High-speed blister packaging machine

A blister packaging machine, blister technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve problems such as deformation and affecting work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

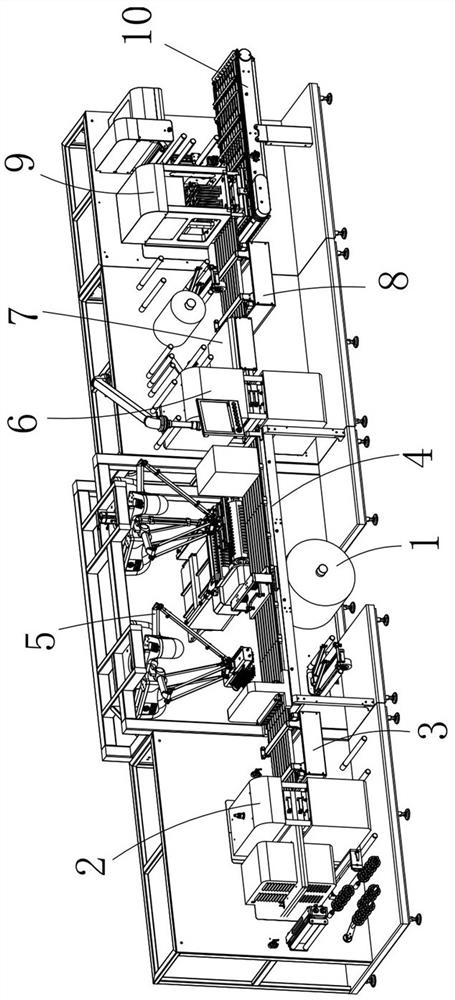

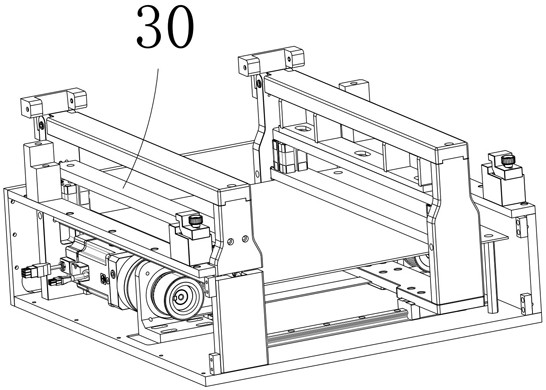

[0030] like figure 1 As shown, this high-speed blister packaging machine includes a frame, and the frame is sequentially provided with a blister forming device 2, a forming pulling device 3, a blister heat sealing device 6, a heat sealing pulling device 8, and a blister punching device. The device 9 and the blister grid conveying device 10. The foam tray forming device 2 includes a forming upper mold and a forming lower mold; the forming pulling device 3 includes a forming pulling clip 30 (such as image 3 The blister heat-sealing device 6 includes a heat-sealing upper mold and a heat-sealing lower mold; the heat-sealing pulling device 8 includes a heat-sealing pulling clip (the heat-sealing pulling device 8 has the same structure as the forming pulling device 3, both of which are existing technology); the blister punching device 9 includes a forming punch and a forming die.

[0031] The working principle of this high-speed blister packaging machine is as follows: the PVC fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com