Floating clamp for flexible metal plate production line feeder

A production line and feeder technology, which is used in metal processing equipment, auxiliary devices, laser welding equipment, etc., can solve the problems that the tightening mechanism cannot float left and right, the equipment rejection rate increases, and the processing accuracy is affected, so as to increase the rejection rate and reduce waste. efficiency, improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

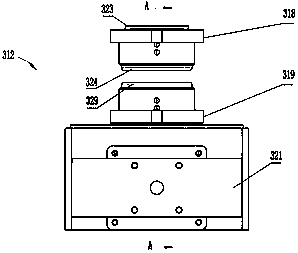

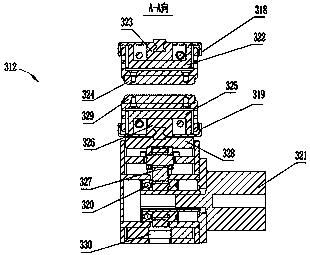

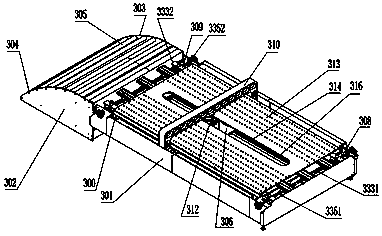

[0040] The flexible sheet metal production line feeding machine of the present invention uses floating clamps, such as Figure 1-2 As shown, the floating clamp 312 is provided with an upper clamp body 318, a lower clamp body 319, a connecting rod 327, an eccentric wheel 320, a swing member and a base 330, and a mounting plate 328 is provided between the lower clamp body 319 and the connecting rod 327;

[0041] A spring plunger 322 is arranged in the upper clamp body 318, and the spring plunger 322 is internally connected with a guide rail 323, and the guide rail 323 is bolted to the middle position of the feeding beam 310. When the floating clamp body 312 is not working, the upper clamp body 318 hangs On the feeding beam 310; an upper jaw 324 is fixed at the bottom of the spring plunger 322, the bottom surface of the upper jaw 324 is flat, and the upper jaw 324 is fixed with the spring plunger 322 by bolts;

[0042] The second spring plunger 325 is arranged in the lower clamp ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com