Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

54results about How to "Improve work safety" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

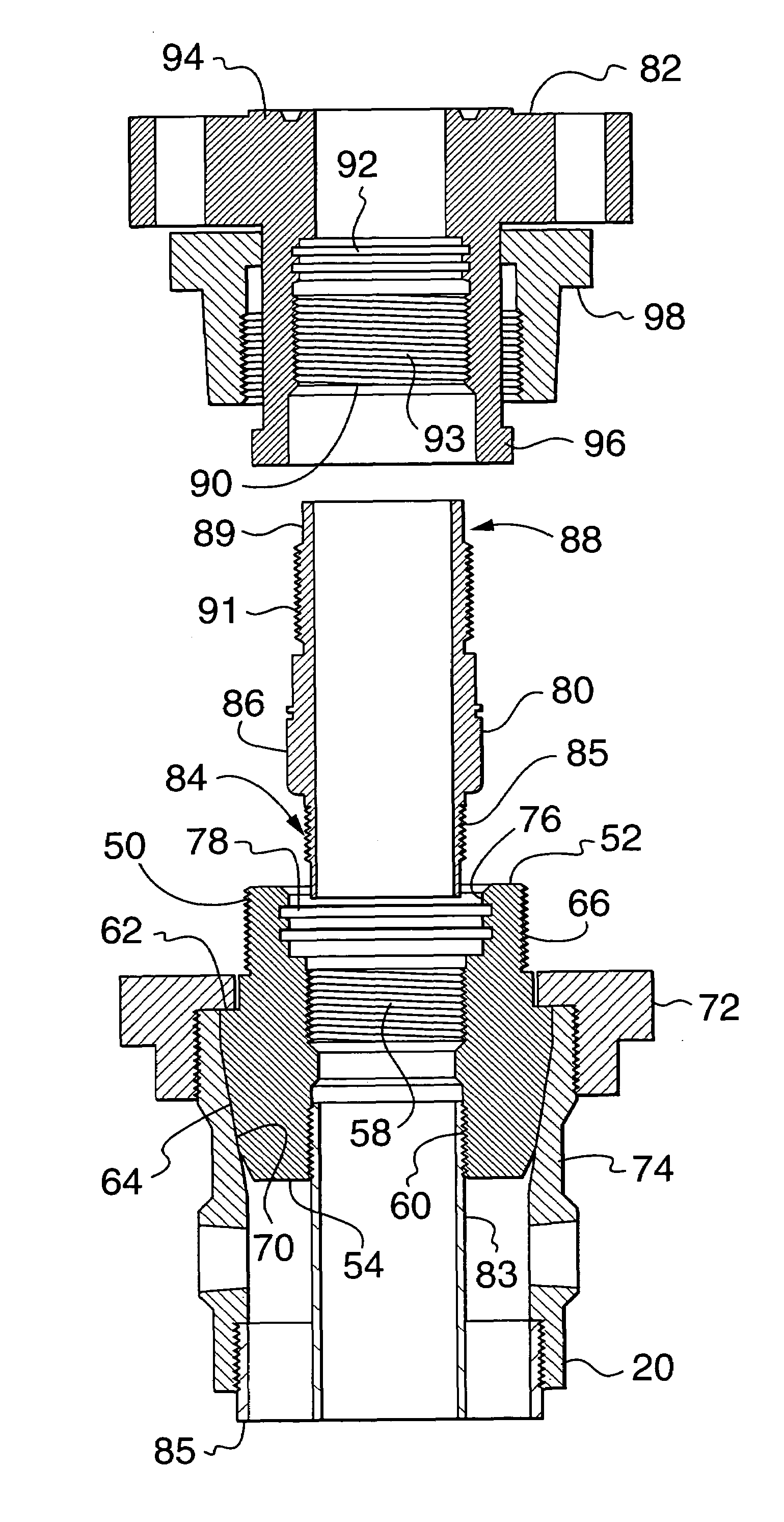

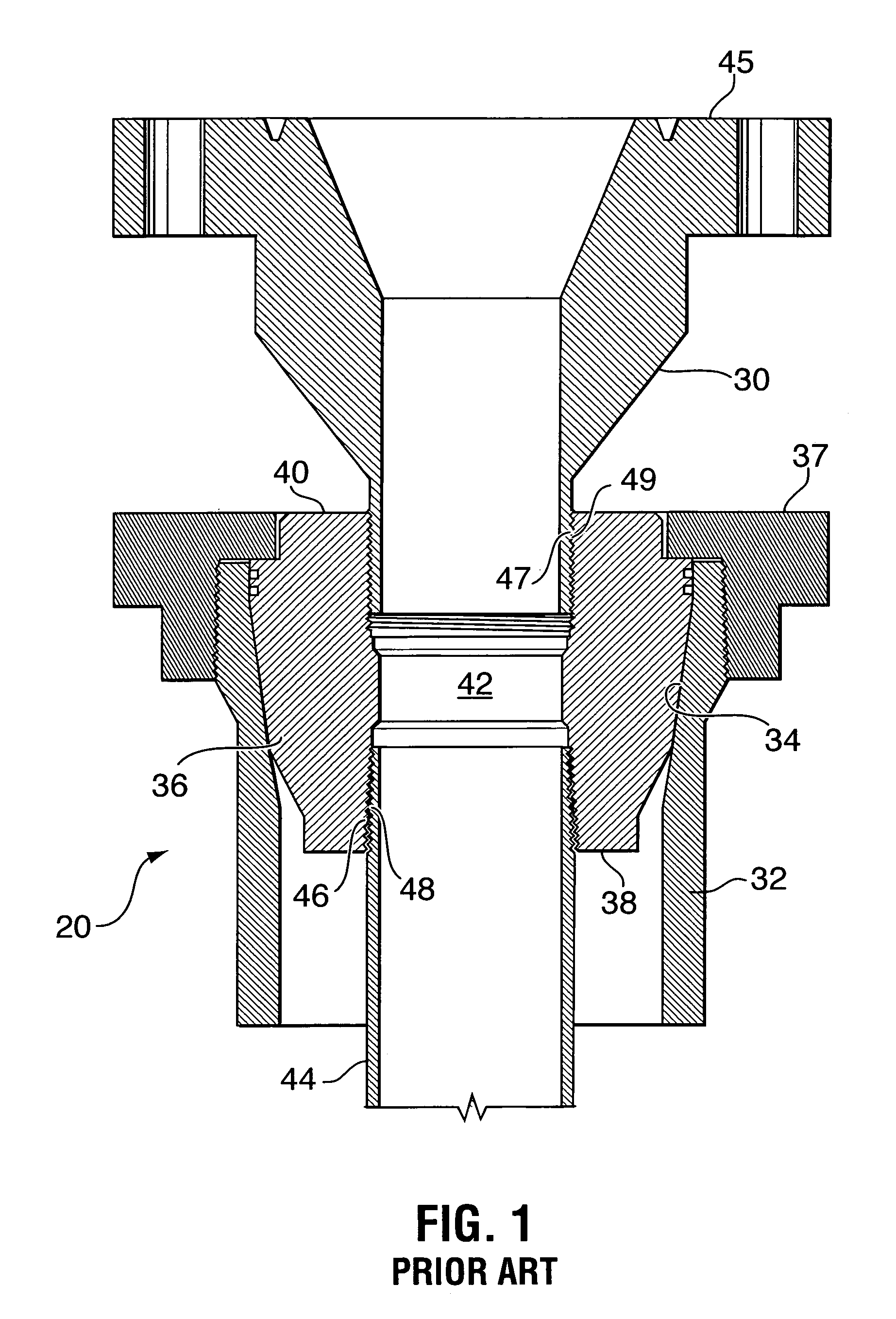

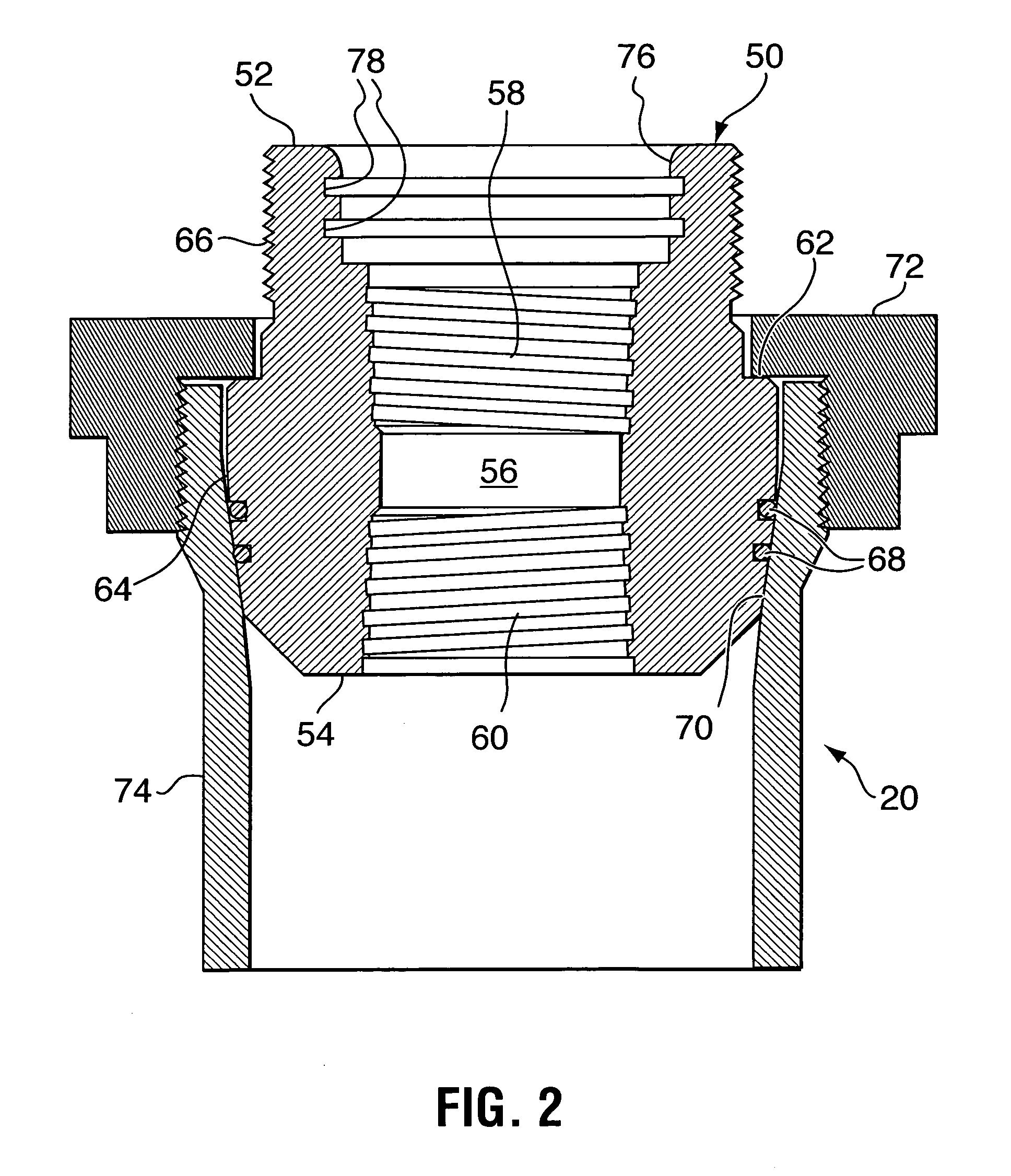

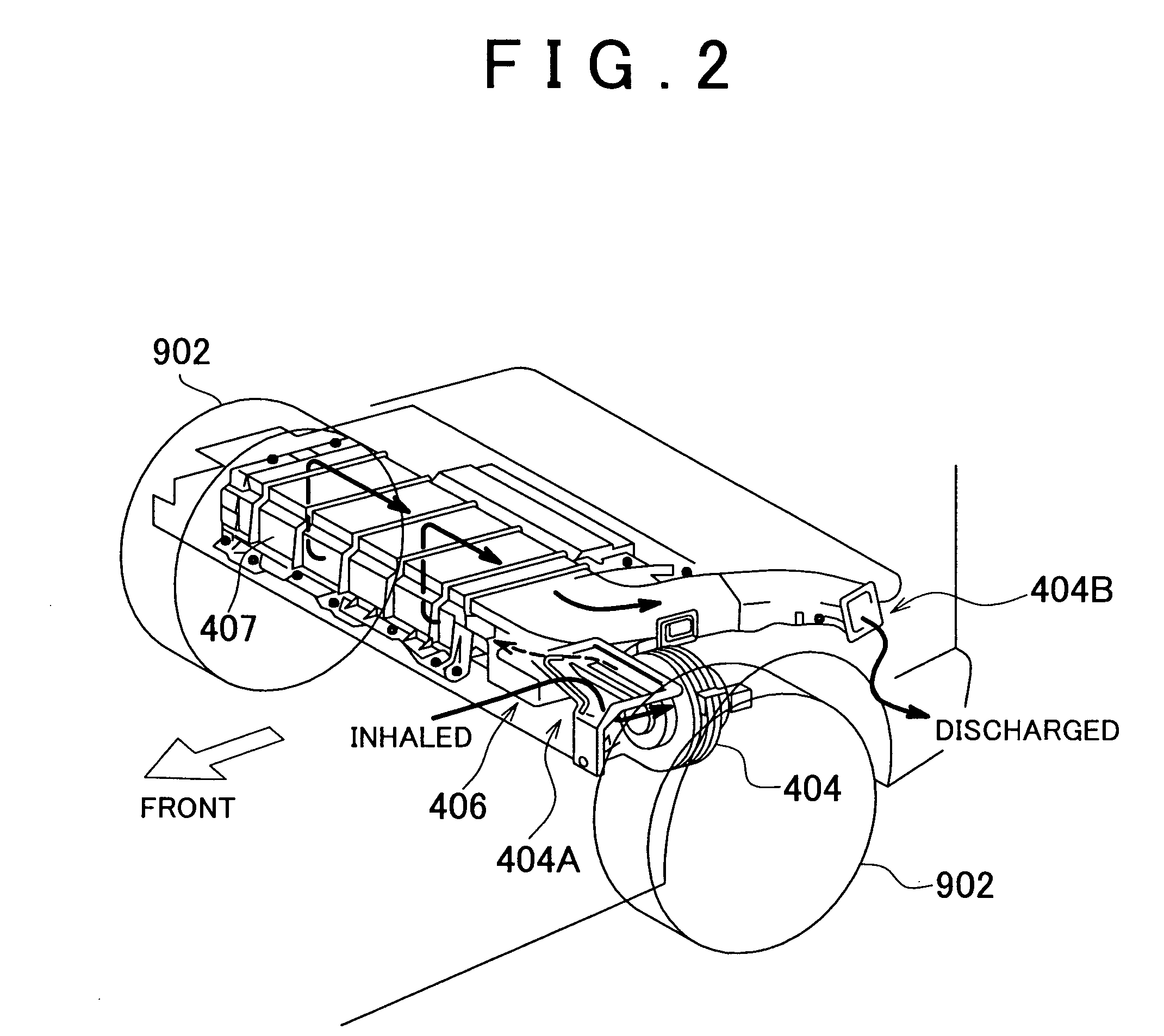

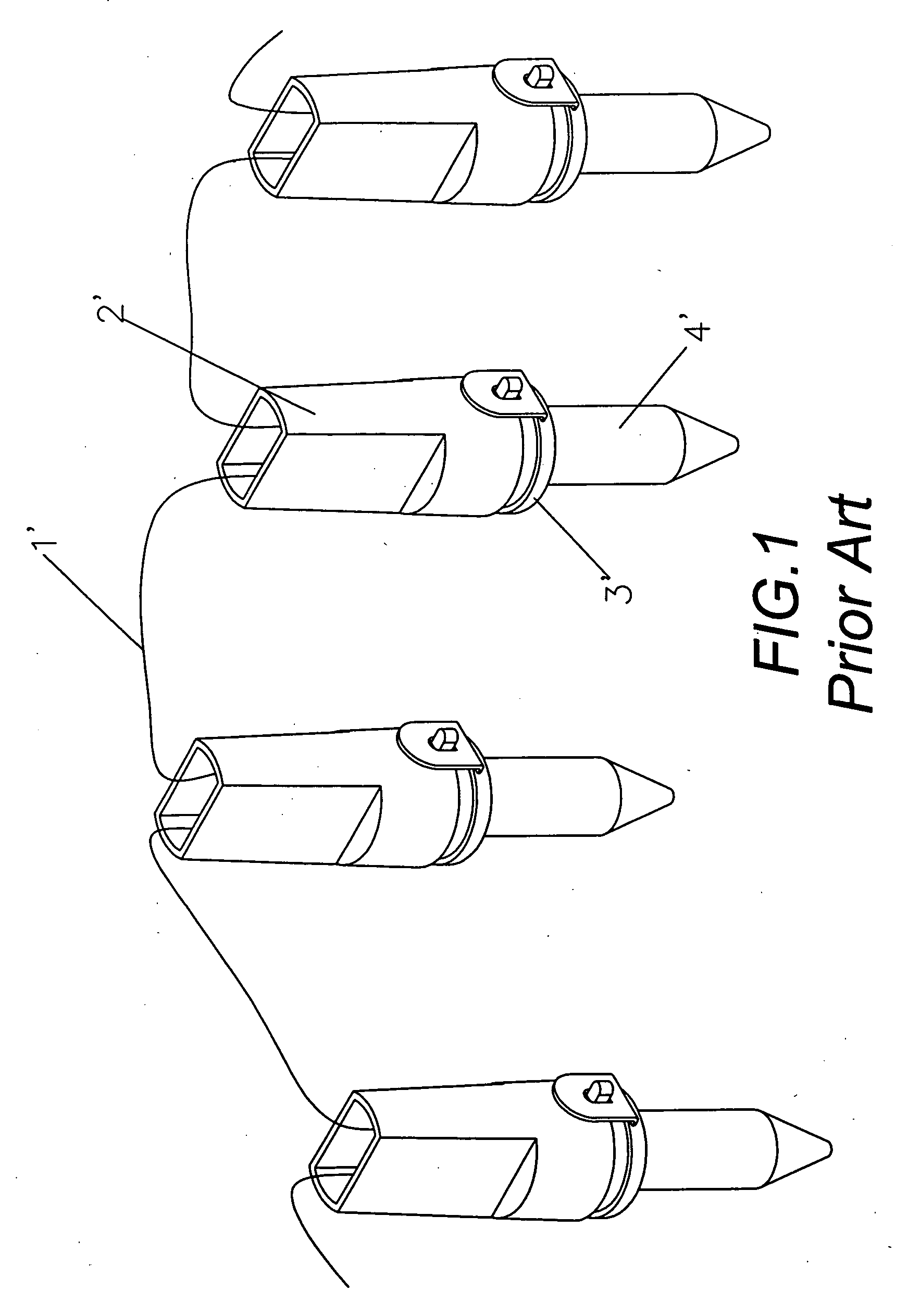

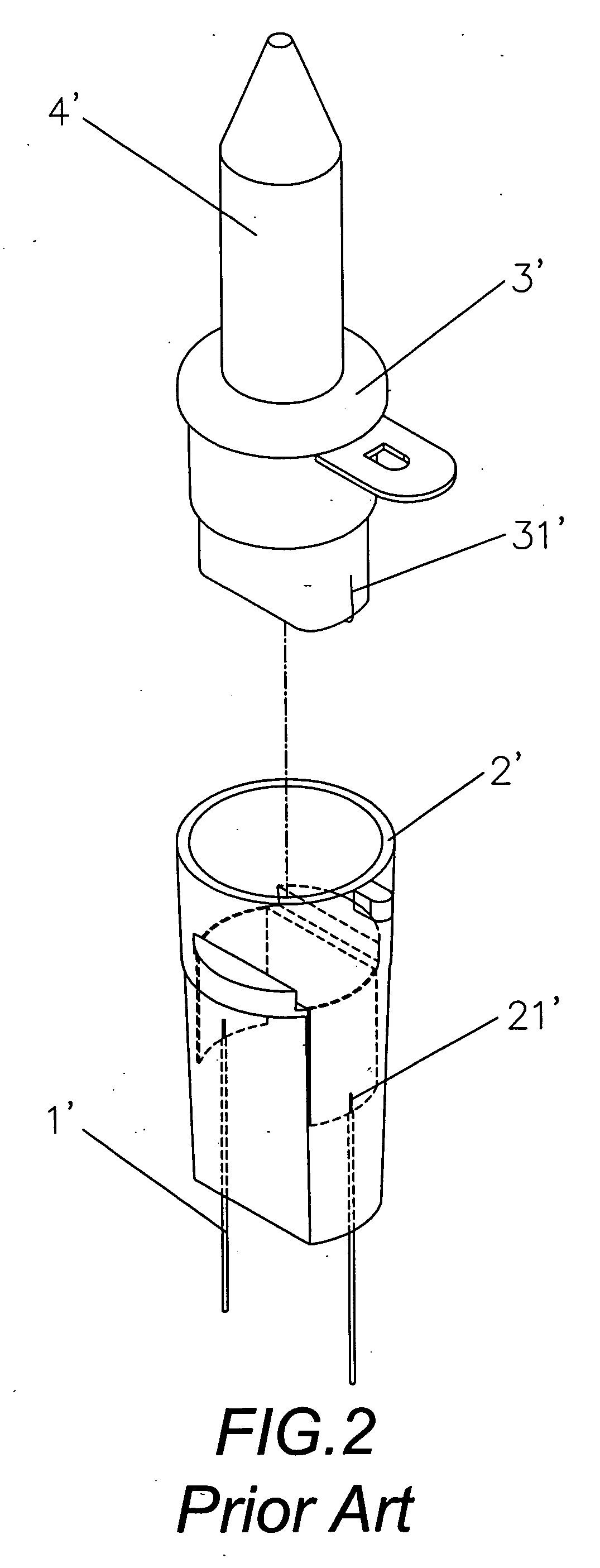

Adapters for double-locking casing mandrel and method of using same

InactiveUS7040410B2Easy procedureImprove work safetyDrilling rodsFluid removalWell stimulationEngineering

Adapters for connecting to a double-locking casing mandrel of an independent screwed wellhead include a lockdown flange with an adapter pin, and a retainer flange that may be used with or without the adapter pin. The retainer flange has a top surface with circumferentially-spaced threaded bores that permit well stimulation equipment to be mounted thereto. The retainer flange threadedly connects to a pin thread at a top of the casing mandrel, and therefore provides a low profile mounting flange for well stimulation equipment.

Owner:OIL STATES ENERGY SERVICES +1

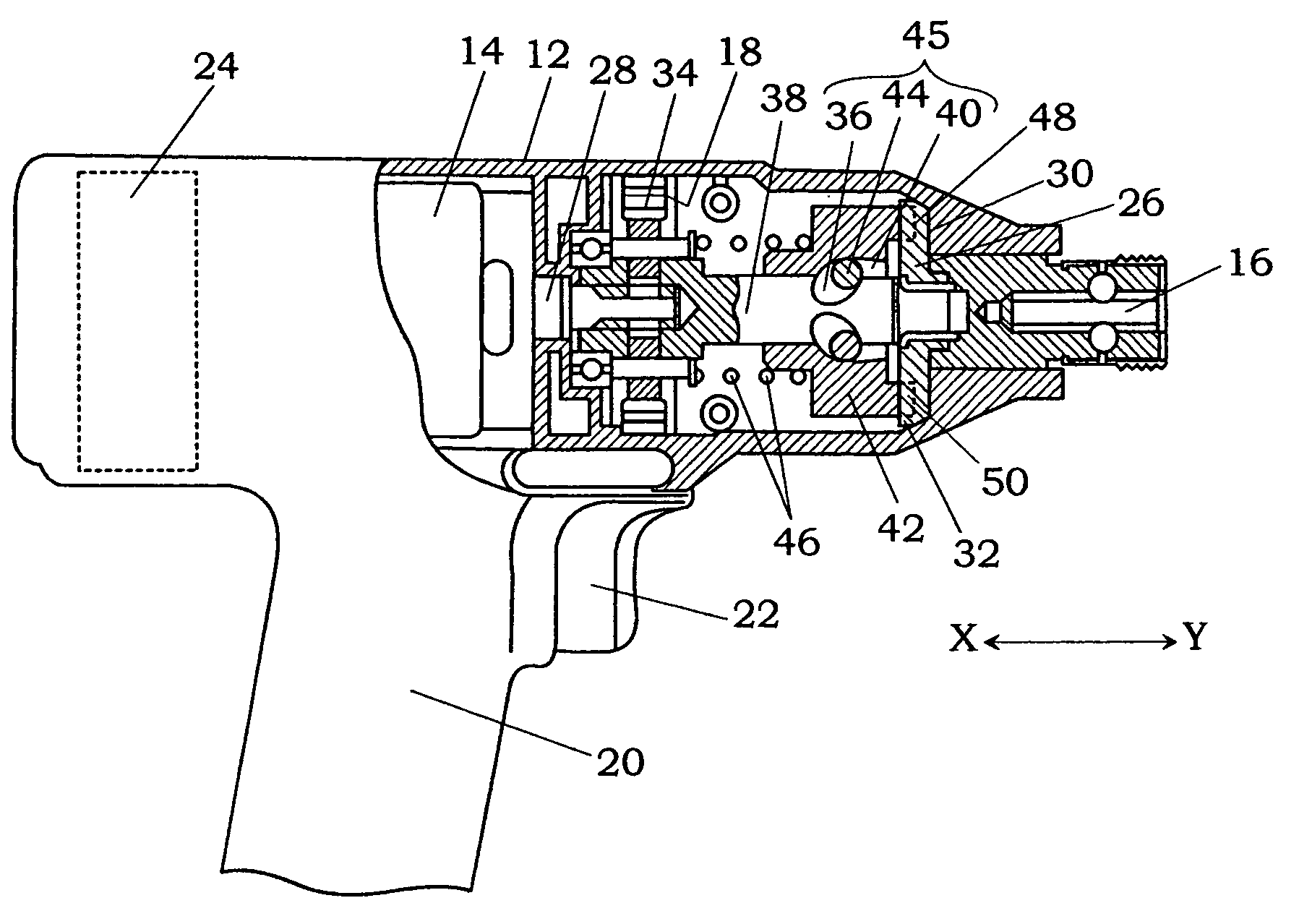

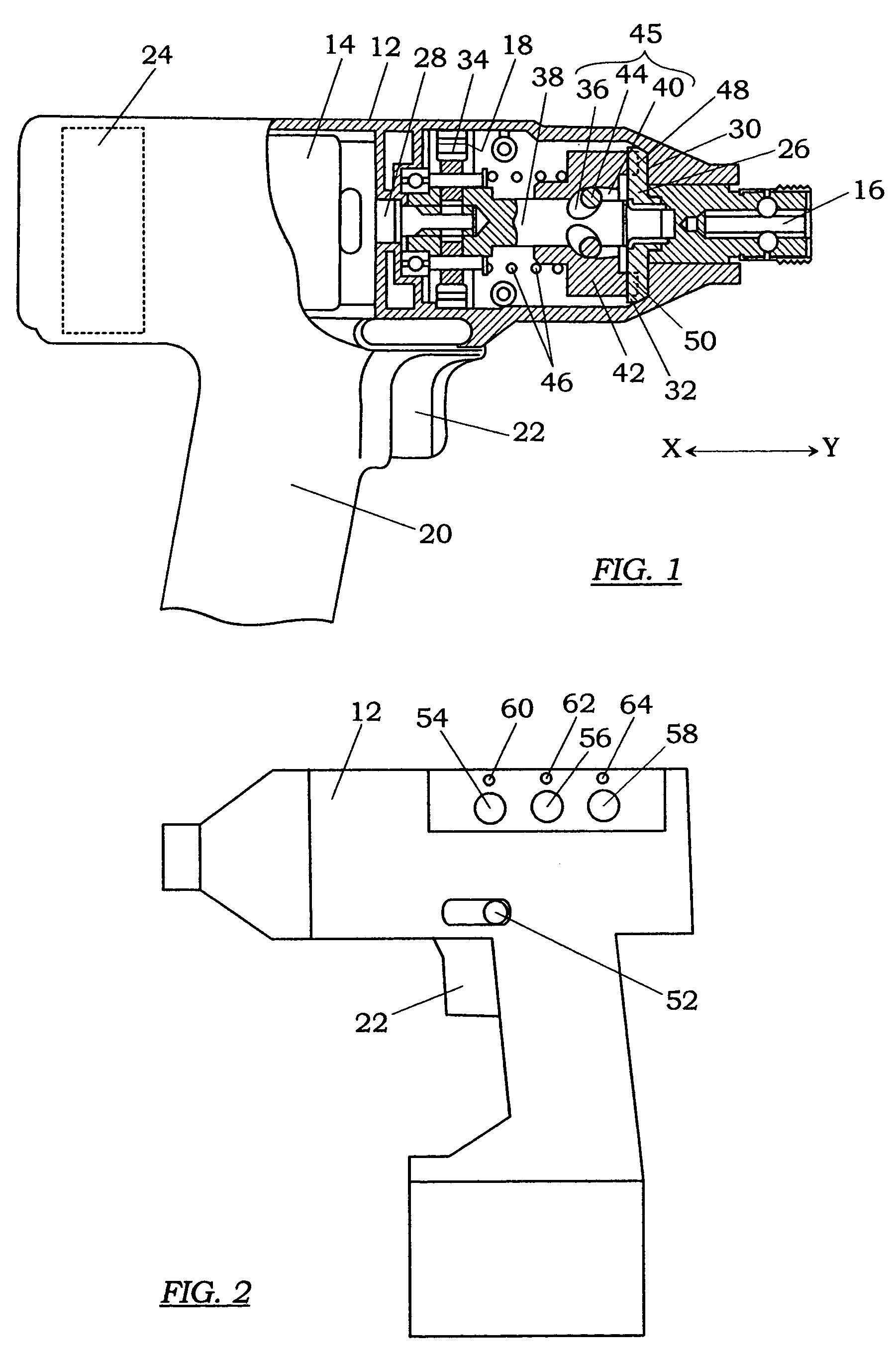

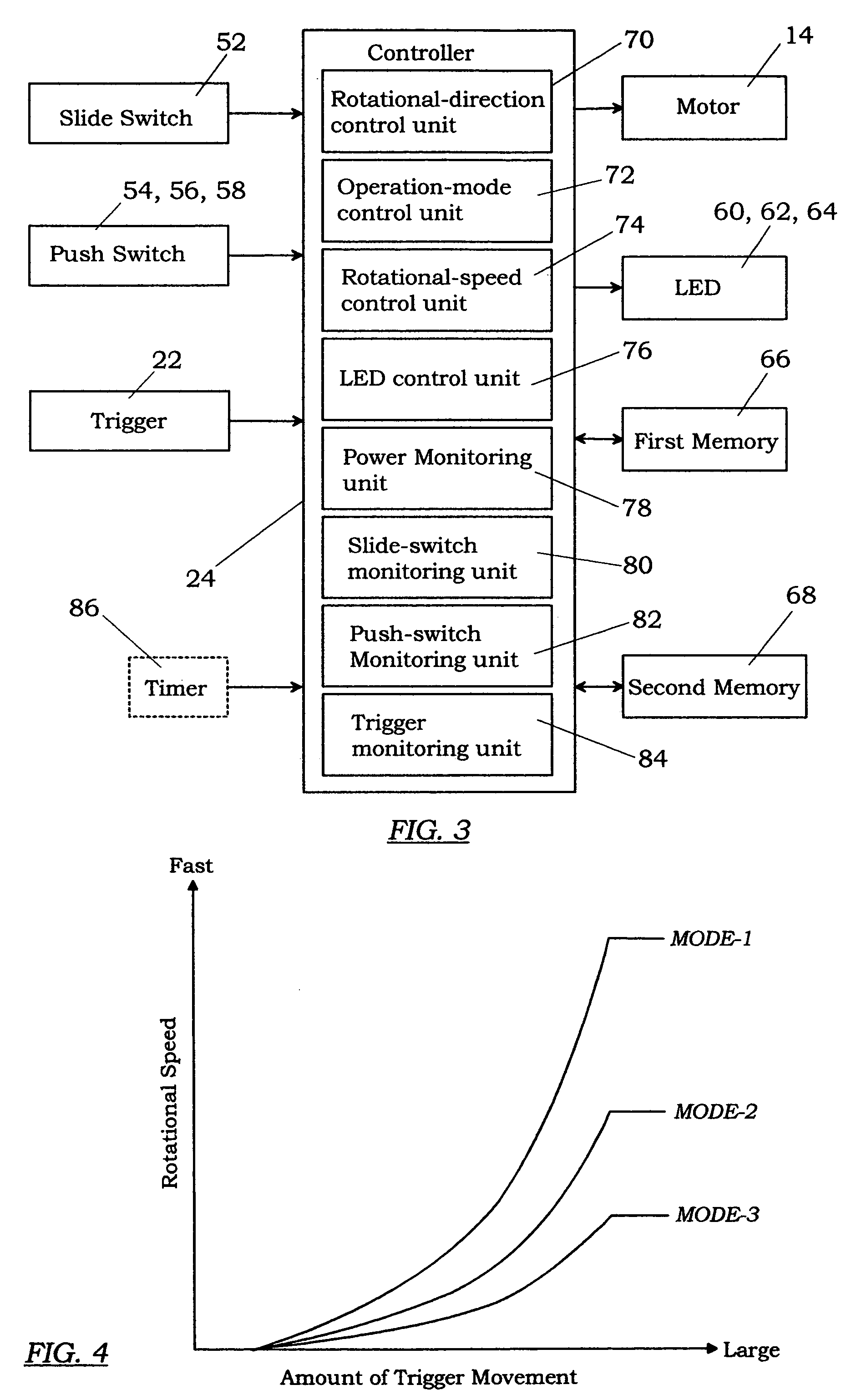

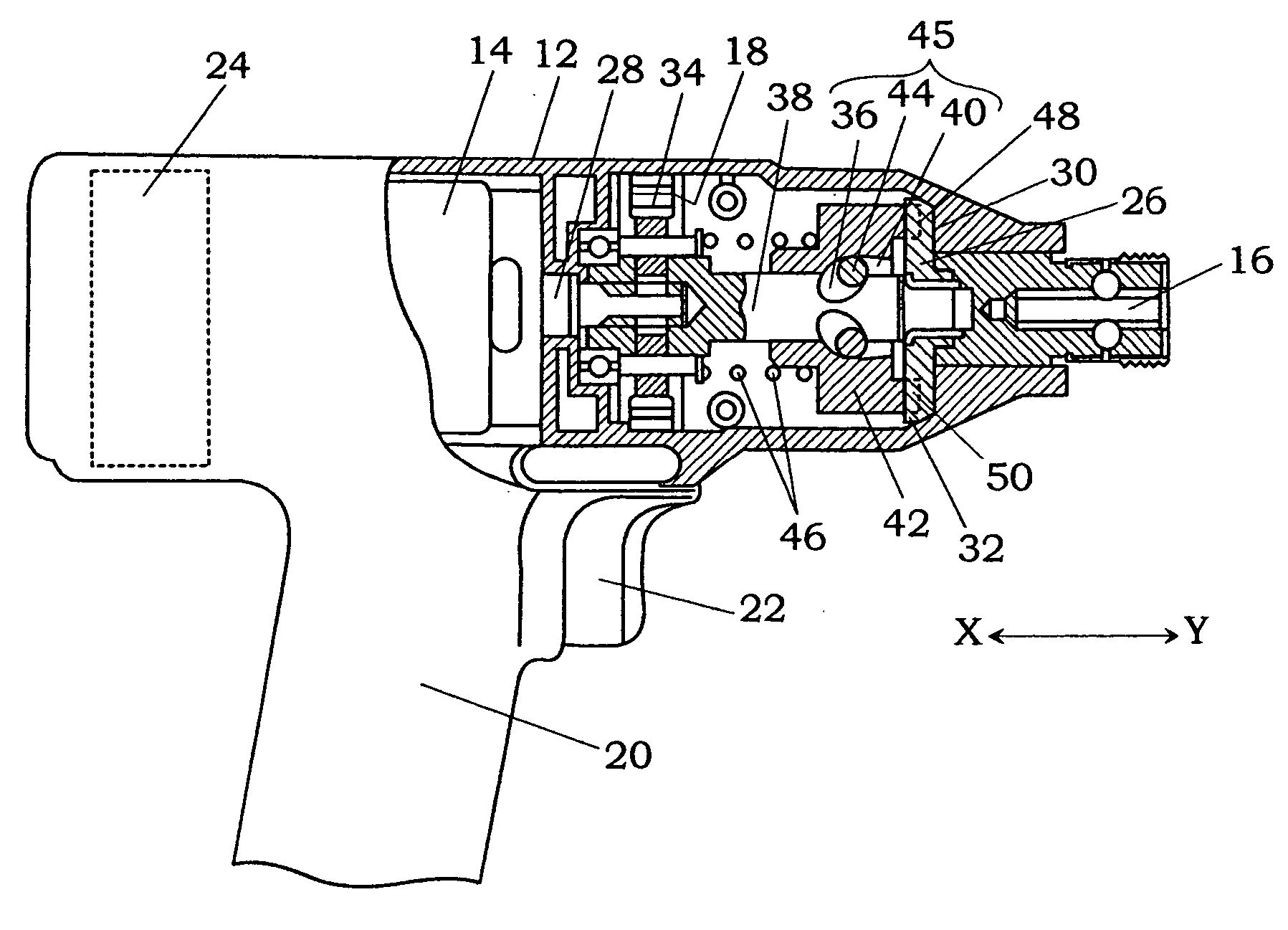

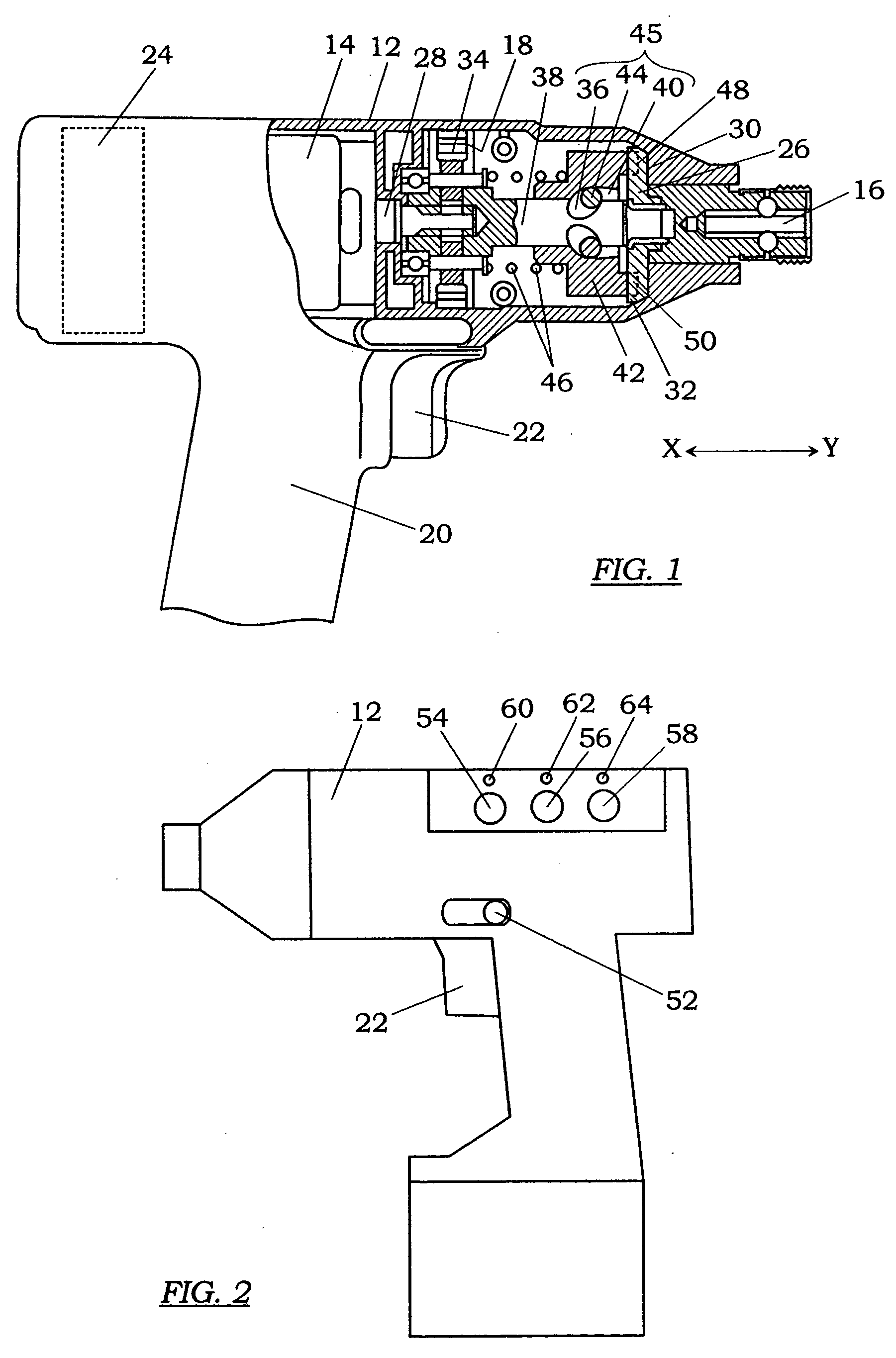

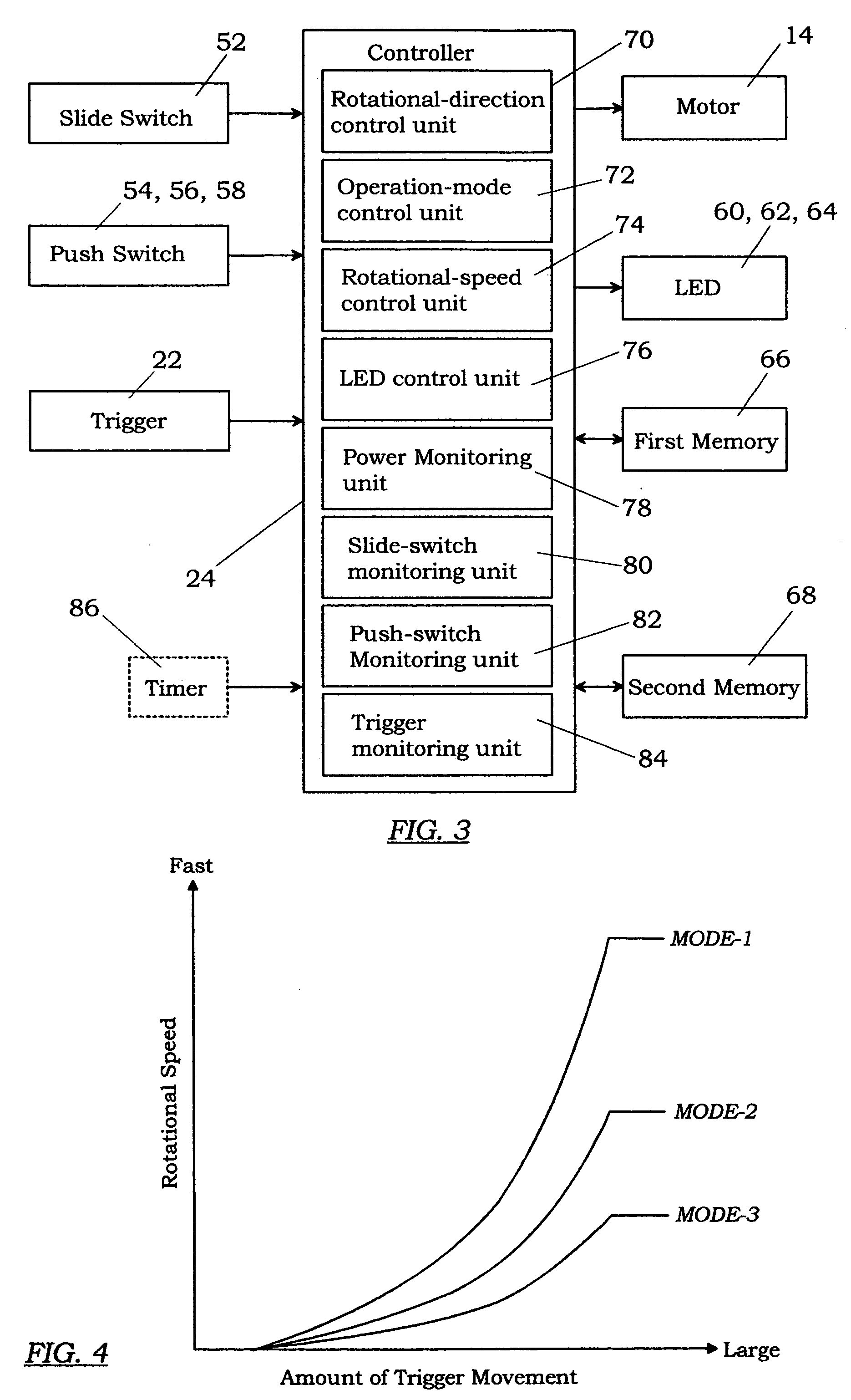

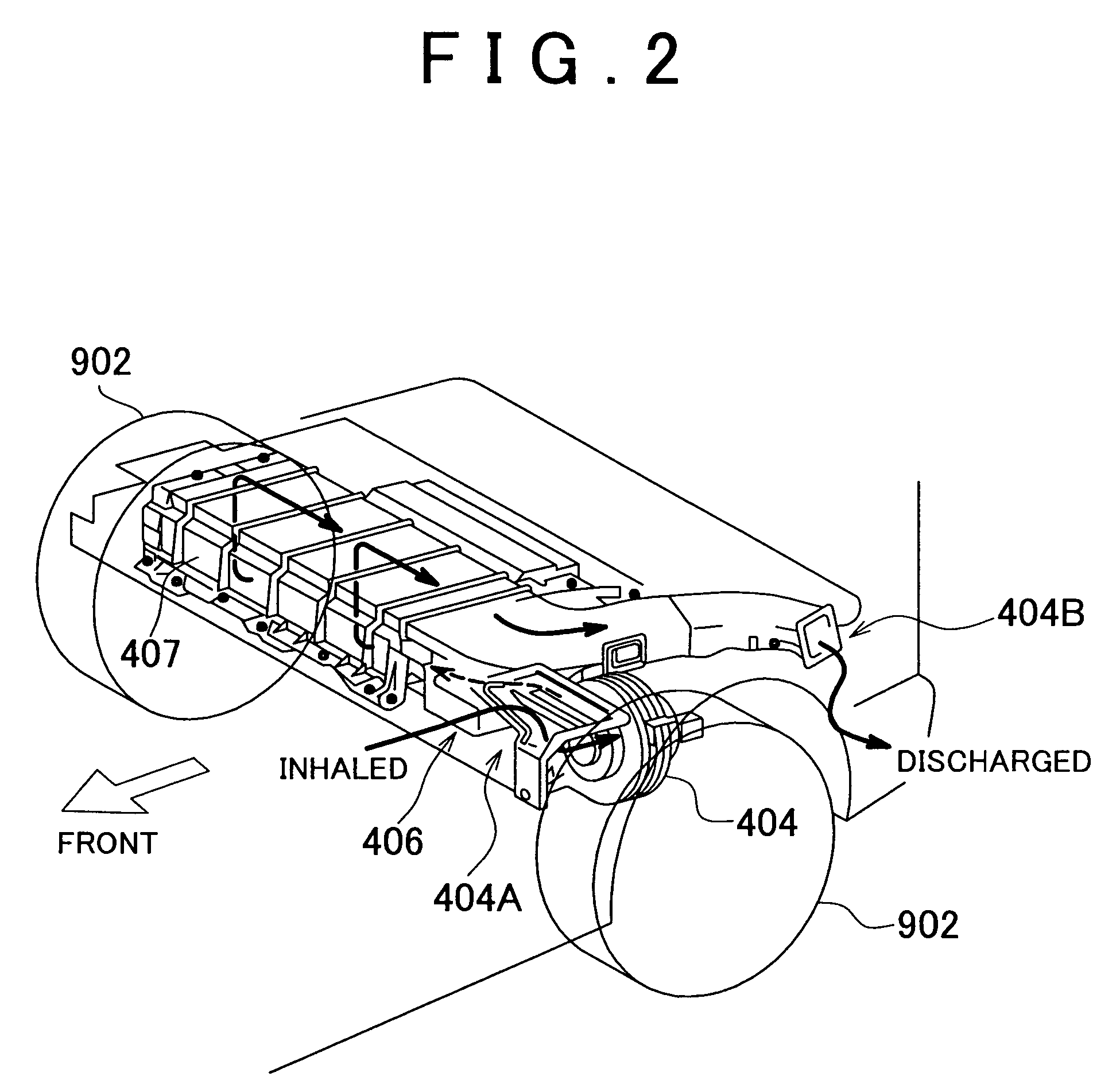

Electric tool

InactiveUS7086483B2Efficient executionImprove work safetyDrilling rodsConstructionsEngineeringOperation mode

An electric tool having the capability of achieving a high working efficiency is provided. This tool comprises an output shaft rotated by reversible motor, a rotational-direction switch for switching a rotational direction of the output shaft in either forward or reverse direction, first memory for storing a plurality of operation modes of the output shaft with respect to one of the forward and reverse directions, operation-mode switch for selecting one from the operation modes, second memory for temporarily storing an operation mode selected by the operation-mode switch in a use of the electric tool at the one of the forward and reverse directions; and a controller for automatically setting the electric tool in the operation mode stored in the second memory in the next use of the electric tool at the one of the forward and reverse directions.

Owner:MATSUSHITA ELECTRIC WORKS LTD

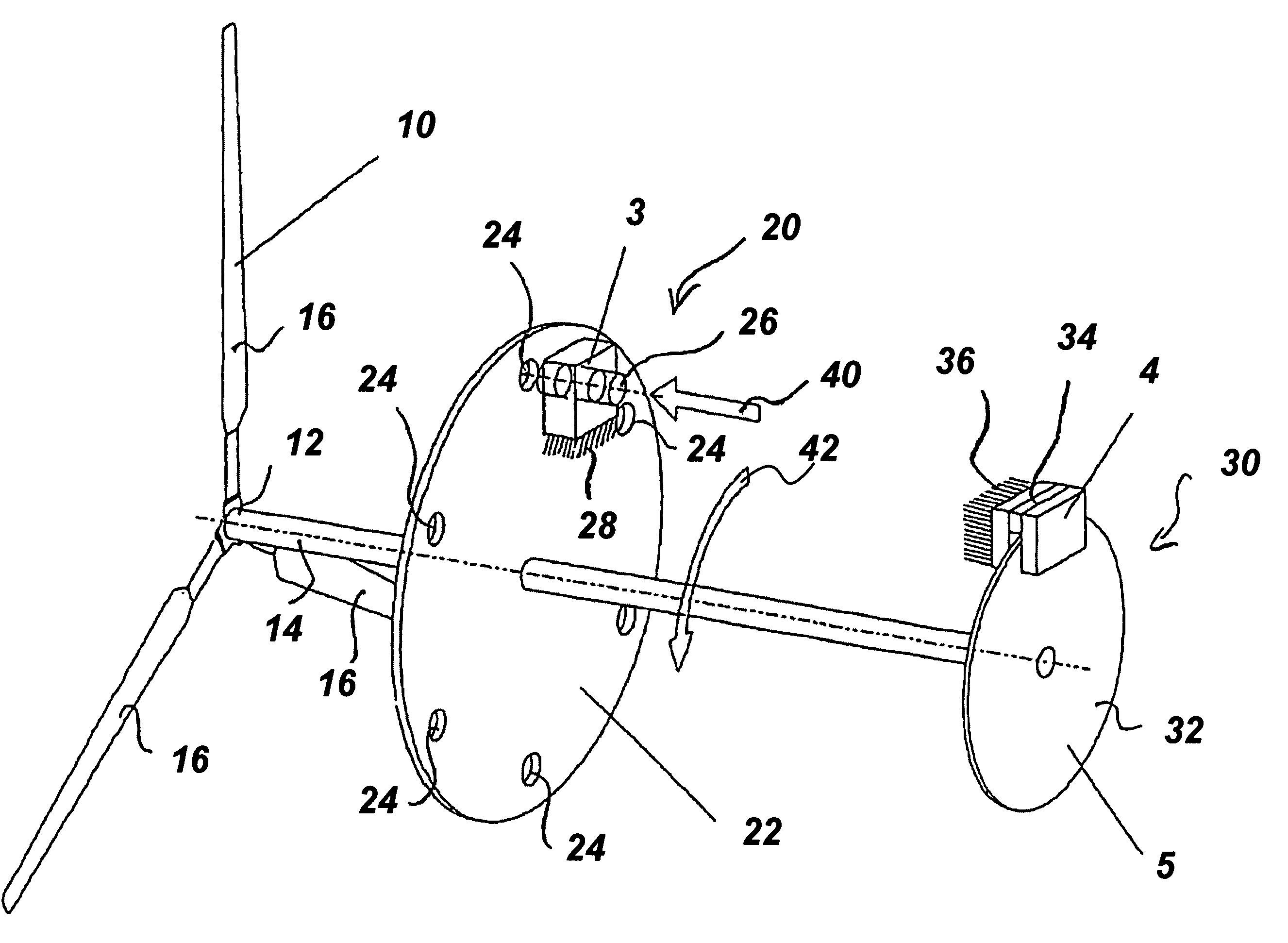

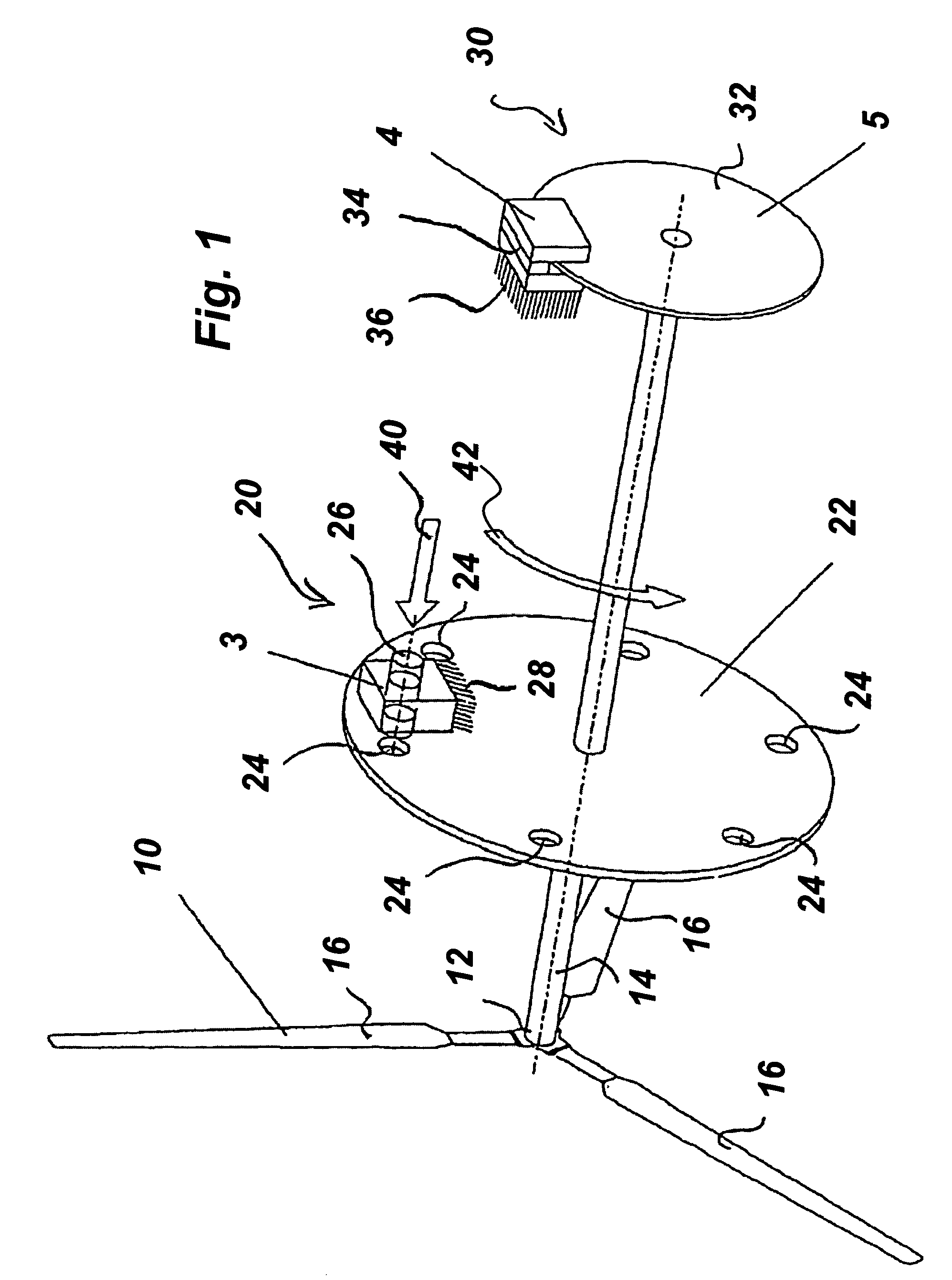

Automatic braking and locking of a wind turbine

InactiveUS7397145B2Reduce riskImprove work safetyWind motor controlEngine fuctionsRotational axisAutomatic braking

A wind turbine rotor is decelerated and locked in a target rotational position in relation to rotation of the rotor about the rotor axis. The rotational position of the rotor in relation to the rotational axis is detected relative to at least one target rotational position. Once the rotor reaches one of the target rotational positions, the rotor is halted and automatically locked in the target rotational position.

Owner:S B PATENT HLDG

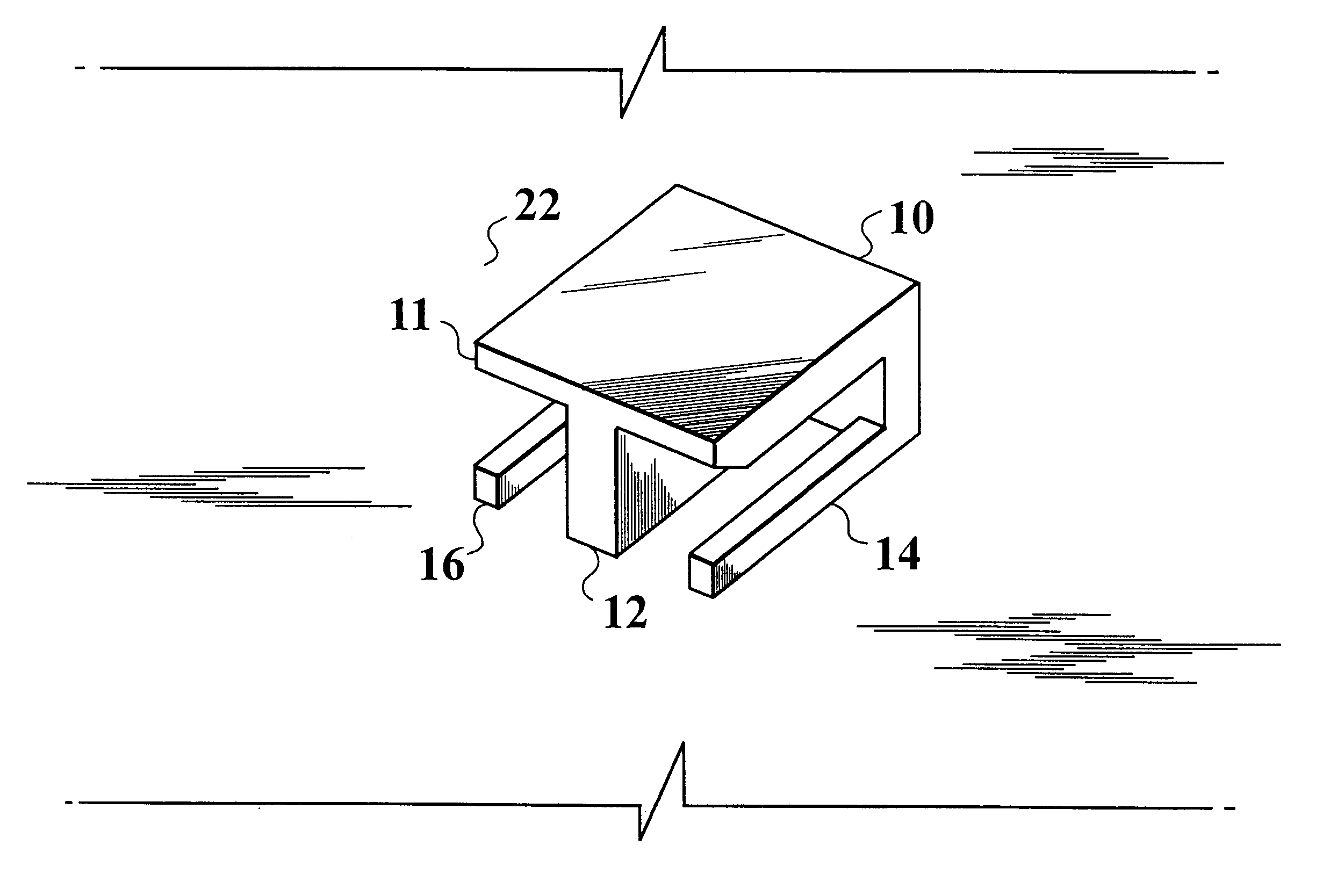

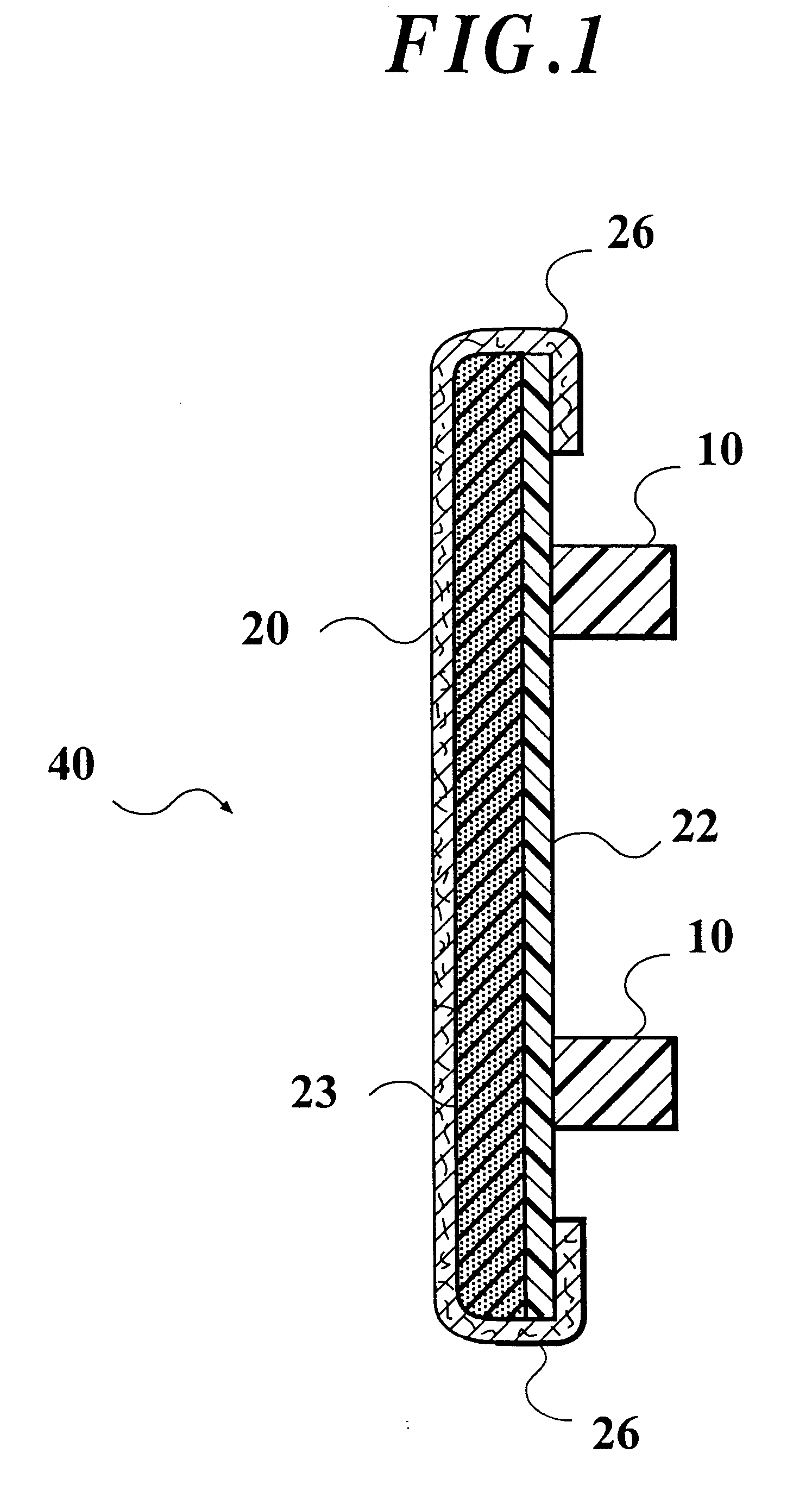

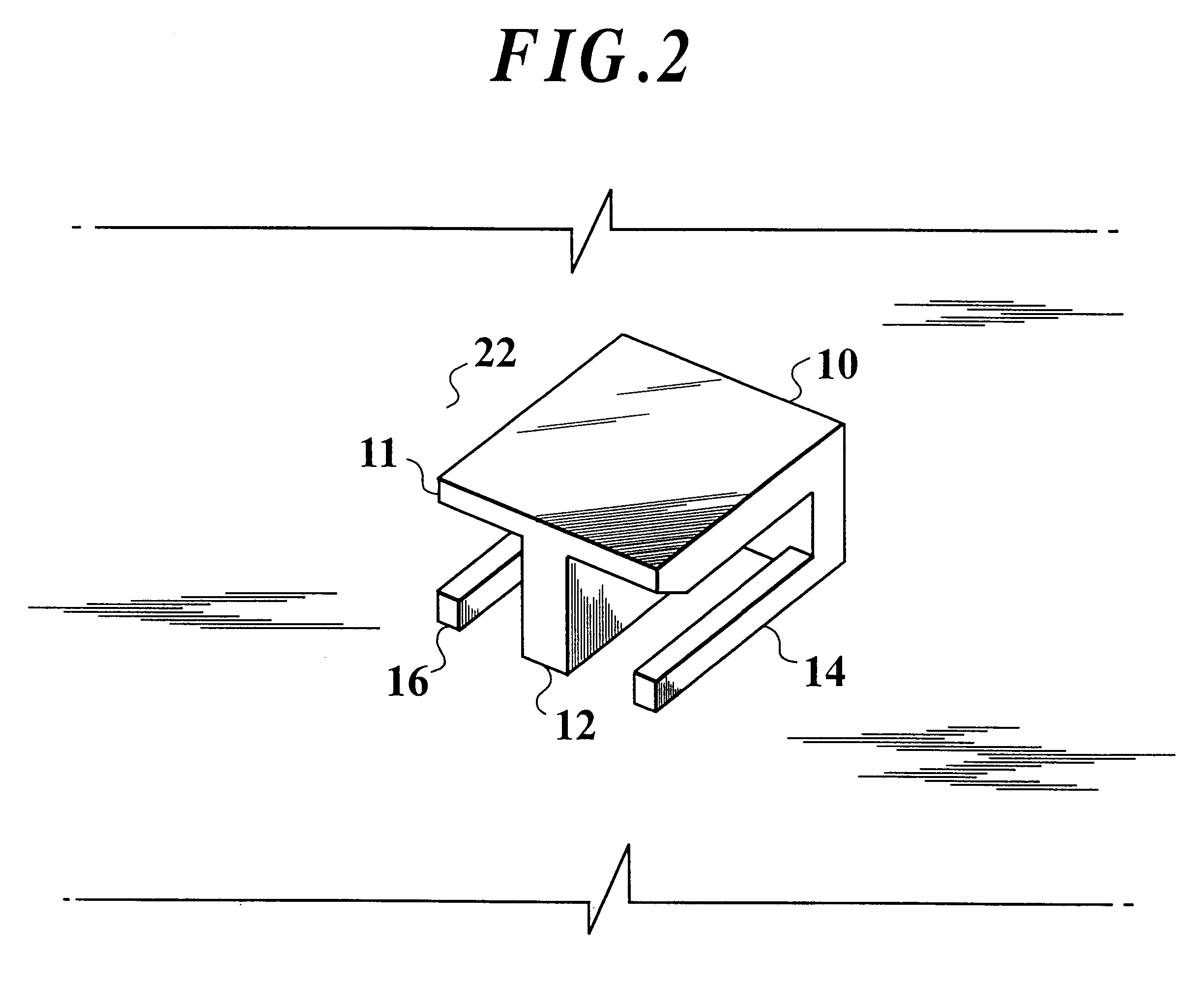

Trim assembly for vehicle

InactiveUS6308488B1High strengthAvoid it happening againConstruction materialLayered productsCushionEngineering

A mounting structure formed on a plate-like member and for mounting the plate-like member to a trim panel for a vehicle, the mounting structure comprises an approximately T-like shape in cross section. A trim assembly for a vehicle comprises: a plate-like member; a cushion member disposed on the plate-like member; and a top cover covering the whole cushion member, wherein peripheral portions of which are secured to peripheral portions of the plate-like member; wherein a mounting structure comprising an approximately T-like shape in cross section, for mounting the trim assembly to a trim panel for a vehicle is formed on the plate-like member.

Owner:TS TECH CO LTD

Electric tool

InactiveUS20050045354A1Different operationalImprove work safetyDrilling rodsConstructionsOperation modePower tool

An electric tool having the capability of achieving a high working efficiency is provided. This tool comprises an output shaft rotated by reversible motor, a rotational-direction switch for switching a rotational direction of the output shaft in either forward or reverse direction, first memory for storing a plurality of operation modes of the output shaft with respect to one of the forward and reverse directions, operation-mode switch for selecting one from the operation modes, second memory for temporarily storing an operation mode selected by the operation-mode switch in a use of the electric tool at the one of the forward and reverse directions; and a controller for automatically setting the electric tool in the operation mode stored in the second memory in the next use of the electric tool at the one of the forward and reverse directions.

Owner:MATSUSHITA ELECTRIC WORKS LTD

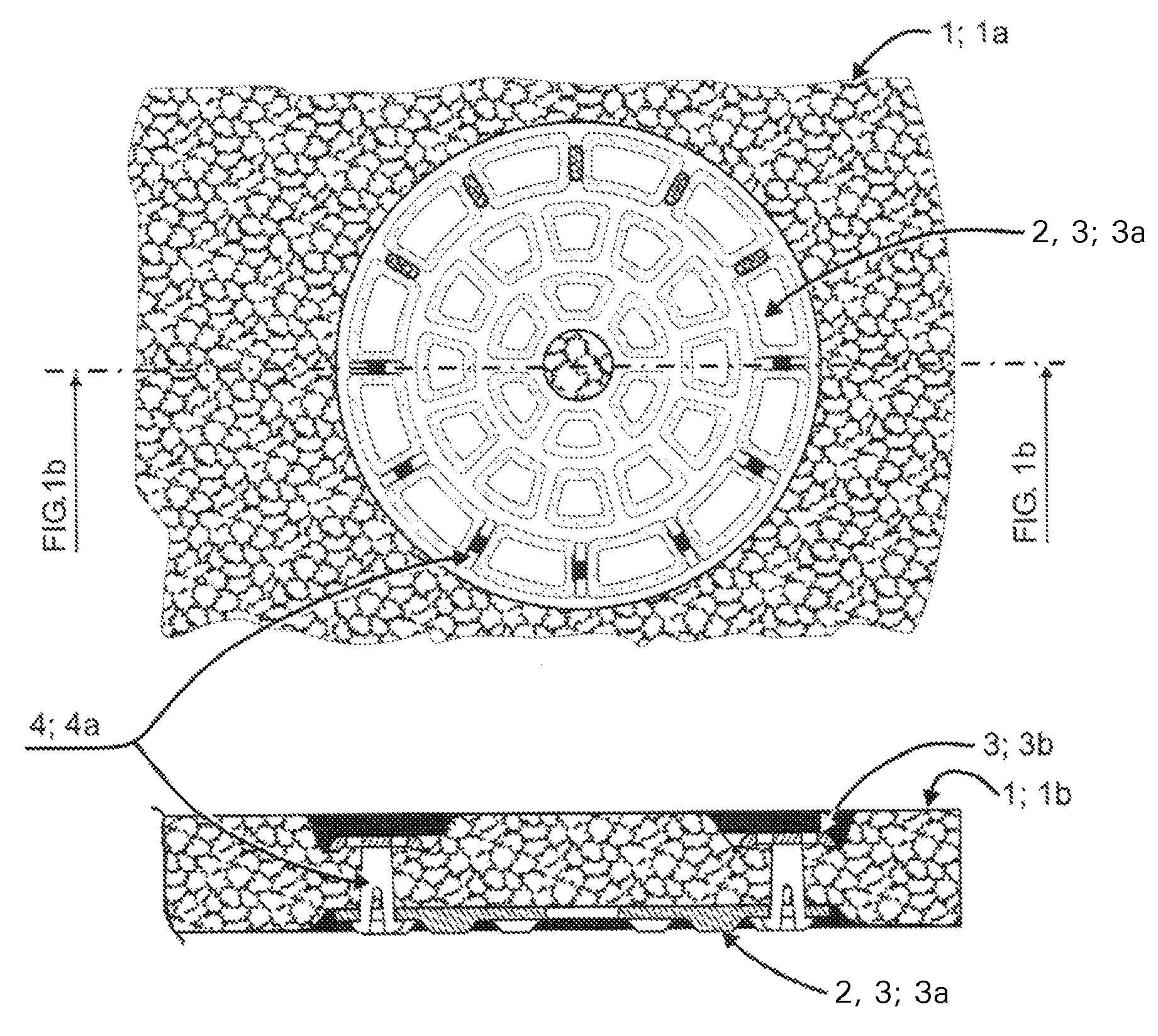

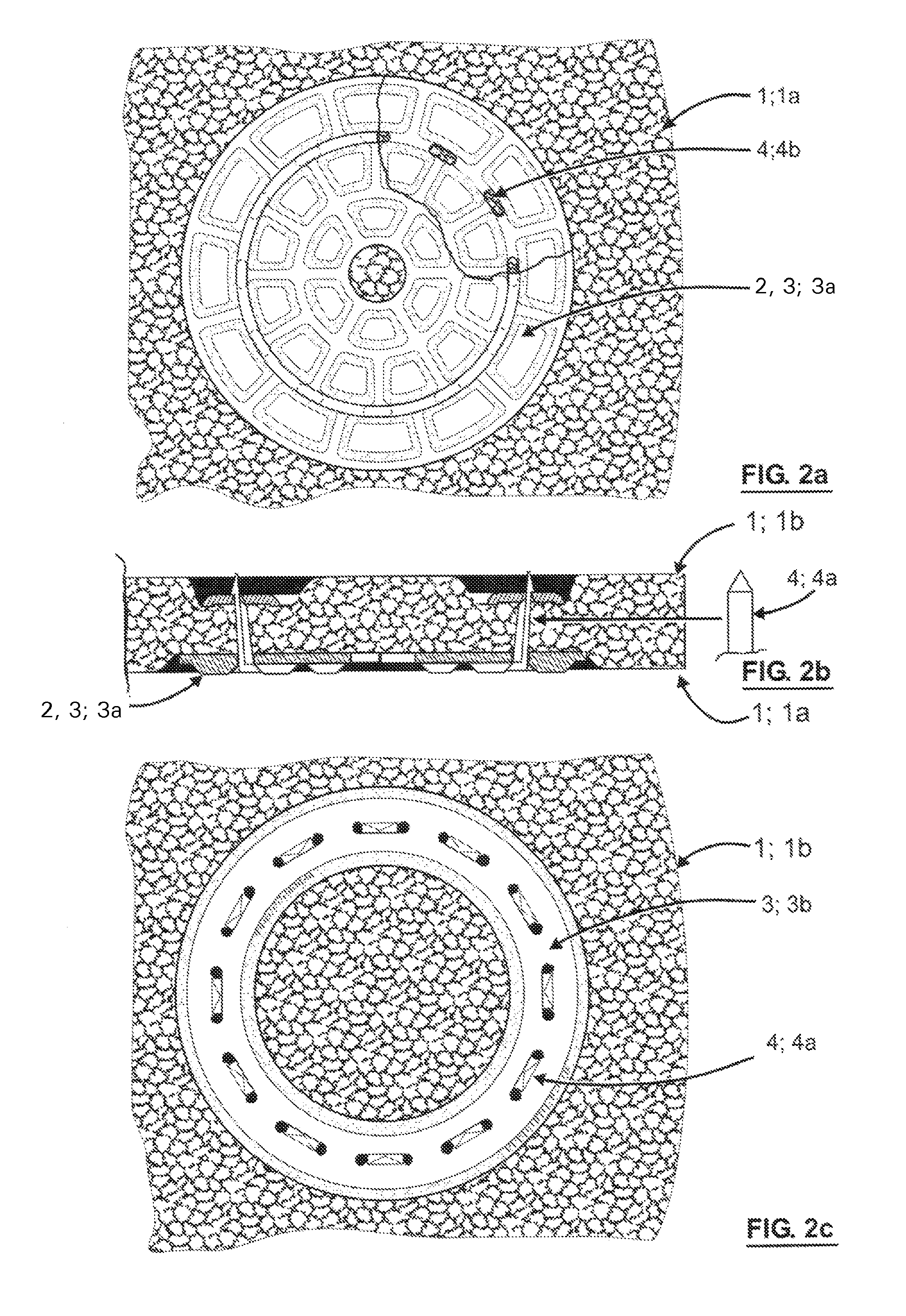

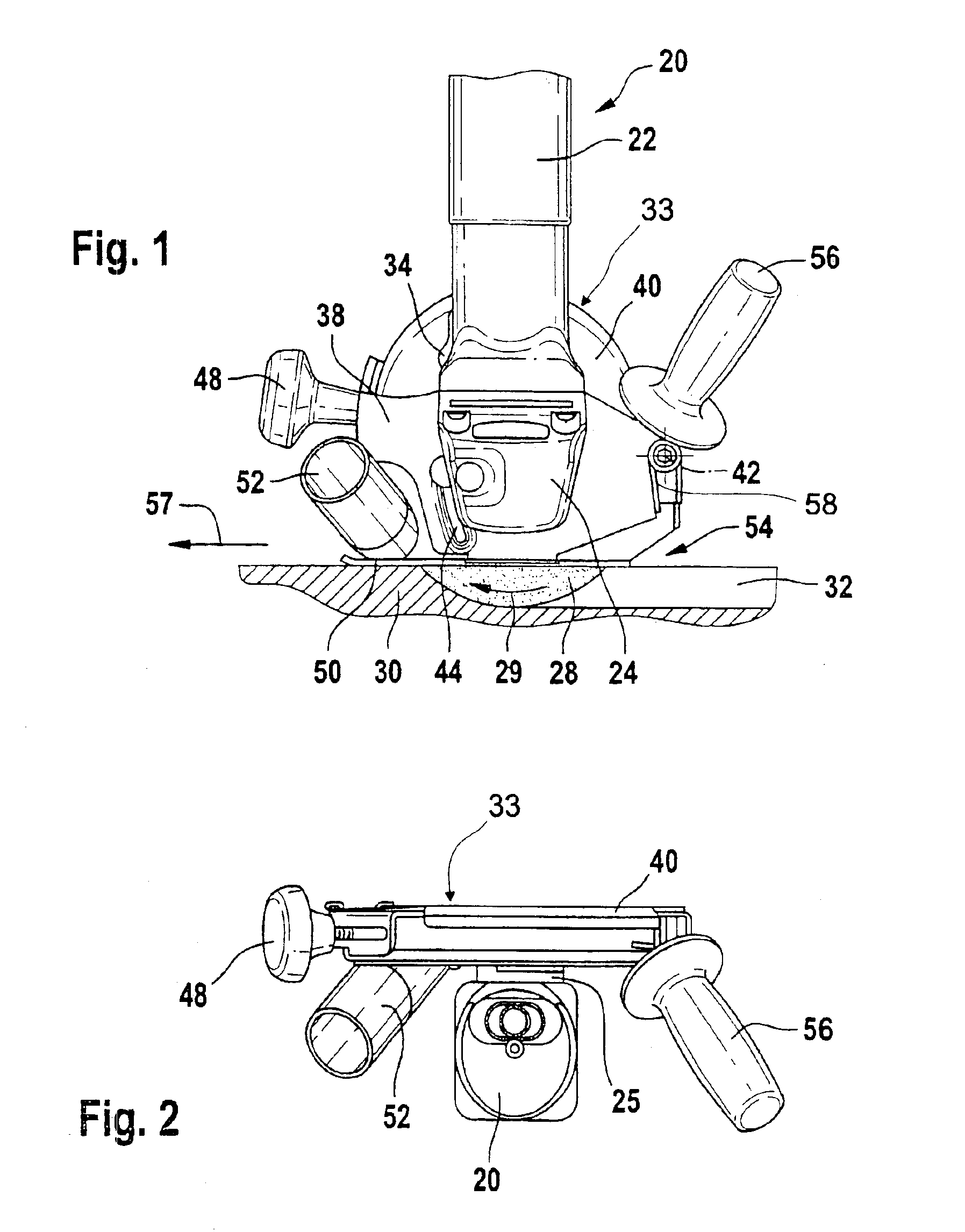

Arrangement for floor grinding

ActiveUS9174326B2Simple and efficient structureRapid and reliable mannerCarpet cleanersFloor cleanersEngineeringBase function

An arrangement for floor grinding with a floor conditioning device. A tool instrument is used in the floor conditioning device by rotating the floor conditioning device. The instrument is an essentially porous washing, polishing, waxing disk for carrying out basic functions of the floor conditioning device. A grinding instrument is removably coupled in connection with the tool instrument. A fastener couples the grinding instrument with the tool instrument by a fastening frame supported on a front surface of the tool instrument and by an auxiliary frame supported on a back surface of the tool instrument.

Owner:AHONEN MIKA

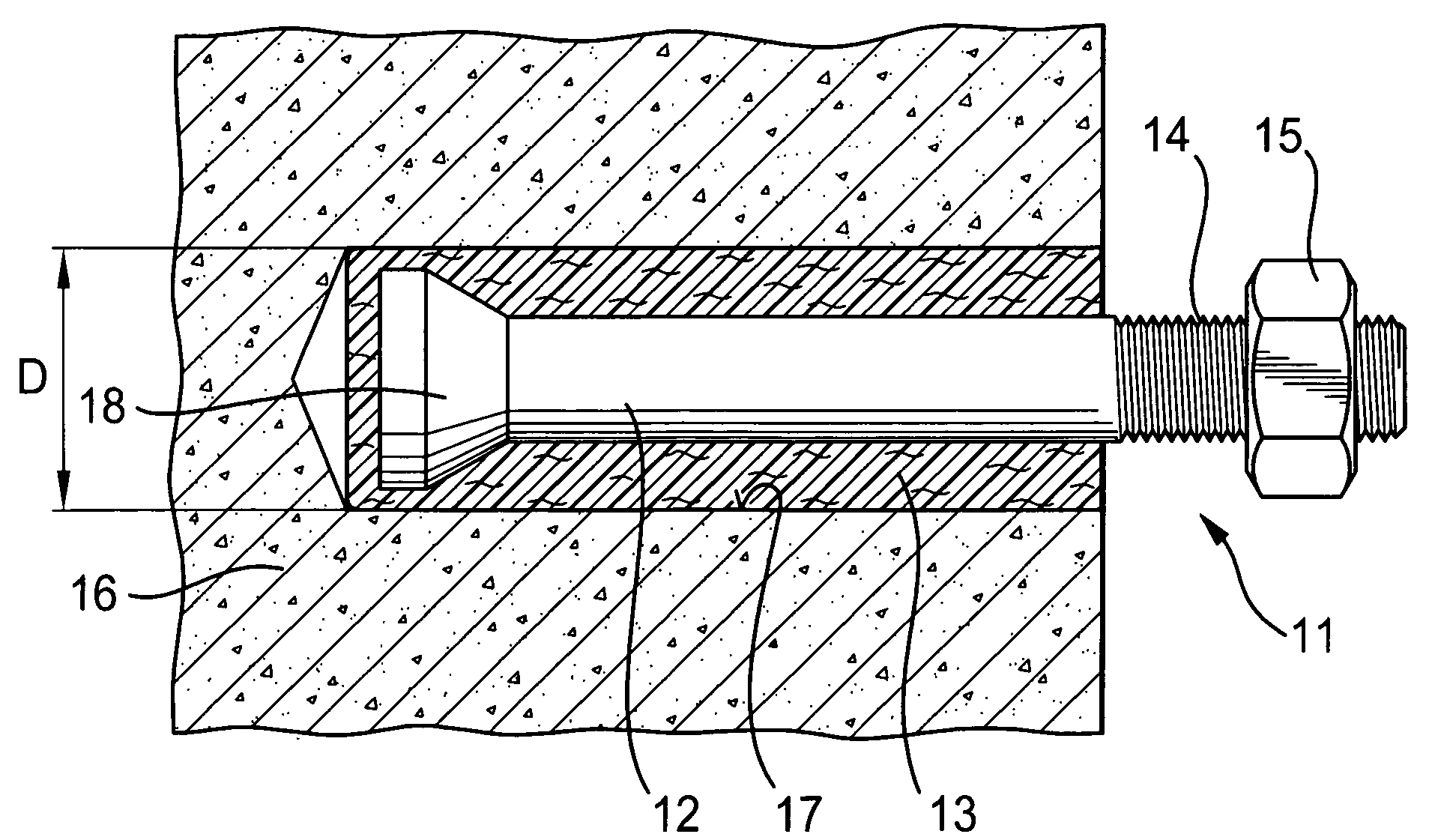

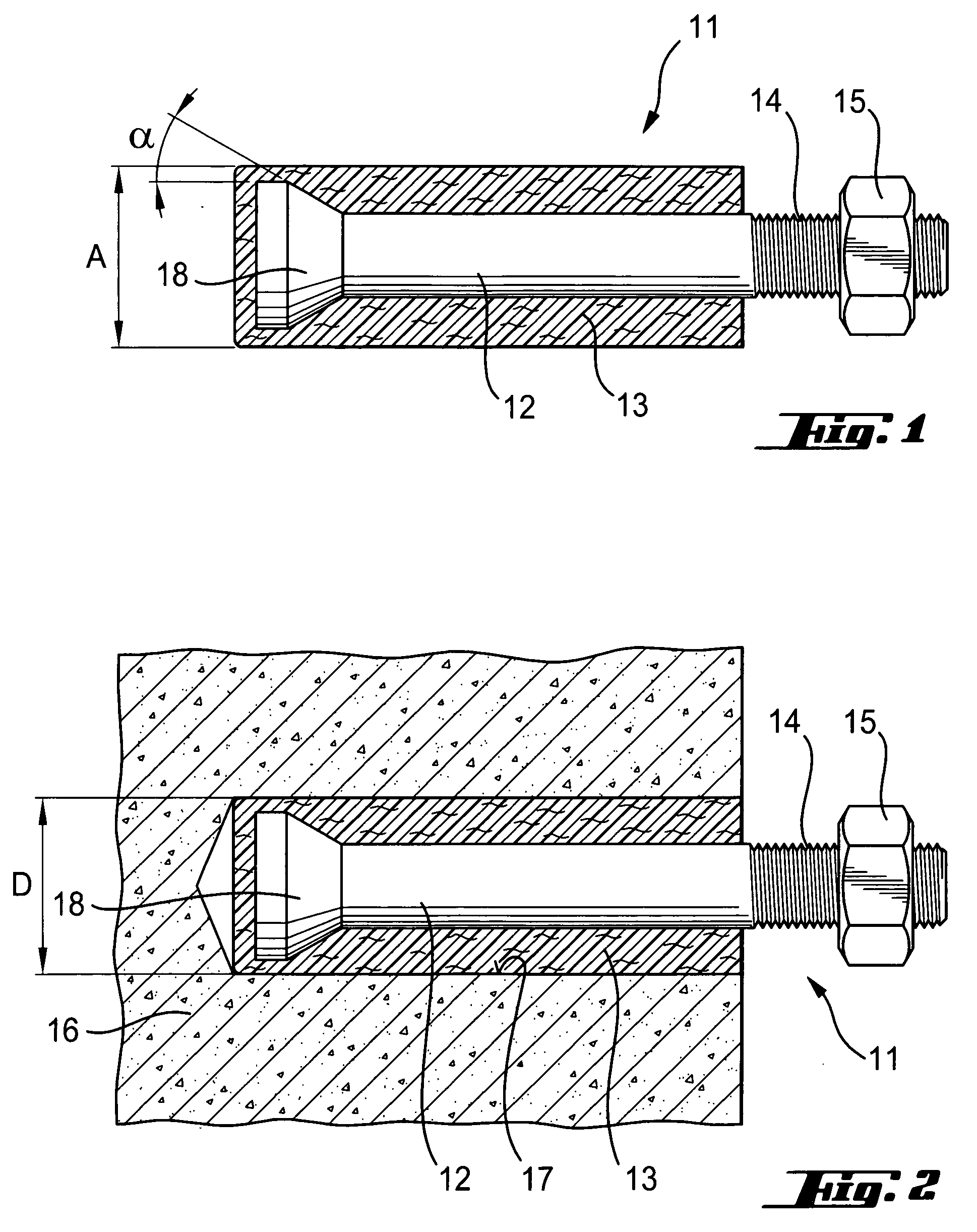

Anchor element

An anchor element (11) has an anchor part (12), a sleeve part (13), and an expansion part (18) for expanding the sleeve part (13). The sleeve part (13) is secured to the anchor part (12) and is made of a thermoplastic.

Owner:HILTI AG

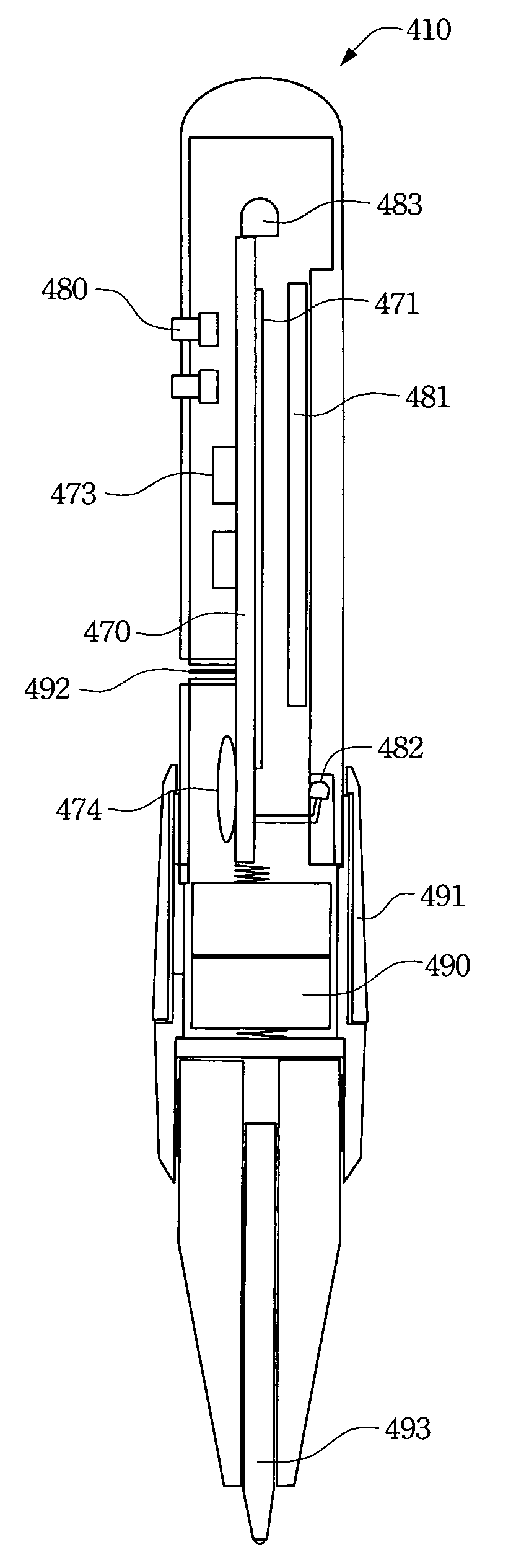

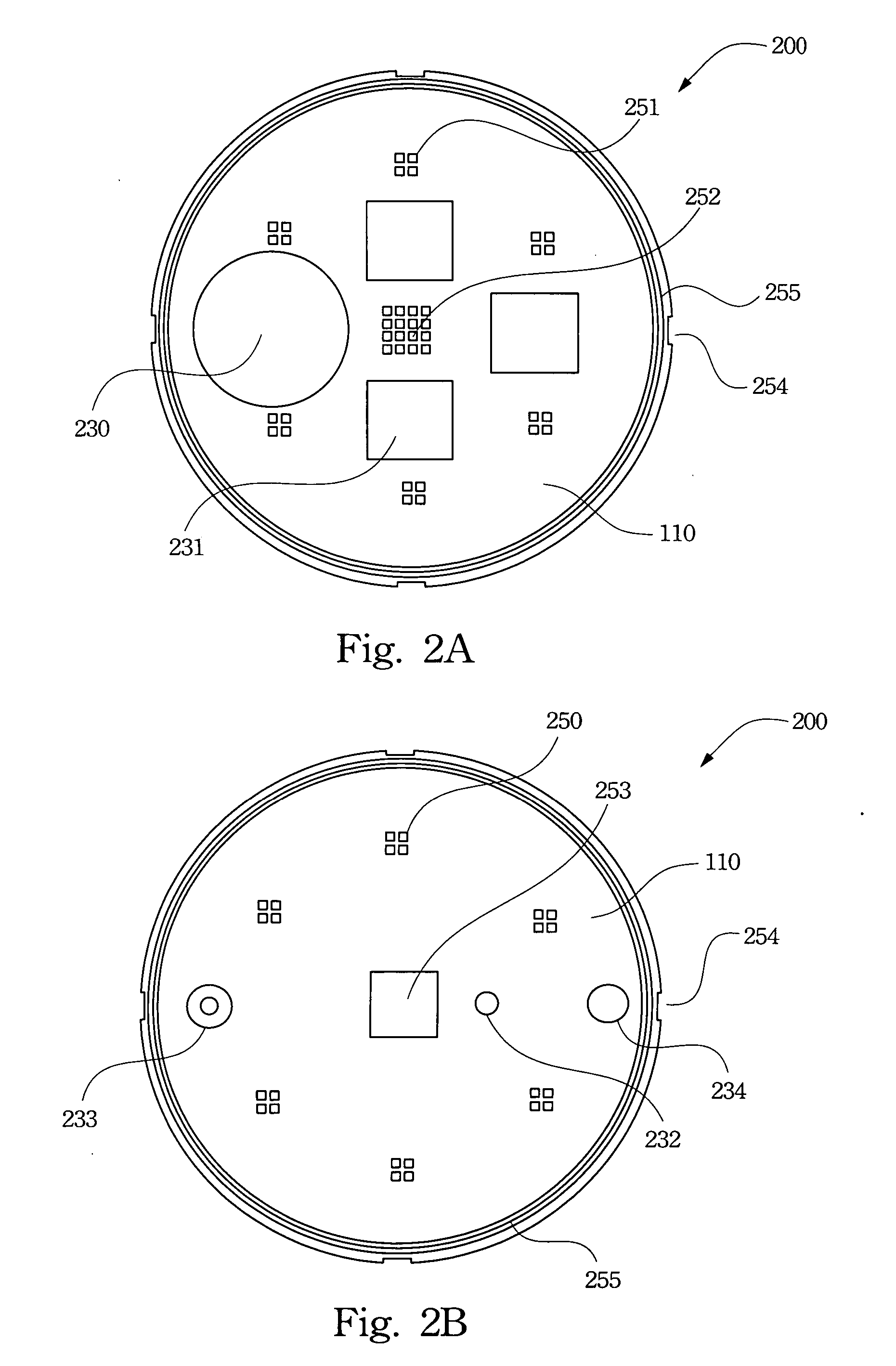

Multi-function wireless detecting device

InactiveUS20070063858A1Improve signal receptionEnhancing emitting capabilityFire alarm smoke/gas actuationAlcoholEngineering

A multi-function wireless detecting device is described. The multi-function wireless detecting device includes a monitoring pen and a wireless detector module to be carried conveniently and controlled easily. The wireless detector module includes at least one environmental parameter detector, and the monitoring pen utilizes wireless technology to control the wireless detector module and displays the data measured by the wireless detector module. The environmental parameter detector preferably includes a temperature detector and a gas concentration detector disposed on both sides of a baseboard of the wireless detector module. The gas concentration detector further includes an alcohol concentration detector, a CO concentration detector, a CO2 concentration detector, a fuel gas concentration detector, or a combination thereof. The environmental parameter detector may further include a humidity detector.

Owner:UNIMEMS MFG

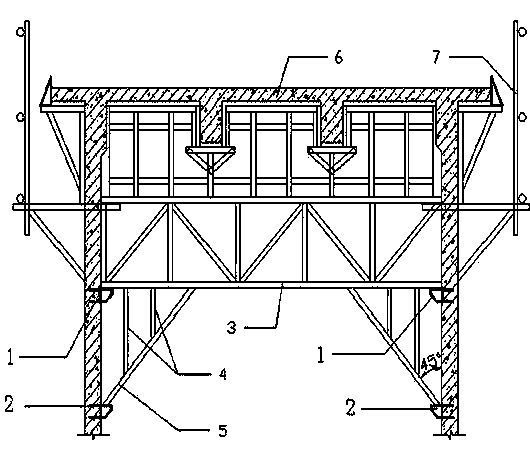

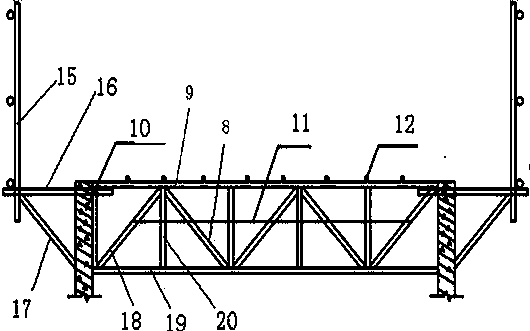

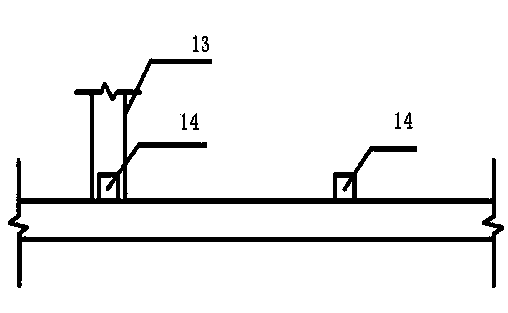

Construction method with silo sliding formwork operating platform as top cover plate formwork supporting system

ActiveCN103556823AReduce support workloadLow costForms/shuttering/falseworksBuilding material handlingSupporting systemVertical bar

The invention provides a construction method with a silo sliding formwork operating platform as a top cover plate formwork supporting system and belongs to the construction and installation field. The construction method comprises performing designing and checking calculation on the silo sliding formwork operating platform; producing the silo sliding formwork operating platform; embedding steel bracket embedded parts into cylinder wall concrete; embedding hanging rings into the cylinder wall concrete; descending the silo sliding formwork operating platform to the design elevation; welding a steel bracket; installing the silo sliding formwork operating platform; installing formwork vertical bars; installing the formwork system; removing the formwork. According to the construction method with the silo sliding formwork operating platform as the top cover plate formwork supporting system, the labor intensity can be reduced, the construction progress can be accelerated, the construction period can be shortened, and the construction potential risk can be reduced.

Owner:SHANXI ERJIAN GRP

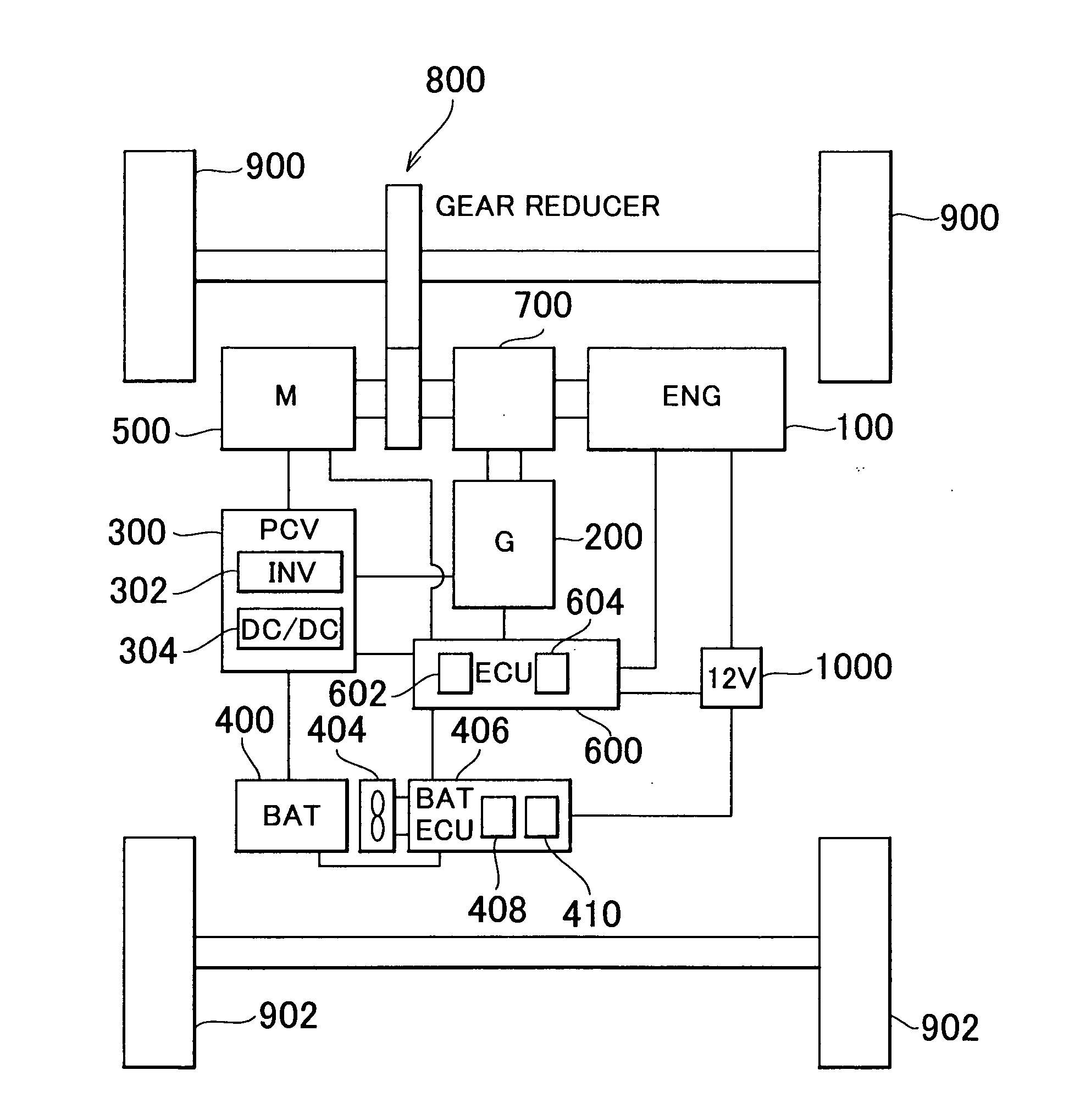

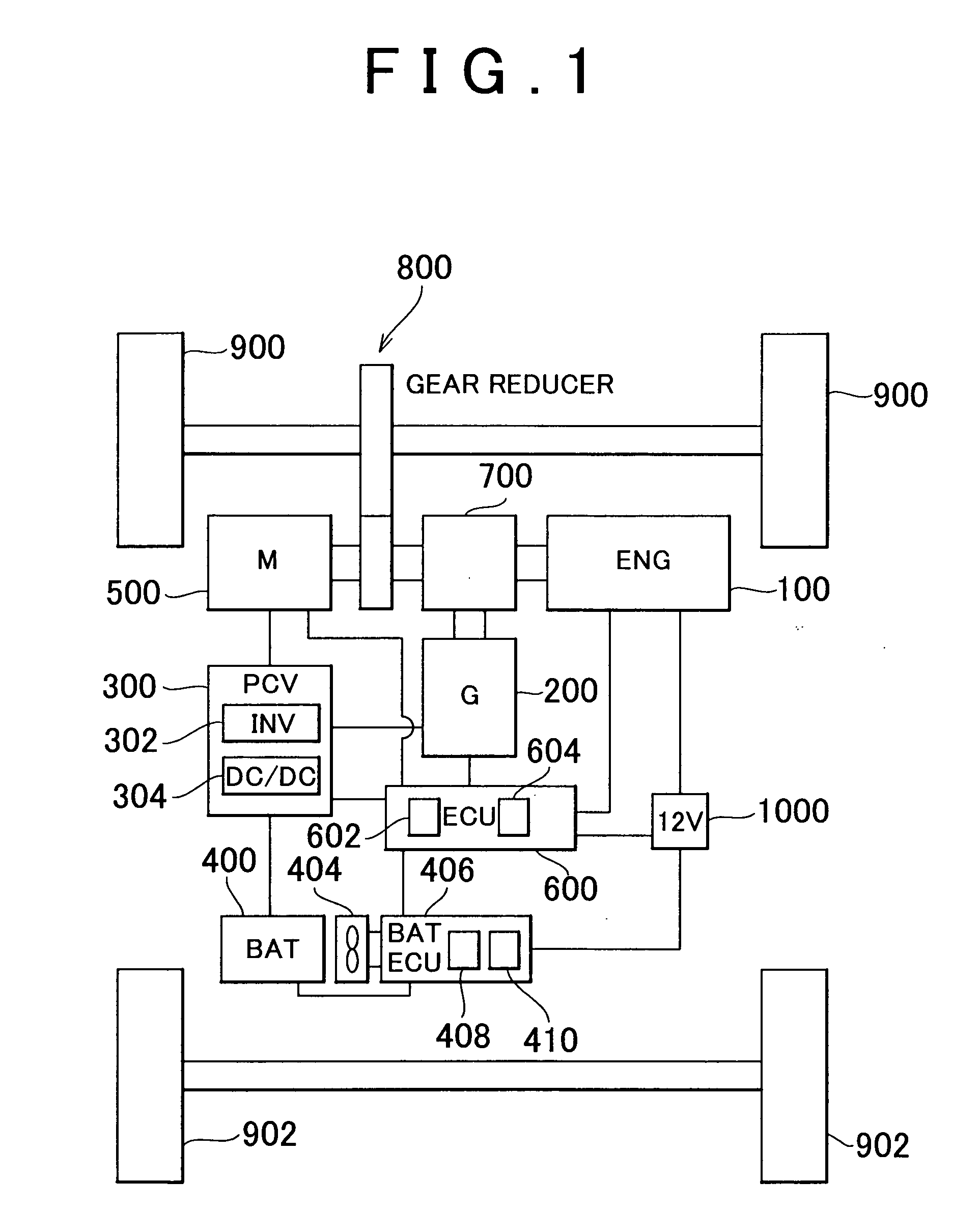

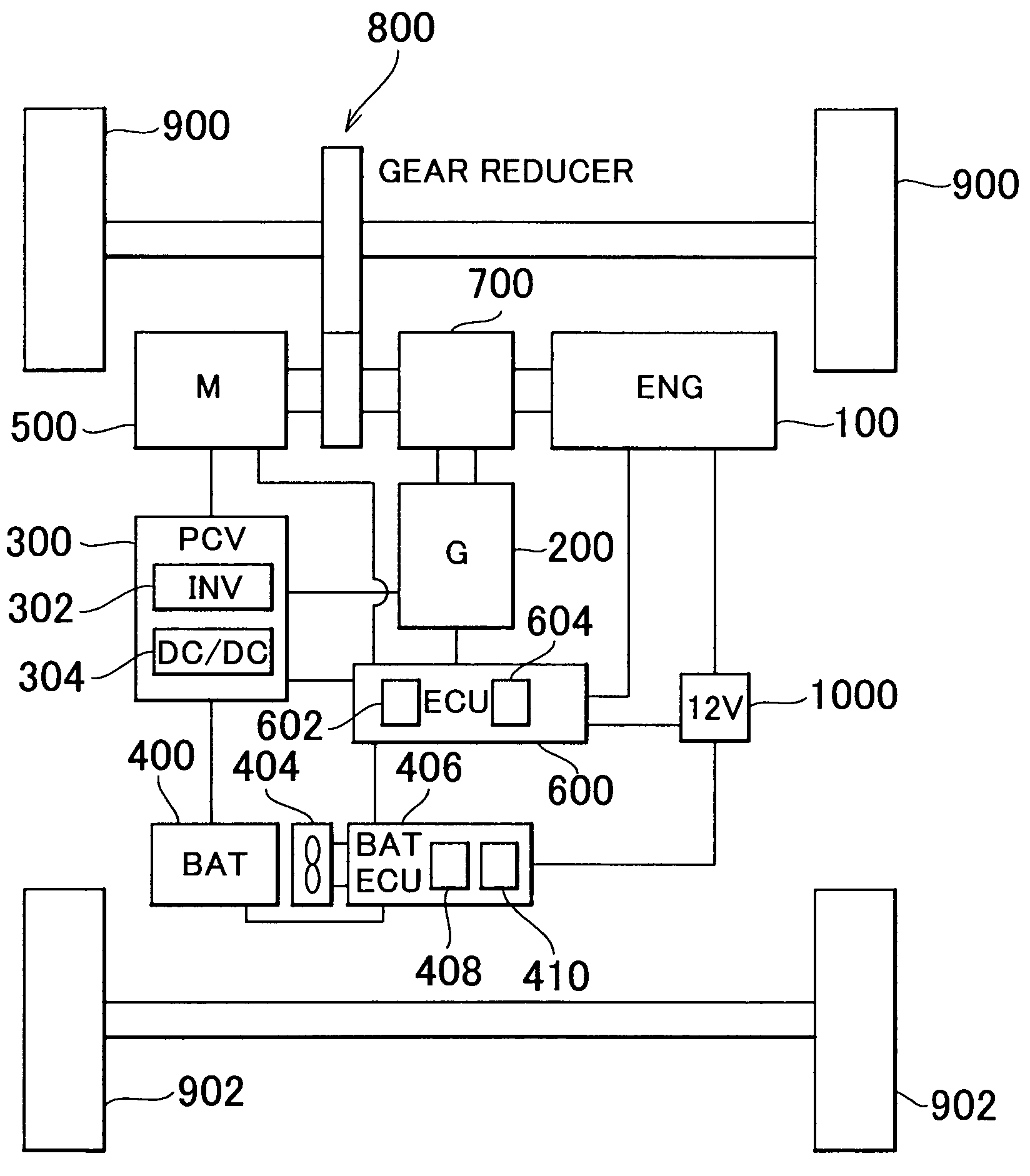

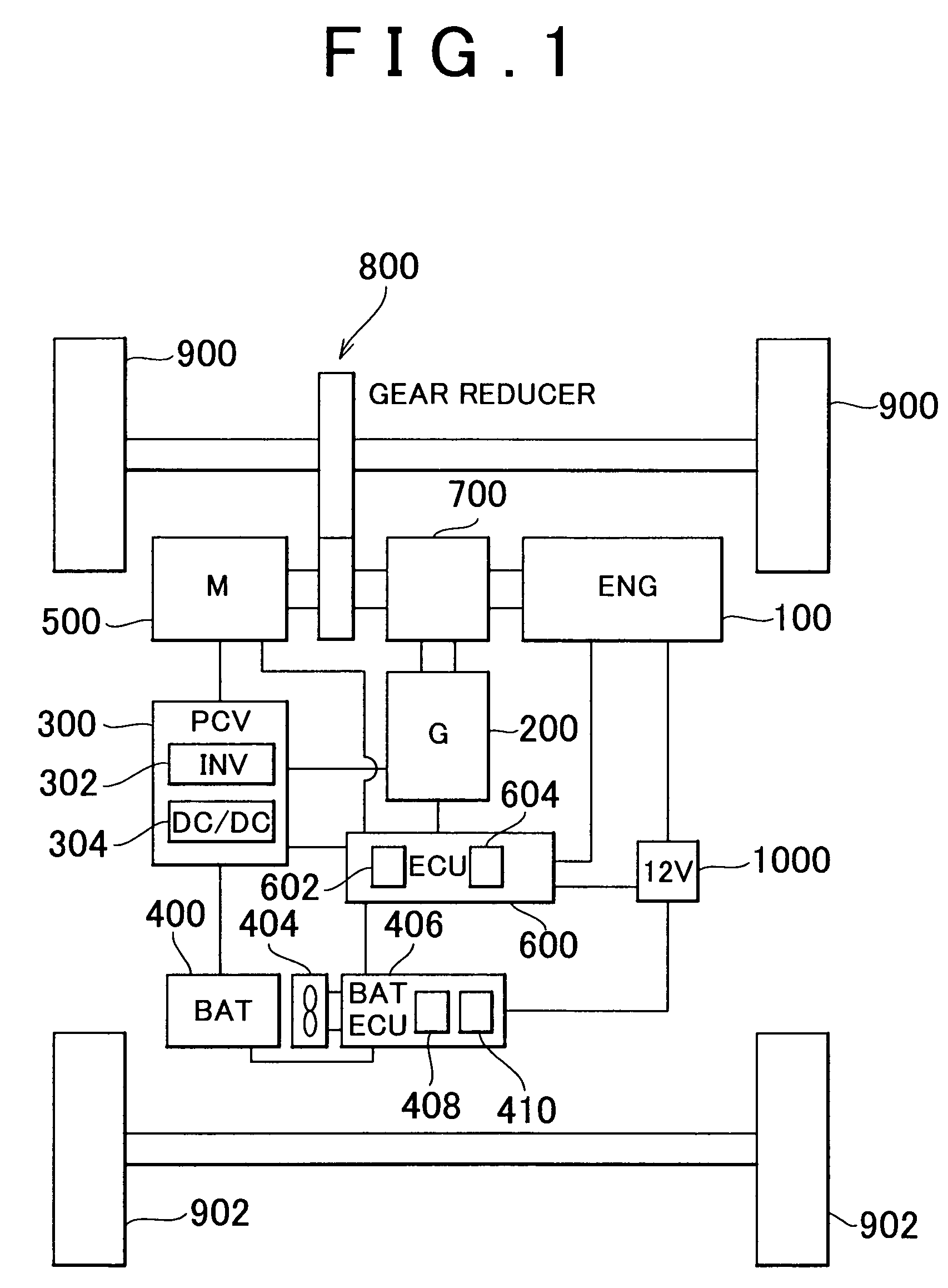

Fan system for vehicles and method for controlling fan in vehicles

ActiveUS20050029870A1Accurate connectionImprove work safetyHybrid vehiclesCell temperature controlEmbedded systemElectrical battery

Owner:TOYOTA JIDOSHA KK

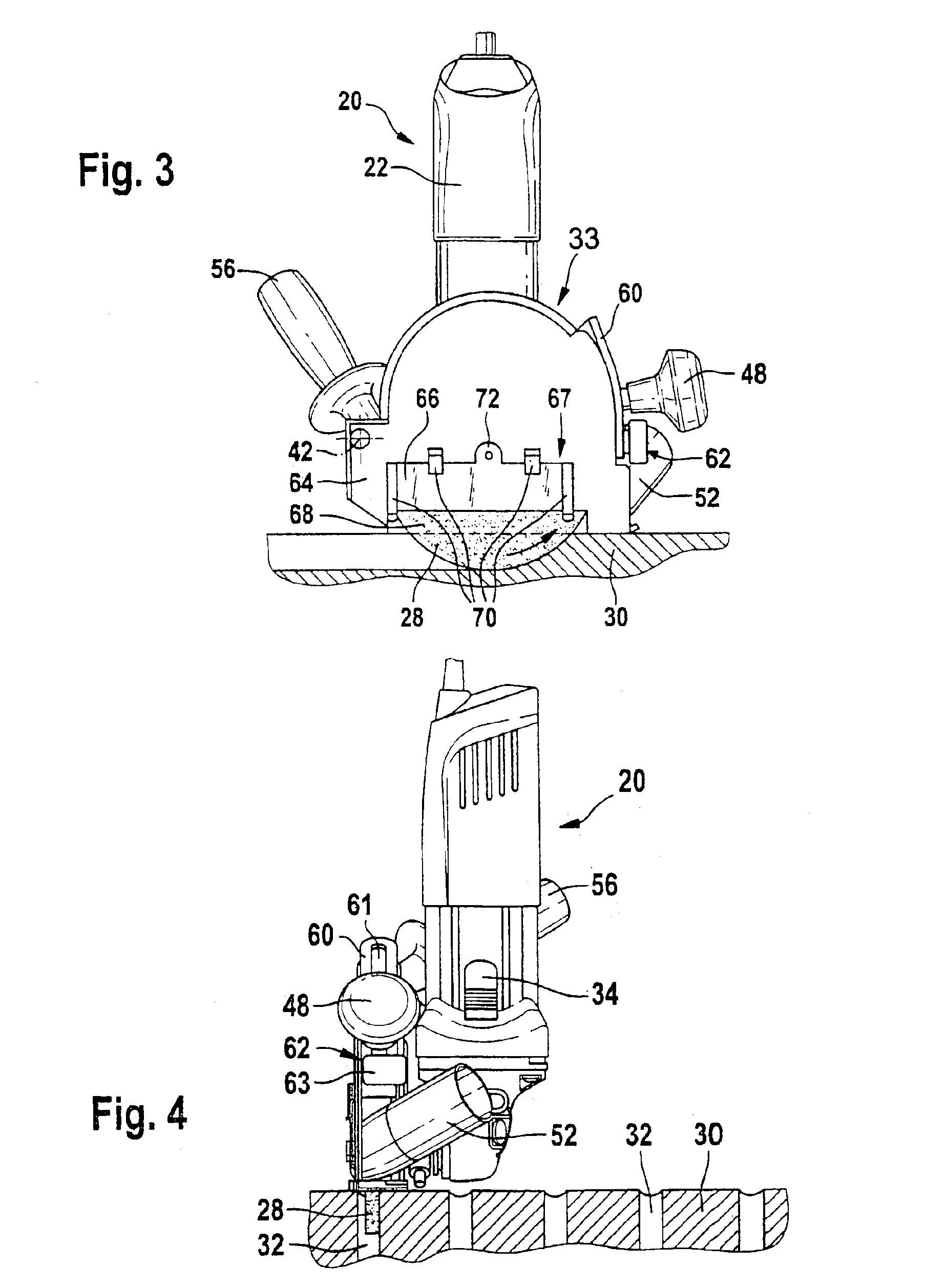

Protective device for a hand machine tool

InactiveUS6953394B2Sanding/grinding dust removal can be managed particularly effectivelyPrevent escapeMetal sawing devicesShearing machinesHand heldEngineering

A guard device for a hand power tool, in the form of a sanding / grinding hand power tool, has a wheel guard enclosing at least part of a rotating tool in a radial direction; a guide for guiding the wheel guard along a work piece, and comprising a fastening device for mounting the wheel guard on the hand power tool, wherein the guide is joined with the wheel guard in torsion-resistant fashion, and the wheel guard is mounted in a fashion that allows it to move relative to the fastening device; and a depth-of-cut stop limiting the relative movement of the wheel guard and fastening device, and being lockable in position with positive engagement in preselected stepped positions.

Owner:ROBERT BOSCH GMBH

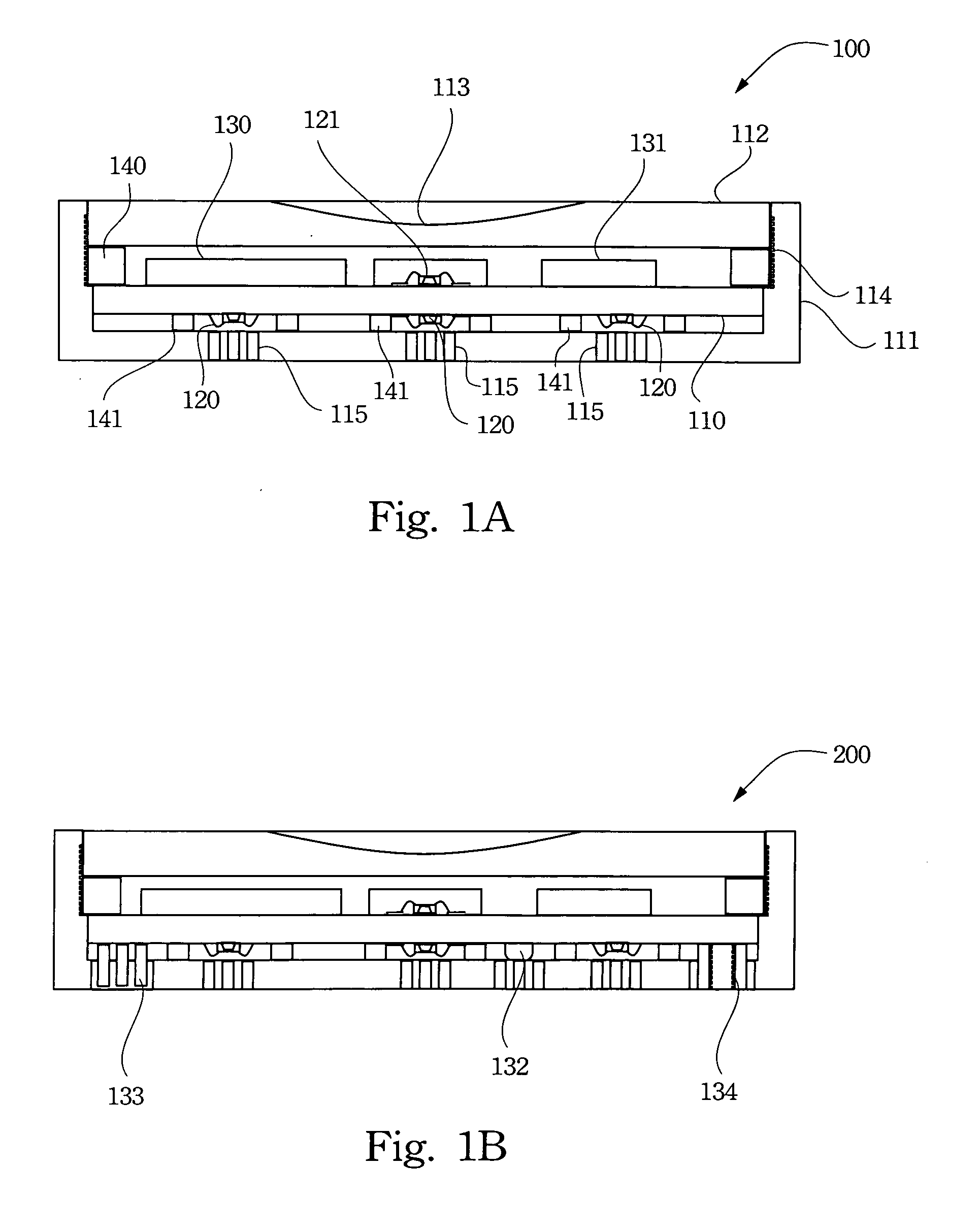

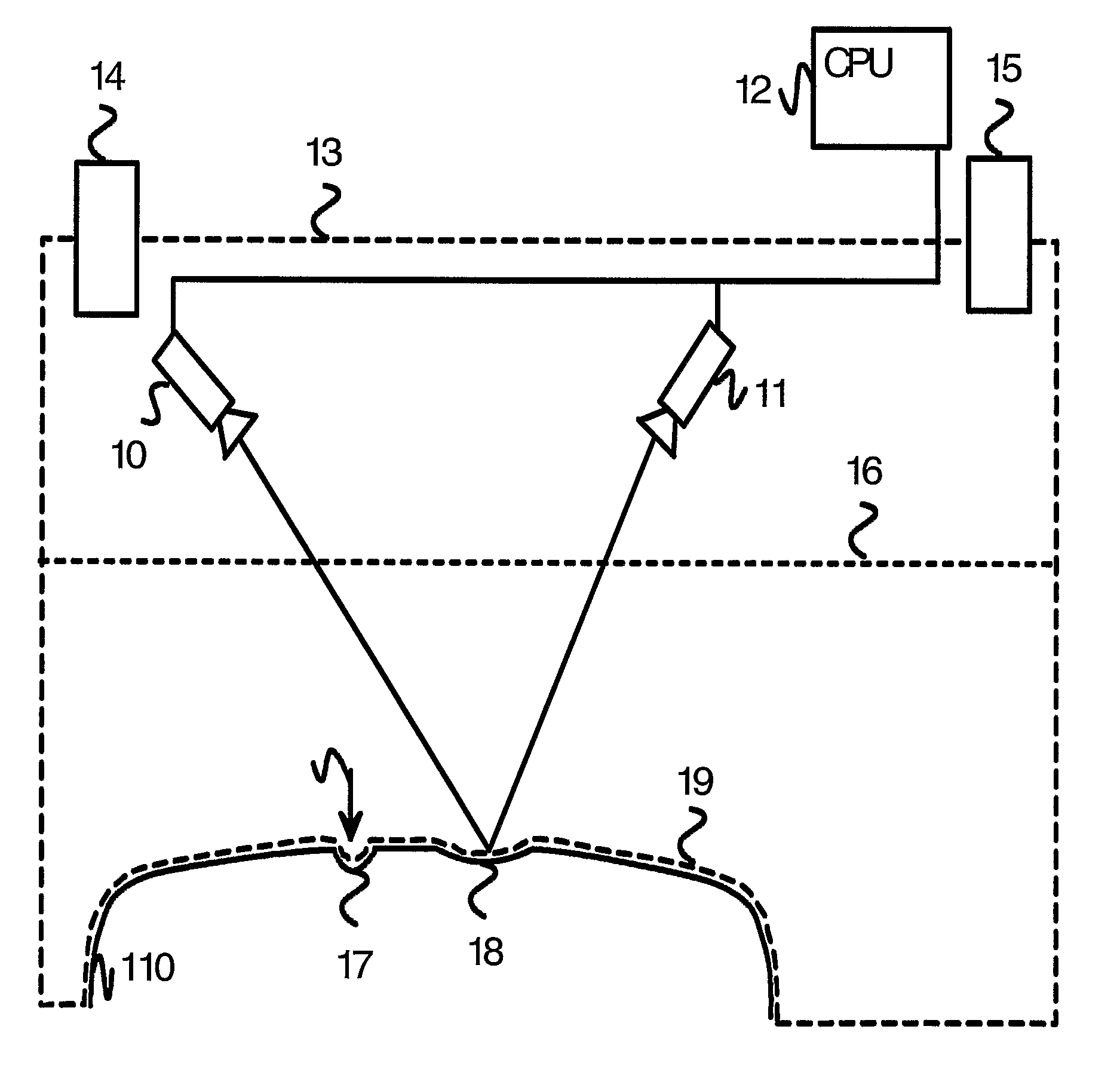

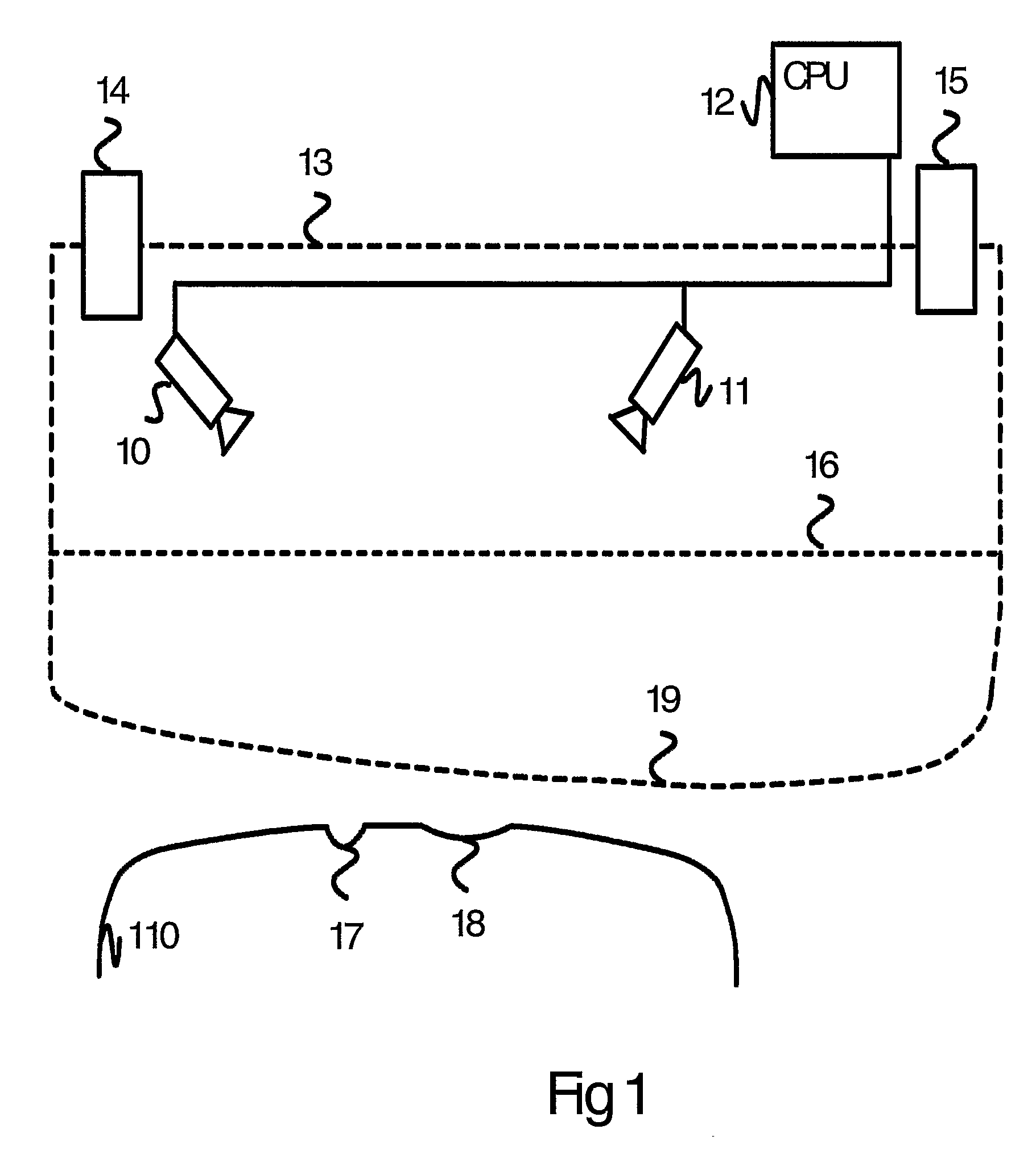

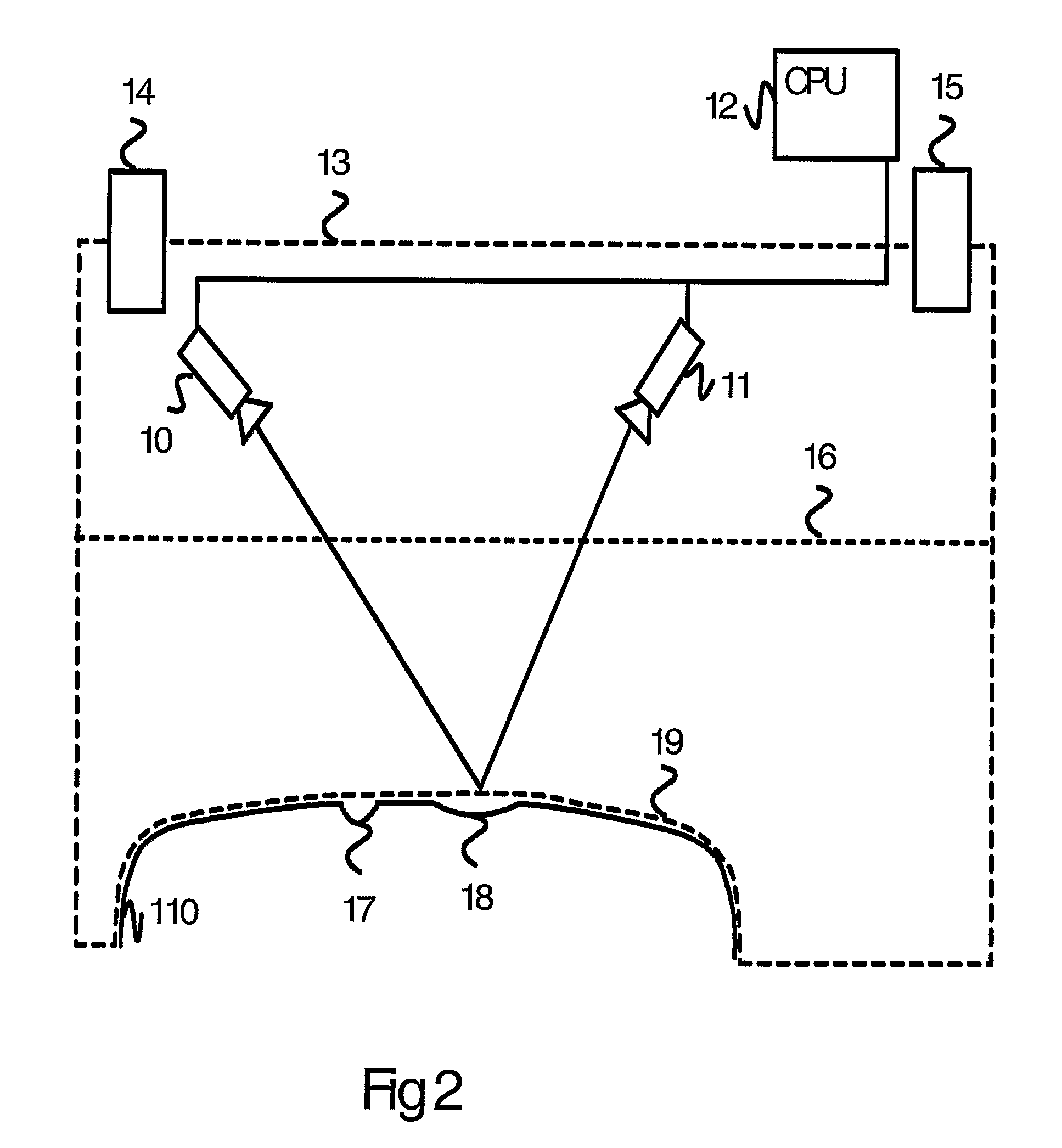

Method And System For Optical Measurement Of The Shape Of An Article

ActiveUS20090009774A1System fasterMake fastMaterial analysis by optical meansUsing optical meansMeasurement pointOptical measurements

The present invention relates to a method and system for measuring articles made of a material that is difficult to measure, such as glass. In the system, an elastic film (19) is arranged on top of an article (110). A number of measurement points that are imaged using a machine vision system. The location of the measurement points imaged are calculated with respect to one another, and based on this, the shape of the article can be measured.

Owner:MAPVISION

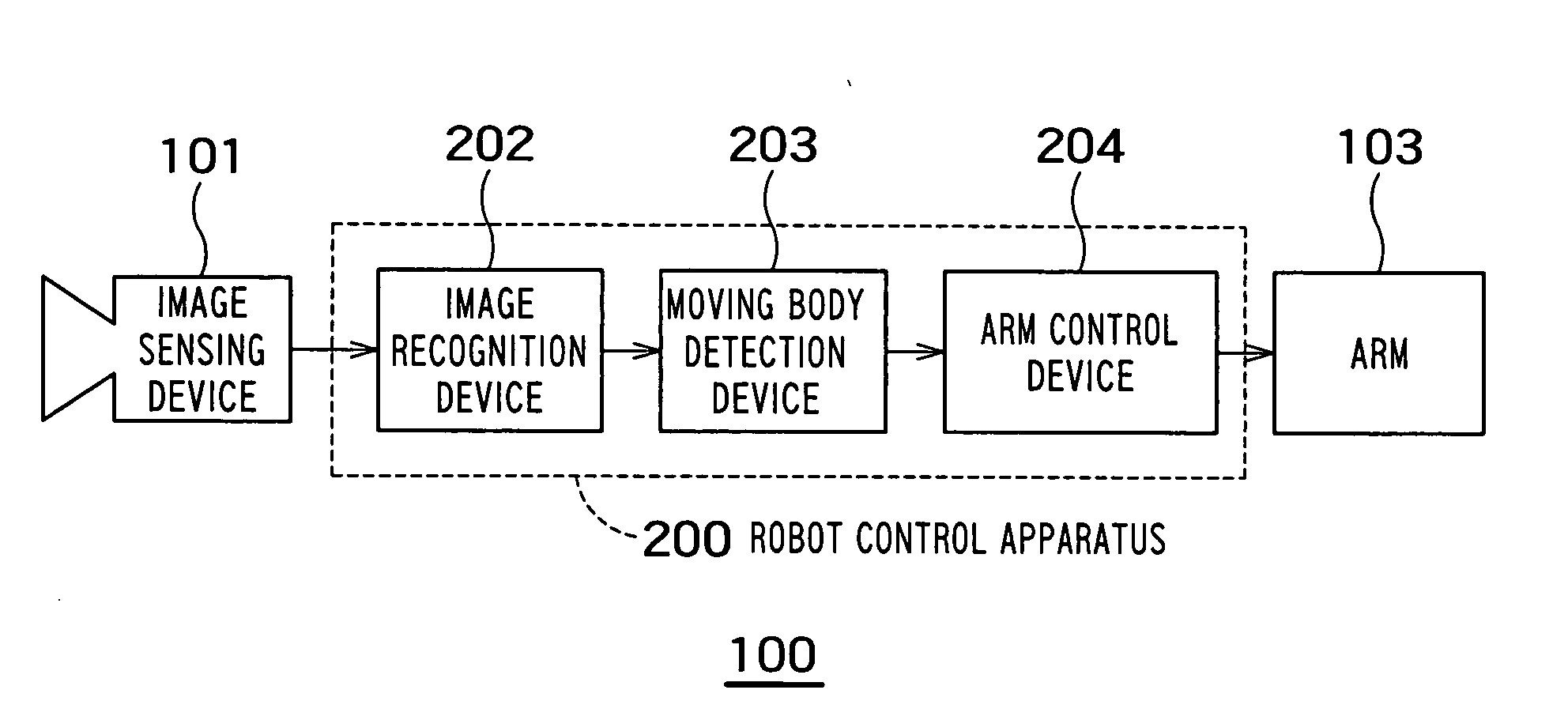

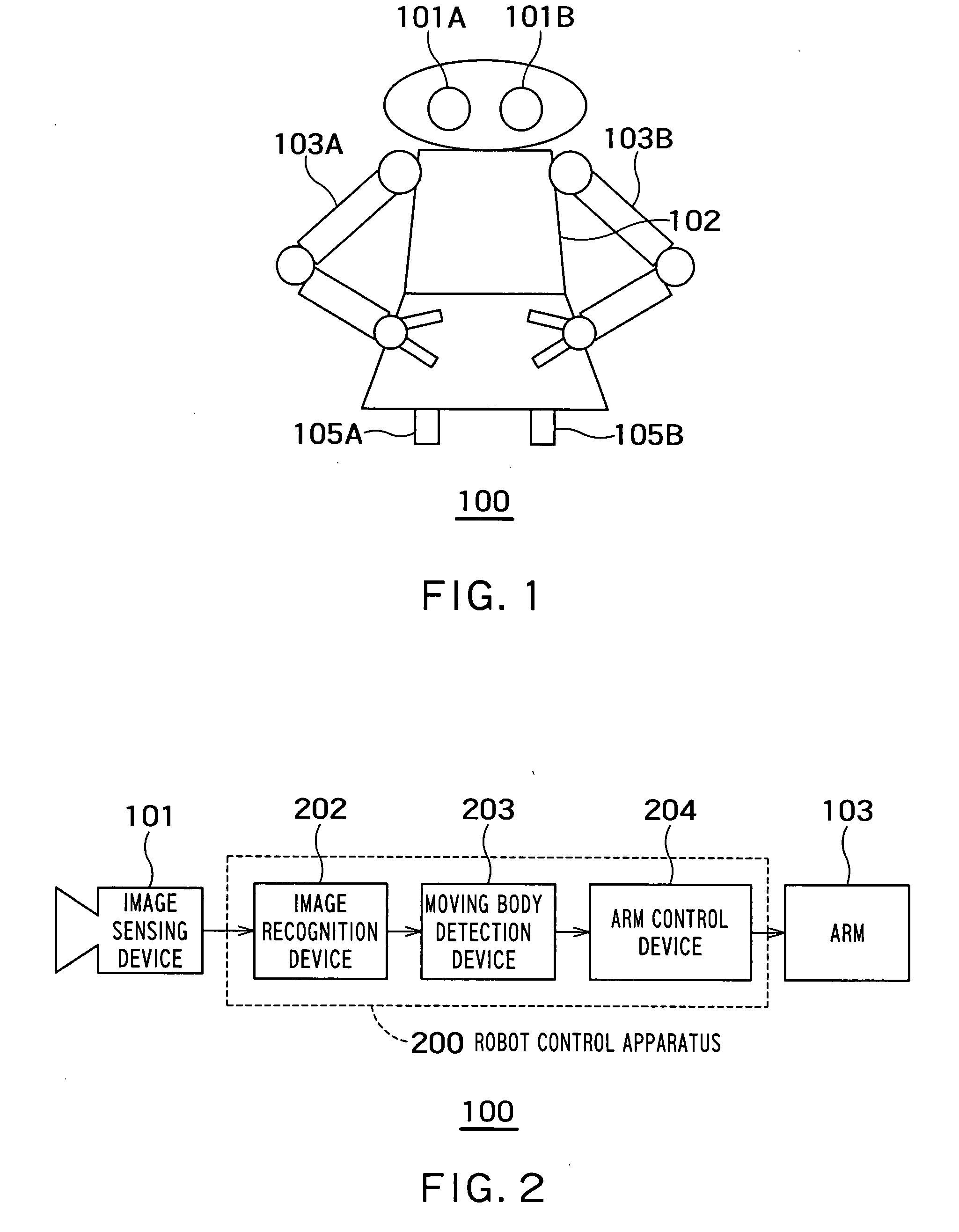

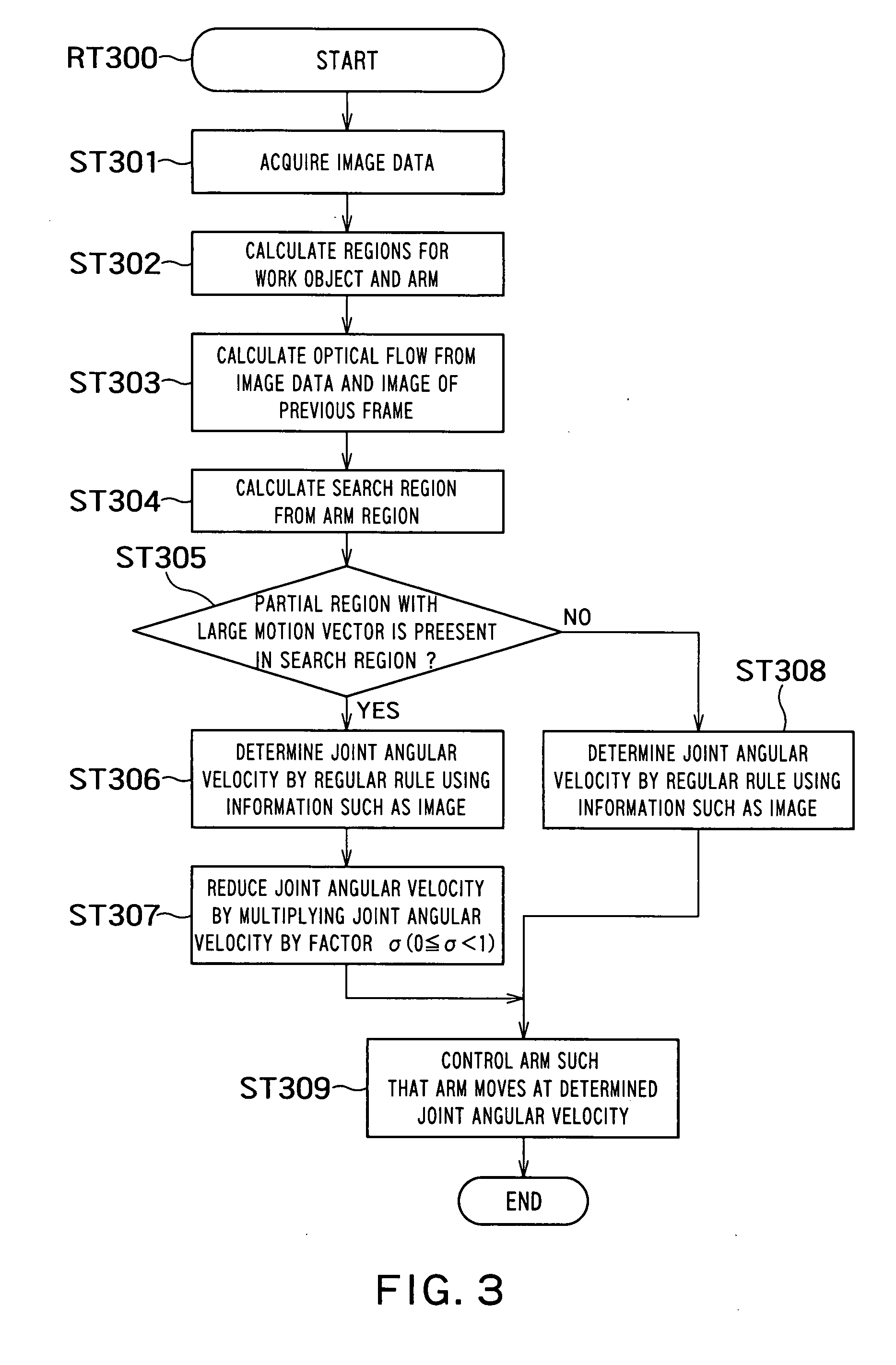

Robot apparatus and control method therefor

InactiveUS20080140256A1Improve work safetyWork at highProgramme-controlled manipulatorComputer controlControl theoryImage sensing

There is provided a robot apparatus which can improve work safety while ensuring high working efficiency and a control method for the robot apparatus. The robot apparatus includes a moving body detection unit which generates a predicted moving range for a movable unit region by predicting a range within which the movable unit region moves using a plurality of images sequentially sensed by an image sensing unit and attempts to detect a moving body in the predicted moving range and a control unit which, if a moving body is detected by the moving body direction unit, changes the operation of a movable unit.

Owner:KK TOSHIBA

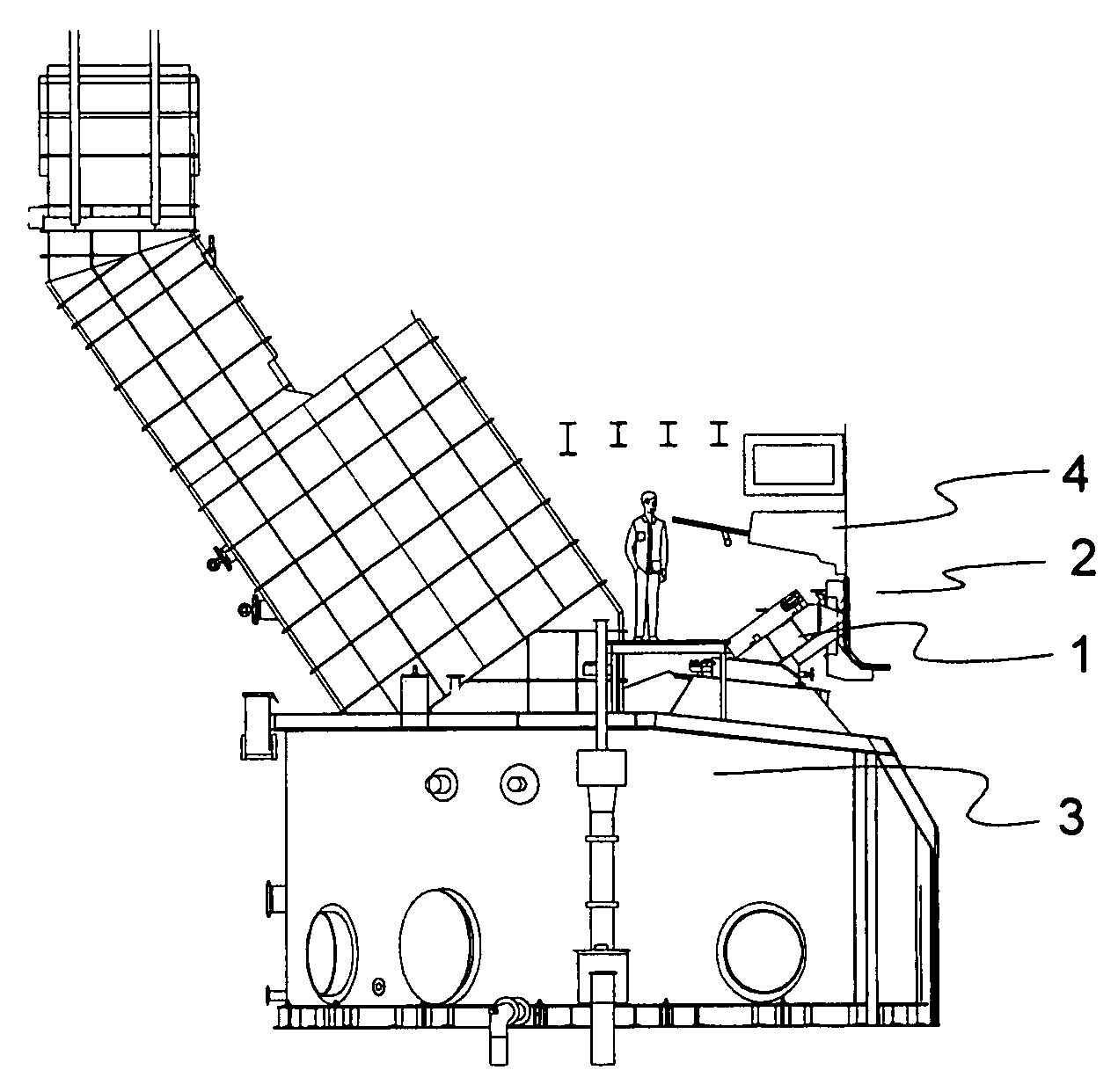

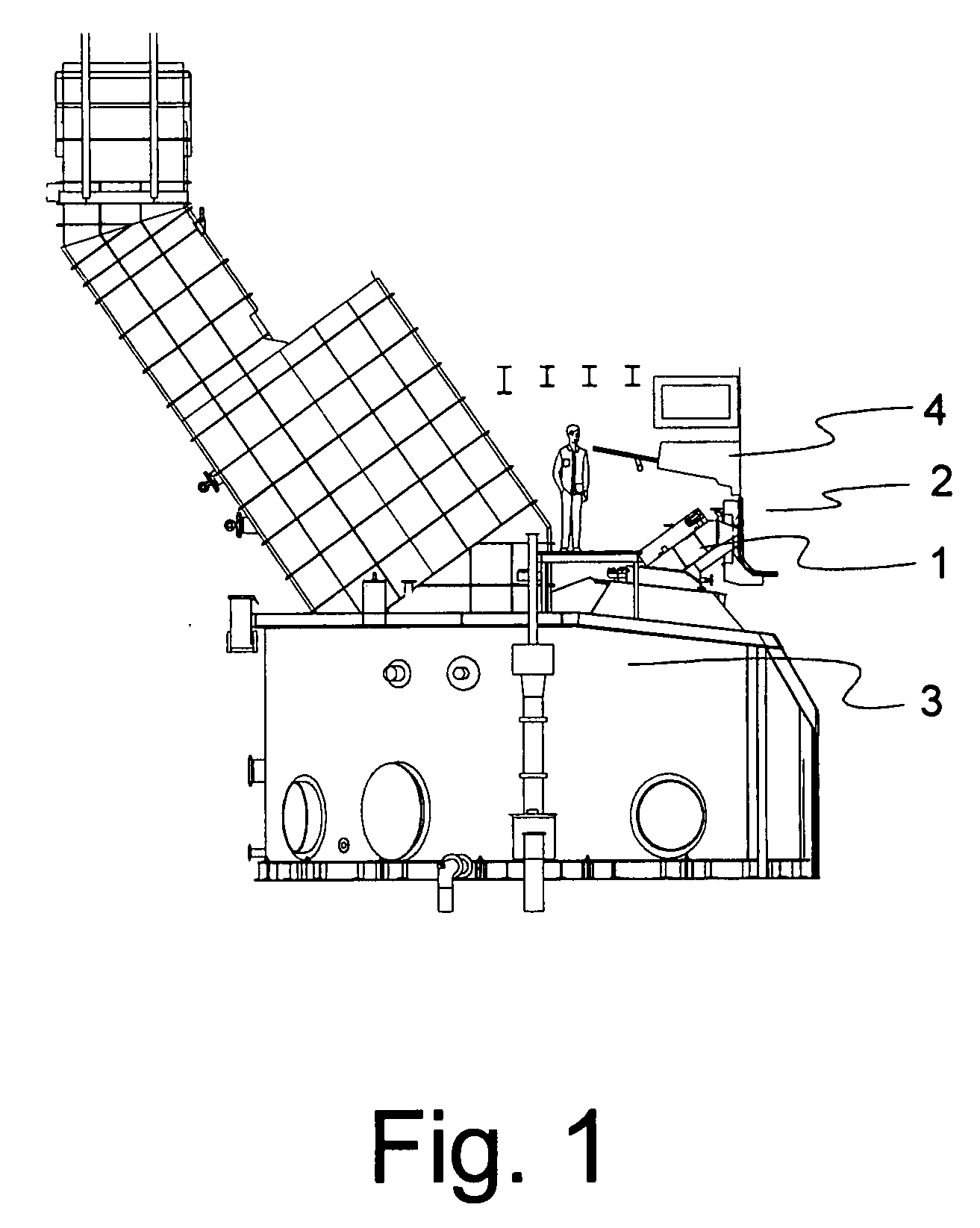

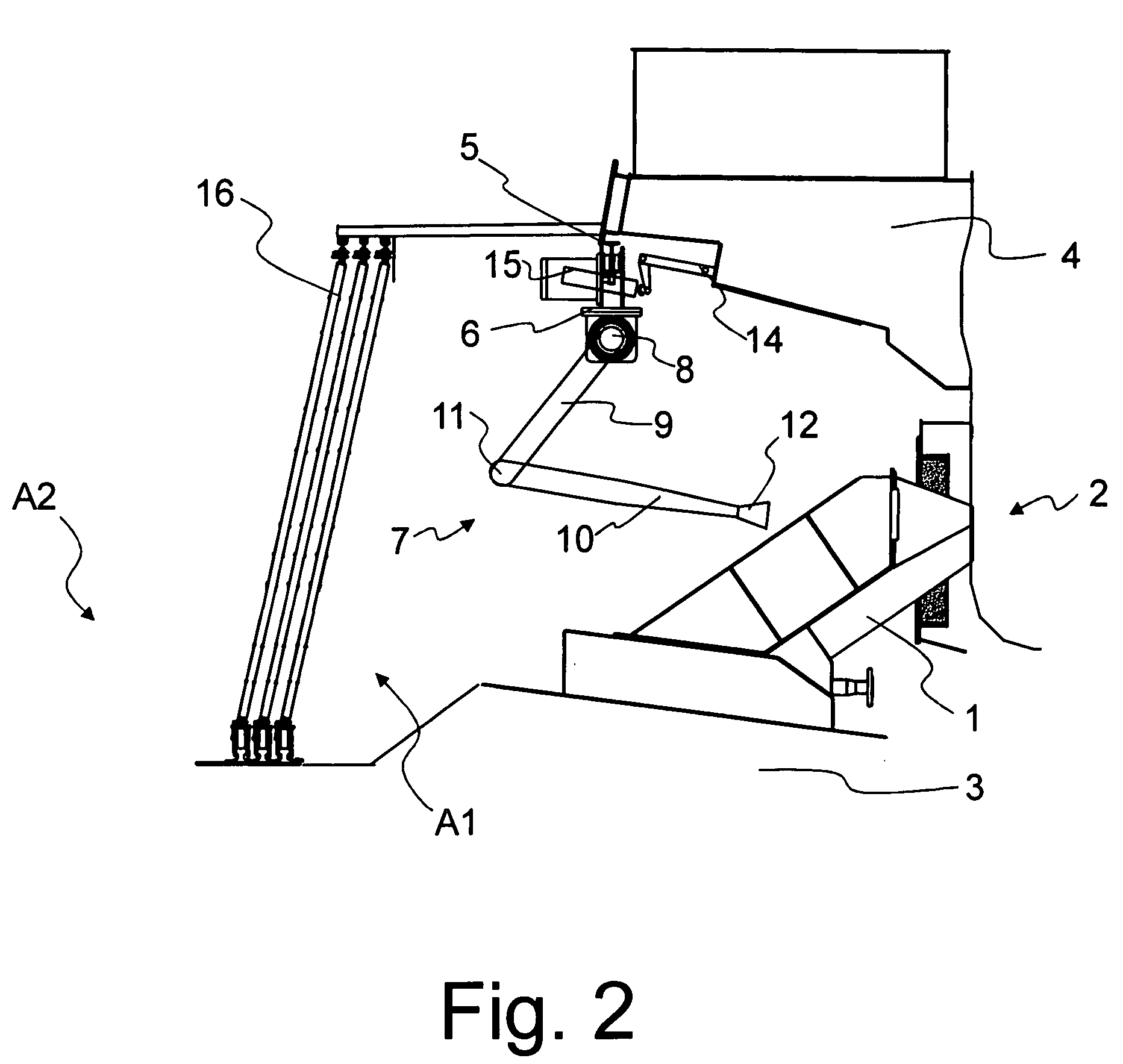

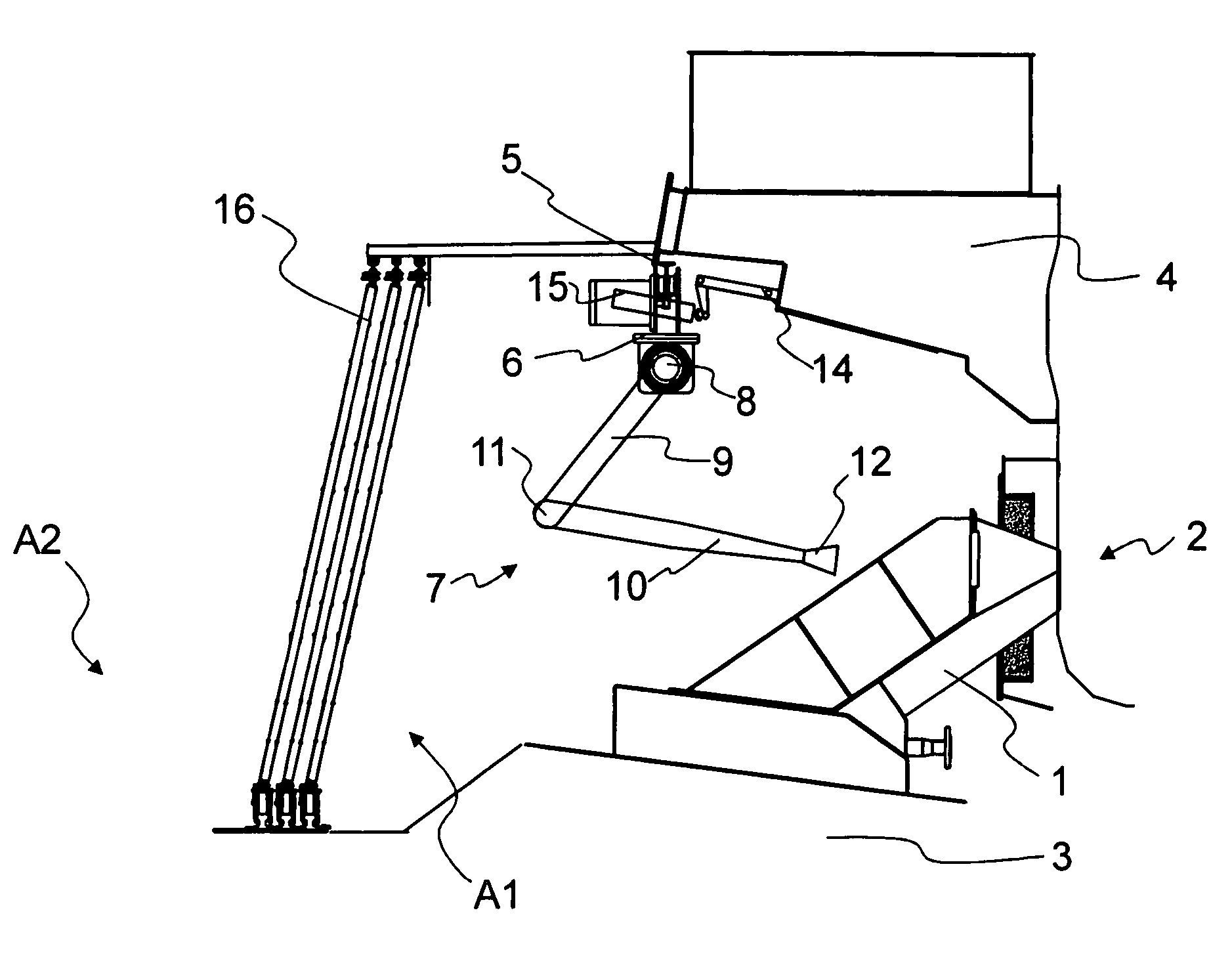

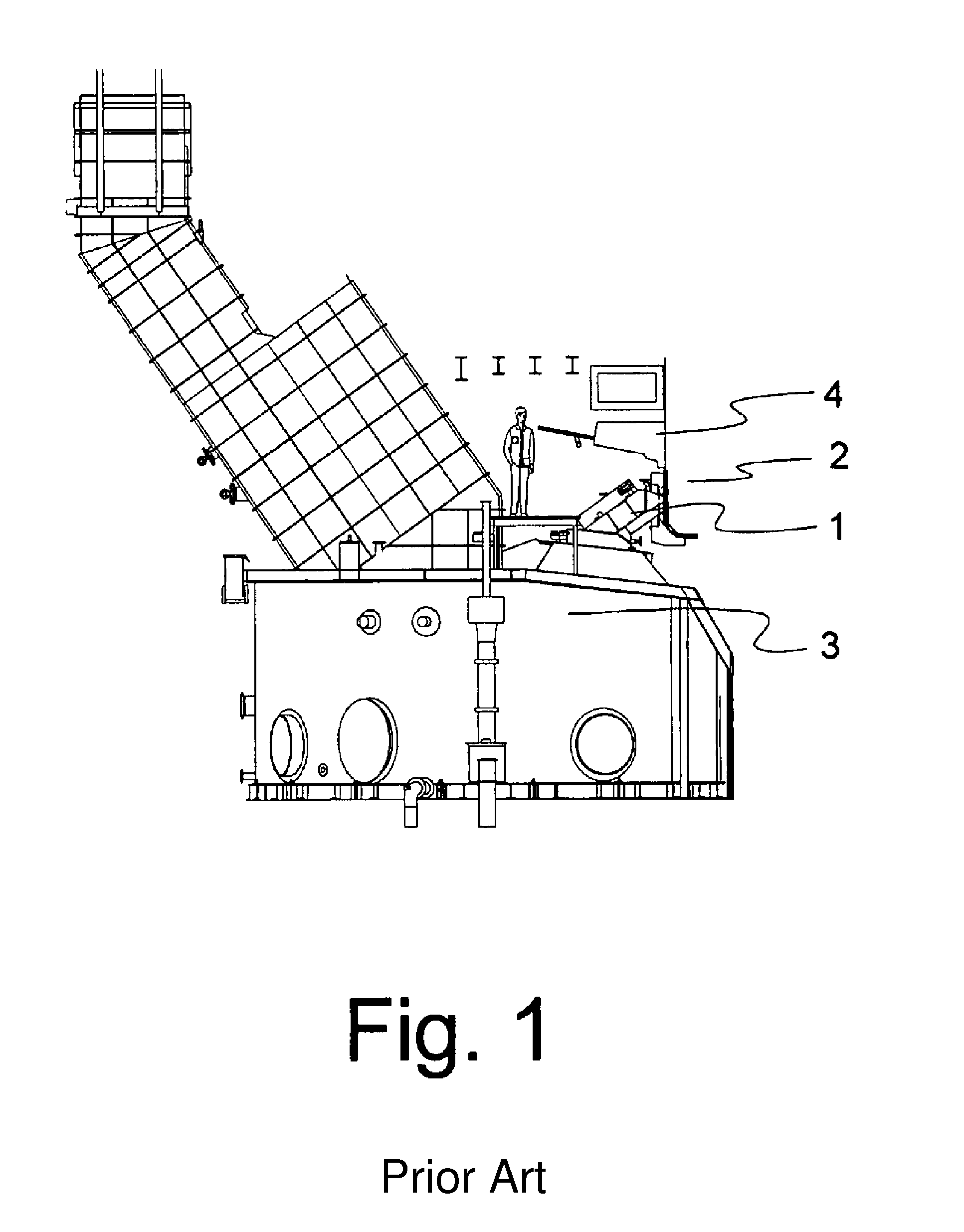

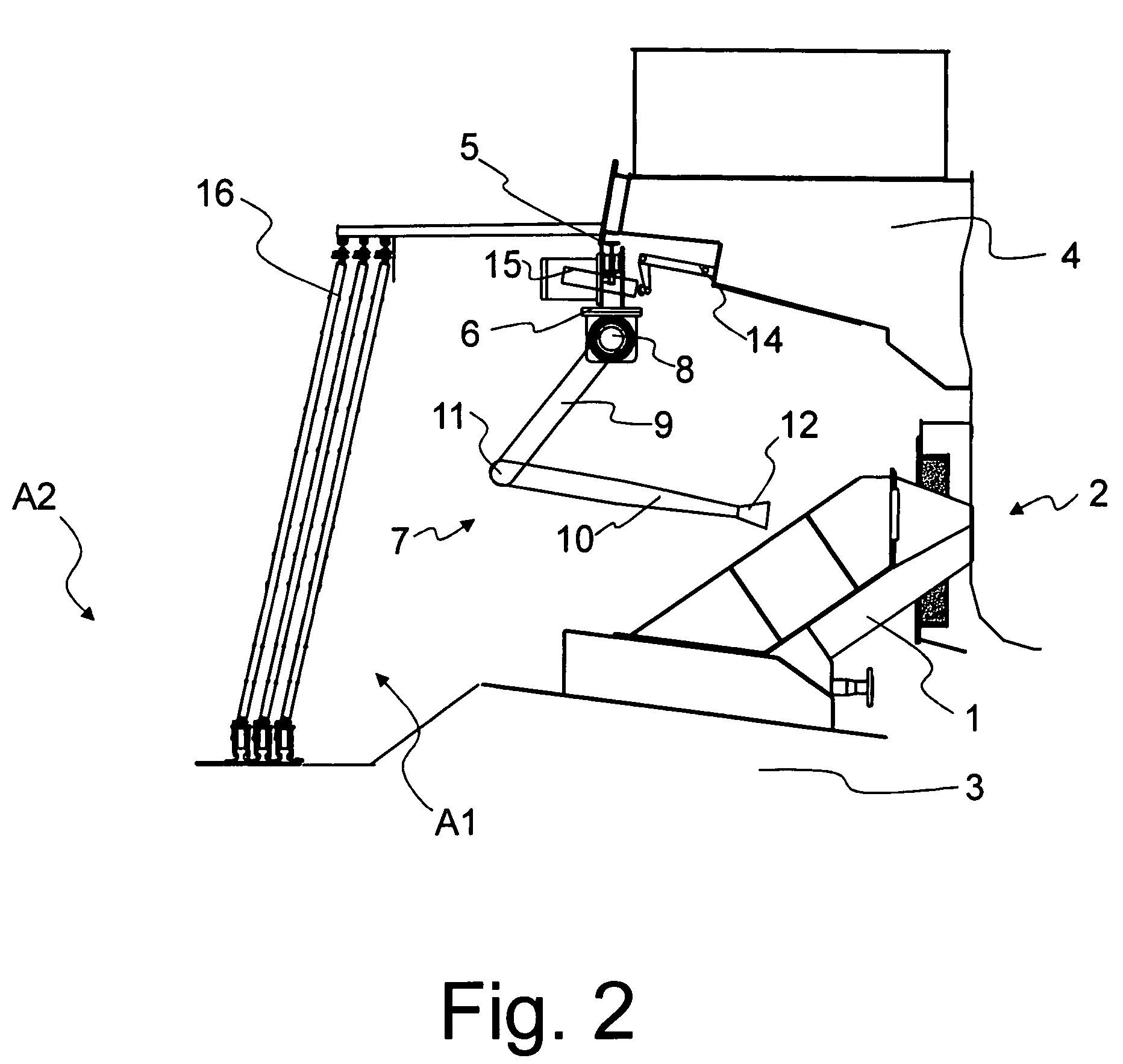

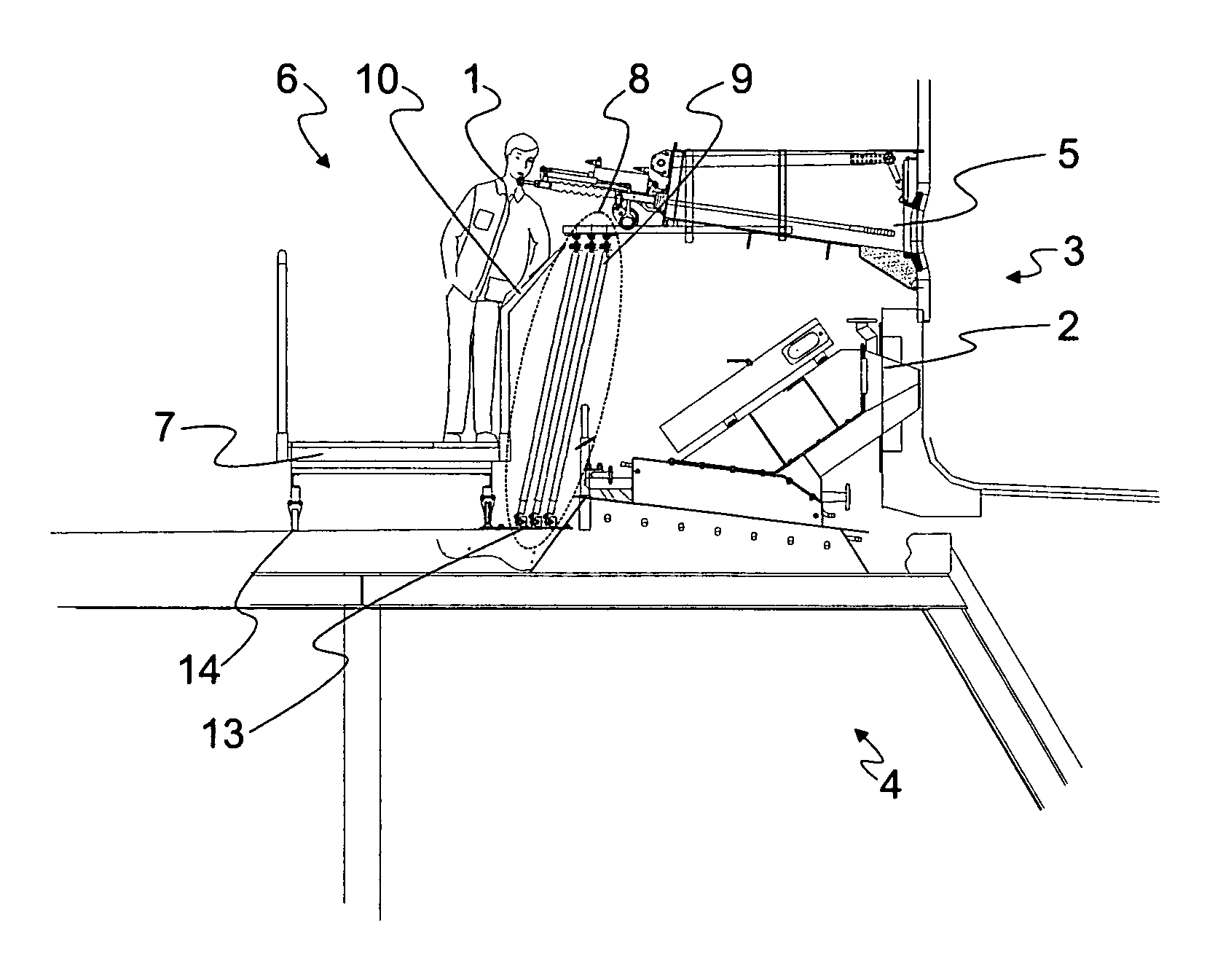

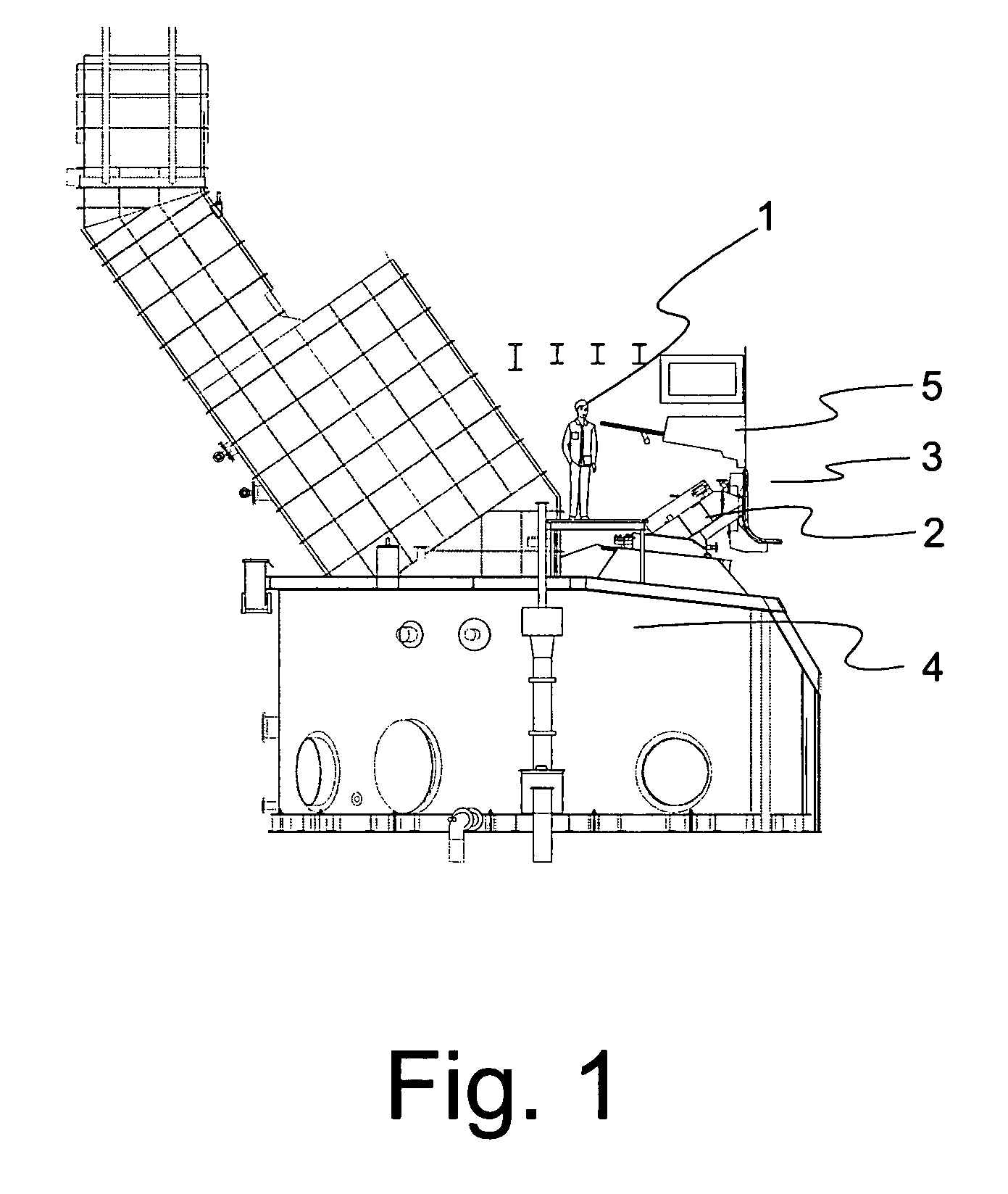

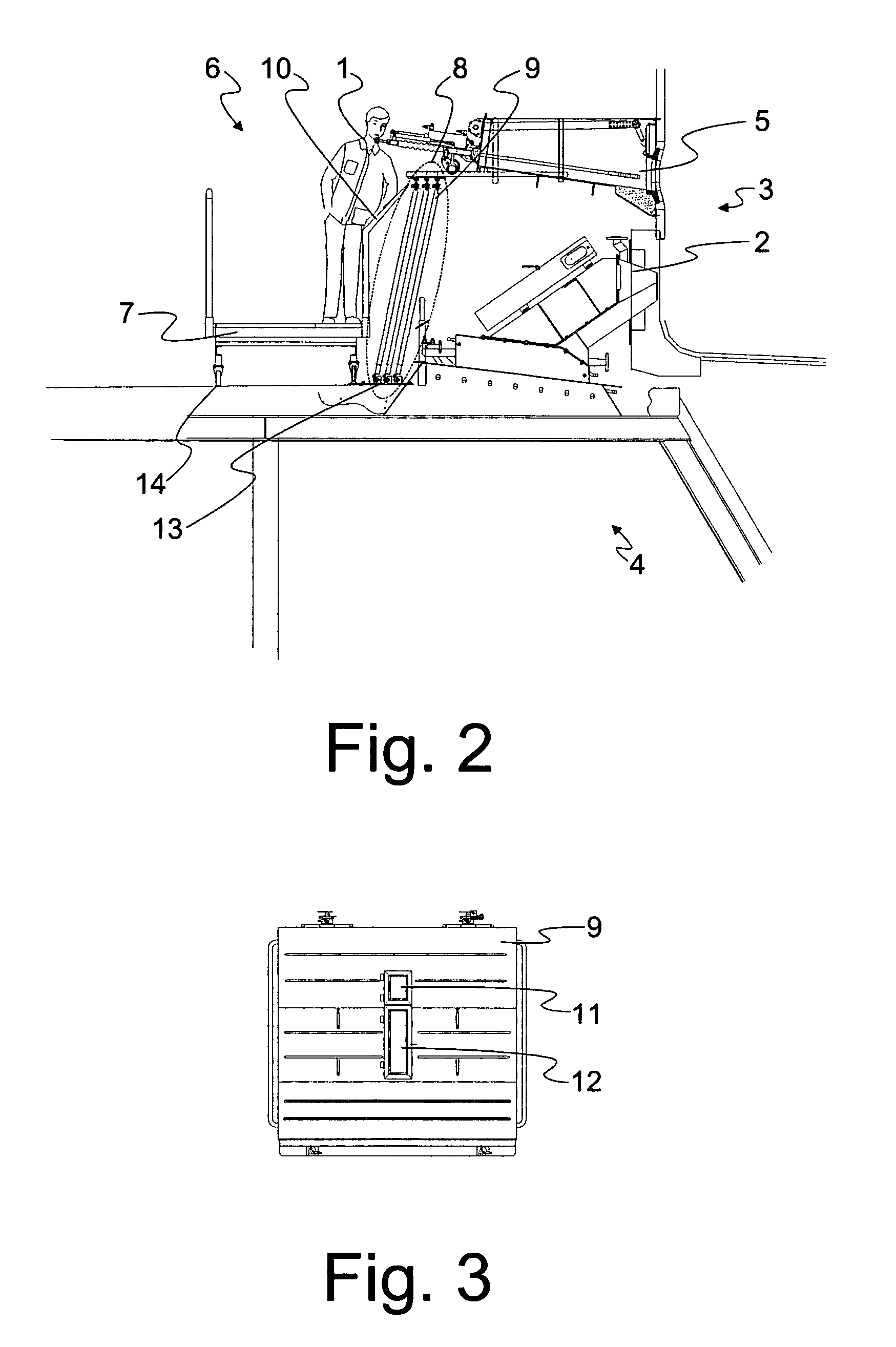

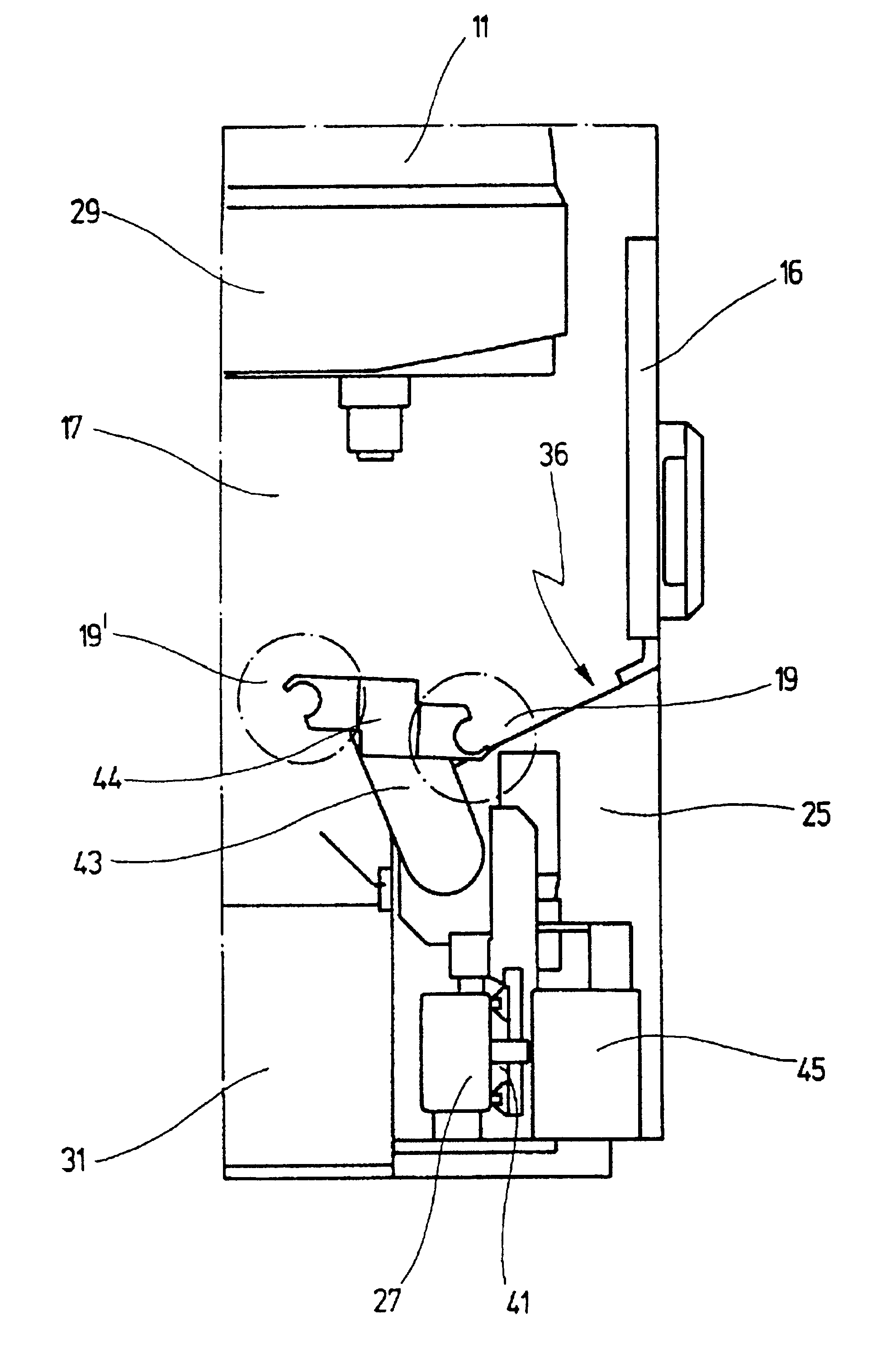

Cleaner for the smelt spout of a recovery boiler

ActiveUS20080087302A1Improve work safetyPulp liquors combustionHollow article cleaningEngineeringMechanical engineering

A cleaning apparatus for a smelt spout of a recovery boiler, which apparatus comprises a motorized cleaning member (7) for cleaning the smelt spout (1). The cleaning apparatus further comprises a path (5) and a cleaning unit, which comprises motorized transfer means for transferring the cleaning unit to the location of the smelt spout (1) along the path.

Owner:METSO POWER OY

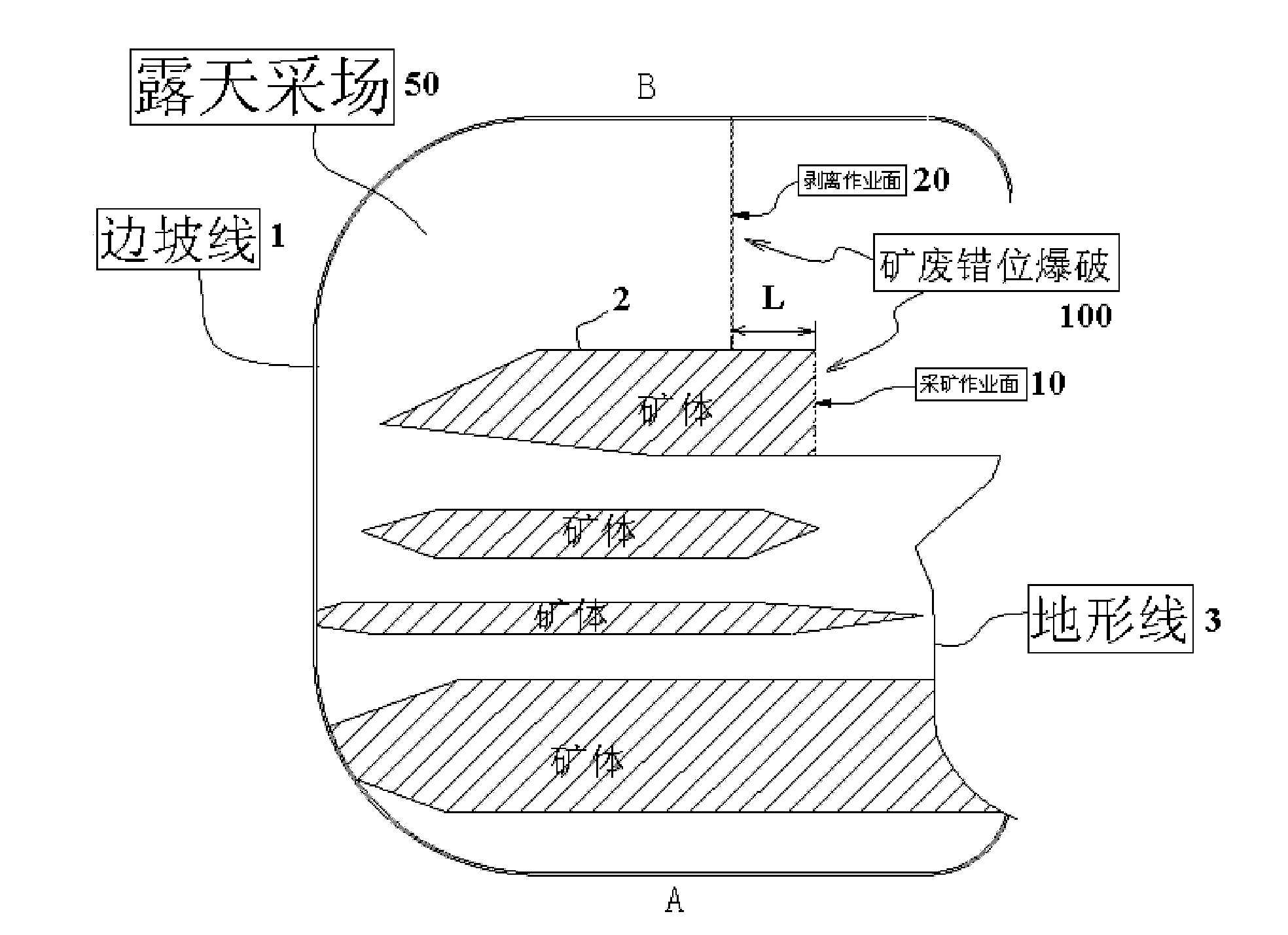

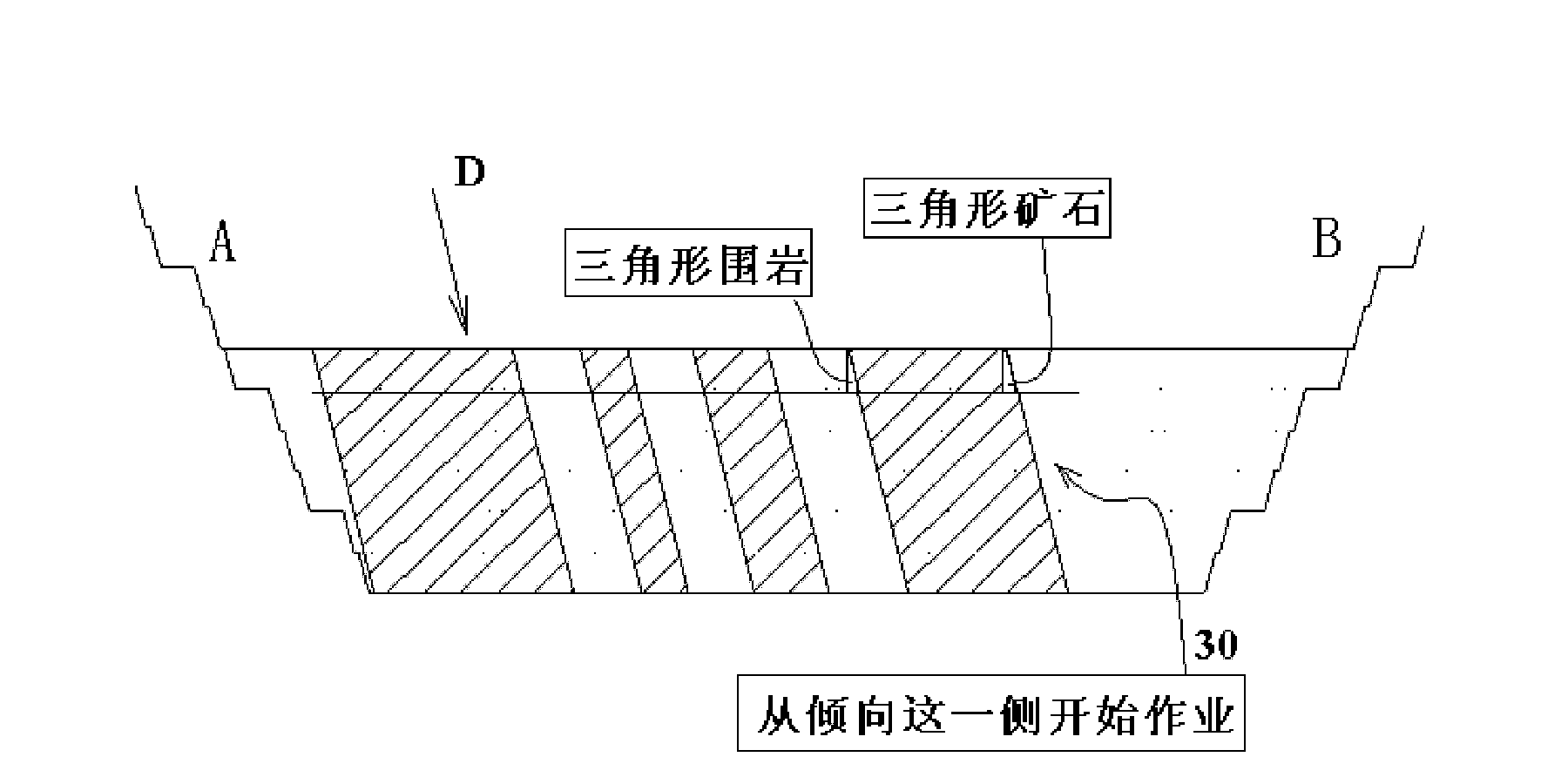

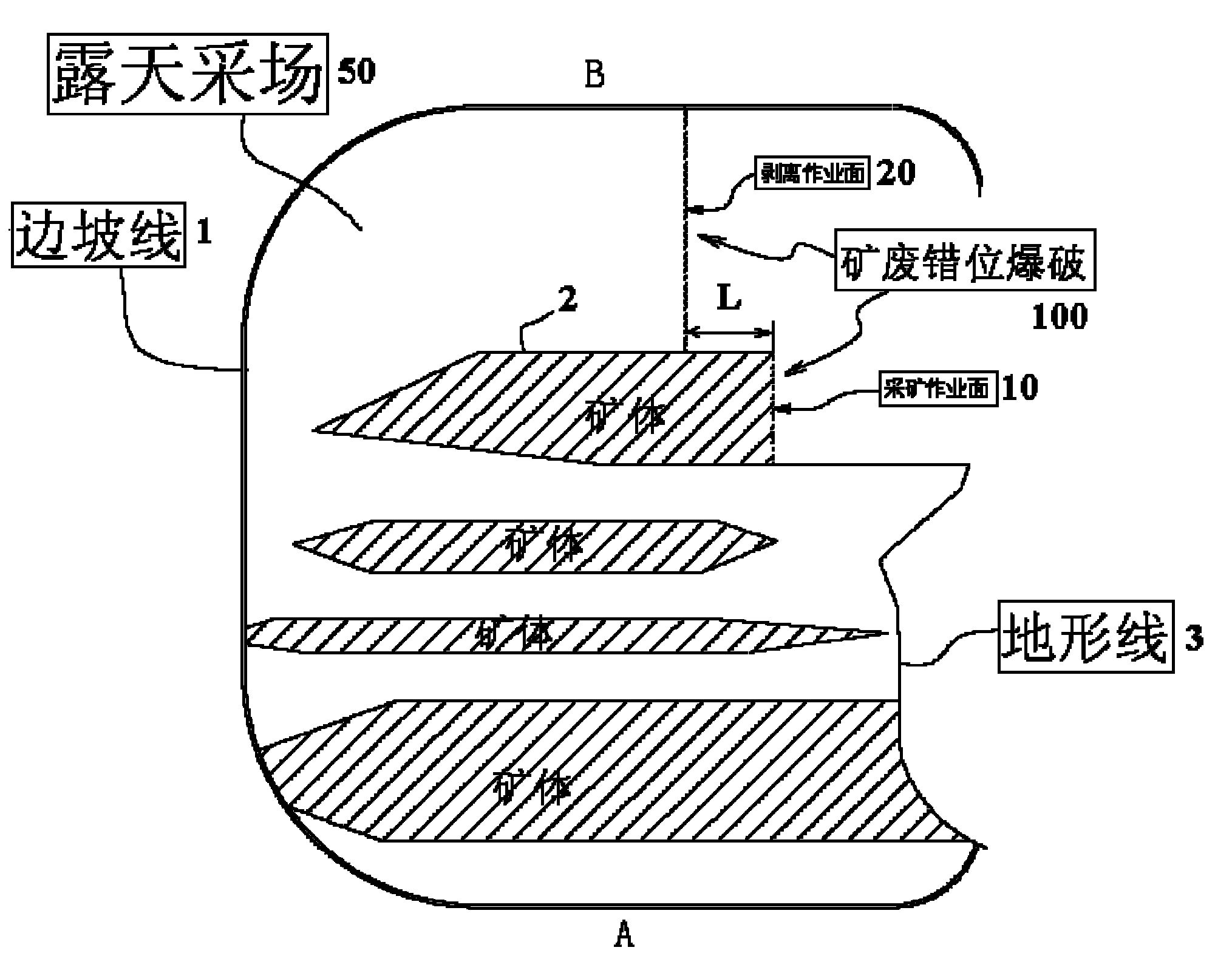

Mining technology for inclined orebodies in opencast mines

The invention provides a mining technology for inclined orebodies in opencast mines. The mining technology is characterized in that boring is carried out in the inclined direction of an orebody; the sequence of operation is from the outer side of the inclined direction of the orebody to the inner side; dissection and mining are staggered for blasting; and the staggered distance of secondary blasting is larger than or equal to 28 meters to avoid mixed stacking of ore and waste. The mining technology can fully utilize mineral resources, improve ore recovery rate, production efficiency and operation safety degree, and reduce ore dilution rate and production cost.

Owner:江西分宜珠江矿业有限公司

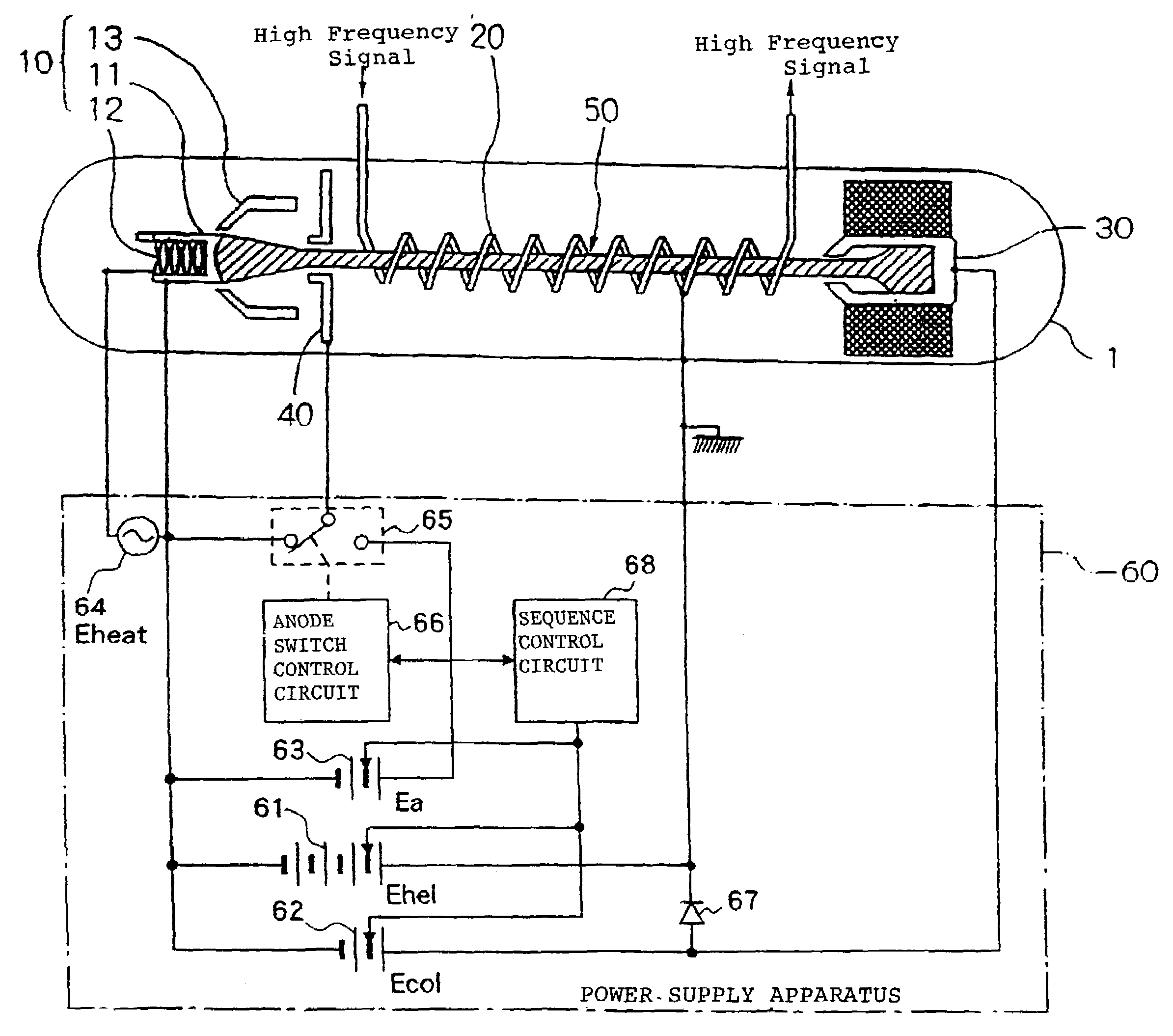

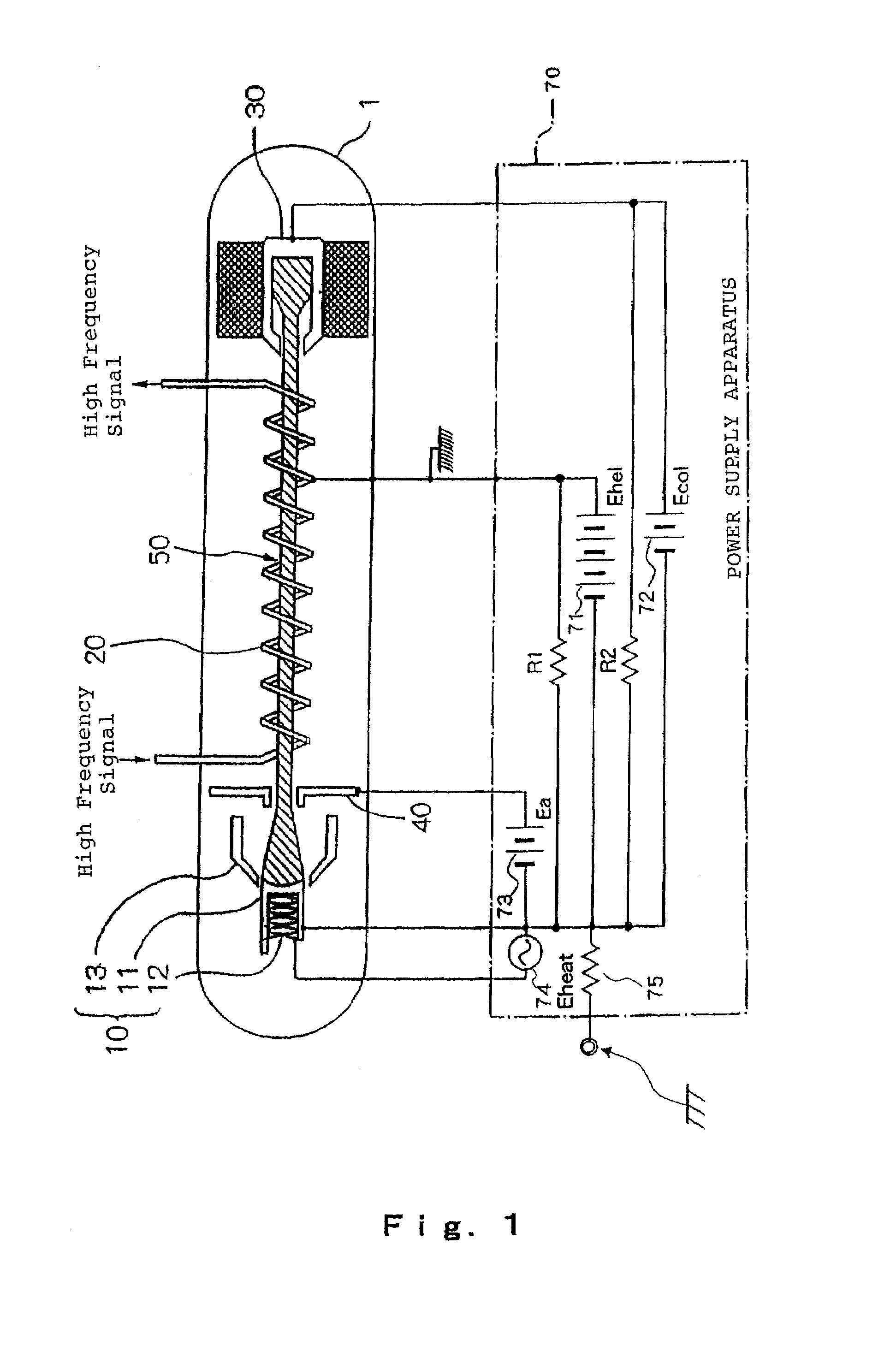

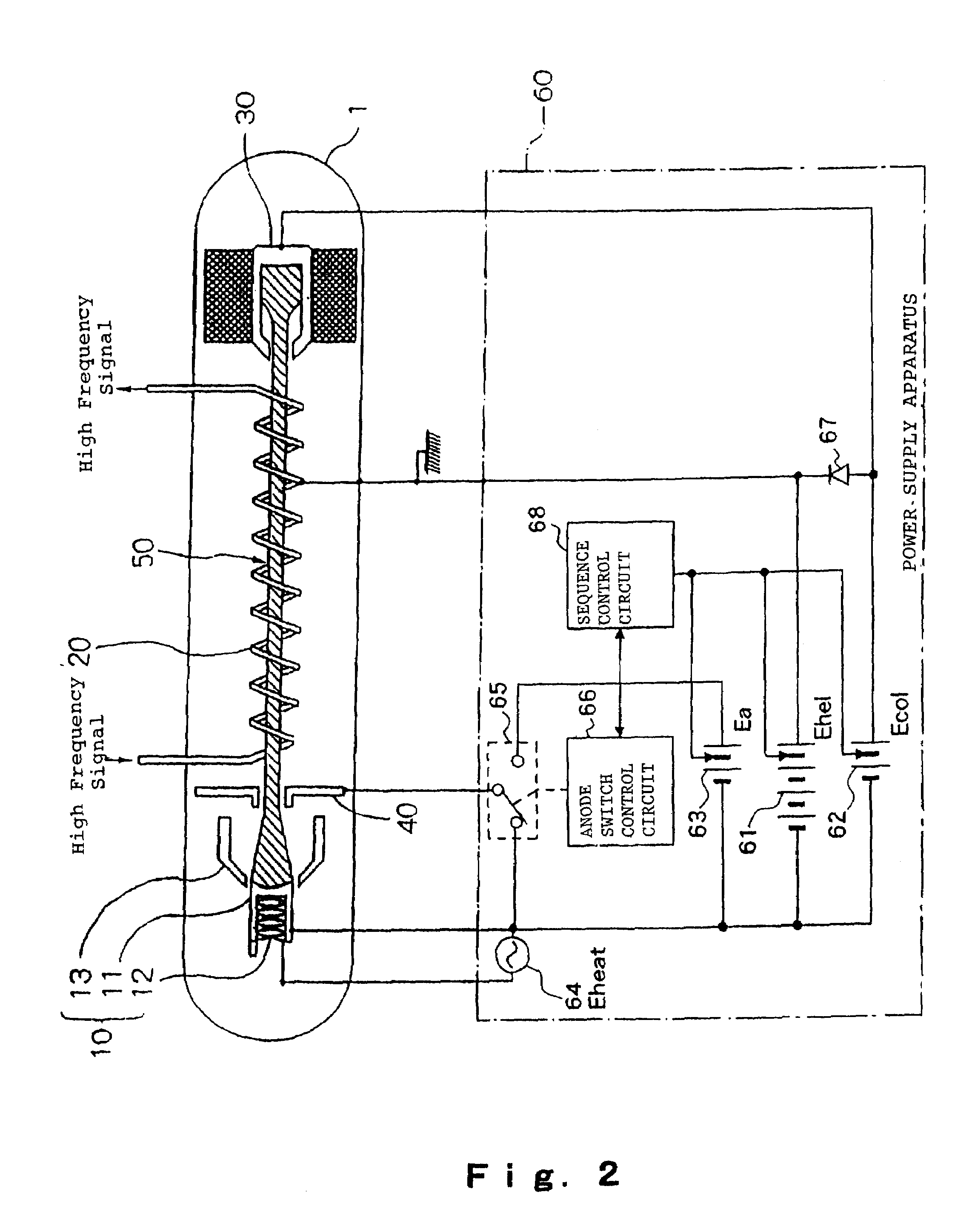

Power supply apparatus and high frequency circuit system

InactiveUS7489084B2Improve work safetyImprove securityPulse automatic controlTravelling-wave tubesAnode voltagePower apparatus

A power supply apparatus for supplying predetermined supply voltages respectively to an anode electrode, a cathode electrode, a collector electrode, and a helix of an electron tube. The power supply apparatus comprises an anode switch for turning on / off the anode voltage output, and an anode switch control circuit for controlling the on / off operation of the anode switch such that a pulsed anode voltage is repeatedly applied to the anode electrode a plurality of times at a predetermined period when operation of a helix power supply and a collector power supply is stopped.

Owner:NEC NETWORK & SENSOR SYST

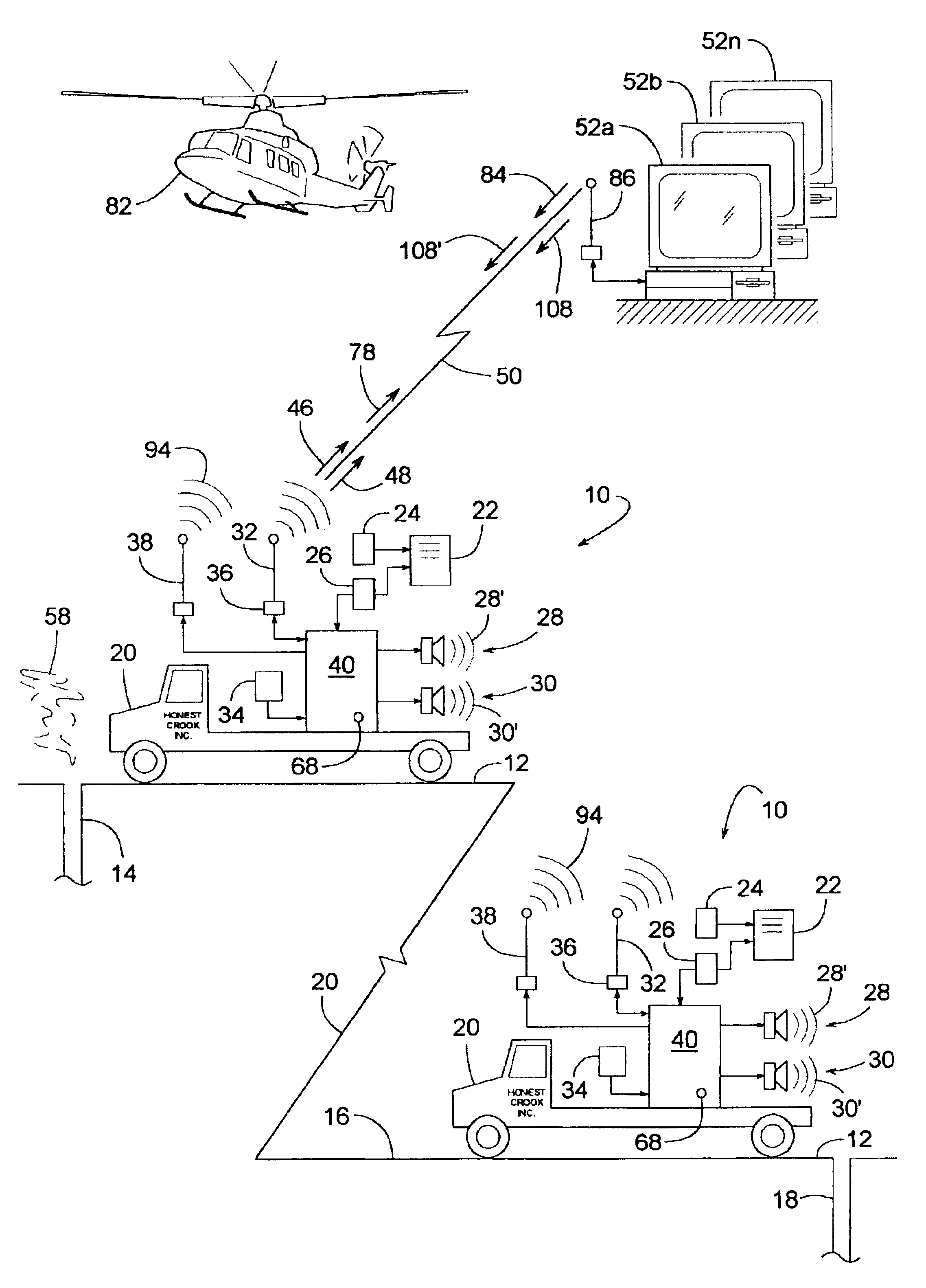

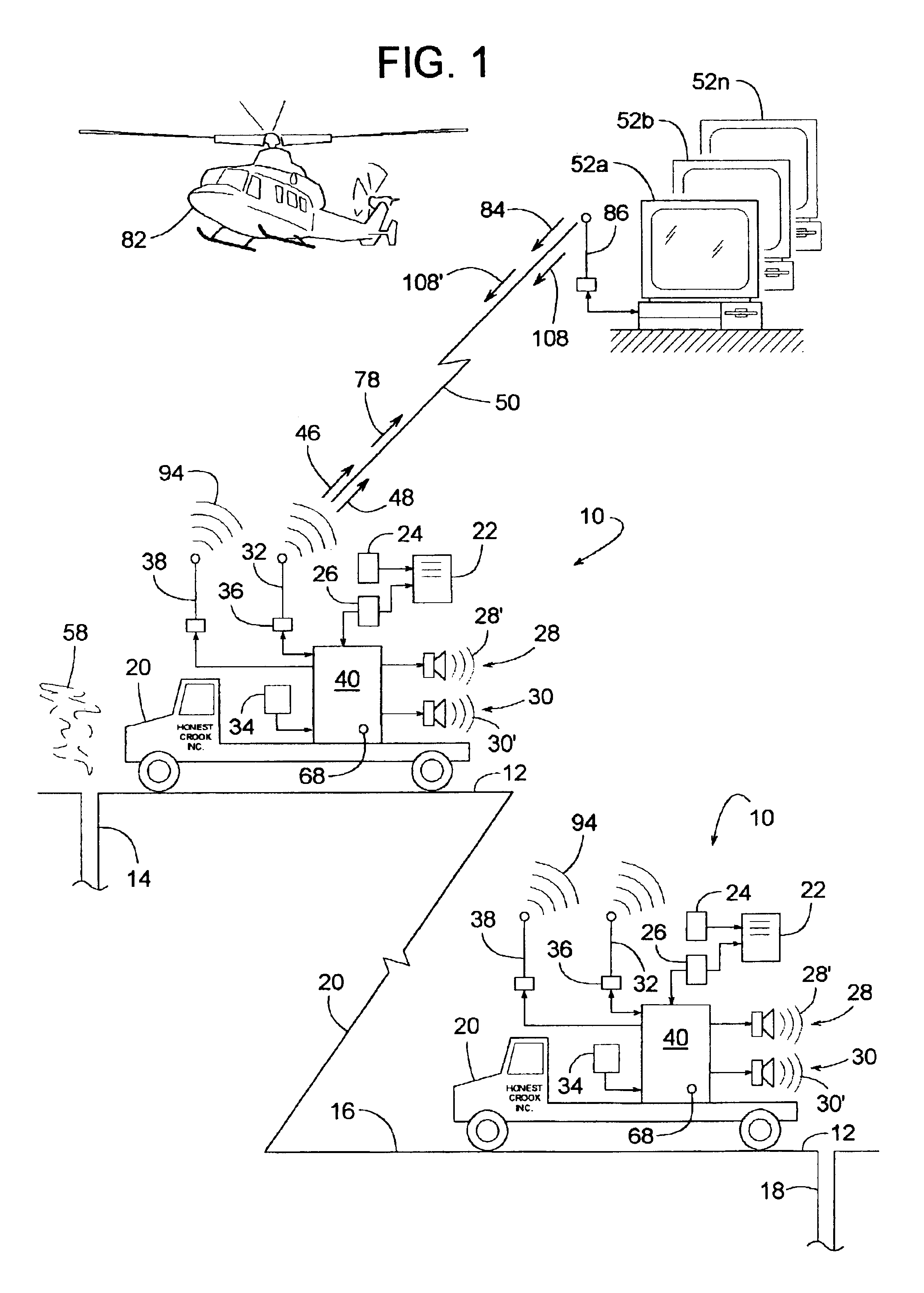

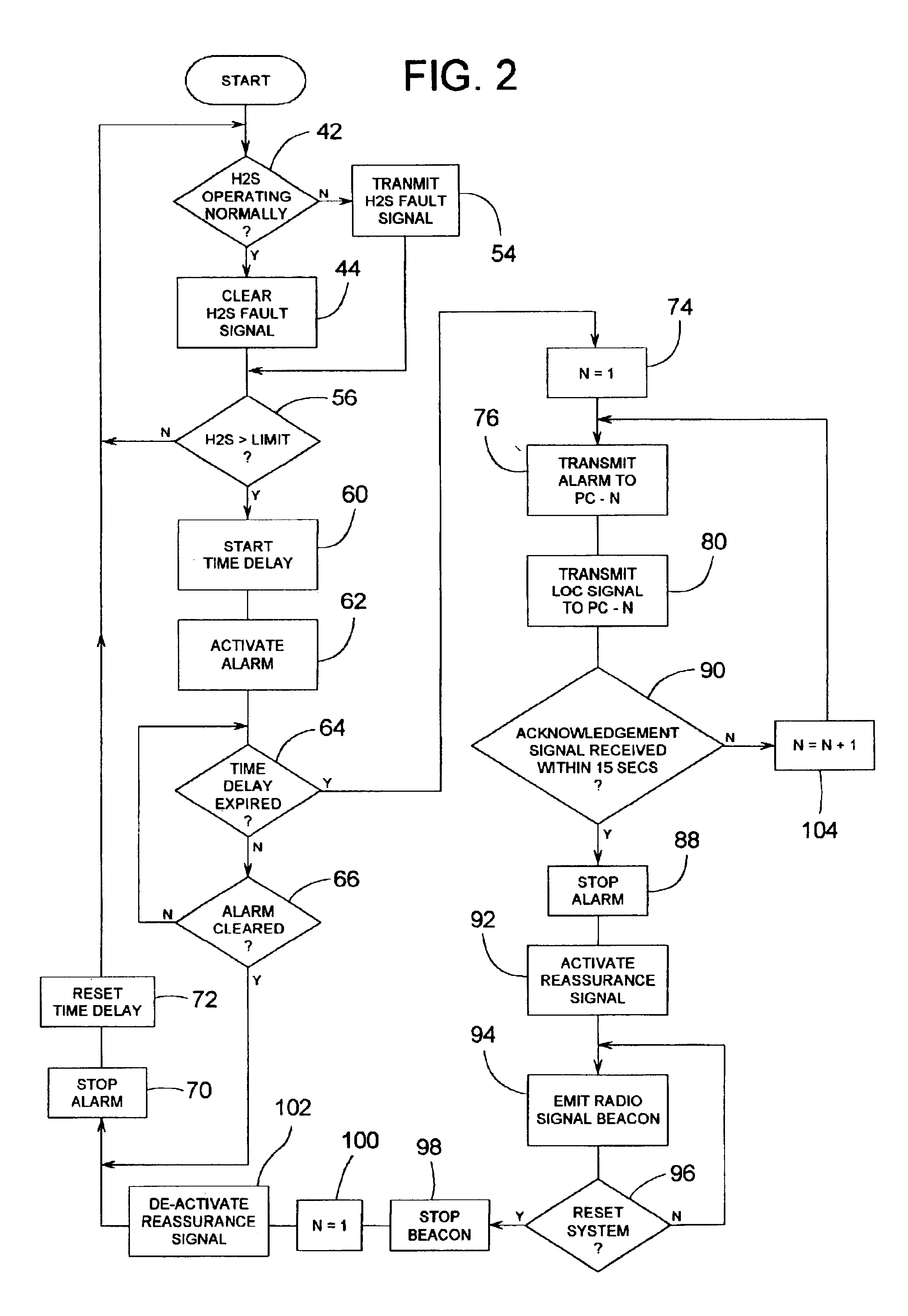

Mobile system for responding to hydrogen sulfide gas at a plurality of remote well sites

ActiveUS6954143B2Improve work safetyAnalysing fluids using sonic/ultrasonic/infrasonic wavesMaterial analysis by electric/magnetic meansEngineeringToxicity

A mobile system travels with a work crew to various remote well sites and monitors the presence of H2S (hydrogen sulfide gas) at those sites. If the concentration of H2S reaches a toxic level, the system notifies a distant host computer of not only the problem but also where the problem exists. Help can then be dispatched to the known area. In some embodiments, the system notifies the work crew when help is on the way.

Owner:SHEPHERD SAFETY SYST LLC

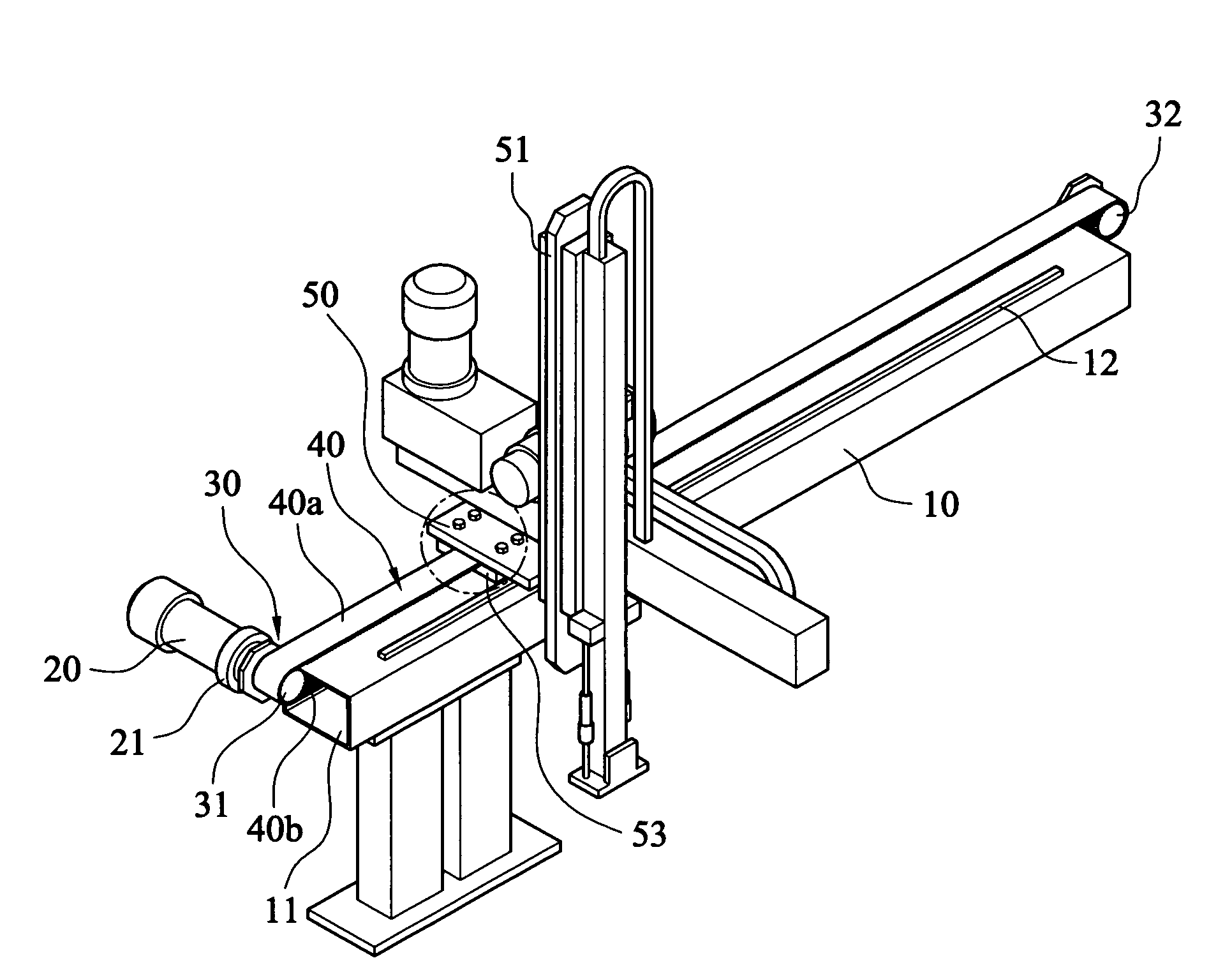

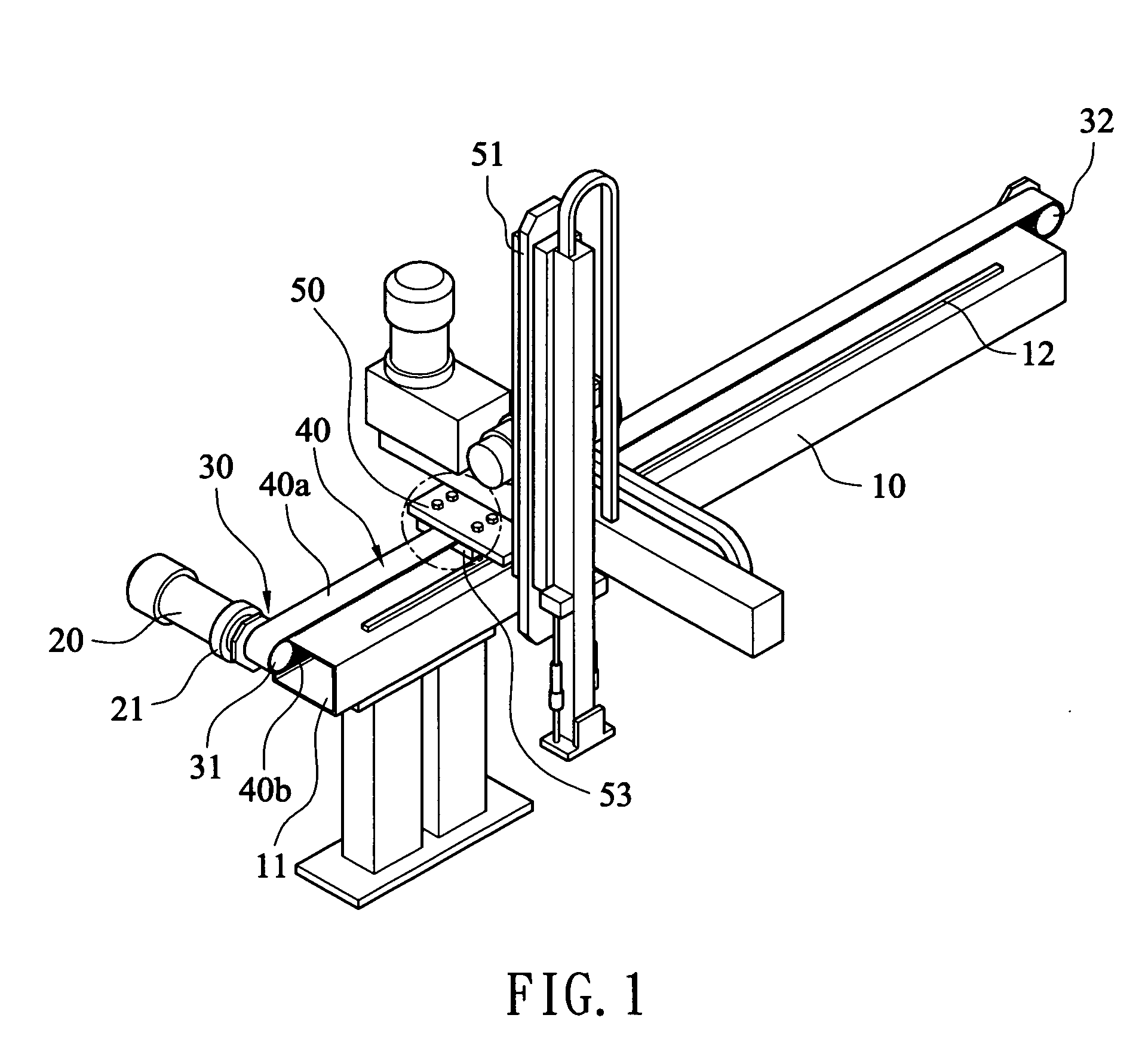

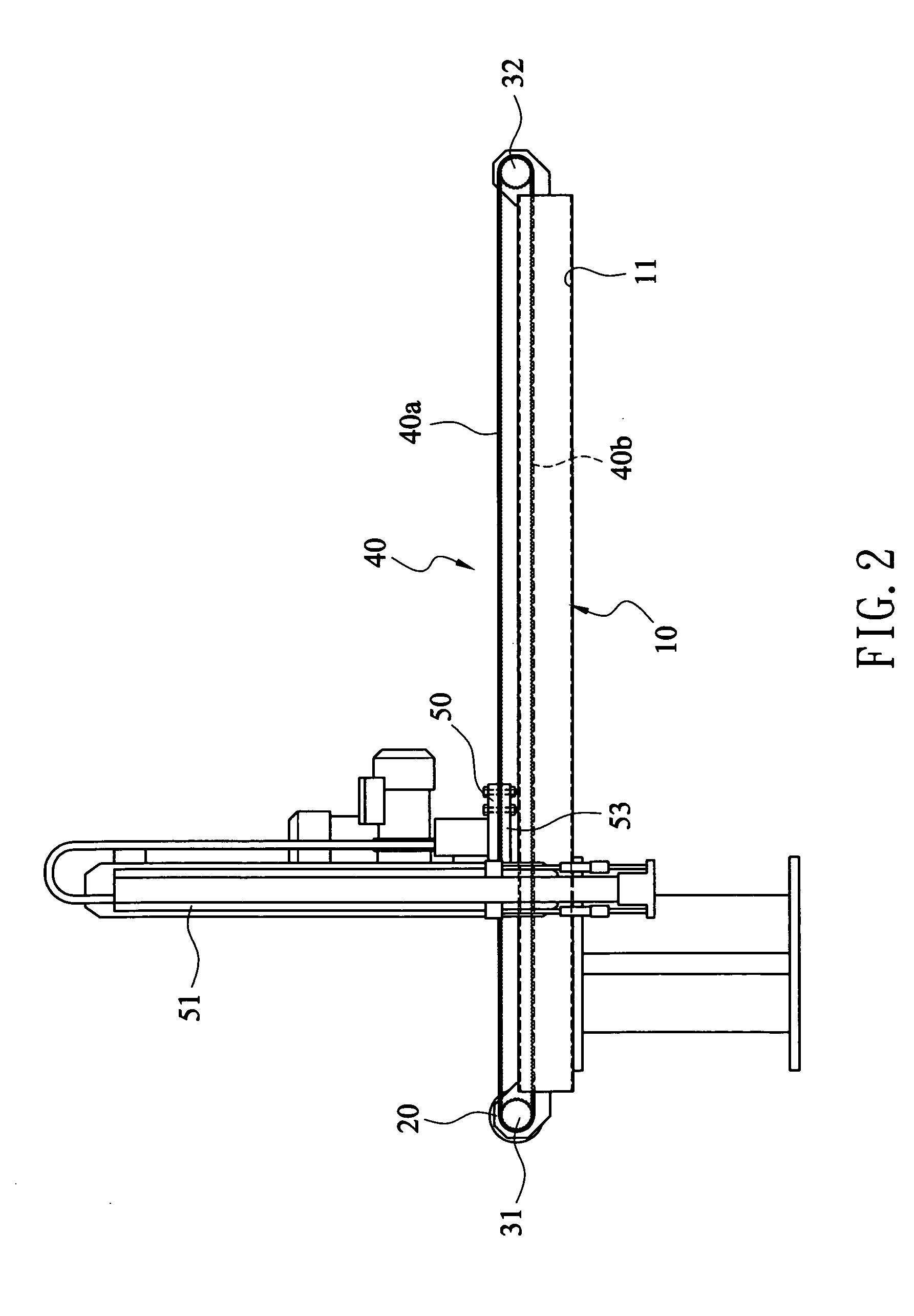

Structure of mechanical arm transmission structure

InactiveUS20080096705A1Improve work safetyPrevent fallingProgramme-controlled manipulatorGearing controlEngineeringTransmission belt

A mechanical arm transmission structure includes a tubular horizontal base, a drive belt wheel and a driven belt wheel mounted inside the horizontal base, a transmission belt mounted on the drive belt wheel and the driven belt wheel with the upper part thereof suspending above the horizontal base, a motor mounted outside the horizontal base for rotating the drive belt wheel through a speed reducer, a slide movable with the transmission belt along longitudinal rails at the top of the horizontal base and carrying a mechanical arm, and a holding down block fastened to the bottom side of the slide to affix the slide to the upper part of the transmission belt for allowing movement of the slide with the transmission belt along the longitudinal rails.

Owner:CHANG SHU MAN

Cleaner for the smelt spout of a recovery boiler

ActiveUS7891325B2Improve work safetyPulp liquors combustionHollow article cleaningEngineeringMechanical engineering

A cleaning apparatus for a smelt spout of a recovery boiler, which apparatus comprises a motorized cleaning member (7) for cleaning the smelt spout (1). The cleaning apparatus further comprises a path (5) and a cleaning unit, which comprises motorized transfer means for transferring the cleaning unit to the location of the smelt spout (1) along the path.

Owner:METSO POWER OY

Installation construction method for boiler facilities

InactiveUS20070089295A1Easily carried in installedImprove work efficiencyBoiler supporting/setting arrangementsAssembly machinesBuilding constructionSteel structures

Owner:MITSUBISHI HITACHIPOWER SYST LTD

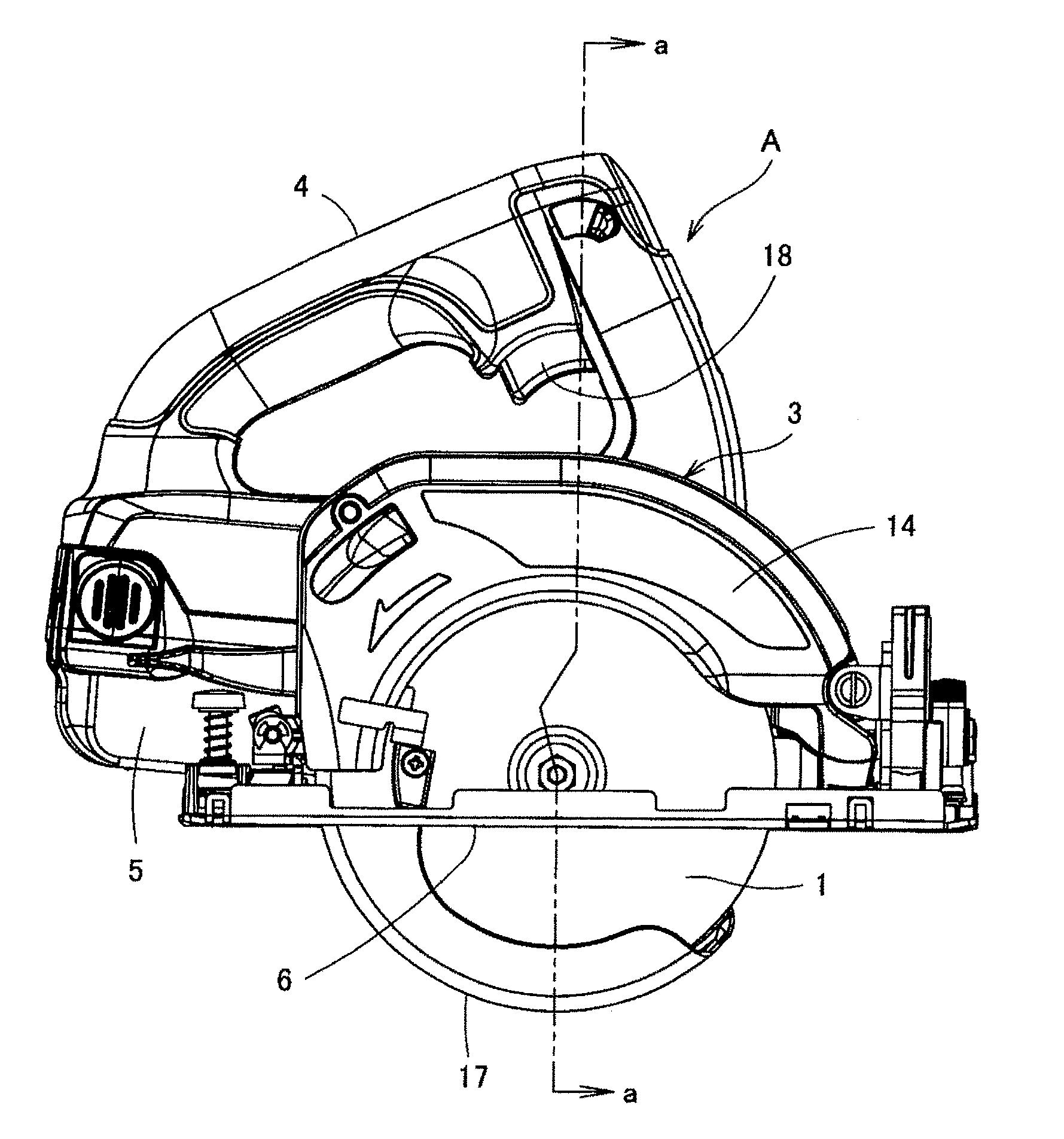

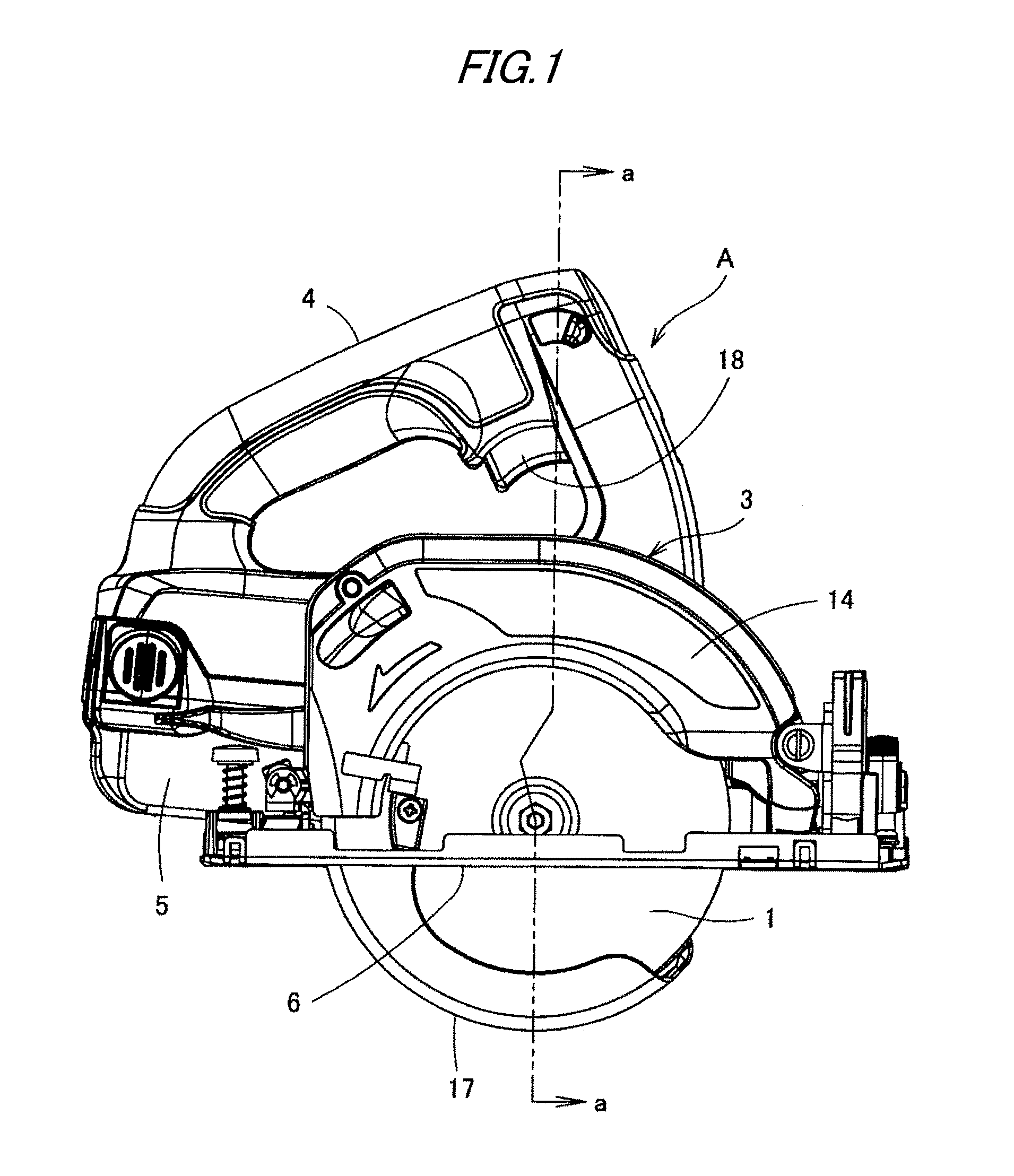

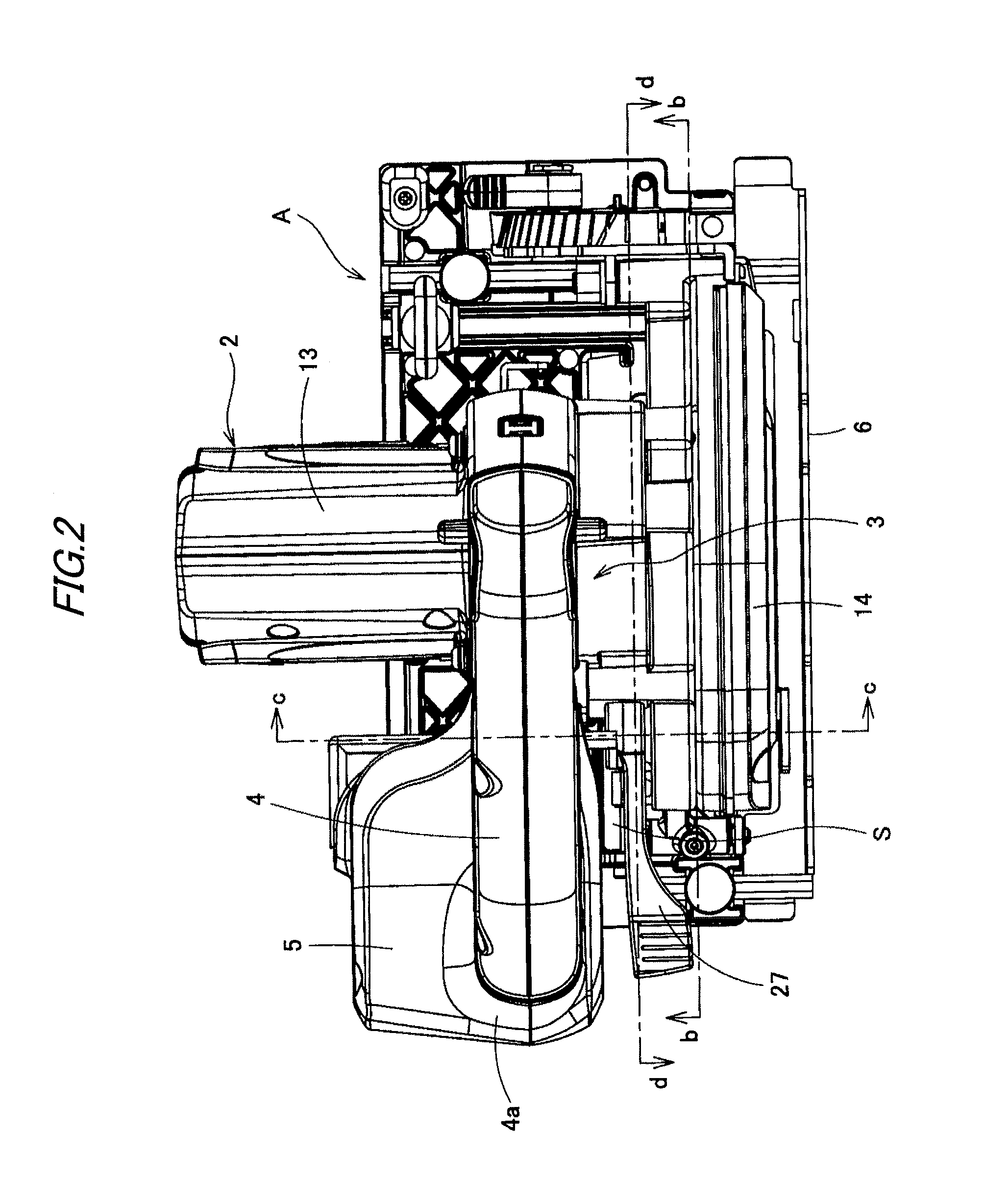

Portable cutting machine

InactiveUS20110308095A1Improve work safetyEasy to operateMetal sawing devicesMetal sawing accessoriesEngineeringElectric motor

A portable cutting machine is provided with: a cutting machine main body (3); a saw blade (1) provided rotatably with respect to the cutting machine main body (3); an electric motor (2) adapted to drive the saw blade (1); a handle (4) which is provided between the saw blade (1) and the electric motor (2) in a first direction parallel to a rotation shaft (9) of the saw blade (1) and extends in a second direction perpendicular to the first direction; a battery pack (5) adapted to drive the electric motor (2); and a surface plate (6) rotatably supported by the cutting machine main body (3). A center in the first direction of the battery pack (5) is located closer to a side of the electric motor (2) than a center in the first direction of the handle (4). The rotation shaft (9) of the saw blade (1) is located on one side of the surface plate (6). A part of the saw blade (1) passes through an opening portion (16) penetrating through the surface plate (6) and is exposed to the other side of the surface plate (6). A projecting amount of the saw blade (1) by which the part of the saw blade (1) projects from the other side of the surface plate (6) is changeable by changing an angle of the surface plate (6) with respect to the cutting machine main body (3). A cutting-depth adjusting mechanism adapted to change the angle of the surface plate (6) with respect to the cutting machine main body (3) is located, in the first direction, closer to a side of the saw blade (1) than the battery pack (5).

Owner:MAX CO LTD

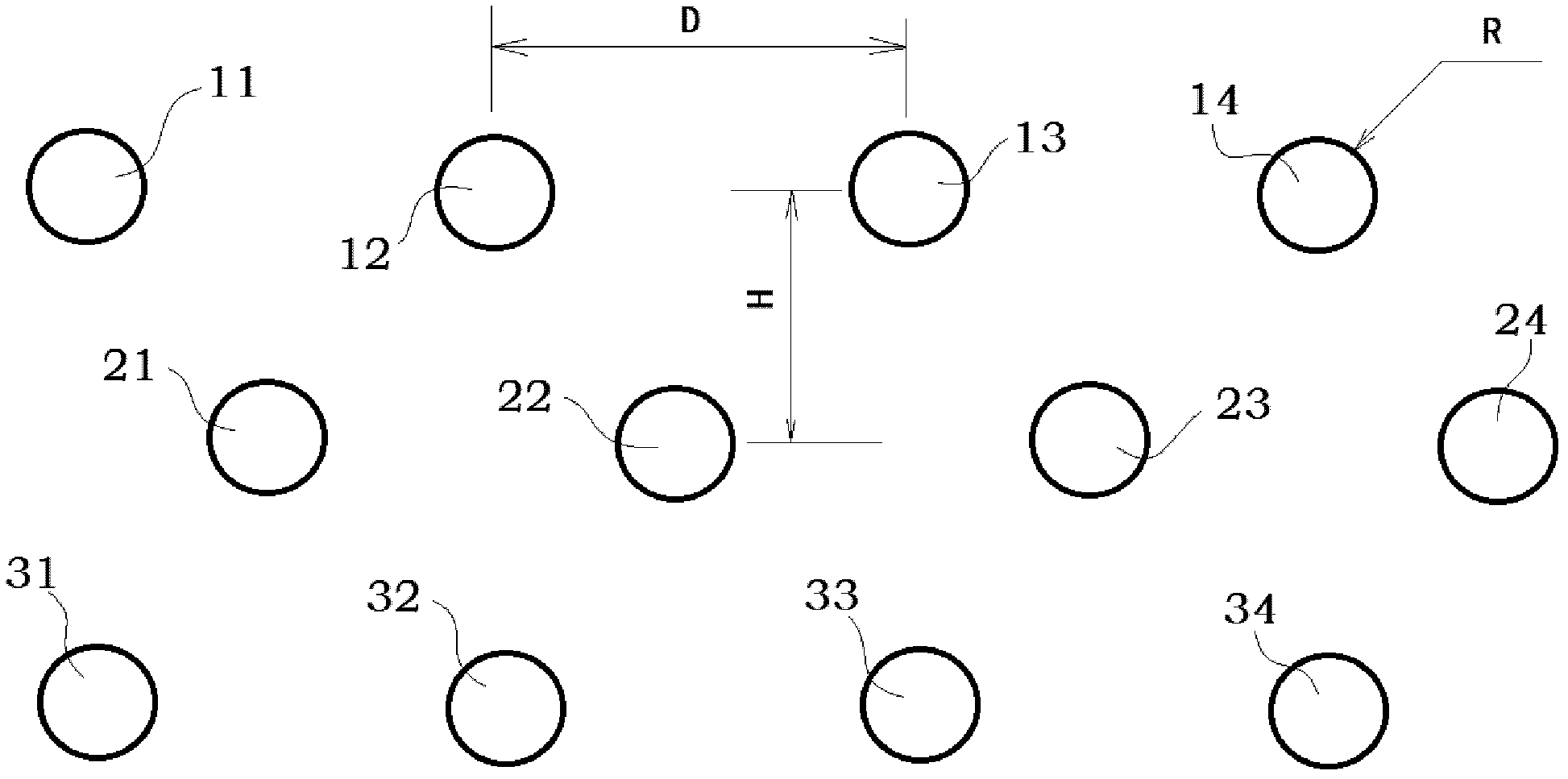

Process and system for striping and mining solid ore rock masses of surface mine

InactiveCN102562070AImproved drilling processLarge block rate and gun root residual rate decreasedOpen-pit miningPetrologyDrill hole

The invention relates to a process for striping and mining solid ore rock masses of a surface mine, which comprises a step of drilling a blast hole array, wherein the blasthole array comprises a plurality of rows of blast holes; adjacent rows of blast holes are mutually staggered along the directions of the rows; each blast hole corresponds to a non-blast hole of the adjacent row of blast holes; on each row, the distance between each two adjacent blast holes serves as a hole pitch; and the distance between each two adjacent blast hole rows serves as a row pitch. The process is characterized in that a small-aperture drill bit and a small hole network spacing are selected to drill the holes; the rock drilling speed is improved for more A times than before; the construction operation is carried out according to the small hole network spacing; the number of the drilled holes is increased to B times that of the original drilled holes; the area of each drilled hole is equivalent to one Bth of the area of the original drilled hole; and both A and B are natural numbers greater than 1. According to the invention, the boulder frequency and the blast root residual ratio can be greatly reduced, the striping and mining operations are continuously carried out, the process is convenient to operate, other investment is not required, the explosive load is unchanged, the drilling time is shortened, and the secondary blast quantity is greatly reduced.

Owner:江西分宜珠江矿业有限公司

Shielding arrangement for the smelt spout area of a recovery boiler

ActiveUS7900567B2Improve work safetyPrevents the possible smelt splashesPulp liquors combustionCurtain suspension devicesEngineeringRecovery boiler

A method for improving the operation safety of the smelt spout area of a recovery boiler, which smelt spout area comprises a working area (6), as well as smelt spouts (2) connected to the lower part of the boiler for directing the smelt from the boiler to a dissolving tank (4). In the method the smelt spouts (2) are separated from the working area (6) by a shielding wall (8, 10) arranged movable in relation to the smelt spouts. The invention also relates to a smelt spout area of a recovery boiler.

Owner:METSO POWER OY

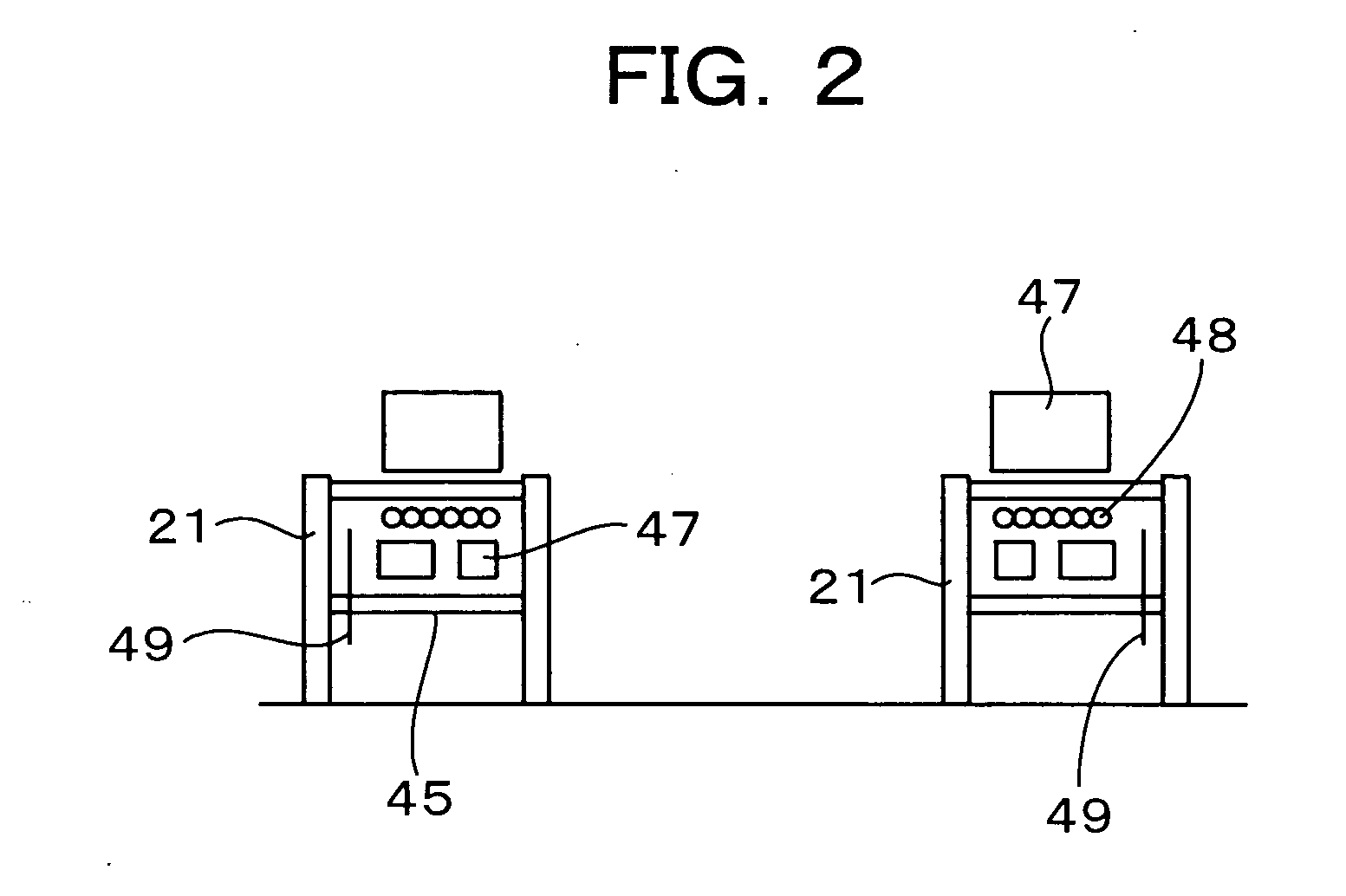

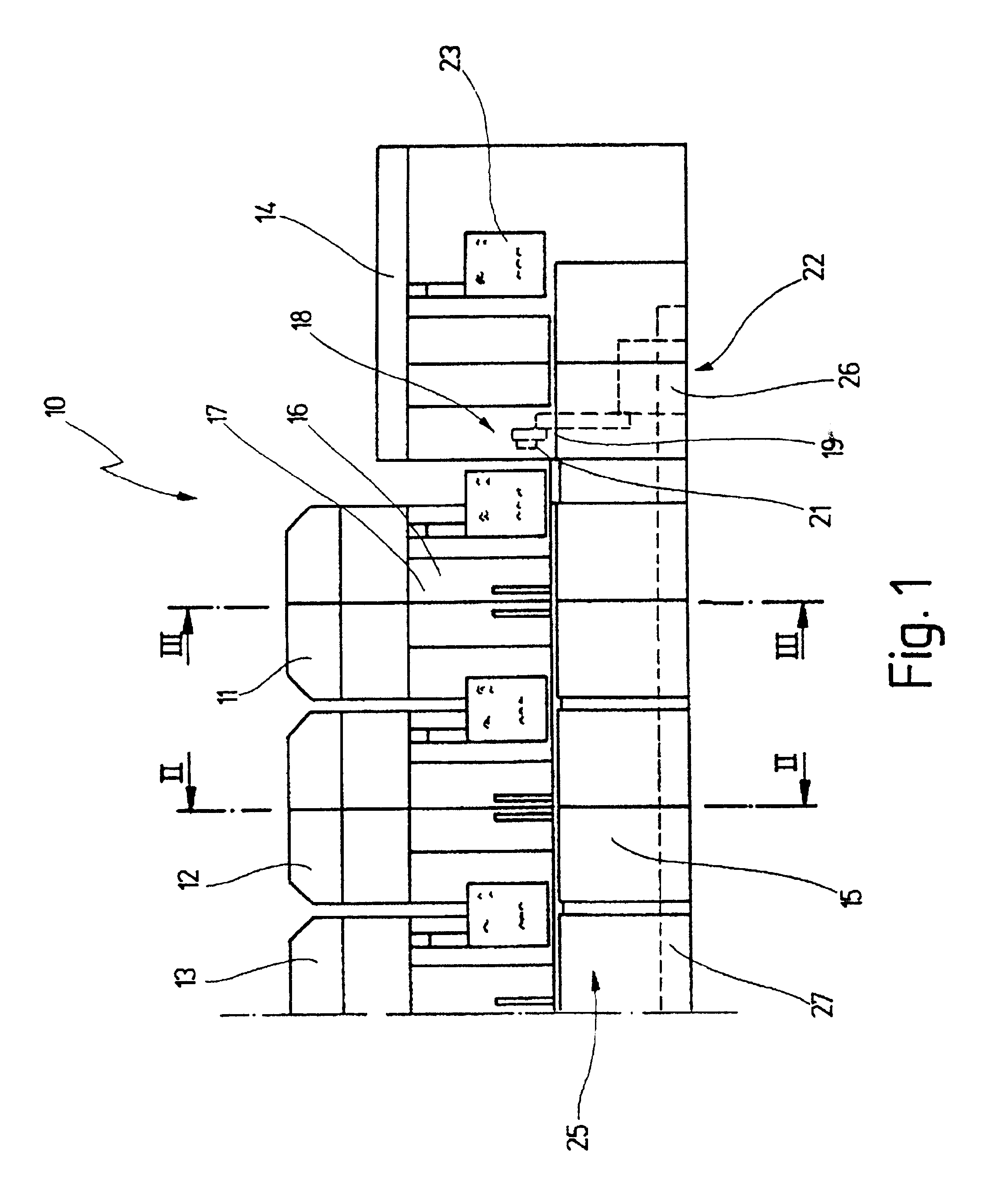

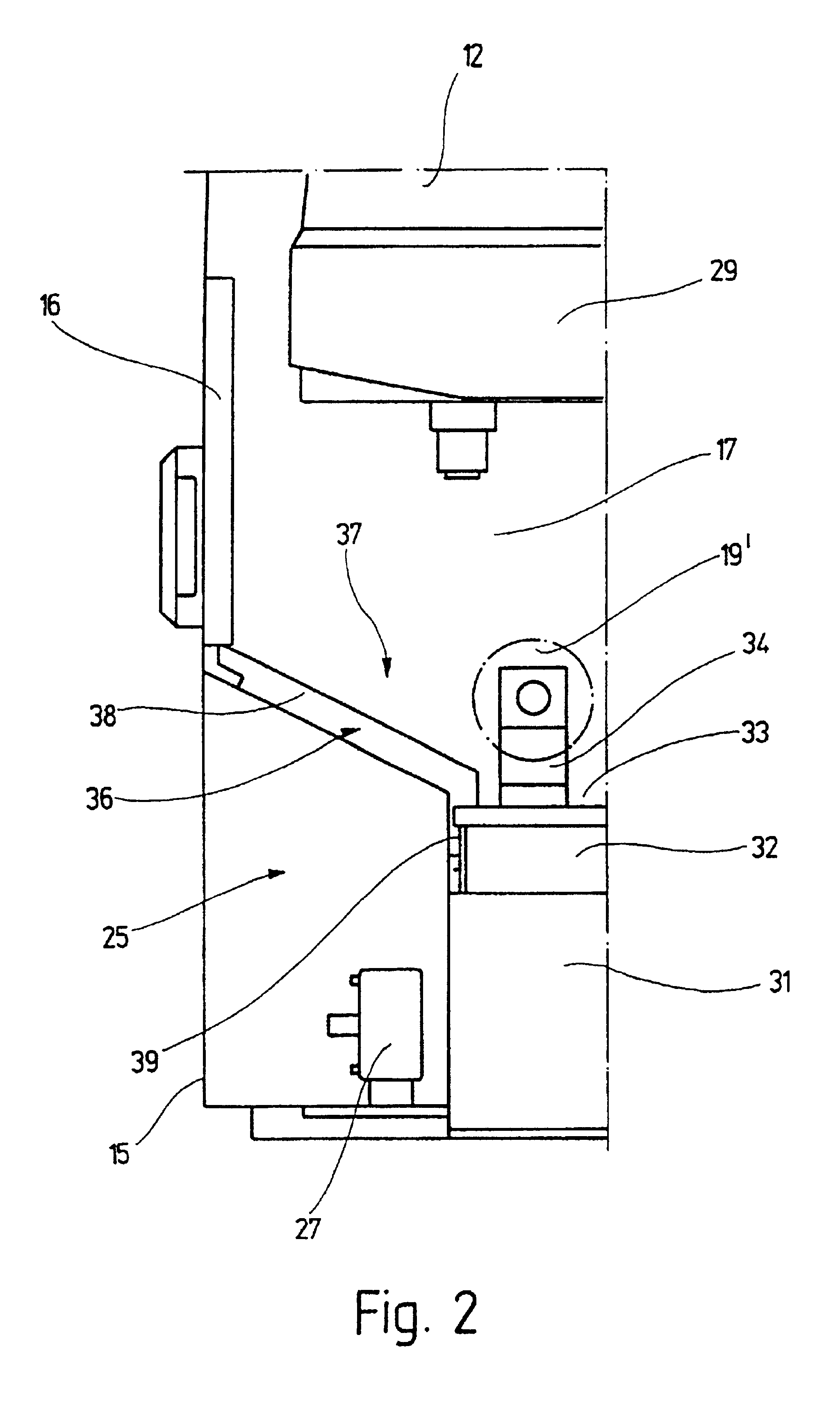

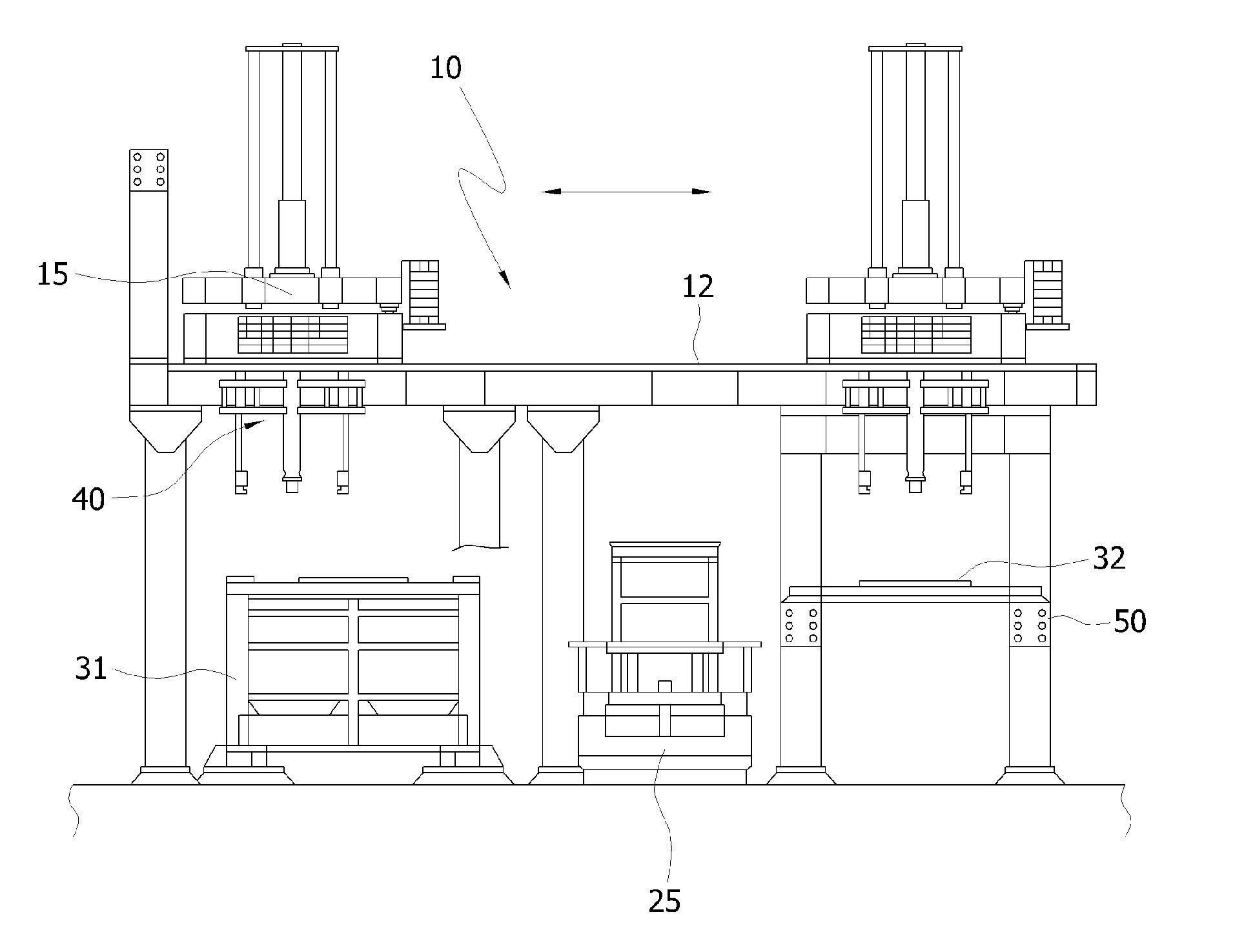

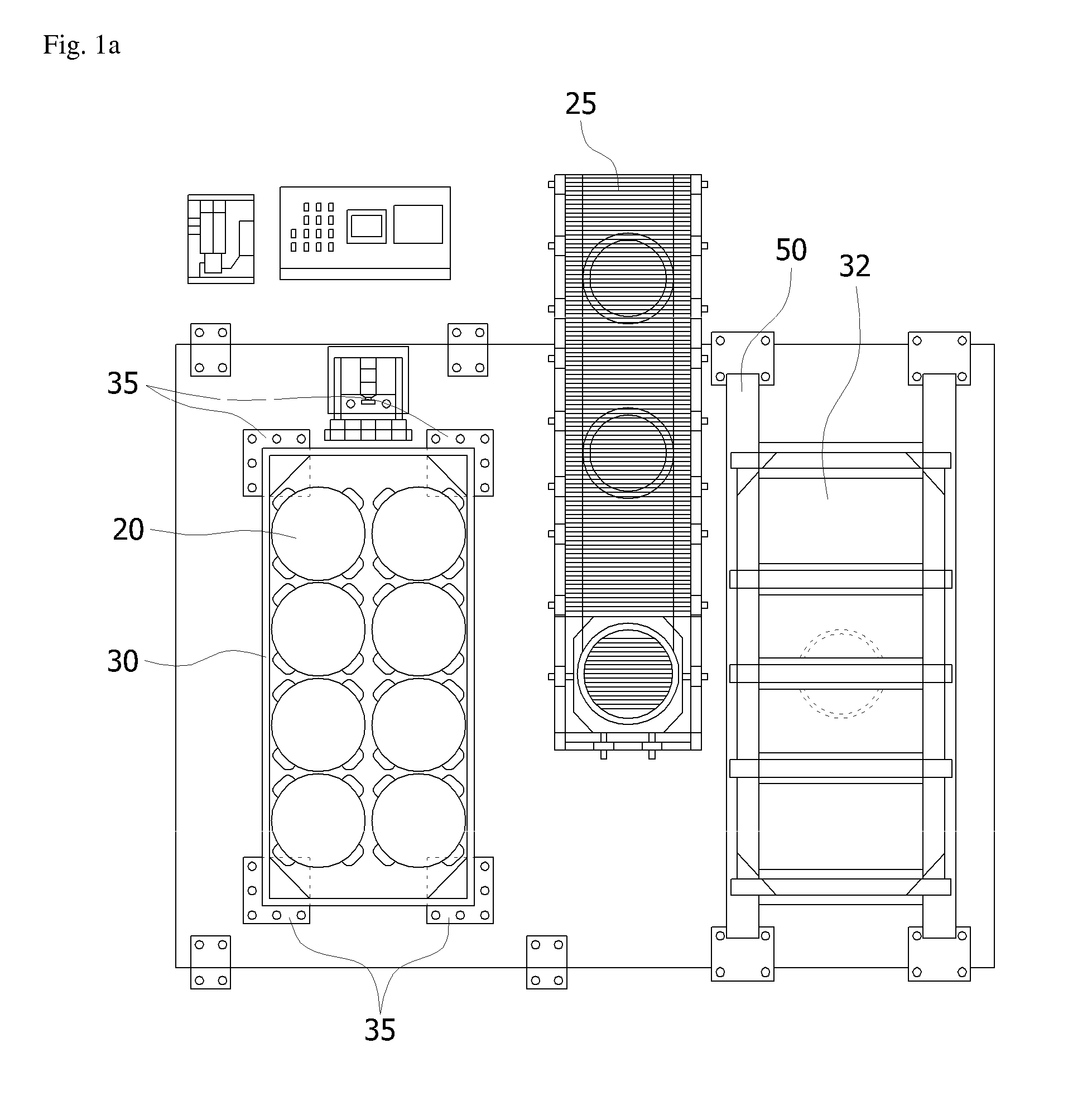

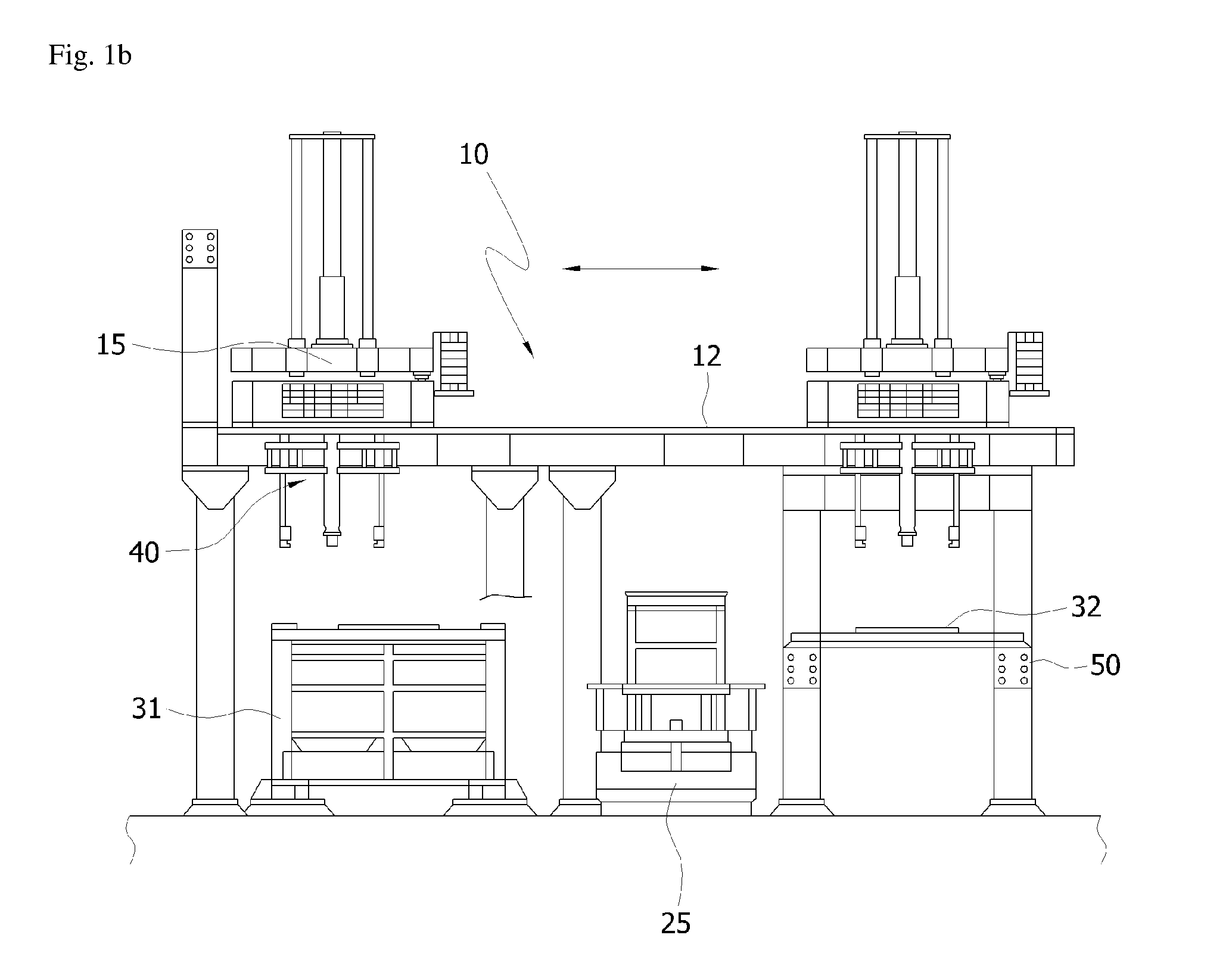

Machine tool center

InactiveUSRE40690E1Increased functional reliabilityImprove work safetyOther manufacturing equipments/toolsMetal working apparatusEngineeringMachine tool

A machine tool center (10) displays at least one machine tool (11, 12, 13) which has a working area (17) accessible through an operator door (16) to process workpieces (21). Furthermore, a loading / unloading station (14) for the workpieces (21) and a loading device (22) which transports the workpieces (21) between the loading / unloading station (14) and the respective machine tool (11, 12, 13) and changes these at the machine tool (11, 12, 13) are also provided. In the new machine tool center (10) the loading device (22) is arranged below the working space (17) of the machine tool (11, 12, 13) (FIG. 1).

Owner:CHIRON WERKE

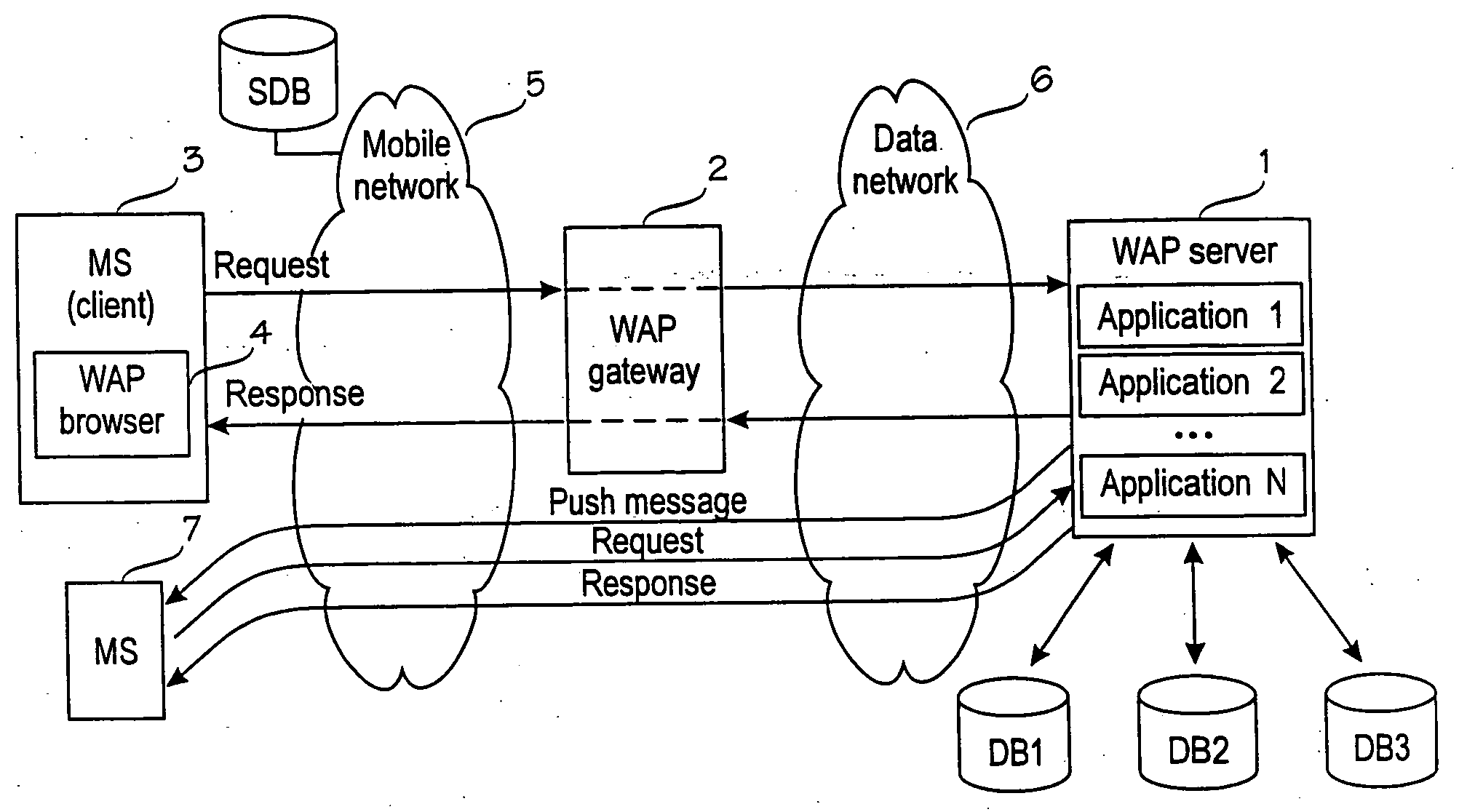

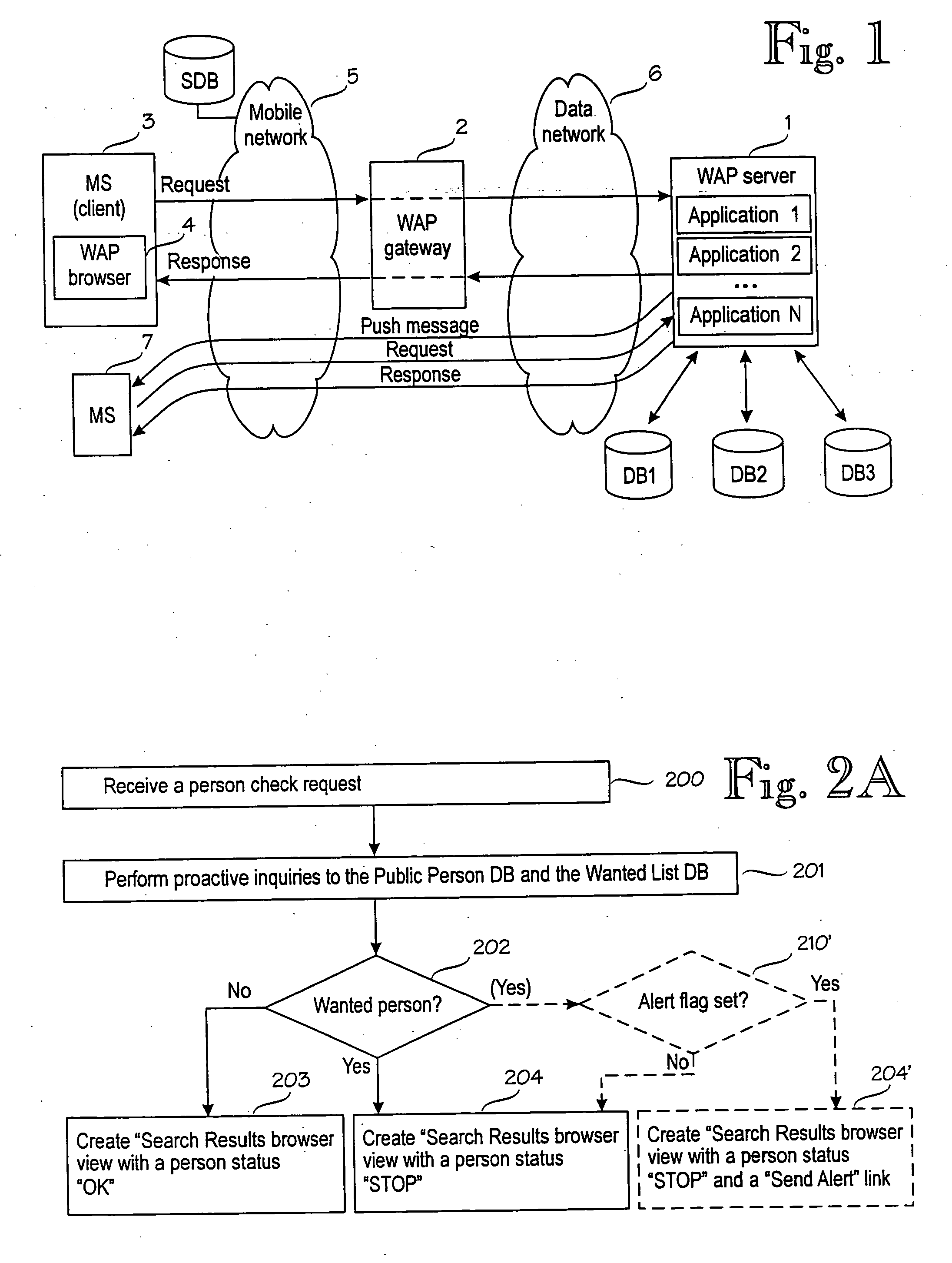

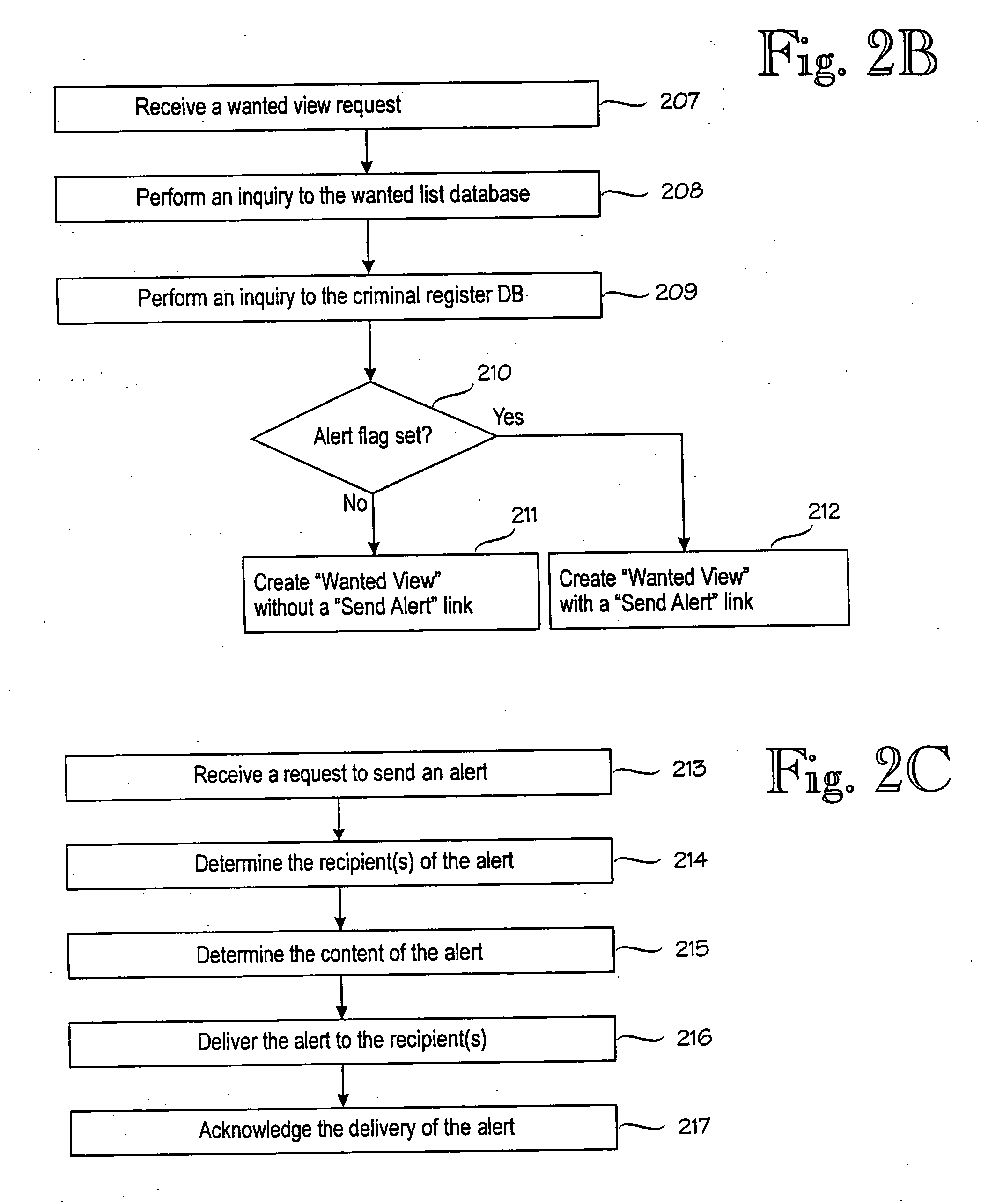

Method and server for providing database inquiry services

InactiveUS20050114301A1Improve work safetyDigital data processing detailsData switching by path configurationUser deviceCommunication device

The present invention relates to computer database searches or inquiries carried out with a user device of a communications network. In an embodiment of the present invention, a person who is querying databases using a user communication device (3) and an inquiry application located on the network server (1) can receive an additional trigger link from the inquiry application in case predefined conditions are met in the query. The querying person may use the trigger link to inform predefined parties (7) that he / she has important and urgent information to share with them. In an alternative embodiment, the inquiry application (1) will deliver a notification to one or more predefined recipient (7) automatically in case the predefined conditions are met in the query.

Owner:NOKIA CORP

Apparatus and method for loading drums into drum container

ActiveUS20110194922A1Improve work safetySimple loading processSemiconductor/solid-state device manufacturingPortable shielded containersReciprocating motionEngineering

An apparatus and method for loading drums into a drum container, in which a function of gripping a lid of the drum container is added to a gripper used when a drum filled with radioactive waste is loaded into the drum container, thereby considerably reducing loading time of the drums, risk of dropping the drum, and preventing a radiation exposure risk. The apparatus includes a drum feeder transferring a drum, a drum container into which the drums transferred through the drum feeder are sequentially loaded, a support frame on which a lid of the drum container is placed when the drums are being loaded, and a crane having a gripper that selectively grips and transfers the drum or the drum container lid. The gripper includes radial gripper arms, an arm hydraulic unit reciprocating the gripper arms, jaws on inner sides of the gripper arms and gripping an outer surface of the drum, and latches for latching the drum container lid.

Owner:KOREA HYDRO & NUCLEAR POWER CO LTD

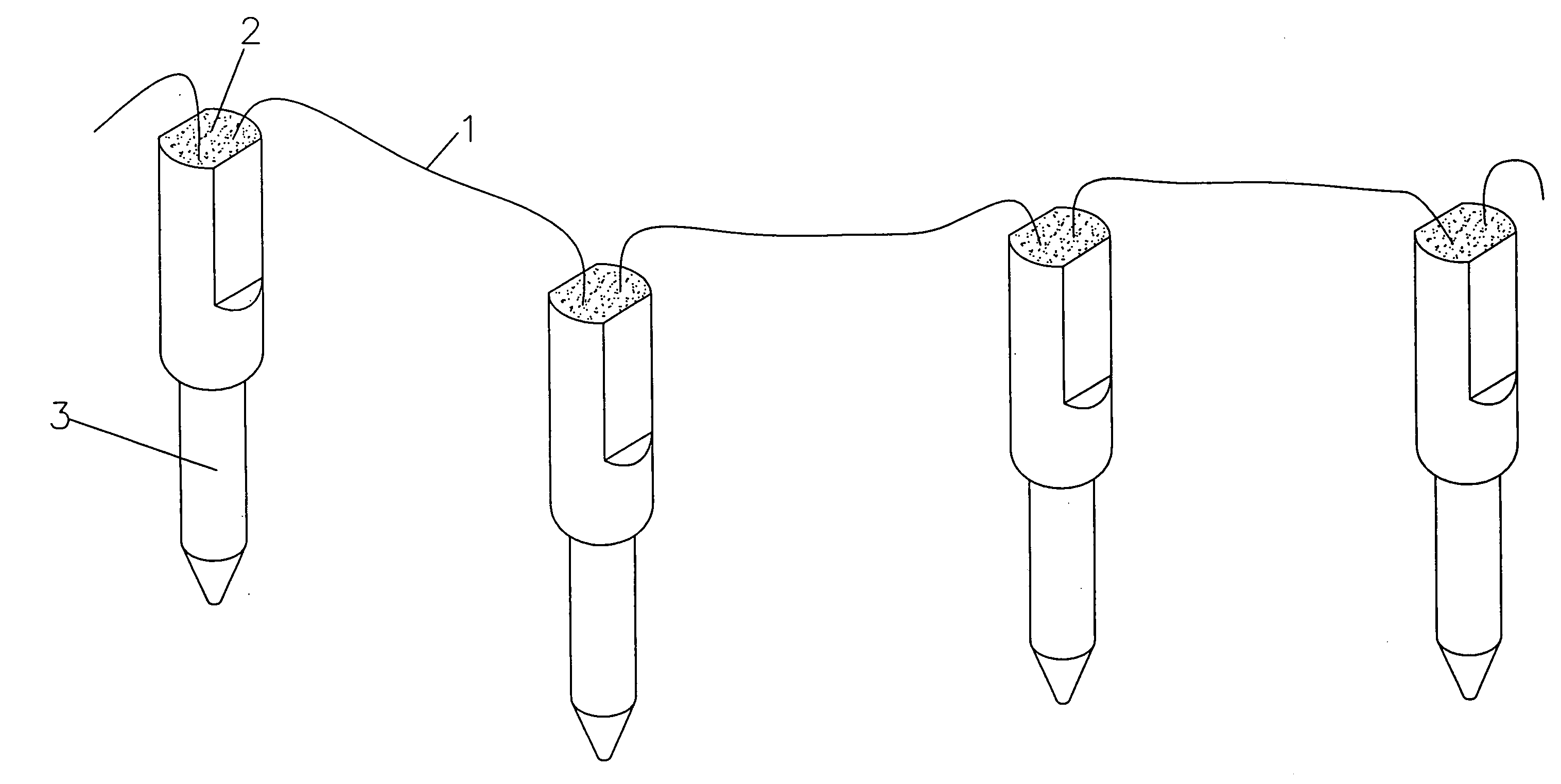

Festival lamp string & its manufacturing method

InactiveUS20070058371A1Simple structureFew partsLighting support devicesDecorative purpose lampsIndustrial scaleEngineering

The present invention involves to a festival lamp string comprised of cords, a certain number of sockets and coordinated illuminators; said illuminators are individually and sequentially connected with the cords, said socket is molded over the contacting portion of the illuminator and the cords by filling package. In manufacturing, firstly connects the sockets to the cords sequentially and individually, then cover the decorated cap on the illuminator respectively, next place the assembled cords and illuminator and the decorated cap into the inside of jetting molder so that the contacting portions of the cords and illuminator and the decorated cap are exactly laid on the die cavity, finally inject resinoid into die so as to fill up all the cavity of the die to form a socket covering the contacting portions of the cords and illuminator and the decorated cap, the temperature of the resinoid is lower than 80° C., so a festival lamp string with decorated cap is manufactured. It possesses some features, such as simple structure, less parts and good tightness which can be used in wider range whatever commercial power or not, wherever inside or outside, and it is also to simplify operation, improve work safety and up-to-standard rate, and suit to industrial scale production.

Owner:CHEN MING PEI

Fan system for vehicles and method for controlling fan in vehicles

ActiveUS7304404B2Prevention of error in such connectionImprove work safetyHybrid vehiclesCell temperature controlElectricityElectrical battery

Owner:TOYOTA JIDOSHA KK

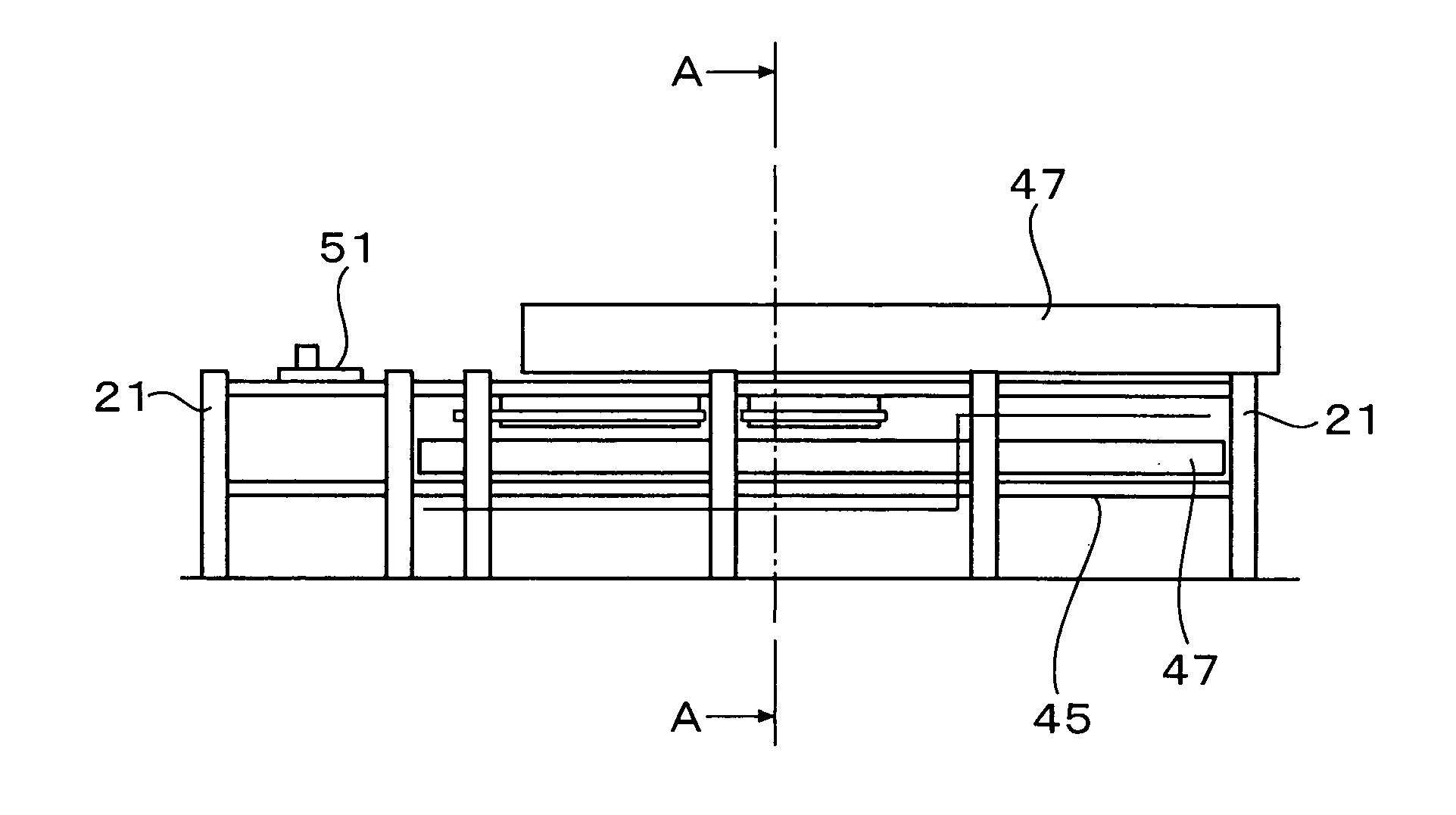

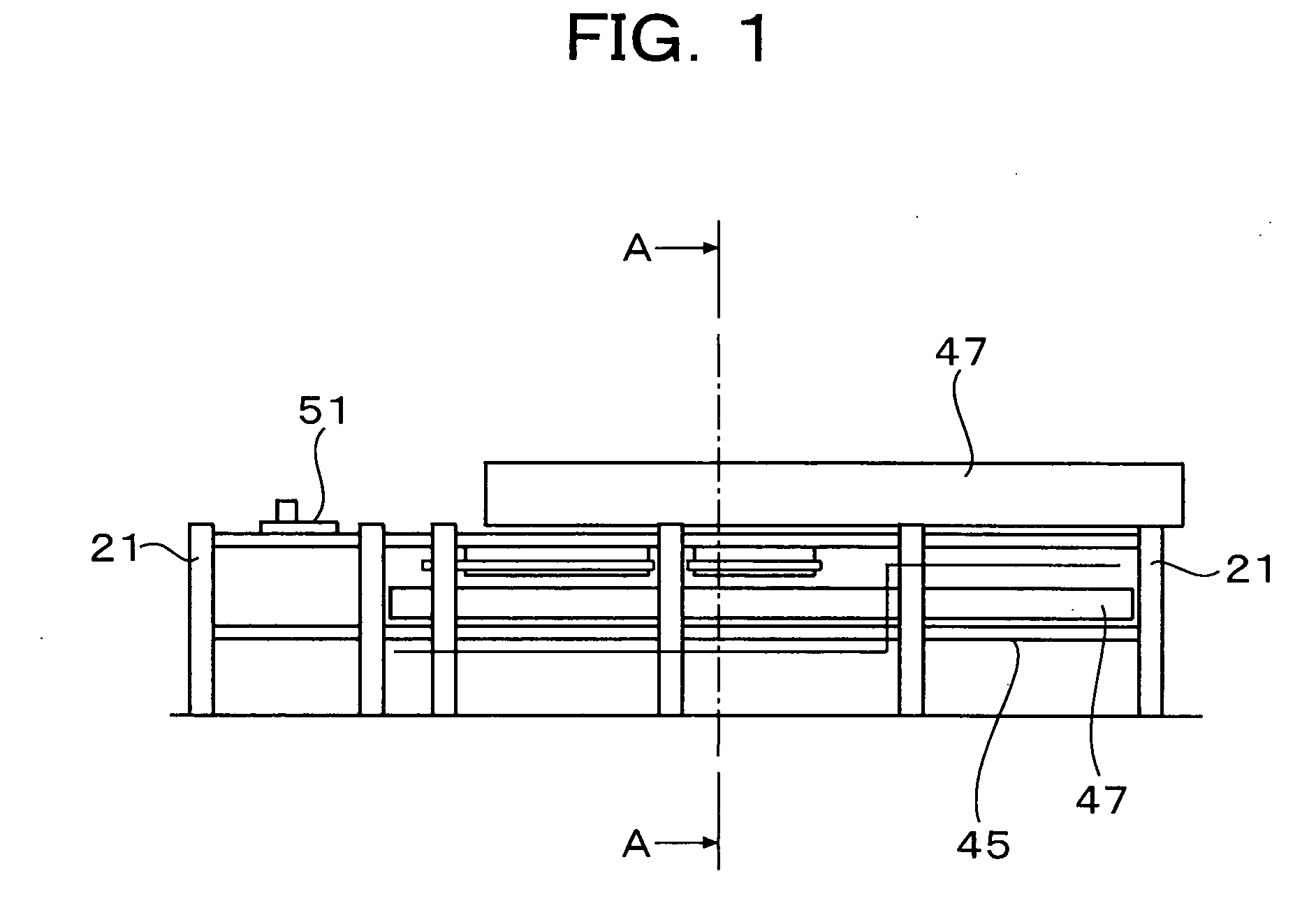

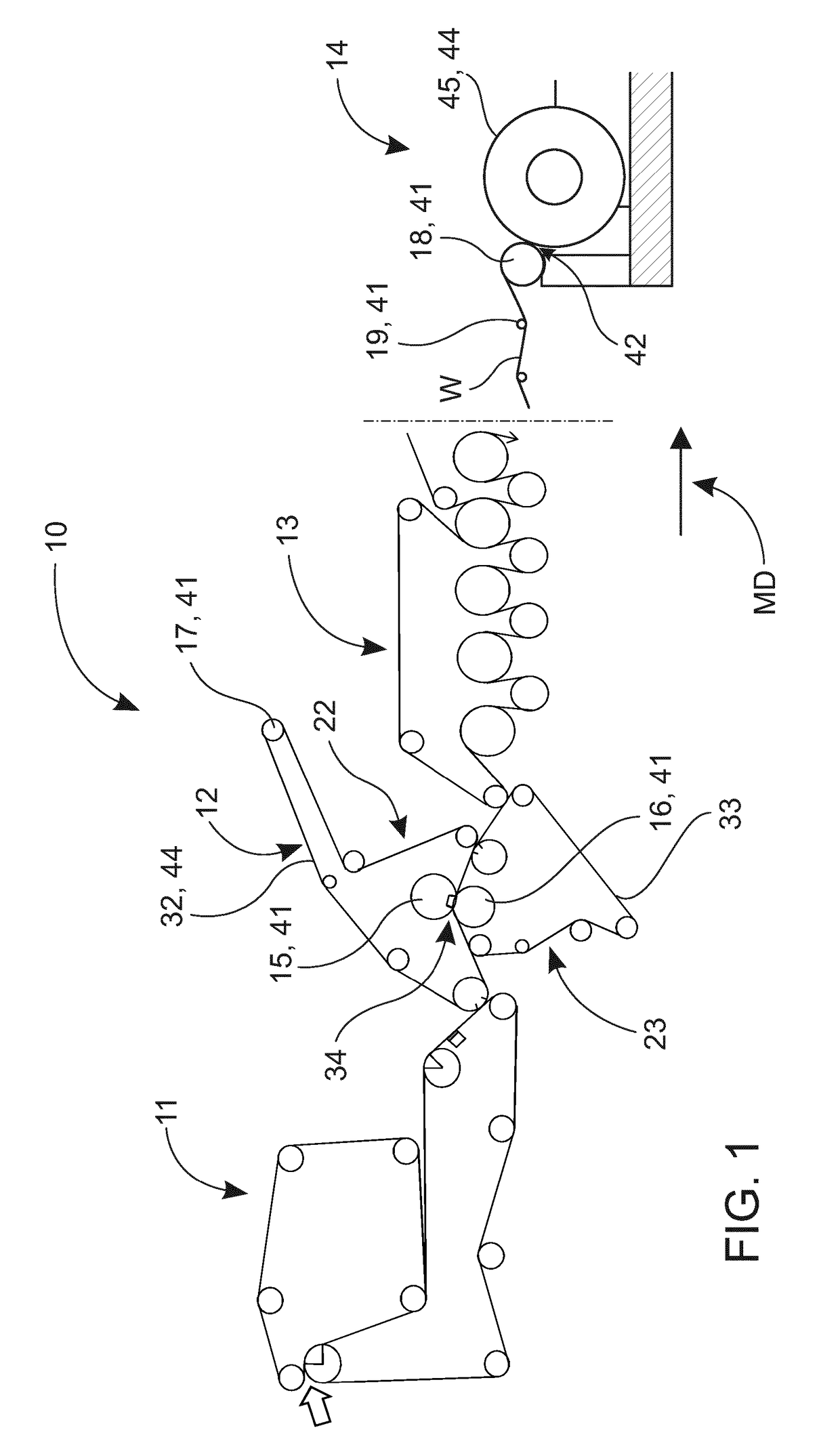

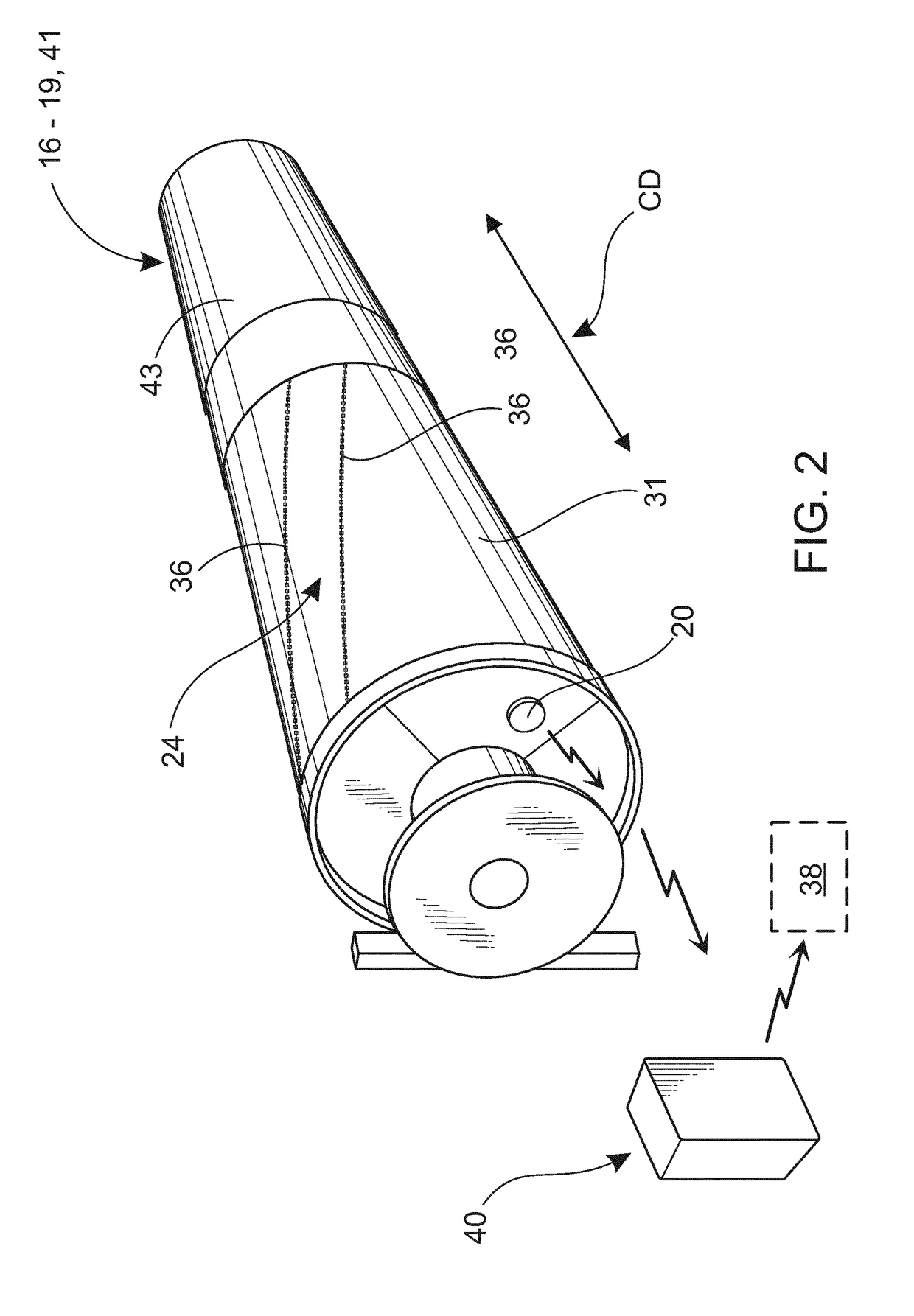

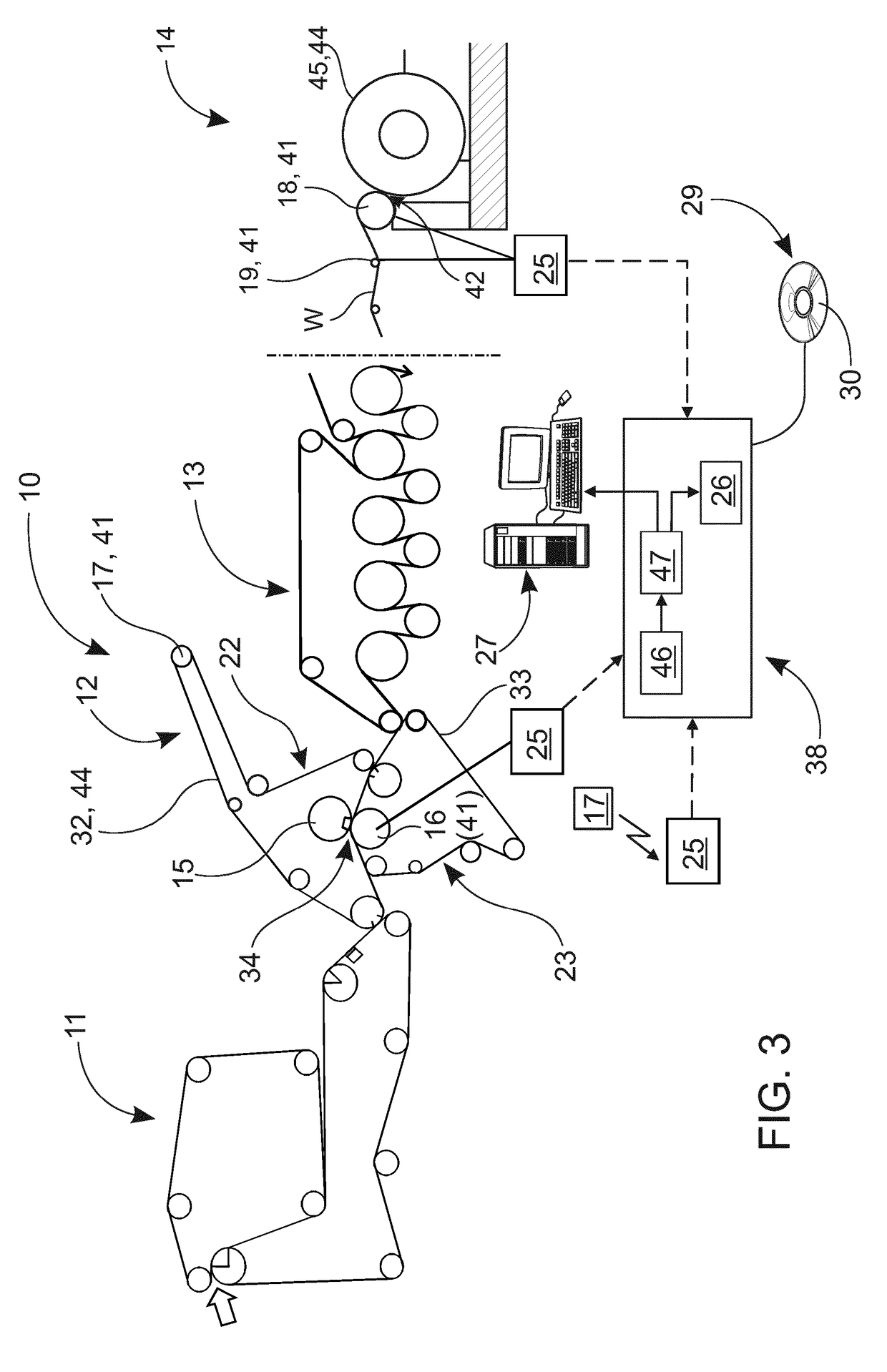

Method, System and a Computer Program Product for Condition Monitoring of a Continuous Element Moving in a Fiber Web or Paper Finishing Machine

ActiveUS20190048526A1Improve work safetyEasy and quick observationTension measurementPaper-making machinesFiberMechanical engineering

The invention relates to a method for monitoring the condition of a continuous element (44) moving in a fiber web or paper finishing machine, said monitoring being performed with a rotating machine element (41), which is equipped with a sensor assembly (24) that measures force or pressure and against which the continuous element moves. In the method, the machine element is made to rotate against the continuous element, a measurement signal (25) is generated between the machine element and the continuous element with the sensor assembly, and a cross-directional profile (21) of force or pressure generated between the machine element and the continuous element is formed from the measurement signal. Said moving continuous element is a fabric (32, 33) installed in a fabric run (22, 23) traveling via the machine element. In the method, the fabric is additionally installed in a fabric run, wherein it moves via said machine element equipped with a sensor assembly, a reference profile (35) is formed for the cross-directional profile after installing the fabric in the fabric run, the cross-directional profile formed from the measurement signal and representing force or pressure generated between the machine element and the fabric is compared with the reference profile, and information (37) is produced from the comparison for monitoring the condition of the fabric. The invention also relates to a corresponding system and a computer program product.

Owner:VALMET TECH OY

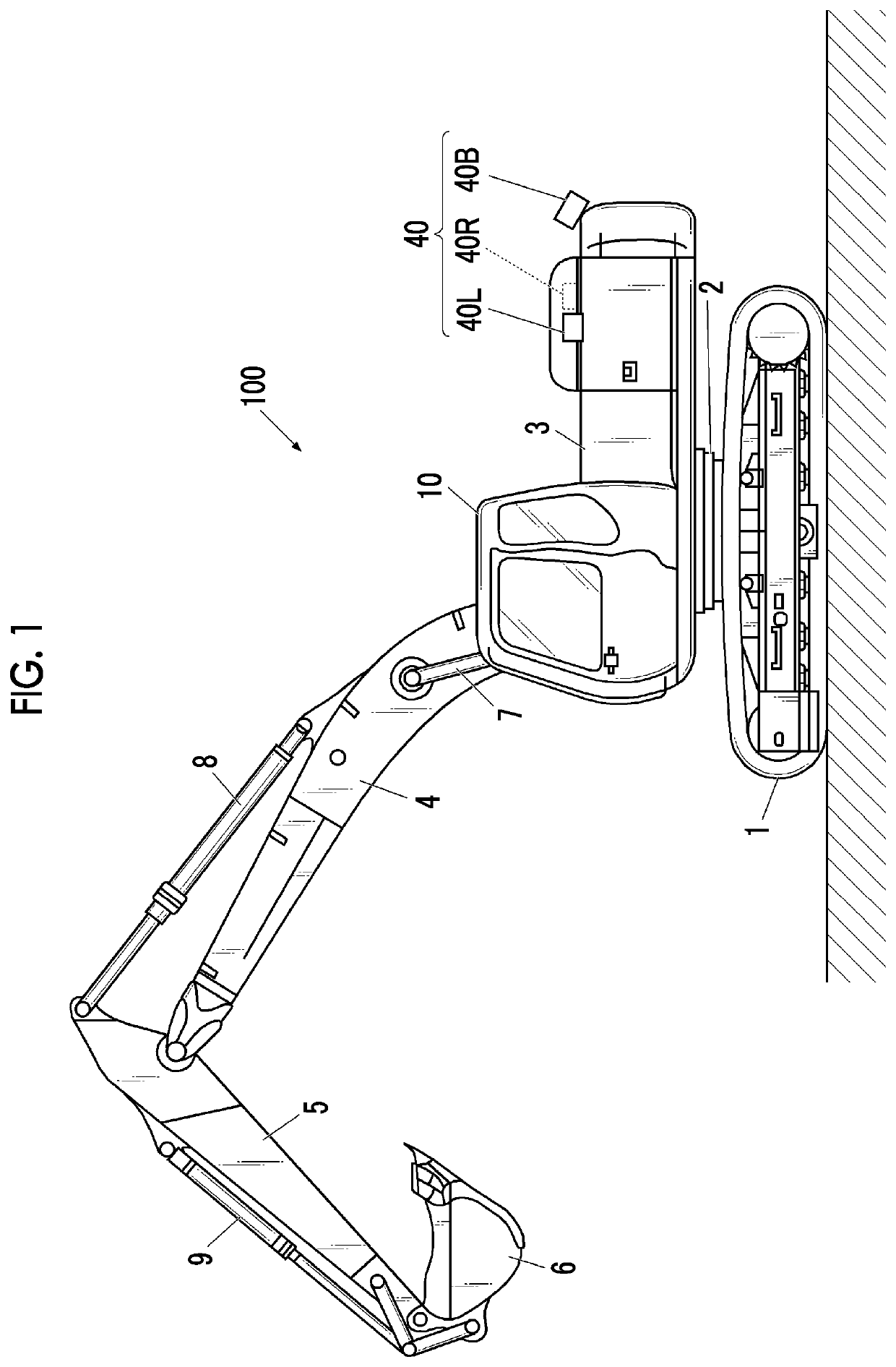

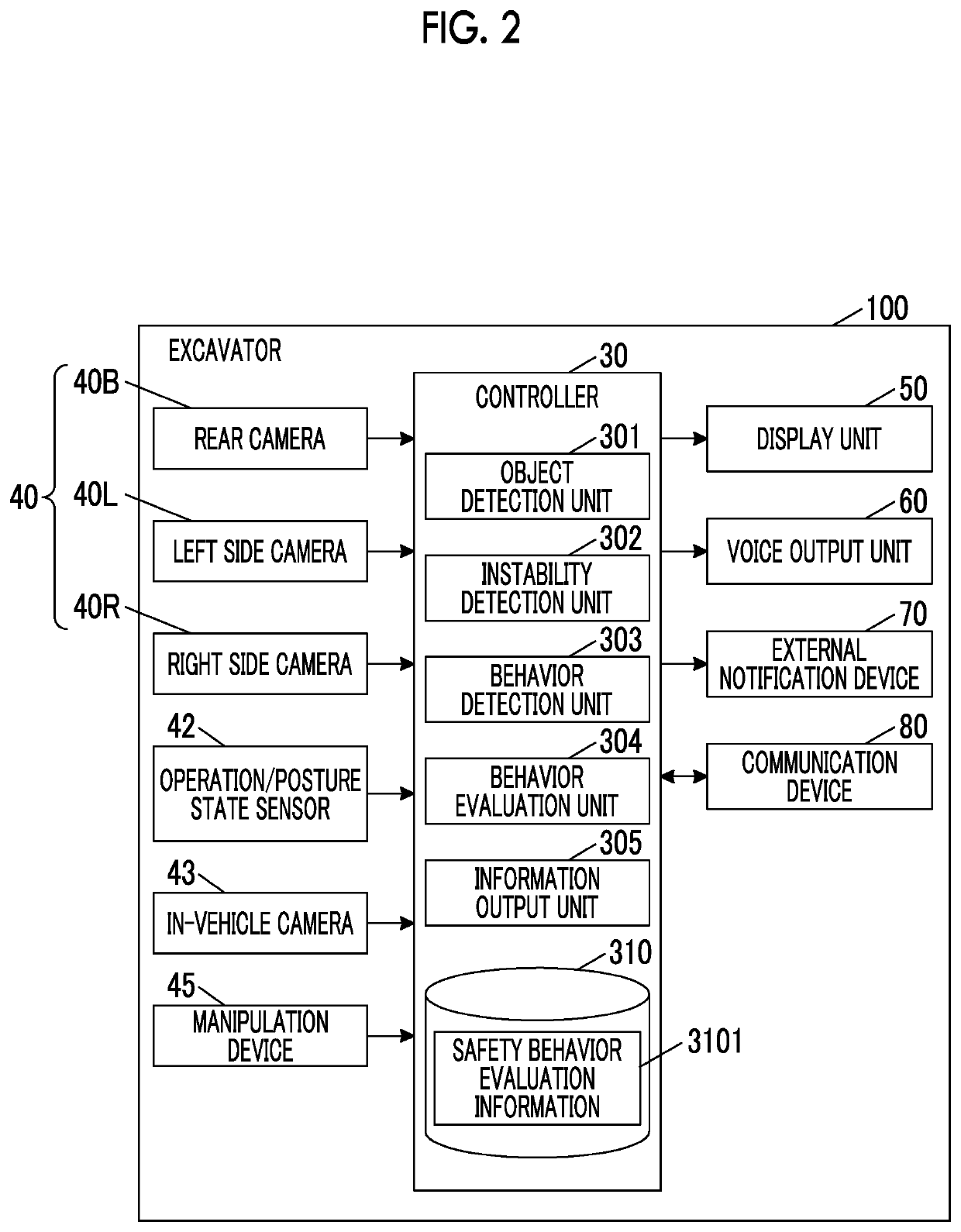

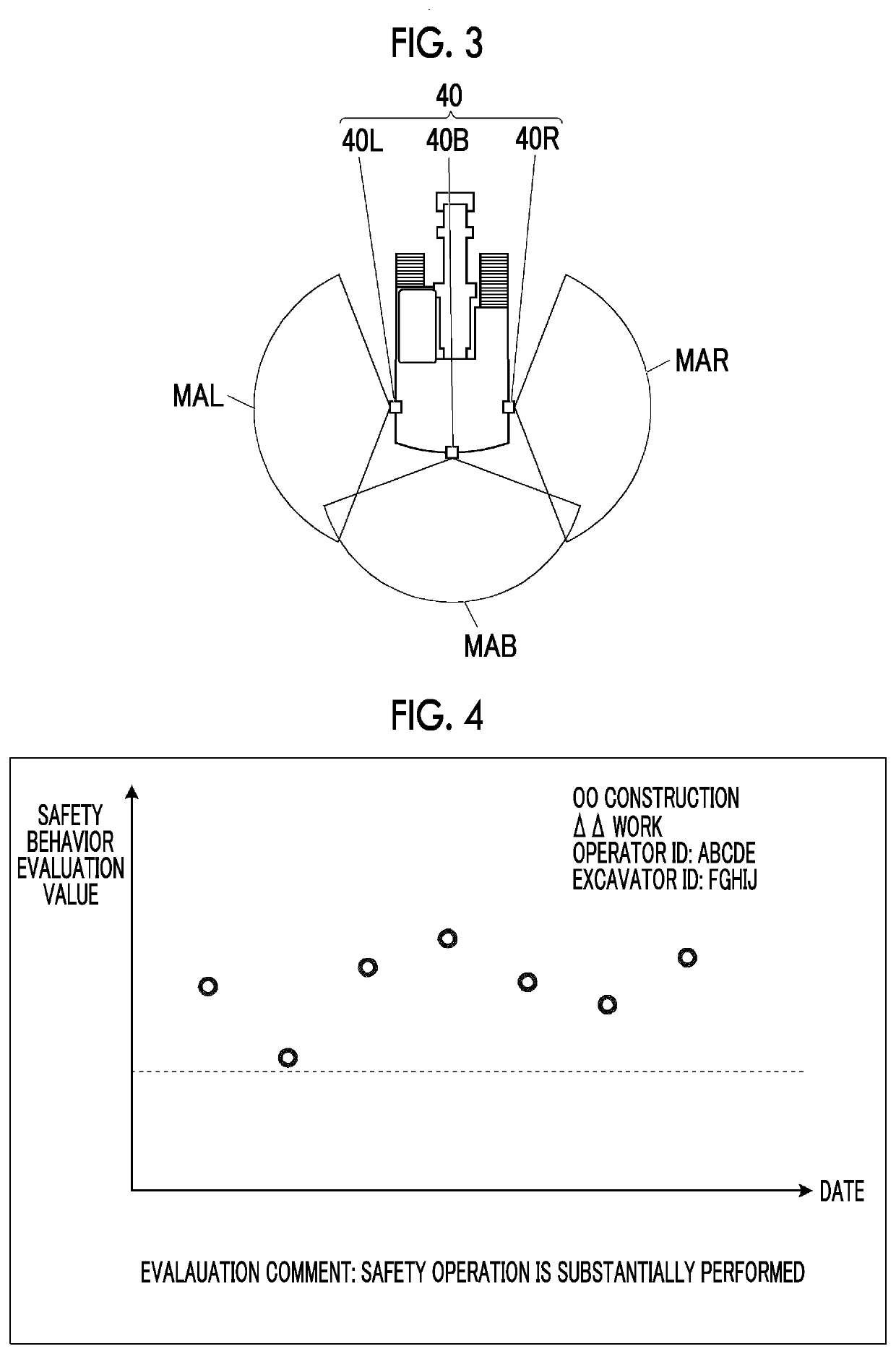

Work machine information processing device, information management system, and work machine information processing program

ActiveUS20220056673A1Improve work safetyImprove securitySoil-shifting machines/dredgersScene recognitionCalculatorData science

There is provided a work machine information processing device including a risk detector configured to detect a risk relating to a state or a surrounding environment of a work machine, notifier configured to notify an operator of the work machine of the risk detected by the risk detector, behavior detector configured to detect a behavior of the operator after the notification of the notifier, and calculator configured to calculate a safety behavior evaluation value obtained by quantitatively evaluating the behavior of the operator in terms of a degree of contribution to the safety, based on contents of the risk detected by the risk detector and the behavior of the operator detected by the behavior detector.

Owner:SUMITOMO HEAVY IND LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com