Automatic deviation rectifying mechanism for abrasive belt of polishing machine

An automatic deviation correction and polishing machine technology, which is applied in the direction of abrasive belt grinders, grinding/polishing equipment, grinding machines, etc., can solve problems such as uneven force on the abrasive belt, achieve improved polishing effect, eliminate surface quality problems, and stabilize surface quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Describe the present invention below in conjunction with specific embodiment:

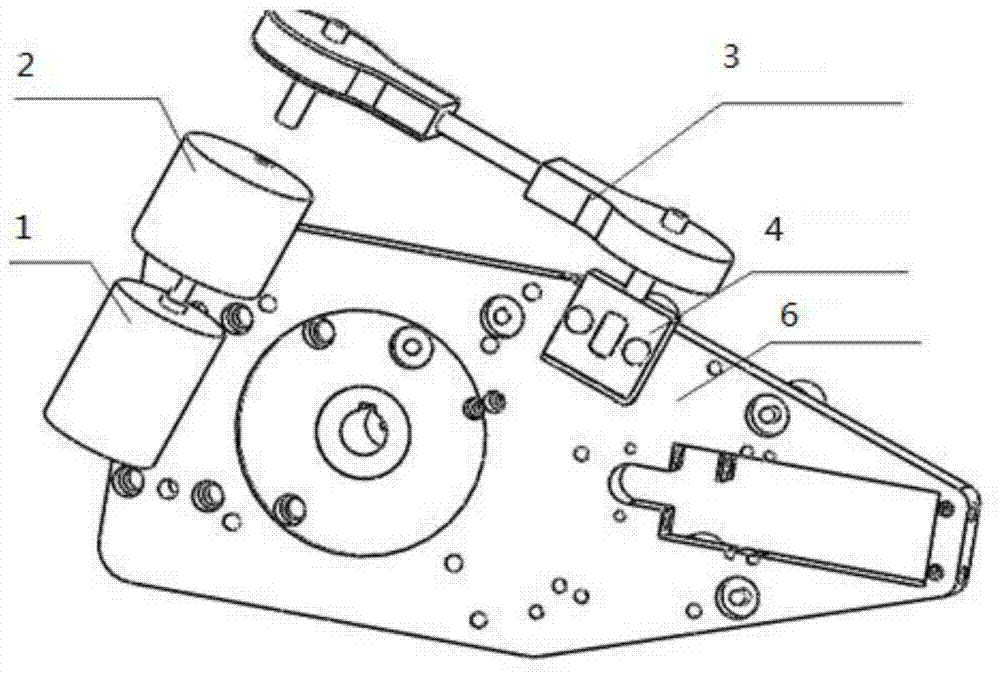

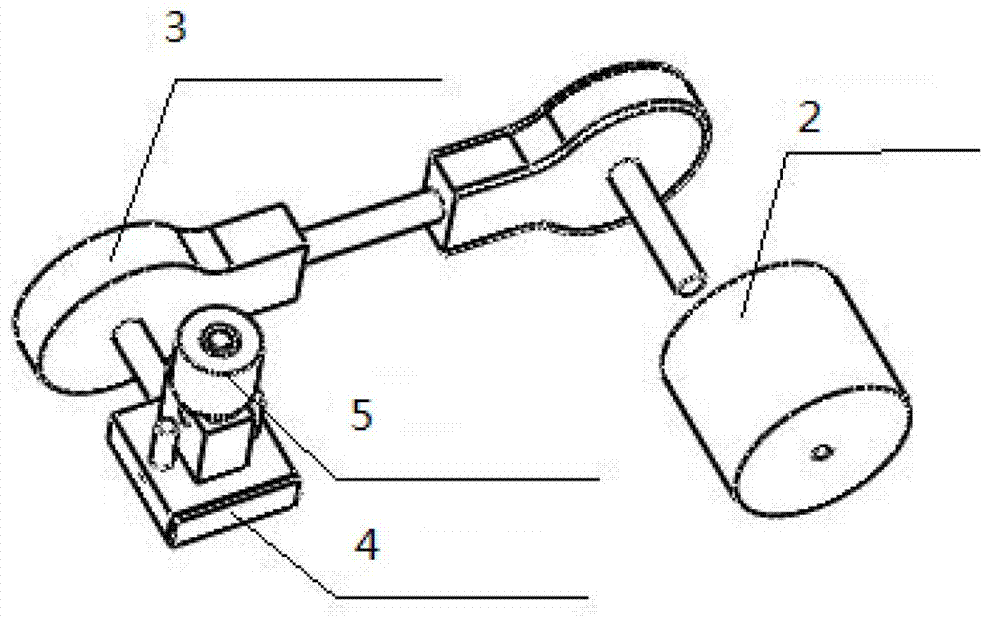

[0015] The automatic deviation correction mechanism of the abrasive belt of the polishing machine in this embodiment includes an infrared sensor, a DC servo motor 1 , an eccentric wheel 2 , a connecting rod 3 , a worm gear transmission mechanism 4 and a deviation correction roller 5 . The infrared sensor, the DC servo motor 1 and the worm and gear transmission mechanism 4 are all fixed on the bottom plate 6 of the polishing machine.

[0016] Such as figure 1 As shown, when the polishing machine polishes the thin-walled blade, the deviation-correcting roller 5 is used as the driving wheel and the deviation-correcting wheel of the polishing abrasive belt. When the abrasive belt deviates, the infrared sensor detects that the abrasive belt deviates from the polishing wheel, and transmits the detected micro-displacement to the external controller. The external controller judges the positive and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com