Automatic pressure relief blowout preventer

An automatic venting and blowout preventer technology, which is applied in wellbore/well components, earthwork drilling, sealing/packing, etc., can solve problems such as hidden safety hazards in oil operations, and achieve the effect of preventing excessive pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The specific content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

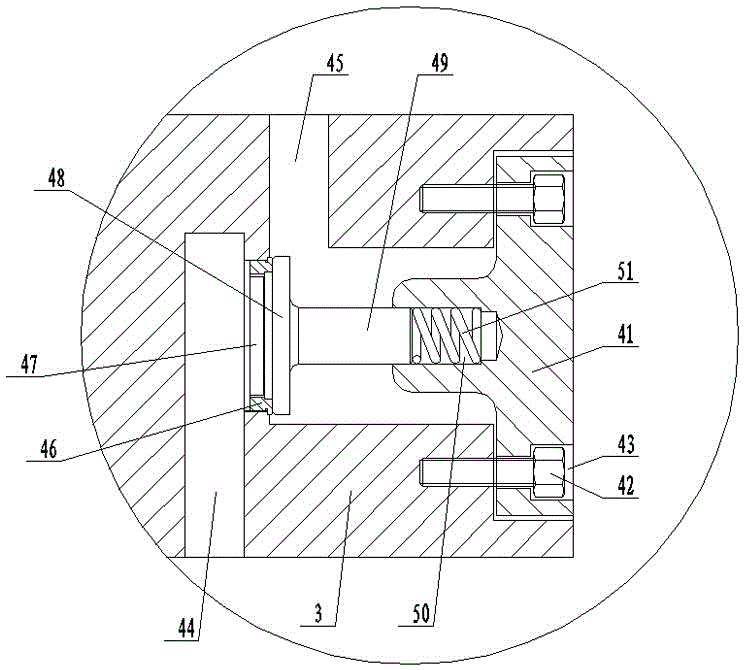

[0011] like figure 1 , figure 2 As shown, the automatic pressure relief blowout preventer includes: a casing 1, side doors 2 arranged on both sides of the casing 1, and a gate 3 arranged in the side door 2, and an automatic pressure relief device is arranged in one of the gates 3 4. The structure of the automatic pressure relief device 4 includes: a valve cover 41 arranged on one side of the gate plate 3, the valve cover 41 is fixed in the gate plate 3 by countersunk screws 42, and on the valve cover 41 A countersunk hole 43 that cooperates with the countersunk head screw 42 is provided, and an inlet channel 44 and an outlet channel 45 are arranged in the gate plate 3 .

[0012] A valve seat 46 is provided on the gate plate 3 at the upper end of the inlet channel 44, and a connecting channel 47 communicating with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com