Wood block wiredrawing bench

A wire drawing machine, wood board technology, applied in machine tools, grinders, metal processing equipment and other directions suitable for grinding workpiece planes, can solve the problems of not following the trend of industrial development, rising production costs of enterprises, waste of resources, etc., to overcome the processing The effect of long time, reduced replacement frequency and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

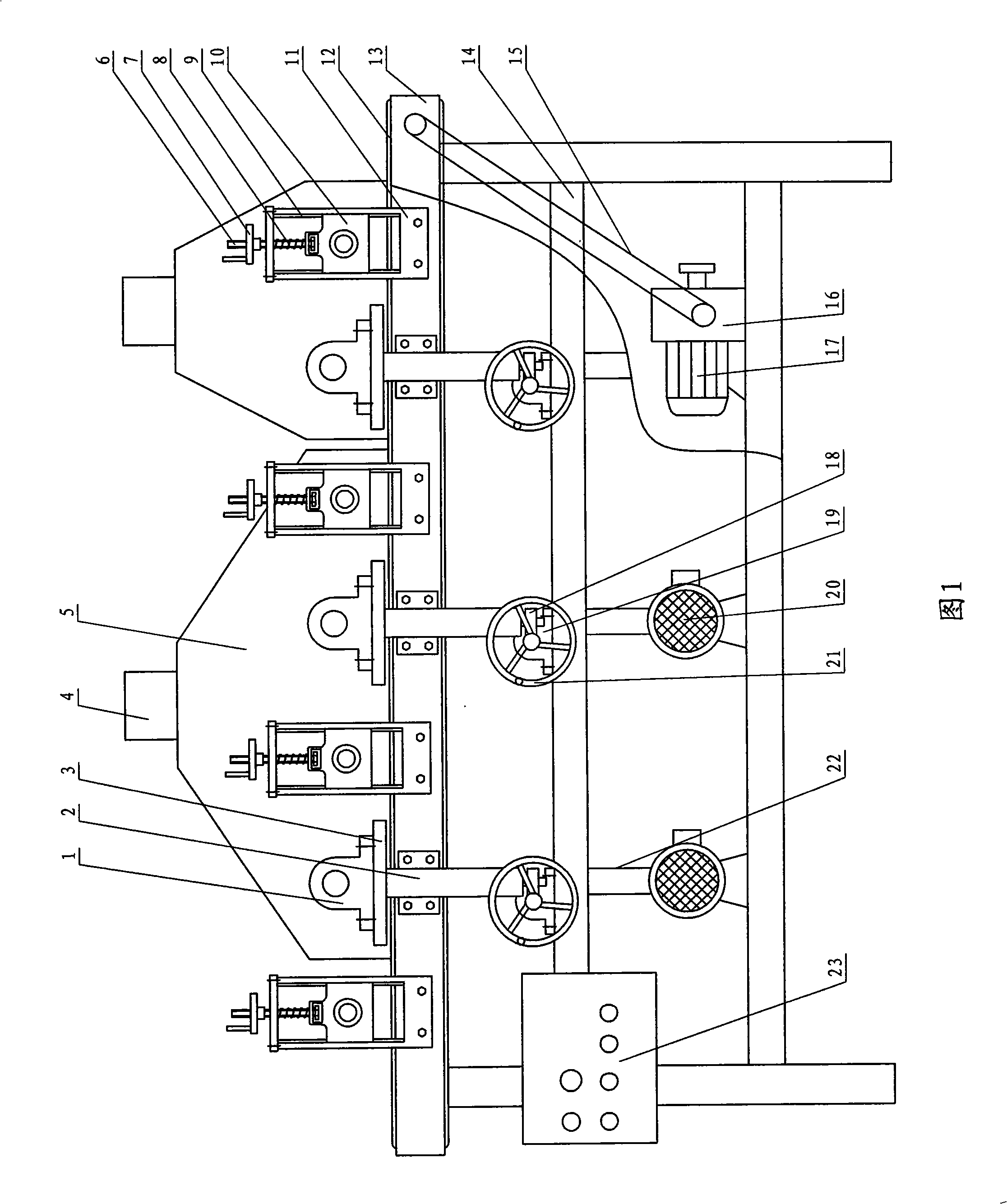

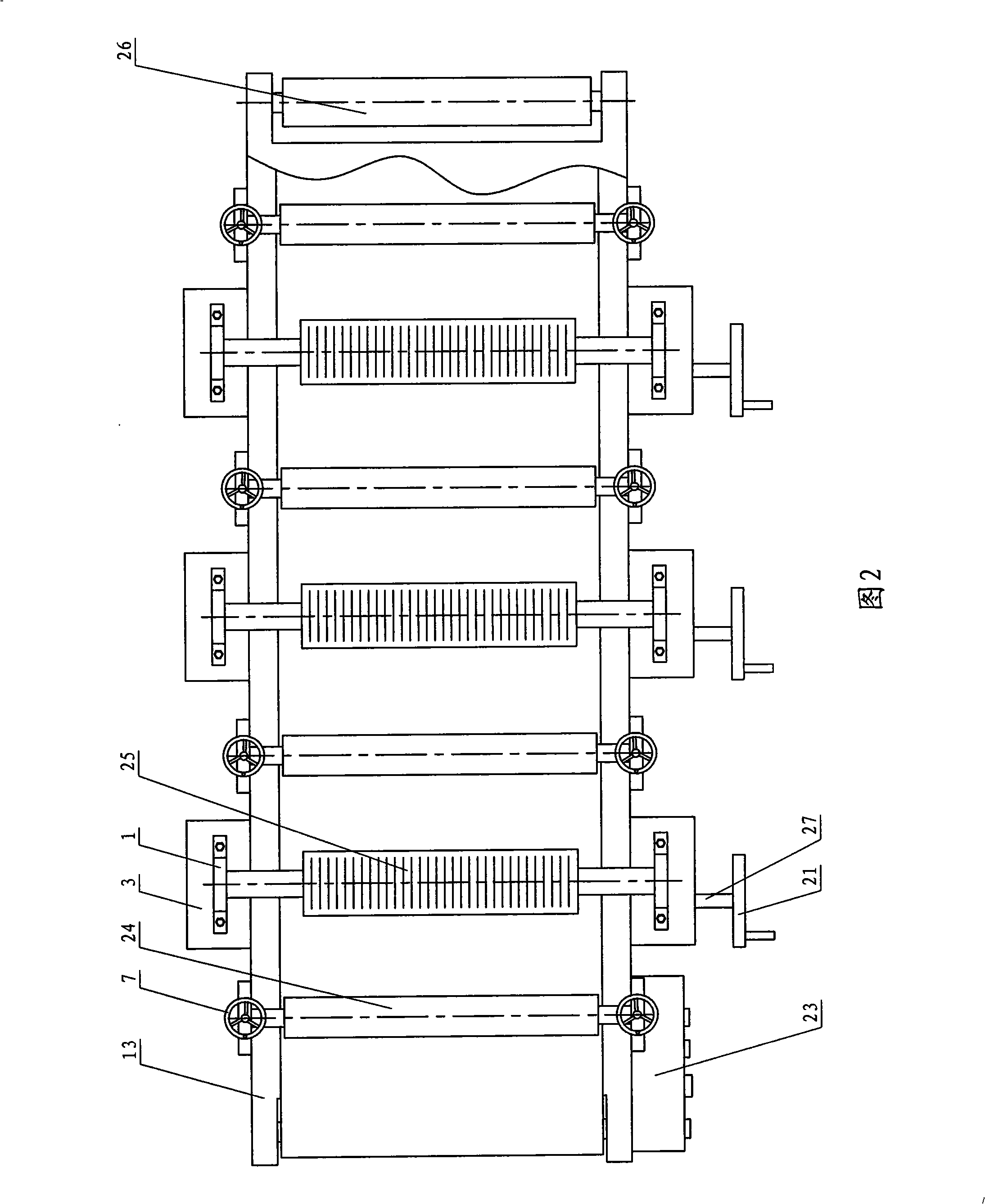

[0026] The wood drawing machine is equipped with three transmission systems on the square frame 13: the board conveying system, the pressure roller transmission system and the steel brush transmission system. The following three systems are respectively stated:

[0027] 1. Board conveying system

[0028] The conveying system is installed on both sides of the upper end of the frame, and the specific structure is: drive wheels 26 are symmetrically installed on both sides of the upper end of the frame, and a drive motor 17 and a reducer 16 of the drive motor are installed at the bottom of the frame. The speed reducer drives a transmission wheel on one side to rotate through the belt 15, and then drives the transmission belt 12 wrapped around th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com