A construction method for precasting bridge segments by adopting a short-line method

A construction method, short-line method technology, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as the geometric alignment of the whole bridge deviates too much from the design alignment, bridge safety hazards, waste of labor costs, etc., to achieve reuse , save production costs, and ensure the effect of measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

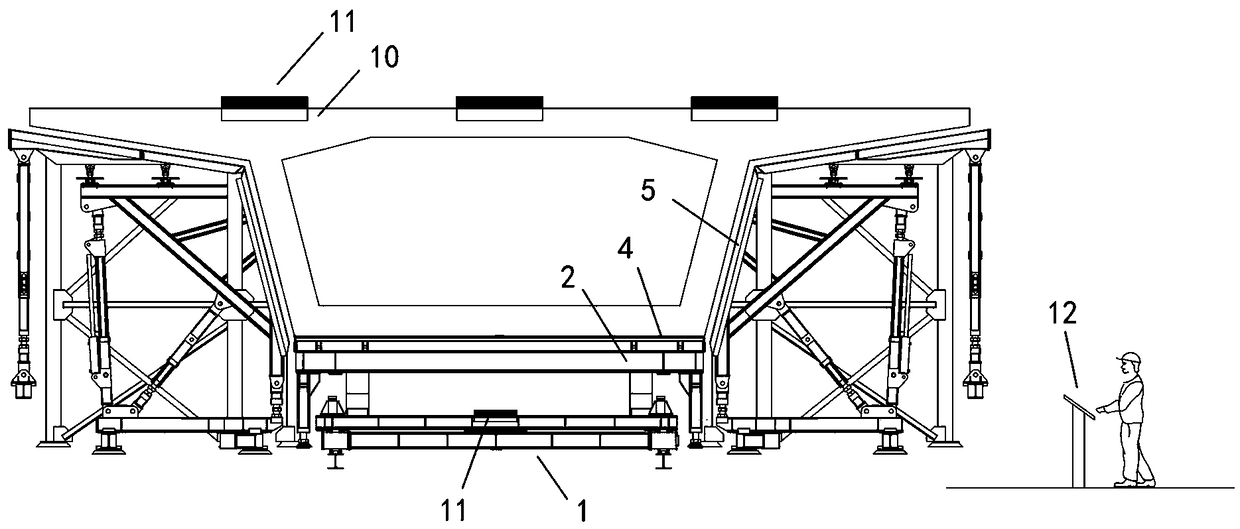

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0032] The present invention provides a kind of construction method that adopts short line method to prefabricate bridge section in implementation, comprises:

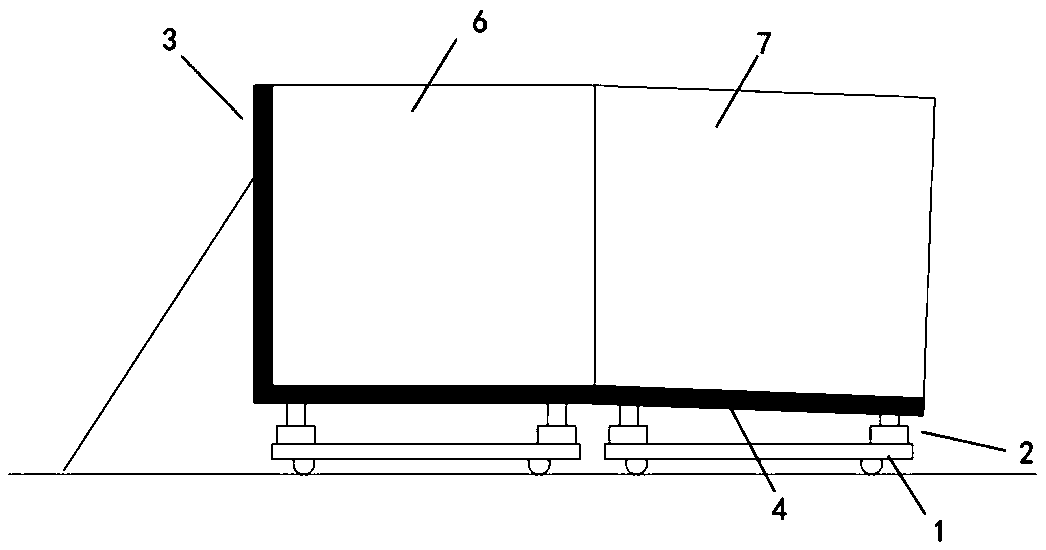

[0033] Step (1), arrange the control tower 12 and several trolleys 1 in the prefabrication factory, install the hydraulic platform 2 on the trolley, and build the end mold 3, bottom mold 4 and side mold 5 of the initial segment 6 on the hydraulic platform 2 (Where side form 5 is not in the attached figure 1 (not shown in ), build the steel frame on the steel tire frame and hoist it in place, install the inner formwork, and pour concrete into the formwork to form the initial segment 6 .

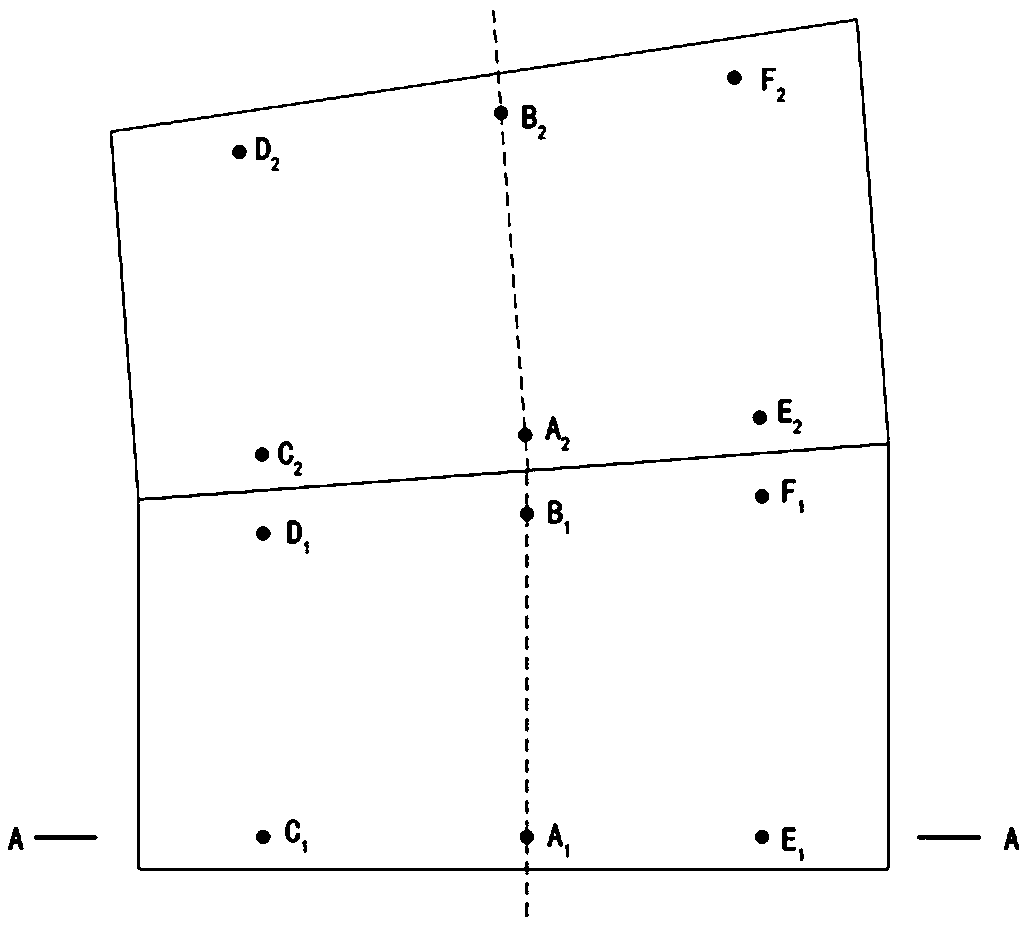

[0034] Step (2), when the initial stage of the concrete in the formwork is initially set, arrange six first numerical control implantation points A1, B1, C1, D1, E1, and F1 on the upper surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com