Valve element assembly of pilot-controlled check valve

A technology for hydraulically controlled check valve and valve core assembly, applied in the field of hydraulic components, can solve the problems of waste, pollute the underground environment, poor versatility, etc., and achieve the effects of improving versatility, improving compactness and high integration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The specific embodiment of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings. contribute to its implementation.

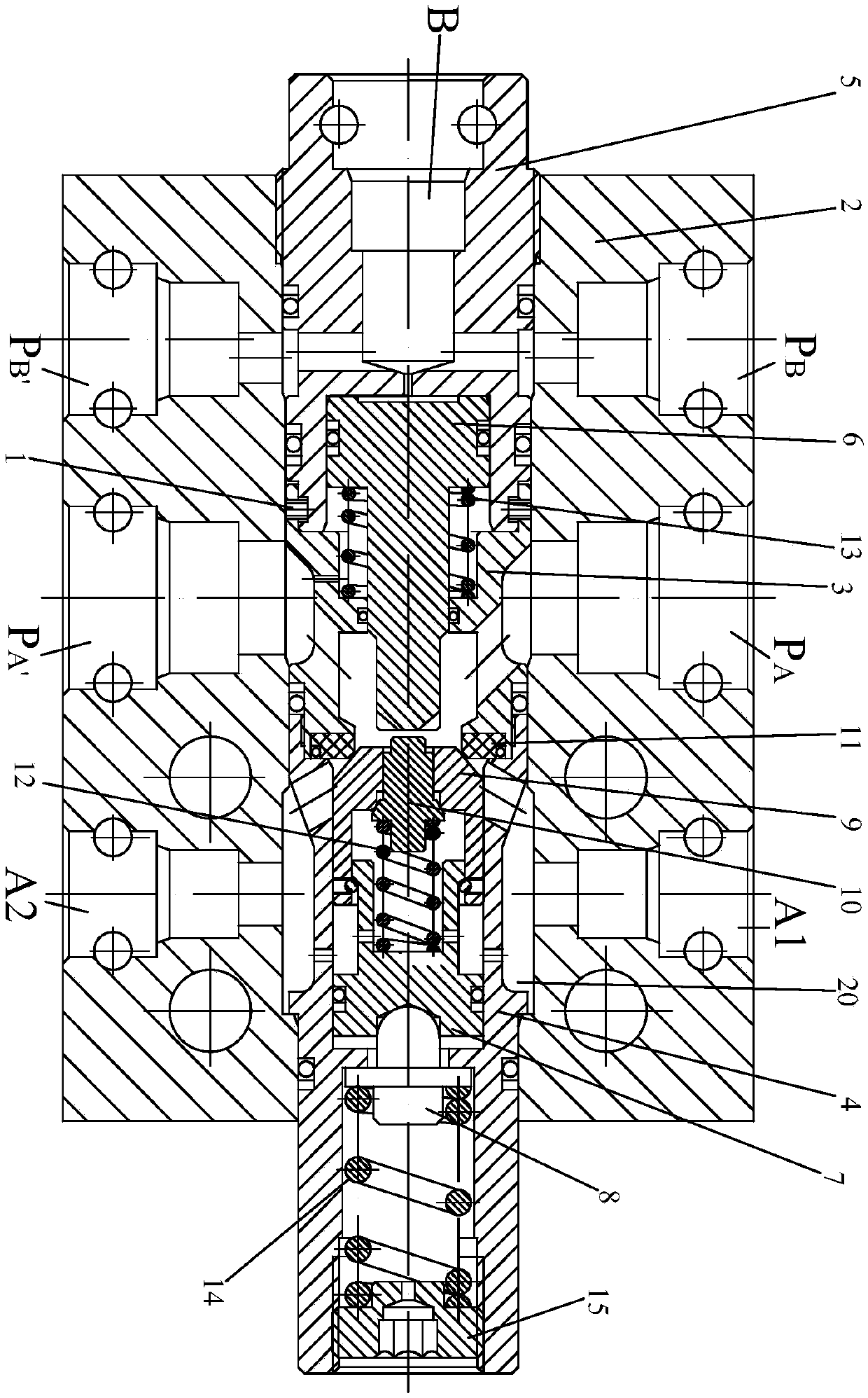

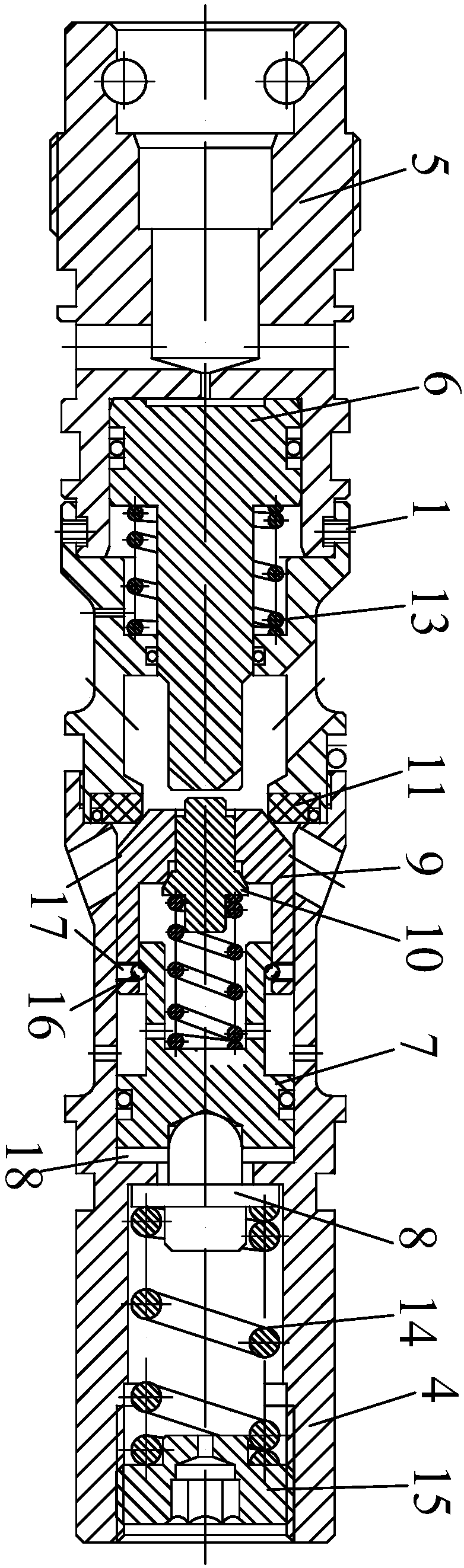

[0041] Such as Figure 1 to Figure 12 As shown, the present invention provides a hydraulically controlled check valve, comprising a valve body 2 and a spool assembly of the present invention. 3. Valve seat 11, valve sleeve 4, first spring 12, second spring 13, large valve core 9 arranged inside valve sleeve 4, small valve core 10 arranged inside large valve core 9, movable Inside the valve sleeve 4 is a differential valve core 7 used to control the movement of the large valve core 9 and a pressure regulating mechanism disposed inside the valve sleeve 4 and used to apply elastic force to the differential valve core 7 .

[0042] Specifically, as figure 1 and figure 2 As shown, the valve sleeve 4, the large valve core 9, the small valve core 10, the liquid inlet sleeve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com