Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

117results about How to "Realize automatic deviation correction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

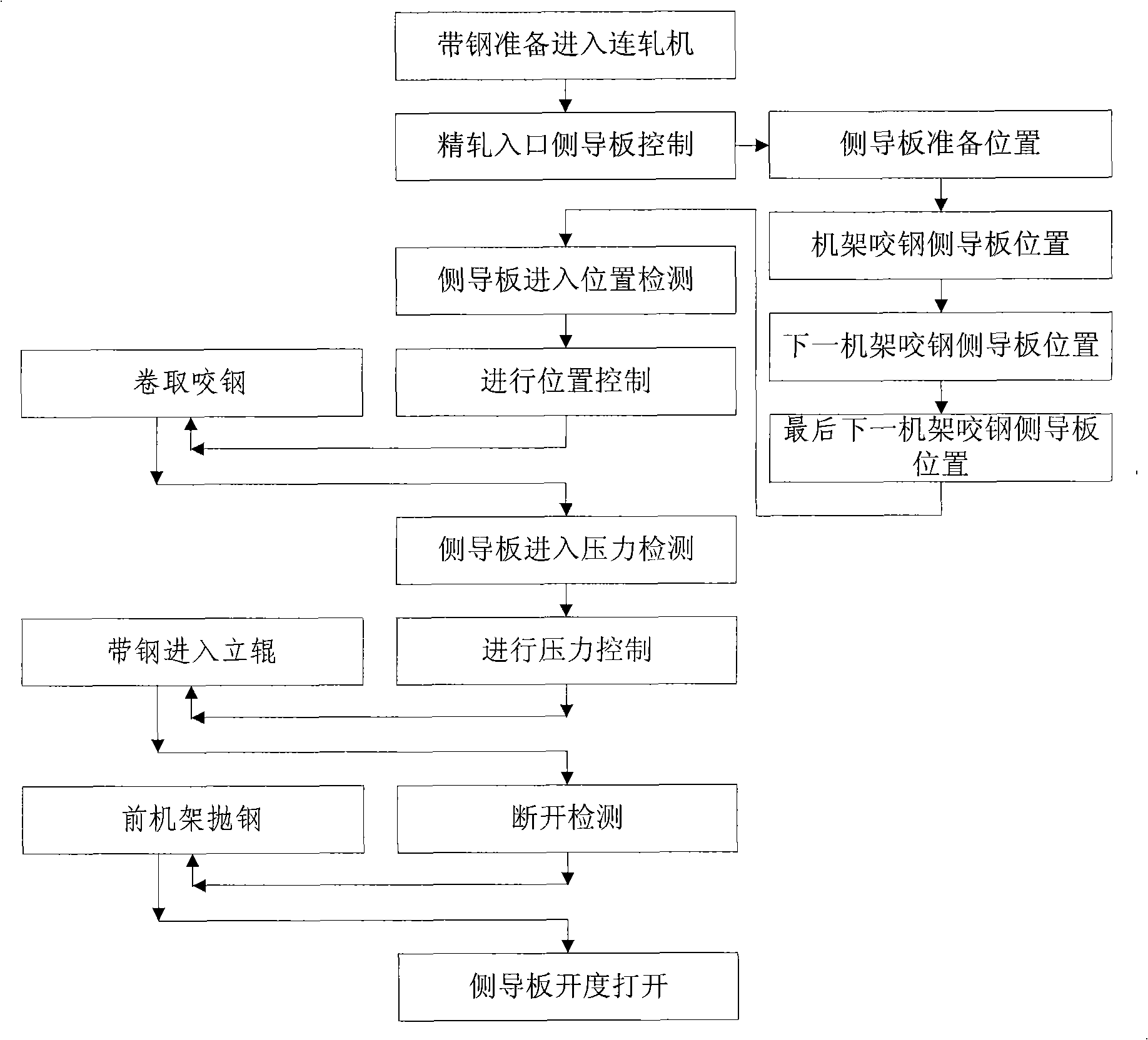

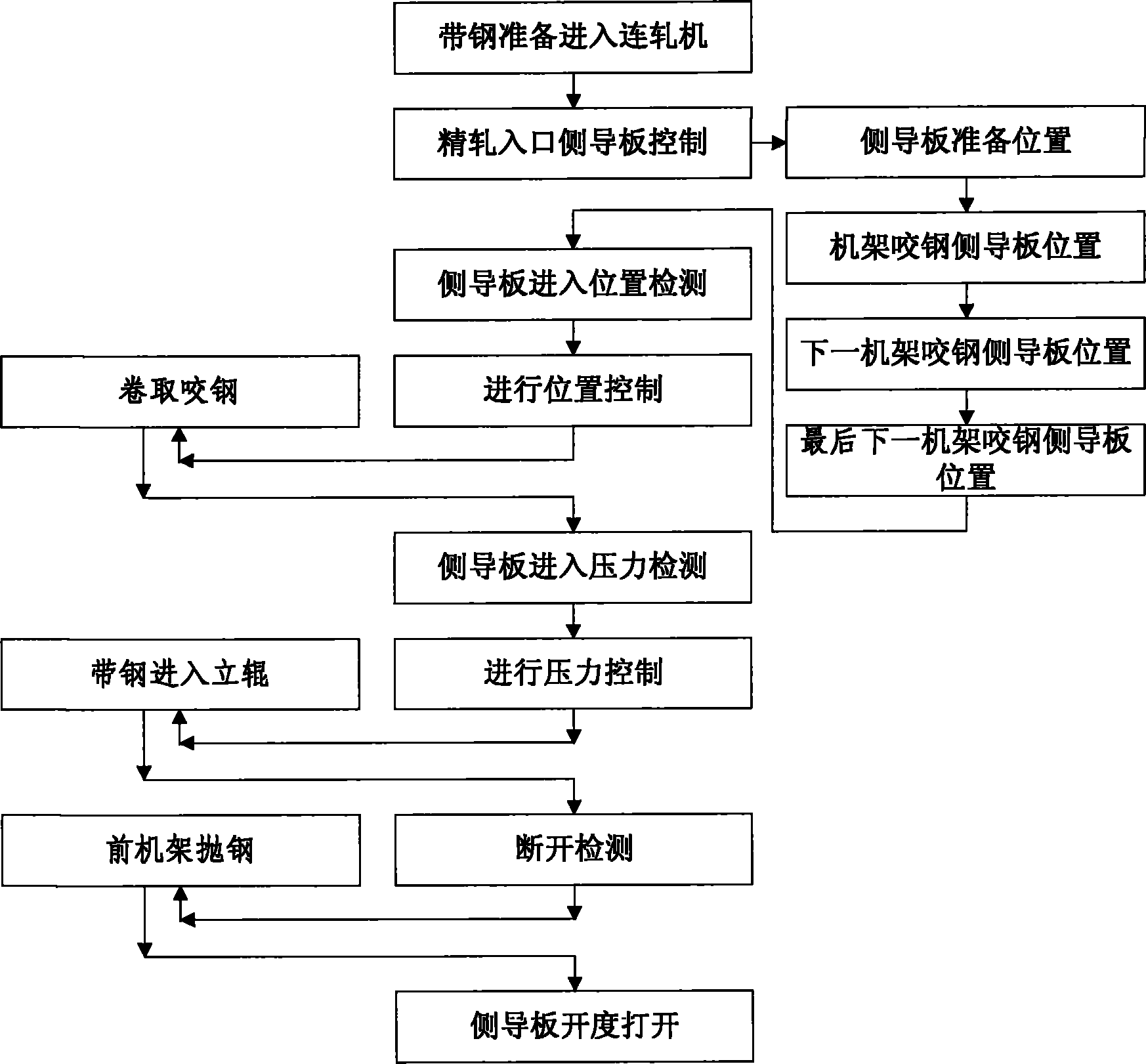

Control method of automatic deviation correction during rolling of hot continuous rolling mill

ActiveCN102120224ARealize automatic deviation correctionImprove stabilityRoll mill control devicesMetal rolling arrangementsPlate pressureStrip steel

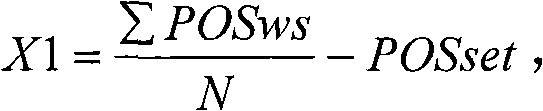

The invention relates to the field of deviation correction in hot continuous rolling, in particular to a control method of automatic deviation correction, which comprises the following steps of: 1, controlling the opening of a side guide plate in a strip steel entering state; 2, opening the side guide plate position detection to control roller gap deviation correction; 3, opening the side guide plate pressure detection to control roller gap deviation correction; and 4, controlling the opening of the side guide plate in a strip steel throwing state, closing the side guide plate pressure detection when the tail of the strip steel leaves from a first stand, and entering the control of the opening of the side guide plate until the strip steel completely leaves from a continuous rolling stand. The control method is perfected by using the traditional equipment condition, adopts a positive and effective means for the treatment of deviation, realizes automatic deviation correction on the strip steel, improves the rolling stability, is accurate in control and capable of ensuring the stability of hot rolling production, and has wider popularization value.

Owner:BAOSHAN IRON & STEEL CO LTD

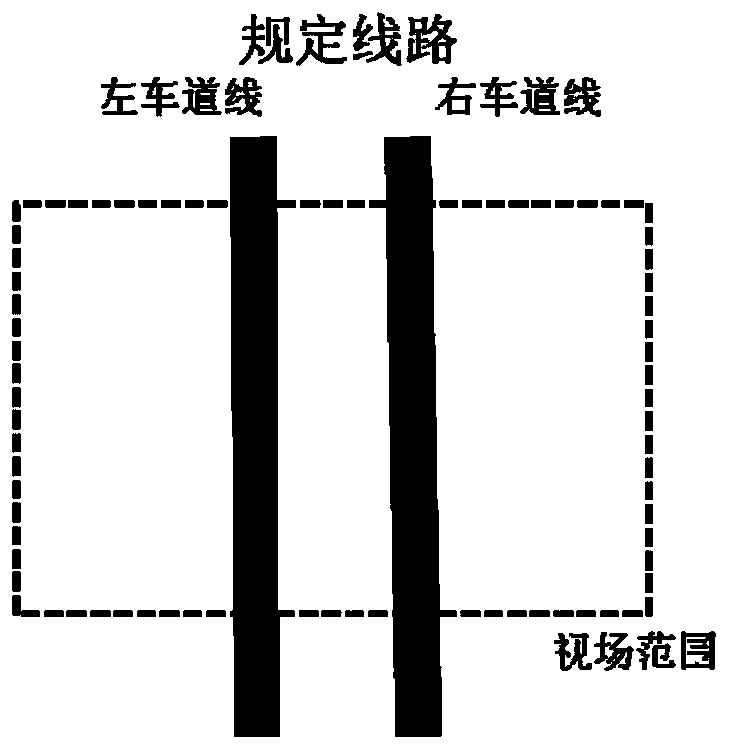

Machine vision automatic deviation rectifying system of tire crane and deviation rectifying method

ActiveCN110054089ARealize automatic deviation correctionImprove work efficiencySafety gearMachine visionControl system

The invention relates to a machine vision automatic deviation rectifying system of a tire crane and a deviation rectifying method. An acquisition module acquires an image of a regulated line in the advancing process of the tire crane; a calibration module acquires coordinates of the feature portion of a calibration reference object in a pixel coordinate system and an actual coordinate system; a coordinate conversion module achieves conversion between the pixel coordinate system and the actual coordinate system; a pre-processing module processes the image of the acquisition module to acquire data with clear and stable features; a line recognition module detects and recognizes the regulated line in the image, determines the direction deviation delta alpha and the distance deviation delta d between the actual line and the regulated line in the actual driving process, and sends the deviations to a PLC communication module; and the PLC communication module stores the data and sends the datato a tire crane control system for deviation rectifying. By means of the machine vision technology, automatic deviation rectifying in the tire crane cart advancing process is achieved, the working efficiency is improved, and accidents are reduced.

Owner:BEIJING AEROSPACE AUTOMATIC CONTROL RES INST +1

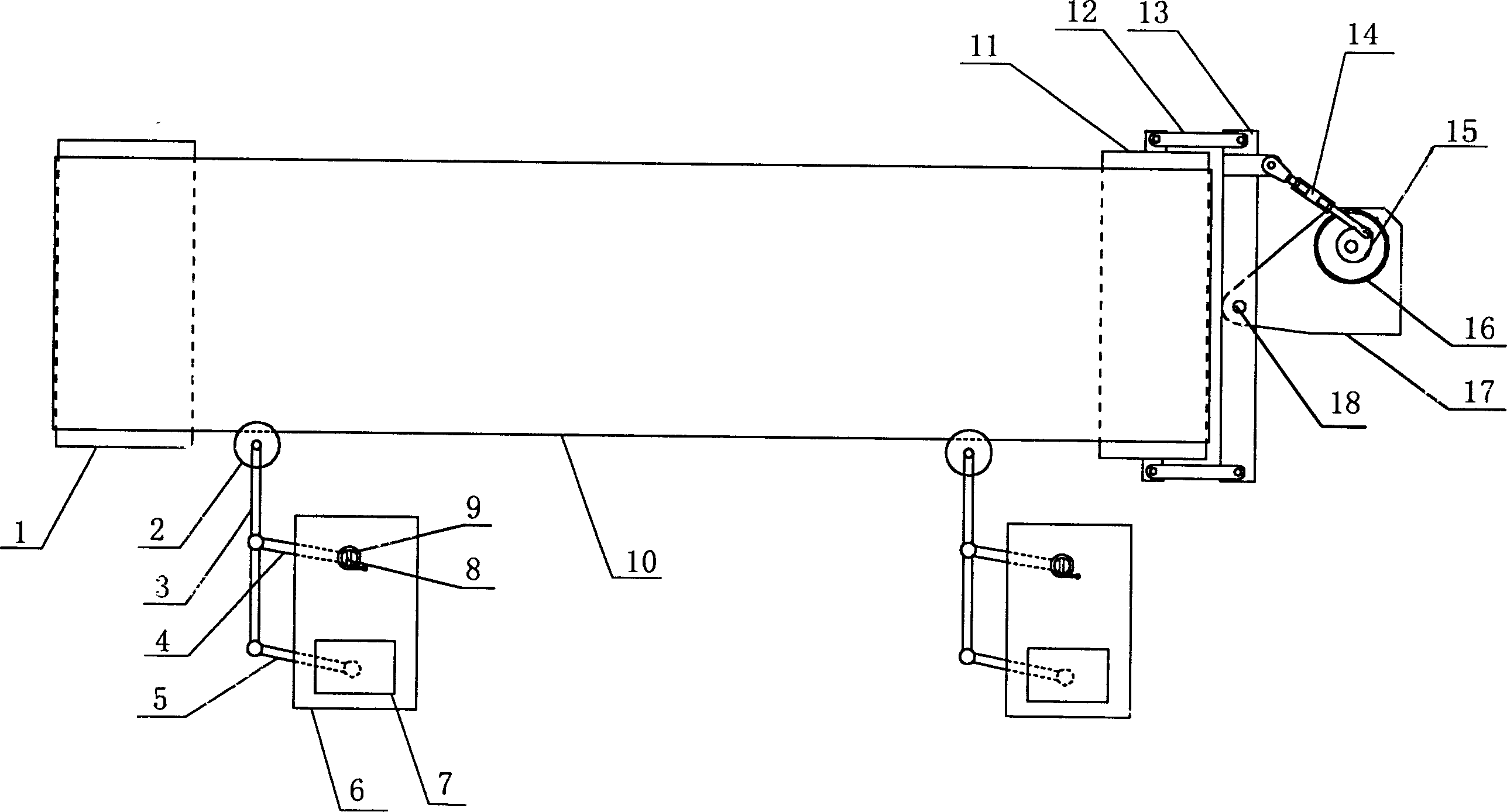

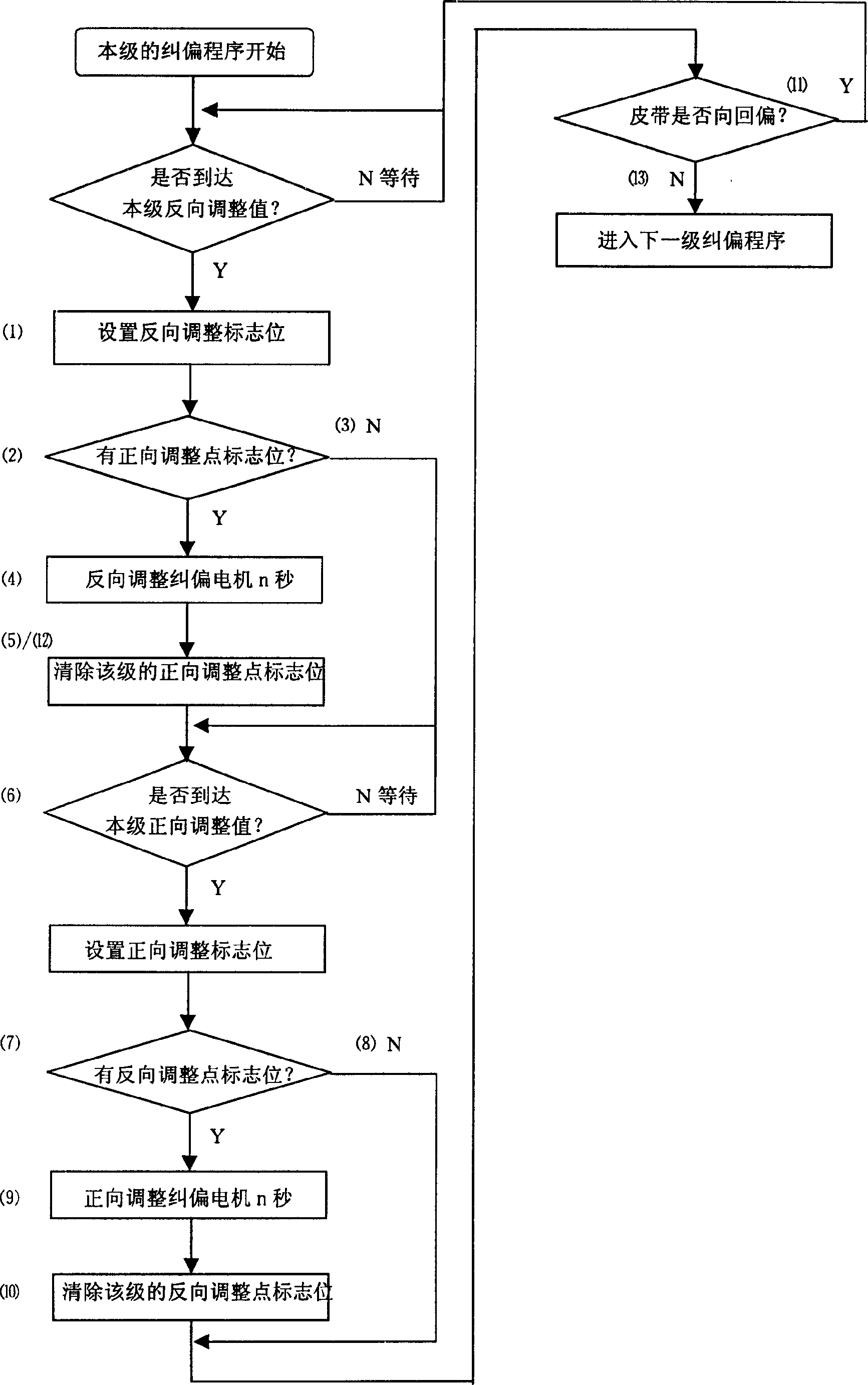

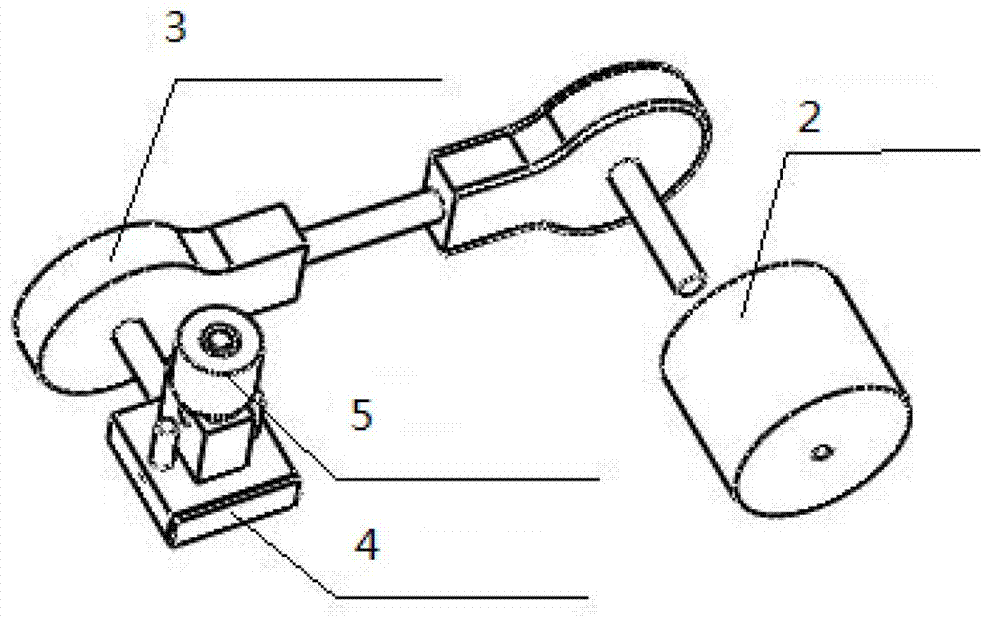

Automatic error correcting system of short leather belt and its method

InactiveCN1597469ACorrection method is reasonable and feasibleCorrection accuracyConveyorsControl devices for conveyorsSystem structureLeather belt

This invention relates to a system and a method for calibrating short belt against a correct position. A system consists of a four-bar-linkage, a motor a cam, which is hinged with a push rod, and a position monitor. The four-bar-linkage is used as an actuator. The motor drives the cam to actuate the four-bar-linkage via the push rod hinged with the cam. The push rod is respectively hinged with the cam and a movable rod of the four-bar-linkage as its both ends. The position monitor is equipped with a detecting lever. A roller is elastically pressed to contact with an edge of the belt. The method is carried out by: feeding the detected position signals into computer system, outputting a calibrating signal to the motor and to change the tension forces on both edges of the conveying belt via the cam mechanism and actuator. It is simple and reliable.

Owner:OCEANOGRAPHIC INSTR RES INST SHANDONG ACAD OF SCI

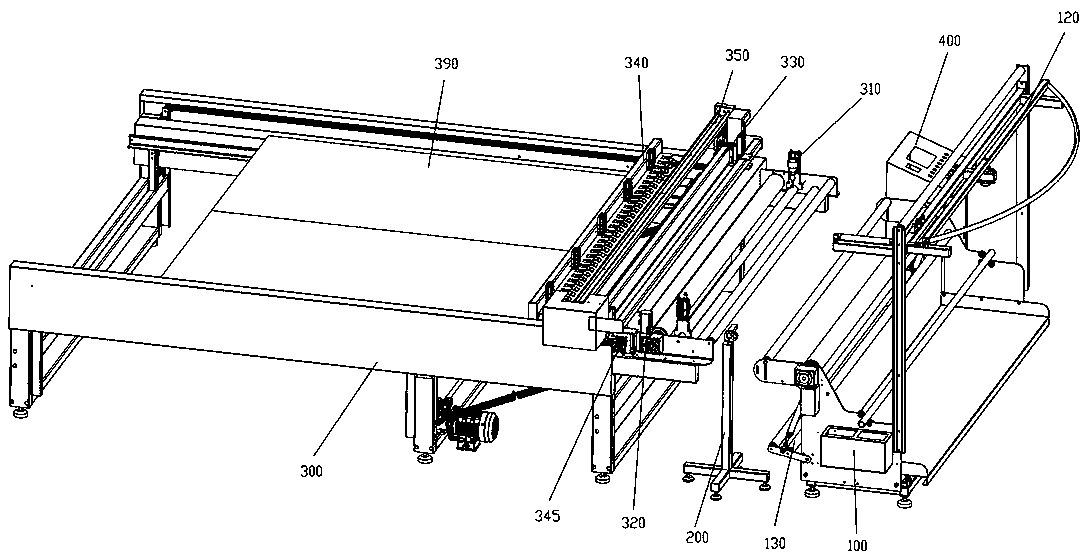

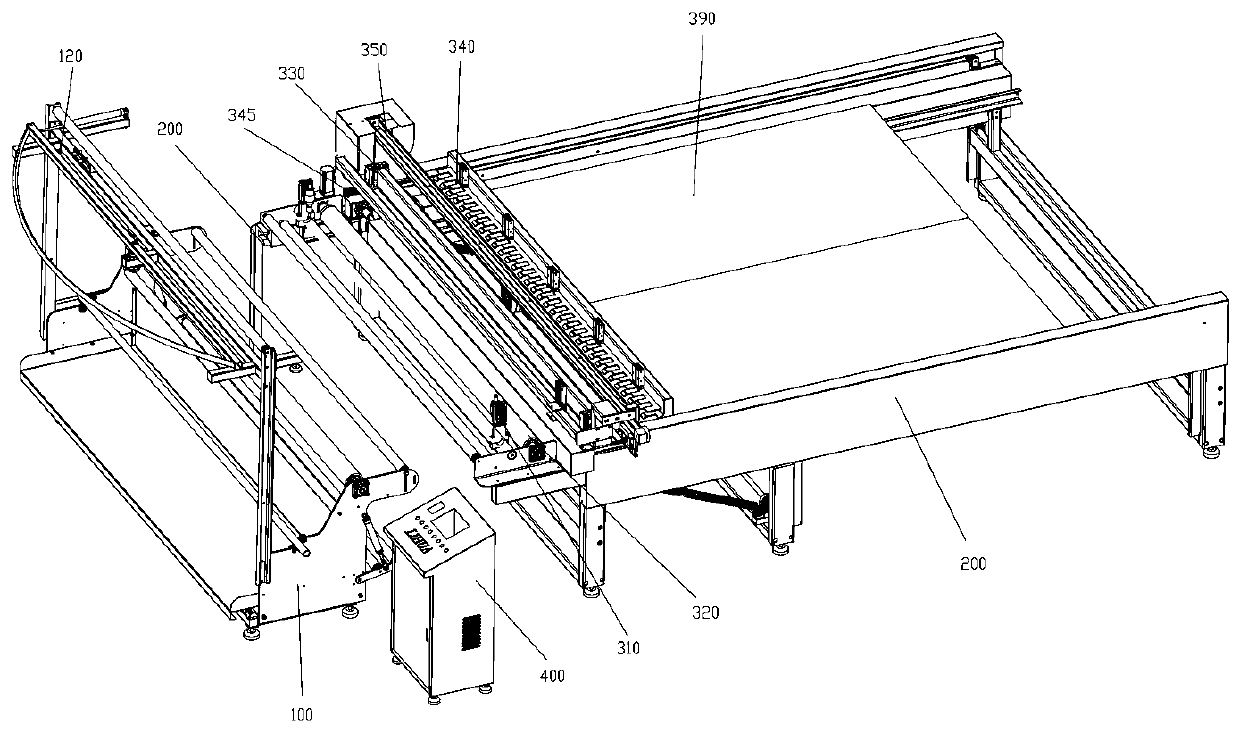

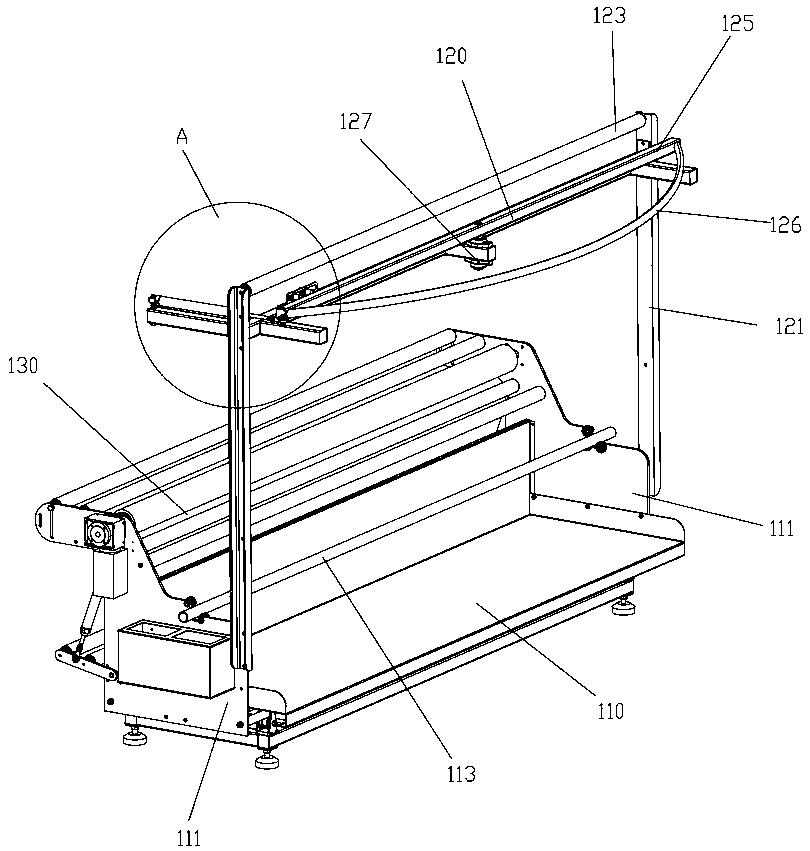

Automatic cloth cutting and discharging equipment and control method thereof

InactiveCN110860935ARealize horizontal deviation correction positioningConsistent cutting tensionSevering textilesMetal working apparatusDistribution controlEngineering

The invention provides automatic cloth cutting and discharging equipment and a control method thereof. The automatic cloth cutting and discharging equipment comprises a feeding platform, a tension adjusting feeding mechanism, an opposite edge deviation rectifying mechanism, a cloth edge cutting mechanism, an automatic cutting and discharging mechanism and a discharging platform which are arrangedin sequence along the advancing direction of cloth; and the equipment further comprises a power distribution control box, wherein the control box realizes control of the whole equipment. The automaticcloth cutting and discharging equipment has the advantages of being reasonable in structural design, quick and accurate in cloth cutting and capable of being applied to various cloth cutting.

Owner:中缝(厦门)自动化科技有限公司

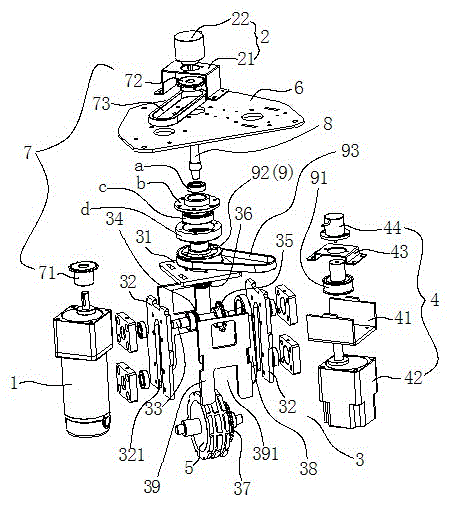

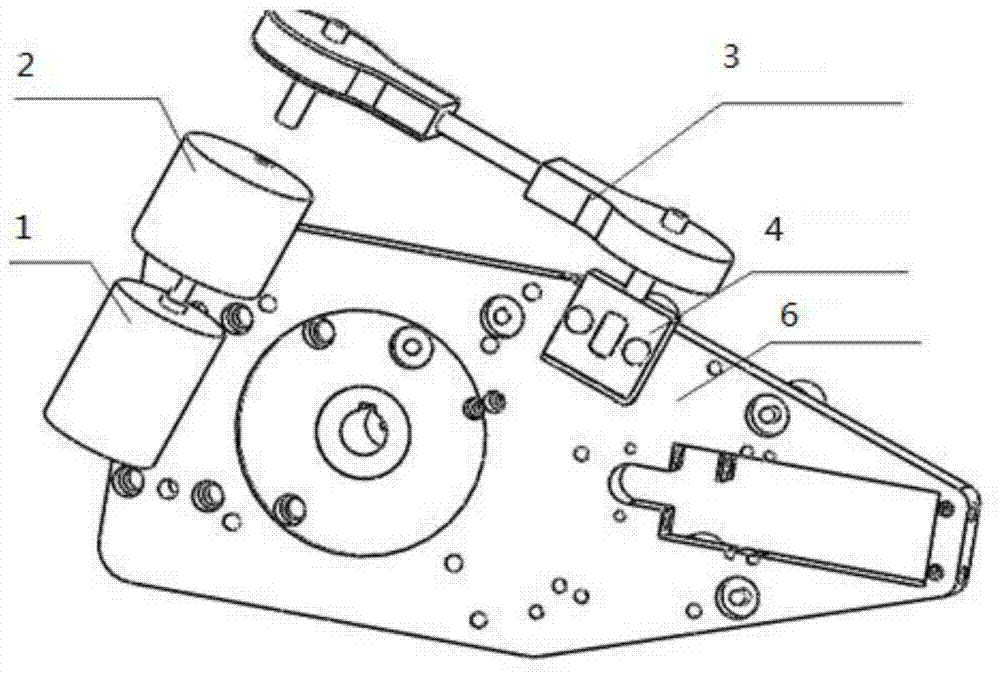

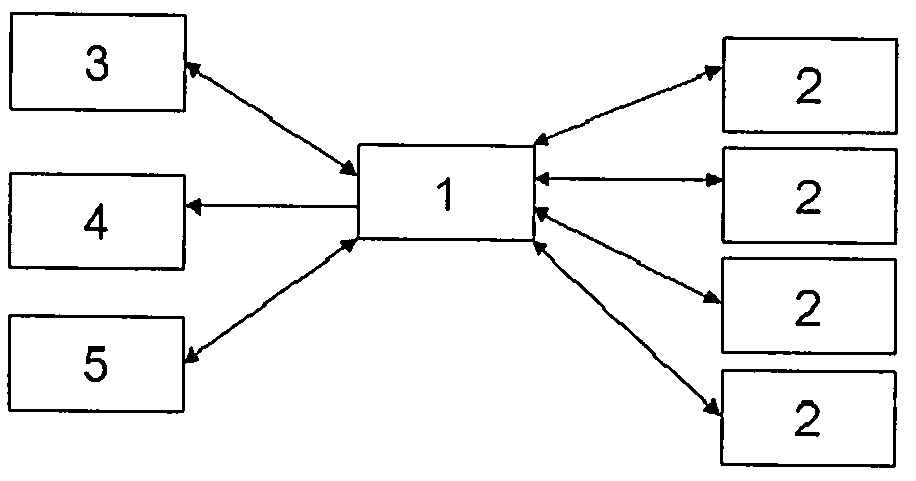

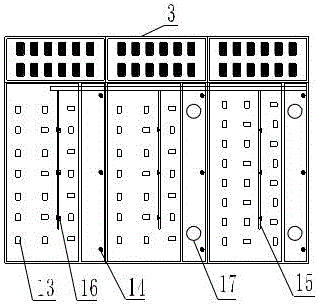

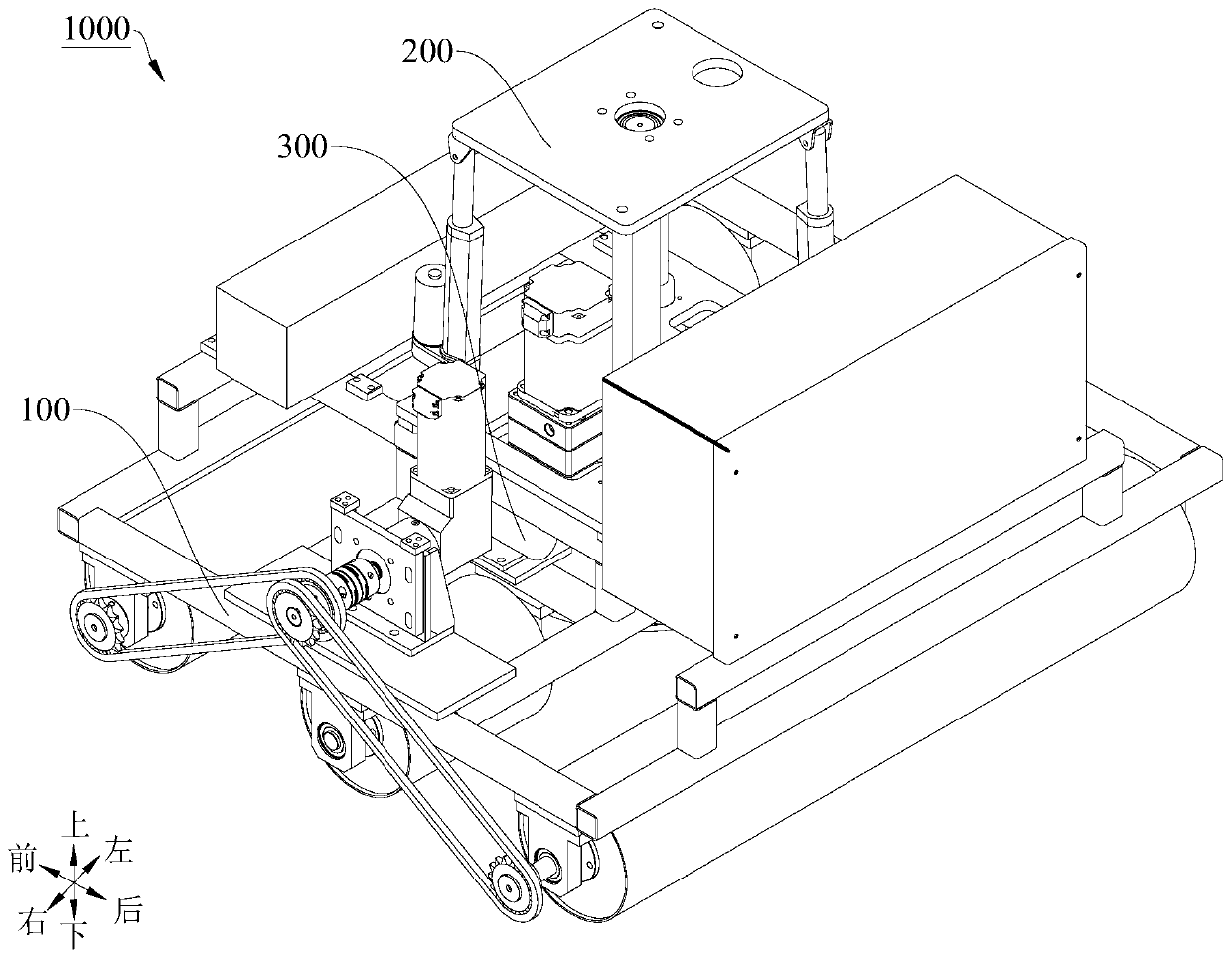

AGV steering wheel drive system module

ActiveCN104986036AChieve progressRealize functionElectrical steeringControl devicesSteering wheelDrive wheel

The invention relates to the technical field of guide transport equipment and discloses an AGV steering wheel drive system module. The AGV steering wheel drive system module comprises a drive unit, a speed feedback unit, a transmission unit, an angle feedback unit and a drive wheel. The drive unit, the speed feedback unit and the angle feedback unit are all arranged on an installation board. One end of the drive unit is connected with the speed feedback unit through a chain wheel mechanism. The speed feedback unit is connected with the transmission unit through a linkage shaft on the connected chain wheel mechanism. The transmission unit is connected with the drive wheel. The linkage shaft is provided with a steering mechanism connected with the angle feedback unit. By the adoption of the AGV steering wheel drive system module, drive power transmission efficiency is high, the accuracy of signals fed back through an encoder and an angle sensor is high, the space occupied by drive steering operation is small, machining cost is low, and installation and maintenance are easy.

Owner:东莞云帝斯科研有限公司

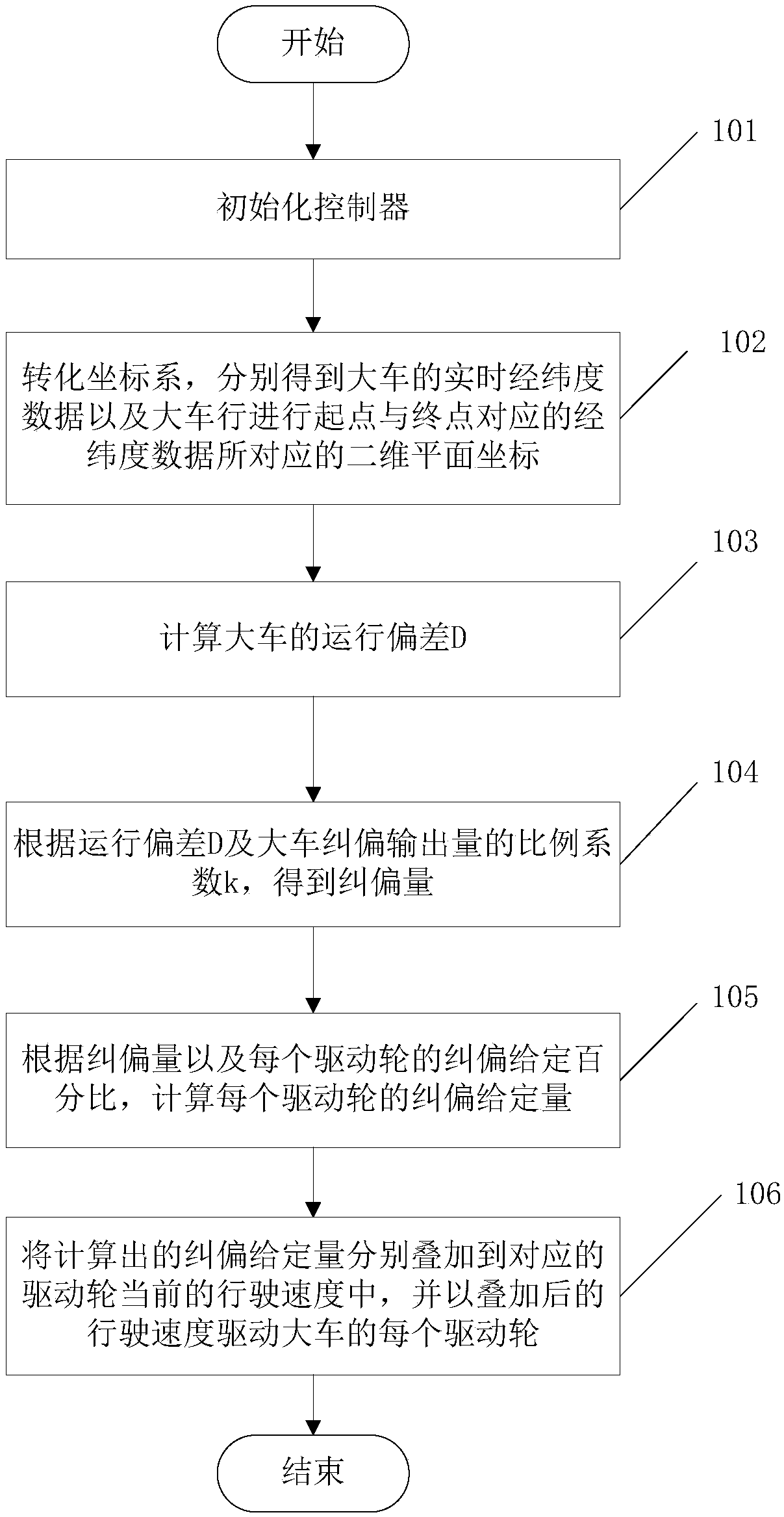

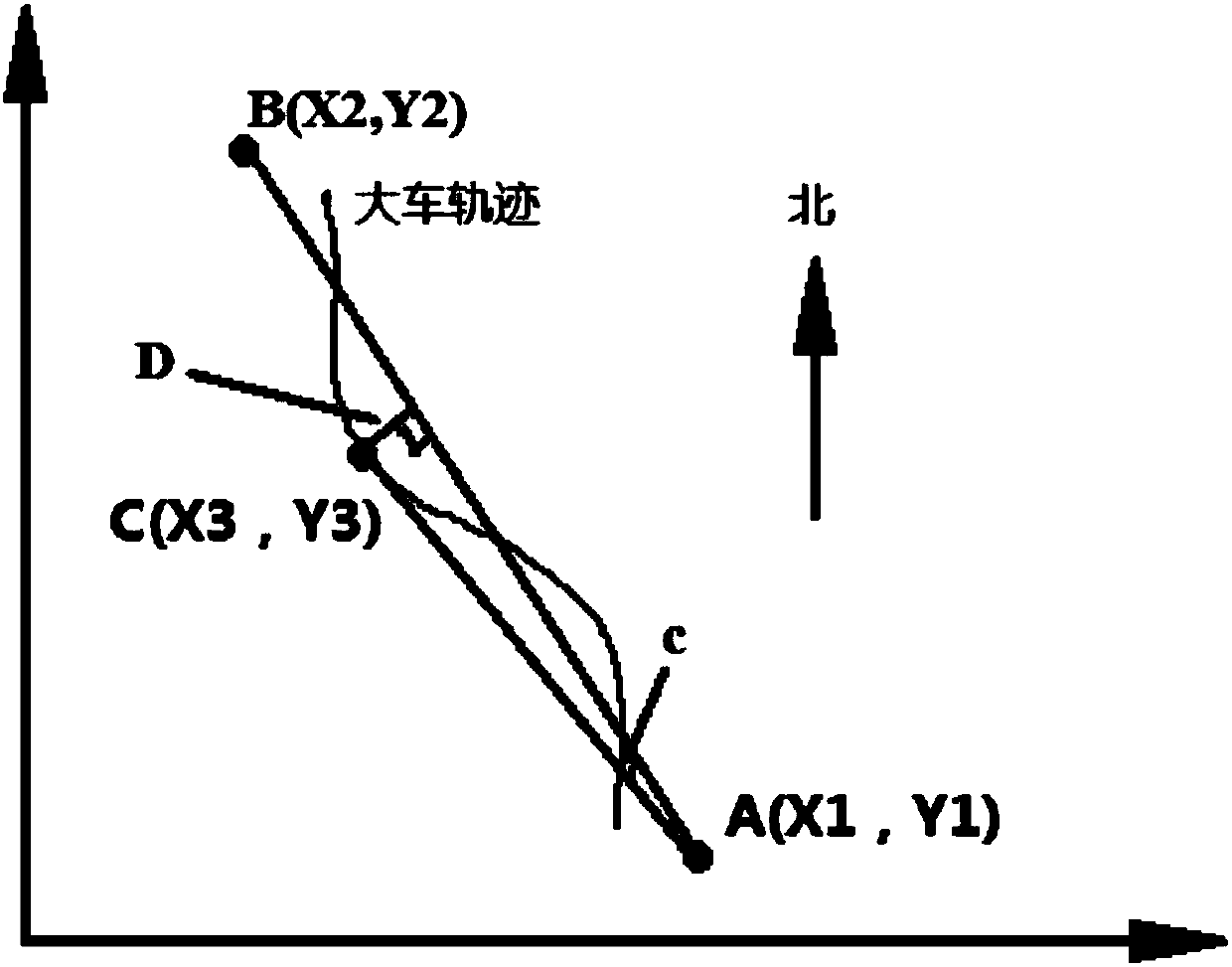

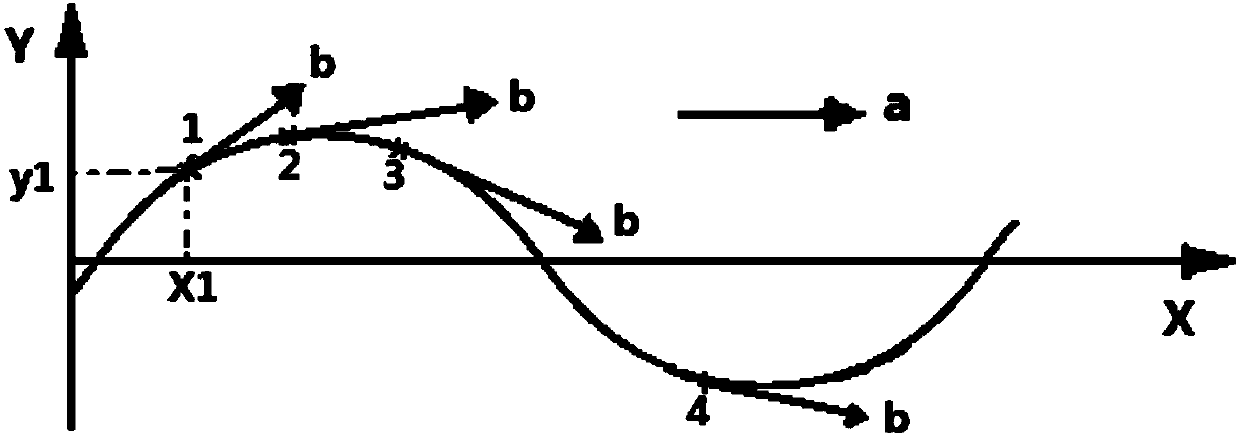

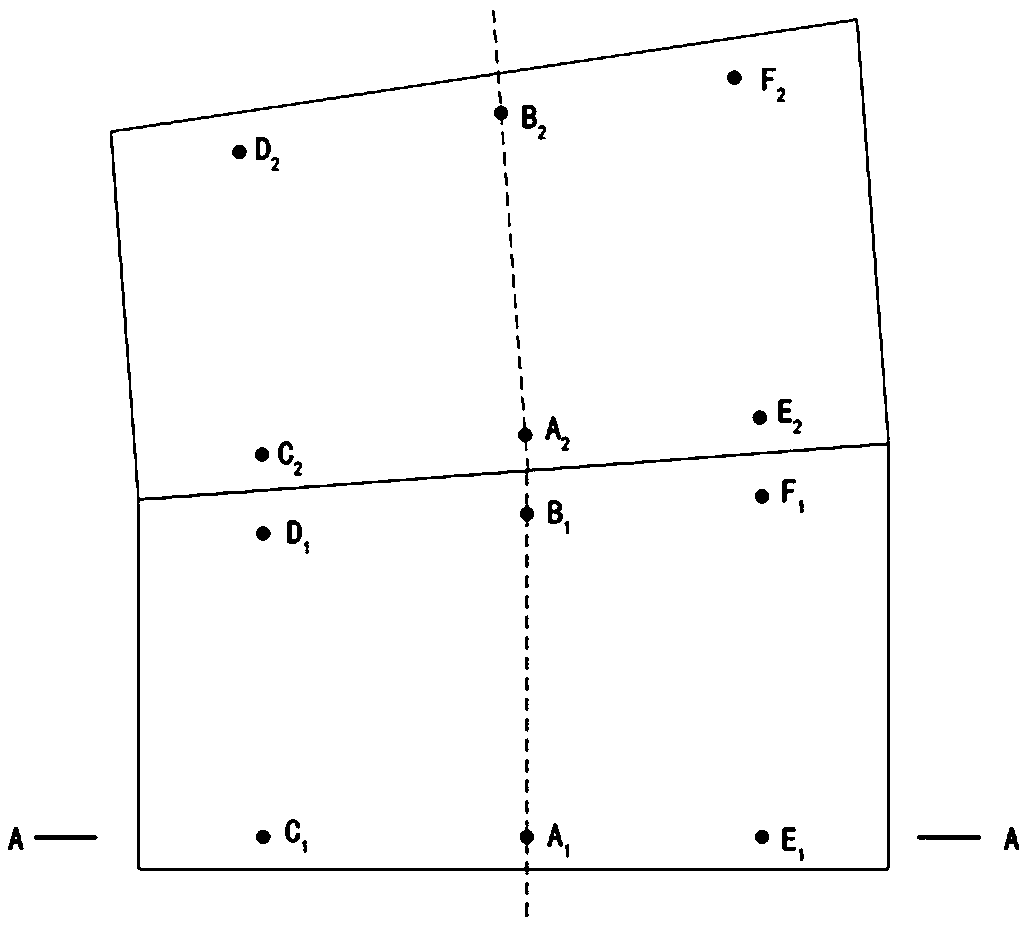

Tire crane cart automatic deviation correcting method

ActiveCN107943020AJudgment of operabilityJudgment bias trendLoad-engaging elementsPosition/course control in two dimensionsSimulationReference line

An embodiment of the invention relates to the field of port machinery, and discloses a tire crane cart automatic deviation correcting method. The tire crane cart automatic deviation correcting methodcomprises the steps of: calculating a current running deviation D of a tire crane cart, wherein the running deviation D is a distance between a real-time coordinate point of the current cart and a trajectory reference line; acquiring a deviation correcting quantity according to the running deviation D and a proportional coefficient k of a cart deviation correcting output quantity; and controllingdriving wheels of the cart according to the deviation correcting quantity, so that the cart can run straight. Compared with the prior art, the tire crane cart automatic deviation correcting method calculates the deviation correcting quantity by combining with the real-time running deviation of the cart, and can judge a real-time running direction and a deviation trend of the card more precisely, so as to conduct calculation of the deviation correcting quantity more precisely, and control the driving direction of the cart more precisely; meanwhile, the automatic deviation correcting method saves labor, reduces the labor intensity of related staff, and is conducive to realizing on-site unattended operation.

Owner:SHANGHAI SIGRINER STEP ELECTRIC

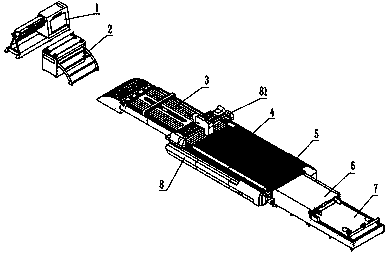

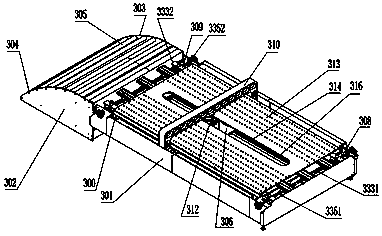

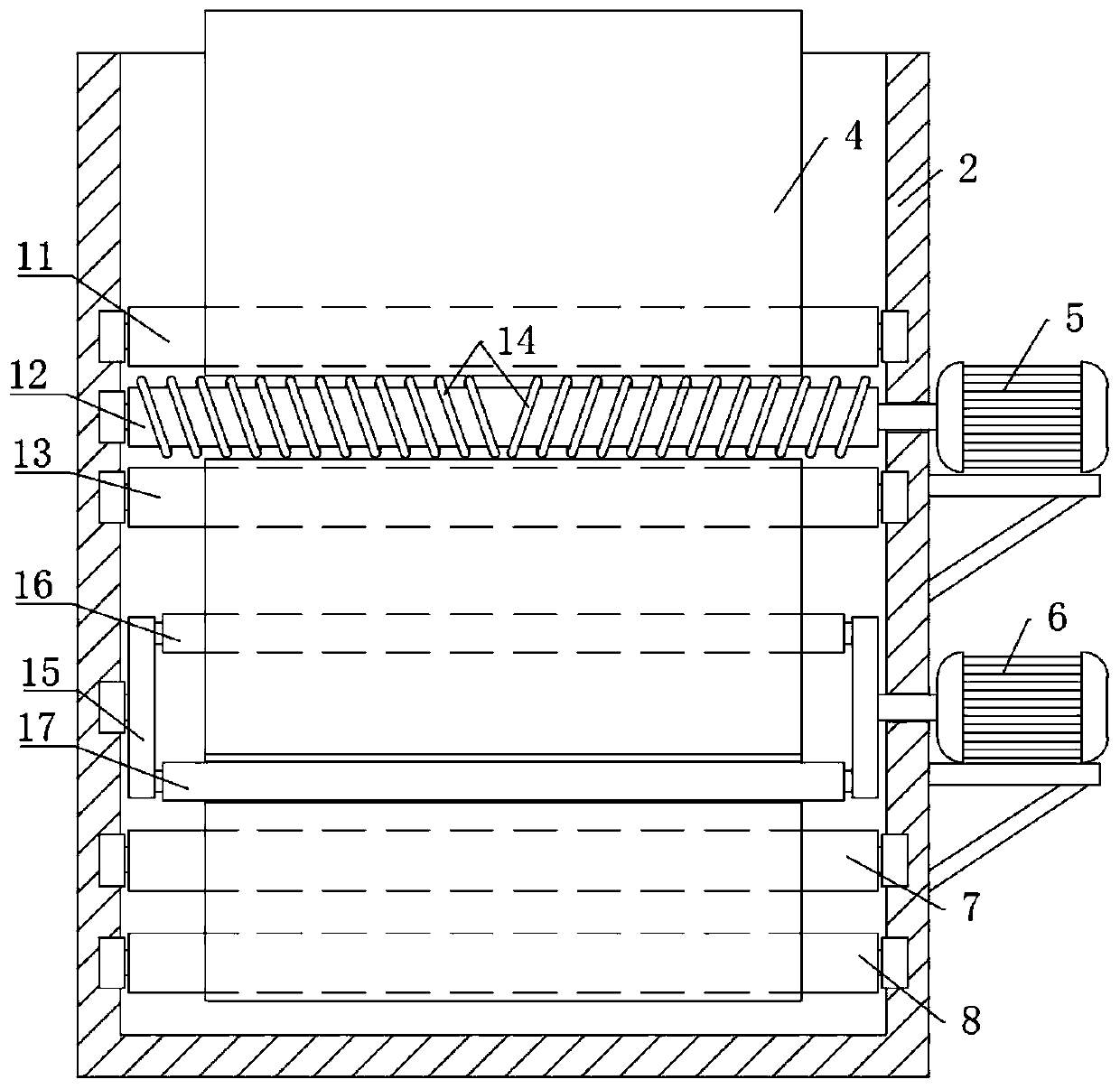

Laser cutting device

PendingCN110170752APrecise cutting and automatic unloadingReduce biasLaser beam welding apparatusStops deviceLaser cutting

The invention belongs to the technical field of metal plate production equipment, and particularly relates to a laser cutting device. The laser cutting device is provided with a main lathe bed (8), afeeding machine (3), a clean material cutting area (4) and a rotary workbench (5), wherein the feeding machine (3), the clean material cutting area (4) and the rotary workbench (5) are arranged from back to front; the feeding machine (3) is provided with a feeding rail (314), a feeding crossbeam (310) and a floating clamp (312); the clean material cutting area (4) is provided with a clean materialcutting support bar (41), a clean material cutting servo motor (42) and a stop device; and the rotary workbench (5) is provided with a rotary support bar (51), a rotary servo motor (52), a chain support rail (53) and a supporting bracket (54). According to the laser cutting machine, the feeding machine can achieve high-precision positioning and automatic deviation rectifying through plate limiting and can achieve automatic feeding; a plate is accurately positioned by the clean material cutting area so to be cleaned and cut and is then conveyed to the rotary workbench to be cut into a workpiece; and laser cutting based on automatic feeding and discharging is achieved, and the production efficiency is improved.

Owner:河南力锋科技有限公司 +1

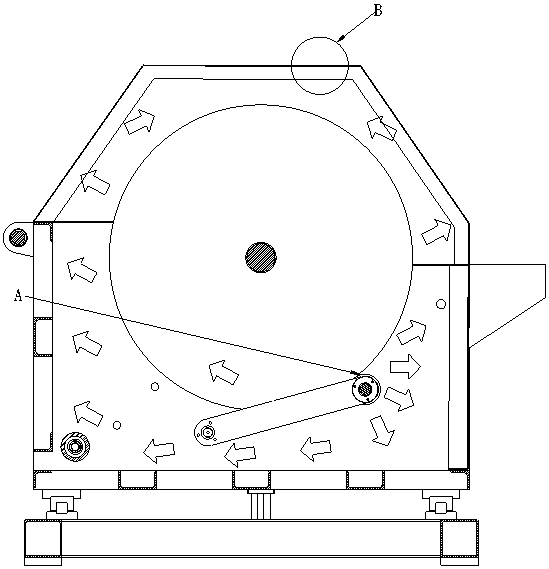

Automatic deviation rectifying mechanism for abrasive belt of polishing machine

InactiveCN102814716AEliminate Surface Quality IssuesSurface quality is stableBelt grinding machinesThin walledEngineering

The invention provides an automatic deviation rectifying mechanism for an abrasive belt of a polishing machine. The polishing condition of the abrasive belt is detected in real time by using a photoelectric sensor; when the abrasive belt deviates, micrometric displacement of deviation is transferred by the photoelectric sensor to a controller, a pulse signal sent by the controller is transferred to a direct current servo motor, an eccentric wheel is driven by the direct current servo motor to rotate, a connecting rod is driven by the eccentric wheel to swing, and then, a swing shaft is driven to rotate to enable a worm gear and worm mechanism to work and realize the linear motion of a worm and a deviation rectifying roller on the worm, so that the deviation rectification of the abrasive belt is realized. The mechanism is simple in structure, easy to realize and capable of realizing automatic deviation rectification in the thin-wall blade polishing process, eliminating the surface quality problem brought by the deviation of the abrasive belt, ensuring the stability of the surface quality of a blade and also improving the polishing effect of the blade.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

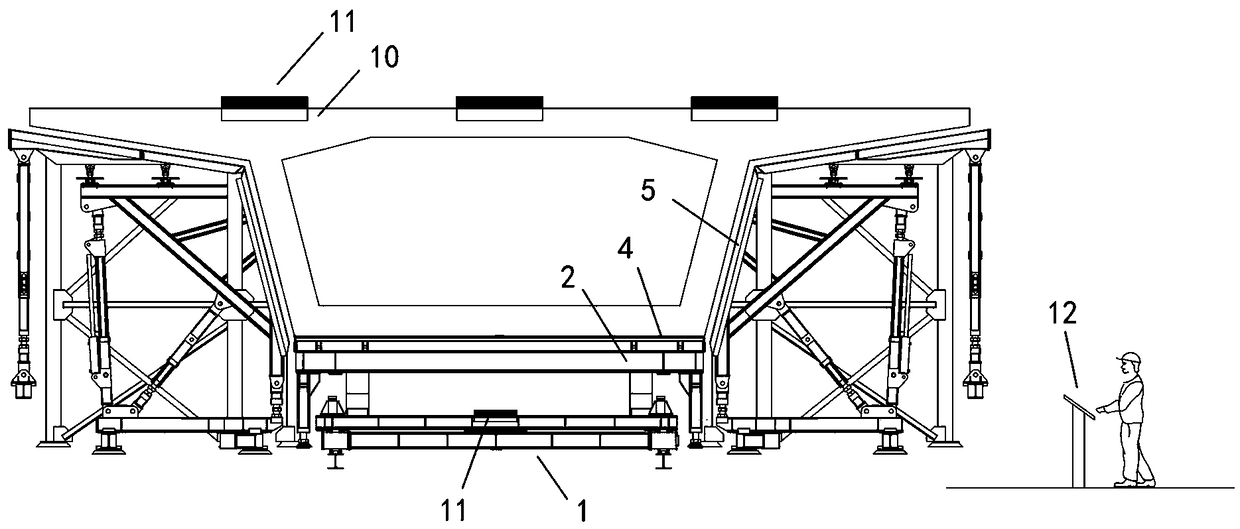

A construction method for precasting bridge segments by adopting a short-line method

ActiveCN108978473AReduce labor costsRealize automatic deviation correctionBridge erection/assemblyNumerical controlControl system

The invention relates to a construction method for precasting bridge segments by adopting a short-line method, which includes the trolleys, Hydraulic pedestals and control towers in the prefabricationplant; A plurality of numerical control implantation points are arranged on each prefabricated segment, A base is mounted at each numerically controlled implantation point, A position controller is arranged at the top of each base, and the distance and inclination of the control points are directly converted into the coordinate values under the local coordinate system through the interaction of the position information of each module of the position controller and the control system of the control tower, and then the correction error is calculated through the control system, so as to directlycorrect the deviation of the template system. Compared with surveying and mapping equipment such as the total station, surveying towers and levellers commonly used in the prior art, -The applicationdoes not require tedious measuring equipment, saves the human cost required for surveying and mapping, and only one staff member is required to stand at the control tower in the whole working processand operate the control system, so that the automatic deviation correction of the segments can be realized, and the measuring accuracy is guaranteed, and the production efficiency is effectively improved.

Owner:瀚阳国际工程咨询有限公司

Deviation rectifying system of shield tunneling machine

InactiveCN106522973AAchieve precise guidanceRealize automatic deviation correctionTunnelsEngineeringShield tunneling

The invention provides a deviation rectifying system of a shield tunneling machine. The deviation rectifying system of the shield tunneling machine comprises the shield tunneling machine, a guide measuring device, a calculation device and a control device, wherein the guide measuring device is used for acquiring the current operating situation of the shield tunneling machine after the deviation rectifying system of the shield tunneling machine is started, and sending the current operating situation to the calculation device; the calculation device is used for receiving and saving the current operating situation; and the control device is used for reading the current operating situation from the calculation device, generating control instructions needed for controlling the shield tunneling machine according to the current operating situation, and rectifying deviation of the shield tunneling machine according to the control instructions. Through the deviation rectifying system of the shield tunneling machine, precise guiding and automatic deviation rectifying of the shield tunneling machine can be achieved, and the working efficiency of the shield tunneling machine is effectively improved.

Owner:XCMG KAIGONG HEAVY IND NANJING

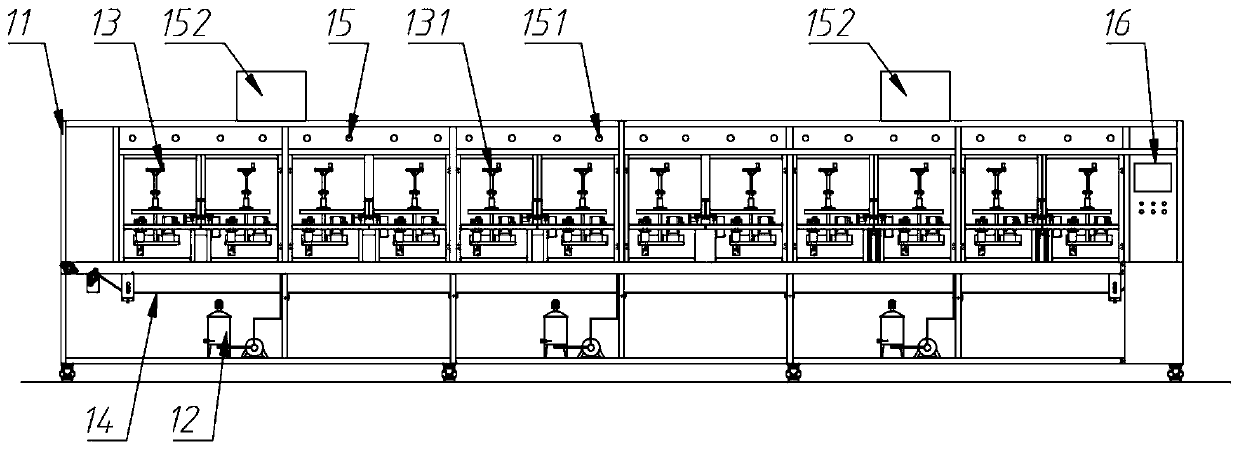

Planar receiving type centrifugal-spinning automatic production equipment and method

ActiveCN110295404ARealize mass productionFix production issuesFilament/thread formingNon-woven fabricsNanofiberNonwoven fabric

The invention discloses a planar receiving type centrifugal-spinning automatic production equipment and method. A continuously moving collection belt is arranged under spinnerets, and after proper height adjustment, spinning solution ejected by the spinnerets in high-speed rotation forms fibers instantly, and the fibers spirally fall down to be collected on the collection belt to finally form a continuous centrifugally-spun fiber net. The centrifugally-spun fiber net is compacted by a compacting device and wound in a winding device to finally form a centrifugally-spun fiber net roll. A whole production process is completed automatically without manual intervention. By the planar receiving type centrifugal-spinning automatic production equipment and the method, the problem of preparation ofcentrifugally-spun continuous filaments is solved, batch production in centrifugal spinning is realized, and the planar receiving type centrifugal-spinning automatic production equipment and the method are applicable to wide nonwoven fabric surface nanofiber or submicron fiber compounding or wide nano or submicron nonwoven fabric production.

Owner:WUHAN TEXTILE UNIV +1

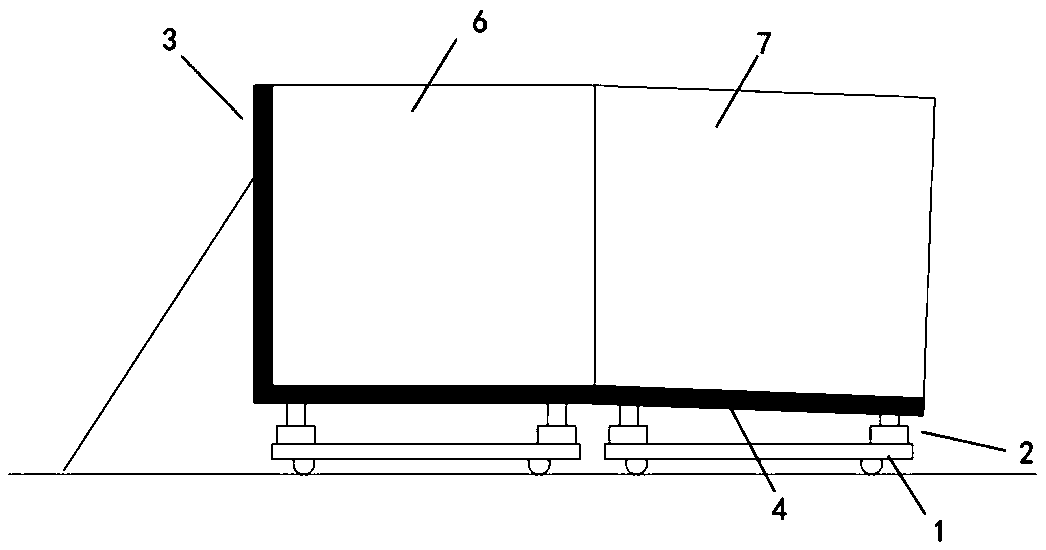

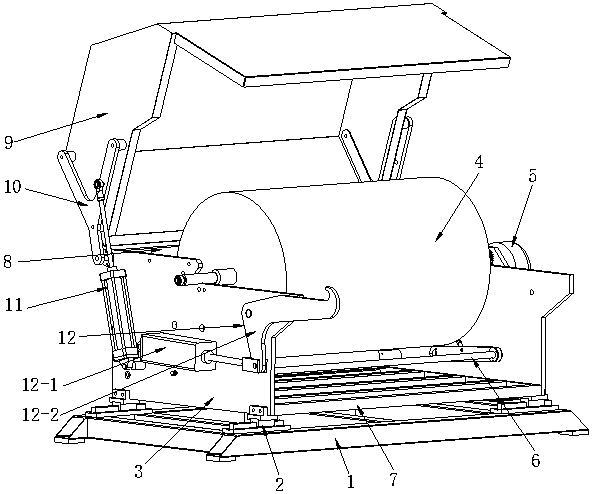

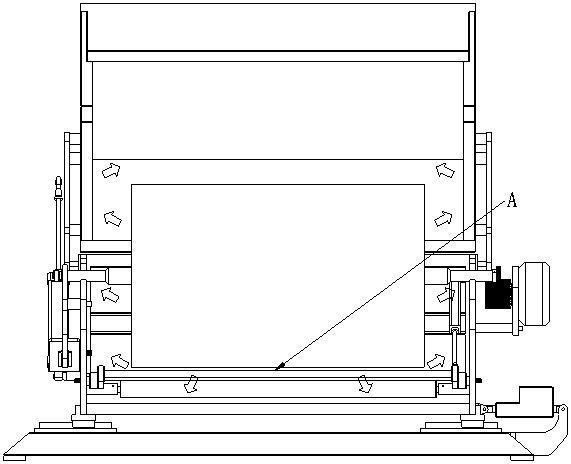

Winding and unwinding rectification device

InactiveCN103101789ASimple structureReduce manufacturing costWebs handlingProgrammable logic devicePower apparatus

The invention relates to a winding and unwinding rectification device comprising a programmable control device, a machine base and a machine frame. The machine base is provided with two parallel guide rails, the machine frame can move along the guide rails under the action of a drive device, and one side of the machine frame is provided with a power device, a transmission device and a tension adjustment device. A hand wheel drives a clamping device to move, a horizontal roller is conveniently assembled and disassembled, and materials are conveniently loaded and unloaded. A photoelectric sensor detects position information of the materials on the horizontal roller and transmits the position information to a programmable controller, and the programmable controller adjusts the power device, further controls the transmission device and the tension adjustment device, and accordingly changes the rotation speed of the horizontal roller to enable tension of the materials to return to normal. Therefore, automatic rectification is achieved, and production efficiency is improved. The winding and unwinding rectification device is simple in structure and low in manufacture cost, achieves convenient loading and unloading of the materials, achieves the automatic rectification of the materials in the winding and unwinding processes, and improves the production efficiency.

Owner:MAXCLEAN WUXI TECH

Middle and low-voltage lateral adaptive contact power acquisition device

The invention relates to a middle and low-voltage lateral adaptive contact power acquisition device, in particular to an automatic power acquisition device which works by electric power from a power grid in a rubber-tyred container gantry crane (RTG) of a large freight yard in a port. A plurality of upright columns are arranged in a direction of an RTG running track in the center of a dummy road in a container yard, bridge members are arranged between the upright columns, two power supply trolley lines are arranged laterally on the bridge members, and a photoelectric detection plate for guiding an RTG cart to travel is arranged in parallel to the power supply trolley lines so as to guide and control the RTG for automatic deviation rectification and keep a distance for power acquisition. The lateral adaptive contact power acquisition device is arranged at a lower transom side of the RTG, and a power acquisition arched plate of the adaptive contact power acquisition device adjusts contact force for power acquisition and is in flexible contact with the power supply trolley lines so as to laterally acquire direct power feed from the power supply trolley lines for operation of two groups of a plurality of RTGs on two sides. The device has high efficiency and safety in use, simple manufacture, convenient transportation, easy installation and low cost.

Owner:WUHAN GUIDE ELECTRIC +2

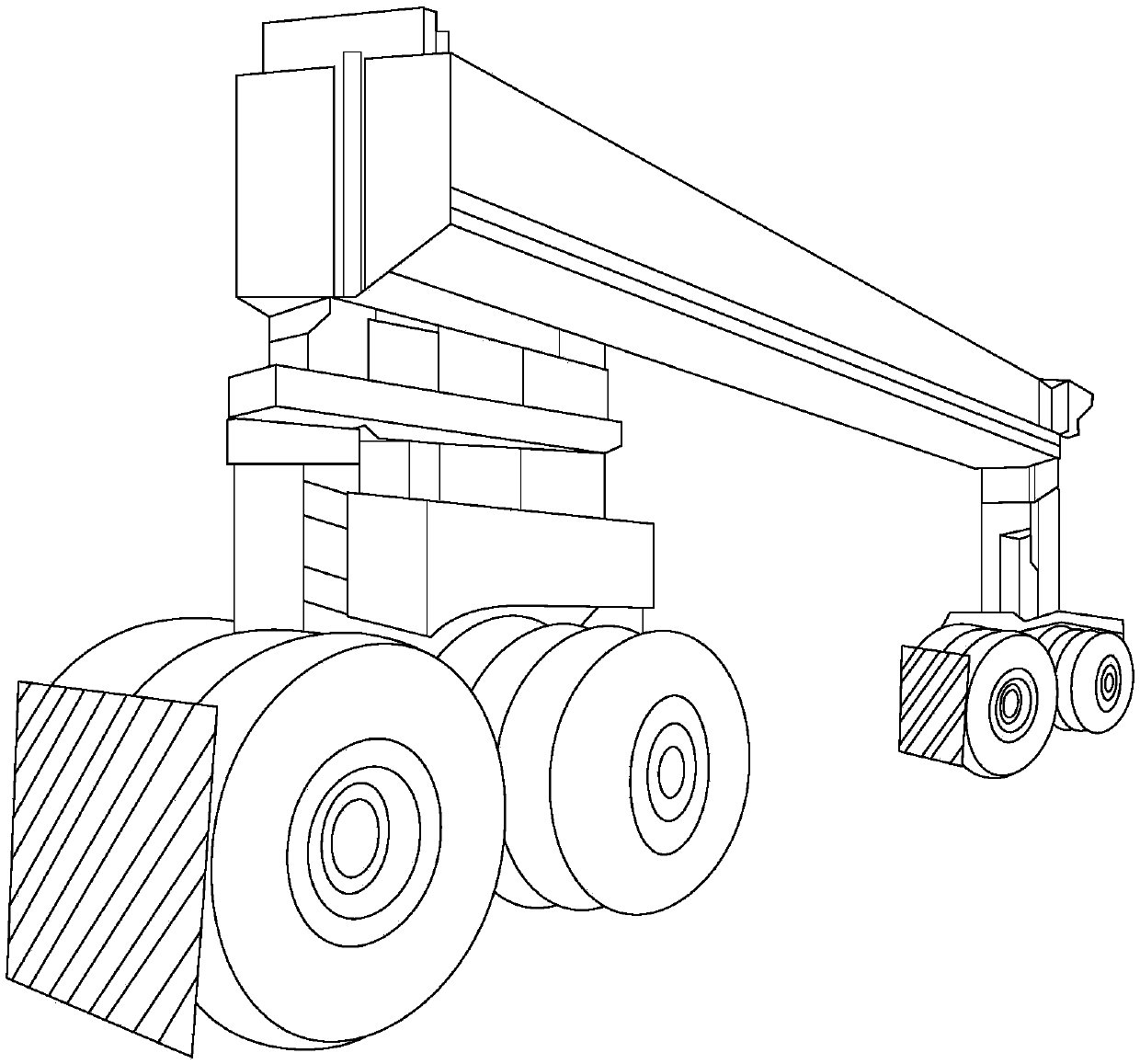

Walking positioning, deviation correcting and collision preventing method for tire crane

InactiveCN105197801AReduce fatigueImprove loading and unloading efficiencySafety gearLaser scanningEngineering

The invention discloses a walking positioning, deviation correcting and collision preventing method for a tire crane. According to the method, by installing laser scanners on four support columns of the tire crane respectively for detecting the gaps between the side faces of containers and the gaps between containers in a container yard, walking positioning of the tire crane, positioning of the containers in the yard, automatic deviation correcting and collision preventing warning are achieved. The laser scanners, the containers, a computer, a warning device, a container position management displayer (cab management system interface terminal) and a rain cover are involved in the method. The laser scanners are installed on supports in front of four support column tires of the tire crane respectively and can rotate along with rotation of the tires. With the gaps between the side faces of the containers and the gaps between the containers in the container yard as the reference, the laser scanners are installed in the rain cover, the computer is installed in an electrical room, and the warning device is installed in a cab of the tire crane. The laser scanners, the warning device and the container position management displayer are all connected with the computer, and the computer is connected with a tire crane PLC and participates in walking control over the tire crane.

Owner:SHANGHAI HAILEI LASER TECH

Multifunctional composite movable gantry friction stir welding device

PendingCN112192016AAchieve levelingAvoid warpingOther manufacturing equipments/toolsNon-electric welding apparatusMilling cutterEngineering

The invention relates to a multifunctional composite movable gantry friction stir welding device, and belongs to the technical field of machine tool equipment. The multifunctional composite movable gantry friction stir welding device comprises a machine head, wherein a friction stir welding tool is arranged on the machine head; a follow-up welding pressing system and a weld joint flash milling system are further arranged on the machine head; the follow-up welding pressing system comprises a first follow-up compression roller device positioned in front of the friction stir welding tool and a second follow-up compression roller device positioned behind the friction stir welding tool; and the weld joint flash milling system comprises a milling cutter positioned behind the second follow-up compression roller device and a milling driving device connected with the milling cutter. The multifunctional composite movable gantry friction stir welding device realizes online flattening, polishing and grinding of workpieces before and after welding, and improves the welding quality and the welding production efficiency.

Owner:CHONGQING MACHINE TOOL GROUP

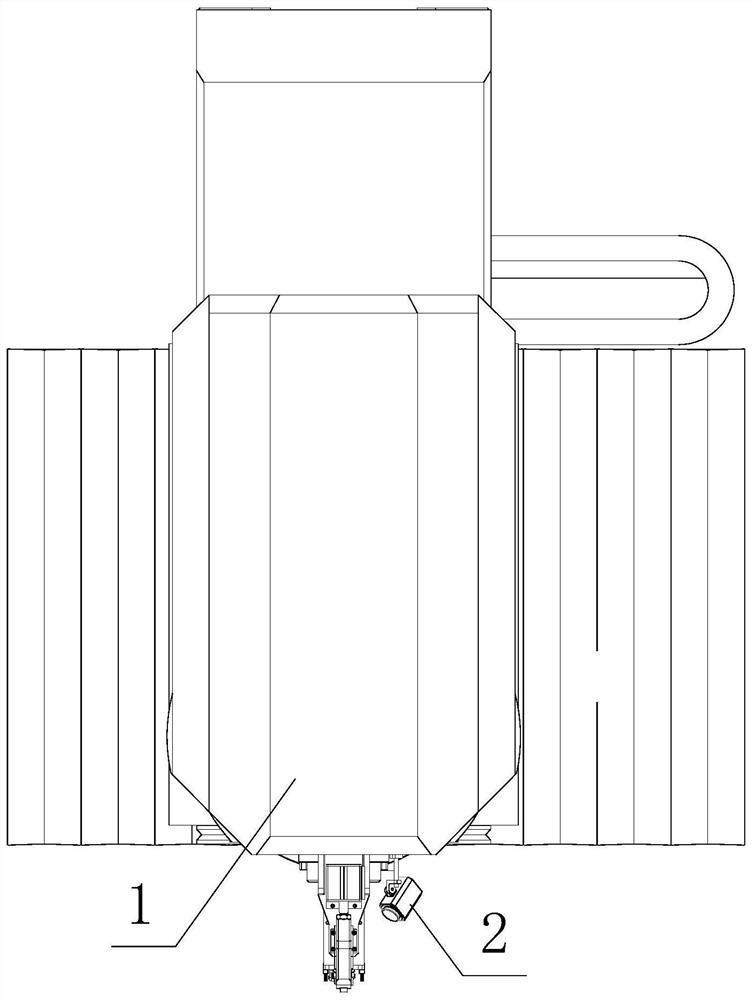

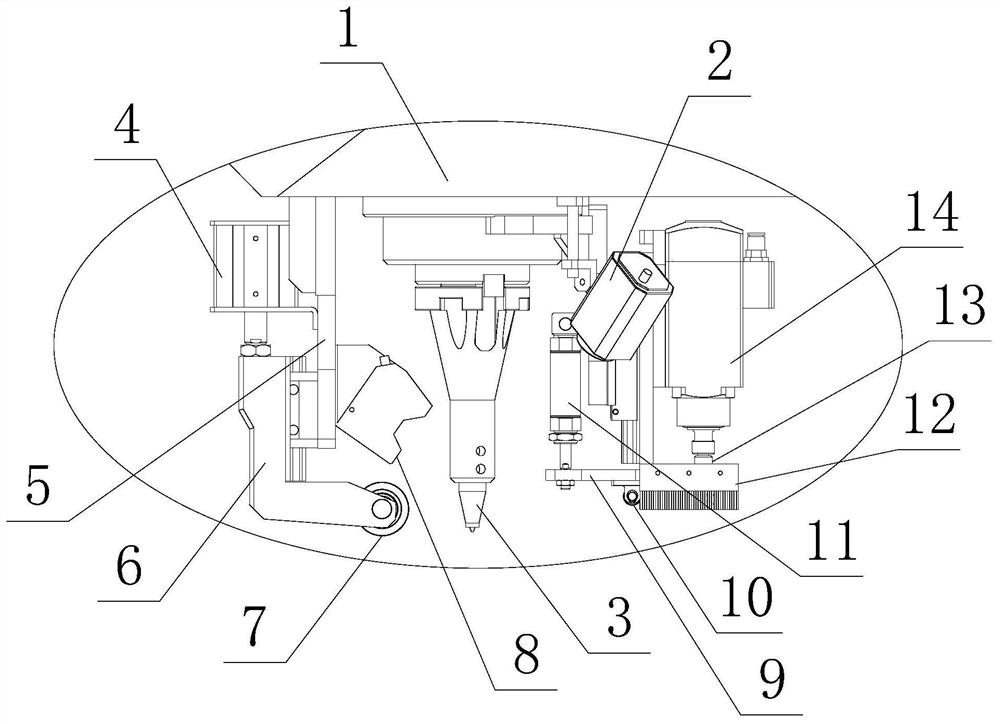

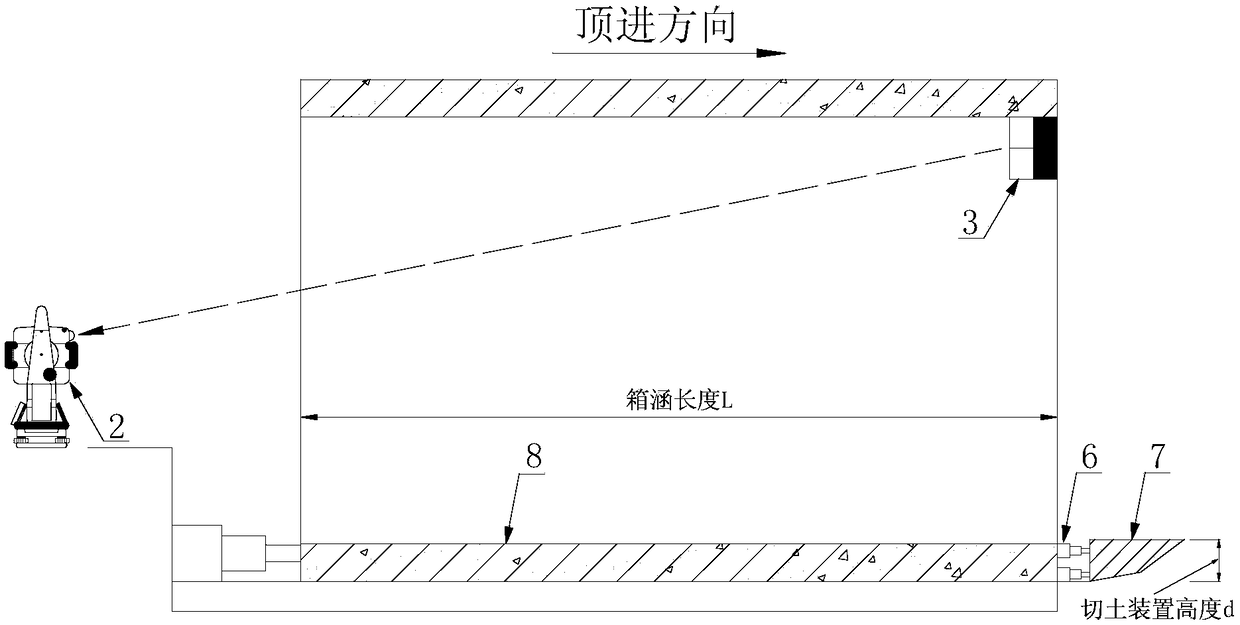

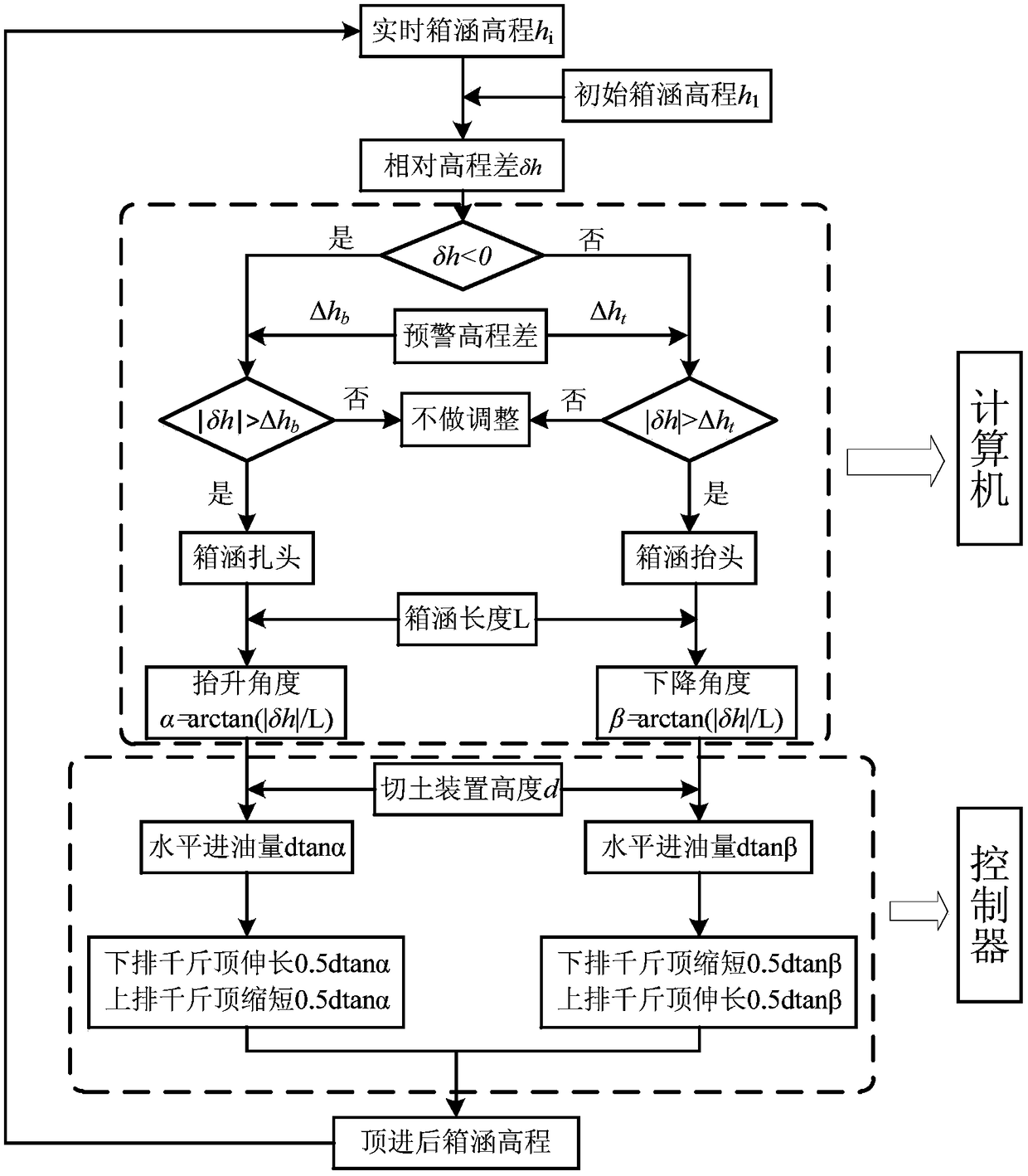

Adjusting device for longitudinal slope of jacking of box culvert and monitoring and controlling method thereof

ActiveCN108625302AEliminates the need for manual measurement readingsImplement automatic trackingGround-workHeight/levelling measurementMonitoring systemEngineering

The invention discloses an adjusting device for a longitudinal slope of jacking of a box culvert and a monitoring and controlling method thereof. The adjusting device comprises a monitoring system, ananalysis system and an adjustment system. The monitoring system transmits the elevation information of the box culvert front end monitored in real time to the analysis system. The analysis system isused for analyzing the elevation information, and the relative elevation difference is compared with the set warning threshold value. If the relative elevation difference exceeds the set warning threshold value, an adjustment command is issued to the adjustment system. The adjustment system controls the longitudinal slope of the jacking of the box culvert according to the adjustment command. According to the adjusting device for the longitudinal slope of jacking of the box culvert and the monitoring and controlling method thereof, the real-time monitoring of the elevation of the box culvert inthe jacking process is realized, and adjustment can be carried out in real time, so that the phenomena of ''head lowering'' and ''head rising'' of the box culvert are restrained, and it is ensured that that the elevation difference of the box culvert is within the allowable range of the standard to realize the automatic rectification of the box culvert in the elevation direction.

Owner:SOUTHEAST UNIV

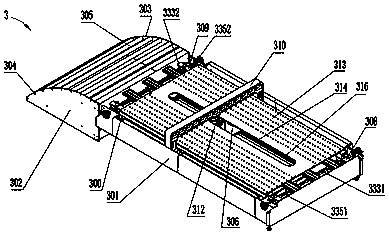

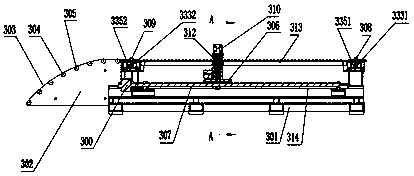

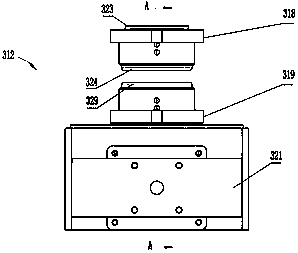

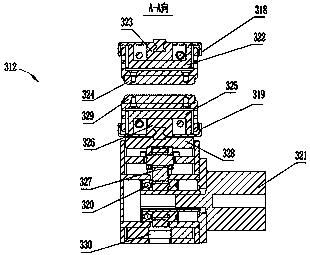

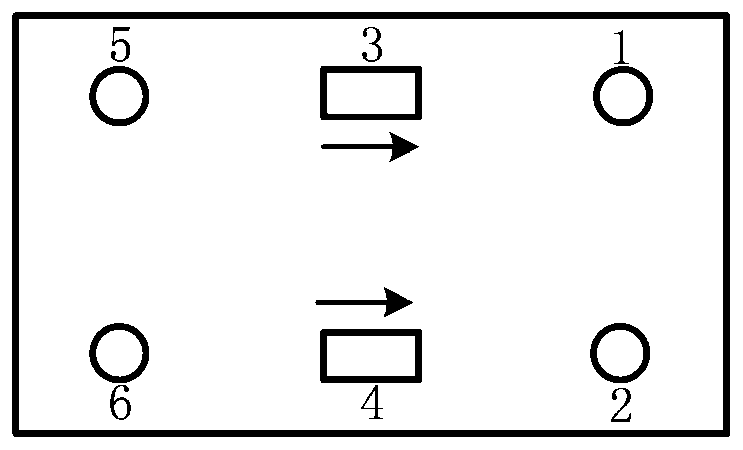

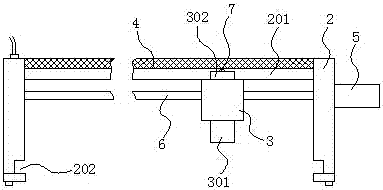

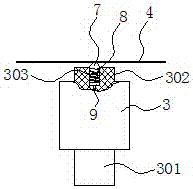

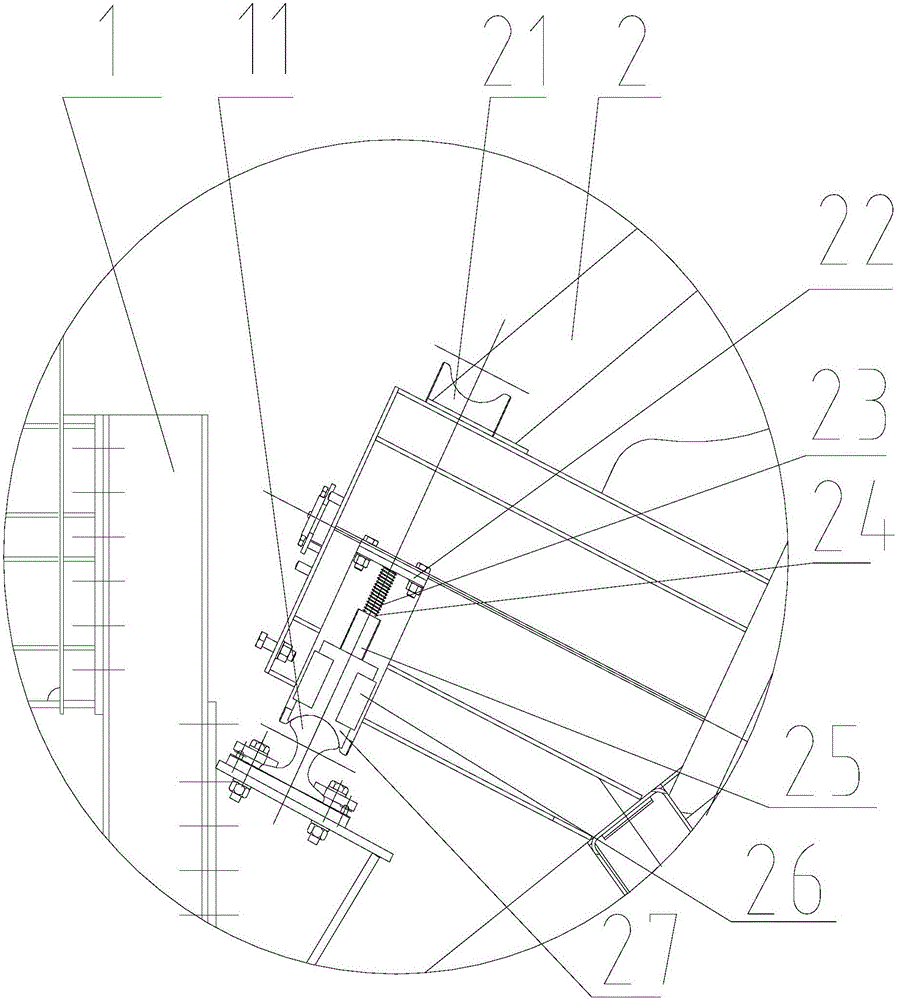

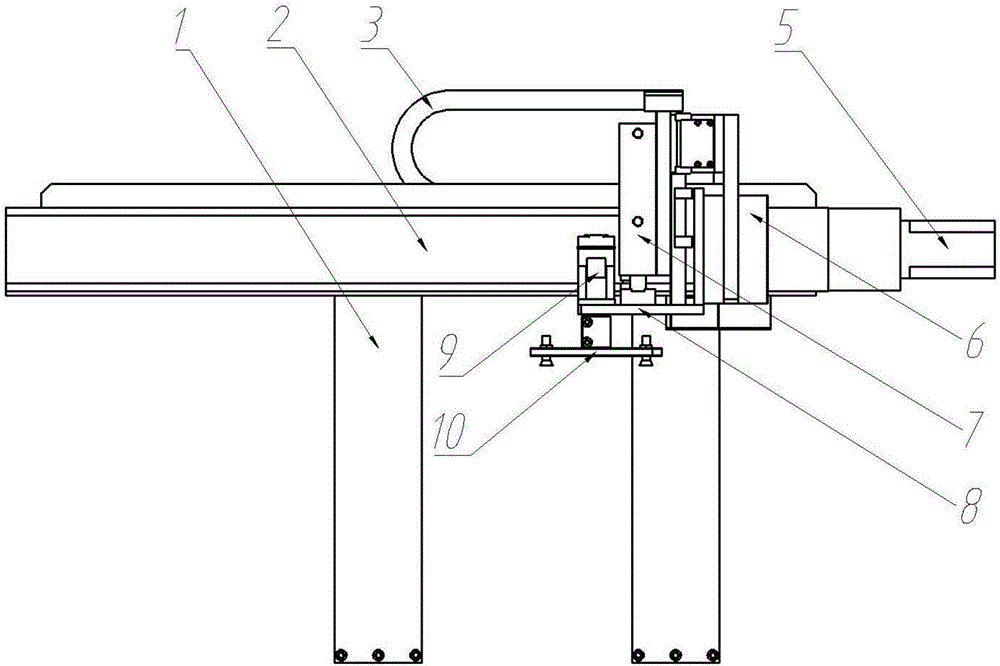

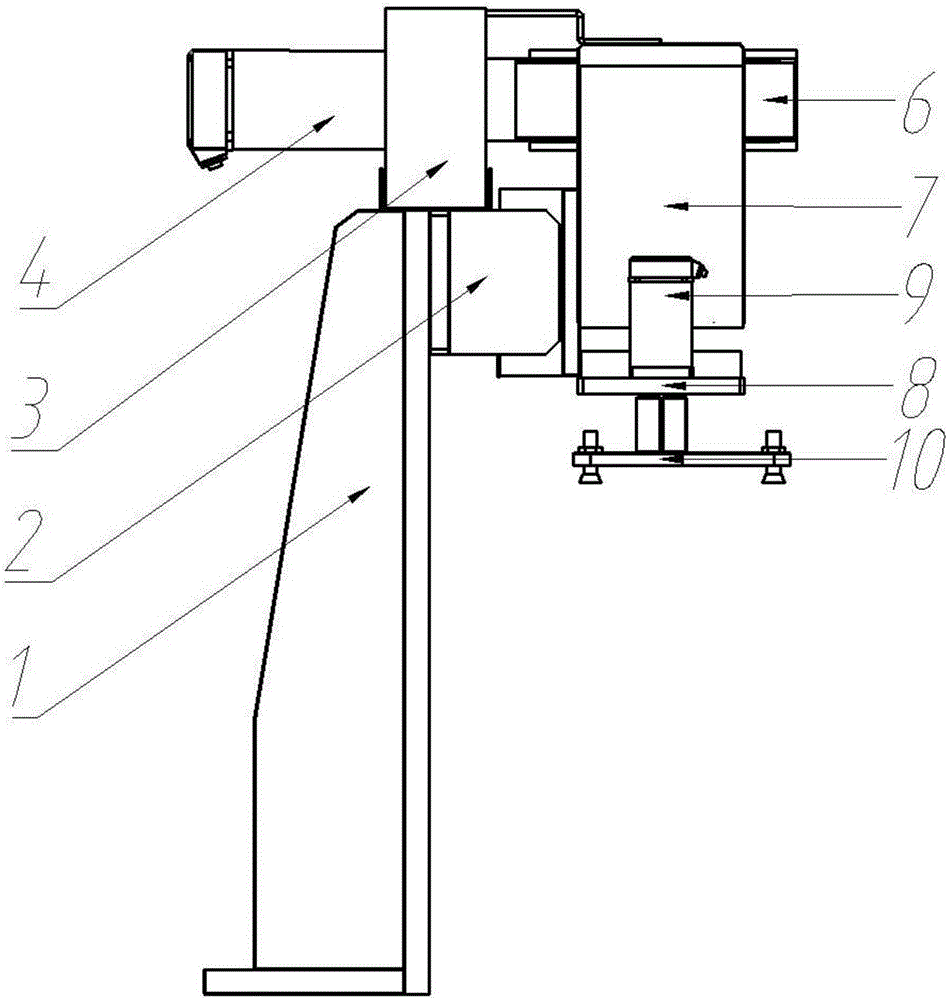

Floating clamp for flexible metal plate production line feeder

PendingCN110142561AAutomatic Deskew CorrectionAvoid curlWelding/cutting auxillary devicesAuxillary welding devicesProduction lineDrive shaft

The invention belongs to the technical field of metal plate production equipment, and particularly relates to a floating clamp for a flexible metal plate production line feeder. The floating clamp (312) is provided with an upper clamp body (318), a lower clamp body (319), a connecting rod (327), an eccentric wheel (320), a swing component and a base (330). A mounting plate (328) is arranged between the lower clamp body (319) and the connecting rod (327), the connecting rod (327) is arranged at the lower part of the mounting plate (328) and can move up and down so as to drive the lower clamp body (319) to move up and down, the eccentric wheel (320) is arranged outside the connecting rod (327) and provided with an intermediate shaft, and a driving shaft of the swing component is connected with the eccentric wheel (320) through a flat key. The floating clamp is arranged on the flexible metal plate production line feeder, plates can be clamped to realize automatic feeding of the feeder, meanwhile the floating clamp (312) can float leftwards and rightwards, automatic deviation rectification can be achieved in the feeding process, and the production efficiency is improved.

Owner:LUOYANG YOUNENG AUTOMATION EQUIP CO LTD

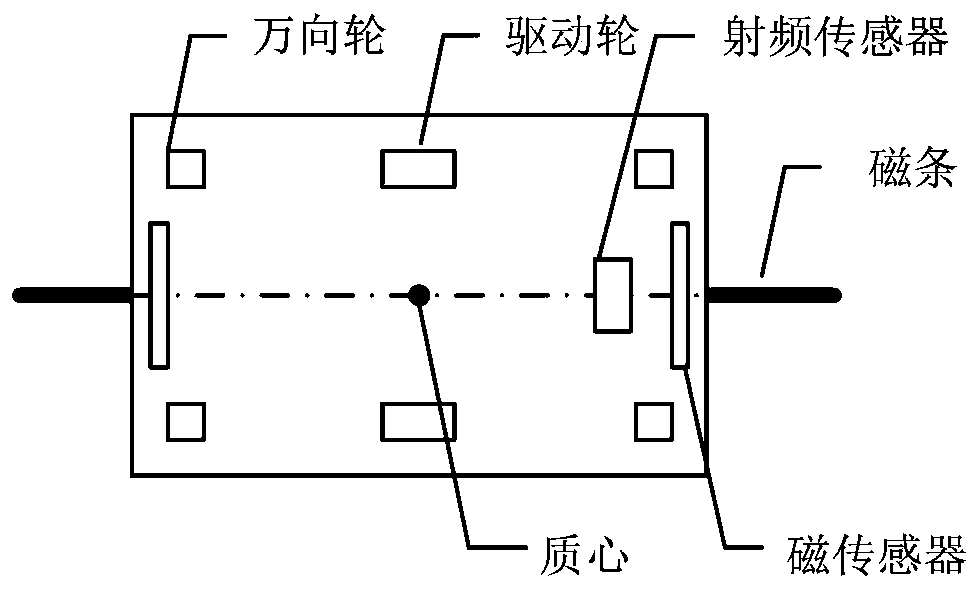

Automatic deviation rectification control method for magnetic guidance AGV

ActiveCN111474933ARealize automatic deviation correctionEliminate declination errorPosition/course control in two dimensionsVehiclesControl engineeringControl theory

The invention discloses an automatic deviation rectification control method for a magnetic guidance AGV. The method is used for realizing automatic deviation rectification operation by controlling theAGV to advance, retreat and rotate according to pose information during demagnetization of the magnetic guidance AGV. After the AGV is demagnetized, automatic deviation rectification and automatic driving recovery can be realized, so that real unattended operation of a railway traction substation can be realized.

Owner:HEFEI UNIV OF TECH

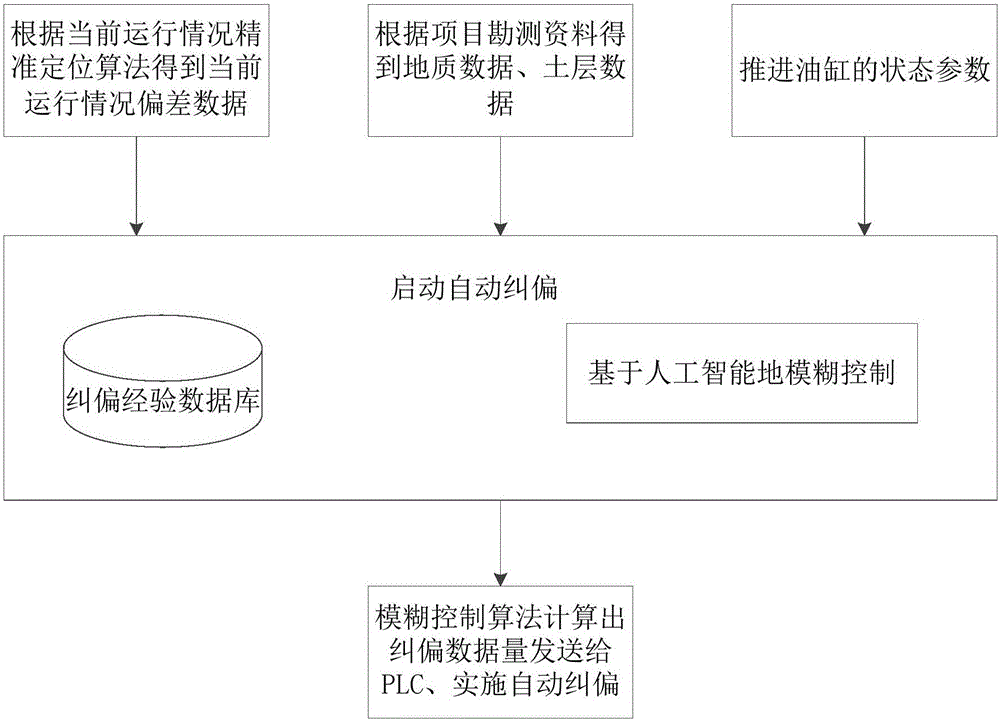

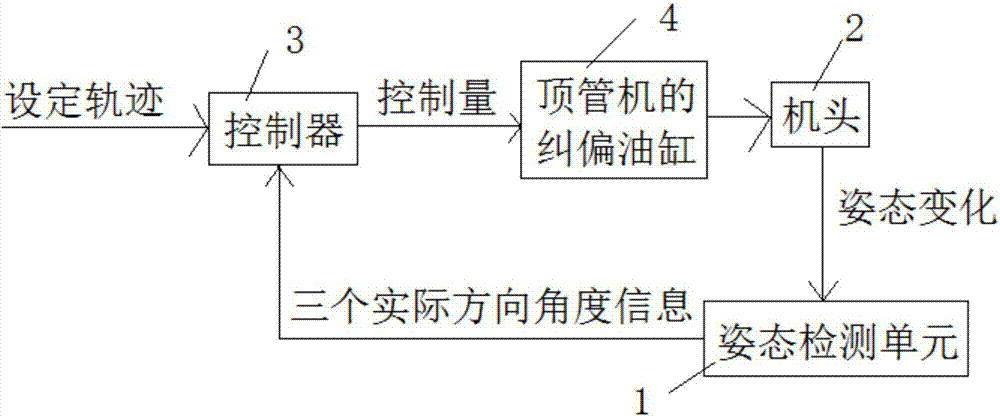

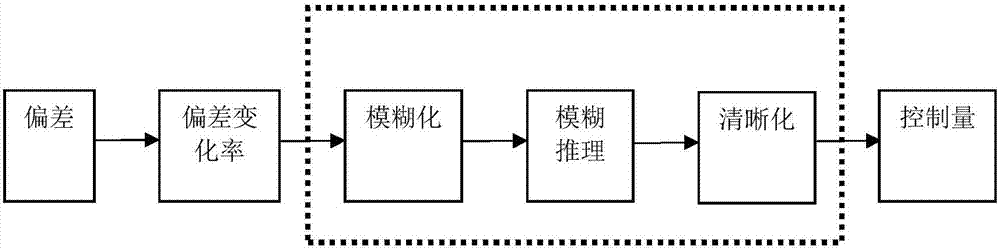

Fuzzy control system for posture of tube push bench based on MEMS gyroscope and method

InactiveCN107328415ARealize automatic deviation correctionRealize automatic deviation correction functionNavigational calculation instrumentsNavigation by speed/acceleration measurementsFuzzy control systemInput/output

The invention discloses a fuzzy control system for a posture of a tube push bench based on a MEMS gyroscope and a method. The system comprises a posture detection unit and a controller, wherein the MEMS gyroscope is adopted for detecting real-time posture change of a machine head of the tube push bench: acquiring the practical direction angle information of the machine head along three vertical axes which are mutually vertical in pairs; a target axis of the machine head is stored; the controller is used for respectively comparing the three pieces of practical direction angle information with three pieces of target direction angle information of the target axis, calculating and controlling the expansion volume of a correcting cylinder of the tube push bench to correct the tube push bench. In the comparison and calculation process, (1) the input volume and the output volume of the controller are defined; (2) an input / output discourse domain of the controller is defined; (3) an input / output fuzzy set of the controller is defined; (4) a fuzzy control rule is established; (5) a fuzzy control query table is established. According to the invention, a fuzzy control technology is adopted for correcting a fuzzy value of the expansion volume of the correcting cylinder, the fuzzy value is corresponding to the expansion volume of the correcting cylinder and the error is minimized.

Owner:HEFEI UNIV OF TECH

Steam box fabric outlet flatness adjustment device for fabric desizing, scouring and bleaching production equipment

InactiveCN110407015AImprove flatnessFew or completely flat surfacesWebs handlingControl systemEngineering

The invention provides a steam box fabric outlet flatness adjustment device for fabric desizing, scouring and bleaching production equipment. The device comprises a width enlargement flattening box, acorrection box and a flatness adjustment control system, a width enlargement mechanism and a flattening mechanism are arranged in the width enlargement flattening box in sequence, and the width enlargement mechanism is driven by a first driving motor; the flattening mechanism is driven by a second driving motor, a first fabric guide roller and a second fabric guide roller which are parallel to each other are arranged on the downstream portion of the flattening mechanism in sequence, and a correction mechanism driven by a driving mechanism is arranged in the correction box; a third fabric guide roller is arranged on the downstream portion of the correction mechanism and rotatably installed in the correction box and is parallel to the second fabric guide roller, and the flatness adjustmentcontrol system comprises a controller in communication connection with the second driving motor. According to the steam box fabric outlet flatness adjustment device, a fabric is monitored in real timein the fabric outlet process, the fabric is automatically corrected when deviating, the flattening intensity can be adjusted according to different kinds of fabrics, and the steam box fabric outlet flatness adjustment device has the advantages of being capable of achieving a good flattening effect and wide in application range.

Owner:CHANGYI FURUN TEXTILE TECH CO LTD

Anti-deviating energy-saving type microwave vulcanization device achieving stable vulcanization and using method thereof

ActiveCN105881793ADoes not affect normal workReduce ineffective work timeConveyorsRollersVulcanizationControl engineering

The invention discloses an anti-deviating energy-saving type microwave vulcanization device achieving stable vulcanization and a using method thereof. The anti-deviating energy-saving type microwave vulcanization device achieving stable vulcanization comprises a support which is provided with a conveying belt, vulcanization tanks are arranged above the conveying belt, a dehumidification device is arranged above each vulcanization tank, a master control device is arranged at the head end of the conveying belt, and a power device is arranged at the tail end of the conveying belt. The master control device comprises a driven shaft, a deviation rectifying device is arranged beside the driven shaft, and an encoder is arranged on the driven shaft. A driving shaft is connected with the driven shaft through the conveying belt. A material sensor is further arranged at the head end of the conveying belt. Magnetrons are distributed in the vulcanization tanks, and temperature sensors are arranged between the magnetrons. Spray nozzles are further arranged above the magnetrons. The deviation rectifying device comprises a deviation rectifying motor which is connected with a sliding block, the sliding block is connected with an adjusting roller, and travel switches are further arranged on the two sides of the conveying belt correspondingly. The anti-deviating energy-saving type microwave vulcanization device achieving stable vulcanization and the using method thereof have the characteristics that energy consumption is reduced, the service life is prolonged, the equipment utilization rate is increased, and transportation is stable.

Owner:GUIZHOU DAZIRAN TECH

Color press horizontal-printing high-difference deviation rectification device

PendingCN107284054ARealize automatic deviation correctionFlatness real-time monitoringOther printing apparatusElectric machineryControl theory

The invention relates to a color press horizontal-printing high-difference deviation rectification device which is used for controlling the space between a nozzle in a color press body and a to-be-printed surface, and comprises the color press body and a deviation rectification device body, wherein the deviation rectification device body is positioned at the printing medium input end of the color press body, and comprises a gantry bracket, a displacement sensor, a threaded rod and a motor; the gantry bracket is relatively fixed with the press head of color press body; a horizontal sliding channel is arranged at the bottom of an upper beam of the gantry bracket; two conducting bars are arranged in the sliding channel in the length direction of the sliding channel, and in conducting connection with a main controller of the color press body; the displacement sensor is in threaded connection with the threaded rod; an induction head is arranged at the bottom of the displacement sensor; a sliding block matched with the sliding channel is arranged at the top of the displacement sensor; two conducting heads being correspondingly in conducting connection with the two conducting bars in the sliding channel and the induction head are arranged on the sliding block; the two ends of the threaded rod are rotationally positioned on vertical fixing seats at the two ends of the gantry bracket; and one end of the threaded rod extends out of the vertical fixing seat and is in drive connection with the motor. By adoption of the above structure, the flatness can be monitored in real time, thereby controlling the automatic deviation rectification for the nozzle.

Owner:湖州南浔金翔彩印厂

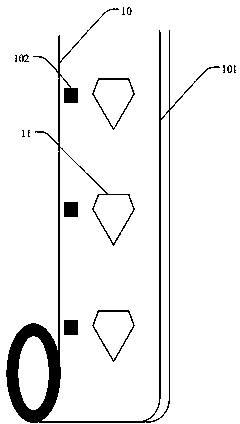

Positional stamping correction gold stamping electrical aluminum and gold stamping equipment

InactiveCN104972781AIncrease productivityImprove product qualityBronze printingThermographyHot stampingEngineering

The invention discloses positional stamping correction gold stamping electrical aluminum and gold stamping equipment. According to the invention, a gold stamping electrical aluminum body is provided with a first positioning part used for identifying left and right locating positions of the gold stamping electrical aluminum body. During hot stamping, a cursor scanning device acquires a positioning image of the first positioning part of the gold stamping electrical aluminum. Whether the gold stamping electrical aluminum moves side to side and displacement distance are judged by a control mechanism according to the positioning image, and a correction device is controlled to correct left-right deviation of the positional stamping correction gold stamping electrical aluminum according to the displacement distance, so as to realize automatic correction. Manual intervention is not required during the production process; production efficiency is greatly raised; and product quality is also enhanced.

Owner:SHENZHEN JINJIA GRP

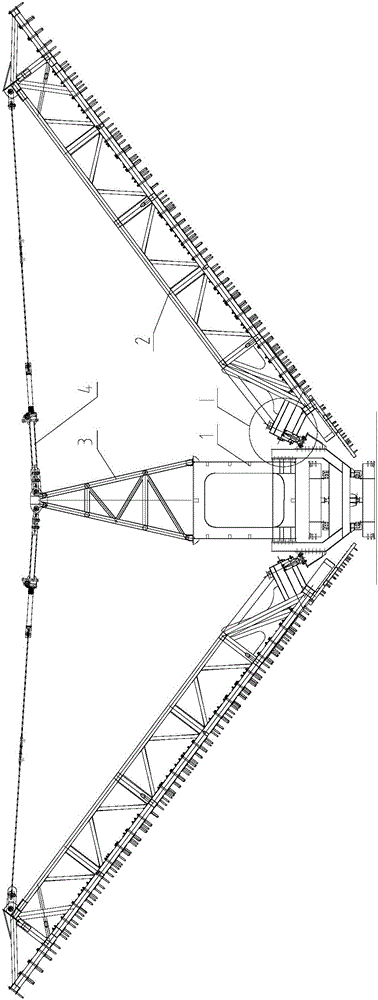

Bridge-type scraper reclaimer

ActiveCN105084025ASmooth slidingReduce supporting weightLoading/unloadingVertical planeReciprocating motion

The invention provides a bridge-type scraper reclaimer which comprises a rack and rakes symmetrically arranged on the two sides of the rack. One ends of the rakes are connected with the rack through connecting mechanisms, and the other ends of the rakes are rotationally supported on tracks of the rack through rollers arranged at the lower ends of the rakes. The rakes are driven by a rake driving mechanism to reciprocate on the tracks, so that the rakes conduct pitching motion around the tracks while swinging around the joints of the connecting mechanisms and the rack. The rakes are supported on the tracks of the rack through the rollers and connected with the rack through the connecting mechanisms, and the rakes are driven by the rake driving mechanism to move along the tracks; due to the fact that the length of the connecting mechanisms is kept unchanged, the rakes conduct curvilinear motion inside the horizontal plane and the vertical plane, component force for scraping materials downwards is generated for material piles, materials slide down uniformly, and the production capacity is balanced. According to the bridge-type scraper reclaimer, a travelling car is not needed any more, the supporting weight of a girder is reduced, the needed strength and rigidity are smaller than those of an existing reclaimer, and the manufacturing cost is lowered.

Owner:TIDFORE HEAVY IND

Mute discharge device for tape slitter

PendingCN108557528ASave human effortImprove stabilitySound producing devicesWebs handlingAdhesive beltEngineering

The invention discloses a mute discharge device for a tape slitter and relates to the technical field of tape slitters. A linear guide rail is mounted at each corner of the upper end of a base; sliders on the linear guide rails are connected with the bottoms of the two wallboards through mounting blocks and bolts; a lower sound-insulating cover is connected to the bottom between the two wallboards; a rear heat-insulating cover is connected to the rear of the two wallboards; the rear walls of the two wallboards are connected with one end of a connection rack through a rotary shaft; the other end of the connection rack is connected with a movable heat-insulating cover through a rotary shaft; the connection rack is connected with a piston rod of a movable heat-insulating cover opening cylinder through a hinge shaft. The mute discharge can automatically feed and discharge master batch for a tape slitter, has low manpower consumption and good stability, and is simple to operate; power supply provided herein can automatically correct a deviation during moving and tape production; in order to facilitate feeding, the movable heat-insulating cover is pushed and opened by the movable heat-insulating cover opening cylinder; the heat-insulating cover is closed during operating; noise can be decreased to > / =20 db through heat insulation.

Owner:江苏台钢智能科技发展有限公司

Deviation rectifying method, device and system for tire crane

ActiveCN109993788ARealize automatic deviation correctionLow costImage enhancementImage analysisImaging processingVideo image

The invention relates to a method, a device and a system for correcting deviation of a tire crane. A video image shot by a camera is received when correcting deviation of the tire crane: when the tirecrane advances along an advancing route with a guide color band, the camera shoots an image of the guide color band in an advancing area of the tire crane in a preset reference view finding frame; image processing is performed on the video image to obtain current position information of a guide color band in the video image in the reference view finding frame; the current position information iscompared with reference position information of a reference guide color band in the reference view finding frame, and when the current position information is different from the reference position information, that the tire crane has deviation is determined and a deviation value of the tire crane is determined; and the deviation value of the tire crane is sent to a tire crane operation control system, so that the tire crane operation control system corrects the deviation of the tire crane. Automatic deviation rectification of the tire crane is achieved.

Owner:SIEMENS CHINA

Rubber-tyred gantry crane walking positioning, correcting and container truck alignment anti-lifting method

InactiveCN105271006AReduce fatigueImprove loading and unloading efficiencySafety gearTruck-trailerLaser scanning

According to the invention, laser scanners are arranged at the center of lower side surfaces between two columns at two sides of a rubber-tyred gantry crane and are slightly higher than a container truck trailer panel and lower than height of a container and are used for detecting gaps between containers' side surface and containers on a container yard. Thus, rubber-tyred gantry crane walking positioning, position location of containers on the container yard, automatic correction, anti-collision warning and container truck alignment anti-lifting are realized. The equipment comprises the laser scanners, containers, a computer, an alarm, a container position management display, display screens, a rainproof cover and a crane PLC. The laser scanners are respectively mounted at the center of lower side surfaces between the two columns at two sides of the rubber-tyred gantry crane, and are slight higher than the container truck trailer panel and lower than height of a container. The gaps between containers' side surface and containers on the container yard are used as reference. The computer is installed in an electrical room. The alarm is mounted inside a cab of the rubber-tyred gantry crane. The display screens are installed at two sides of the rubber-tyred gantry crane and positioned at the same eye level of a driver in the container truck cab.

Owner:SHANGHAI HAILEI LASER TECH

Full-casing full-rotary drilling machine equipment

ActiveCN112459723AAchieve dual controlRealize automatic deviation correctionDerricks/mastsDrilling machines and methodsControl engineeringControl theory

The embodiment of the invention provides a full-casing full-rotary drilling machine device. The full-casing full-rotary drilling machine device comprises a main rack, a rotary drilling device, a deviation rectifying rod and a controller, wherein the main rack is provided with vertical supporting columns, horizontal supporting columns, a first sensor and an adjusting piece, the first sensor and theadjusting piece are arranged at the lower ends of the vertical supporting columns, the rotary drilling device is connected to the horizontal supporting columns and used for driving a casing to do rotary motion, the deviation rectifying rod is connected to the vertical supporting columns and provided with a telescopic rod, a second sensor and a contact end, the contact end is used for making contact with the outer cylindrical surface of the casing, the second sensor is arranged between the contact end and the telescopic rod, the controller is used for controlling the adjusting piece to adjustthe corresponding vertical supporting rods when it is determined that the main rack is inclined according to the detection result of the first sensor, and is further used for controlling the telescopic rod to adjust the casing until the perpendicularity of the casing meets a preset requirement when it is determined that the casing is inclined according to the detection result of the second sensor.According to the equipment, automatic deviation rectification of the equipment and the casing is achieved, and the flexibility and the repeated utilization rate are high.

Owner:CHINA RAILWAY FIFTH SURVEY & DESIGN INST GRP +2

Deviation correction device and method of screeding robot and screeding robot

ActiveCN110593573ATroubleshoot deviation from normal direction of motionRealize automatic deviation correctionBuilding material handlingDrive wheelEngineering

The invention discloses a deviation correction device and method of a screeding robot and the screeding robot. The deviation correction device comprises a rack, a drive wheel, a drive part and deviation correction wheels. The drive wheel is rotationally arranged on the rack. The drive part is connected with the drive wheel so as to drive the drive wheel to rotate. At least the two deviation correction wheels are arranged and are arranged on the two sides of the rack, and damping devices are arranged at the shaft ends of the two deviation correction wheels. The damping devices are configured toapply preset resistance to all the deviation correction wheels when motion of the screeding robot is deviated, and therefore the motion deviation direction of the screeding robot is corrected. By means of the deviation correction device and method of the screeding robot and the screeding robot, the correction deviation wheels are additionally arranged on the two sides of the rack, the friction force between the correction deviation wheels on the two sides and the construction face is controlled through the damping devices, the problem that the screeding robot is deviated from the normal running direction is solved, and automatic deviation correction of the work direction of the robot is achieved.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

Automatic skew detection silicon chip series welding feeding device

ActiveCN106298610ARealize adjustment and correctionRealize automatic deviation correctionWelding/cutting auxillary devicesSemiconductor/solid-state device manufacturingControl theorySilicon chip

The invention provides an automatic skew detection silicon chip series welding feeding device which comprises a support frame, a horizontal moving guiderail fixed at the top end of the support frame, a horizontal position adjustment motor installed at the end part of the horizontal moving guiderail, a slide platform installed on the horizontal moving guiderail and moving in the horizontal direction, a vertical moving guiderail fixed on the slide platform, a vertical position adjustment motor installed at the rear end of the vertical moving guiderail, a cylinder installed on the vertical moving guiderail and moving along the vertical moving guiderail vertically, a grip support plate installed at an expansion end of the cylinder, an angle position adjustment motor installed on the support plate, and a negative pressure retraction grip connected on an output shaft of the angle position adjustment motor in a sleeving manner, and the output shaft of the angle position adjustment motor faces downwards. The automatic skew detection silicon chip series welding feeding device automatically feeds a silicon chip and automatically rectifies the position, the adjustment and correction of the silicon chip in the horizontal, vertical and angular positions of a horizontal plane is implemented through three axes association in the moving process of the silicon chip, and the accuracy is greatly improved.

Owner:FOSHAN NANHAI GUANGDONG TECH UNIV CNC EQUIP COOP INNOVATION INST +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com