Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

48results about How to "Not deform" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

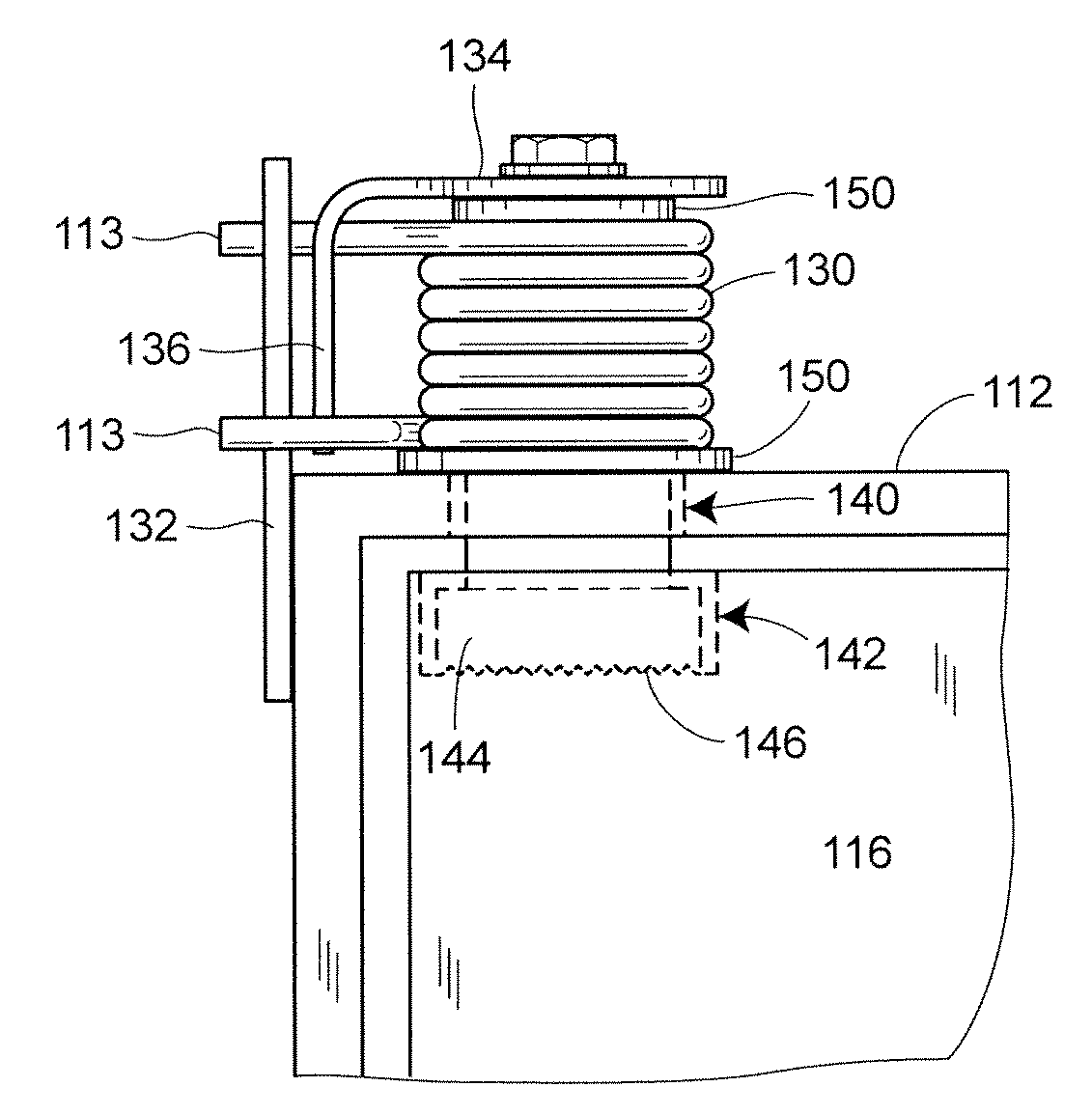

Thermoplastic elastomer composition, insulating glass using the composition, process for producing the insulating glass

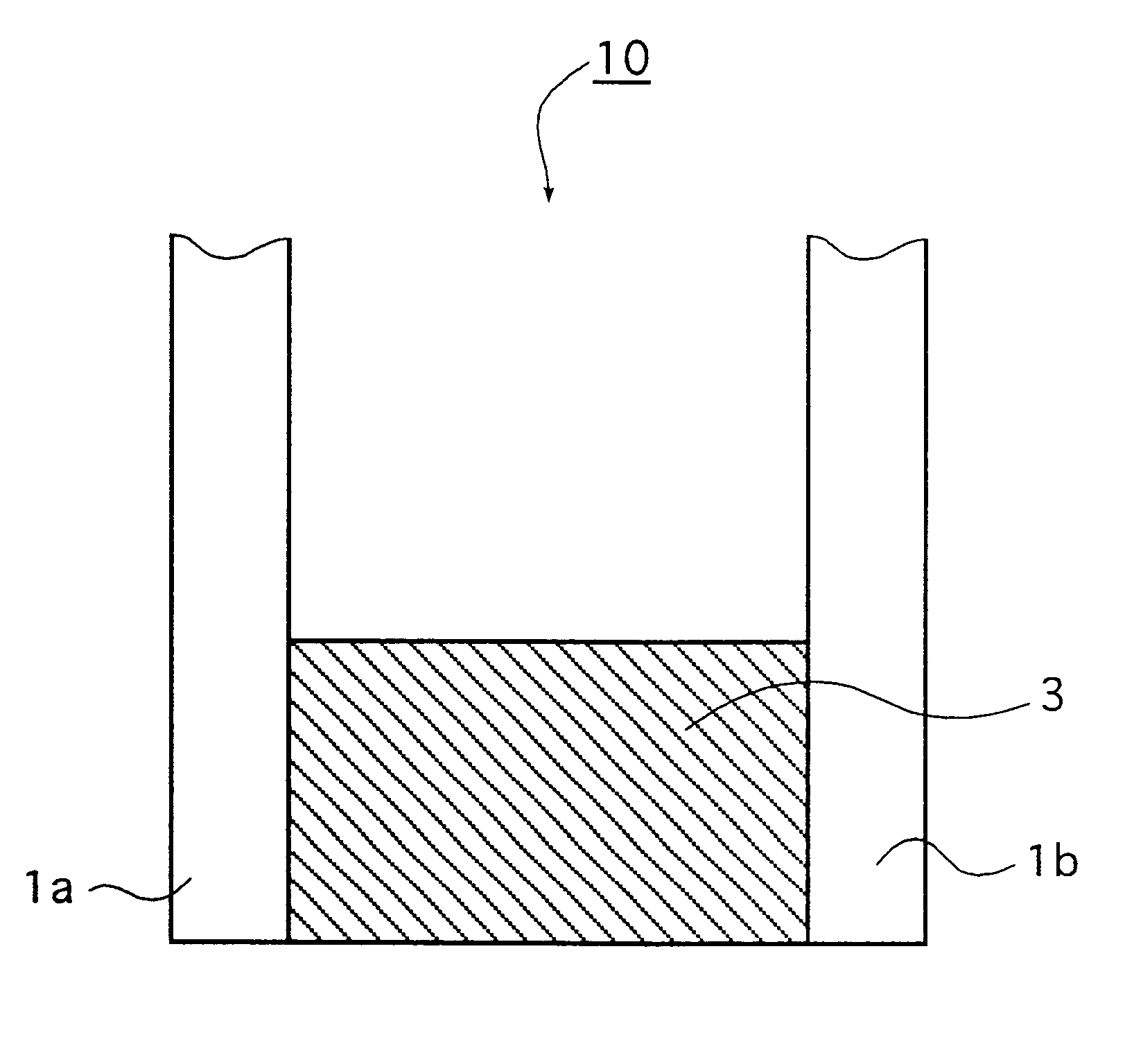

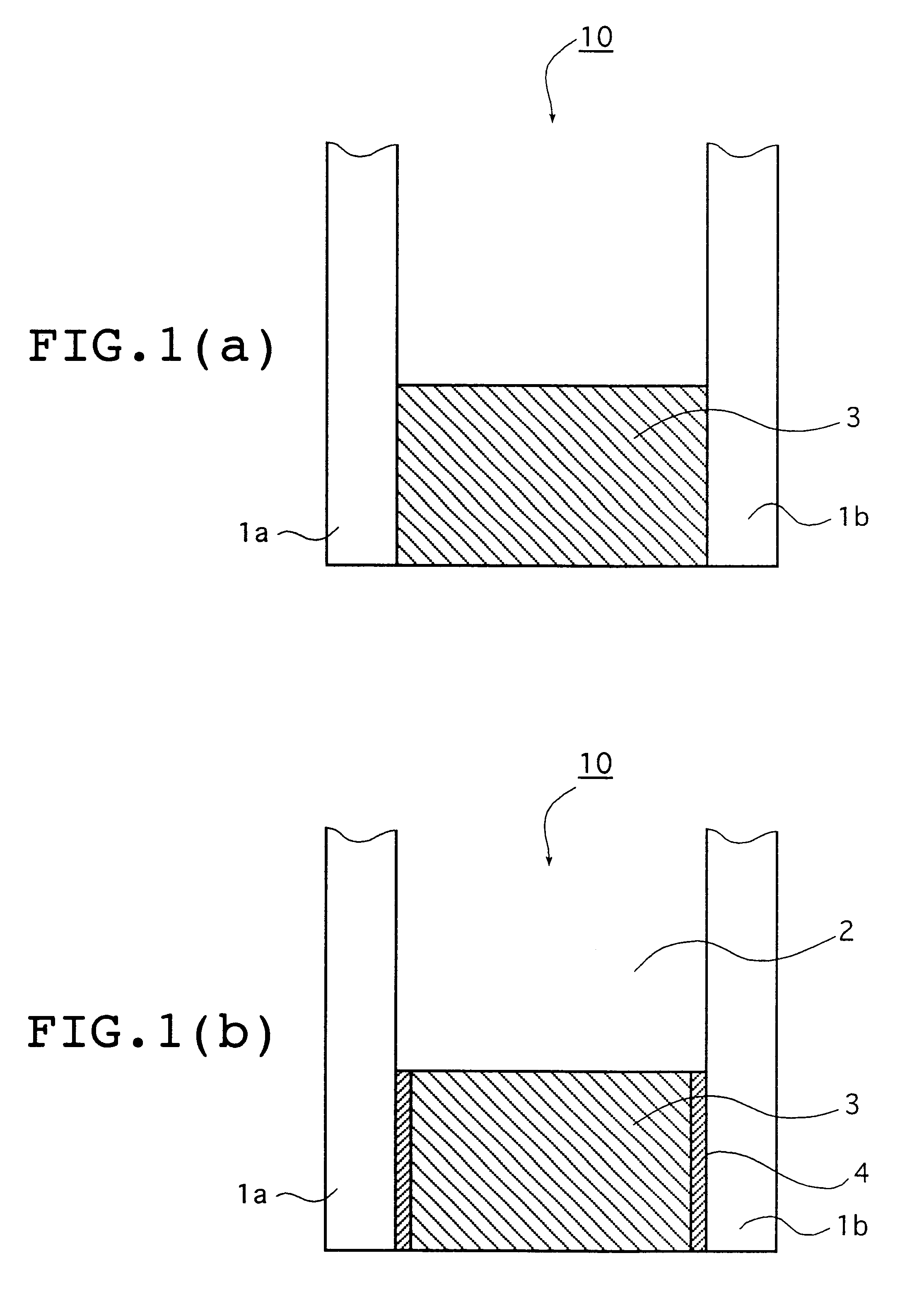

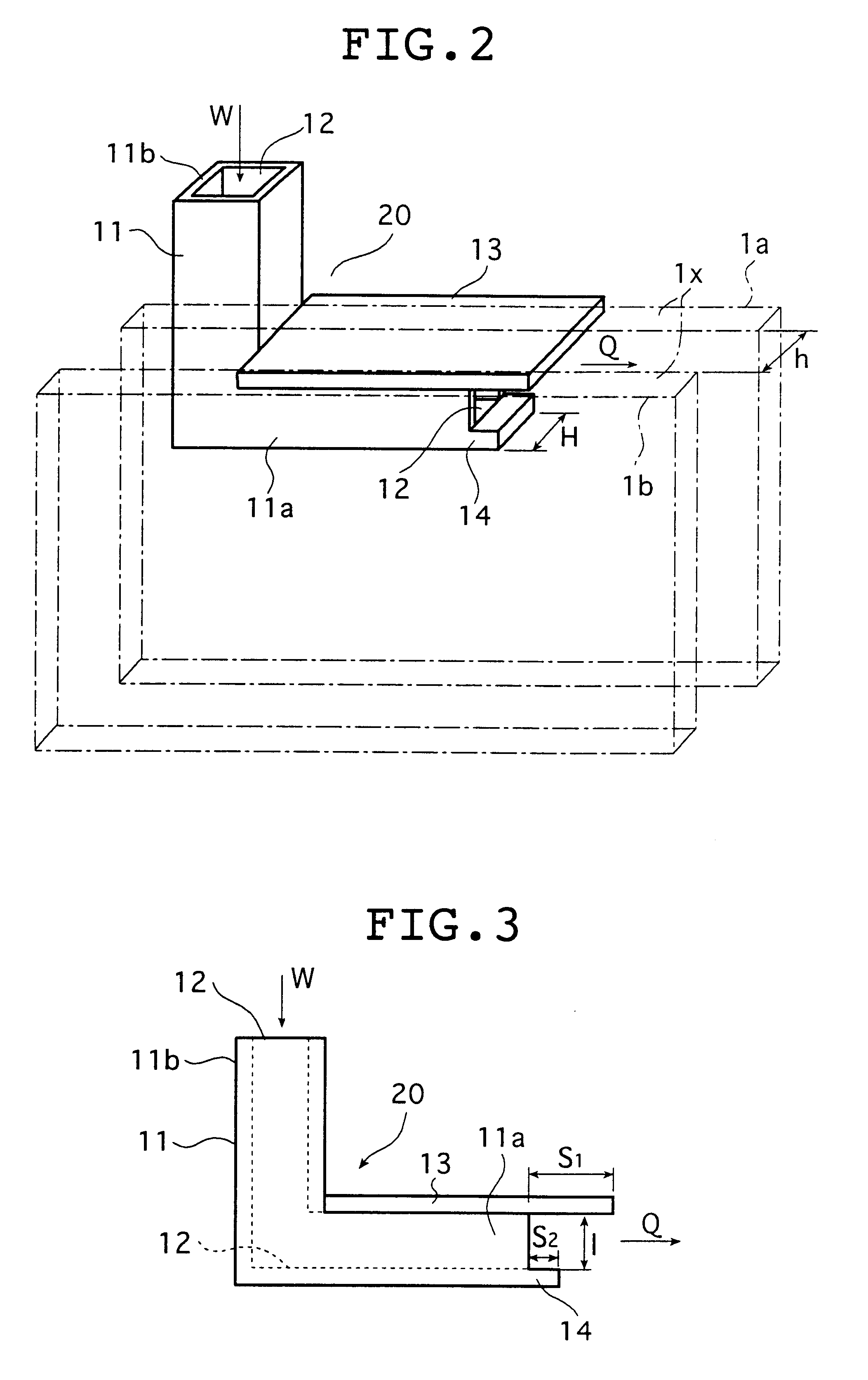

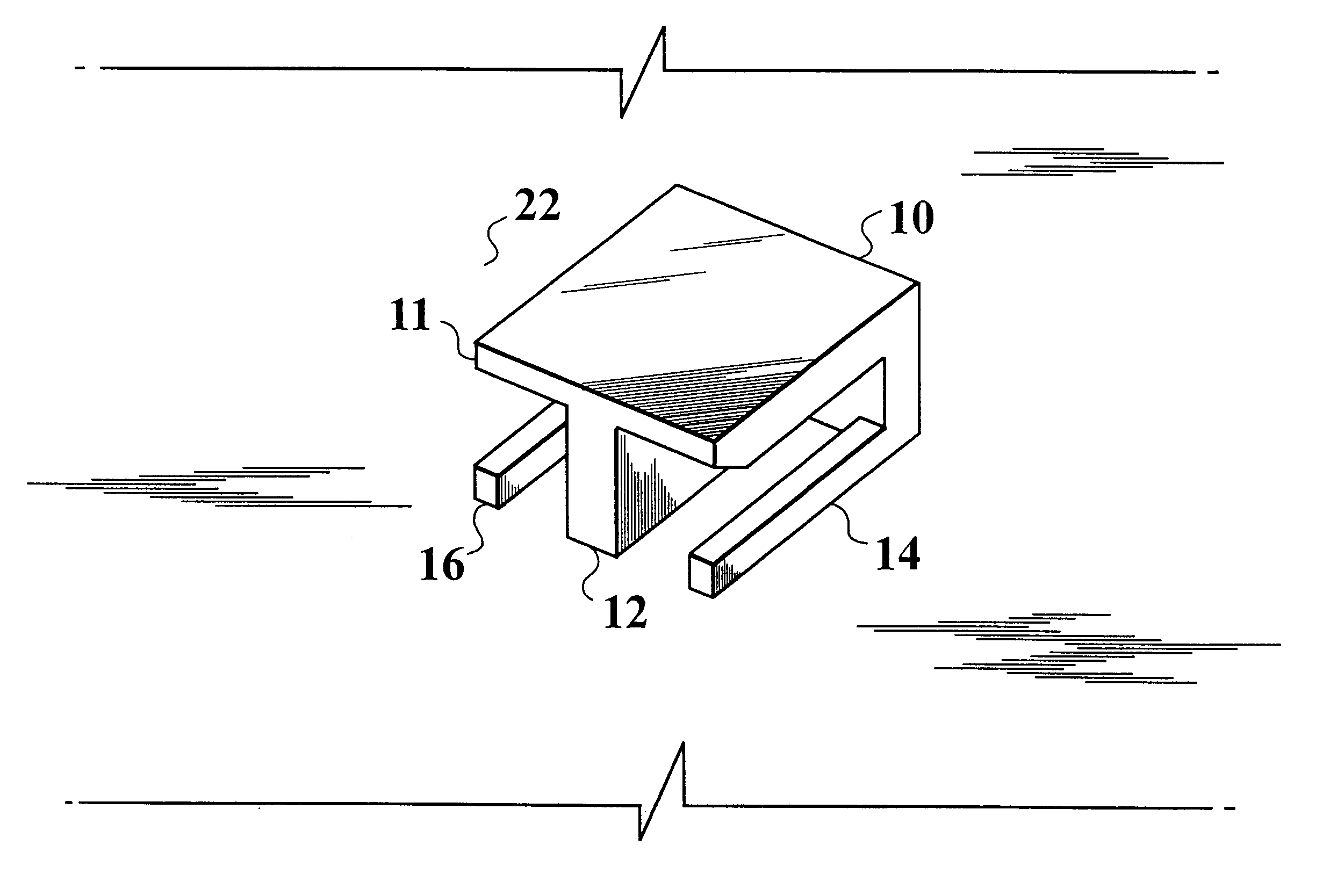

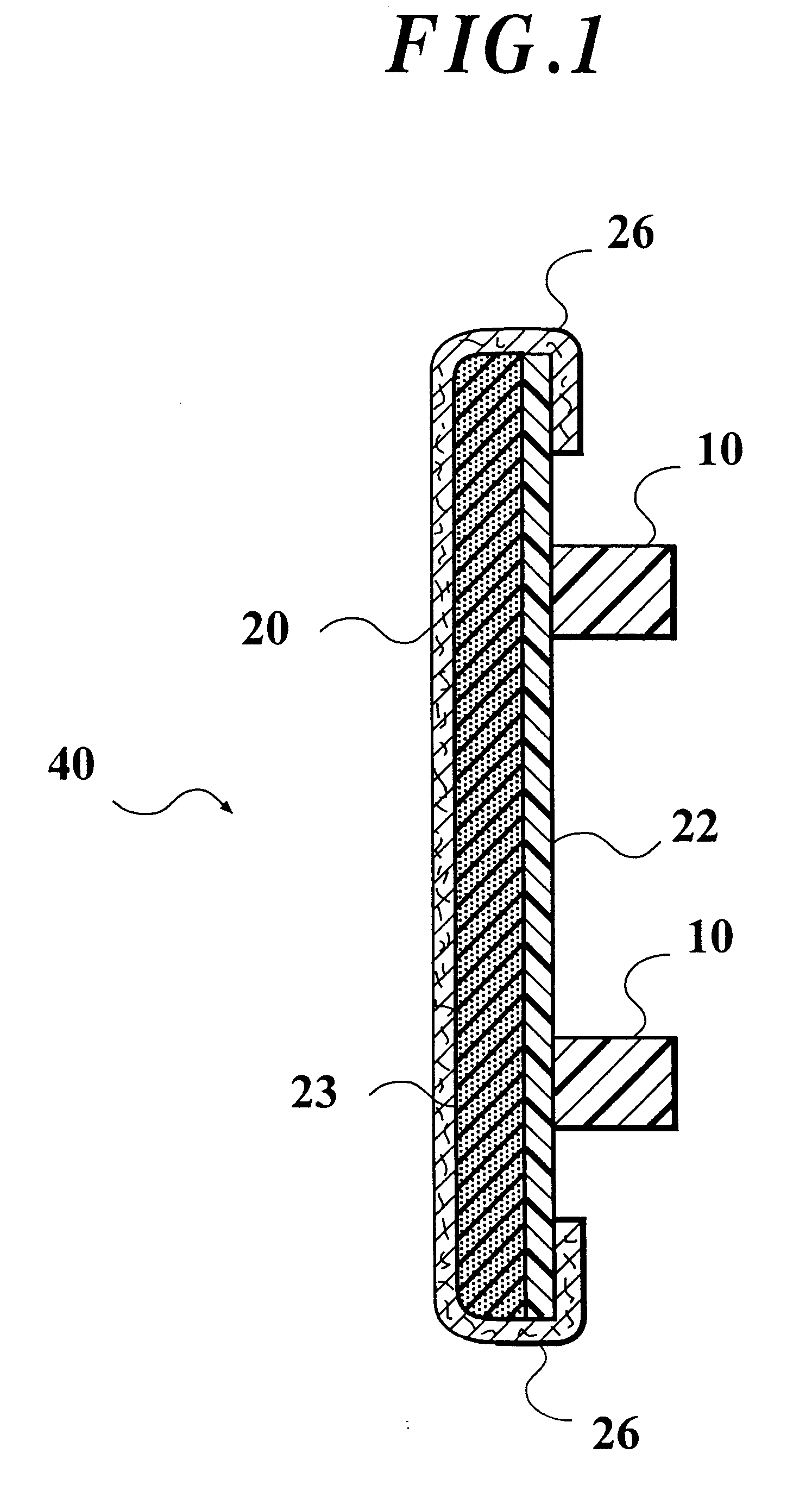

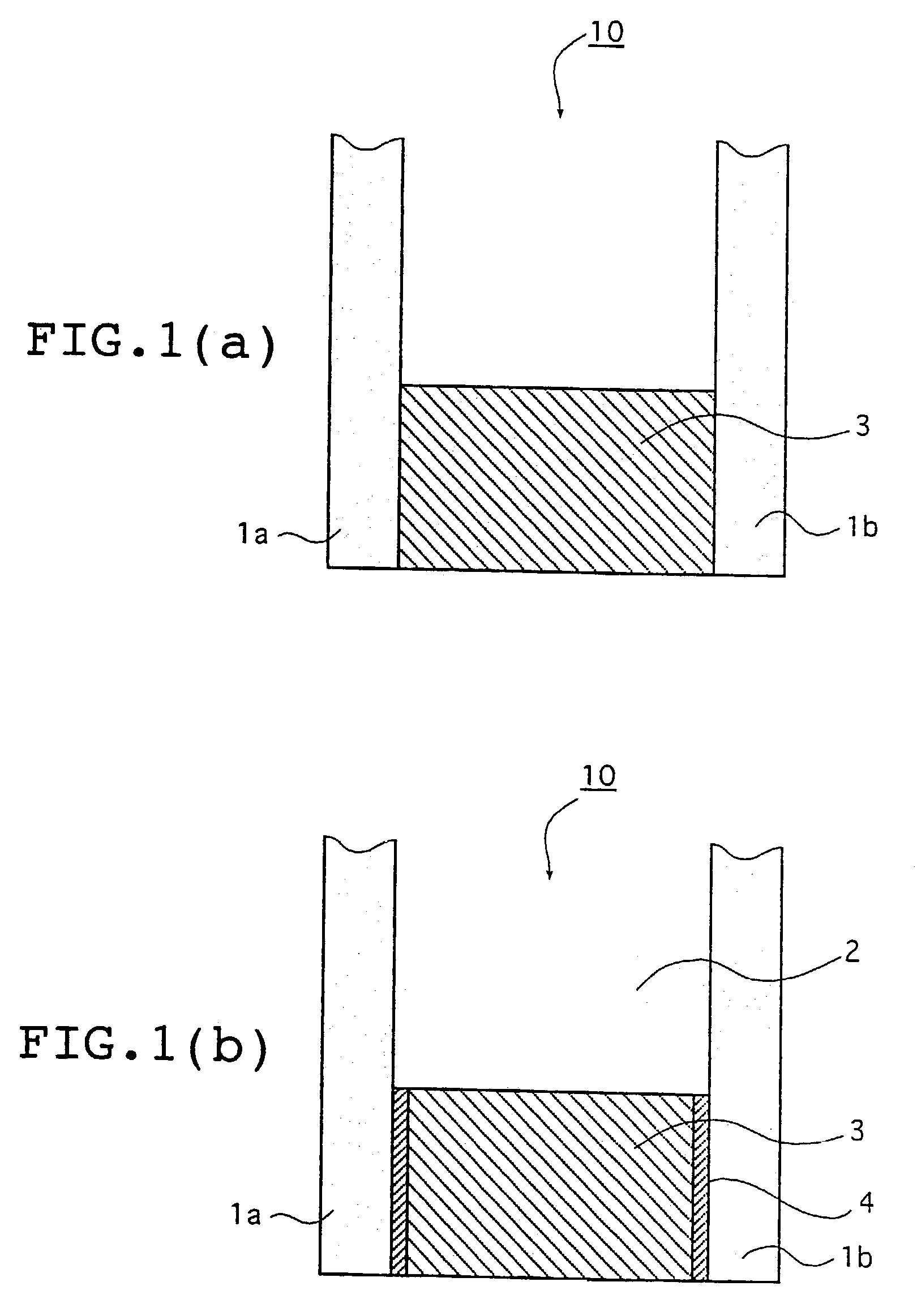

InactiveUS6491992B1Excellent steam permeation resistanceEasy to produceWing framesUnits with parallel planesThermoplastic elastomerGlass sheet

A thermoplastic elastomer composition produced from a thermoplastic resin and rubber and having a dispersion phase formed of a rubber composition at least part of which is dynamically crosslinked in the continuous phase of the thermoplastic resin, insulating glass using the thermoplastic elastomer composition as a sealing material and spacer, a process for producing the insulating glass using a sealing material made from the thermoplastic elastomer composition, comprising the steps of inserting the leading end of a charging nozzle into a space between the peripheral portions of a plurality of glass sheets, discharging the sealing material from the leading end of the nozzle body at a predetermined rate, and moving the glass sheets or the nozzle body relative to each other to charge the sealing material made from the thermoplastic elastomer composition into the space between the peripheral portions of the glass sheets, and a nozzle used in this process.

Owner:THE YOKOHAMA RUBBER CO LTD

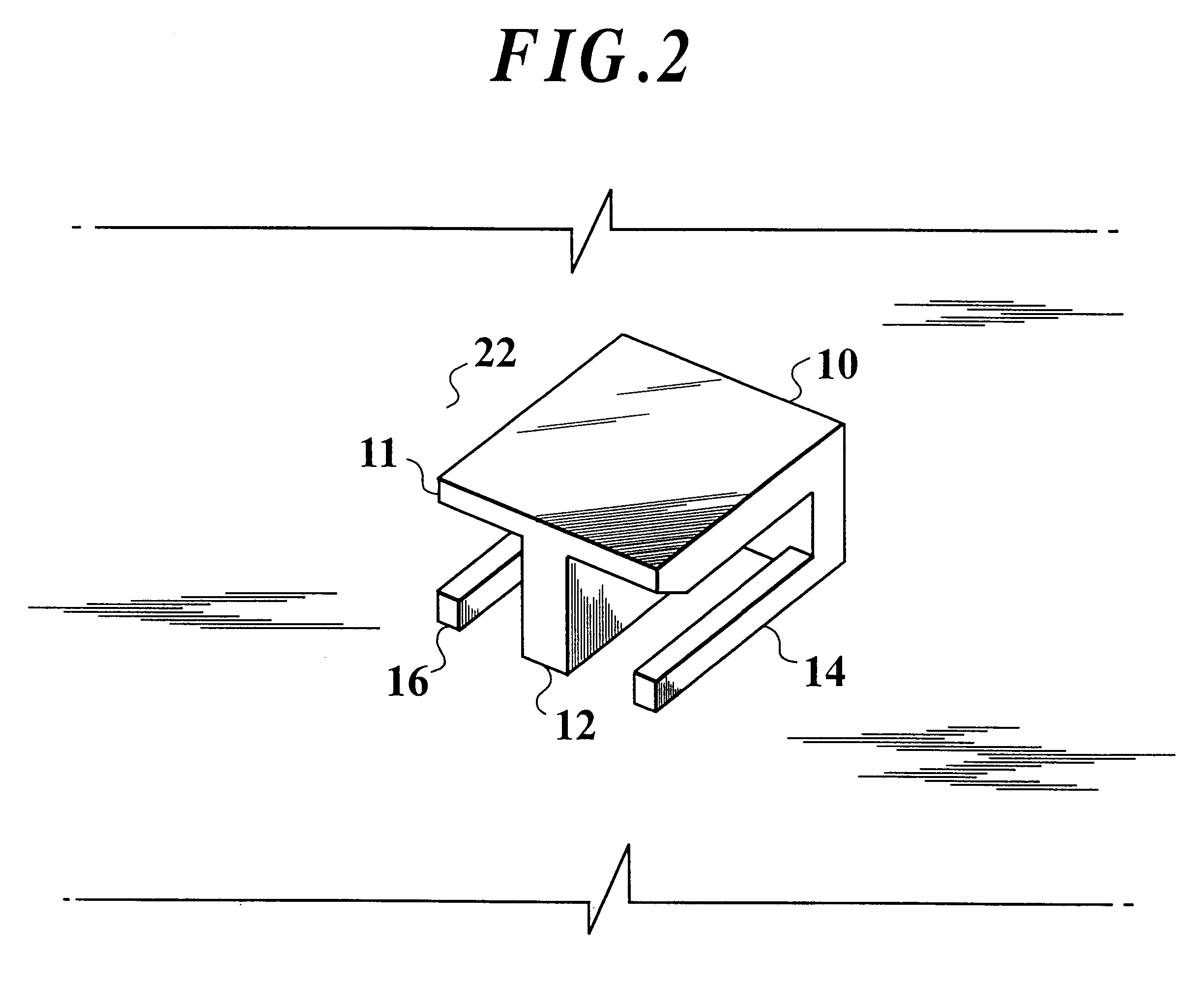

Trim assembly for vehicle

InactiveUS6308488B1High strengthAvoid it happening againConstruction materialLayered productsCushionEngineering

A mounting structure formed on a plate-like member and for mounting the plate-like member to a trim panel for a vehicle, the mounting structure comprises an approximately T-like shape in cross section. A trim assembly for a vehicle comprises: a plate-like member; a cushion member disposed on the plate-like member; and a top cover covering the whole cushion member, wherein peripheral portions of which are secured to peripheral portions of the plate-like member; wherein a mounting structure comprising an approximately T-like shape in cross section, for mounting the trim assembly to a trim panel for a vehicle is formed on the plate-like member.

Owner:TS TECH CO LTD

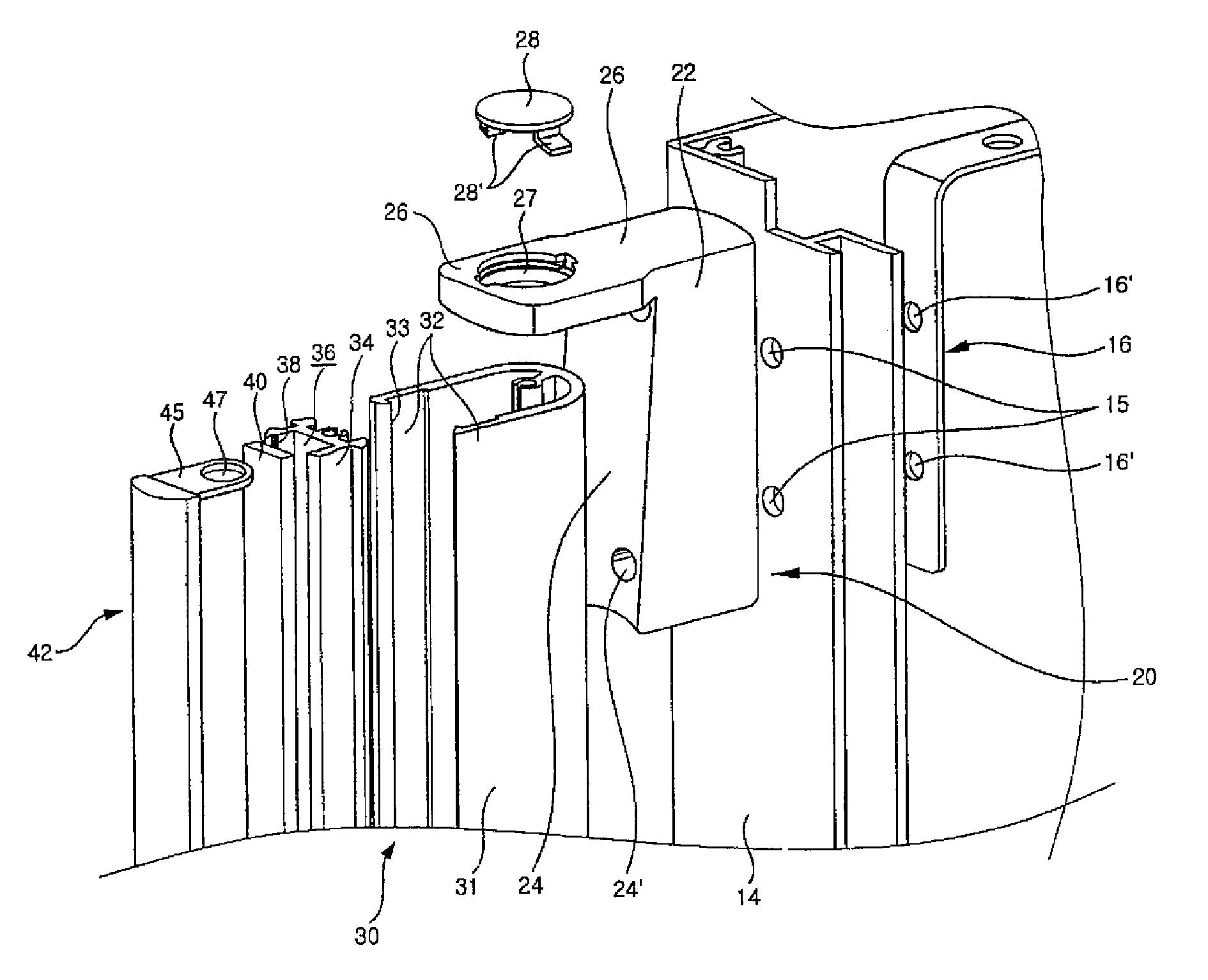

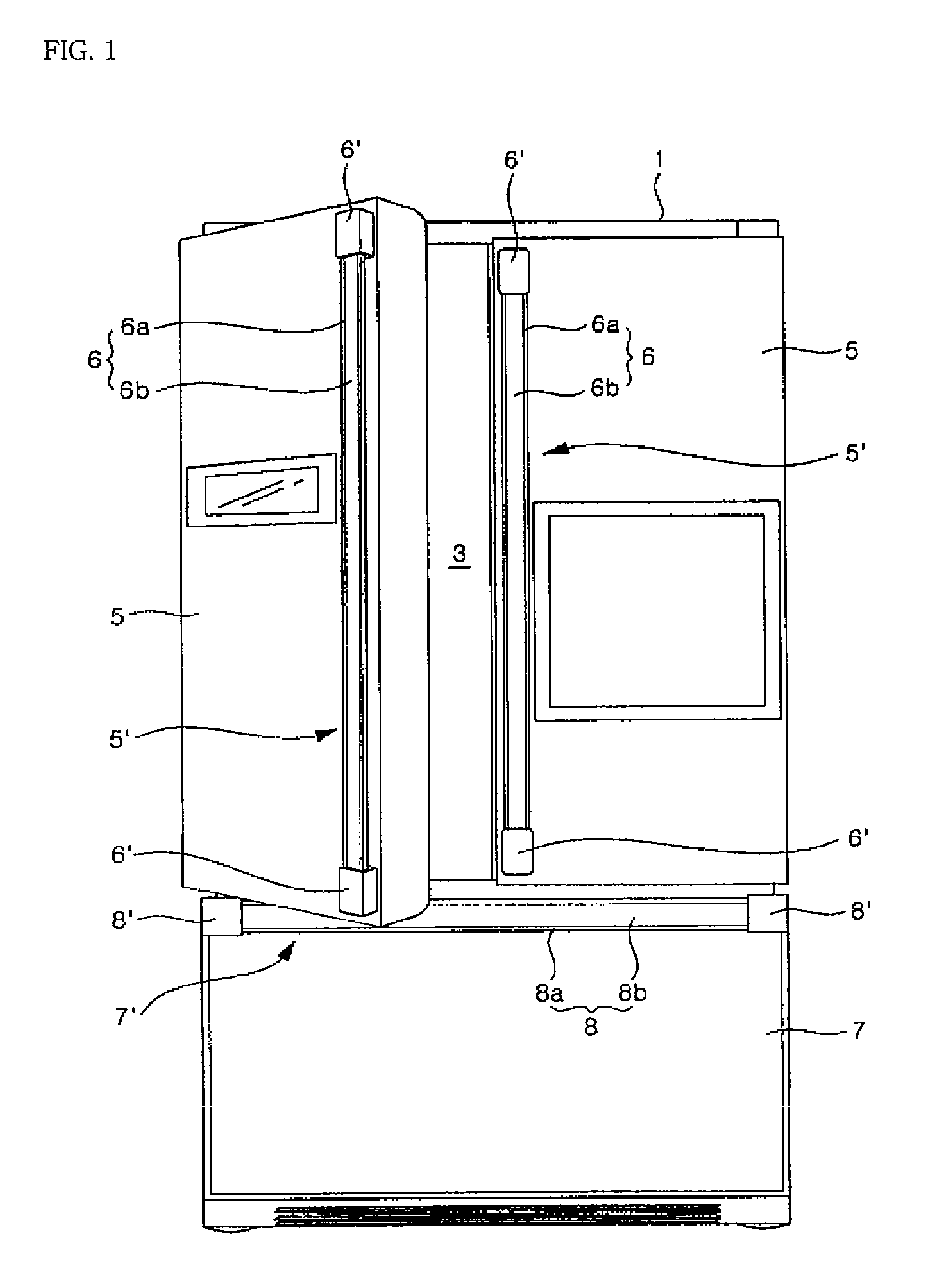

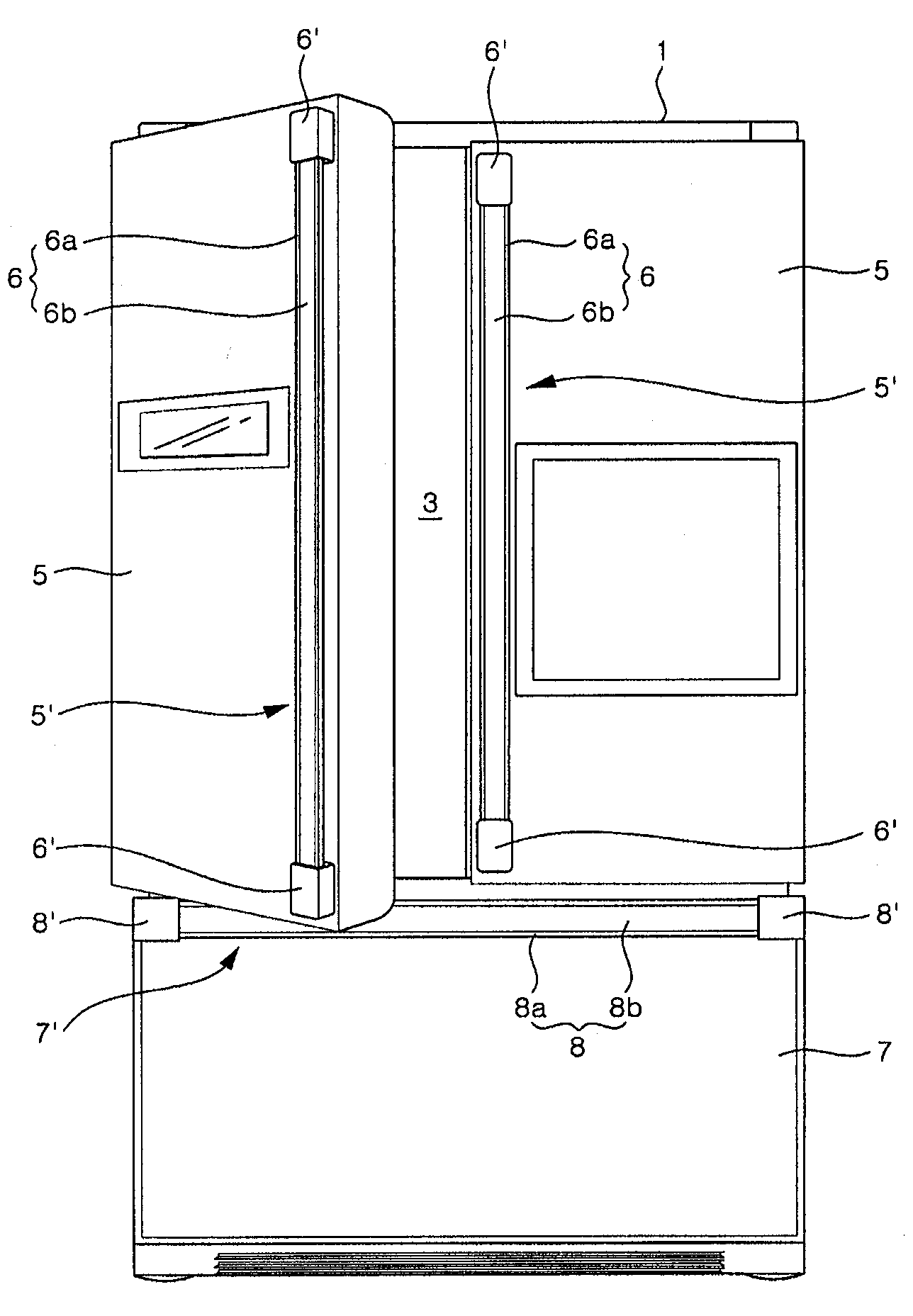

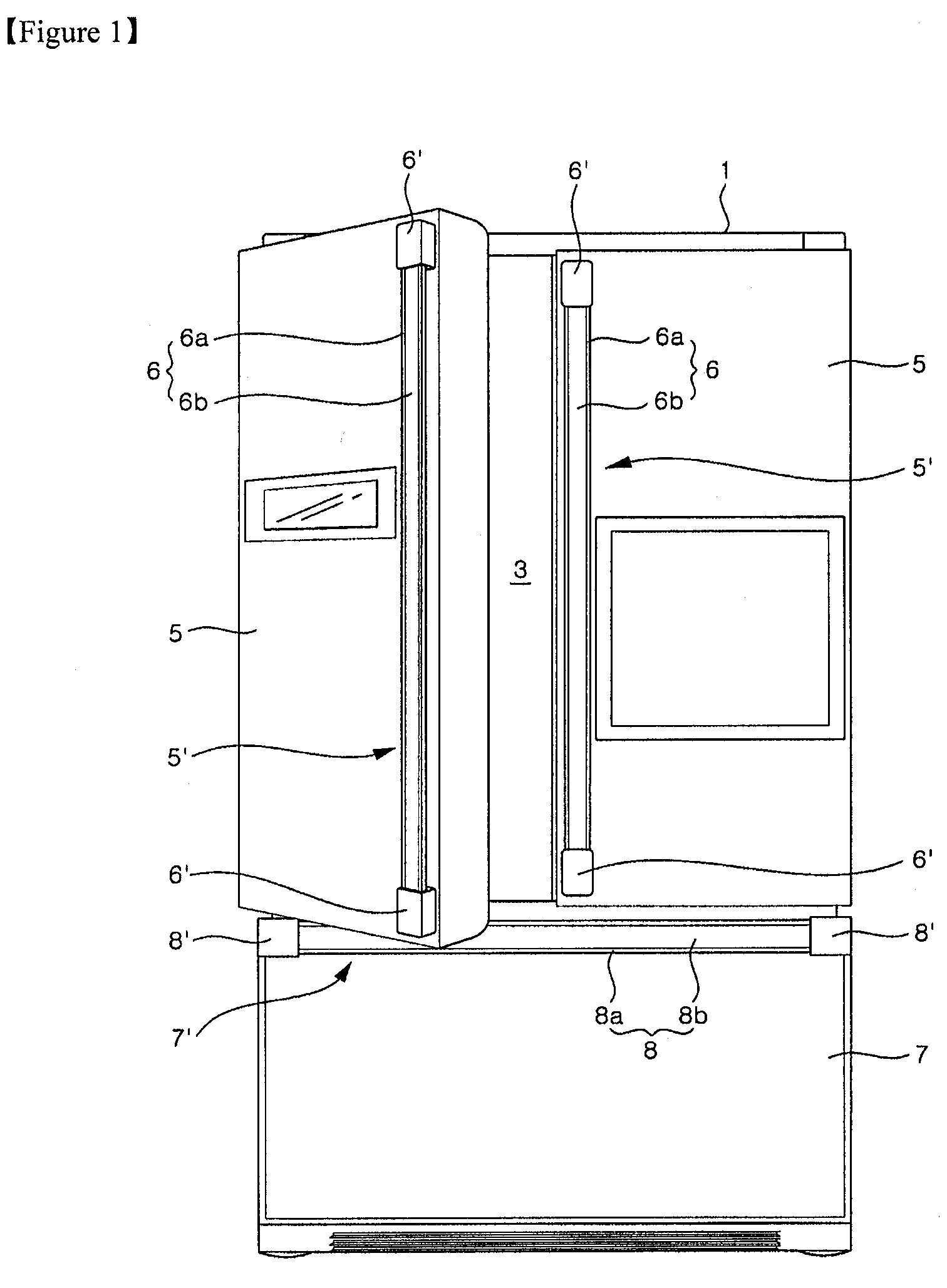

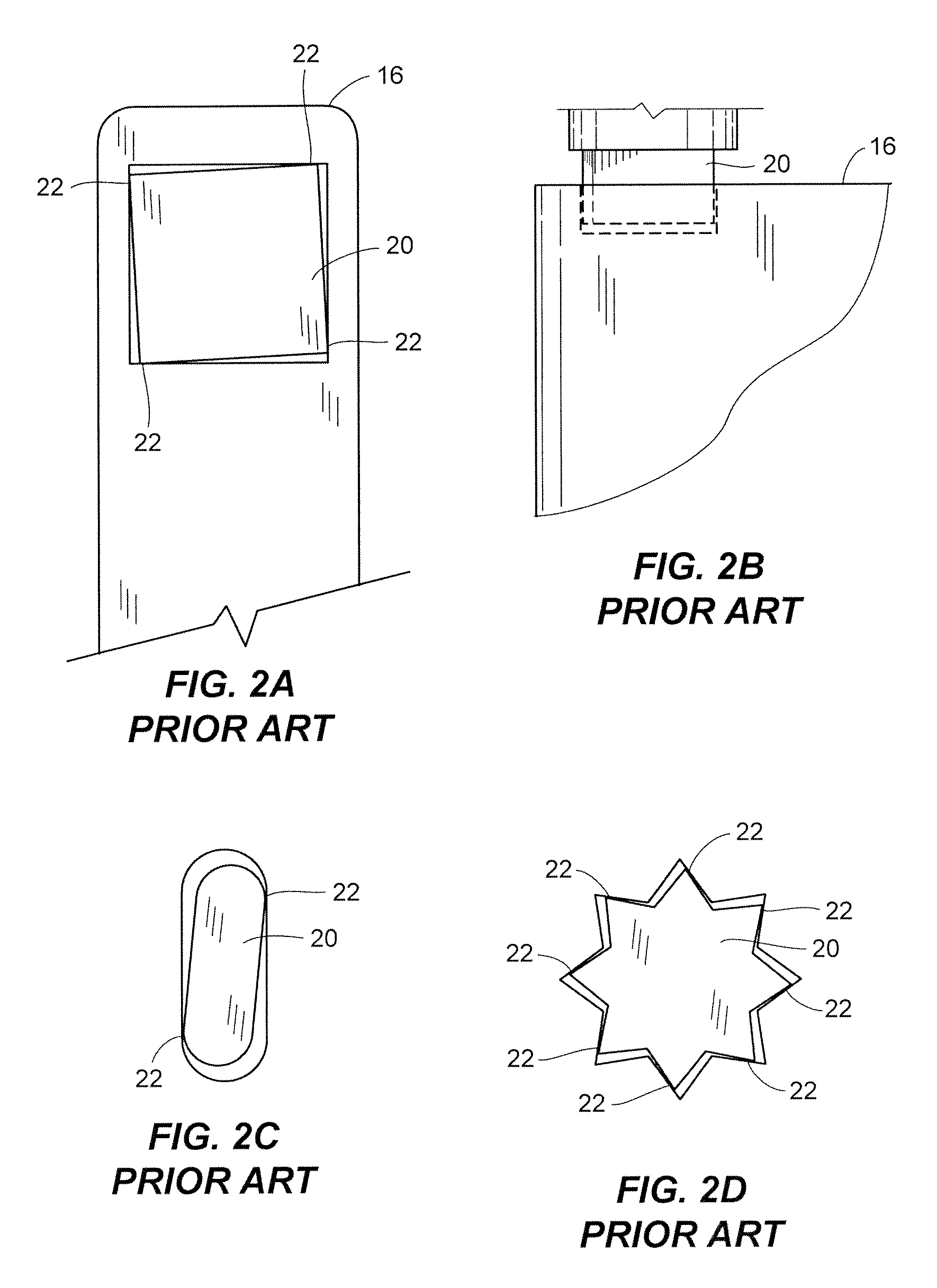

Door handle for refrigerator

InactiveUS8108972B2High strengthNot deformTravelling carriersHoldersMechanical engineeringRefrigerated temperature

A decoration is installed in a seating channel provided in a handle bar. The seating channel with the decoration installed therein is shielded by a transparent or translucent handle cover. Cover end coupling pieces are provided at both ends of the handle cover and coupled with coupling ribs of a handle bar body of the handle bar or a cover base. The cover end coupling pieces protrude and extend from both ends of the handle cover to be perpendicular to other portions. A luminous body or jewel may be used as the decoration.

Owner:LG ELECTRONICS INC

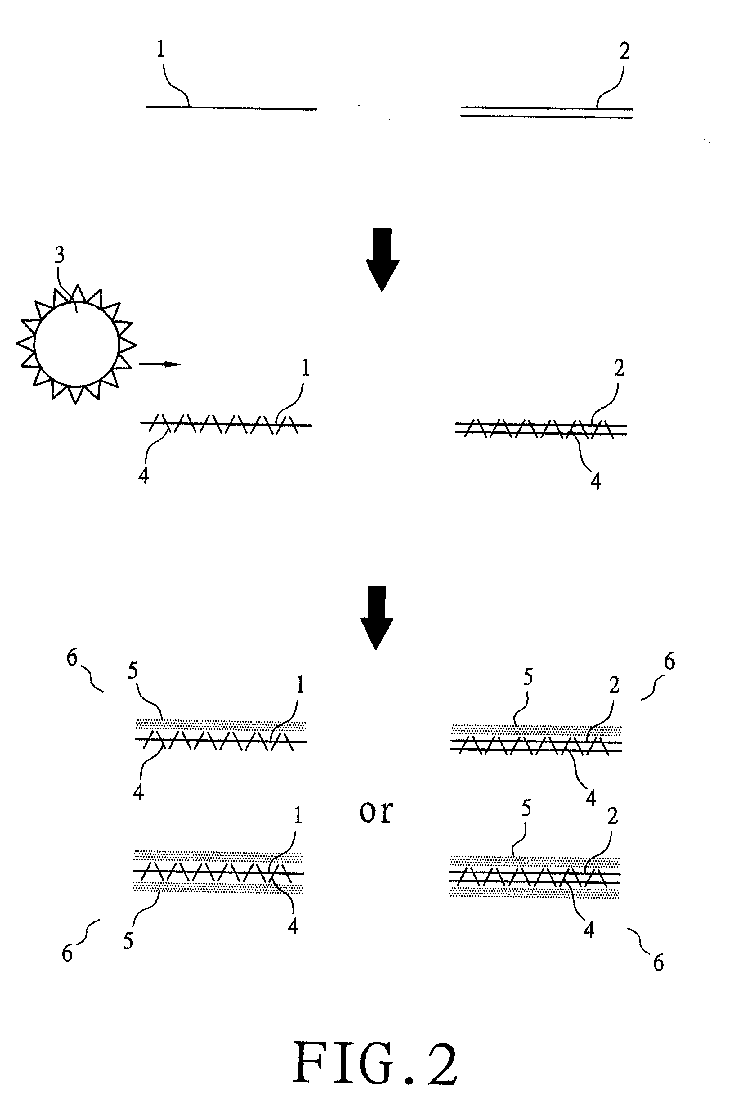

Method of manufacturing a release liner

InactiveUS20060228480A1High mechanical strengthEasy to tearLamination ancillary operationsFilm/foil adhesivesEngineeringMechanical engineering

The present invention relates to a method of manufacturing a release liner to be temporarily adhered to the surface of an adhesive. A single-layer or multi-layer film is obtained by impressing a plastic base liner substrate. At least one surface of the base liner substrate is coated with a release agent to form a tearable release liner. There is no fibrous debris along the edges when the release liner is torn apart.

Owner:LIN DAVID

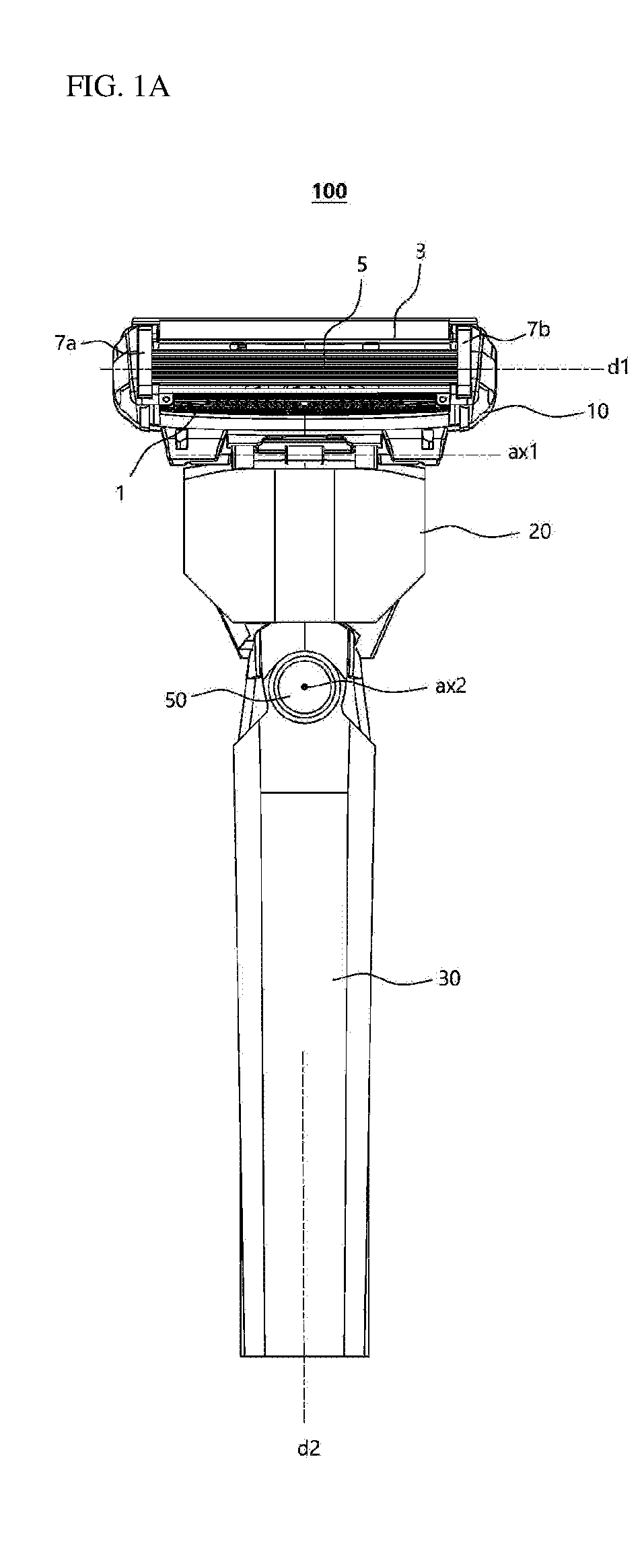

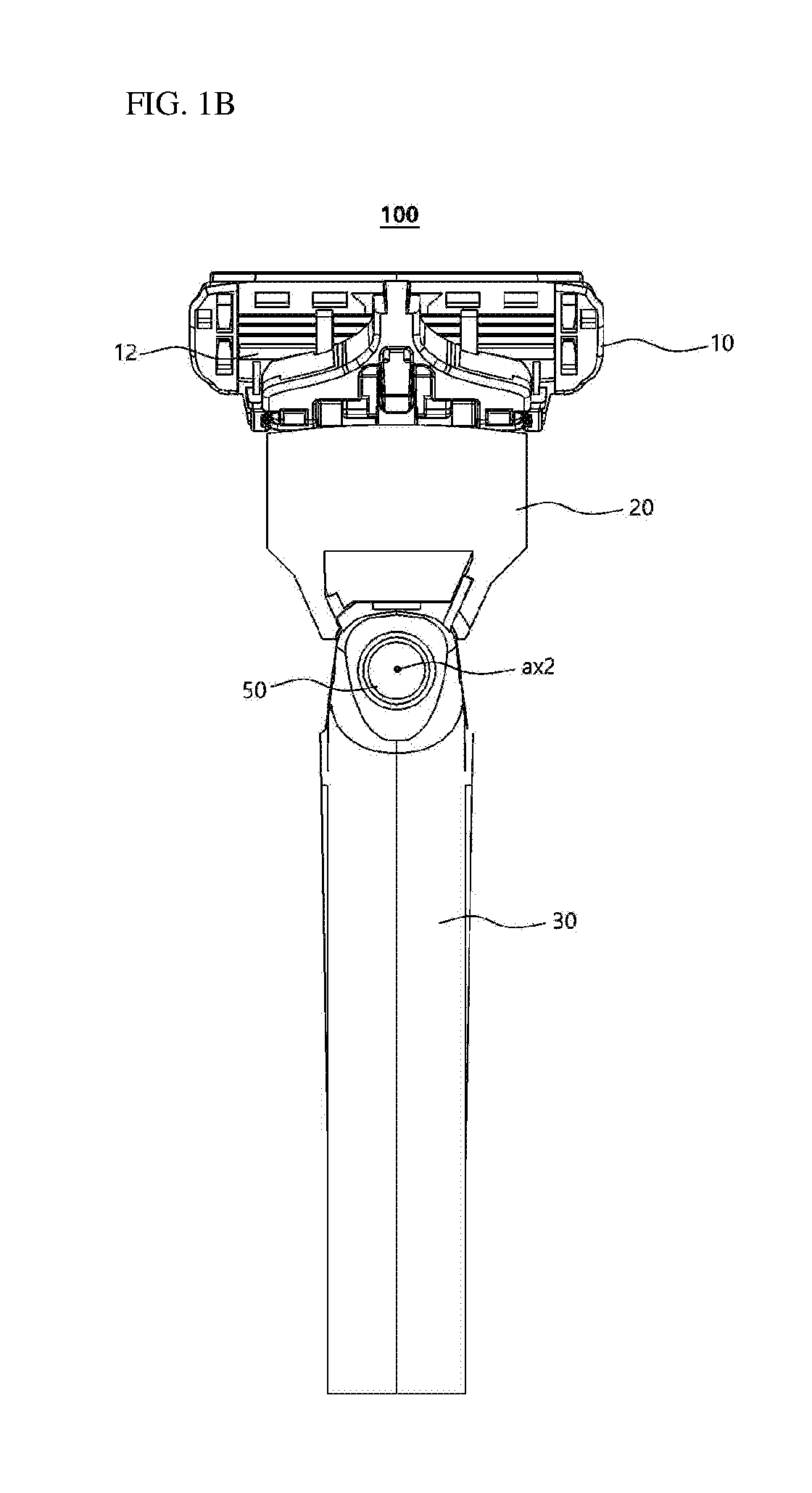

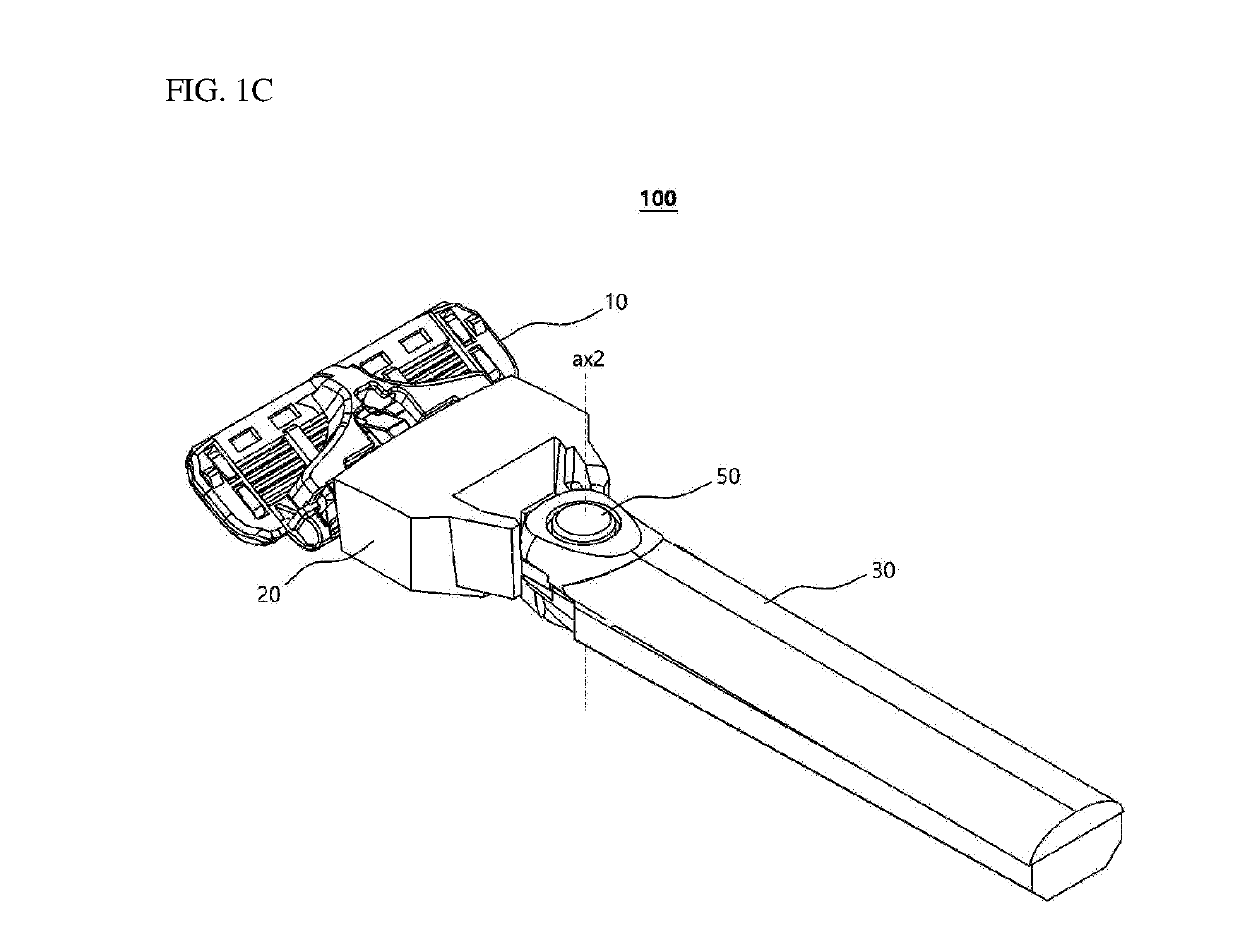

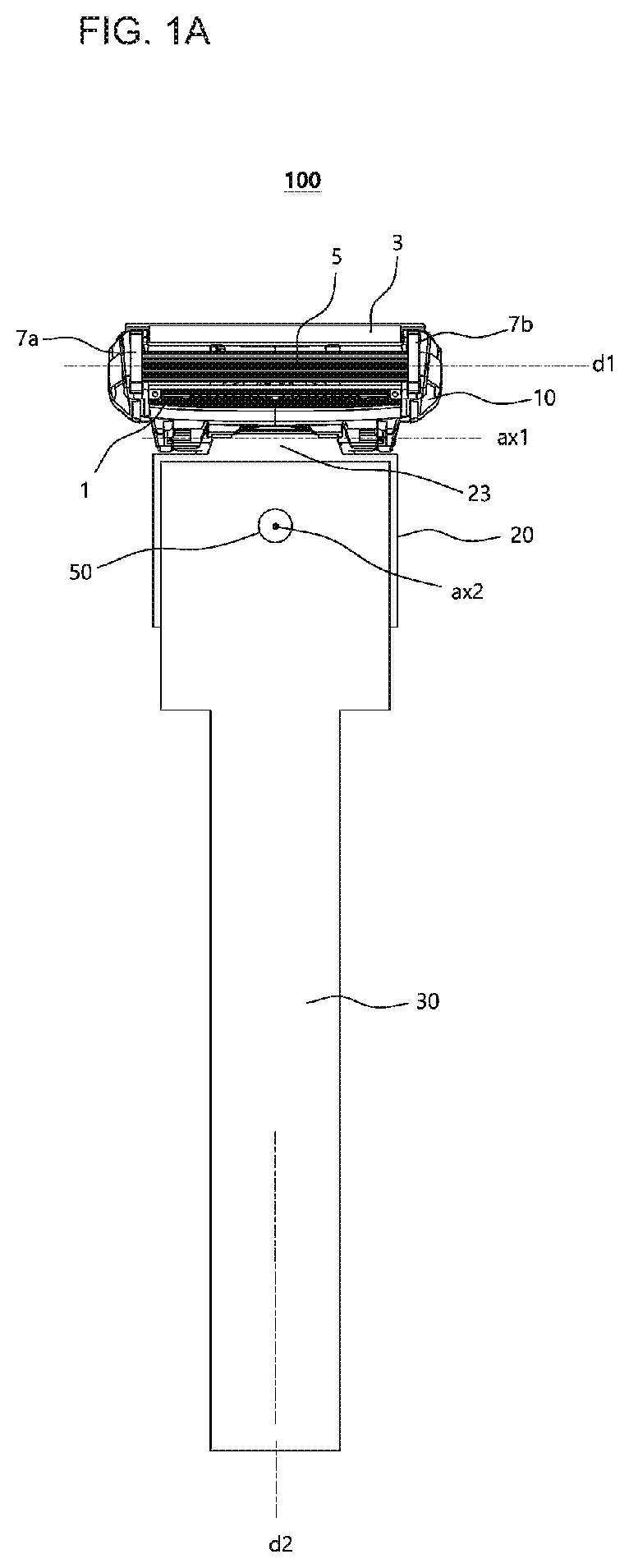

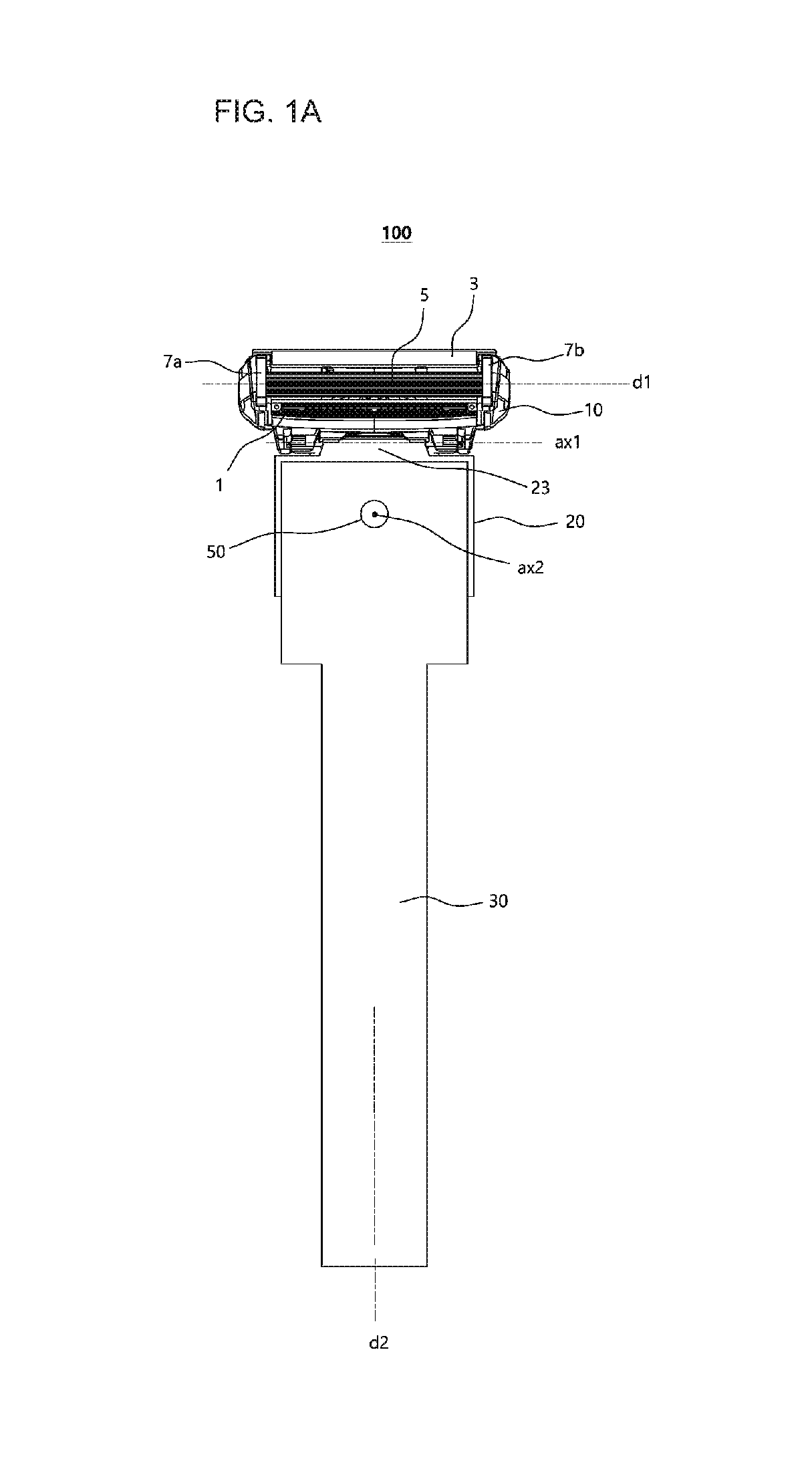

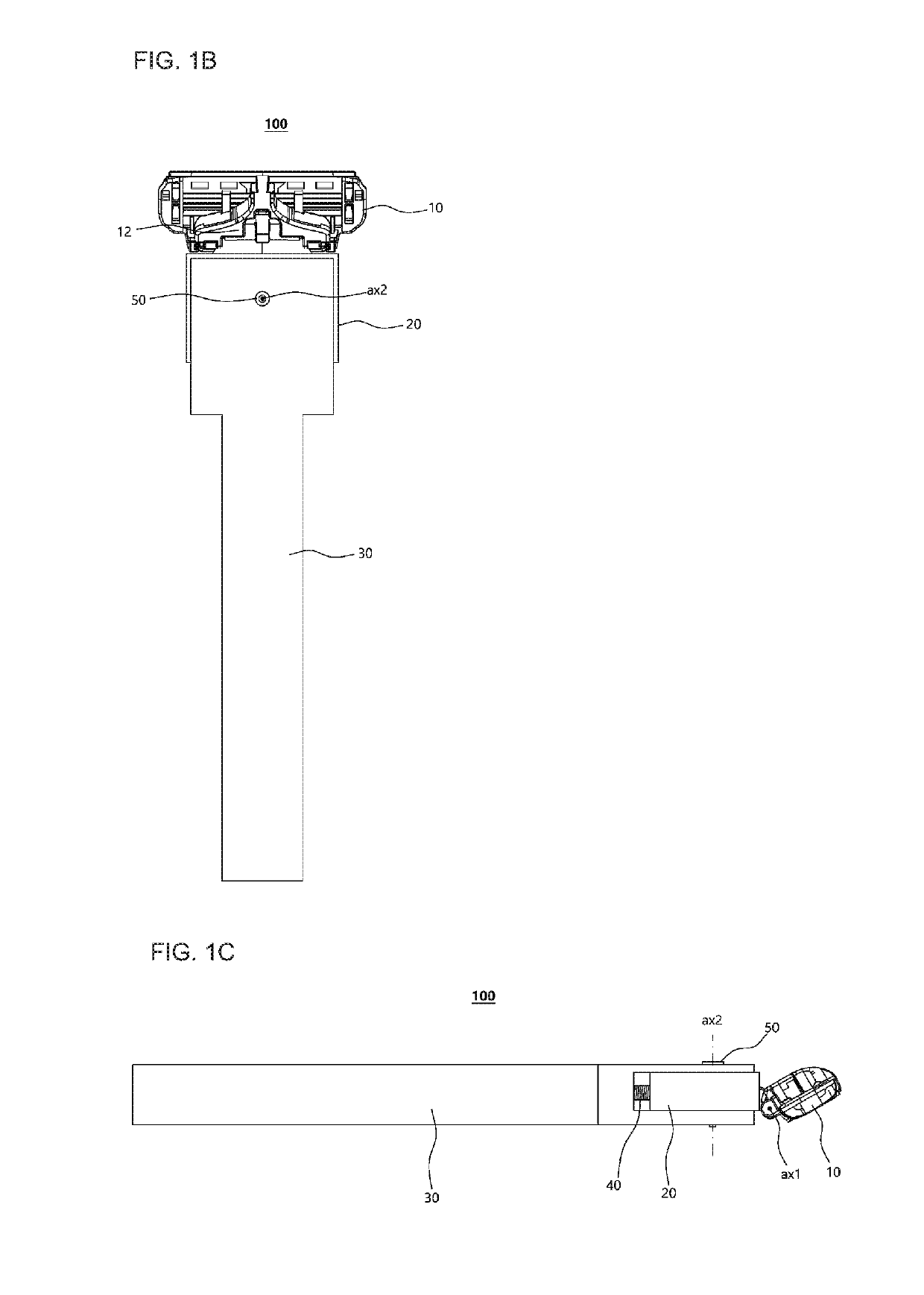

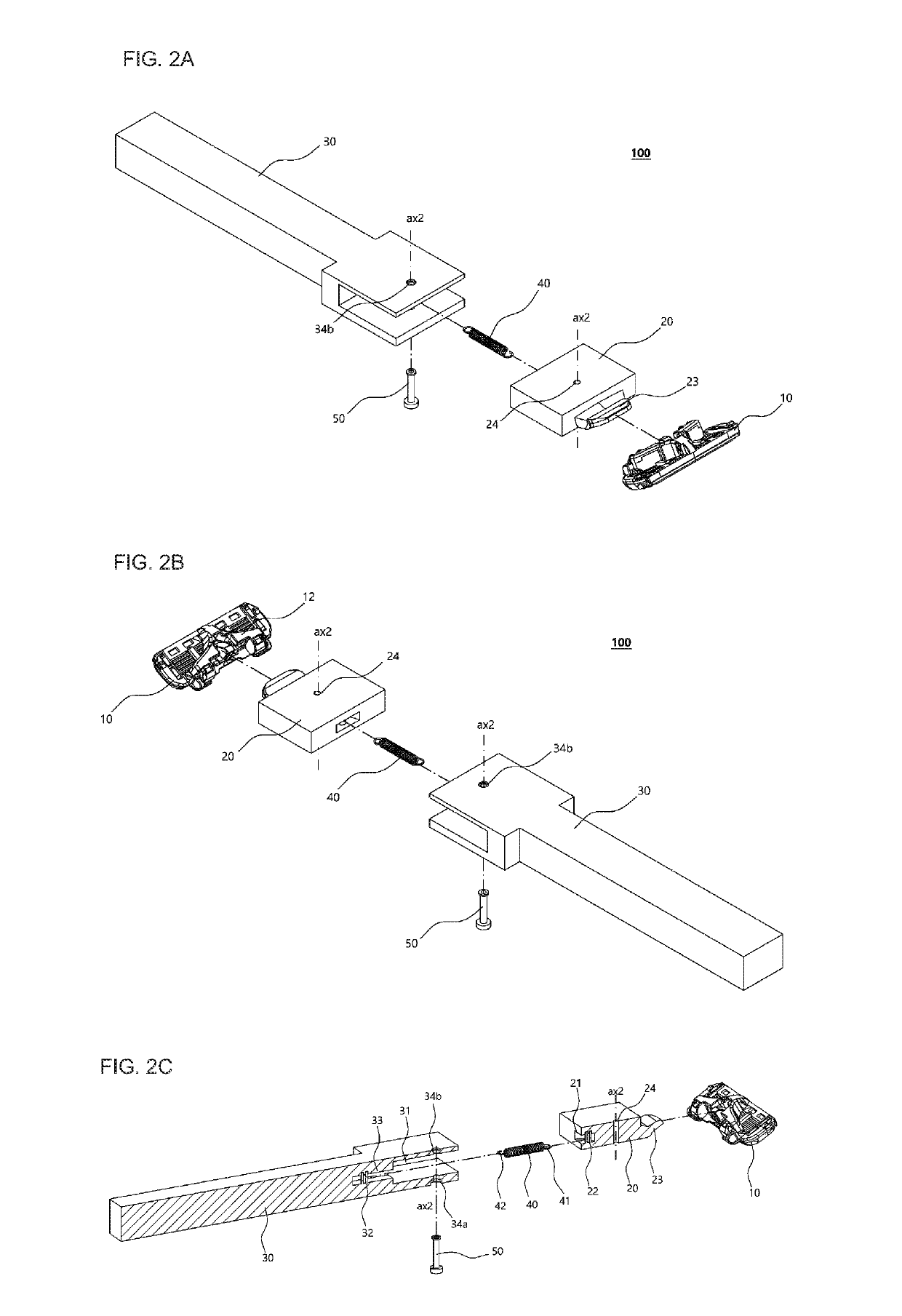

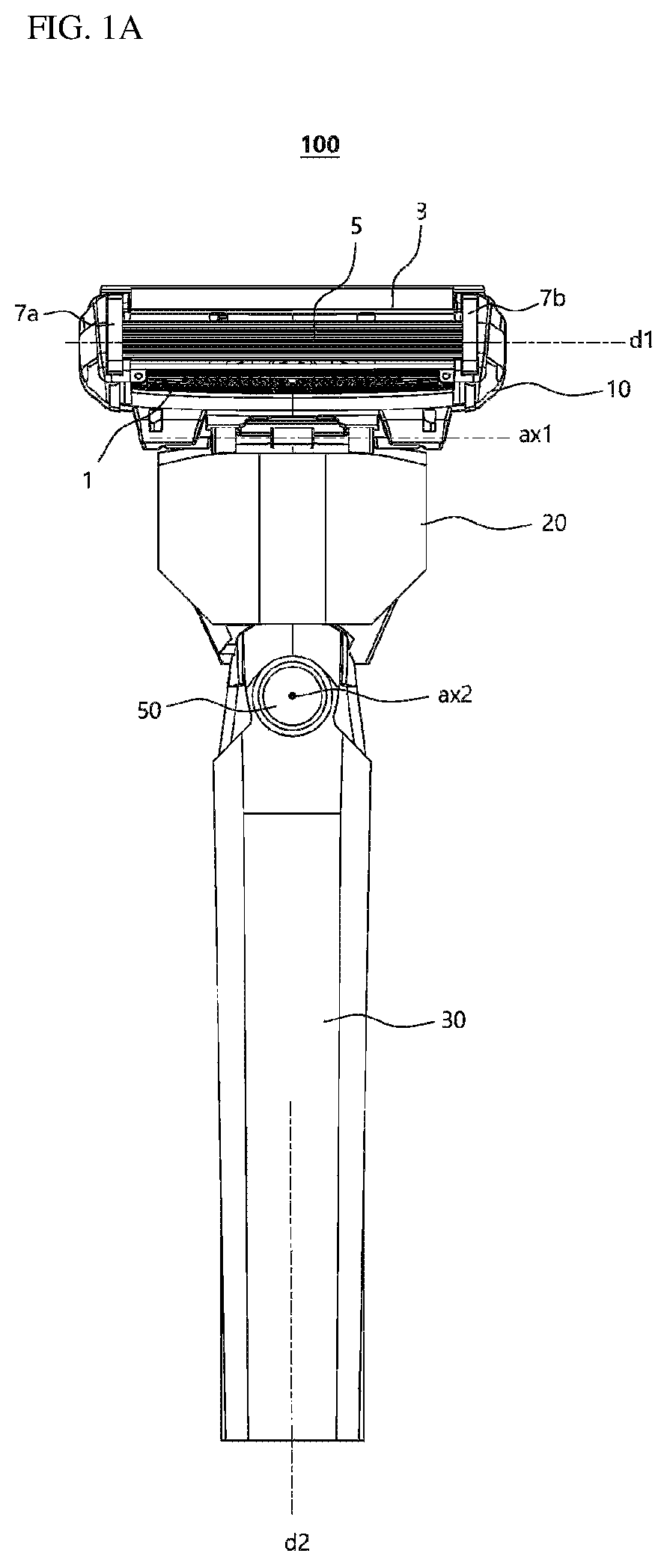

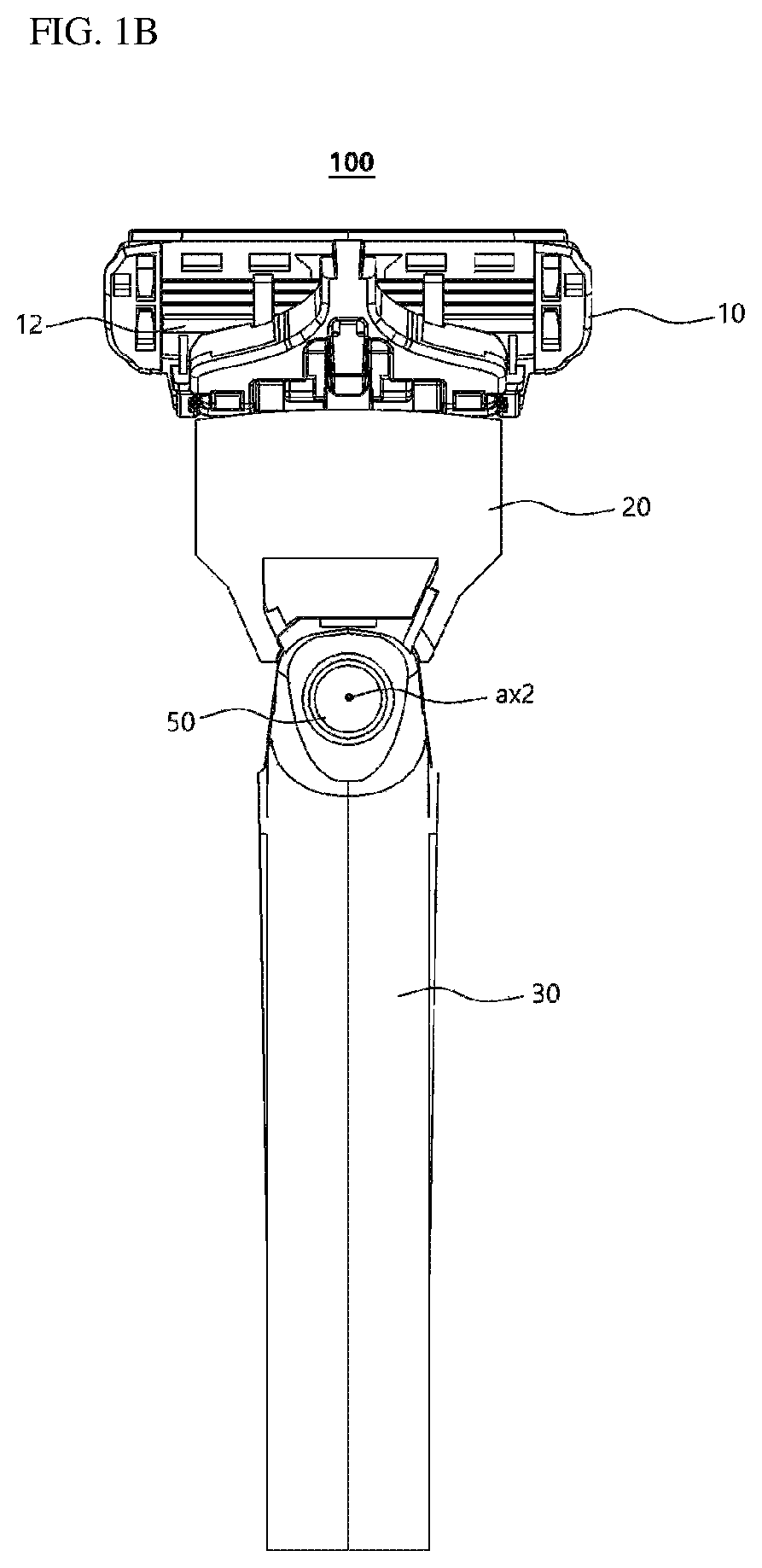

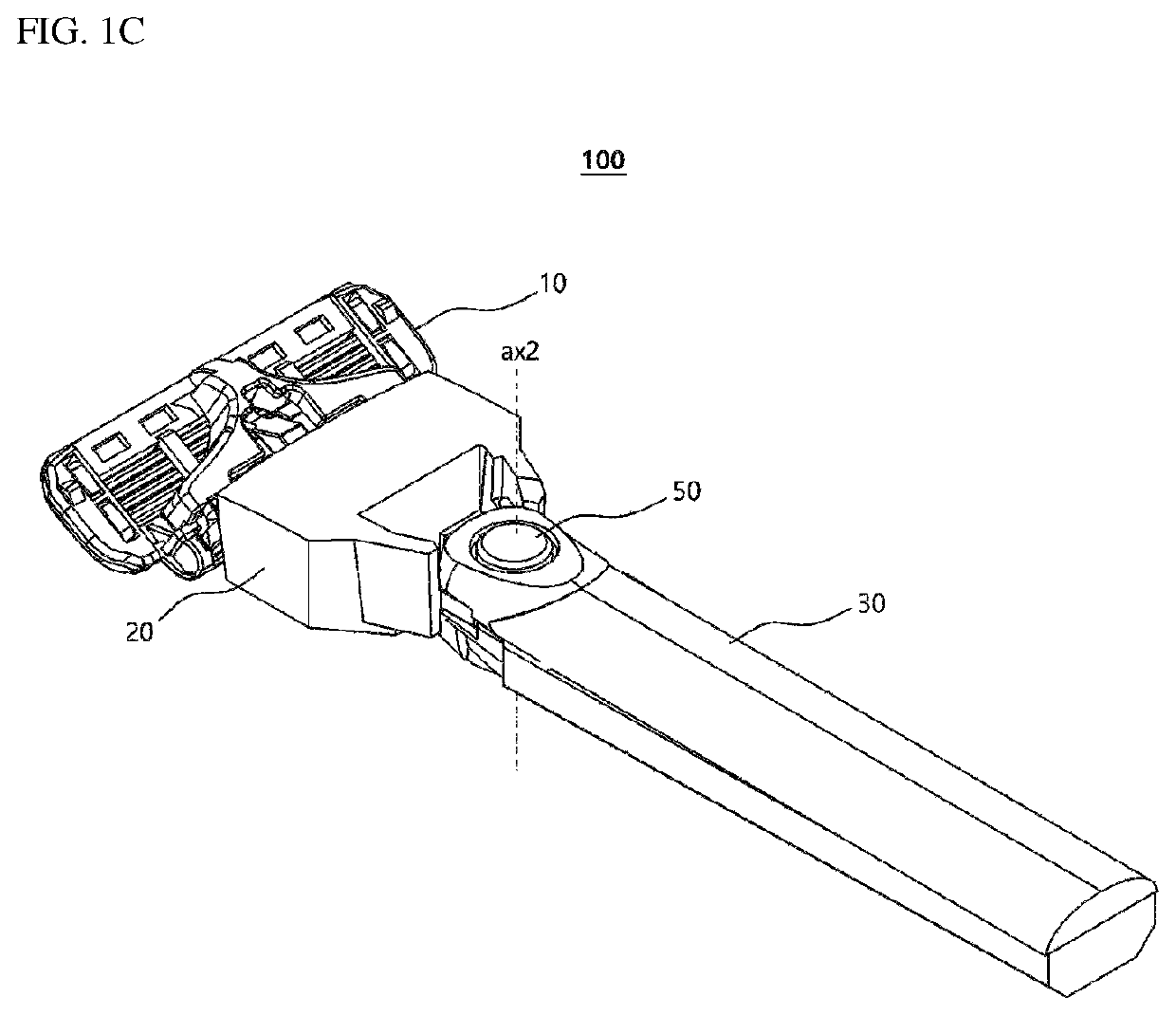

Razor assembly

A razor assembly includes at least one razor blade having a cutting edge, a blade housing configured to accommodate the at least one razor blade aligned along first direction, a connecting head configured to be detachably coupled to the blade housing, a razor handle configured to support the connecting head so that the connecting head is pivotable about a rotation axis, which is perpendicular to the first direction, and a torsion spring configured to be elastically deformed when the connecting head pivots about the rotation axis from a neutral position so that the torsion spring provides a restoring force for the connecting head to return to the neutral position.

Owner:DORCO CO LTD

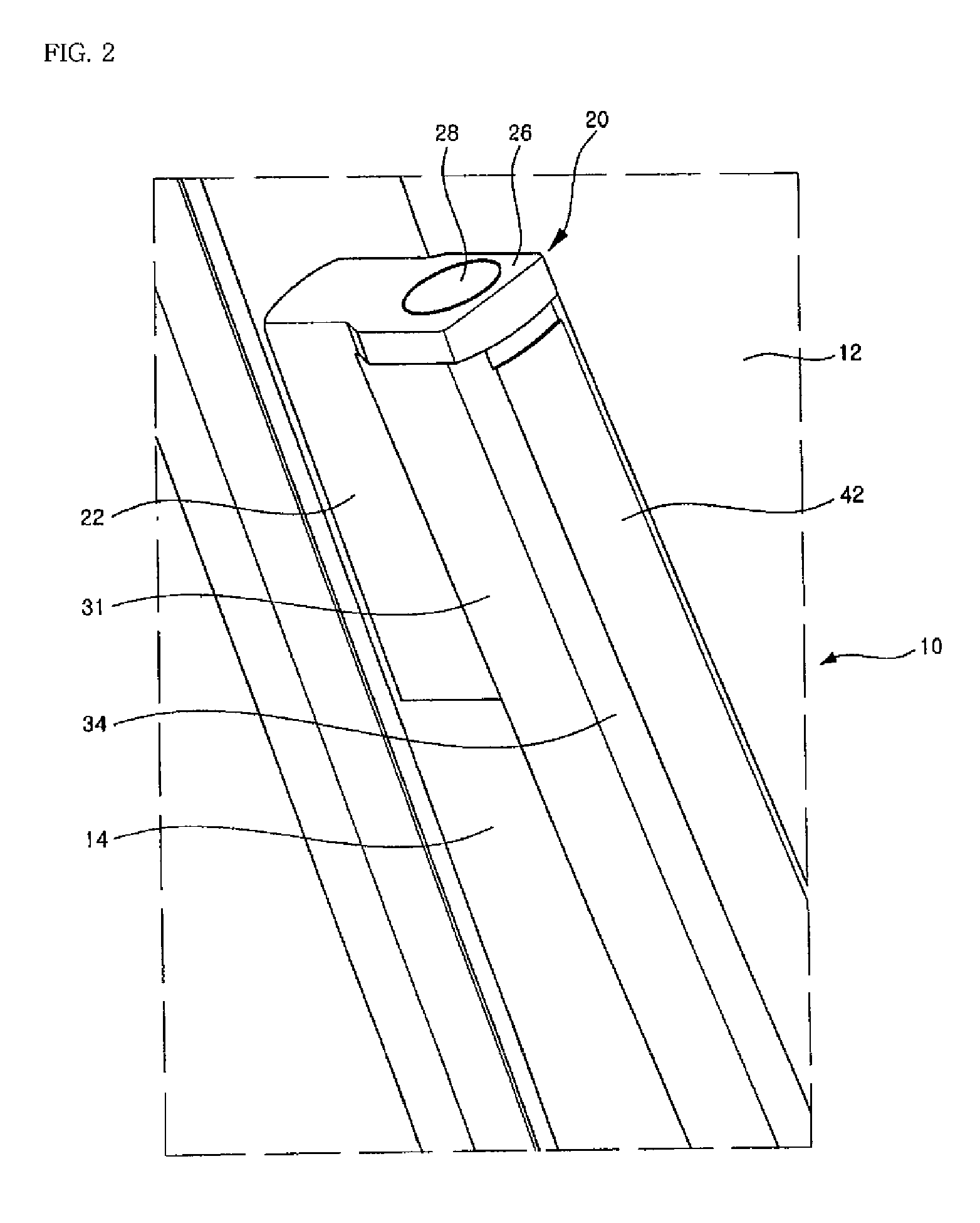

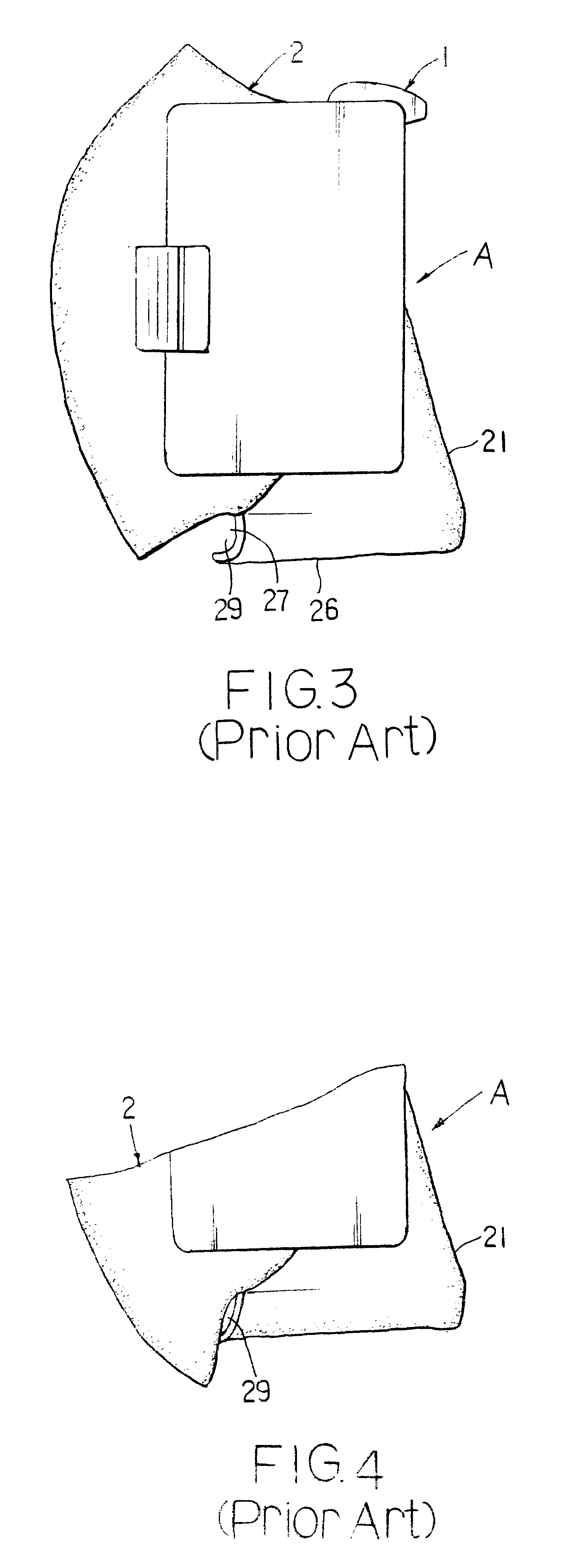

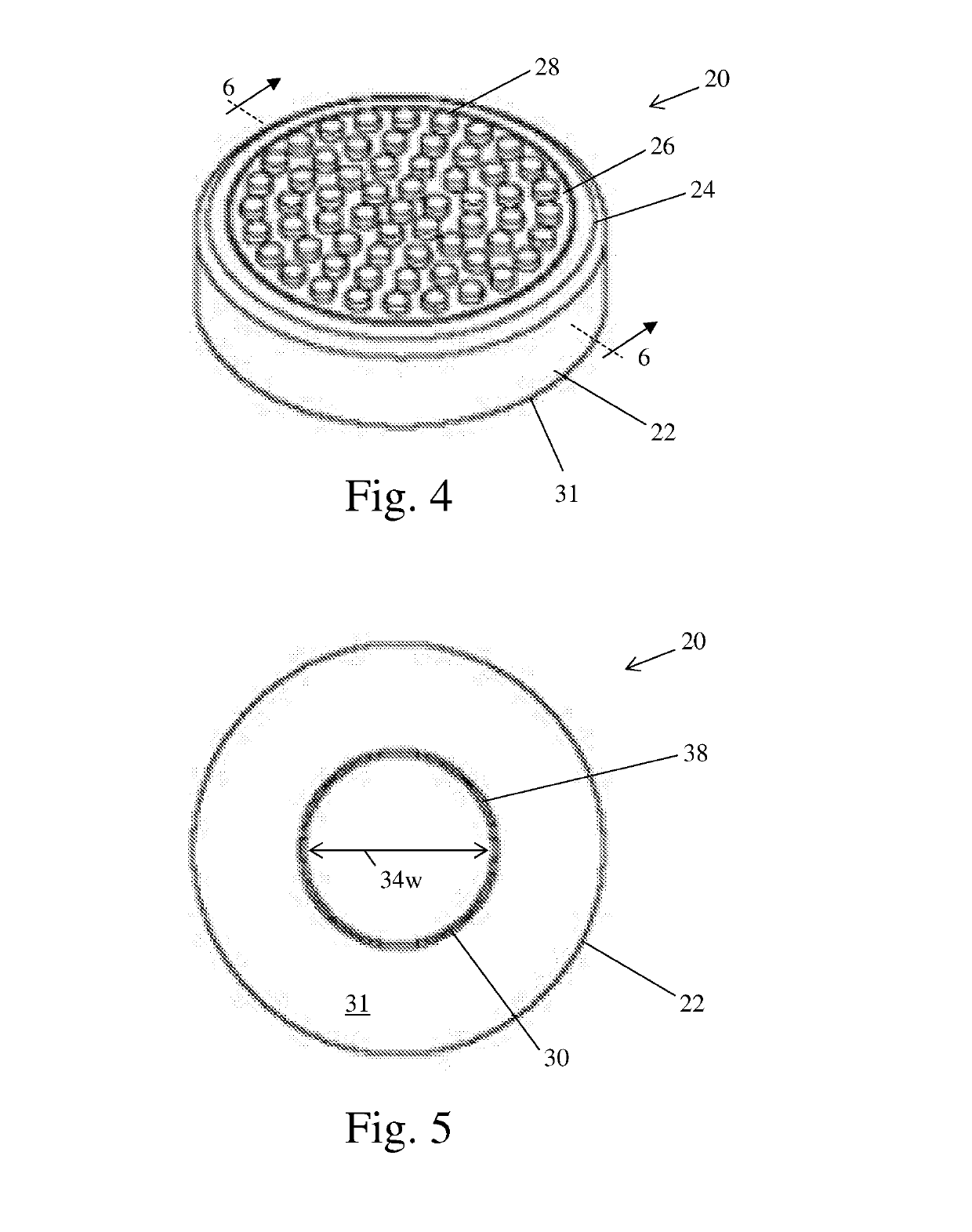

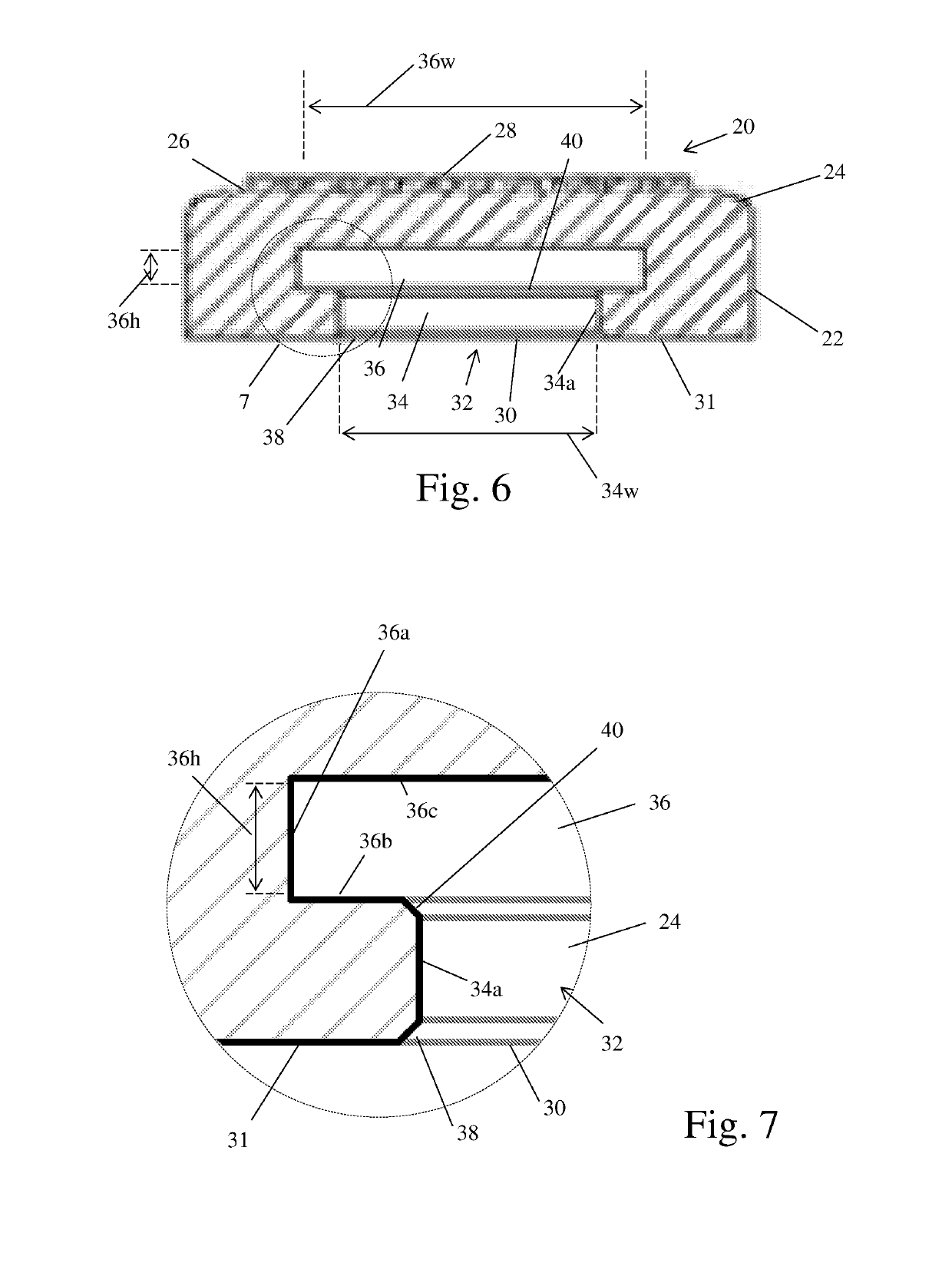

Door Handle for Refrigerator

InactiveUS20080244869A1No deformationHigh strengthTravelling carriersWing handlesEngineeringMechanical engineering

The present invention relates to a door handle for a refrigerator. In the present invention, a decoration 40 is installed in a seating channel 36 provided in a handle bar 30. The seating channel 36 with the decoration 40 installed therein is shielded by a transparent or translucent handle cover 42. Cover end coupling pieces 45 are provided at both ends of the handle cover 42 and coupled with coupling ribs of a handle bar body 31 of the handle bar 30 or a cover base 34. The cover end coupling pieces 45 protrude and extend from both ends of the handle cover 42 to be perpendicular to other portions. A luminous body or jewel may be used as the decoration 40. With the door handle of the present invention constructed as above, the aesthetic sense of the door handle is improved to meet various consumers' demands for design, and the handle bar 30 becomes more firm to enhance the reliability of the door handle.

Owner:LG ELECTRONICS INC

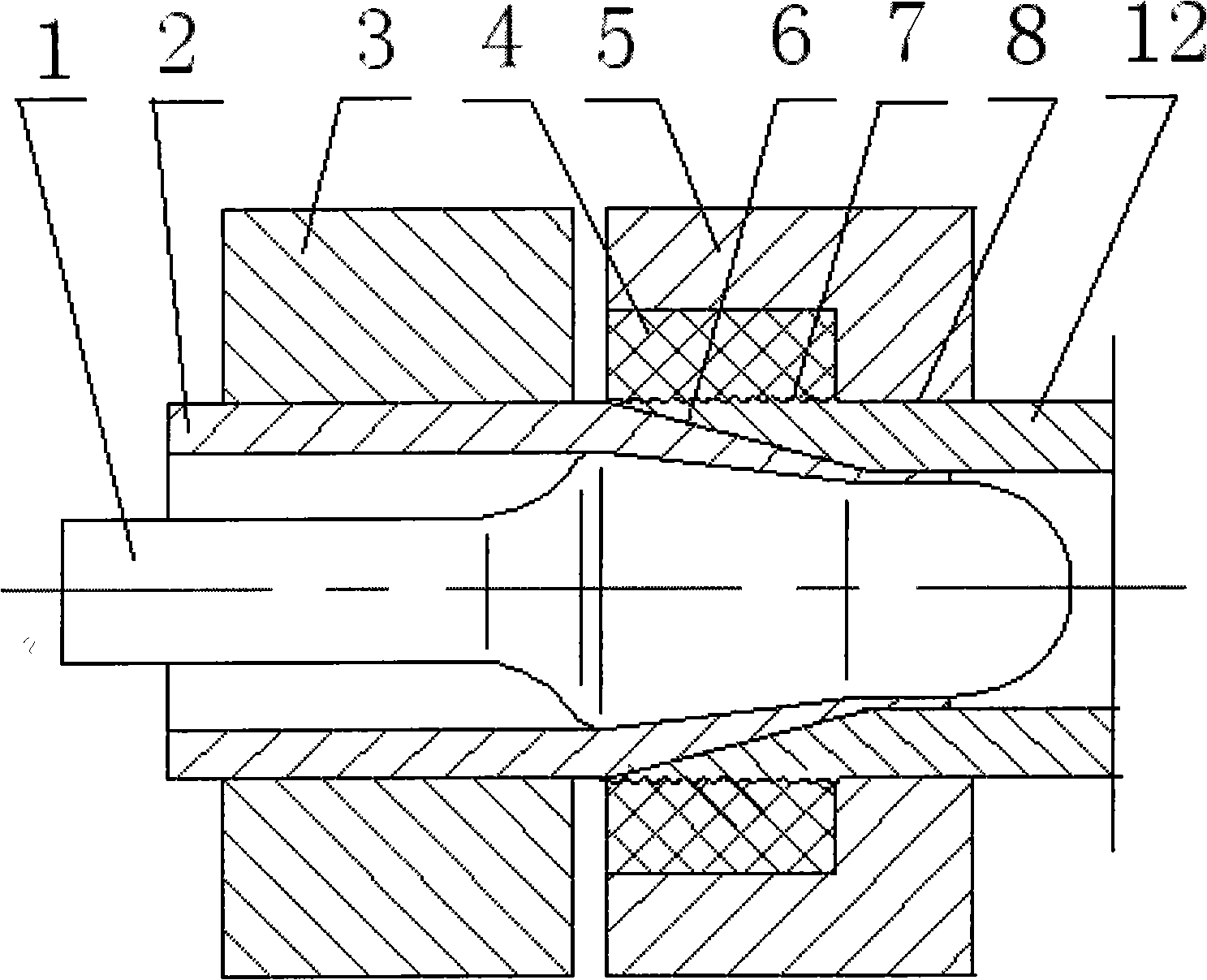

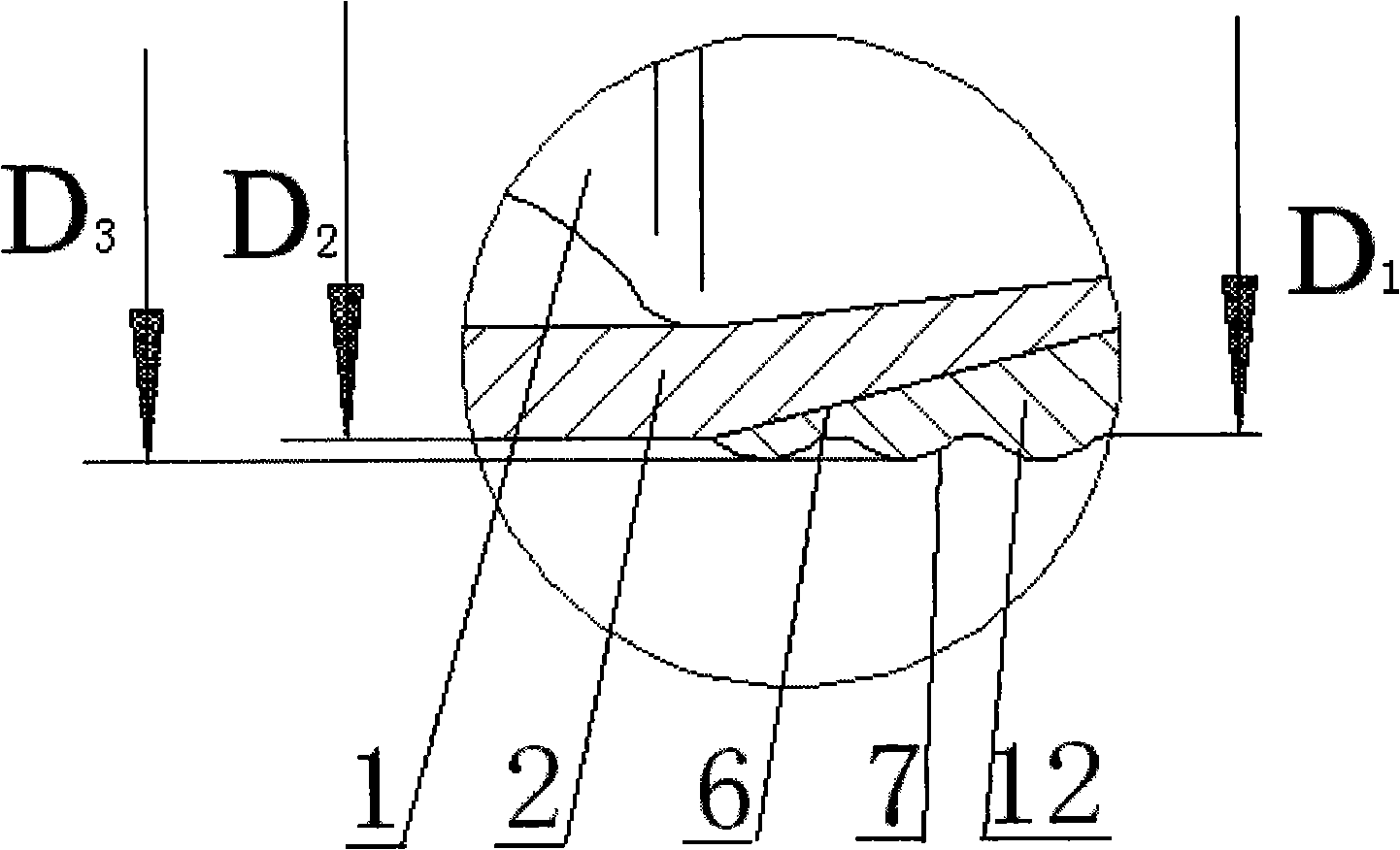

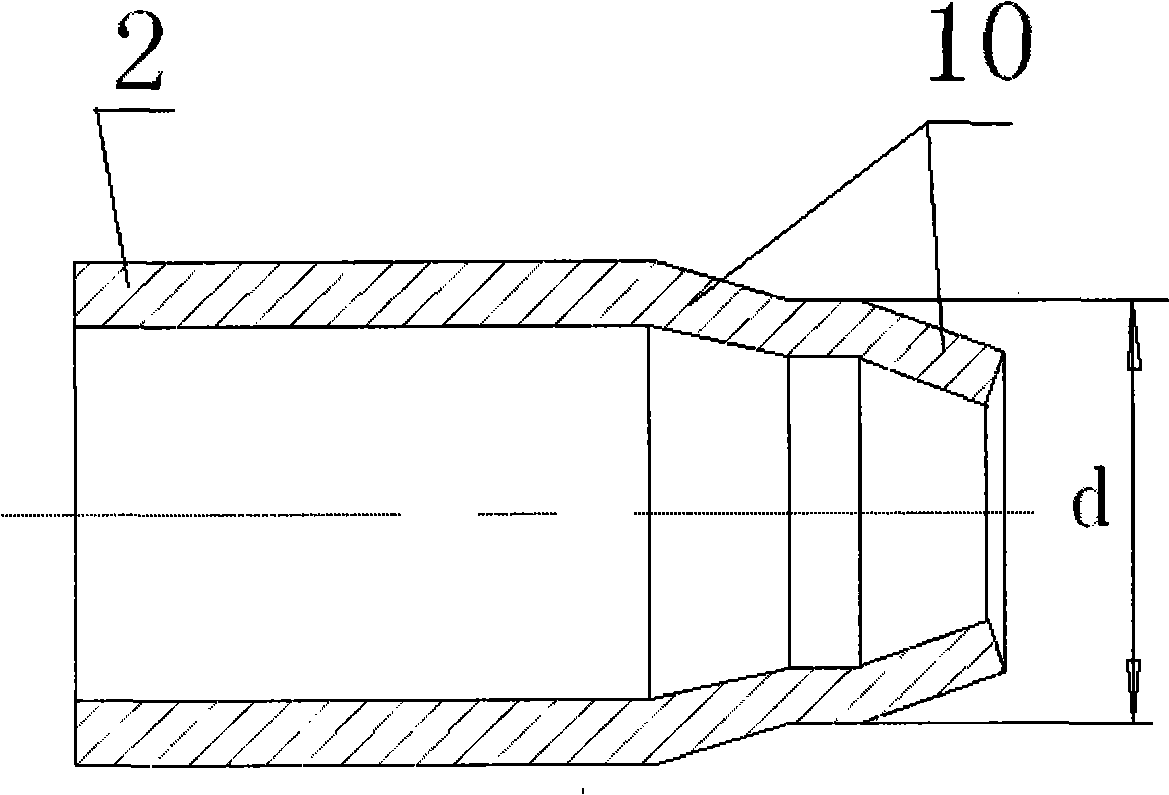

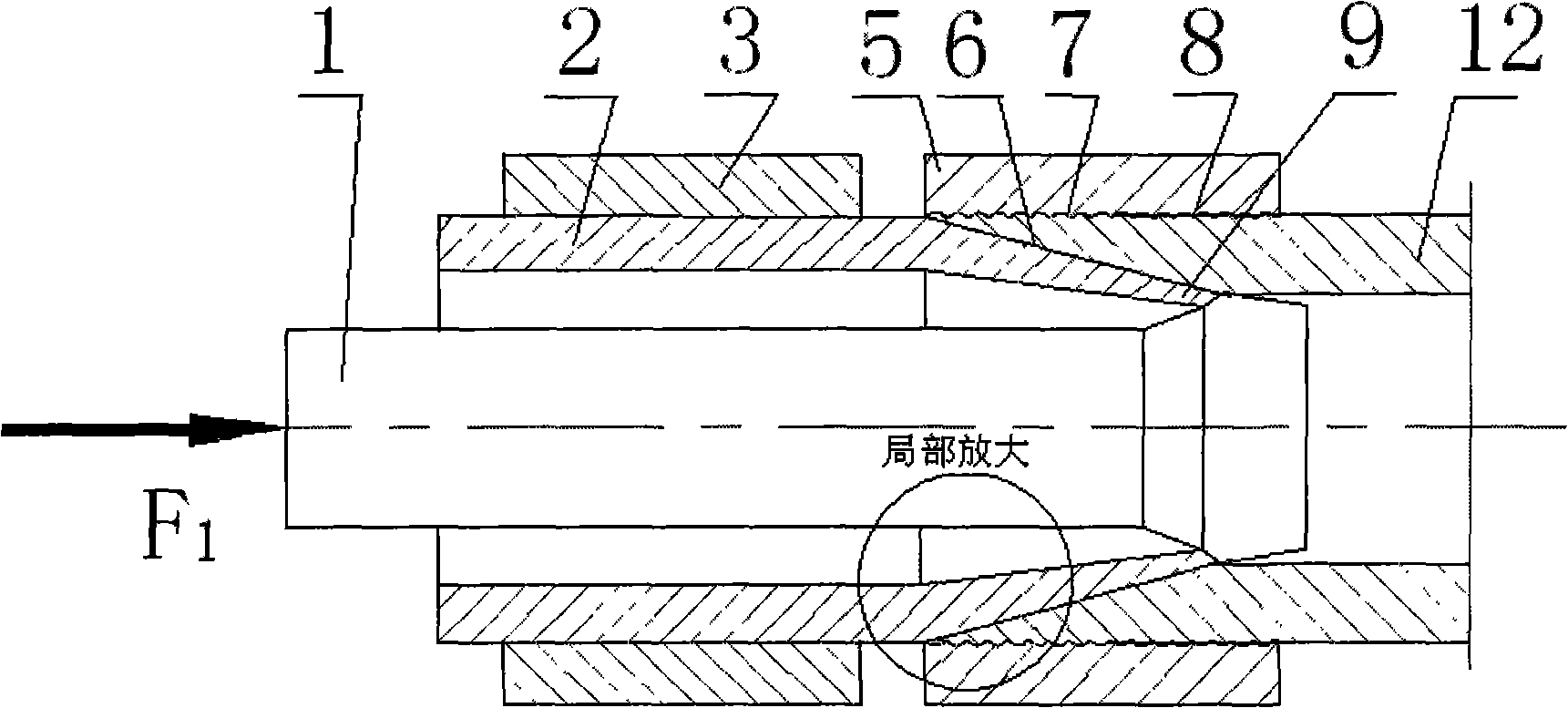

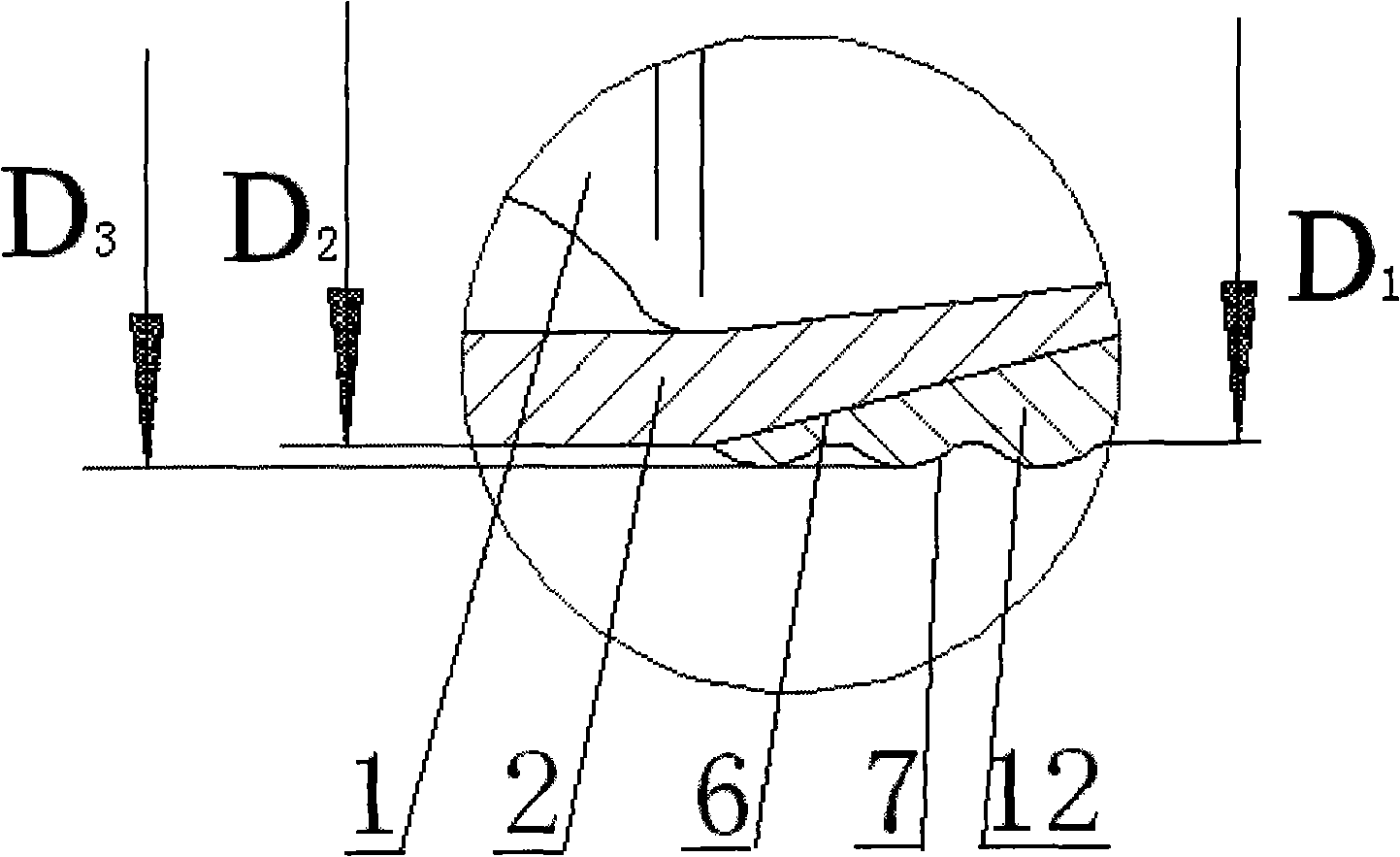

Plug-in type copper aluminum pipe welded joint and method of producing the same

InactiveCN101319741ASame outer diameterNot easy to fall offElectrode featuresNon-disconnectible pipe-jointsMaterials scienceCopper tubing

The invention relates to an inserting copper-aluminum pipe welded joint and a method of fabrication thereof. A taper face of weld is arranged at the joint welding position of a copper pipe, and raised grains are arranged on the outer wall of an aluminum pipe. During welding, a mosaic block is arranged at the welding position of the fixed electrode; a groove is arranged in the mosaic block, and raised grains are prepared on the groove; and the nominal diameter of the groove which bears raised grains is identical with the outer diameter of the aluminum pipe. The aluminum fluid melted during welding can be filled in the raised grains of the groove of the mosaic block, so that the deformation of the aluminum pipe is avoided, and the quality and strength of the product are improved. By such welding method, the aluminum pipe can be clamped to avoid breaking off; in addition, the outer diameter of the welding position of the copper-aluminum pipe joint is kept identical with the outer diameter of the aluminum pipe.

Owner:左铁军 +1

Handle of trunk

A handle grip of a trunk having an upper cover unit and a seat unit receiving in the upper cover unit. The seam of the seat unit and the upper cover unit are placed on a top of the handle grip and the stomach portion of the seat unit has no seam. Therefore, when it is held, the hand of the user will not be in contact with the seam of the seat unit and the upper cover unit so as to have a preferred handling feeling.

Owner:CHAW KHONG TECH

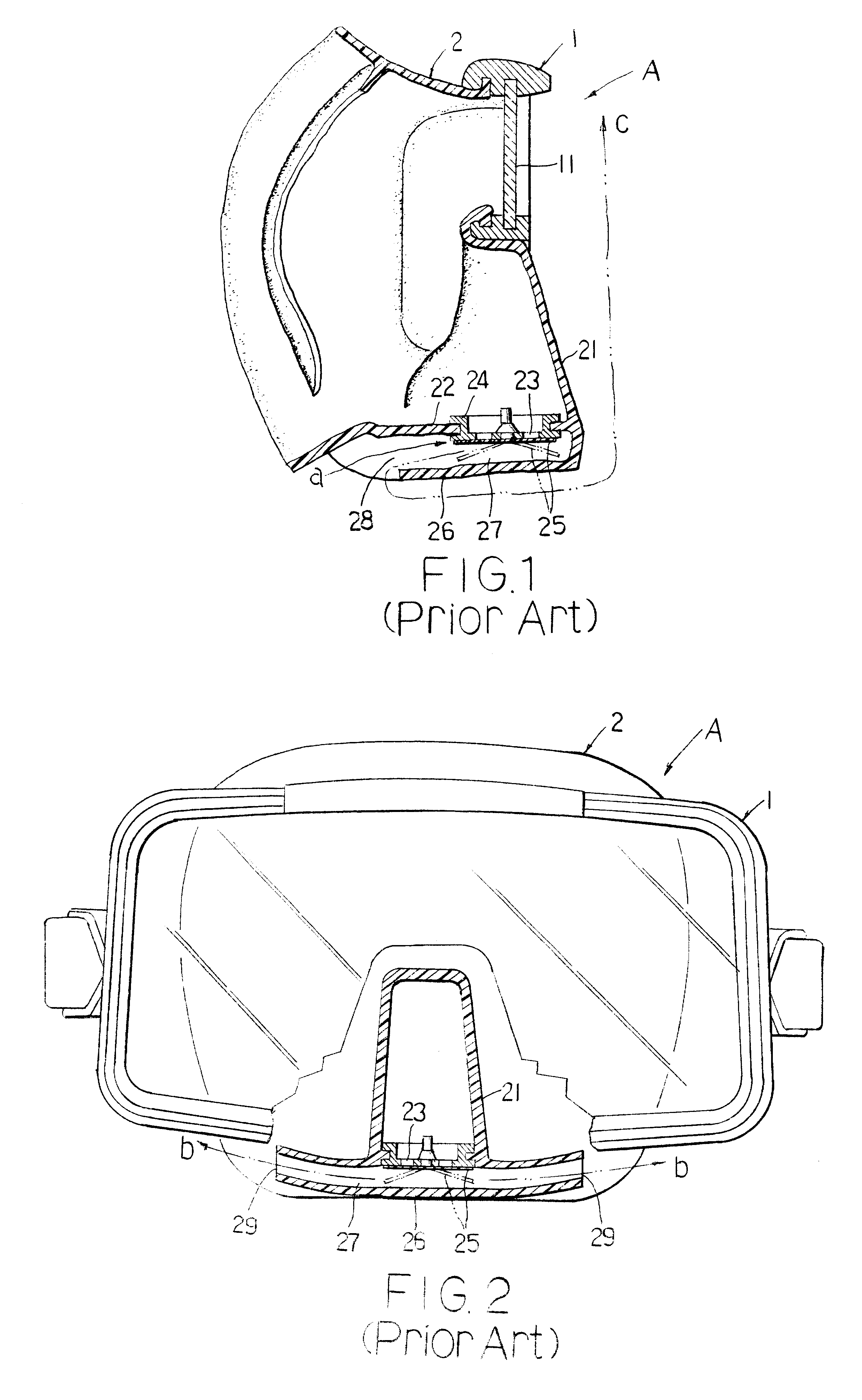

Draining structure for diving mask

InactiveUS6598239B1Reduce vertical opennessHigh compressive strengthGogglesProtective garmentNoseEngineering

A draining structure for diving mask includes a soft head cover fixedly connected to a rigid skirt framing a lens. The soft head cover includes a forward projected nose portion having a draining valve provided at a bottom thereof to be openable only in an outward direction. A draining guide is provided below the nose portion and has a hole formed directly below the draining valve to prevent water from sideward flushing open the draining valve when a diver jumps into water in a vertical position. An upward projected flange is provided at a rear end of the draining guide to guide air bubbles produced by the diver's expiration to two side outlets of the draining guide. The flange also reinforces the two side outlets and prevents them from deformation when the head cover is put on the diver's head and presses against the side outlets.

Owner:HSIEH HSING CHI

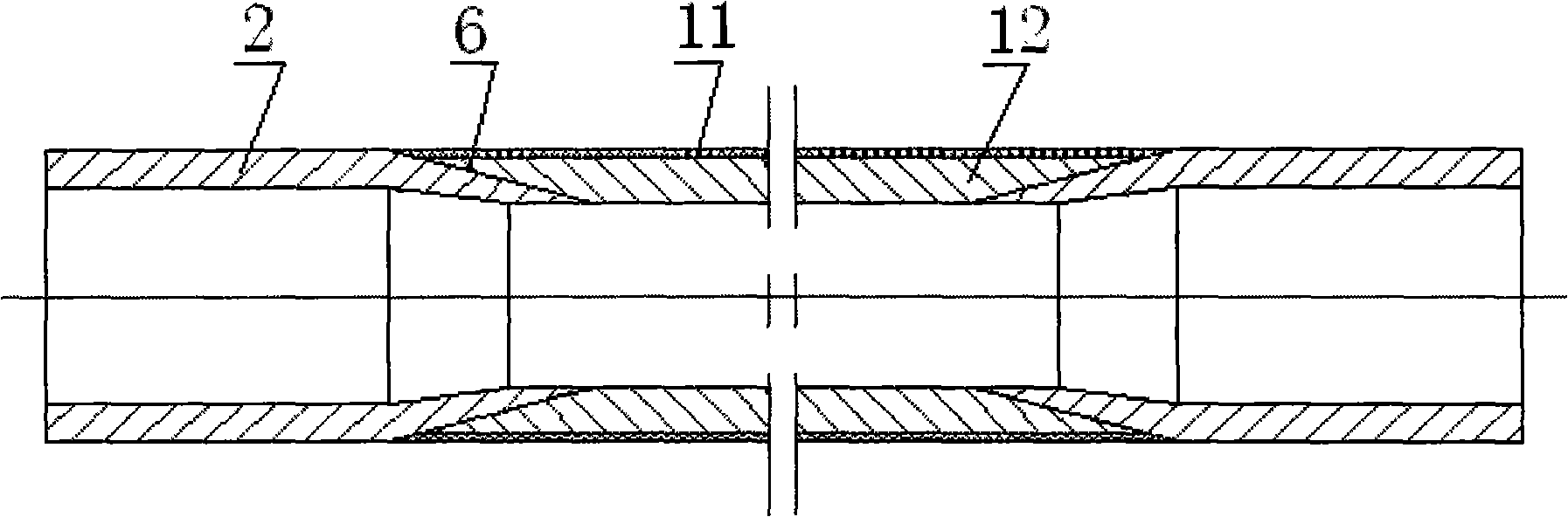

Pipe connection used for indoor and outdoor units of air conditioner and its method for making production method

ActiveCN101319742ASame outer diameterNot easy to fall offElectrode featuresNon-disconnectible pipe-jointsEngineeringUltimate tensile strength

The invention relates to a connection tube applied to the indoor machine and outdoor machine of an air conditioner and a manufacture method thereof. A taper face of weld is arranged at the joint welding position of a copper pipe, and raised grains are arranged on the outer wall of an aluminum pipe. During welding, a mosaic block is arranged at the welding position of the fixed electrode; a groove is arranged in the mosaic block, raised grains are prepared on the groove; and the nominal diameter of the groove which bears raised grains is identical with the outer diameter of the aluminum pipe. The aluminum fluid melted during welding can be filled in the raised grains of the groove of the mosaic block, so that the deformation of the aluminum pipe is avoided, and the quality and strength of the product are improved. By such welding method, the aluminum pipe can be clamped to avoid breaking off; in addition, the outer diameter of the welding position of the copper-aluminum pipe joint is kept identical with the outer diameter of the aluminum pipe.

Owner:青岛津海制冷管业有限公司

Razor assembly

A razor handle assembly includes a connector which is detachably coupled to a razor cartridge; a razor handle which is elongated along a longitudinal axis and coupled to the connector such that the connector is capable of pivoting about a rotation axis perpendicular to both the longitudinal axis and a transverse axis along which the razor cartridge is elongated, the transverse axis being perpendicular to the longitudinal axis; and an elastic member having a first end engaged with a first fixing portion formed in the connector and a second end engaged with a second fixing portion formed in the razor handle. When the connector pivots about the rotation axis with respect to the razor handle, the elastic member is deformed to provide a restoring force that causes the connector to return to a neutral position at which the transverse axis is perpendicular to the longitudinal axis.

Owner:DORCO CO LTD

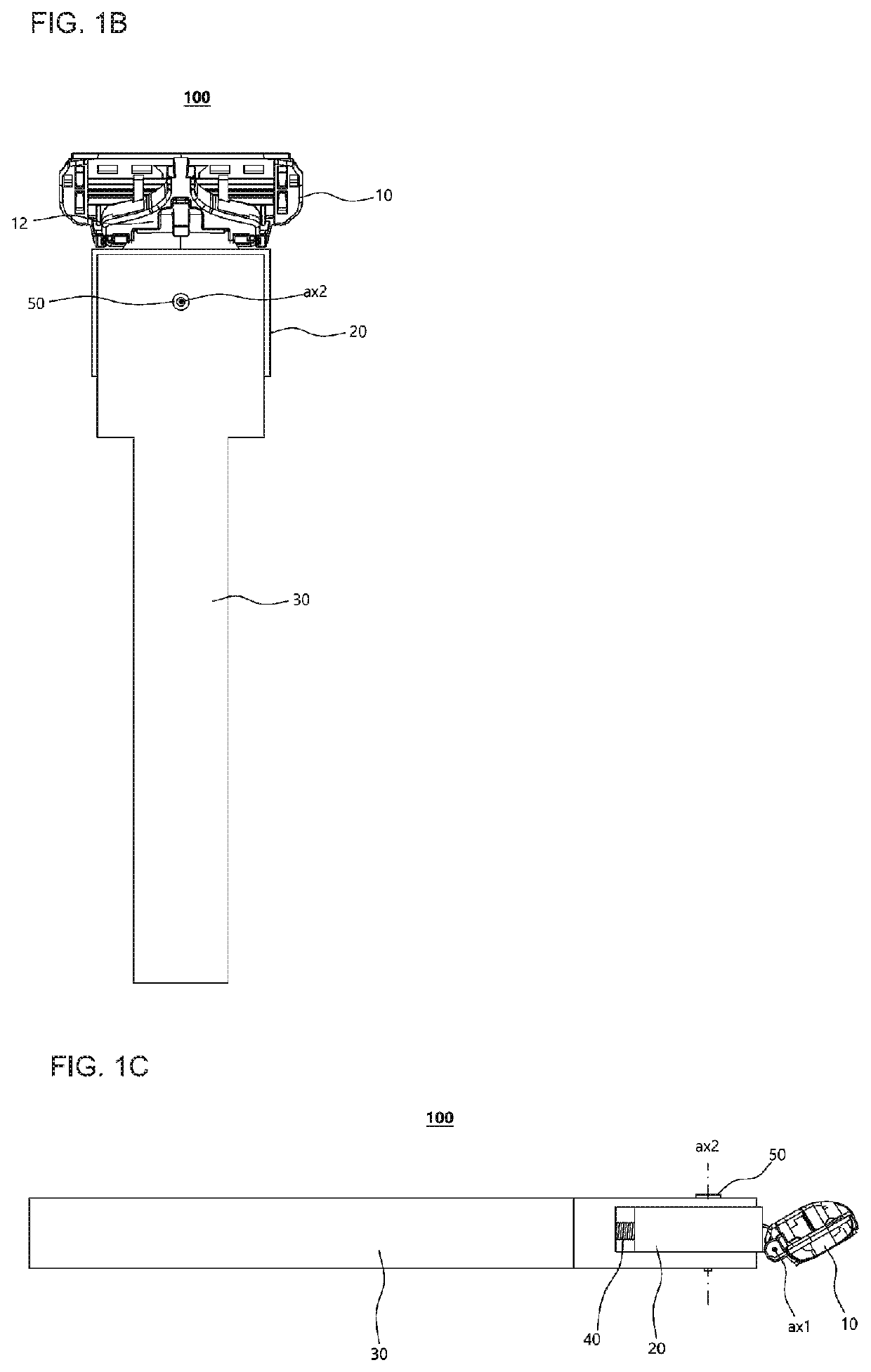

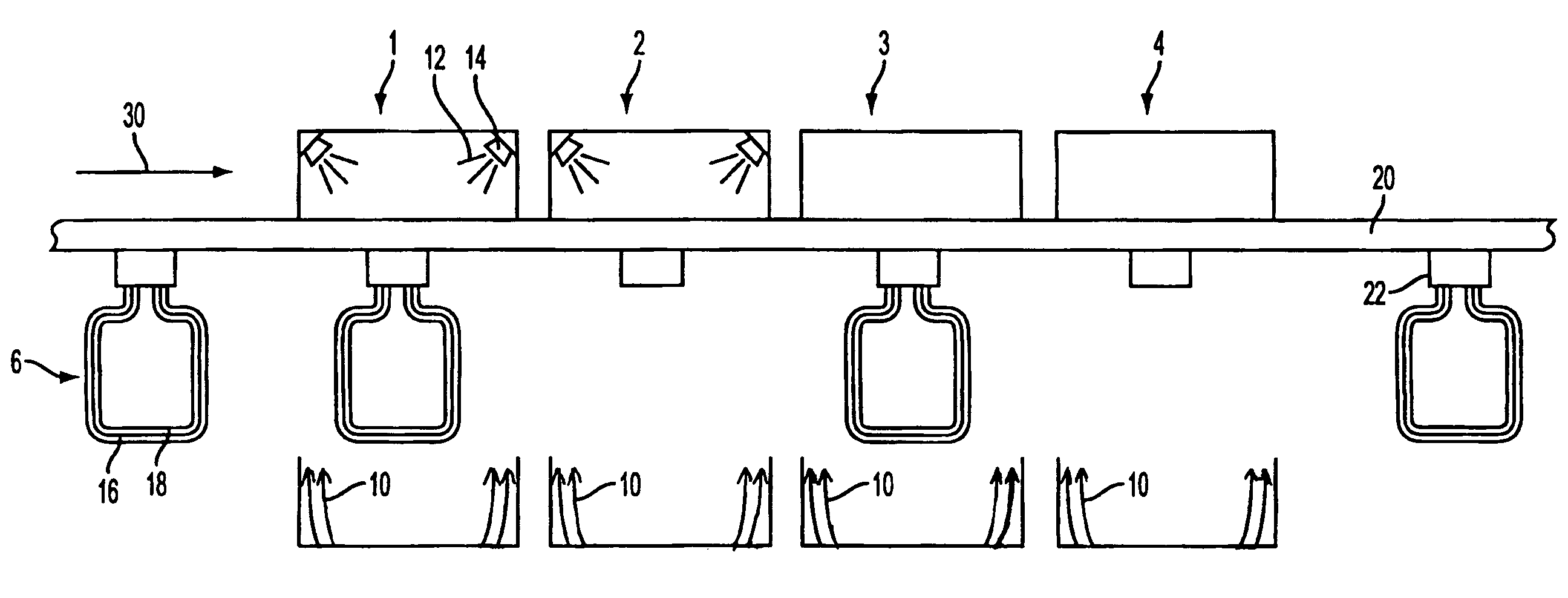

Controlled infrared/fluid coating cure process

InactiveUS20060127616A1Improve optical qualityImprove curingDrying solid materials with heatSynthetic resin layered productsHeat sensitiveCoating

A method of curing a heat curable coating on a heat sensitive substrate includes initially heating the coated substrate by exposure to infrared radiation in order to increase the temperature at a point near to the coating with time, and subsequently heating the coated substrate by contact with a warm fluid in order to increase the temperature at a point near to the coating with time. After subsequently heating the coated substrate, the coating can be substantially cured, the coating can have good optical quality, and the heat sensitive substrate can be not substantially deformed.

Owner:GRAHAM PACKAGING CO LP

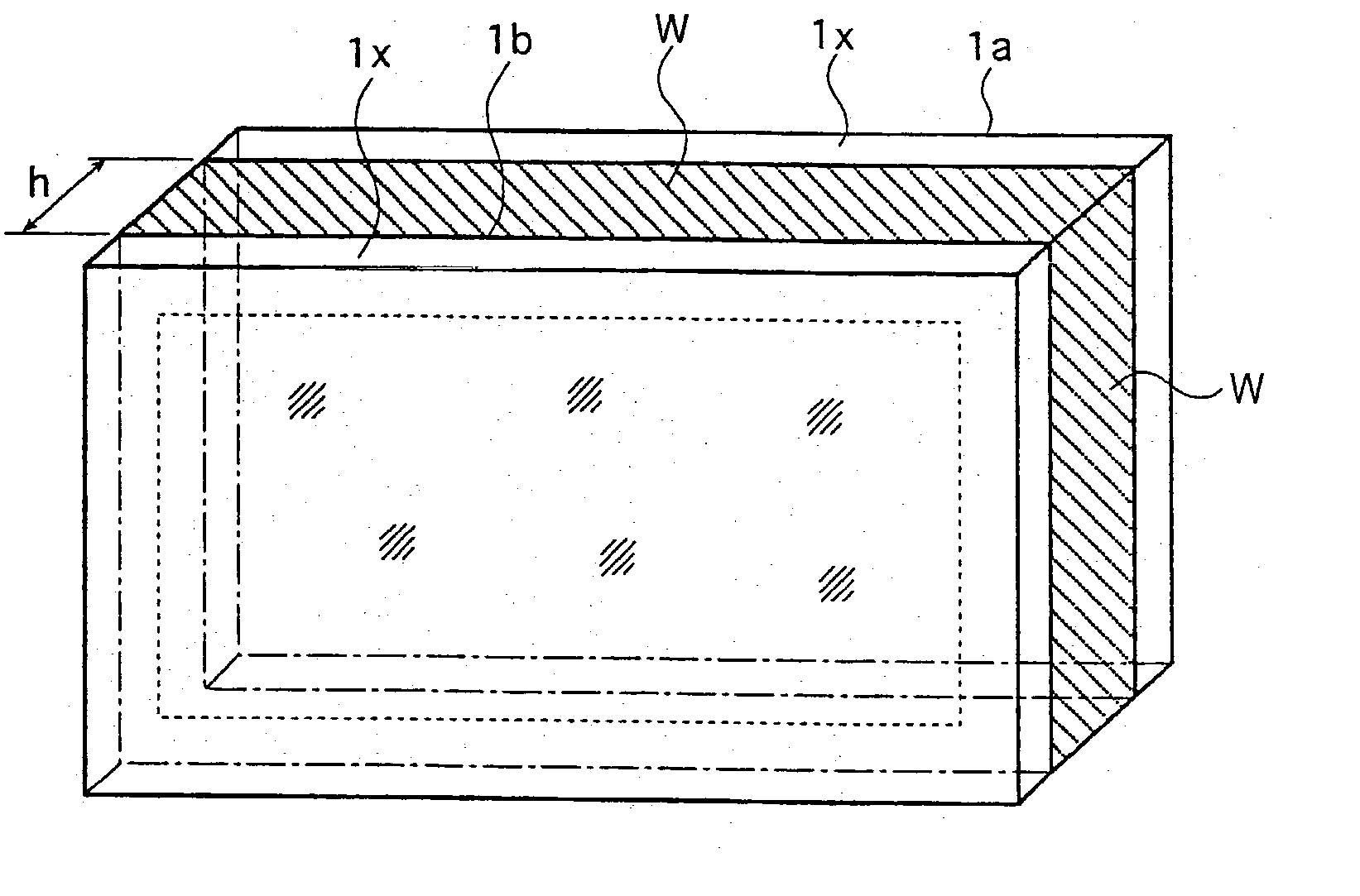

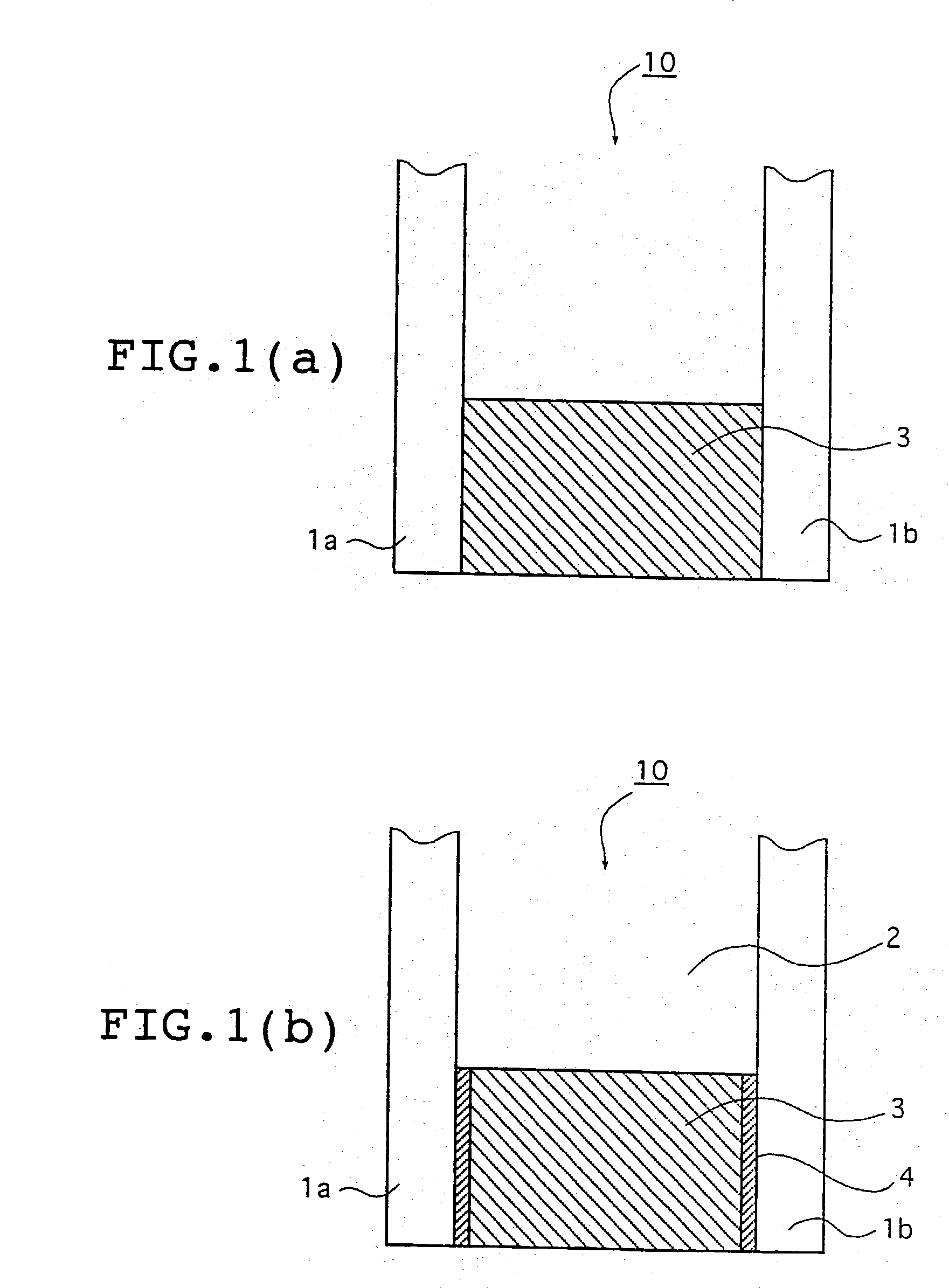

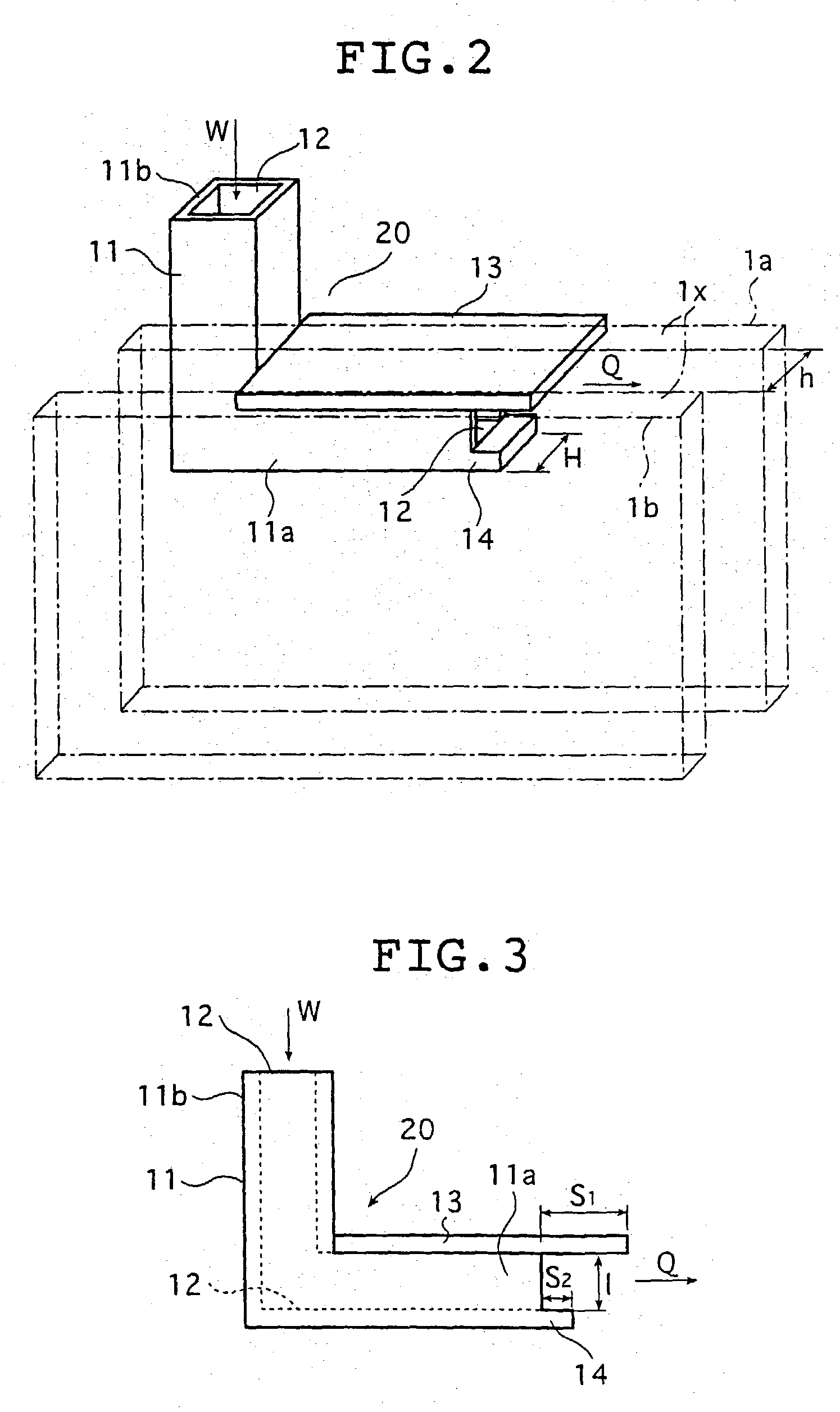

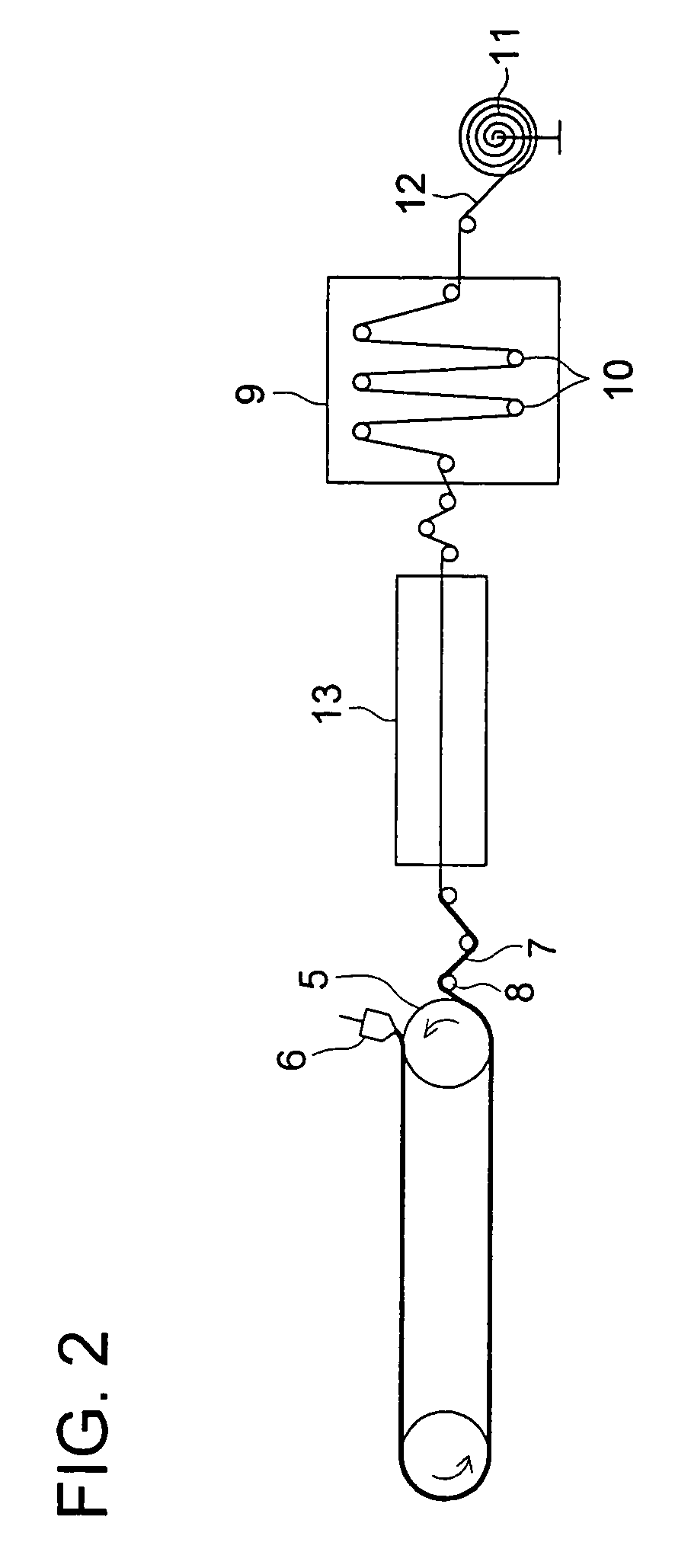

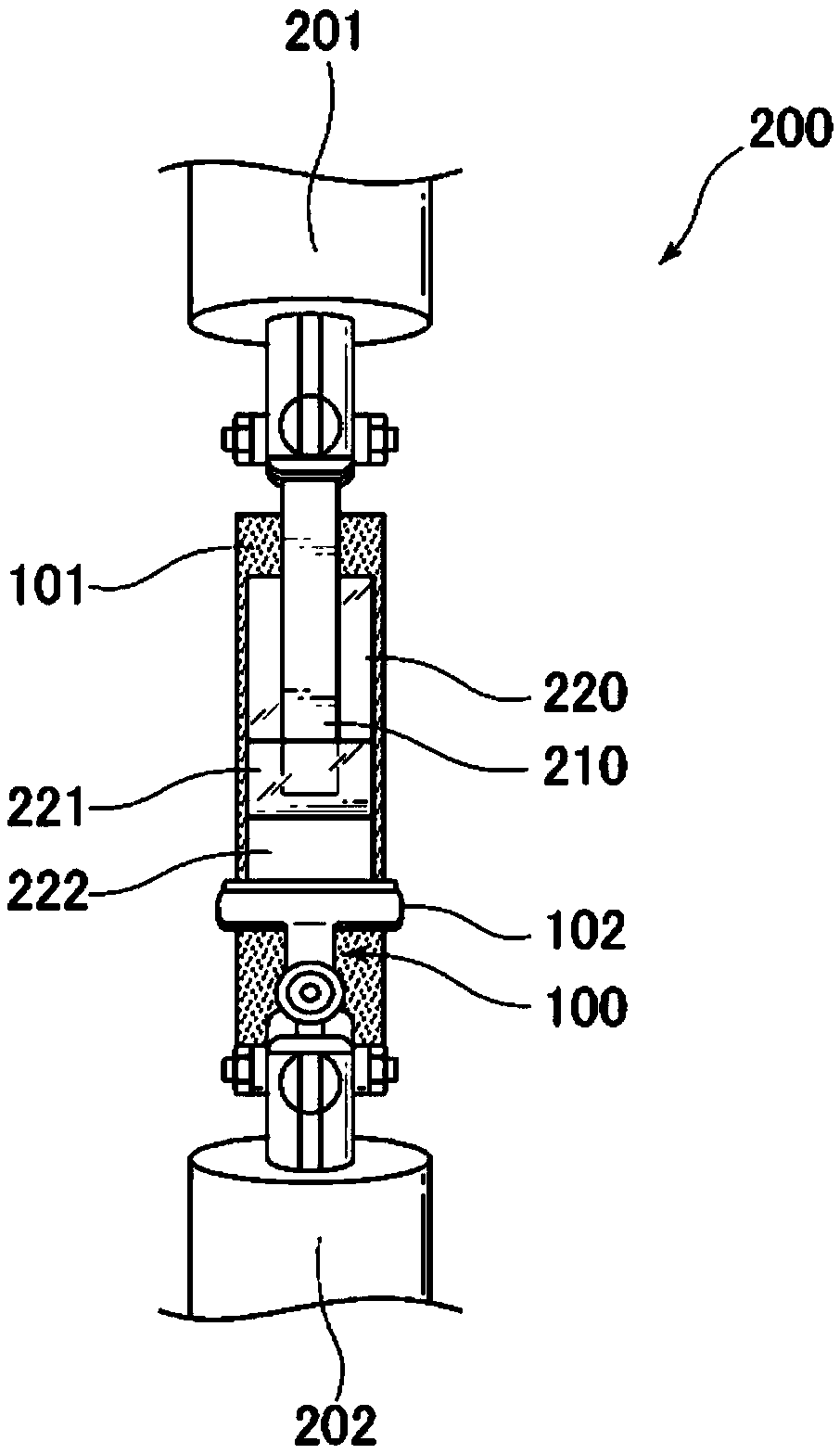

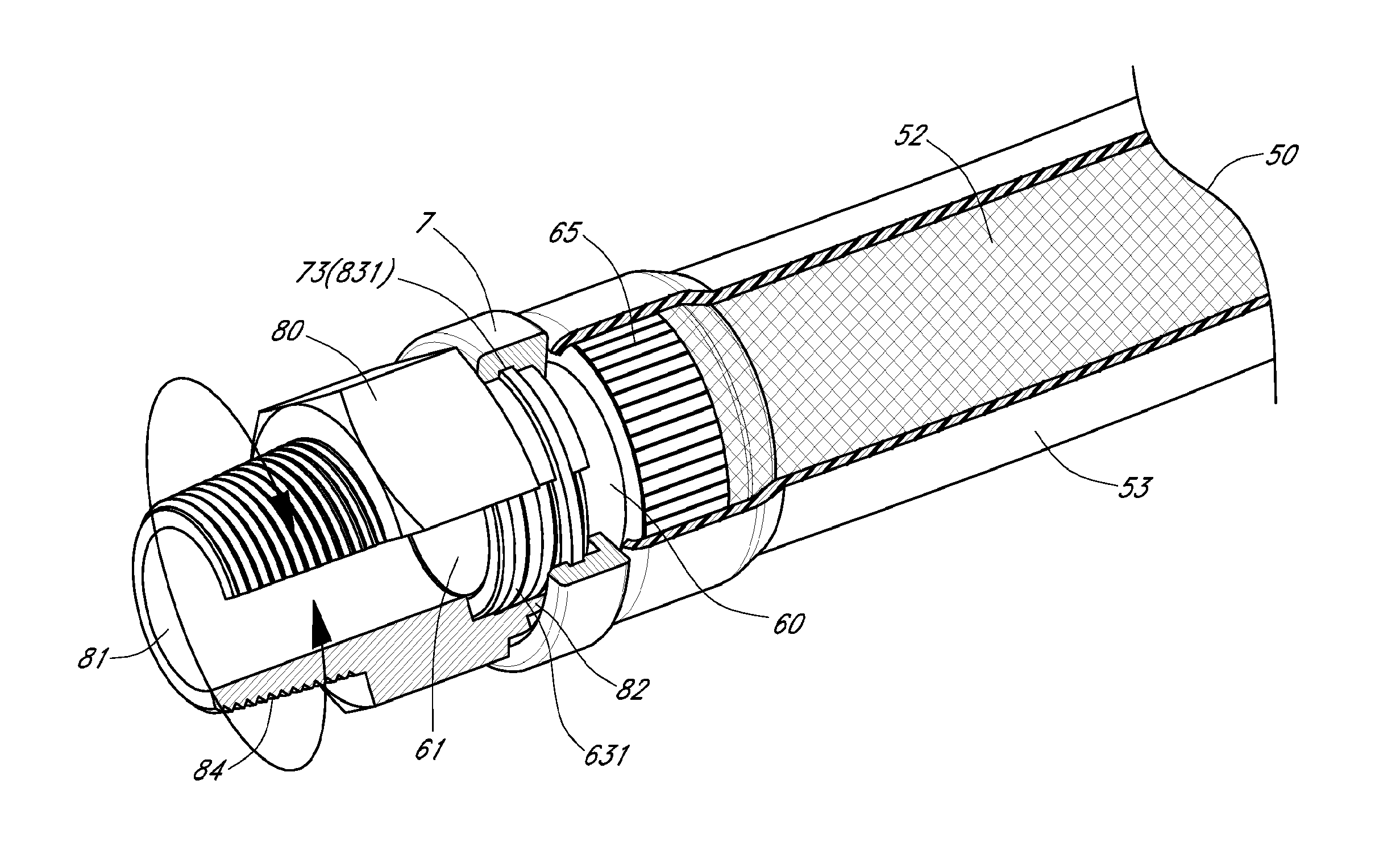

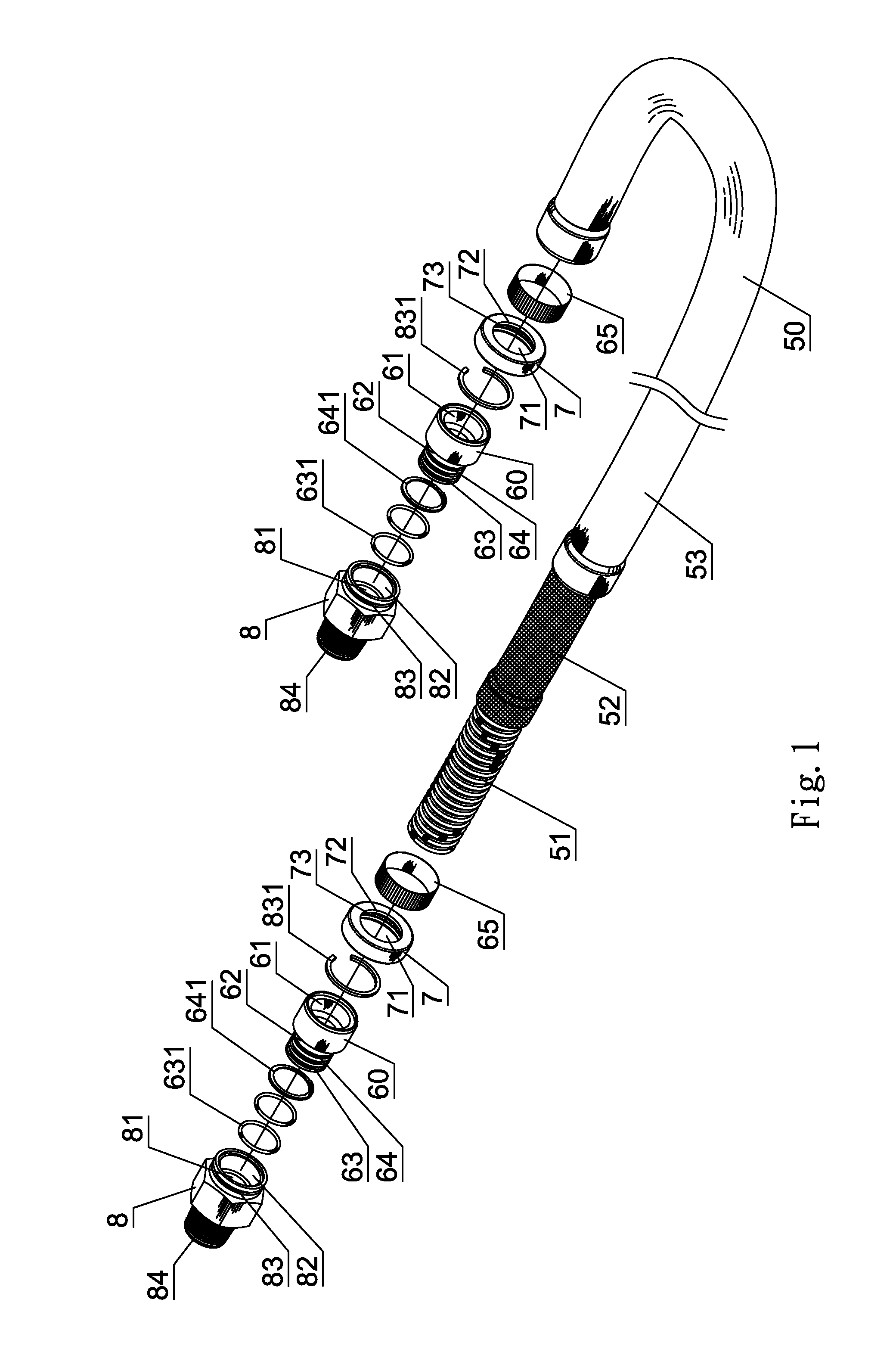

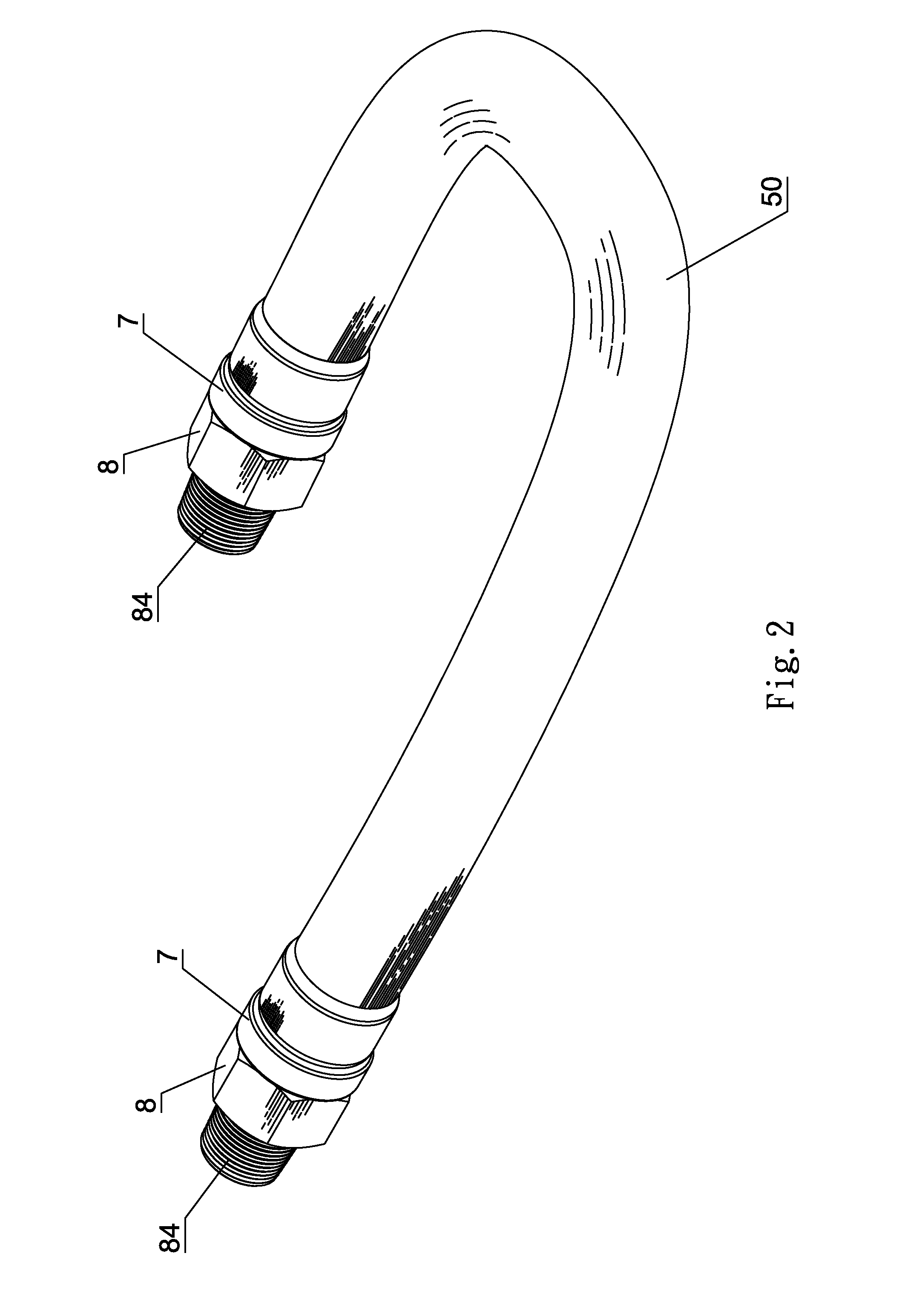

Thermoplastic elastomer composition, insulating glass using the composition, process for producing the insulating glass and nozzle for producing the insulating glass

InactiveUS20030219583A9Excellent steam permeation resistanceEasy to produceDoors/windowsCellulosic plastic layered productsThermoplastic elastomerGlass sheet

A thermoplastic elastomer composition produced from a thermoplastic resin and rubber and having a dispersion phase formed of a rubber composition at least part of which is dynamically crosslinked in the continuous phase of the thermoplastic resin, insulating glass using the thermoplastic elastomer composition as a sealing material and spacer, a process for producing the insulating glass using a sealing material made from the thermoplastic elastomer composition, comprising the steps of inserting the leading end of a charging nozzle into a space between the peripheral portions of a plurality of glass sheets, discharging the sealing material from the leading end of the nozzle body at a predetermined rate, and moving the glass sheets or the nozzle body relative to each other to charge the sealing material made from the thermoplastic elastomer composition into the space between the peripheral portions of the glass sheets, and a nozzle used in this process.

Owner:THE YOKOHAMA RUBBER CO LTD

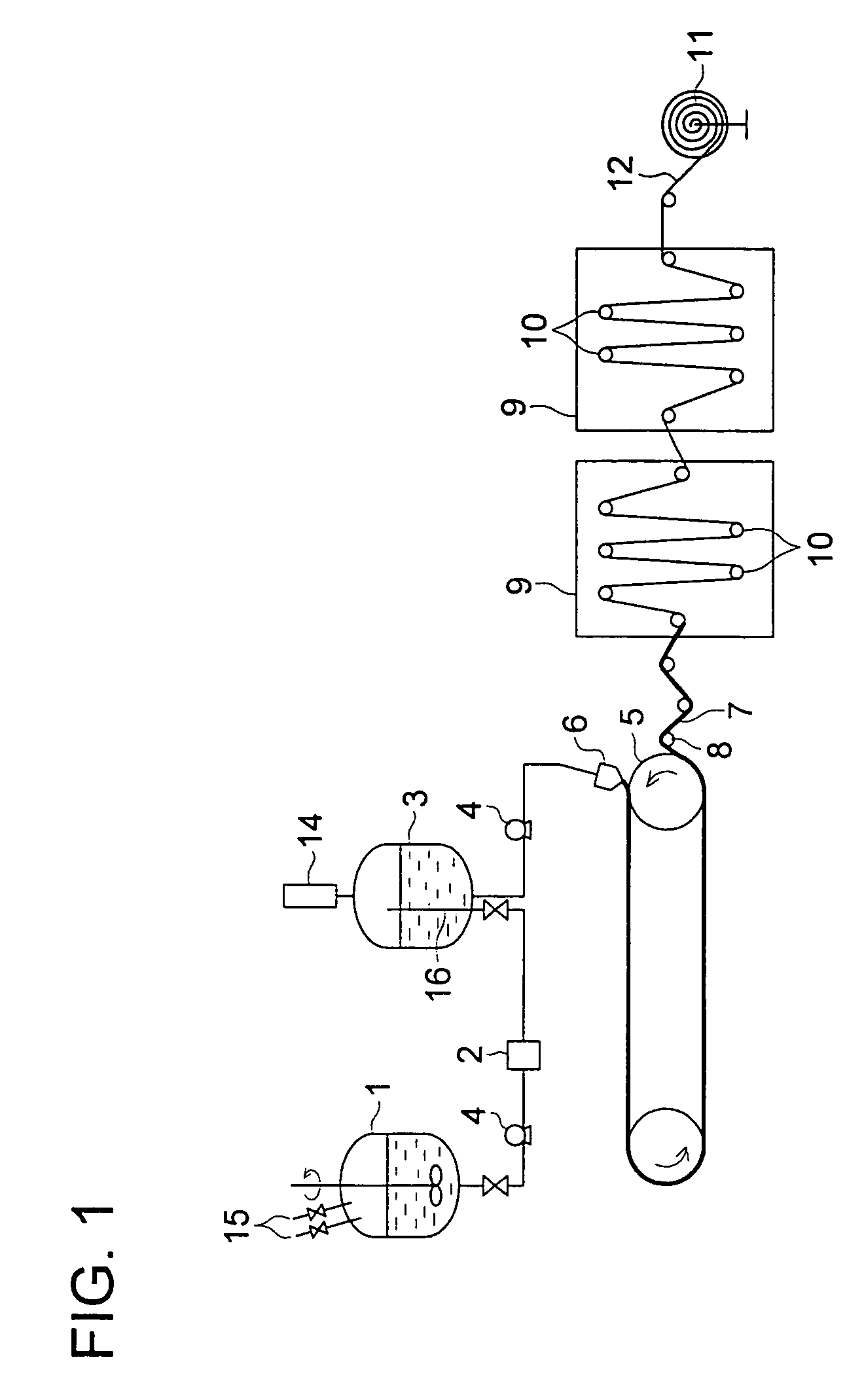

Cellulose ester film and its manufacturing method

Disclosed is a cellulose ester film having a dry thickness of 20 to 60 μm, wherein the cellulose ester film is manufactured according to a solution cast film manufacture process comprising the steps of providing a cellulose ester dope, casting the cellulose ester dope on a support to form a cellulose ester web, peeling the cellulose ester web at a peel position from the support, transporting the peeled web to a dryer, drying the peeled web therein to form a cellulose ester film, and winding the cellulose ester film around a spool, the residual solvent content at the winding step of the cellulose ester film being not more than 0.05% by weight.

Owner:KONICA CORP

Adhesive layer with separator, method for producing same, polarizing film with adhesive layer with separator, method for producing polarizing film with adhesive layer with separator, and image display device

ActiveCN105518092AImprove gel fractionEasy to processNon-macromolecular adhesive additivesSynthetic resin layered productsMeth-Phenolic antioxidant

Provided are: an adhesive layer with a separator, which has excellent workability and durability, and wherein a separator exhibits adequate easy separability from an adhesive layer; and a method for producing this adhesive layer with a separator. A method for producing an adhesive layer with a separator, which comprises: a first step for forming a layer of an adhesive composition, which contains a (meth)acrylic polymer, a peroxide and a phenolic antioxidant, on the releasing surface of a separator, said surface having been subjected to a release treatment; and a second step for forming an adhesive layer by heating the adhesive composition after the first step so that the adhesive composition is crosslinked.

Owner:NITTO DENKO CORP

Thermoplastic elastomer composition, insulating glass using the composition, process for producing the insulating glass and nozzle for producing the insulating glass

InactiveUS20030143387A1Excellent steam permeation resistanceEasy to produceCellulosic plastic layered productsLaminationChemistryInsulated glazing

A thermoplastic elastomer composition produced from a thermoplastic resin and rubber and having a dispersion phase formed of a rubber composition at least part of which is dynamically crosslinked in the continuous phase of the thermoplastic resin, insulating glass using the thermoplastic elastomer composition as a sealing material and spacer, a process for producing the insulating glass using a sealing material made from the thermoplastic elastomer composition, comprising the steps of inserting the leading end of a charging nozzle into a space between the peripheral portions of a plurality of glass sheets, discharging the sealing material from the leading end of the nozzle body at a predetermined rate, and moving the glass sheets or the nozzle body relative to each other to charge the sealing material made from the thermoplastic elastomer composition into the space between the peripheral portions of the glass sheets, and a nozzle used in this process.

Owner:YOKOHAMA RUBBER CO LTD

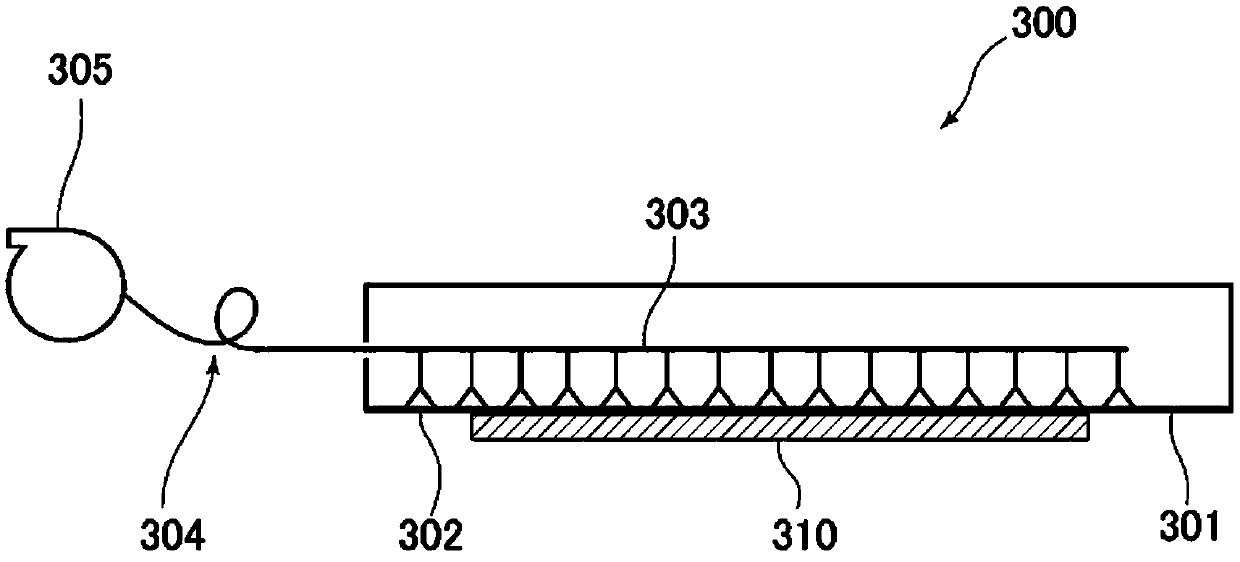

Light diffuser plate surface emission light source apparatus and liquid crystal display

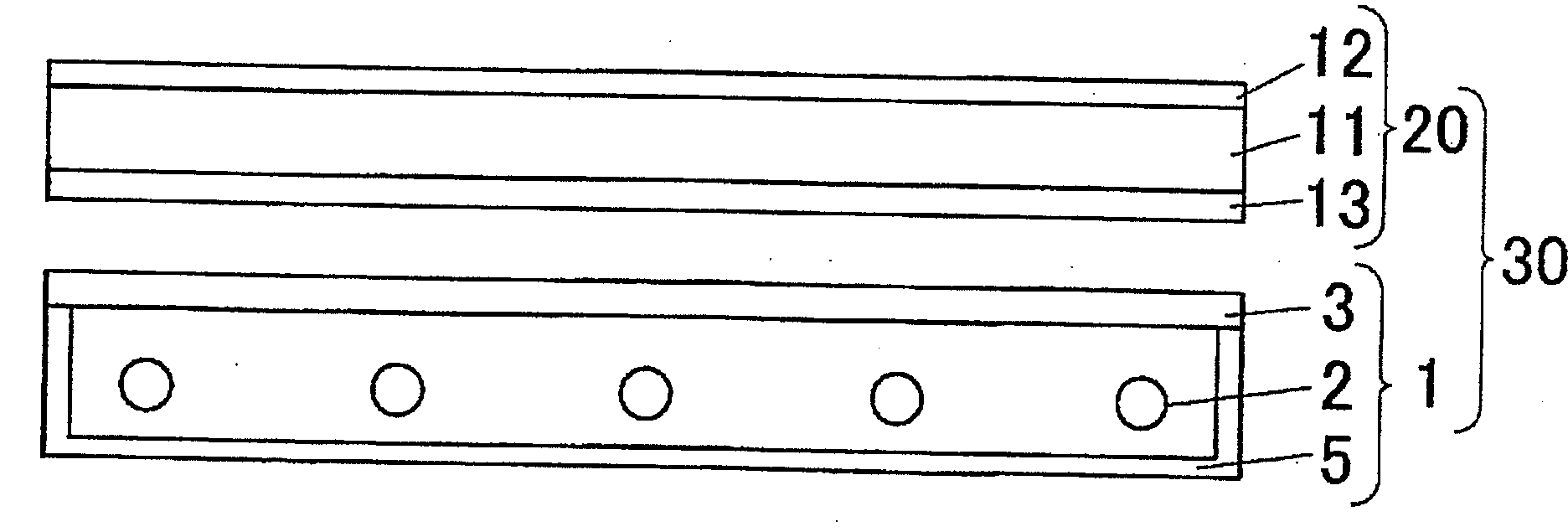

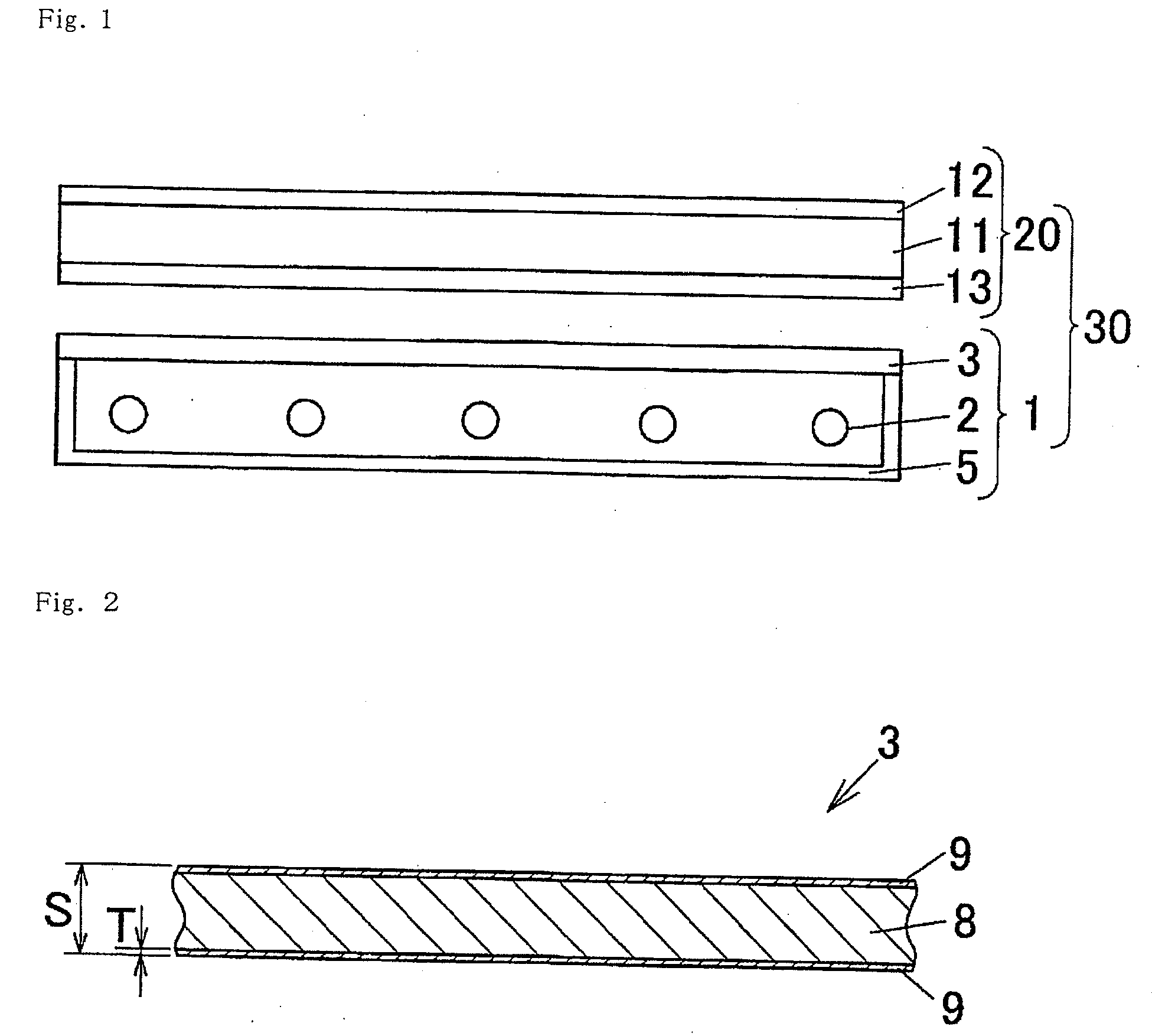

InactiveUS20080186429A1High qualityHigh strengthAdjusting/maintaining mechanical tensionDiffusing elementsLiquid-crystal displayPolymer chemistry

To provide a light diffuser plate which is lightweight and has sufficient strength and is not deformed by heat or humidity, and also has sufficient surface hardness and is also excellent in scratch resistance.A light diffuser plate 3 of the present invention comprises a base layer 8 which is made of a resin composition containing light diffusing particles in an amount of 0.1 parts by mass or more and less than 5 parts by mass based on 100 parts by mass of a propylene polymer, and a surface layer 9 which is integrally laminated on one or both surfaces of the base layer 8, and the surface layer 9 is made of a resin composition containing particles having a volume average particle diameter of 10 to 200 μm in an amount of 5 to 50 parts by mass based on 100 parts by mass of a propylene polymer.

Owner:SUMITOMO CHEM CO LTD

Razor assembly

Provided is a razor assembly including: one or more razor blades, each having a cutting edge; a housing which accommodates the razor blades in a transverse direction perpendicular to a shaving direction; a connector which is detachably coupled to the housing at the back of the housing; a razor handle which is coupled to the connector such that the connector can pivot about a rotation axis perpendicular to the transverse direction; and an elastic member which has a first end engaged with a first fixing portion formed in the connector and a second end engaged with a second fixing portion formed in the razor handle, wherein when the connector pivots about the rotation axis with respect to the razor handle, the elastic member is deformed to provide a restoring force that causes the connector to return to a neutral position.

Owner:DORCO CO LTD

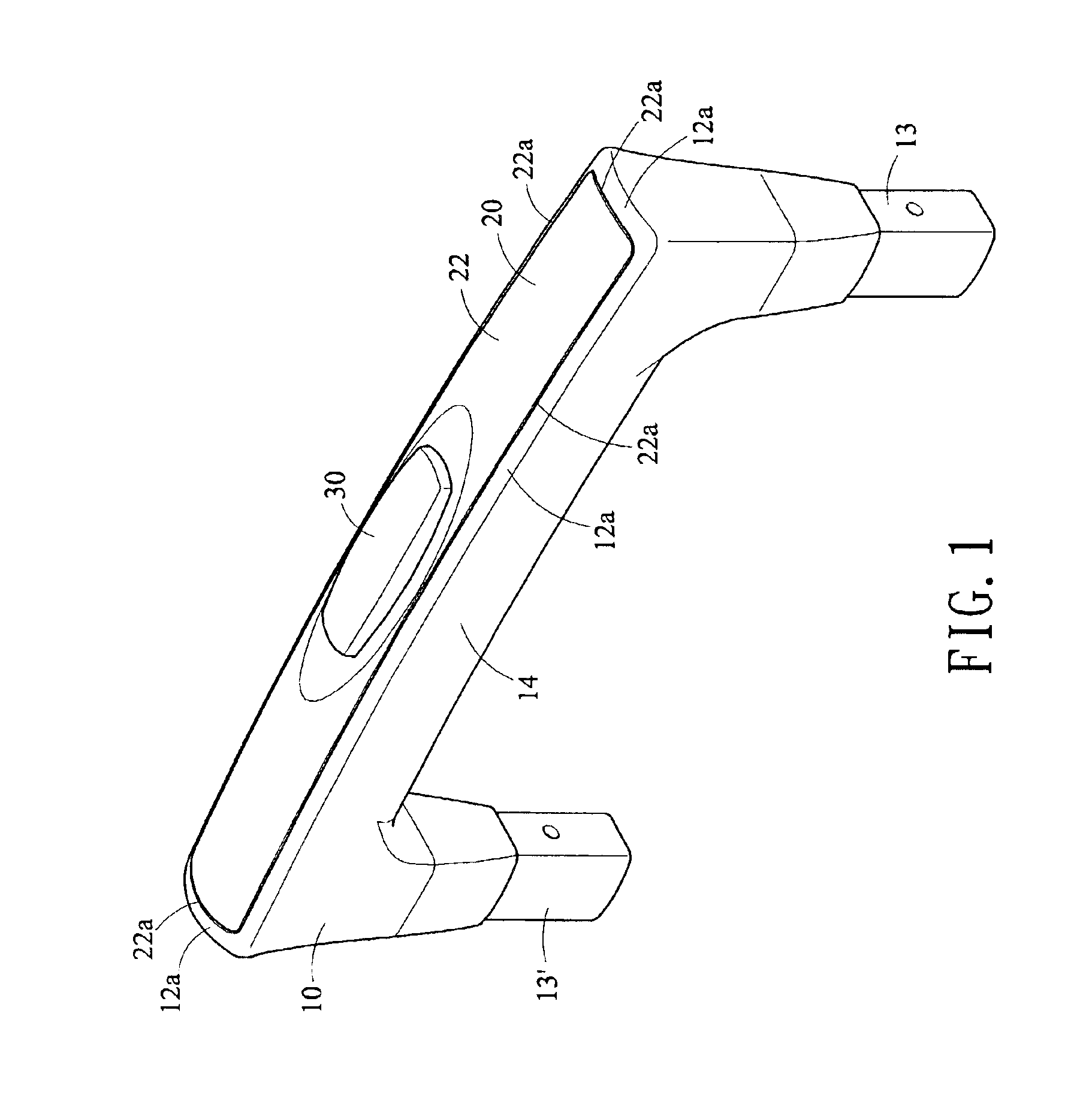

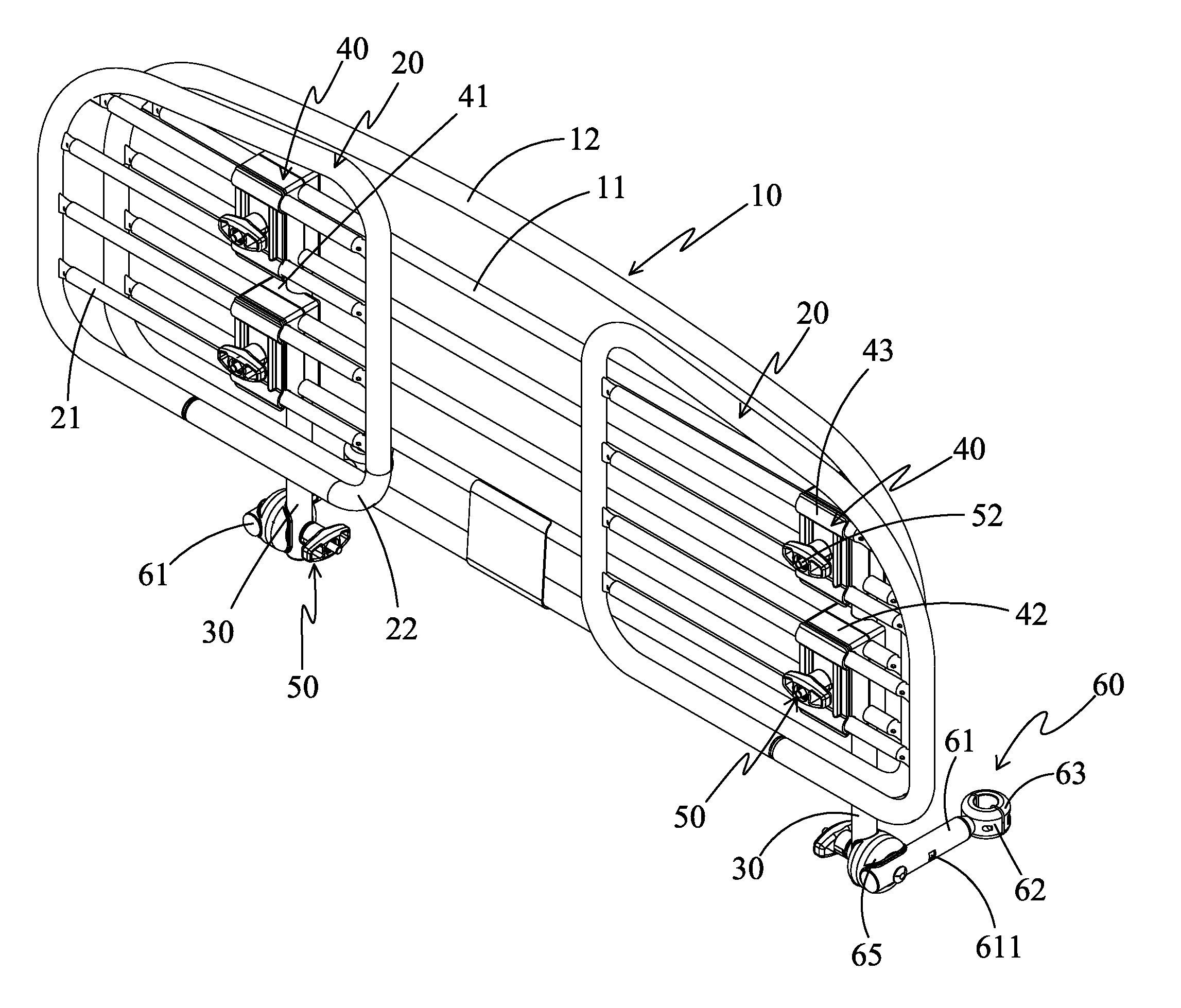

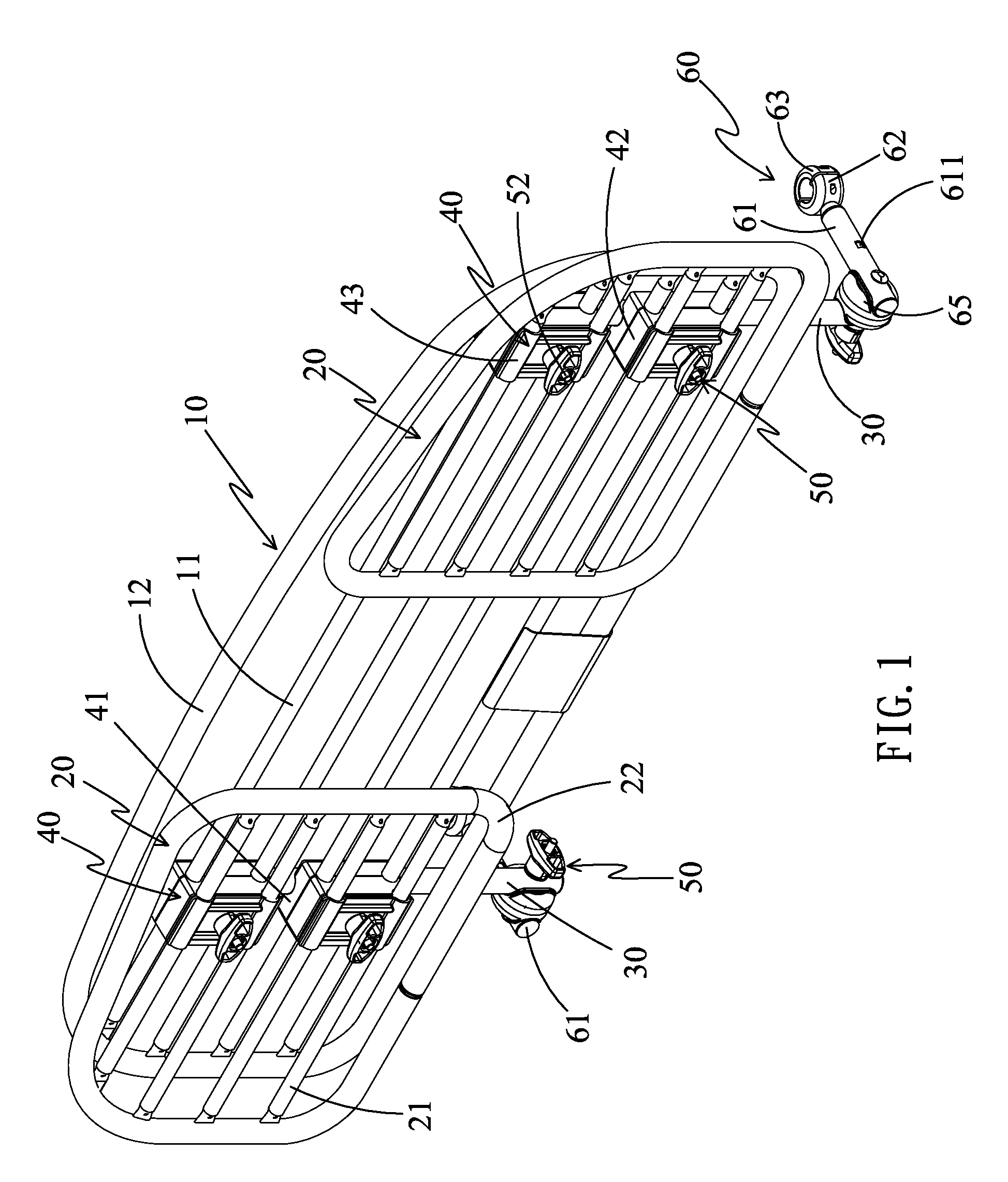

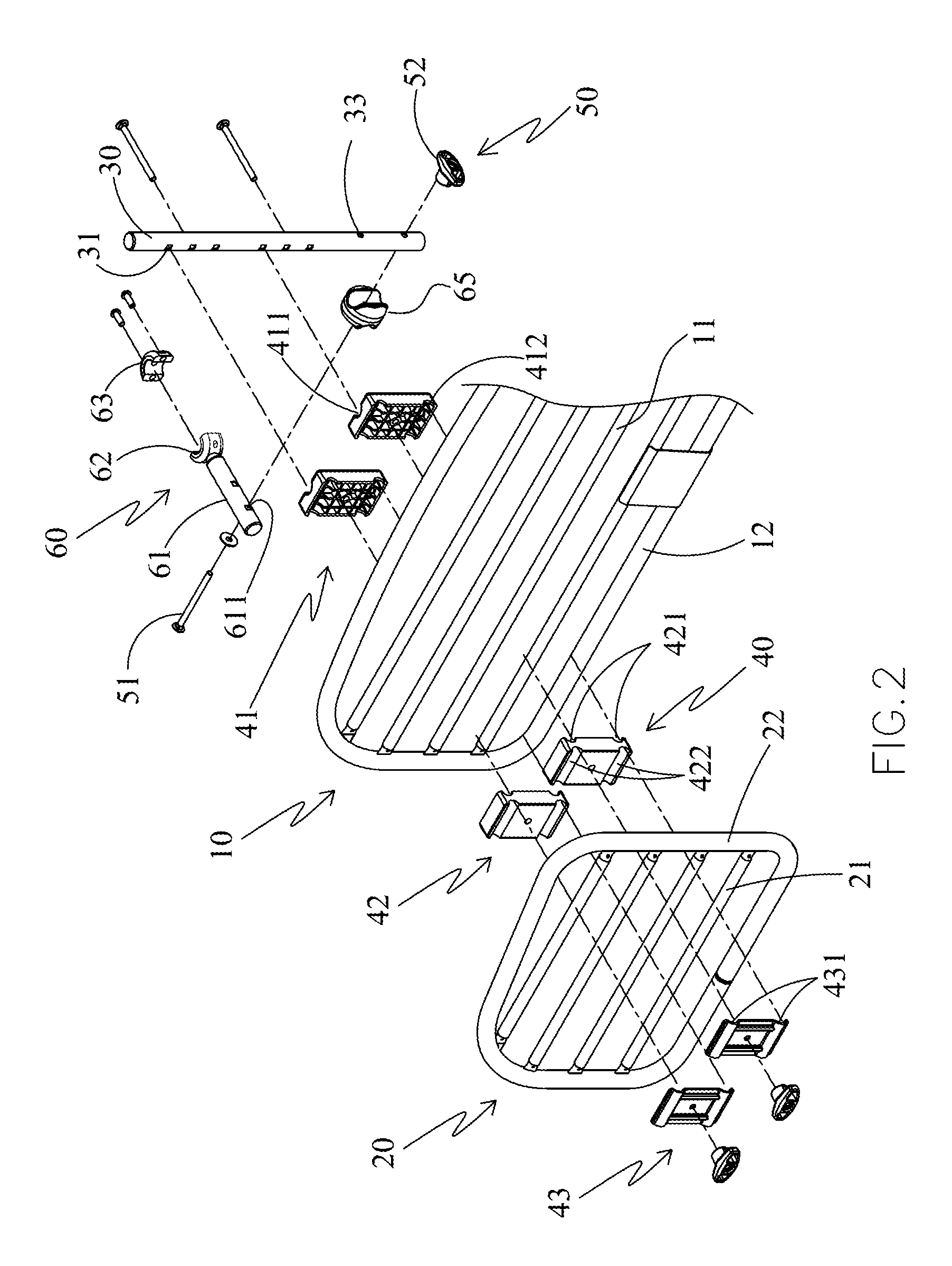

Adjustbale pet fence in vehicle

ActiveUS9174599B2Reduce partHigh strengthPedestrian/occupant safety arrangementAnimal housingIn vehicleEngineering

Owner:KING RACK INDUSTRIAL CO LTD

Razor assembly with spring-biased connecting head

A razor assembly includes at least one razor blade having a cutting edge, a blade housing configured to accommodate the at least one razor blade aligned along first direction, a connecting head configured to be detachably coupled to the blade housing, a razor handle configured to support the connecting head so that the connecting head is pivotable about a rotation axis, which is perpendicular to the first direction, and a torsion spring configured to be elastically deformed when the connecting head pivots about the rotation axis from a neutral position so that the torsion spring provides a restoring force for the connecting head to return to the neutral position.

Owner:DORCO CO LTD

Pivot pin with gripper feature

ActiveUS8136207B2Reduce stress concentrationNot deformPin hingesWing openersStress concentrationEngineering

Owner:AMBROSE JOSEPH V

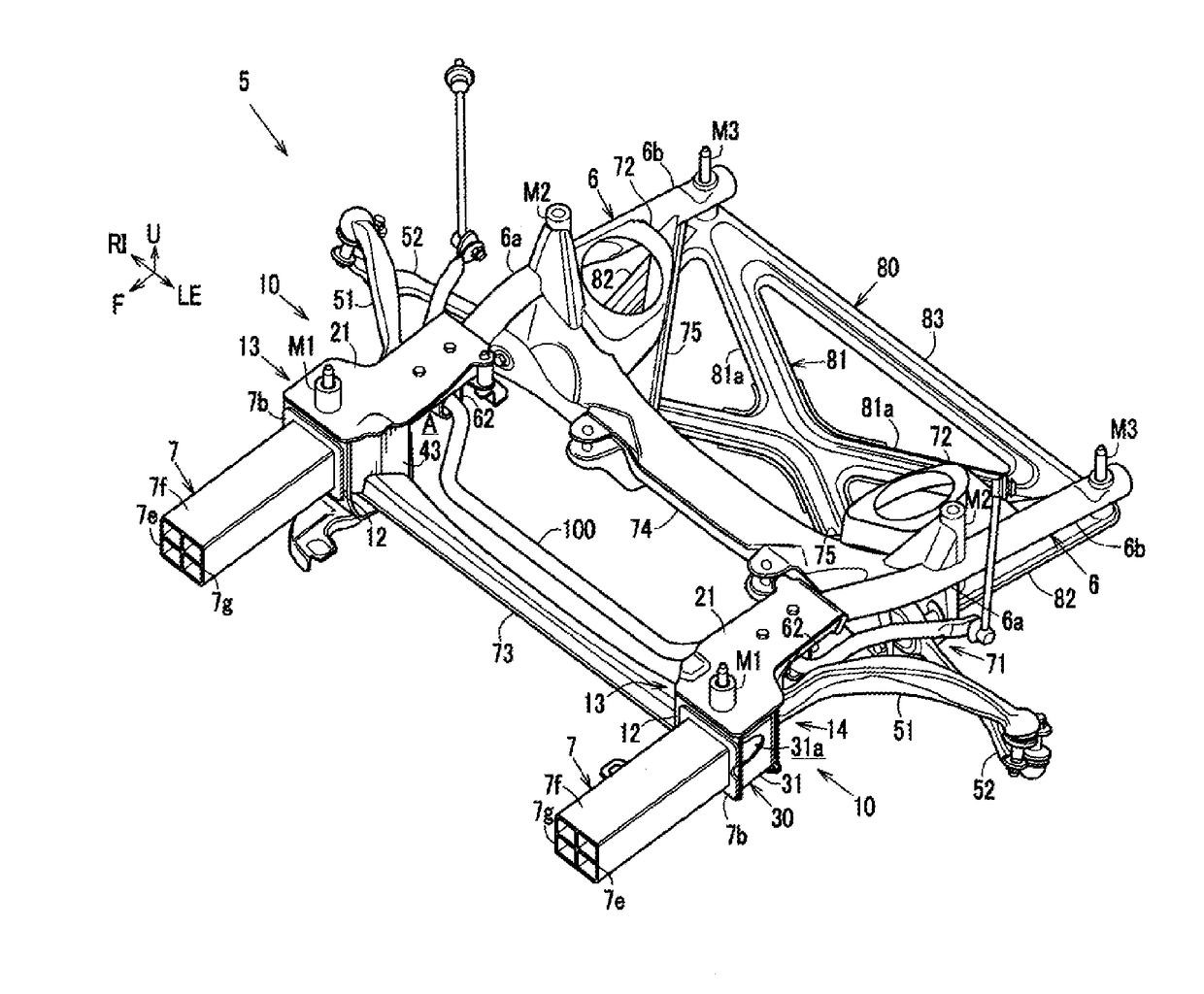

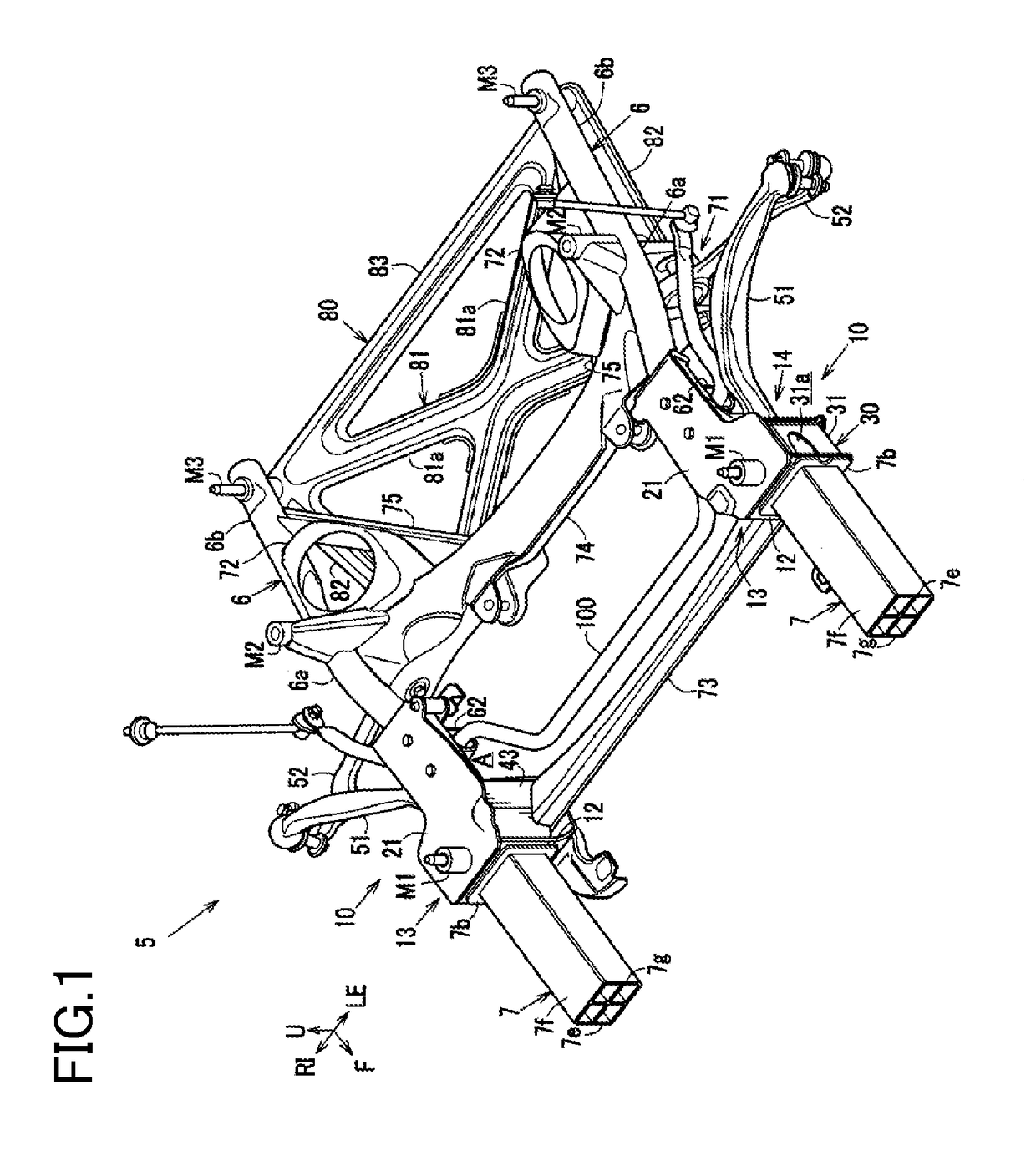

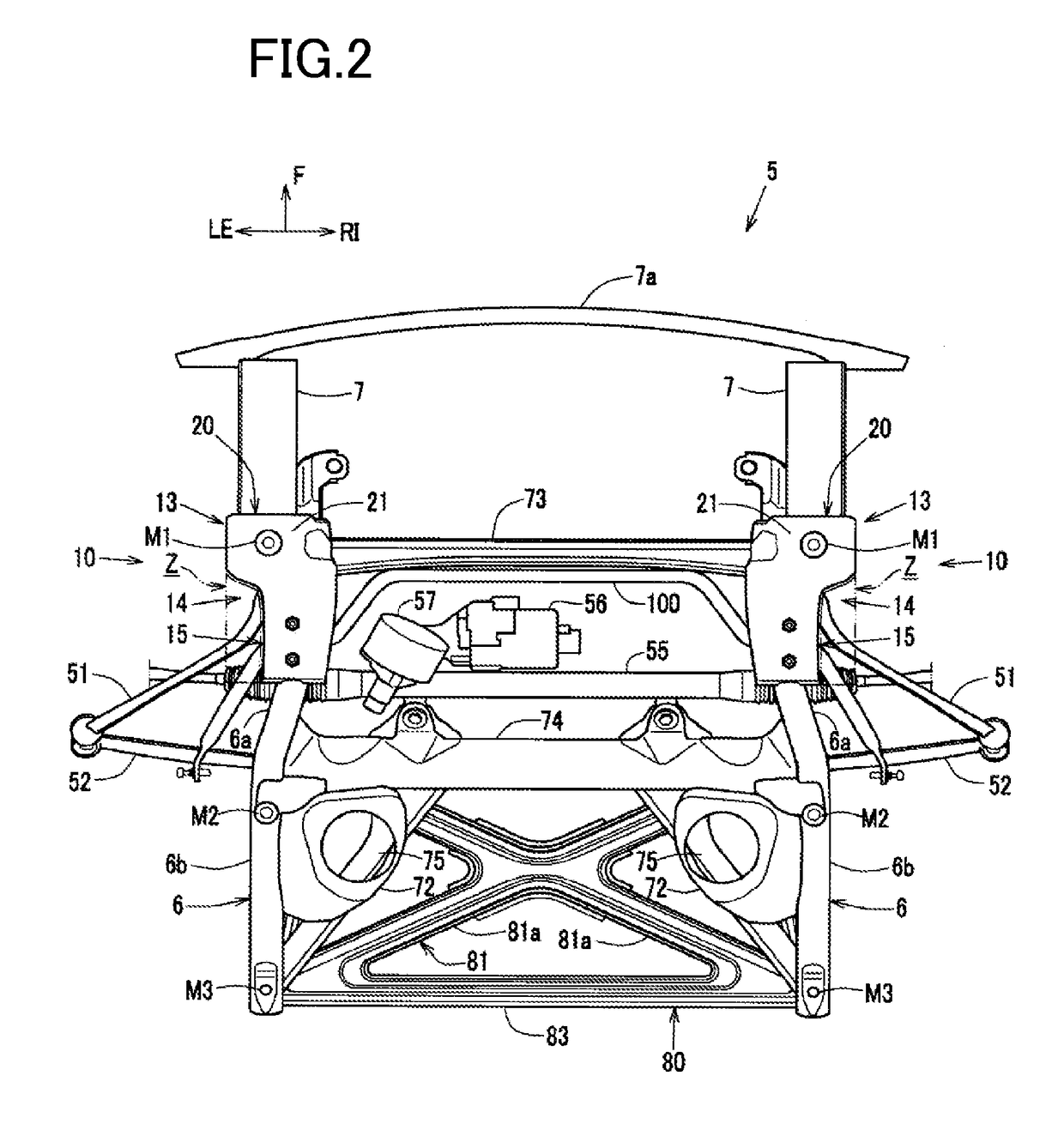

Front sub-frame structure

To reinforce a front sub-frame in such a manner that the front sub-frame having a trapezoidal shape formed by a cross member and left and right side members extending to one side is not deformed to a rhombus shape at the one side, a front sub-frame structure includes: a rear cross member (74) coupling arm supporting parts (71, 71) supported on left and right side members (6, 6); tilt members (75) coupling left and right intermediate portions of the rear cross member (74) to rear vehicle attachment parts (M3) of the side members (6); a brace (80) coupling the left and right arm supporting parts (71, 71) to the rear vehicle attachment parts (M3); and intermediate coupling parts (91) coupling the brace (80) to intermediate portions of the tilt members (75).

Owner:MAZDA MOTOR CORP

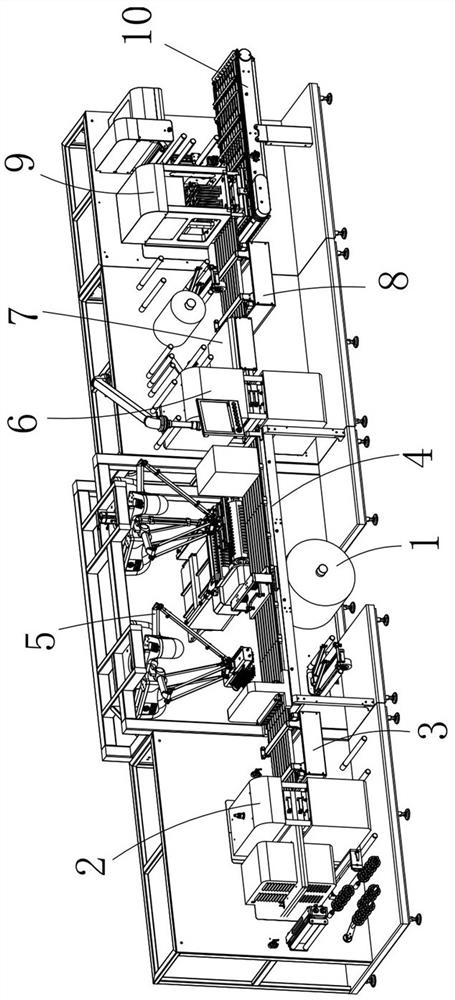

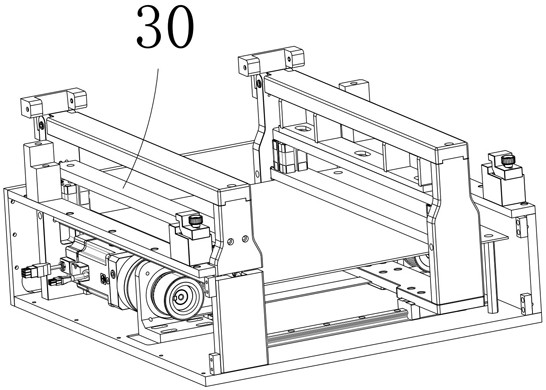

High-speed blister packaging machine

The invention relates to a novel high-speed blister packaging machine. The high-speed blister packaging machine comprises a rack which is sequentially provided with a blister support forming device, a forming traction device, a blister heat sealing device, a heat sealing traction device, a blister punching device and a blister grating conveying device, and is characterized in that a blister cooling device is arranged between the blister heat sealing device and the heat sealing traction device; the bubble cap cooling device comprises a cooling box and a cooling plate, the cooling plate is arranged in the cooling box, and a cooling channel for the bubble cap to pass through is arranged below the cooling plate. According to the high-speed blister packaging machine, the blisters subjected to heat sealing can be quickly cooled down, so that the blisters are prevented from being deformed in the blister traction process of the heat sealing traction device.

Owner:ZHEJIANG HOPING MACHINERY

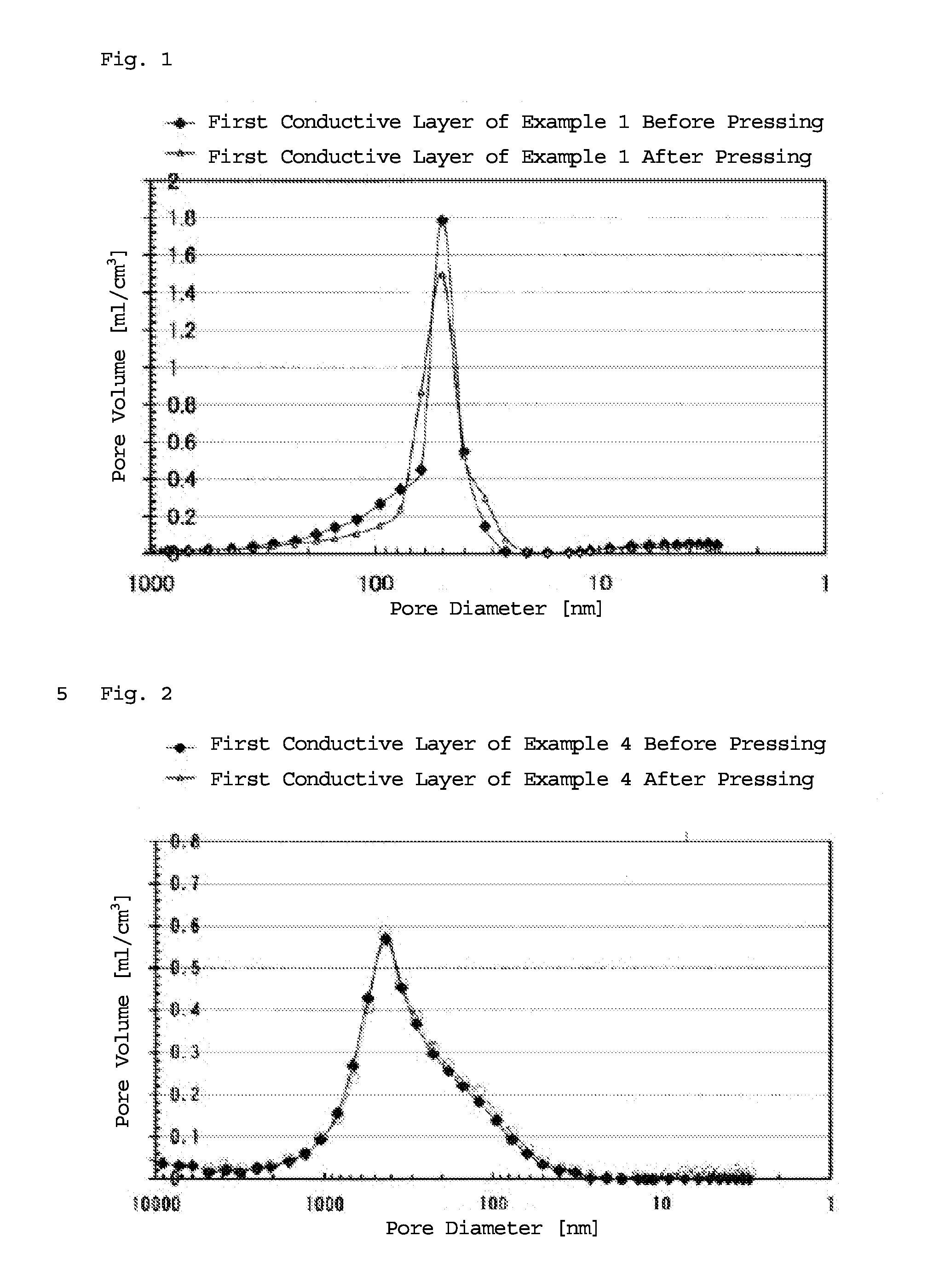

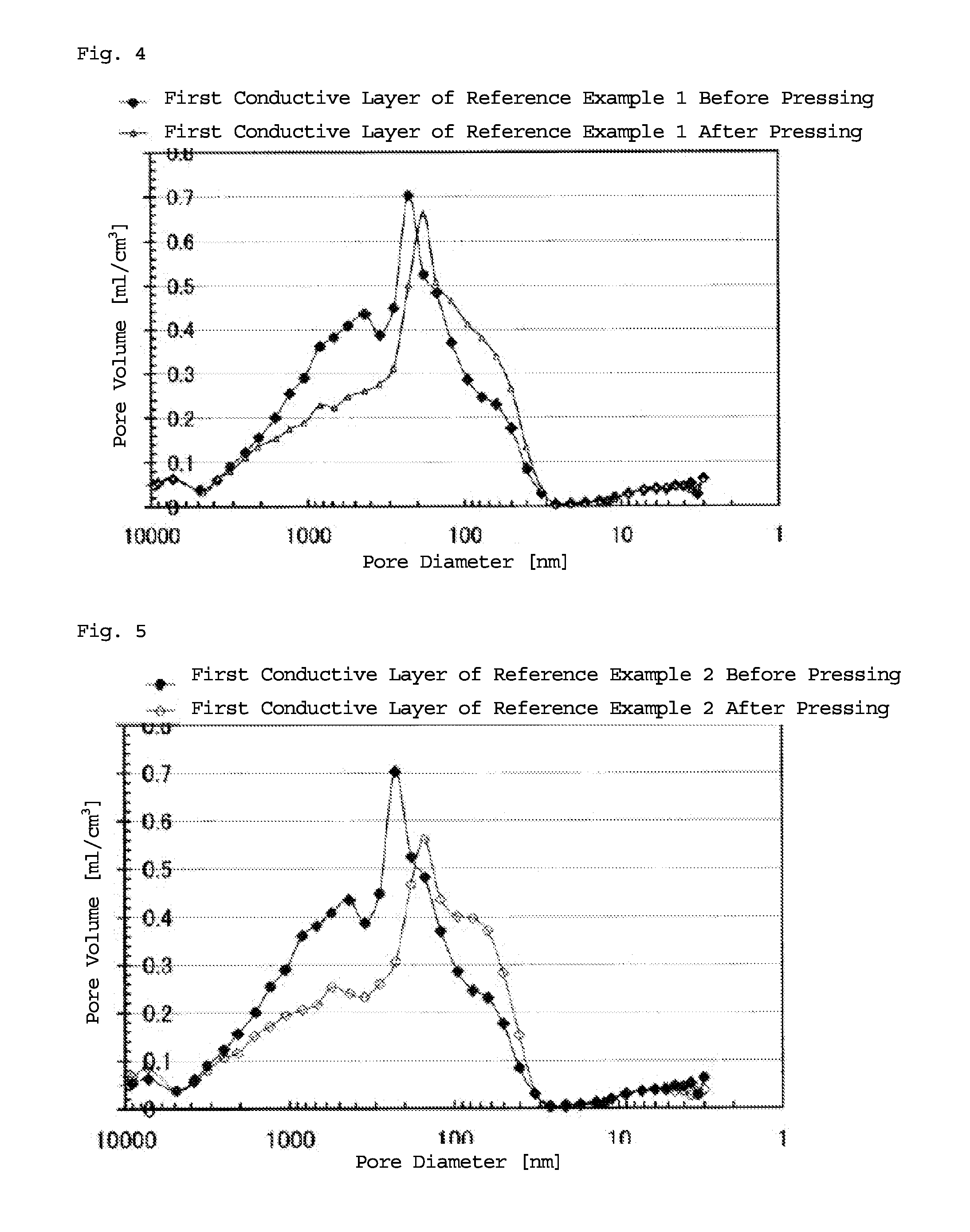

Conductive porous layer for battery, and manufacturing method for same

InactiveUS20150132668A1Good adhesionNot deformFuel and primary cellsSolid electrolytesOptoelectronicsPorous layer

An object of the present invention is to provide a conductive porous layer for batteries in which adhesion between a conductive porous substrate and the conductive porous layer is excellent, and pores in the conductive porous layer are maintained without being deformed. The conductive porous layer for batteries of the present invention contains a laminate containing a first conductive layer and a second conductive layer, the first conductive layer including a conductive carbon material and a polymer, and the second conductive layer including a conductive carbon material and a polymer, and the polymer contained in the first conductive layer having a glass transition temperature (Tg) 30° C. or more higher than the glass transition temperature (Tg) of the polymer contained in the second conductive layer.

Owner:DAI NIPPON PRINTING CO LTD

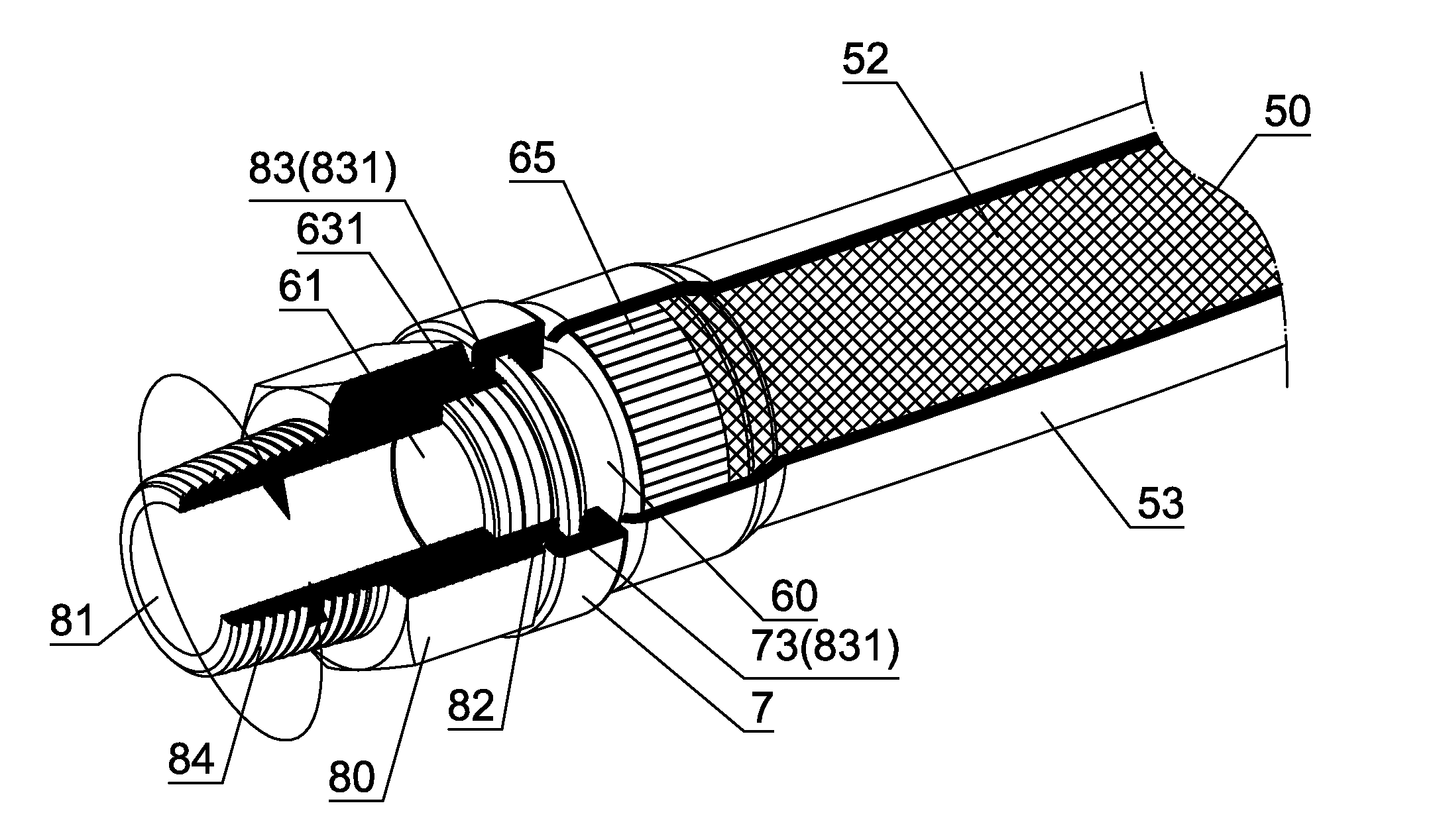

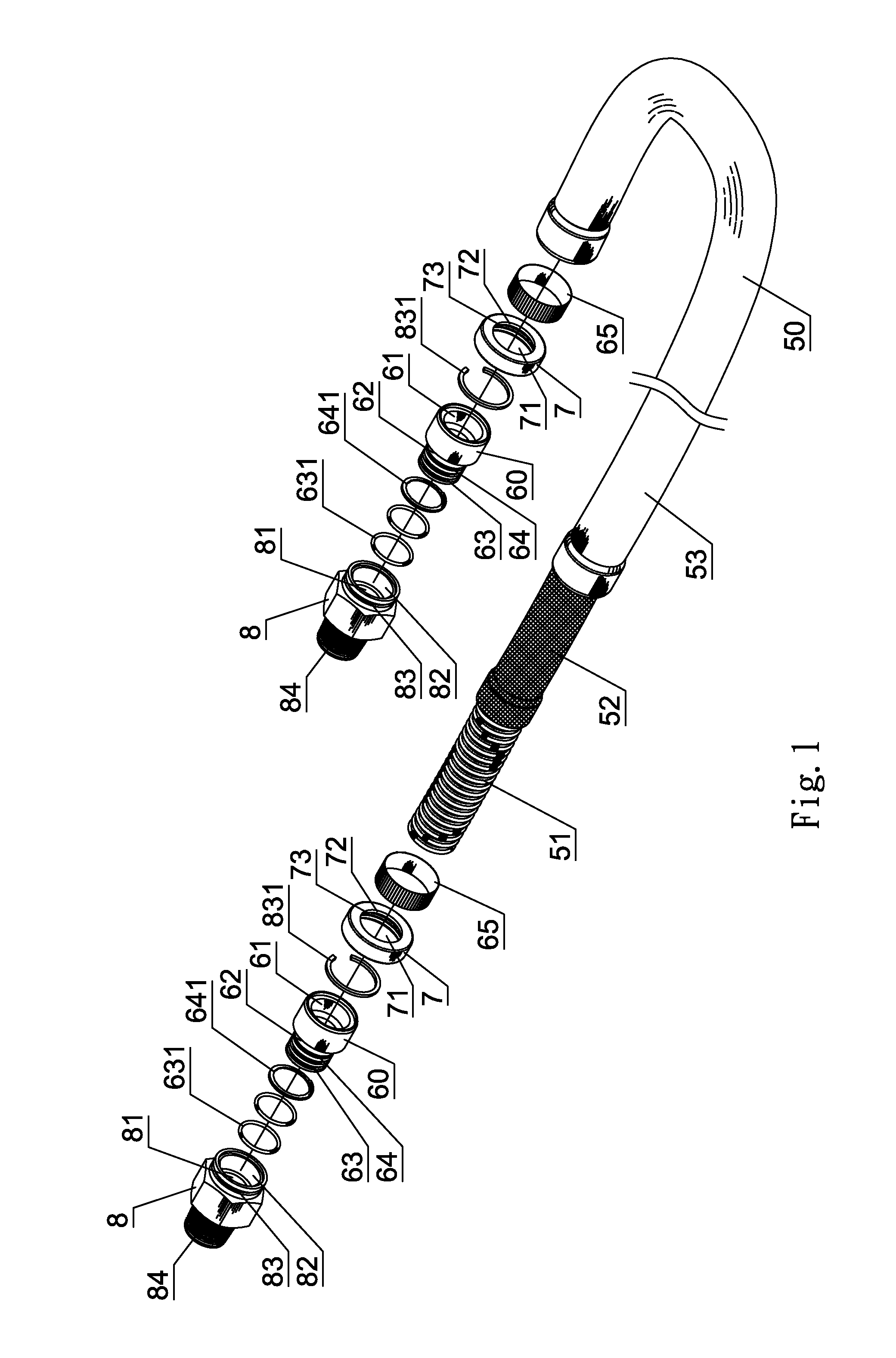

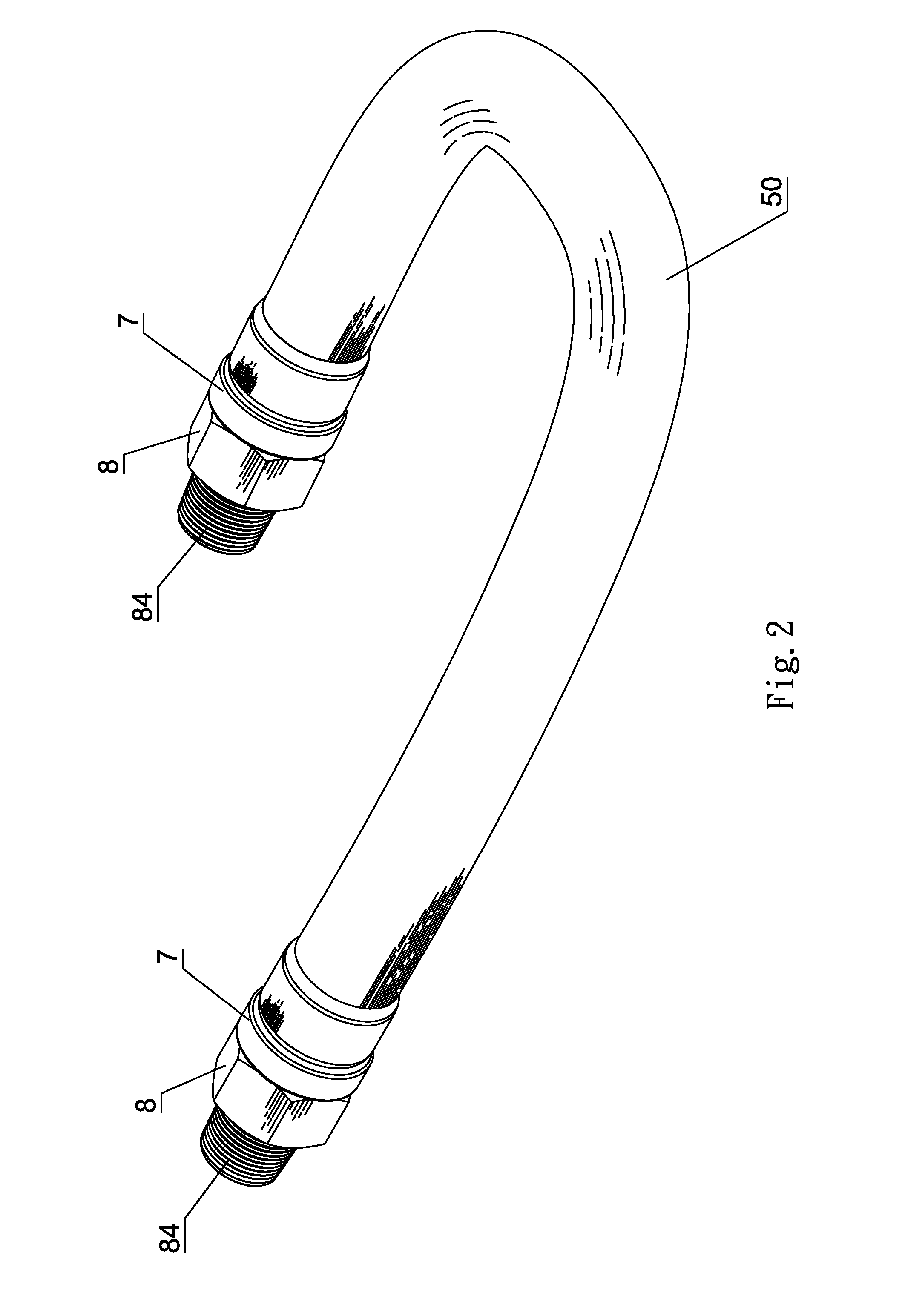

Gas tube structure

A gas tube structure includes a flexible tube. The end of the flexible tube is connected with a fixed connector. A sleeve is fitted on the fixed connector. The fixed connector and the sleeve are connected to a movable connector. The fixed connector has a connection section extending from an outer end thereof. The connection section has an annular seal groove and an annular buckle groove thereon. The sleeve has a sleeve hole therein, a stop flange at one end thereof and an engaging groove formed on in inner wall thereof. One end of the movable connector has a receiving hole and a C-shaped groove formed on an outer wall of the receiving hole. The C-shaped groove is adapted to receive a C-shaped buckle. The present invention has a stable connection, is safe for use, can lower the cost and enhances assembly efficiency.

Owner:CHUNG CHIU CHIH

Gas tube structure

A gas tube structure includes a flexible tube. The end of the flexible tube is connected with a fixed connector. A sleeve is fitted on the fixed connector. The fixed connector and the sleeve are connected to a movable connector. The fixed connector has a connection section extending from an outer end thereof. The connection section has an annular seal groove and an annular buckle groove thereon. The sleeve has a sleeve hole therein, a stop flange at one end thereof and an engaging groove formed on in inner wall thereof. One end of the movable connector has a receiving hole and a C-shaped groove formed on an outer wall of the receiving hole. The C-shaped groove is adapted to receive a C-shaped buckle. The present invention has a stable connection, is safe for use, can lower the cost and enhances assembly efficiency.

Owner:CHUNG CHIU CHIH

Control Stick Cap with Retention Features

InactiveUS20190138044A1Not deformControlling membersManual control with multiple controlled membersEngineeringMechanical engineering

A control stick assembly includes a control stick with a body and an extension. The control stick assembly also includes a control stick cap with a recess. The recess includes a first portion and a second portion. A portion of the control stick body is located in the first portion of the recess. Further, the extension is located in the second portion of the recess. The control stick cap is not deformed by the control stick.

Owner:SLOTTA MARK

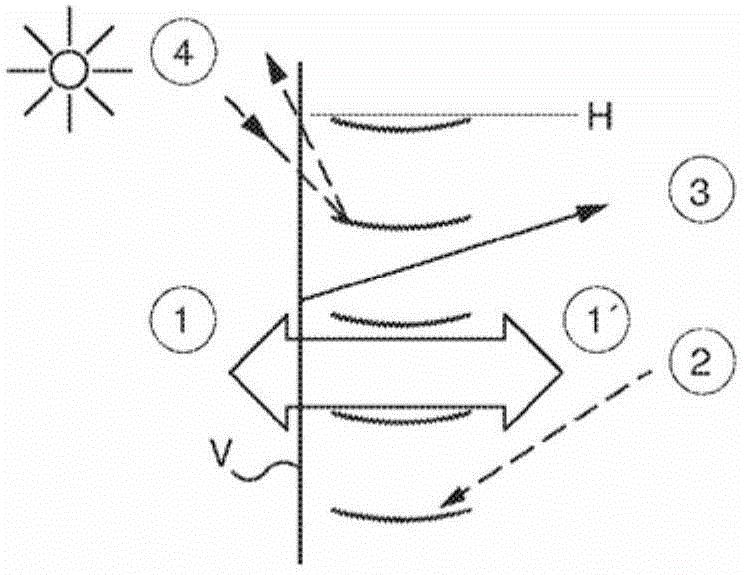

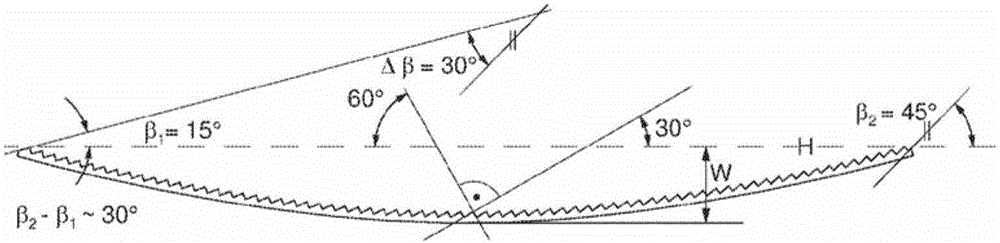

Wind-up light-directing slat, method of production, application, and sun protection system

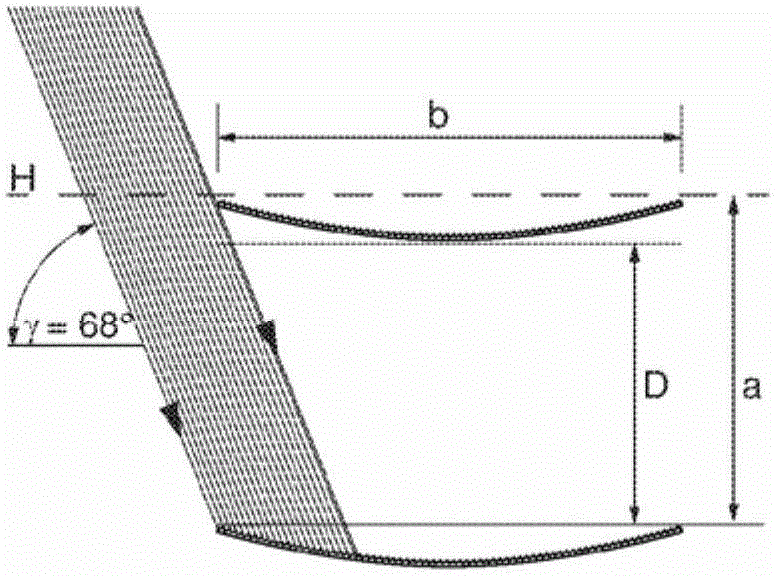

Light guiding slat for a sun protection system, wherein the light guiding slat is made of a band material equipped with a Fresnel reflector made by folding and / or bending the band material whereby the light guiding slat has a total height (G) which is so small that the light guiding slat has a form to be coilable with a coiling radius of 1 m or less without any substantial plastic deformation.

Owner:于水

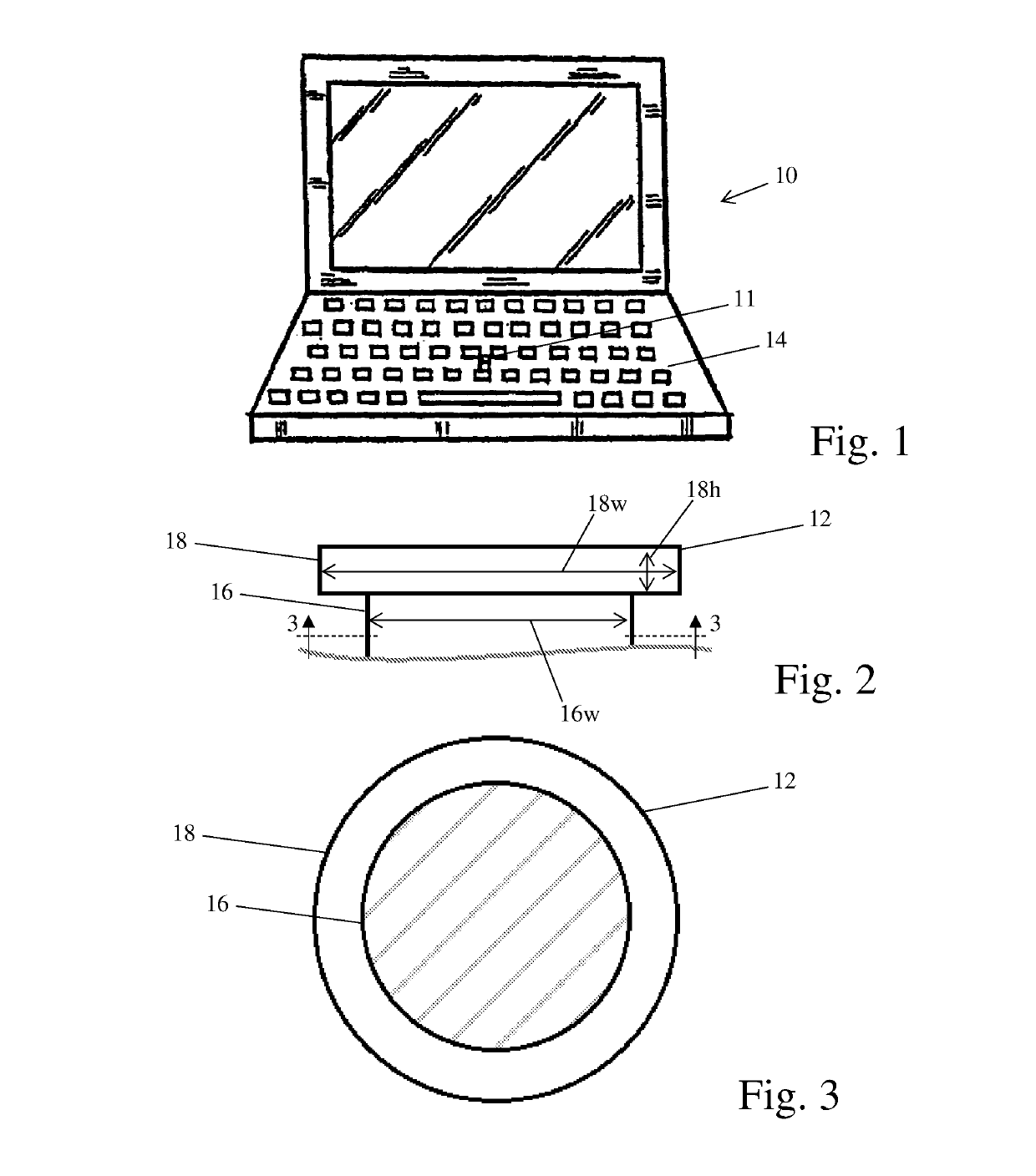

Localized panel stiffener

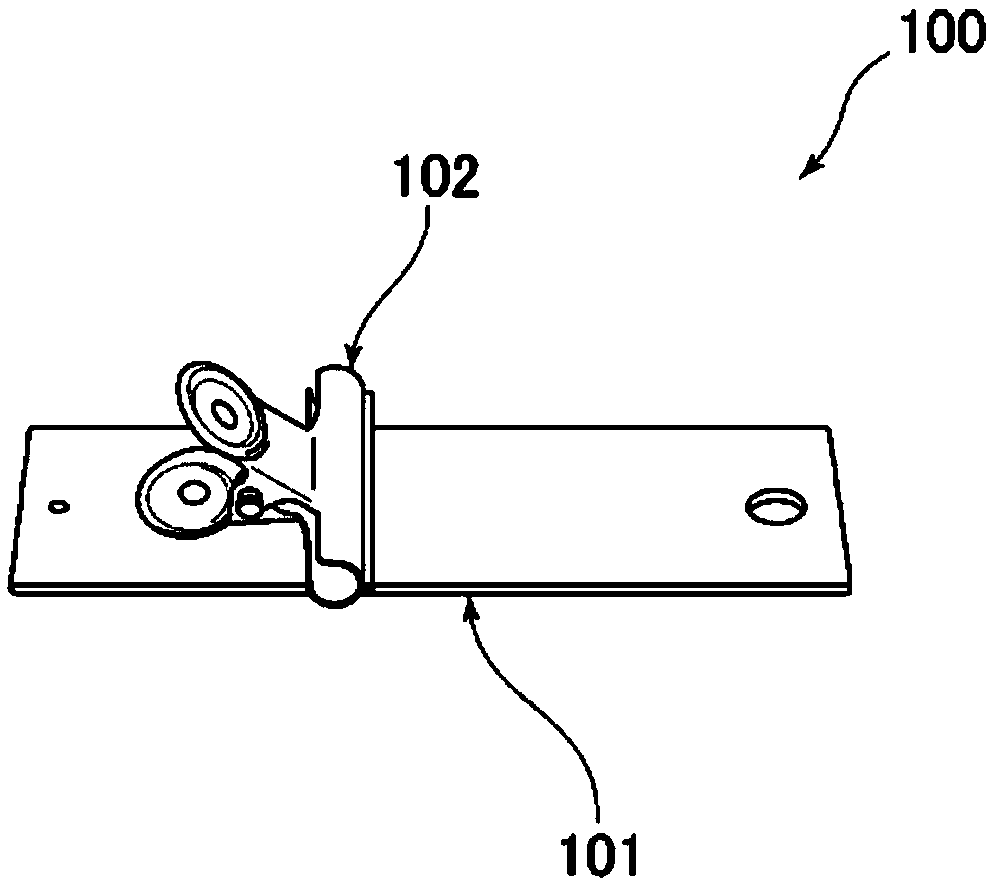

ActiveUS20180111351A1Increase stiffnessAvoid issuingDomestic articlesThin material handlingEngineeringCarrier material

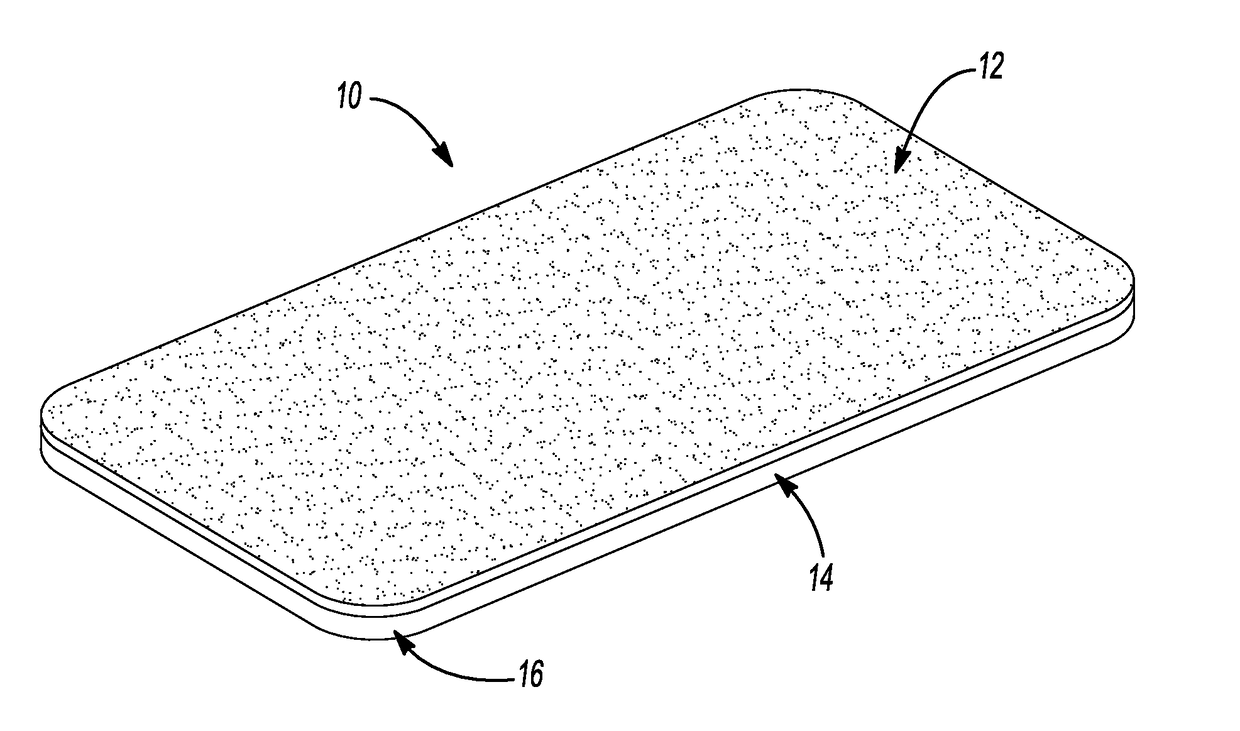

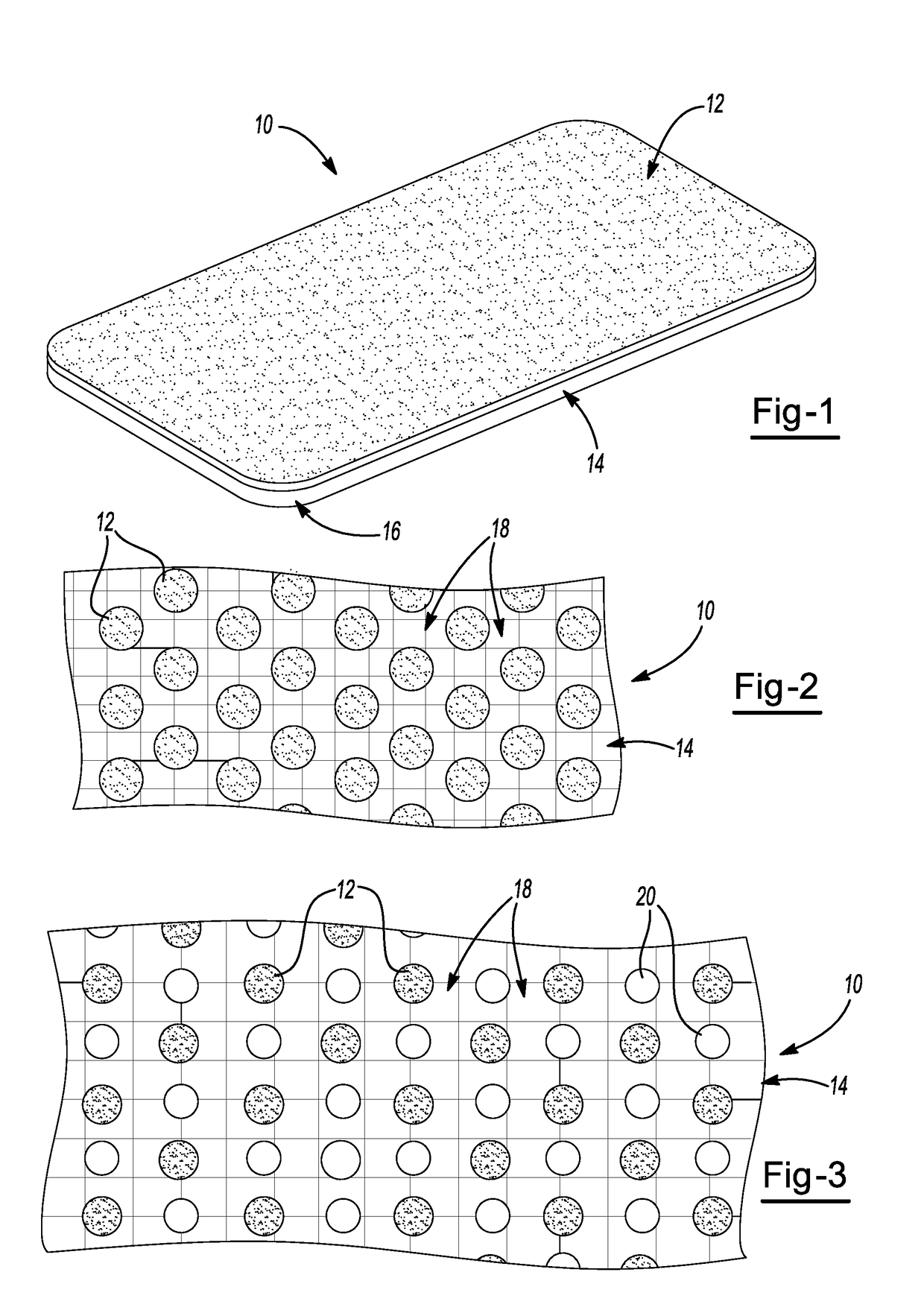

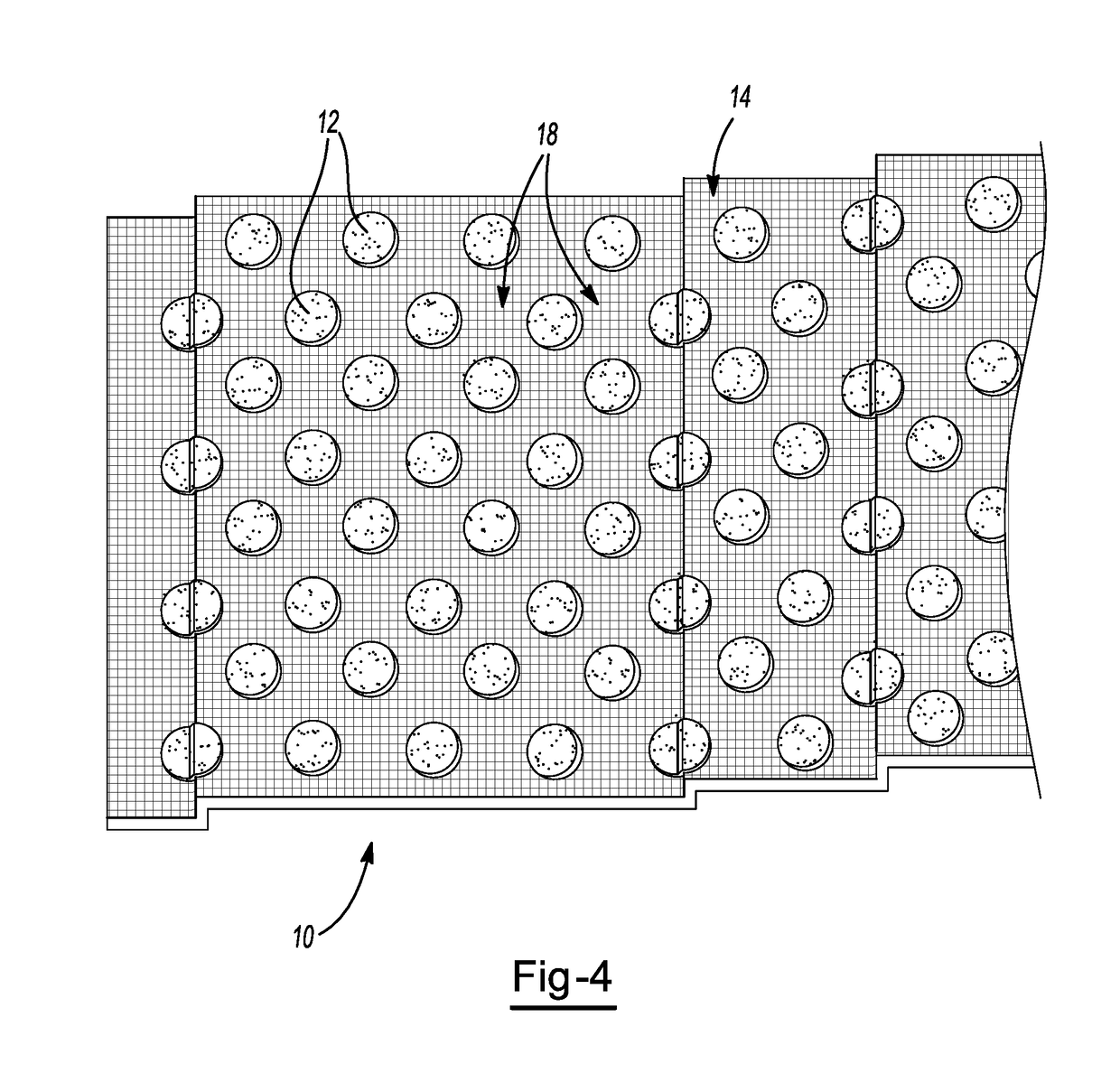

A device (10) comprising a carrier material (14) and a matrix material (12) deposited onto the carrier material in a pattern that leaves a predetermined amount of space (18) between each deposition of matrix material.

Owner:ZEPHYROS INC

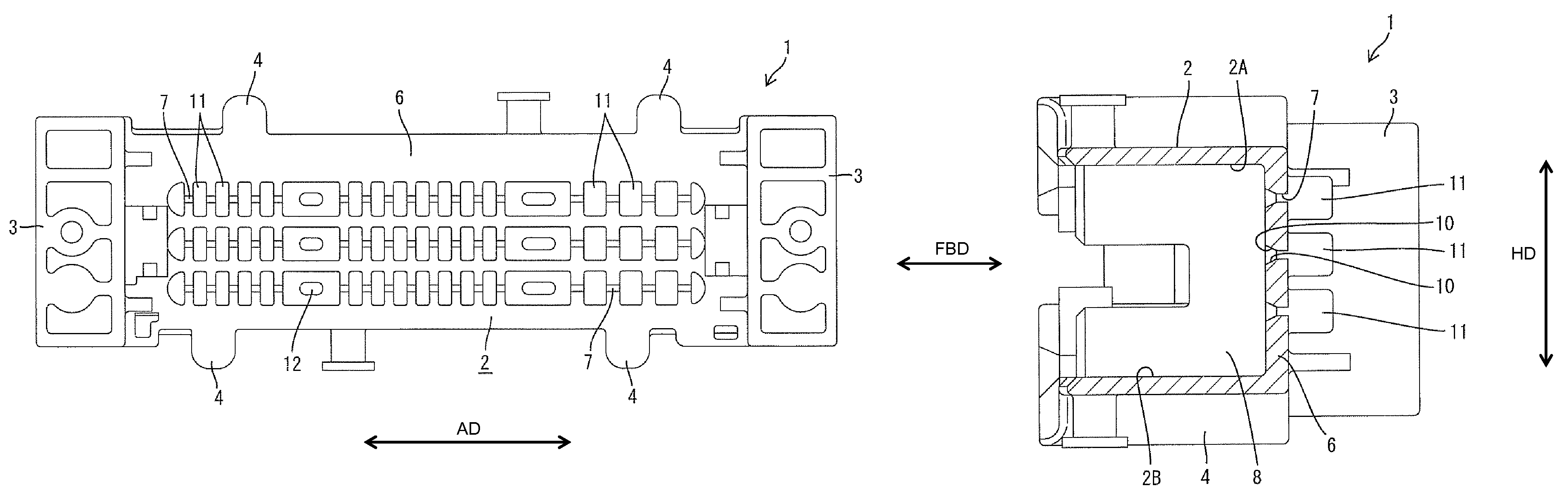

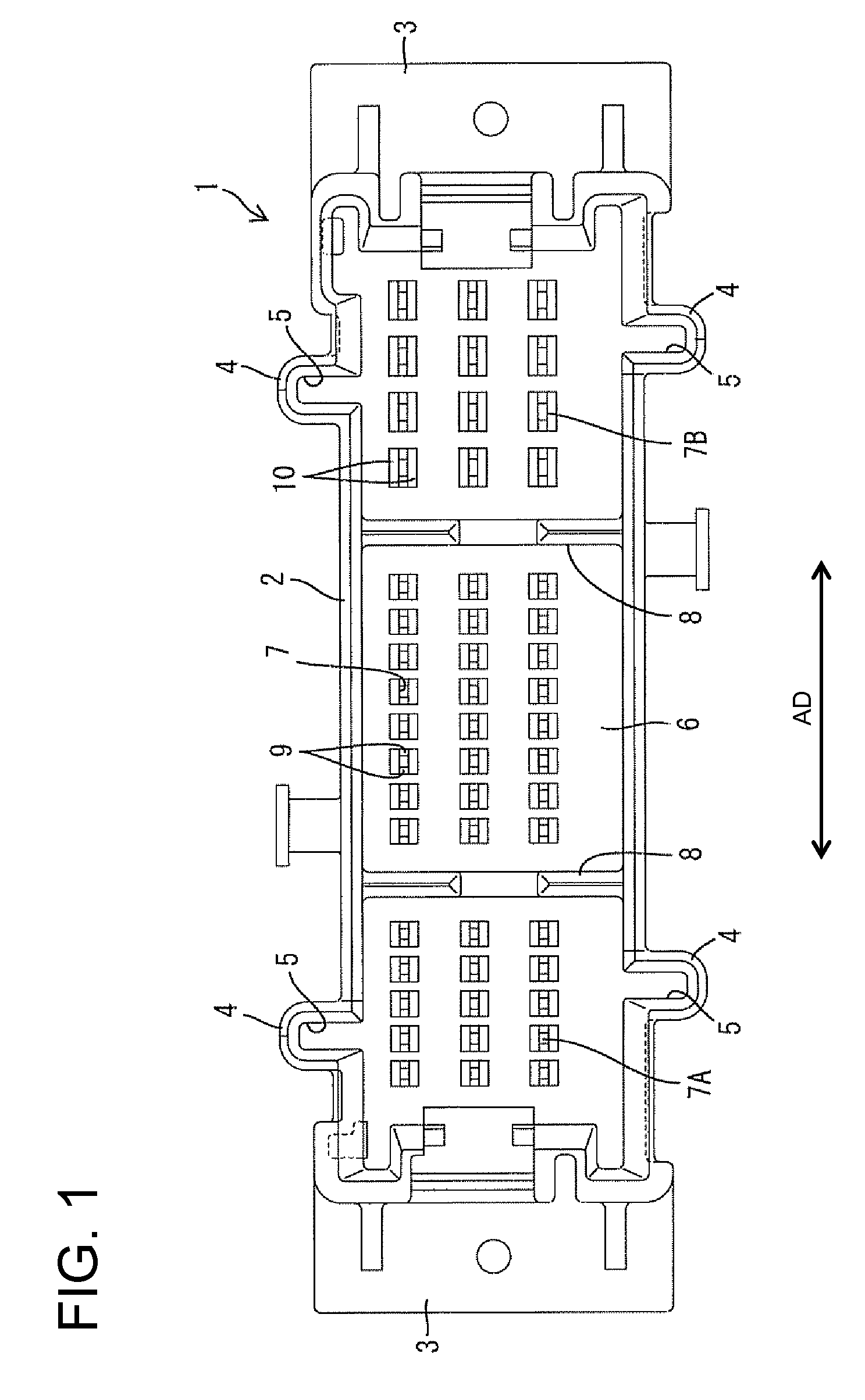

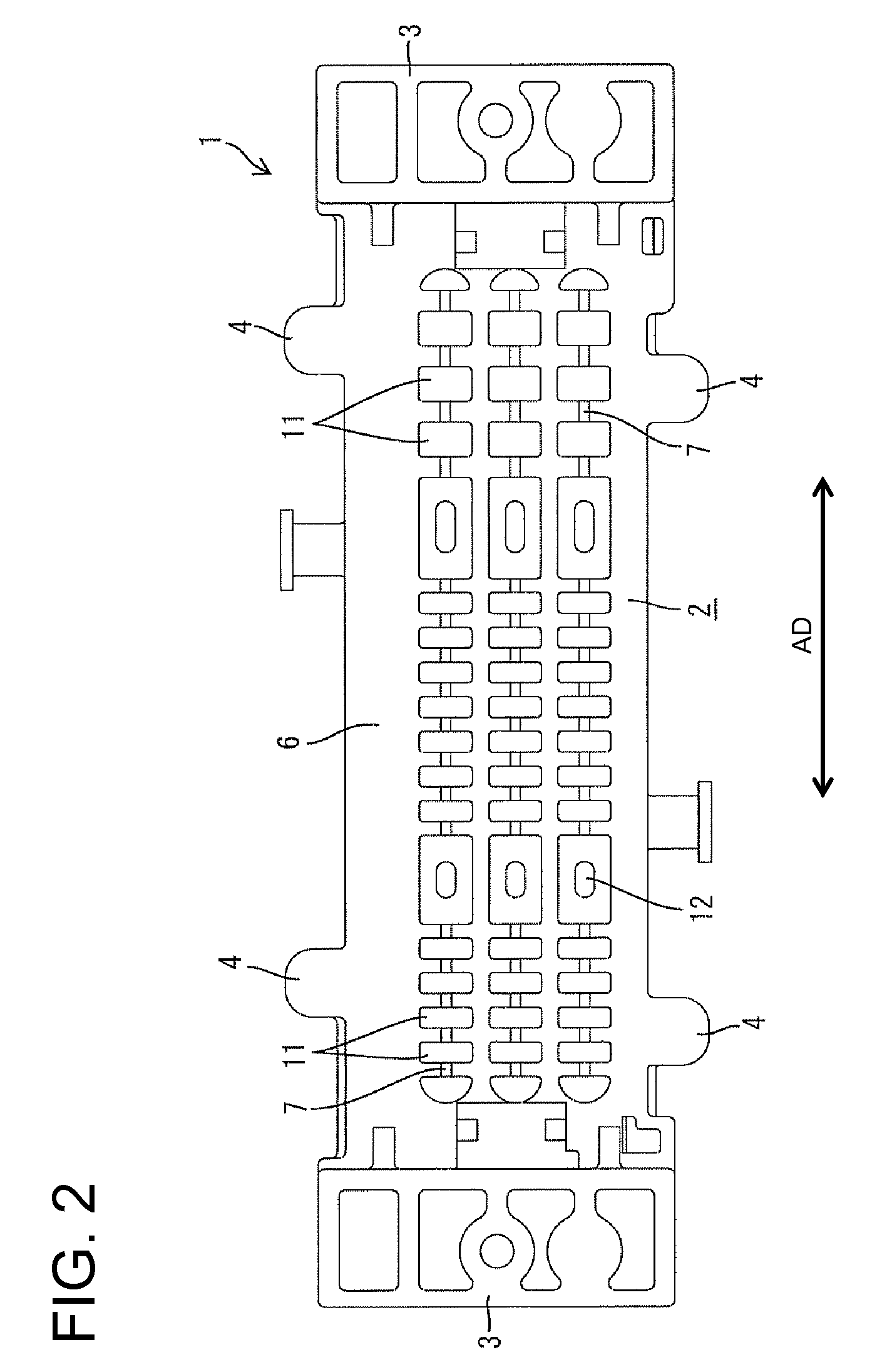

Connector, a forming mold therefor

InactiveUS7568948B2High strengthNot deformContact member assembly/disassemblyMouldsEngineeringMechanical engineering

Owner:SUMITOMO WIRING SYST LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com