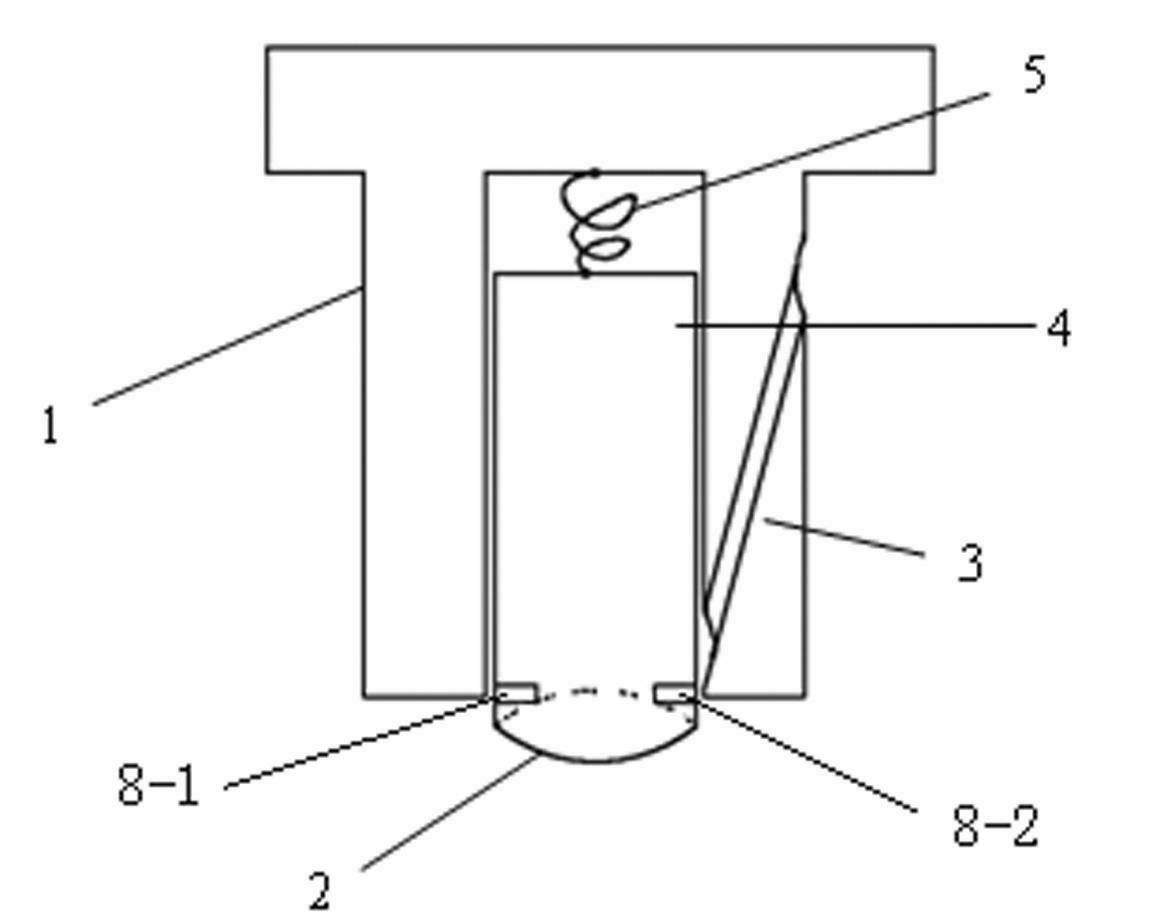

The invention relates to a radiator. The radiator comprises a cold plate and a quick connector male head arranged on the cold plate; the quick connector male head comprises a male head shell; a male head valve core is assembled in a male head fluid channel of the male head shell in a guiding and moving manner; a pressure relief channel which is used for communicating the male head fluid channel and the external atmosphere is formed in the male head valve core; the pressure relief channel comprises a liquid through hole section which is connected with the male head fluid channel and a mounting hole section which is connected with the external atmosphere; a plugging piece is assembled in the mounting hole section in the guiding and moving manner; a pressure relief spring which is used for applying elastic acting force to the plugging piece so as to enable the plugging piece to plug the liquid through hole section is arranged on the male head valve core; a communicating channel which is used for communicating the liquid through hole section and the mounting hole section after the plugging piece is separated from the liquid through hole section is formed in the plugging piece, in the male head or between the plugging piece and the male head valve core. According to the radiator, the problem that the quick connector male head cannot release pressure automatically in the prior art is solved.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

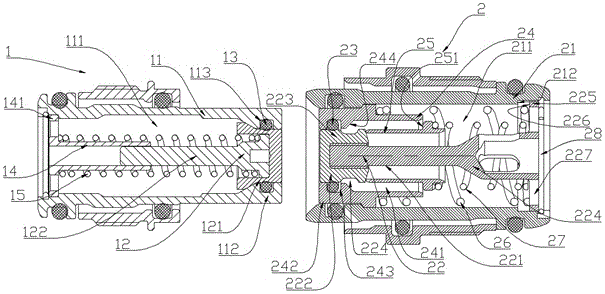

Female connector and fast connector assembly using same

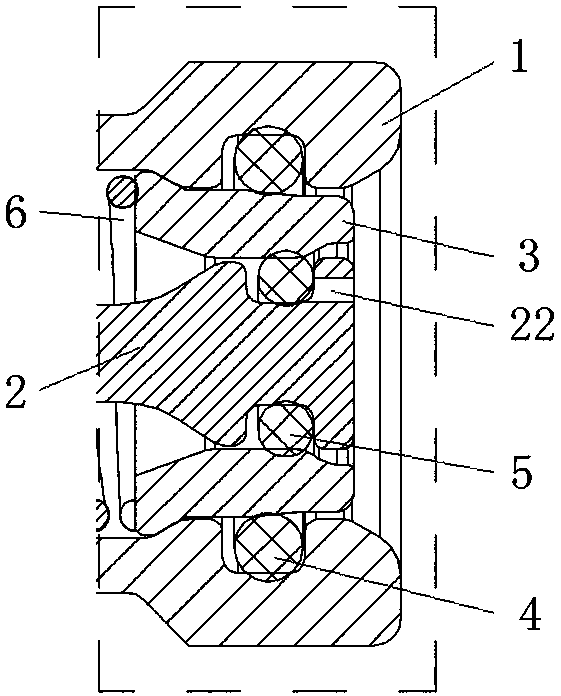

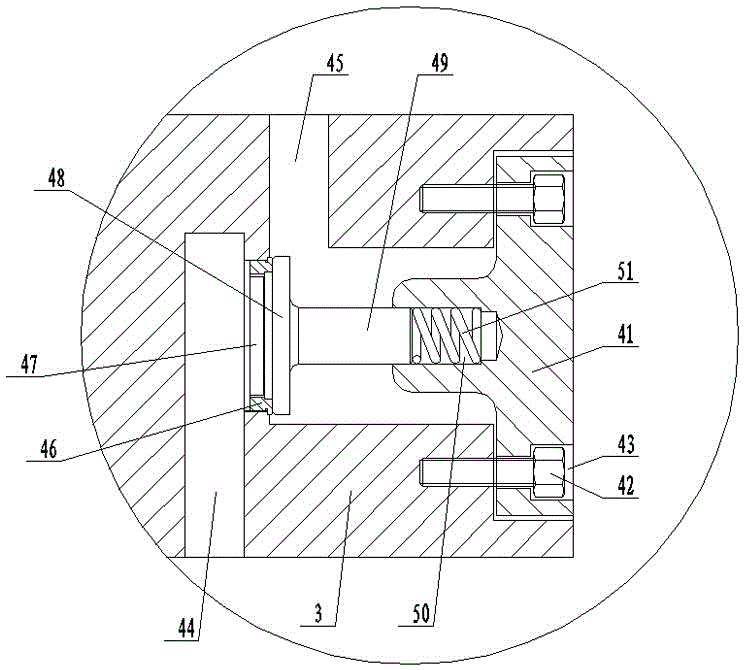

The invention relates to the field of connectors for gas-liquid pipelines, in particular to a female connector and a fast connector assembly using the same. A female connector valve core is assembled in a female connector shell in a front-back moving mode. An elastic tightly-jacking device is arranged in the female connector shell. The female connector valve core is provided with a first stop face toward the front of the female connector. A second stop face is arranged in the female connector shell which is toward the back of the female connector and used for being in stop fit with the first stop face after sliding forwards by a set stroke when the female connector valve core overcomes elastic force of the elastic tightly-jacking device. A female connector seal ring is arranged on a female connector valve core seal section / seal jacket seal section. A movable seal jacket / the female connector valve core is provided with an avoiding concave part which is located on the front side / rear side of the female connector seal ring before the first stop face is in stop fit with the second stop face and is in clearance fit with the female connector seal ring when the first stop face is in stop fit with the second stop face. The problem that after pressure in an existing cold plate is increased, a female connector connected with the cold plate cannot relieve pressure automatically is solved.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

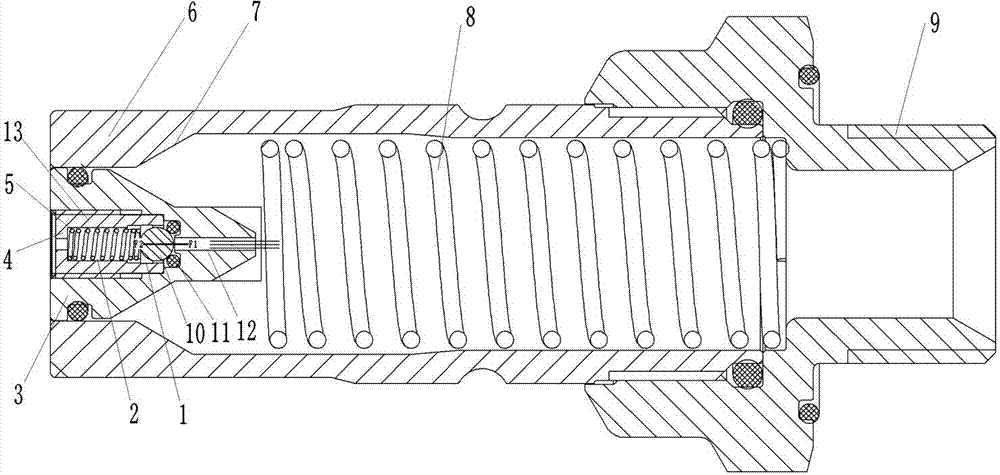

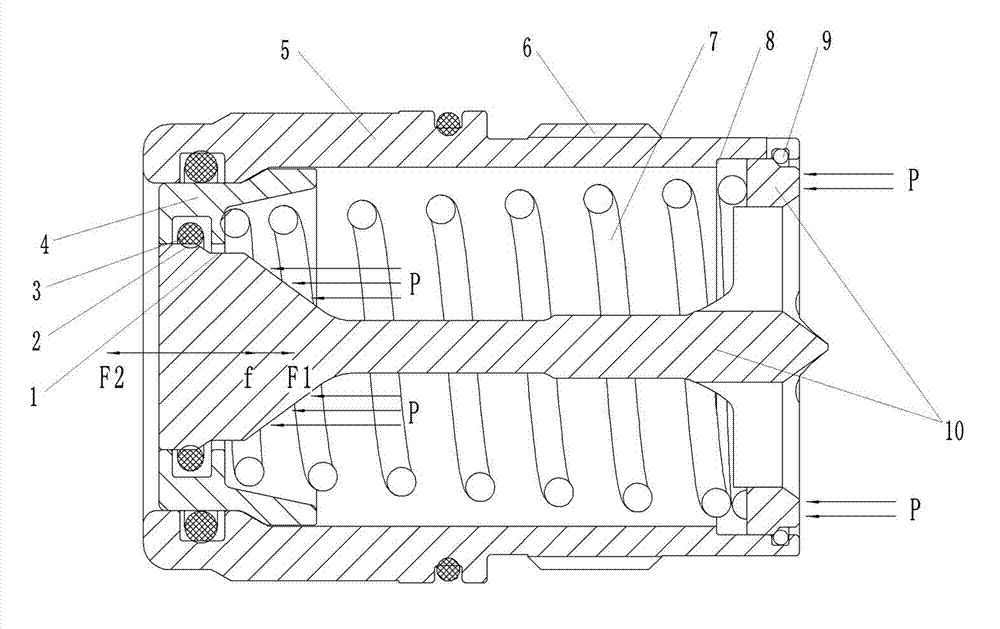

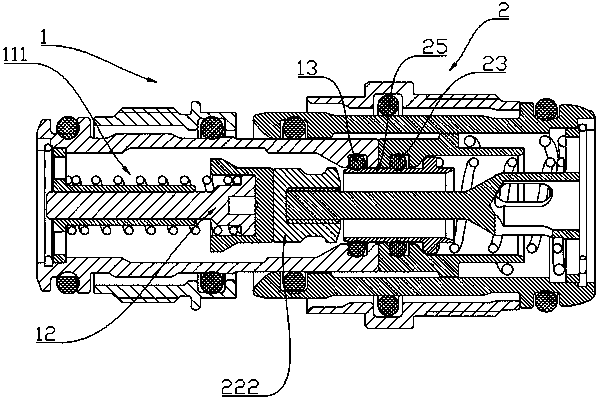

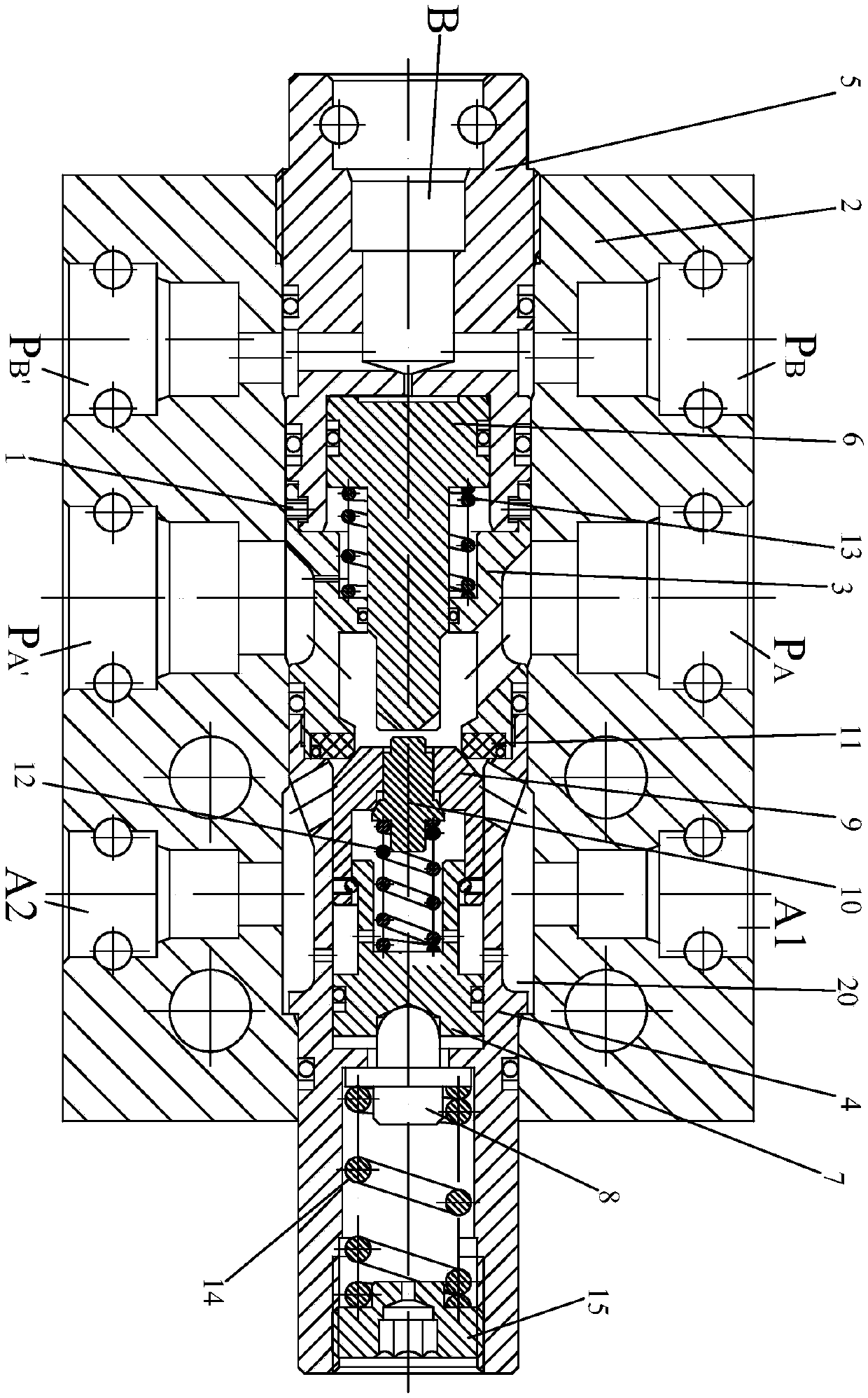

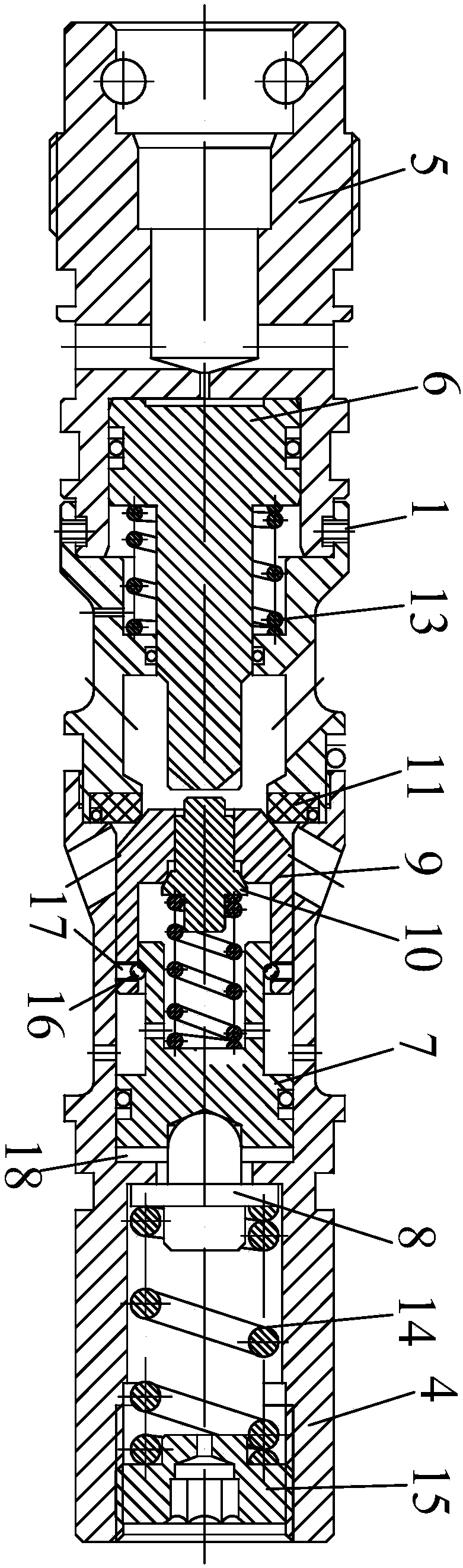

Quick coupling assembly

ActiveCN104500895ARealize automatic pressure reliefGuaranteed not to be crushed by pressureCouplingsL-shellEngineering

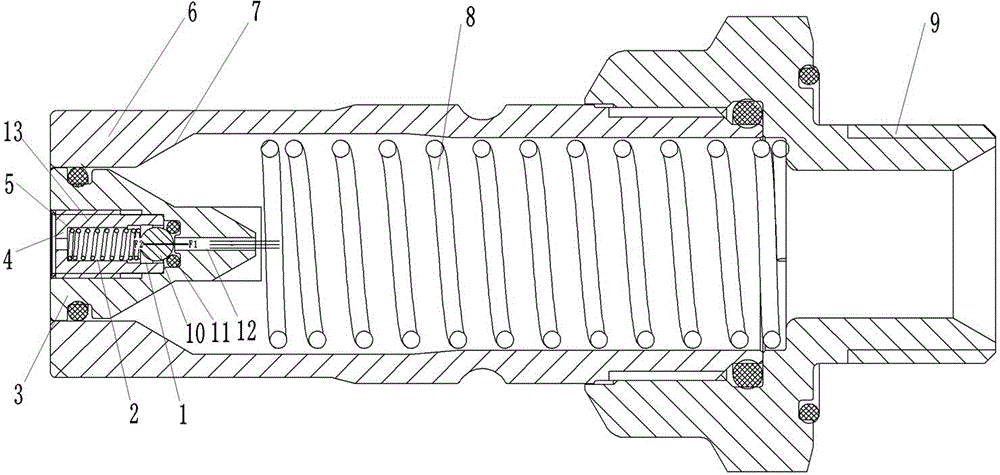

The invention relates to a quick coupling assembly, which comprises a quick coupling female and a quick coupling male; the quick coupling male comprises a male shell; a male valve core is assembled in a male fluid flow passage of the male shell in a guide moving manner; a pressure relief passage used for communicating the male fluid flow passage with the outside atmosphere is arranged in the male valve core; the pressure relief passage comprises a liquid through hole section and a mounting hole section, wherein the liquid through hole section is connected with the male fluid flow passage, and the mounting hole section is connected with the outside atmosphere; a blocking piece is assembled in the mounting hole section in the guide moving manner; the male valve core is provided with a pressure relief spring used for applying an elastic acting force to the blocking piece so as to enable the blocking piece to block the liquid through hole section; a communicating passage used for communicating the liquid through hole section with the mounting hole section after the blocking piece is separated from the liquid through hole section is arranged on the blocking piece or the male valve core or between the blocking piece and the male valve core. The quick coupling male cannot automatically release pressure in the prior art is solved by the quick coupling assembly disclosed by the invention.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

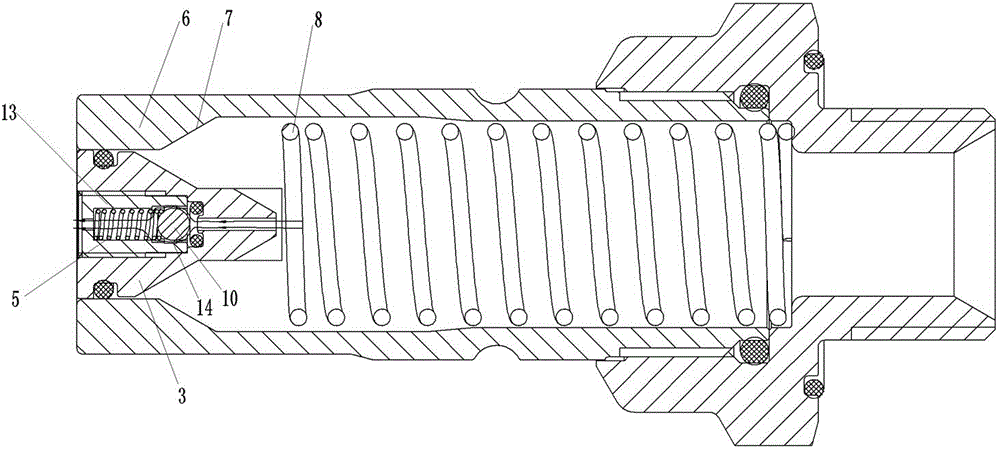

Female head of quick coupling

The invention relates to a female head of a quick coupling. The female head comprises a female head shell, wherein a female head valve core and a movable seal sleeve are movably assembled in a female head fluid passage of the female head shell in a guide manner; a female head spring is abutted between the movable seal sleeve and the female head valve core; a sealing section, which is in seal fit with a sealing structure of the seal sleeve to seal the female head fluid passage when being located at a backward limit position, is arranged at the periphery of the female head valve core; a pressure relief section, which is positioned on the rear side of the sealing section for forming a pressure relief passage with the sealing structure of the seal sleeve after the female head valve core moves forwards, is also arranged at the periphery of the female head valve core. The invention provides the female head of the quick coupling capable of realizing automatic pressure relief.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

Pressure relief device

ActiveCN104948789ALarge displacementRealize automatic pressure reliefEqualizing valvesSafety valvesAir volumeEngineering

Owner:BROADWELL SHENZHEN TECH

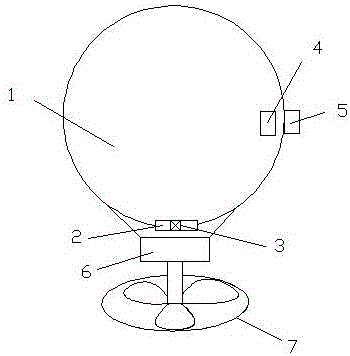

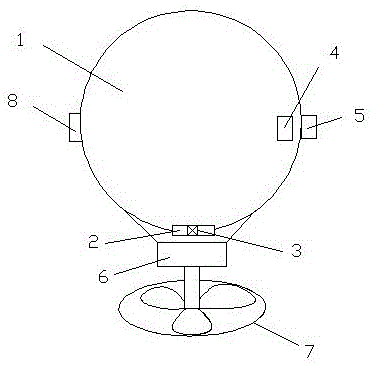

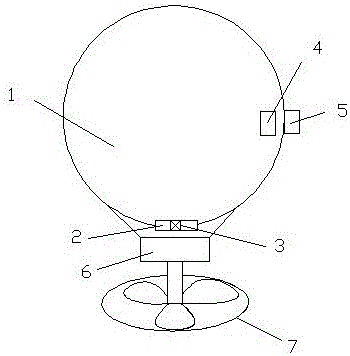

Application method of sounding balloon capable of fixed point monitoring

InactiveCN106291757AAvoid breakingOvercome the defect that the pressure inside the ball is increasing and it is easy to burstInstrumentsInternal pressureWeather balloon

The invention discloses an application method of a sounding balloon capable of fixed point monitoring, and the method comprises the following steps: 1, assembling the sounding balloon; inflating an air bag; 3, deflating the air bag when the sounding balloon rises; 4, adjusting the height of the sounding balloon; 5, adjusting the position of the sounding balloon; 6, providing compensation power during the recycling of the sounding balloon; 7, recycling the sounding balloon. Compared with the prior art, the invention has the beneficial effects that the method irons out the defect that the sounding balloon is liable to explode because the internal pressure of the sounding balloon is increased gradually in a rising process of the sounding balloon; the method provides the compensation power to the sounding balloon in the recycling process of the sounding balloon, and protects the sounding balloon from crashed; in addition, a height sensor can assist the control of the height of the sounding balloon; and a GPS positioning module can precisely locate the sounding balloon.

Owner:WUXI NUIST WEATHER SENSOR NETWORK TECH

Hydraulic tensioner with safe pressure relief device

InactiveCN102756266AEasy to observeEasy to operateMetal working apparatusHydraulic cylinderPulp and paper industry

The invention relates to a hydraulic tensioner with a safe pressure relief device, comprising a hydraulic oil cylinder, a piston, and a tensioning piece, wherein the piston is arranged in the hydraulic oil cylinder, the tensioning rod of the tensioning piece is arranged in a through hole at the centre of the piston, and is limited via a tensioning head. As one or more limit grooves are arranged on the inner wall close to the top, of the hydraulic oil cylinder, when the pressure in the hydraulic oil cylinder exceeds a set value, a second sealing ring on the piston is pushed to the limit groove, and high-pressure oil overflows via the limit groove, so that the pressure of the oil in the hydraulic oil cylinder is reduced and automatically relieved; and via the plurality of limit grooves, many times of the automatic pressure relief can be realized, so that the hydraulic tensioner is safer and more reliable.

Owner:BEIJING KELU IND EQUIP

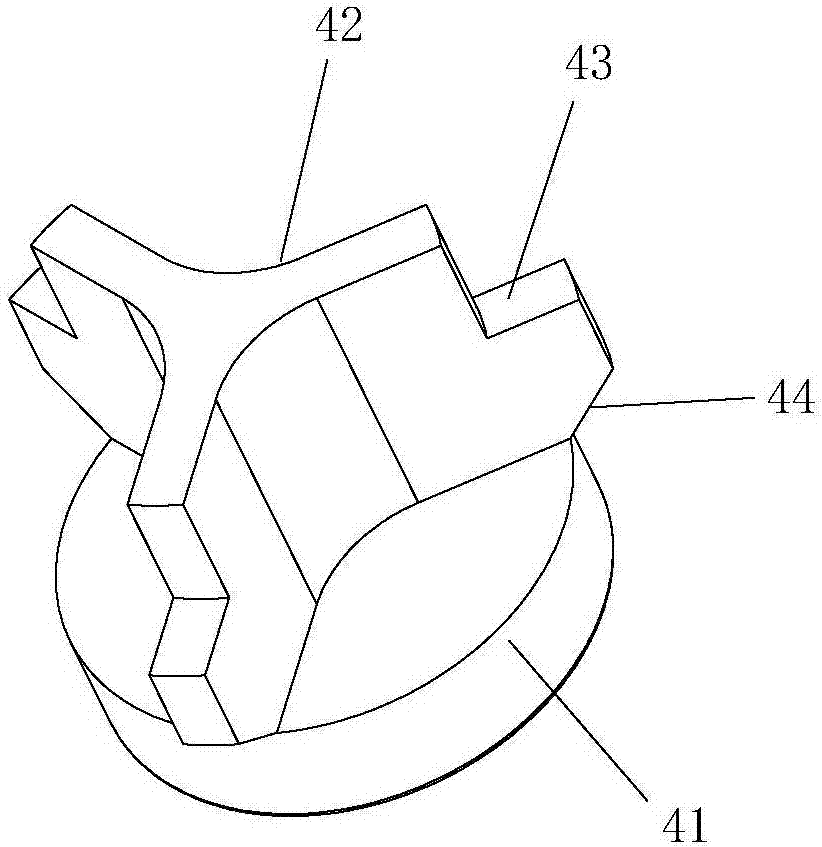

Male joint of fast connector

ActiveCN104633348ARealize automatic pressure reliefUnprepared to crushCouplingsAtmospheric airMechanical engineering

The invention relates to a male joint of a fast connector. The male joint of the fast connector comprises a male joint shell, a male joint valve element is movably assembled in a male joint fluid channel of the male joint shell in a guiding mode, a pressure relief channel used for connecting the male joint fluid channel and the outside atmosphere is arranged in the male joint valve element and comprises a liquid passing hole segment connected with the male joint fluid channel and an installing hole segment connected with the outside atmosphere, a plugging piece is movably assembled in the installing hole segment in a guiding mode, a pressure relief spring used for applying elastic acting force to the plugging piece and enabling the plugging piece to plug the liquid passing hole segment is arranged on the male joint valve element, and a guiding channel used for connecting the liquid passing hole segment and the installing hole segment after the plugging piece is separated from the liquid passing hole segment is arranged on the plugging piece and the male joint valve element or between the plugging piece and the male joint valve element. The male joint of the fast connector can perform automatic pressure relief.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

Self-pressure-relief quick coupling and working method thereof

The invention relates to a self-pressure-relief quick coupling and a working method of the self-pressure-relief quick coupling. The self-pressure-relief quick coupling comprises a male plug and a female plug which are matched in a plugged mode. The male plug and the female plug are in sealed fit with annular sealing portions of sleeves through a movable first valve element and a movable second valve element correspondingly, and the structure is simple. The third annular sealing portion of the second valve element is provided with a pressure relief channel, and an inlet of the pressure relief channel is formed in an annular inner wall. The position relation between a second O-shaped sealing ring and the inlet of the pressure relief channel is changed by moving a second sealing disc, pressure relief of the female plug is effectively achieved, sliding fit between the second sealing disc and the annular inner wall of the second valve element is not affected, and the phenomenon that a valve rod is clamped and cannot be reset is avoided. By means of fit between an annular groove and an annular support, the movement stroke of the valve rod is effectively limited, and the valve rod is prevented from being disengaged from the female plug first sleeve.

Owner:丹阳市裕桥精密元件有限公司

Fire extinguishing agent filling equipment and filling method thereof

ActiveCN110778912AGood for vacuuming and leak detectionReduce filling pressure errorVessel geometry/arrangement/sizeFire rescuePumping vacuumNitrogen gas

The invention discloses fire extinguishing agent filling equipment and a filling method thereof. The equipment comprises a vacuum pump, a first storage container, a first filling assembly, a second storage container, a second filling assembly, a third storage container, a third filling assembly, a fourth storage container and a fourth filling assembly. According to the fire extinguishing agent filling equipment, a fire extinguisher is vacuumized through the vacuum pump, and then the fire extinguisher is sequentially filled with at least one solvent stored in the second storage container through the second filling assembly, helium stored in the third storage container through the third filling assembly, at least one fire extinguishing agent stored in the first storage container through thefirst filling assembly, and nitrogen stored in the third storage container. According to the fire extinguishing agent filling equipment and the filling method thereof, vacuumizing and leakage detection are facilitated, the internal air pressure of the fire extinguisher is increased, the fire-extinguishing-agent filling pressure error caused by pipeline factors is effectively reduced, therefore thefilling efficiency is improved, and various filling requirements are met.

Owner:安徽英杰精工机械股份有限公司

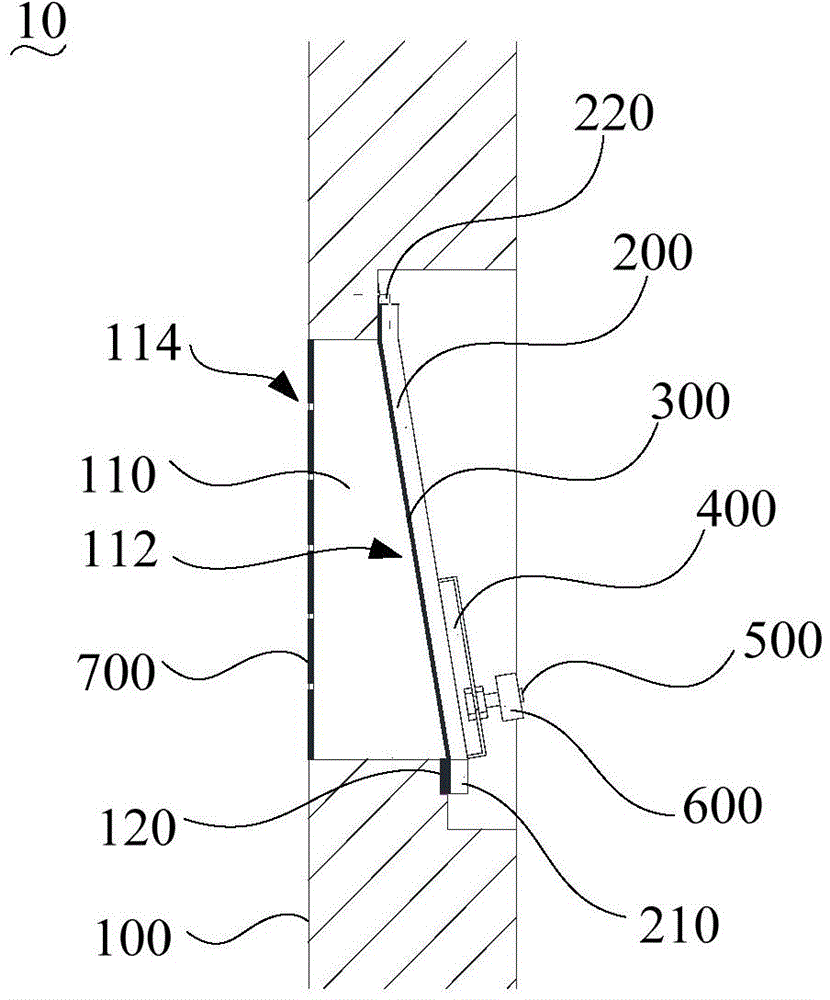

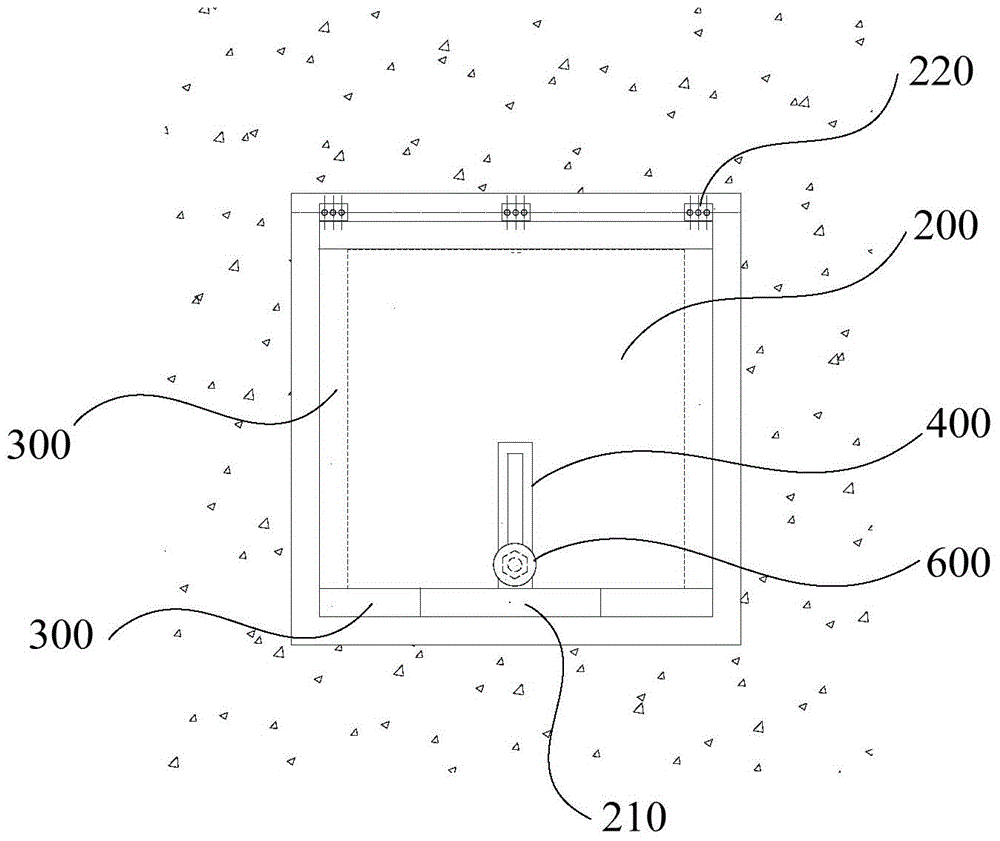

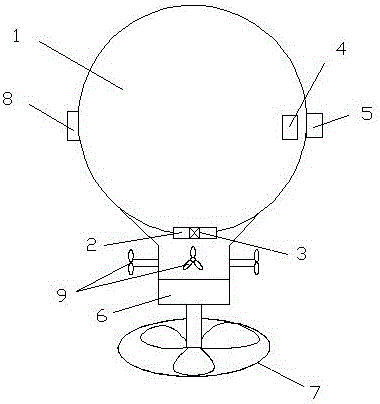

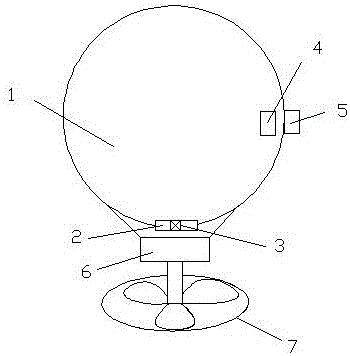

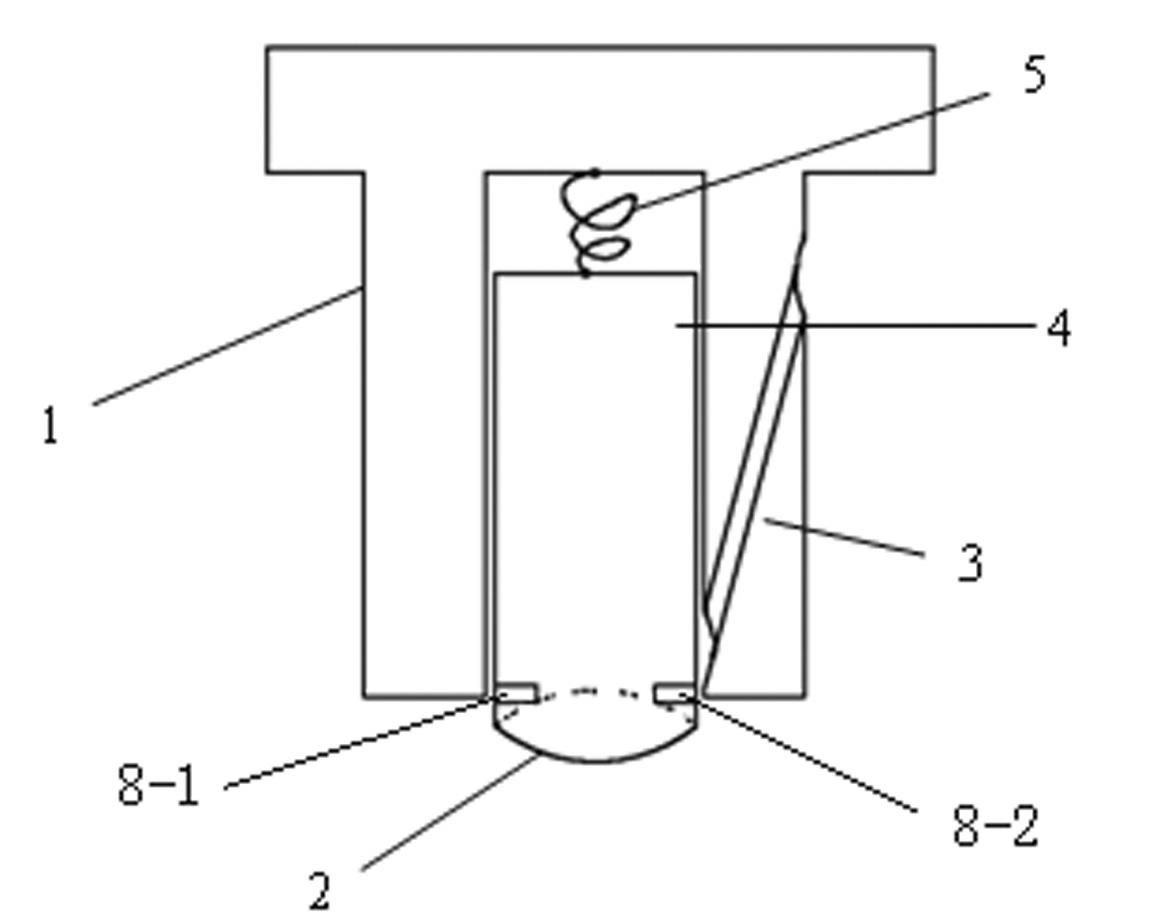

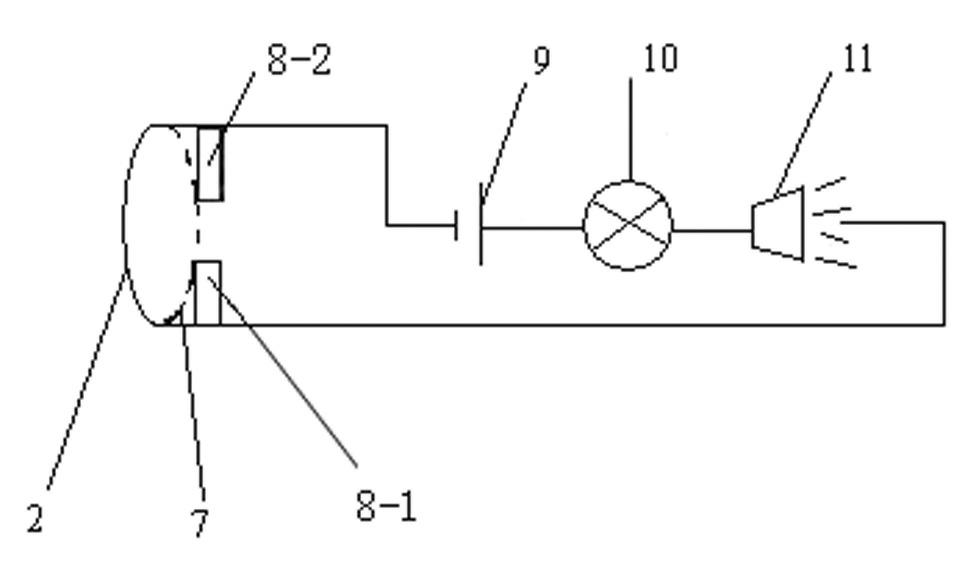

Sounding balloon with precise positioning

InactiveCN106291758AAvoid breakingOvercome the defect that the pressure inside the ball is increasing and it is easy to burstSatellite radio beaconingEngineeringGps positioning

The invention discloses a sounding balloon with precise positioning. The sounding balloon comprises an air bag filled with hydrogen and helium, a gas inflation and exhaustion component, a power compensation component and a controller. A GPS positioning module is integrated in the controller which is connected to the gas inflation and discharge component and the power compensation component. Compared with the prior art, the sounding balloon has the advantages that the disadvantages of the larger and larger pressure in a ball and easy burst in the lift-off process of the sounding balloon is overcome, in the recovery process of the sounding balloon, due to the gas discharge in the past, the buoyant force is reduced, added with the load of a meteorological data measuring device, the speed of decline is faster and faster, the balloon is in the danger of falling, the controller starts a motor according to the pressure signals fed by a built-in pressure sensor and an external pressure sensor, the motor drives a spiral wing to provides compensation power for the sounding balloon, and a crash is prevented. In addition, the sounding balloon can be precisely positioned by the GPS positioning module.

Owner:WUXI NUIST WEATHER SENSOR NETWORK TECH

Using method of altitude-controllable sounding balloon

InactiveCN106240787AAvoid breakingRealize automatic pressure reliefBatteries circuit arrangementsElectric powerInternal pressureMotor drive

The invention discloses a using method of an altitude-controllable sounding balloon. The using method includes the following steps that firstly, the sounding balloon is assembled; secondly, an air bag is inflated; thirdly, deflation is carried out when the sounding balloon rises; fourthly, the rising altitude is adjusted; fifthly, compensating power is provided when the sounding balloon is collected. Compared with the prior art, the using method has the advantages that the defect that the pressure in a balloon becomes larger and larger in the rising process of the sounding balloon, and explosion is likely to occur is overcome, and the defect that when the sounding balloon is collected, buoyancy is gradually reduced in the deflating process, due to the load on a meteorological data measuring device, the descending speed becomes higher and higher, and the crashing danger exists is also overcome; a controller starts a motor according to pressure signals fed back by an internal pressure sensor and an external pressure sensor, and the motor drives spiral wings to provide compensating power for the sounding balloon to prevent crashing; besides, an altitude sensor can assist in controlling the altitude of the sounding balloon.

Owner:WUXI NUIST WEATHER SENSOR NETWORK TECH

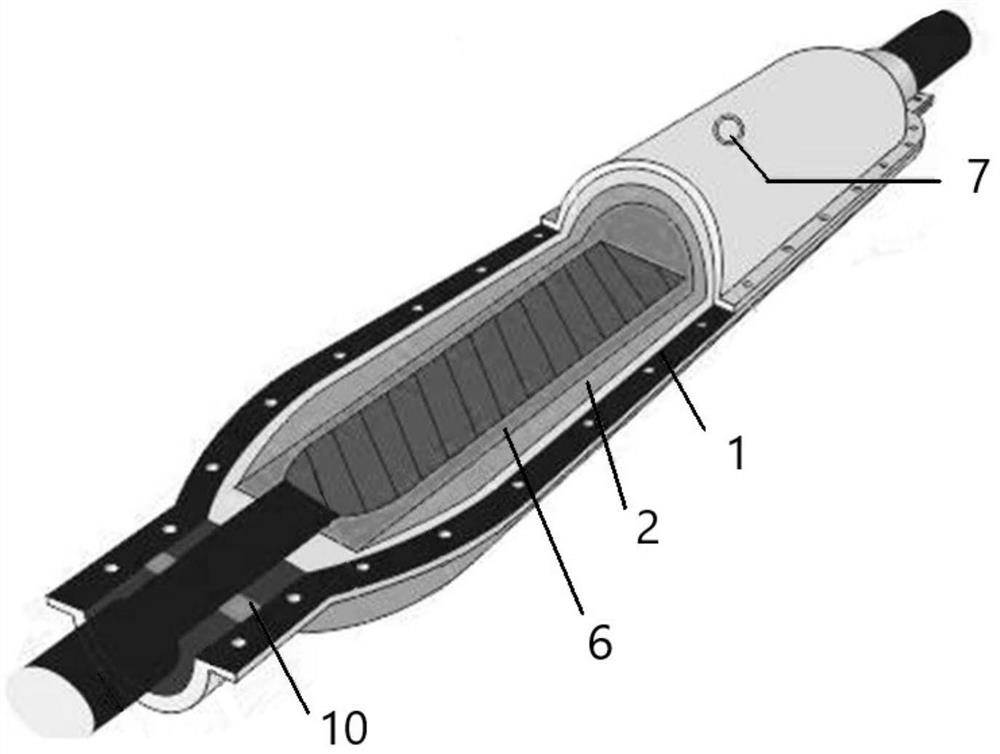

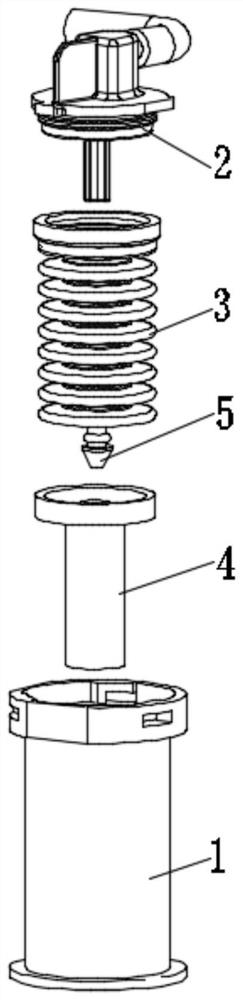

Liquid cooling system, and quick connector female connector

ActiveCN109114341ASelf-sealingRealize automatic pressure reliefEqualizing valvesSafety valvesInternal pressureLiquid cooling system

The invention relates to a liquid cooling system, and a quick connector female connector. The liquid cooling system includes a cooling module; the cooling module is provided with the quick connector female connector; the quick connector female connector includes a cylindrical shell; a sealing rod is installed in the cylindrical shell; a sealing ring is movably installed between the plugging end ofthe cylindrical shell and the sealing rod; the sealing rod is movably assembled in the cylindrical shell along an axial direction; a pressure spring whose two ends act on the sealing rod and the sealing ring to make the sealing ring keep at the position sealing a gap between the sealing rod and the cylindrical shell is installed in the cylindrical shell; and the sealing rod overcomes the action of the pressure spring to move outward and release the sealing cooperation relation with the sealing ring when internal liquid pressure is larger than a set value. The quick connector female connectorcan realize automatic pressure releasing through the axial movement of the sealing rod when the internal pressure of the cooling module rises, so that the cooling module can be prevented from being burst because of overpressure, and therefore, the service life of the liquid cooling system can be prolonged.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

Female connector and quick connector assembly using the female connector

The invention relates to the field of connectors for gas-liquid pipelines, in particular to a female connector and a fast connector assembly using the same. A female connector valve core is assembled in a female connector shell in a front-back moving mode. An elastic tightly-jacking device is arranged in the female connector shell. The female connector valve core is provided with a first stop face toward the front of the female connector. A second stop face is arranged in the female connector shell which is toward the back of the female connector and used for being in stop fit with the first stop face after sliding forwards by a set stroke when the female connector valve core overcomes elastic force of the elastic tightly-jacking device. A female connector seal ring is arranged on a female connector valve core seal section / seal jacket seal section. A movable seal jacket / the female connector valve core is provided with an avoiding concave part which is located on the front side / rear side of the female connector seal ring before the first stop face is in stop fit with the second stop face and is in clearance fit with the female connector seal ring when the first stop face is in stop fit with the second stop face. The problem that after pressure in an existing cold plate is increased, a female connector connected with the cold plate cannot relieve pressure automatically is solved.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

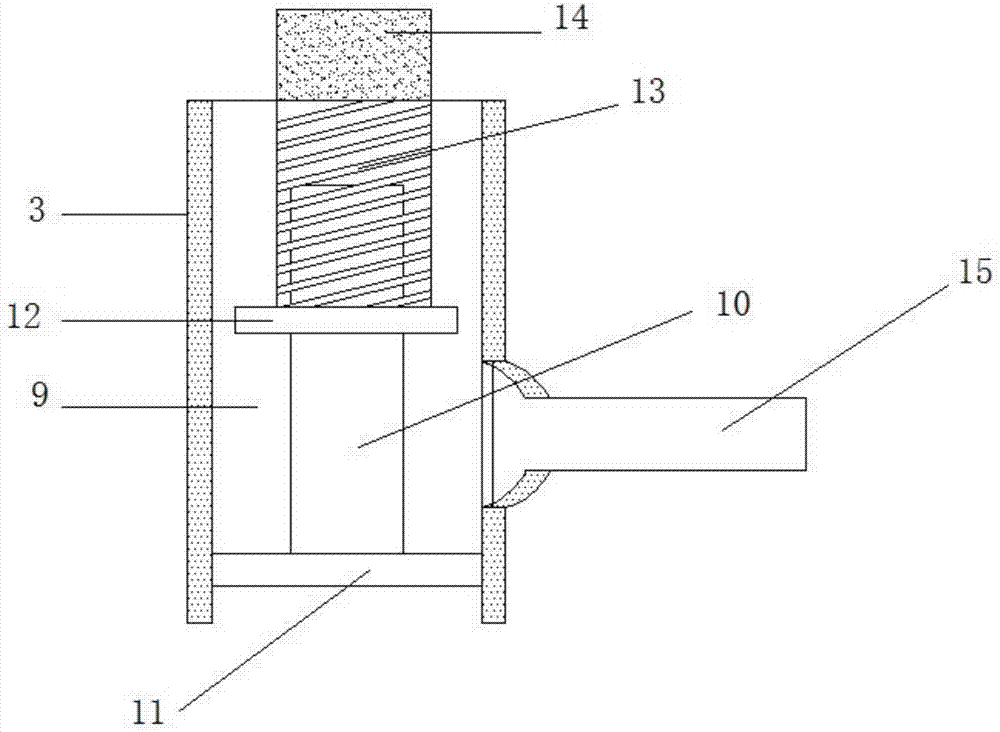

Explosion-proof pressure relief method used for microwave metallurgical furnace

The invention discloses an explosion-proof pressure relief method used for a microwave metallurgical furnace. By arranging an explosion-proof protection layer made of stainless steel on the peripheryof the microwave metallurgy furnace, the microwave metallurgy furnace can be effectively protected, and the situation that equipment is damaged due to excessively internal pressure is prevented; by utilizing a pressure relief control valve, automatic pressure relief can be realized when the internal pressure of the microwave metallurgy furnace is large; when the internal pressure is large, a piston is pushed upwards, when the position of the piston exceeds the height of a pressure relief channel, a spring contracts, and the piston communicates with the pressure relief channel for pressure relief; when the pressure becomes small, a limiting plate is pushed to move downwards under elastic force action of the spring, the piston is driven to move downwards through a connecting rod so as to seal a hydraulic channel, automatic sealing of a hydraulic control valve is achieved, and using is more convenient; and when the pressure in the microwave metallurgical furnace is large, a pressure sensitive resistor in a pressure sensor communicates with an alarm circuit to remind workers, at this time, an air pump can be opened, and a hydraulic pipe is utilized for quick pressure relief, so that equipment is effectively protected.

Owner:陕西盛华冶化有限公司

Novel cable joint explosion-proof box

PendingCN112467680ARealize automatic pressure reliefReduce lossesFire rescueCable junctionsPolyolefinStructural engineering

The invention provides a novel cable joint explosion-proof box. The novel cable joint explosion-proof box comprises a shell, a ceramic polyolefin inner layer, a high-strength fiber layer, a pressure relief hole, a pressure relief cover plate, a fire extinguishing egg, a shell glue filling port and a shell fastening device; the shell is of an upper and lower double-petal combined structure, the twosides of the shell are in a contracted state, the upper and lower shells wrap and clamp a cable, shell fastening devices are arranged at the clamping positions of the two sides, a pressure relief hole and a shell glue filling port are formed in the shell, and a pressure relief cover plate is arranged below the pressure relief hole; the outer layer of the cable is sequentially wrapped with the high-strength ceramic polyolefin inner layer and the high-strength fiber layer. In the using process, when the internal pressure of the explosion-proof box is too high, internal gas is exhausted throughthe pressure relief holes, the explosion-proof box automatically relieves pressures, fire extinguishing eggs can be started instantly to extinguish fire, the temperature of a large amount of heat released by explosion is reduced in the fire extinguishing process, the purposes of fire extinguishing and cooling are achieved, and the functions of automatic pressure relief, explosion prevention, fireextinguishing and water prevention are achieved; and the loss and harm of accidents are greatly reduced.

Owner:STATE GRID LIAONING ELECTRIC POWER CO LTD SHENYANG POWER +1

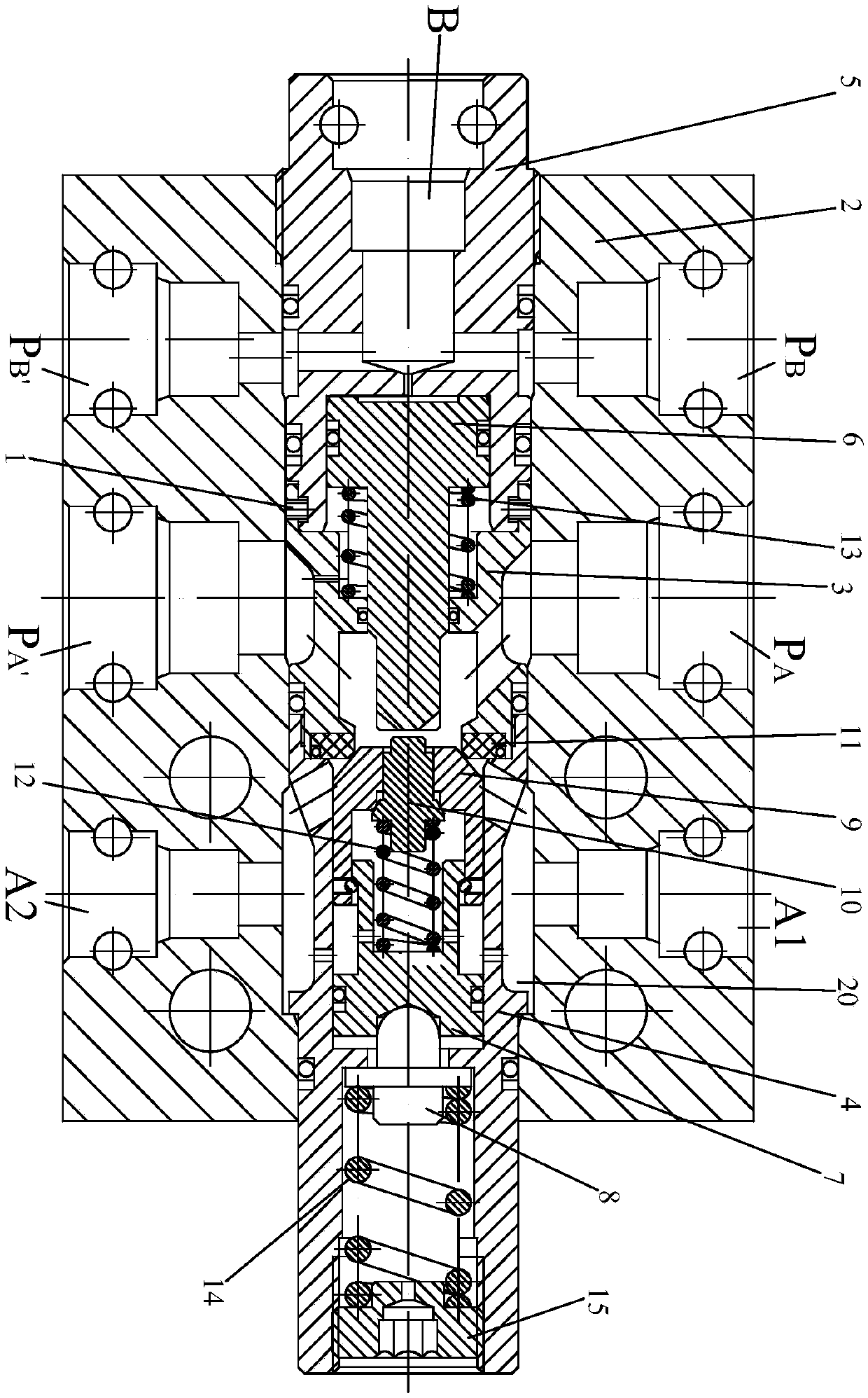

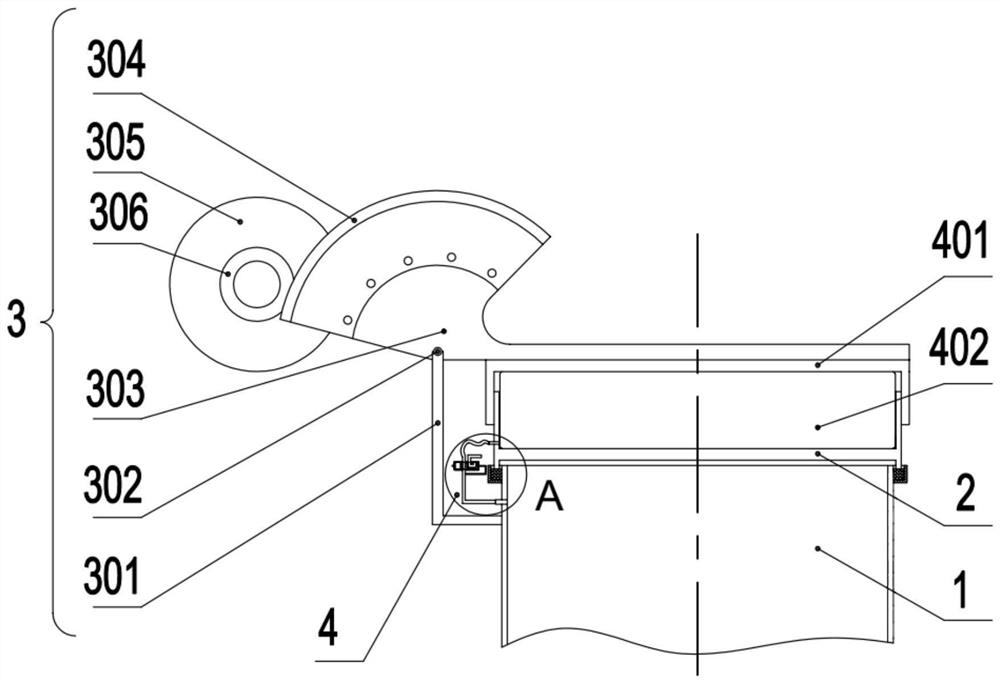

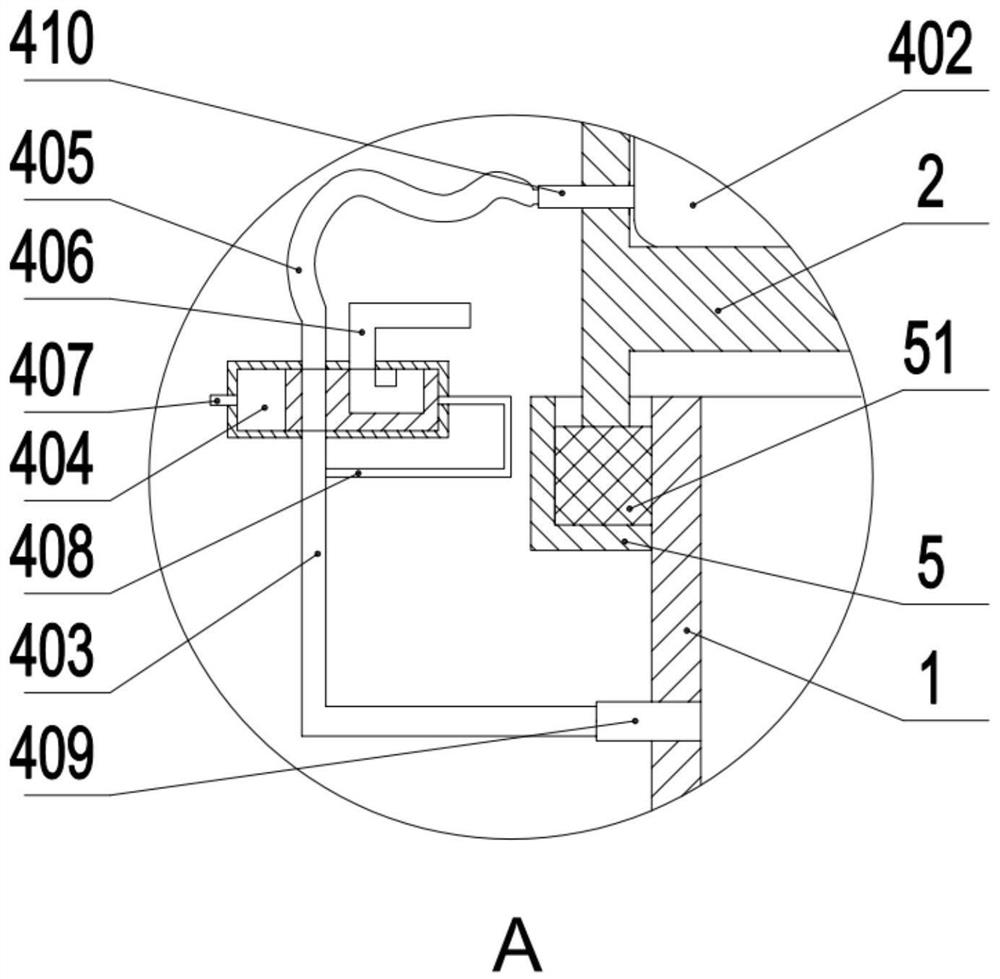

Valve element assembly of pilot-controlled check valve

InactiveCN107859524AImprove versatilityImprove compactnessMine roof supportsProps/chocksEngineeringCheck valve

The invention discloses a valve element assembly of a pilot-controlled check valve. The valve element assembly comprises a screw sleeve, a liquid inlet sleeve, a valve seat, a valve sleeve, a large valve element arranged inside the valve sleeve, a small valve element arranged inside the large valve element, a differential valve element movably arranged inside the valve sleeve and used for controlling the large valve element to move, and a pressure adjusting mechanism arranged inside the valve sleeve and used for applying elastic acting force to the differential valve element. According to thevalve element assembly of the pilot-controlled check valve, by arranging the differential valve element inside the valve sleeve, automatic pressure relief of the pilot-controlled check valve can be realized; by arranging the pressure adjusting mechanism, the working pressure of the pilot-controlled check valve can be adjusted so that the pilot-controlled check valve can meet the working requirements of the different pressure, and universality of the pilot-controlled check valve is improved; and the pressure adjusting mechanism is arranged inside the valve sleeve, thus the compactness of the overall structure of the valve element assembly is improved, the integration level of the valve element assembly is high, and disassembly and assembly are convenient.

Owner:HONGDA INTELLIGENT MACHINERY CO LTD

Automatic pressure relief blowout preventer

InactiveCN106223896ASafety life safetyRealize automatic pressure reliefWell/borehole valve arrangementsSealing/packingInlet channelEngineering

The invention discloses an automatic pressure relief blowout preventer which comprises a shell, side doors and gate segments. The side doors are arranged on two sides of the shell, the gate segments are arranged in the side doors, an automatic pressure relief device is arranged in one of the gate segments and structurally comprises a bonnet, the bonnet is arranged in a side of the corresponding gate segment and is fixed into the gate segment by the aid of countersunk head screws, countersunk head holes which are matched with the countersunk head screws are formed in the bonnet, an inlet channel and an outlet channel are arranged in the gate segment, a valve seat is arranged on the gate segment and is positioned on a side of the upper end of the inlet channel, a connecting channel which is communicated with the inlet channel is arranged in the valve seat, a valve clack which is matched with the valve seat is arranged in the gate segment and is connected with one end of a valve stem, a slide cavity is arranged in the bonnet, the other end of the valve stem is slidably arranged in the slide cavity, and a pressure spring is arranged in the slide cavity. The automatic pressure relief blowout preventer has the advantage that the automatic pressure relief blowout preventer is safe in use.

Owner:YANCHENG JINRUI PETROLEUM MACHINERY CO LTD

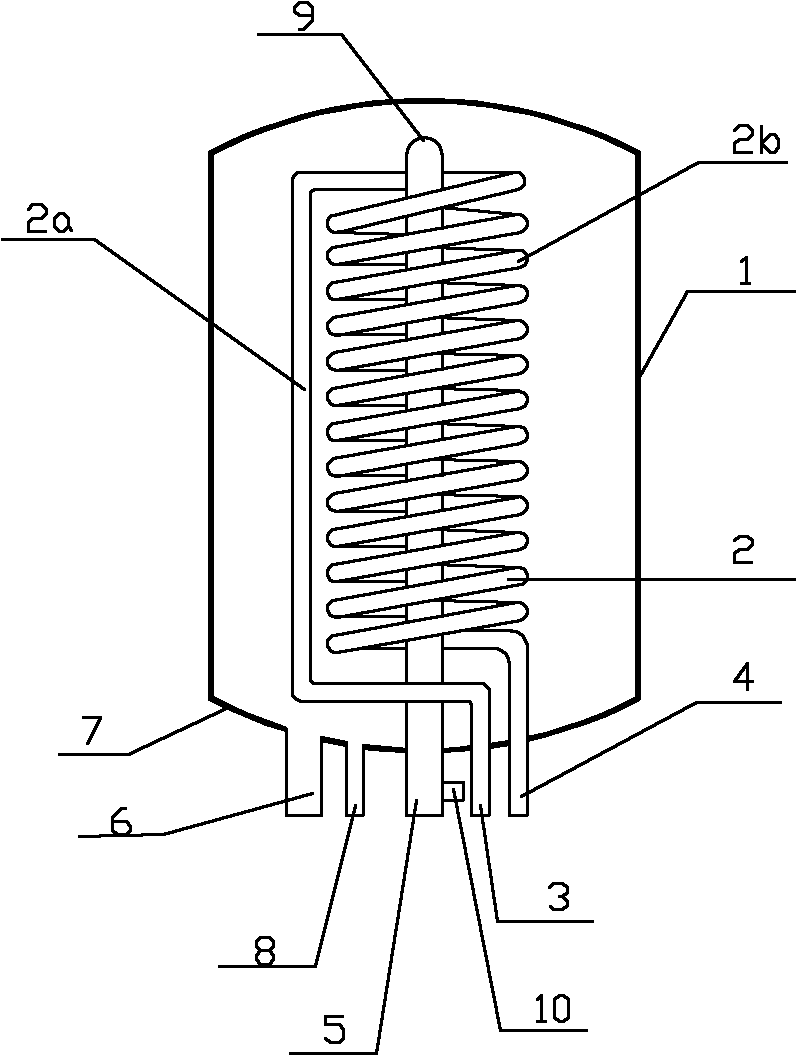

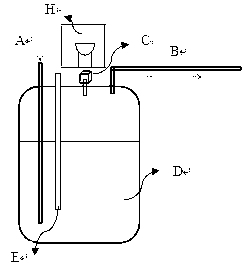

Heat exchange device

InactiveCN101871736ASimple structureSimple processStationary conduit assembliesProduct gasEngineering

The invention relates to a heat exchange device, which comprises a closed container. A heat exchange module is arranged in the container; two ends of the heat exchange module are connected with a first working substance pipe and a second working substance pipe respectively; a first heat exchange pipe and a second heat exchange pipe are fixedly connected on the container; the first working substance pipe, the second working substance pipe, the first heat exchange pipe and the second heat exchange pipe are all fixedly connected on the bottom wall of the container; a top opening of the second heat exchange pipe is directly formed on the bottom wall of the container and communicated with the cavity of the container; and the first heat exchange pipe passes through the bottom wall of the container and extends to the interior of the container. All pipes of the device are fixedly connected at the bottom of the container so that the integral structure of the heat exchange device is simpler; meanwhile, the heat exchange device simplifies the machining process, greatly reduces the material and manufacturing costs, and can improve the reliability; in addition, by adjusting the height of the first heat exchange pipe, effective demixing of heat exchange liquid or gas in the container can be realized so as to obtain liquid or gas with different temperatures and improve the heat exchange efficiency of the whole device.

Owner:谷东照

Using method of precisely positioned sounding balloon

InactiveCN106291759AAvoid breakingOvercome the defect that the pressure inside the ball is increasing and it is easy to burstSatellite radio beaconingMotor driveWeather balloon

The invention discloses a using method of a precisely positioned sounding balloon. The using method comprises followings steps of: 1, assembling a sounding balloon; 2, inflating an air bag; 3, discharging the sounding balloon during lift-off; and 4, providing compensation power when withdrawing the sounding balloon. Compared with the prior art, the using method has the beneficial effects that a disadvantage that a sounding balloon is easily blasted since the pressure in the balloon becomes higher and higher during the lift-off process is overcome; a risk is avoided that during the withdrawing process of the sounding balloon, the sounding balloon may crash since the sounding balloon was discharged before, the floating force is reduced, and with the load of a meteorological data measuring device, the sounding balloon descends faster and faster; a controller starts a motor according to pressure signals fed back by a built-in pressure sensor and an externally-arranged pressure sensor, and the motor drives spiral wings to provide compensation power for the sounding balloon so as to prevent the sounding balloon from crashing; and in addition, a GPS positioning module can precisely position the sounding balloon.

Owner:WUXI NUIST WEATHER SENSOR NETWORK TECH

Sounding balloon

InactiveCN106114811AAvoid breakingOvercome the defect that the pressure inside the ball is increasing and it is easy to burstBalloon aircraftsInstrumentsBurstingMeasurement device

The invention discloses a sounding balloon. The sounding balloon comprises airbags filled with hydrogen and helium, and further comprises an inflating and deflating module, a power compensation module and a controller; and the controller is respectively connected with the inflating and deflating module and the power compensation module. Compared with the prior art, the sounding balloon has the following beneficial effects: the defect of easy bursting of the sounding balloon in the rising process due to higher pressure in the balloon is overcome; in the recovery process of the sounding balloon, because of previous deflation, the buoyancy is reduced; and because of load of a weather data measuring device, the descending speed is faster and faster to generate the falling danger; the controller opens a motor according to pressure signals returned by an internal pressure sensor and an external pressure sensor; and the motor drives a spiral wing to provide compensation power to the sounding balloon to prevent crash.

Owner:WUXI NUIST WEATHER SENSOR NETWORK TECH

Application method of sounding balloon

InactiveCN106218852AAvoid breakingOvercome the defect that the pressure inside the ball is increasing and it is easy to burstBatteries circuit arrangementsElectric powerWeather balloonEngineering

The invention discloses an application method of a sounding balloon. The application method comprises the following steps of I, assembling the sounding balloon; II, inflating an air sac; III, performing deflation when the sounding balloon is lifted off; and IV, providing compensation power when recovering the sounding balloon. Compared with the prior art, the application method disclosed by the invention has the beneficial effects that the defect that in the process that the sounding balloon is lifted off, pressure in the balloon is larger and larger, so that the sounding balloon is easy to blow up is overcome; in the recovery process of the sounding balloon, because the sounding balloon is deflated, buoyance is reduced, and the load of a meteorological data measuring device is added, so that the falling speed of the sounding balloon is faster and faster, the danger that sounding balloon drops exist, a controller turns on an electric motor according to pressure signals fed by a built-in pressure sensor and an external pressure sensor, and the electric motor drives a screw wing to provide the compensation power for the sounding balloon, so that the sound balloon is prevented from crashing.

Owner:WUXI NUIST WEATHER SENSOR NETWORK TECH

Hydraulic control check valve

InactiveCN107842382ARealize automatic pressure reliefImprove versatilityMine roof supportsProps/chocksCheck valveHydraulic control

The invention discloses a hydraulic control check valve. The hydraulic control check valve comprises a valve body, a thread sleeve, a liquid inlet sleeve, a valve seat, a valve sleeve, a large valve core arranged in the valve sleeve, a small valve core arranged in the large valve core, a differential-motion valve core movably arranged in the valve sleeve and used for controlling the large valve core to move and a pressure regulating mechanism arranged in the valve sleeve and used for applying elastic acting force to the differential-motion valve core. According to the hydraulic control check valve, the differential-motion valve core is arranged in the valve sleeve so that automatic pressure relief of the hydraulic control check valve can be achieved, the working pressure of the hydraulic control check valve can be regulated by arranging the pressure regulating mechanism, therefore the hydraulic control check valve can adapt to working requirements of different pressure, and the universality of the hydraulic control check valve is improved; and the pressure regulating mechanism is arranged in the valve sleeve, the compactness of the integral structure of the hydraulic control checkvalve is improved, and dismounting and mounting are convenient.

Owner:HONGDA INTELLIGENT MACHINERY CO LTD

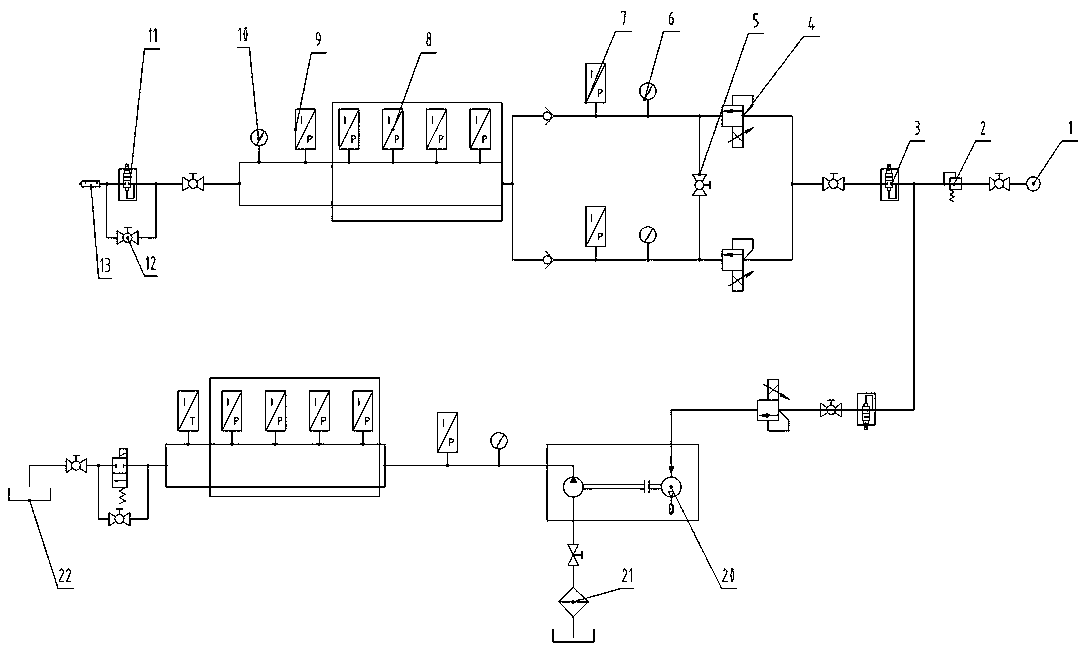

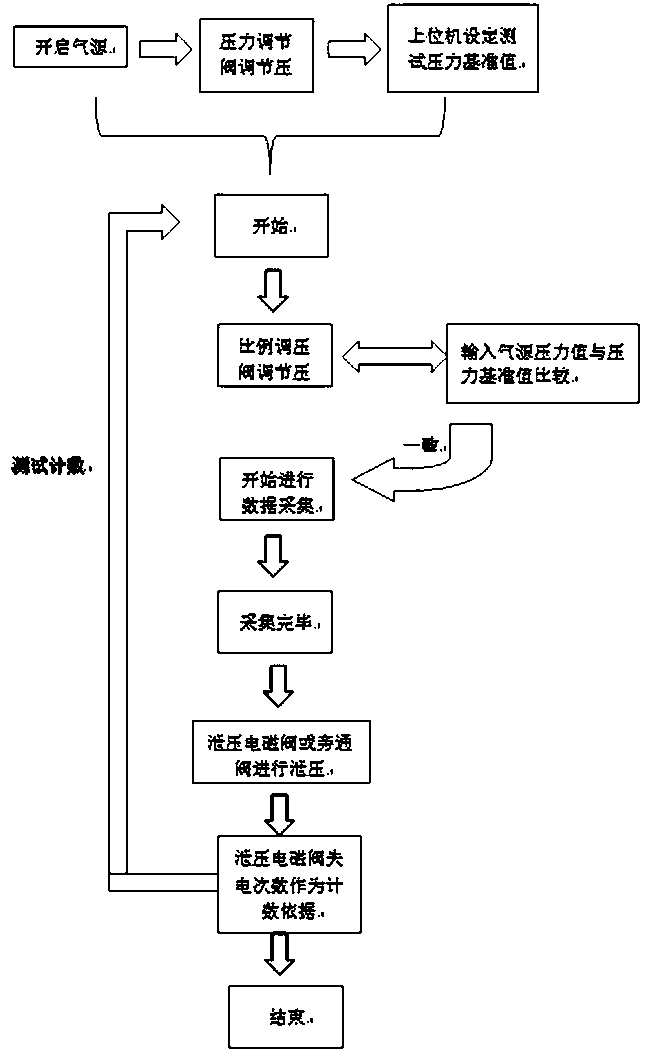

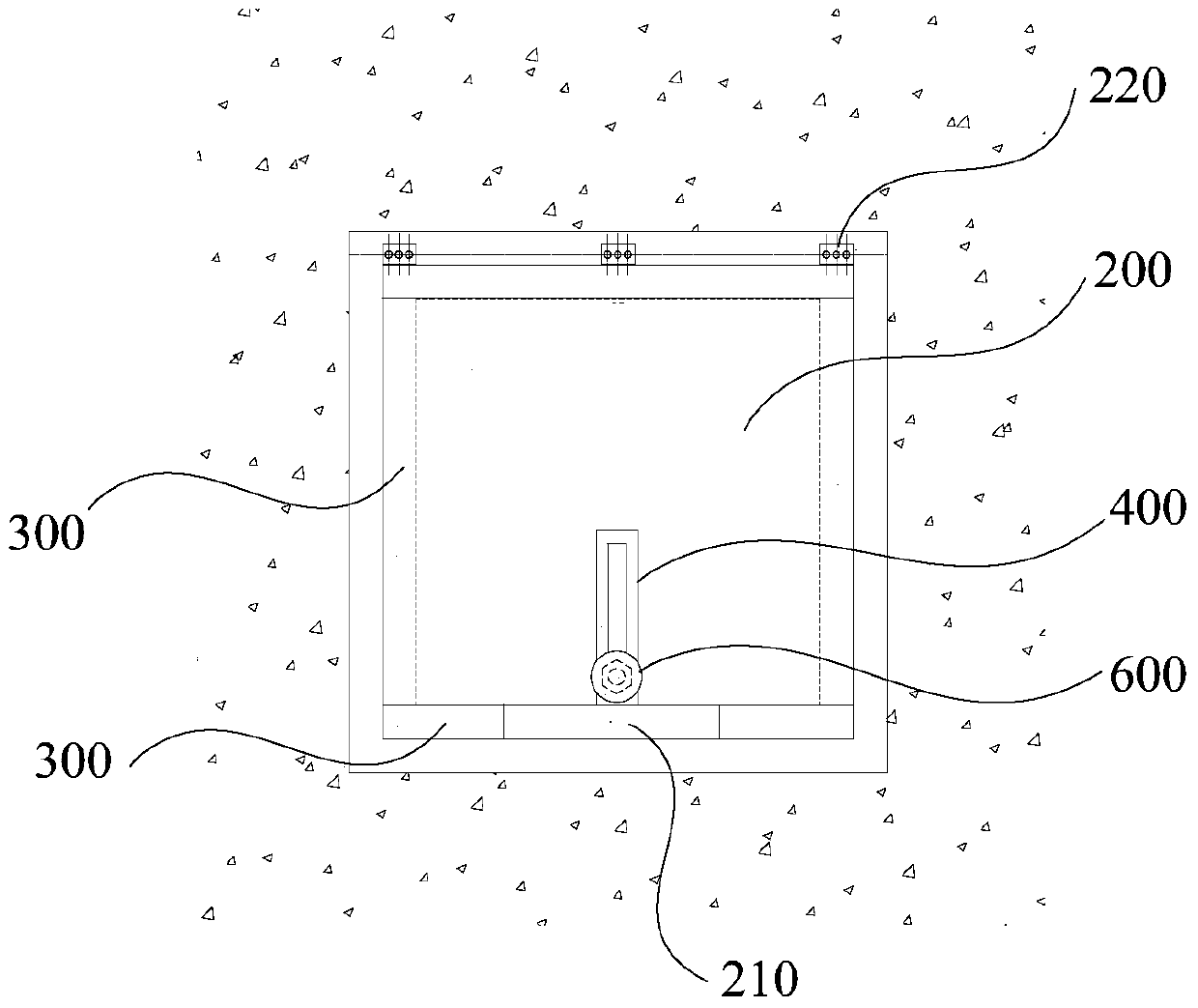

Sensor life test system and working method

InactiveCN111442877AAir pressure output pressure continuous and stable adjustmentEasy to observeFluid pressure measurementRemote controlControl engineering

The invention provides a sensor life test system and a working method. The sensor life test system comprises an air source, wherein the air source communicates with an air processing pipe network, andthe air processing pipe network respectively communicates with a low-pressure test pipe network and a high-pressure test pipe network; a first pressure control pipeline and a second pressure controlpipeline are respectively arranged in the low-pressure test pipe network and the high-pressure test pipe network; a sensor test pipeline and a pressure relief pipeline are arranged in each of the low-pressure test pipe network and the high-pressure test pipe network, the first pressure control pipeline and the second pressure control pipeline both communicate with the sensor test pipeline, and thesensor test pipeline communicates with the pressure relief pipeline; and the air processing pipe network, the first pressure control pipeline, the second pressure control pipeline, the sensor test pipeline and the pressure relief pipeline are all connected with an upper computer. According to the invention, through real-time data acquisition of automatic pressurization and pressure relief processes, the sensor life test is effectively carried out, the overall operation is simple, and remote control can be realized.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

Pressure relief device

ActiveCN104948789BLarge displacementRealize automatic pressure reliefEqualizing valvesSafety valvesAir volumeEngineering

Owner:BROADWELL SHENZHEN TECH

Explosion-proof source bottle for diffusion technology

InactiveCN102851742ARealize automatic pressure reliefAvoid dangerDiffusion/dopingEngineeringAtmospheric pressure

The invention discloses an explosion-proof source bottle for a diffusion technology. The explosion-proof source bottle for the diffusion technology comprises an air inlet pipe, an air outlet pipe, a temperature measuring pipe, a metal block and a buzzer, wherein through the design of automatic pressure-relieving and alarming functions, a metal block pressure relief device is additionally arranged on the source bottle, so that when air pressure in the source bottle is too high, the metal block is ejected to relieve pressure, a circuit is switched on and the buzzer alarms, and when the air pressure is restored, the metal block falls down and the buzzer stops alarming. The explosion-proof source bottle for the diffusion technology has the advantage as follows: when the air pressure in the source bottle is too high, the air pressure is automatically relieved and people are informed of checking by alarming, so that the danger caused by explosion of the source bottle is successfully avoided.

Owner:ZHEJIANG FORTUNE ENERGY

Direct-acting pressure relief pneumatic device, pneumatic control drain valve and water tank

The invention discloses a direct-acting pressure relief pneumatic device, a pneumatic control drain valve and a water tank, the direct-acting pressure relief pneumatic device comprises a shell, an air inlet cover, an inflation telescopic piece, a driven piece and a self-pressure-relief mechanism, the inflation telescopic piece can expand and extend in the shell after being inflated, and the driven piece is arranged in the shell; the self-pressure-relief mechanism comprises an air leakage hole and a touch part, the air leakage hole is formed in the inflatable telescopic part and is in a normally-closed state, the touch part is fixed to the movable end of the inflatable telescopic part, and after the inflatable telescopic part expands and extends in place, the touch part is in a normally-closed state. And the triggering piece can open the deflation hole, so that the inflatable telescopic piece is deflated and contracted. The pneumatic control drain valve comprises the direct-acting pressure relief pneumatic device. The water tank comprises the pneumatic device for direct-acting pressure relief. By the adoption of the air inflation device, pressure relief can be automatically conducted after air inflation is in place, operation is reliable, the structure is very simple, and cost is low.

Owner:GUANGDONG LEHUA HOME FURNISHING CO LTD

Blow-off valve in carbon black production line

PendingCN113757434AEasy maintenanceEasy to cleanOperating means/releasing devices for valvesEqualizing valvesProduction lineProcess engineering

The invention relates to the technical field of blow-off valves, in particular to a blow-off valve in a carbon black production line. The blow-off valve comprises a valve body, a valve cover, a driving mechanism and an air adjusting mechanism. The blow-off valve is used for a carbon black production line, during normal production, waste gas is conveyed to a desulfurizing tower through a pipeline for treatment, and at the moment, the device must be closed so as not to leak waste gas to the outside; when the pressure is too high due to unstable production in a box body, the blow-off valve can timely relieve the pressure to prevent a bag filter from being damaged; and during shutdown maintenance, the blow-off valve can be automatically opened to discharge all waste gas in the box body and keep the box body communicated with the outside. The sealing effect is good, and the tail gas leakage problem is effectively prevented; and the pressure in the valve body is utilized to realize automatic adjustment of pressure relief or sealing. The blow-off valve is simple in structure, easy to match, capable of achieving rapid and automatic blow-off, easy to maintain and capable of guaranteeing long-time stable operation.

Owner:唐山黑猫炭黑有限责任公司

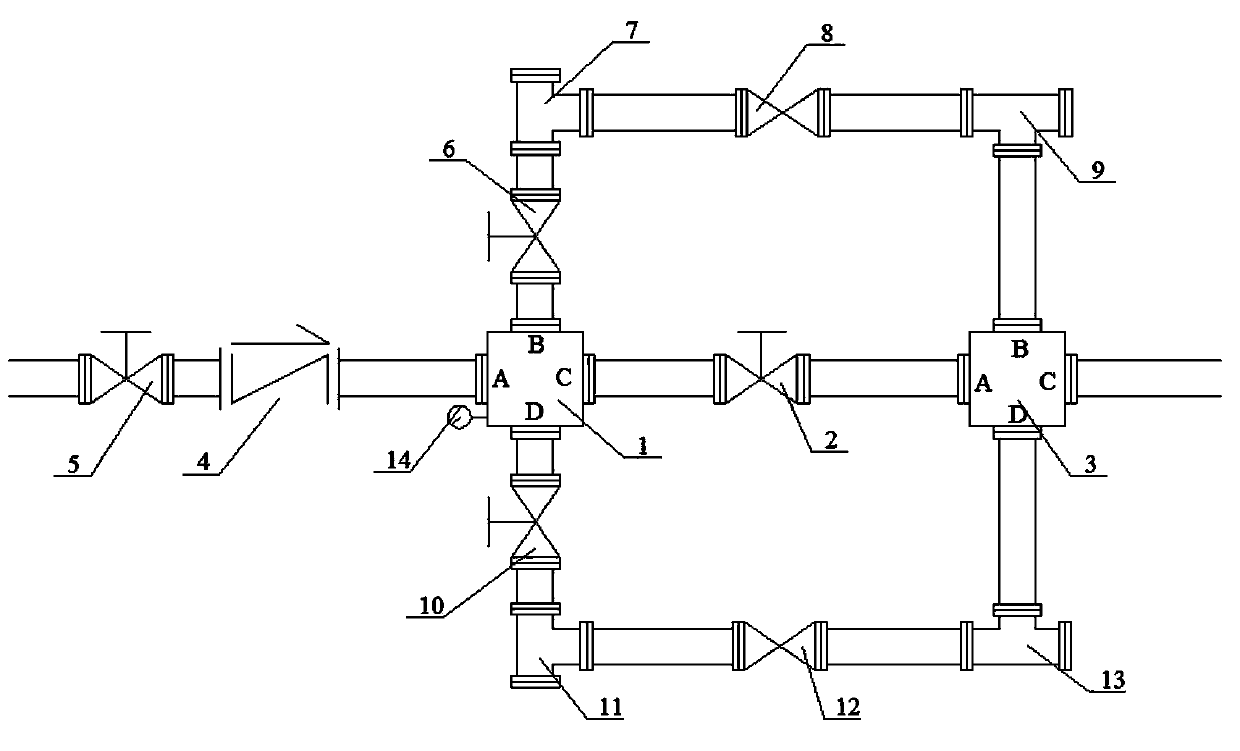

Automatic well mouth pressure relief device and method for overflow shut-in

InactiveCN104196490AFluid pressure reliefAvoid direct impactWell/borehole valve arrangementsSealing/packingEngineeringCheck valve

The invention discloses an automatic well mouth pressure relief device for overflow shut-in. The automatic well mouth pressure relief device for overflow shut-in comprises a main pressure relief pipe, a standby pressure relief pipe and a main flow pipe, wherein the inlet end A of a four-way pipe I (1) is connected with a second manual valve (5), a check valve (4) is connected onto the second manual valve (5), the main pressure relief pipe consists of a third manual valve (6), a target-shaped elbow A (7), a first overflow valve (8) and a target-shaped elbow B (9), the third manual valve (6), the target-shaped elbow A (7), the first overflow valve (8) and the target-shaped elbow B (9) are connected between the outlet end B of the four-way pipe I (1) and the inlet end B of a four-way pipe II (3), and the standby pressure relief pipe consists of a fourth manual valve (10), a target-shaped elbow C (11), a second overflow valve (12) and a target-shaped elbow D (13). The invention further discloses a pressure relief method. The automatic well mouth pressure relief device and method for overflow shut-in has the advantages of being compact in structure, high in reliability, simple in operation and high in pressure control accuracy and automation degree.

Owner:SOUTHWEST PETROLEUM UNIV

Safety pressure-relieving valve for explosion-proof compressed-air storing tank

The invention relates to a safety pressure-relieving valve for an explosion-proof compressed-air storing tank, which comprises a safety valve body, wherein a movable tappet is arranged in the safety valve body, the movable tappet is connected with the safety valve body through an elastic supporting part, the lower end of the movable tappet is provided with an elastic metallic diaphragm, a metallic contact piece I and a metallic contact piece II are arranged above the elastic metallic diaphragm, a pressure-relieving groove is arranged on the safety valve body, and the metallic contact piece I and the metallic contact piece II are connected to the inner part of an early-warning circuit. The safety pressure-relieving valve has the advantages of simple and compact structure, reliability in working and good safety performance. By using the safety pressure-relieving valve, the total mass of the air storing tank is decreased, the cost is saved, and the application range is wide.

Owner:刘立文

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com