Radiator

A technology of radiators and male connectors, which is applied in the direction of heat exchanger shells, couplings, heat exchange equipment, etc., can solve the problem that the male connectors of quick connectors cannot automatically release pressure, so as to ensure that no pressure is crushed and realize automatic The effect of pressure relief

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

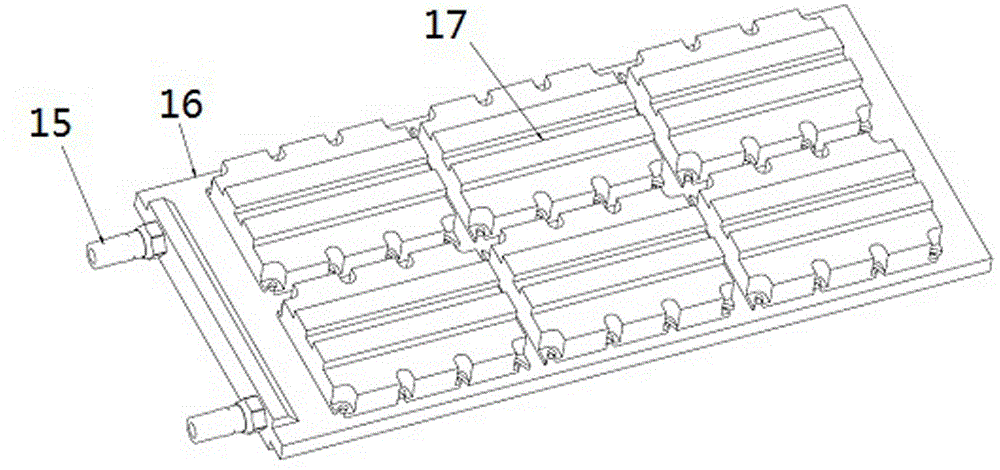

[0017] Examples of radiators are Figure 1~3 As shown: it includes a cold plate 16 provided with a quick connector male head, the quick connector male head includes a male head housing 6 for pushing the movable sealing sleeve of the corresponding quick connector female head at the front end, and the rear end of the male head housing 6 is set There is an external thread 9 for connecting with the corresponding cold plate. The male head housing is provided with a male head fluid passage that runs through the male head housing along the front and rear directions. The front end of the male head fluid passage is guided and sealed. The male spool is pushed by the female spool, and a male spring 8 is arranged between the male spool and the male housing. On the inner wall of the male housing, there is a tapered hole wall section 7 whose diameter gradually increases from front to back, and the tapered hole wall section of the housing cooperates with the male valve core to limit the forw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com