Machine vision automatic deviation rectifying system of tire crane and deviation rectifying method

An automatic deviation correction and tire crane technology, applied in the field of computer vision, can solve problems such as failure to work normally, heavy impact of rain and snow, and unstable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0088] Automatic deviation correction method of tire crane, combined with figure 2 , including the following specific steps:

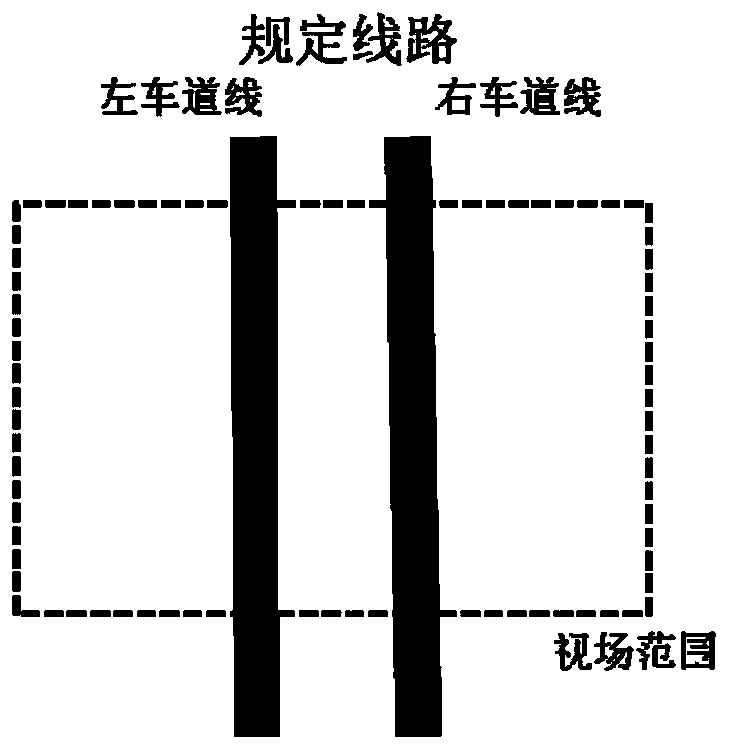

[0089] Step 1: Install a camera on the lower beam on either side of the tire crane to obtain images of the lane line and surrounding scenes in the direction of the tire crane. Preferably, according to the actual situation, the field of view of the camera should cover two left and right (or 2*N, N=1, 2, 3...) lane lines on the specified line on the side; figure 1 shown;

[0090] Step 2: Determine the use mode of the tracking system. If the automatic tracking system of the tire crane is used for the first time or is in the calibration mode, start the calibration module of the automatic tracking system of the tire crane and continue to step 3. If it is in the real-time tracking mode, go to step 4.

[0091] Step 3: Start the calibration module of the automatic deviation correction system of the tire crane, and store the coordinates of the characteristic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com