Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "Rapid Grouting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing geopolymer grouting material and method for applying geopolymer grouting material to static pressure grouting

ActiveCN106587782AReduce labor intensityLow viscosityCement productionRoads maintainenceSilica fumeSodium silicate

The invention provides a method for preparing a geopolymer grouting material and a method for applying the geopolymer grouting material to static pressure grouting. Raw materials for preparing the geopolymer grouting material include steel slag, mineral slag, sodium silicate, silica fume, calcium bentonite, softened water and a composite alkali activator. The method for preparing the geopolymer grouting material comprises the steps that 1, a component A is prepared; 2, a component B is prepared; 3, a component C is prepared; and 4, the geopolymer grouting material is prepared. The method for static pressure grouting comprises the steps of 1, survey; 2, assessment; 3, pit sounding; 4, hollowing general survey; 5, deflection value check; 6, comprehensive evaluation; 7, measurement and hole arrangement; 8, drilling; 9, grouting; 10, check; 11, grouting hole sealing; and 12, recheck to complete static pressure grouting. The methods have the advantages of environmental friendliness, low viscosity, high elasticity modulus, high cohesiveness, low cost, high efficiency and high durability.

Owner:中能化江苏矿山生态研究院有限公司

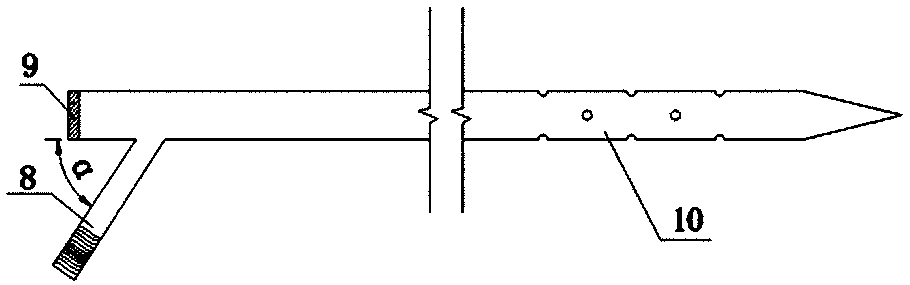

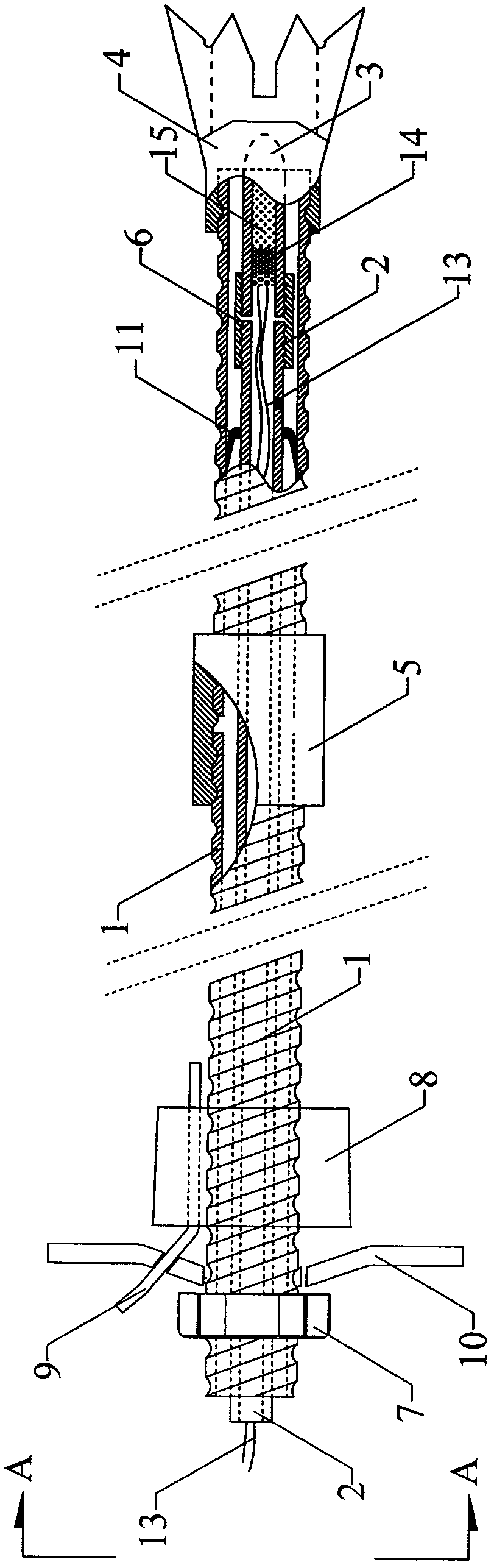

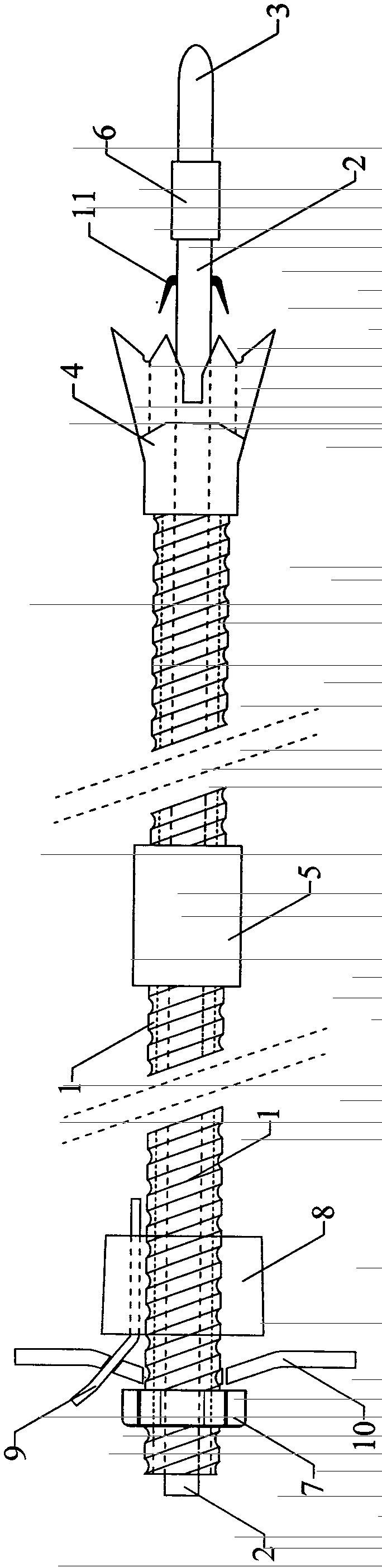

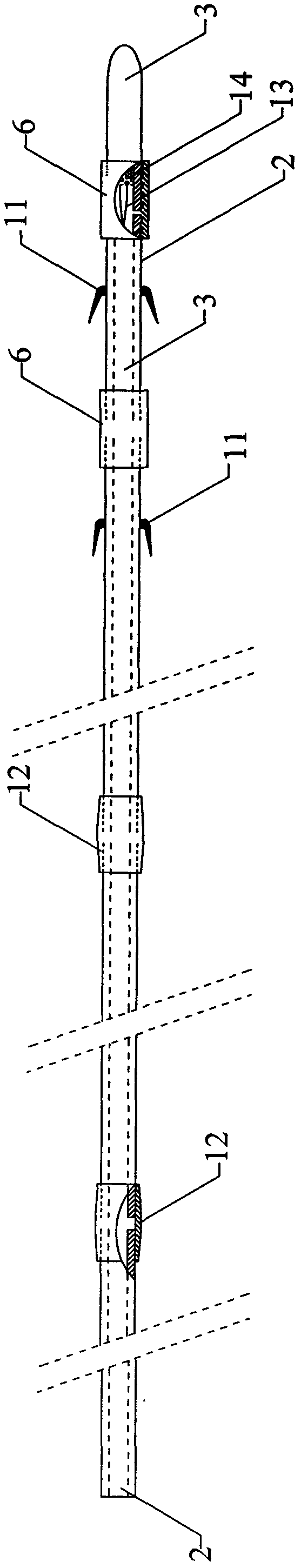

Pre-explosion drilling, grouting and anchoring integrated anchor rod and construction method thereof

ActiveCN102505687AActive Support ConceptExpand the scope of groutingExcavationsAnchoring boltsDetonatorSlurry

The invention discloses a pre-explosion drilling, grouting and anchoring integrated anchor rod and construction method thereof, and belongs to geotechnical engineering. The pre-explosion drilling, grouting and anchoring integrated anchor rod consists of a sectional type drilling anchor rod, a drill bit and a sectional type hollow grouting pipe, wherein the internal hollow grouting pipe is connected with a multi-section explosive pipe at the front end of the grouting pipe; a plurality of return stoppers are arranged on the tip of the front end of the grouting pipe, which is connected with the explosive pipe; and when the integrative anchor rod is drilled to reach a specified position, a drilling rod is taken back reversely, the internal hollow grouting pipe is pushed forwards, the return stoppers work, and then the drilling rod is stopped from being taken back. A detonating cord is connected with a detonator to detonate explosive sections, a rubber stopper provided with a slurry guide pipe (exhaust pipe) follows up on the end part of the drilling rod for sealing, and a supporting liner plate, a nut and a hollow drilling rod cooperate with one another on the end part; and the supporting liner plate, through which the detonating cord penetrates, is provided with a drill way, and one section of a pipeline penetrates through the drill way of the supporting liner plate. The pre-explosion drilling, grouting and anchoring integrated anchor rod has the advantages that: the anchor integrates drilling, grouting and anchoring and molded in one step; the integrative anchor rod is applied to reinforcement of laneways, pit shafts and side slopes, and temporary or permanent supporting in water control; and the construction method has a certain promotion value.

Owner:中煤长江基础建设有限公司

High-pressure gas multistage pre-splitting grouting transformation method for surrounding rock of deep soft rock roadways

ActiveCN105156134AGood injectabilityPrevent closureUnderground chambersFluid removalHigh pressureMechanical property

The invention relates to a high-pressure gas multistage pre-splitting grouting transformation method for surrounding rock of deep soft rock roadways. The high-pressure gas multistage pre-splitting grouting transformation method has the advantages that the surrounding rock of the deep soft rock roadways is subjected to multistage pre-splitting by the aid of high-pressure gas, special propping agent materials are added into popping agent containers when last-stage gas pre-splitting is carried out, the particle sizes of the propping agent materials are larger than those of cement particles, the propping agent materials are used for propping crack of the artificially pre-split expanded surrounding rock, the crack can be prevented from being closed again under the effect of deep high ground stress, the groutability of the surrounding rock can be improved, then the surrounding rock with the crack can be grouted and reinforced, weak surrounding rock structures and mechanical properties of the roadways can be greatly transformed, the surrounding rock of the deep soft rock roadways can be stably controlled, and difficult problems of closing of crack of existing surrounding rock of existing deep soft rock roadways, extremely poor groutability of the existing surrounding rock and poor grouting effects can be solved; the weak surrounding rock structures and the mechanical properties can be obviously transformed and enhanced, and the bearing capacity of the surrounding rock can be improved; high-pressure gas pre-splitting holes and grouting holes of the surrounding rock are combined with one another, and the high-pressure gas multistage pre-splitting grouting transformation method is easy to operate and implement in fields.

Owner:CHINA UNIV OF MINING & TECH

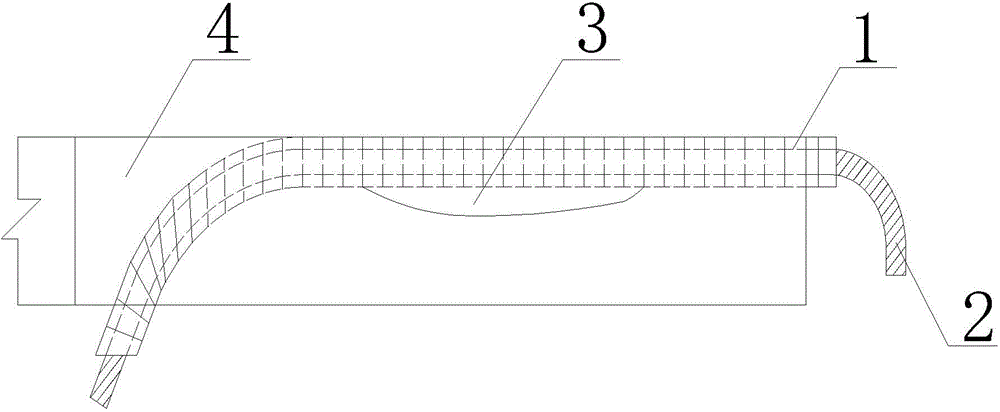

Construction method of reserved grouting pipe of tunnel vault

InactiveCN104895585ARapid GroutingGrouting omittedUnderground chambersTunnel liningEngineeringRadar detection

The invention discloses a construction method of a reserved grouting pipe of a tunnel vault. According to the technical scheme, the construction method comprises arranging waterproof fabrics on the primary supporting surface of a tunnel and binding secondary lining rebars; arranging a corrugated pipe with a hole in close attachment with the waterproof fabrics and enabling the corrugated pipe with the hole to penetrate a rubber bar; pouring secondary lining concrete and timely drawing the rubber bar at two ends; drawing out the rubber bar after initial setting is achieved and forming a secondary lining concrete vault grouting hole channel; grouting a reserved hole channel and enabling a vault cavity to be filled with grout after the grout passes through the small hole of the corrugated pipe with the hole. According to the construction method of the reserved grouting pipe of the tunnel vault, the grouting hole channel is reserved during tunnel construction and accordingly the grouting on the secondary concrete vault cavity can be rapidly achieved, the process of vault drilling after radar detection is omitted, the construction time is saved, the construction cost is reduced, and the construction quality of the tunnel concrete is ensured.

Owner:CHINA RAILWAY 21ST BUREAU GROUP THE FOURTH ENG

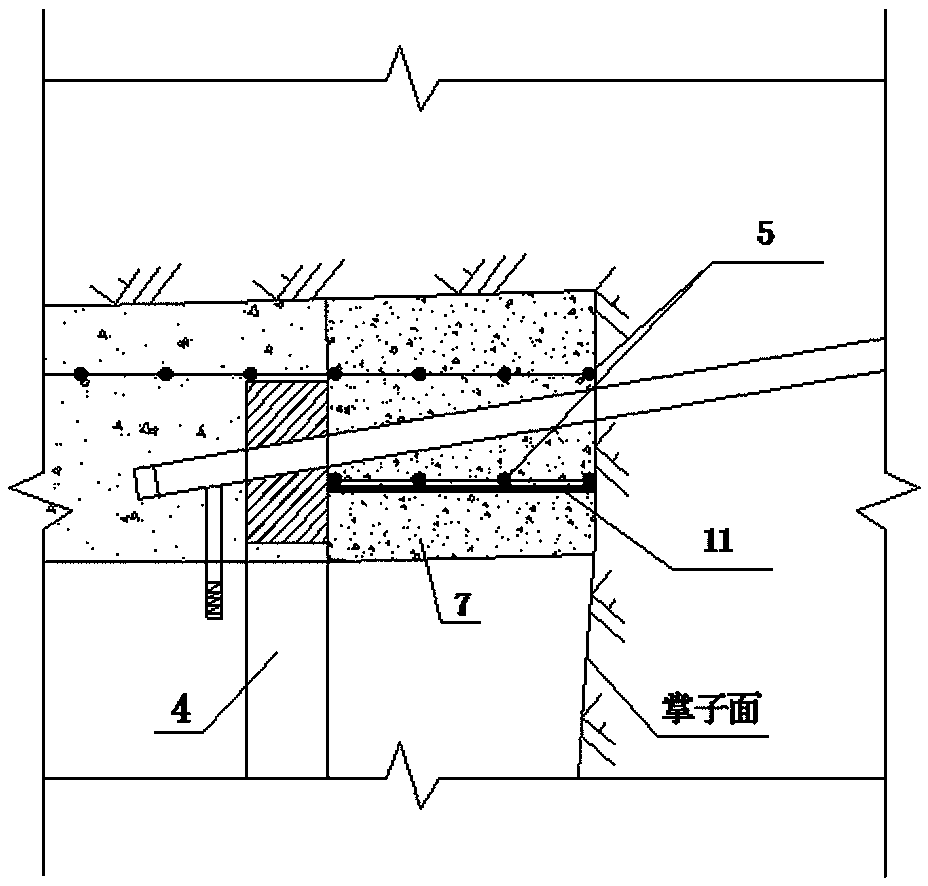

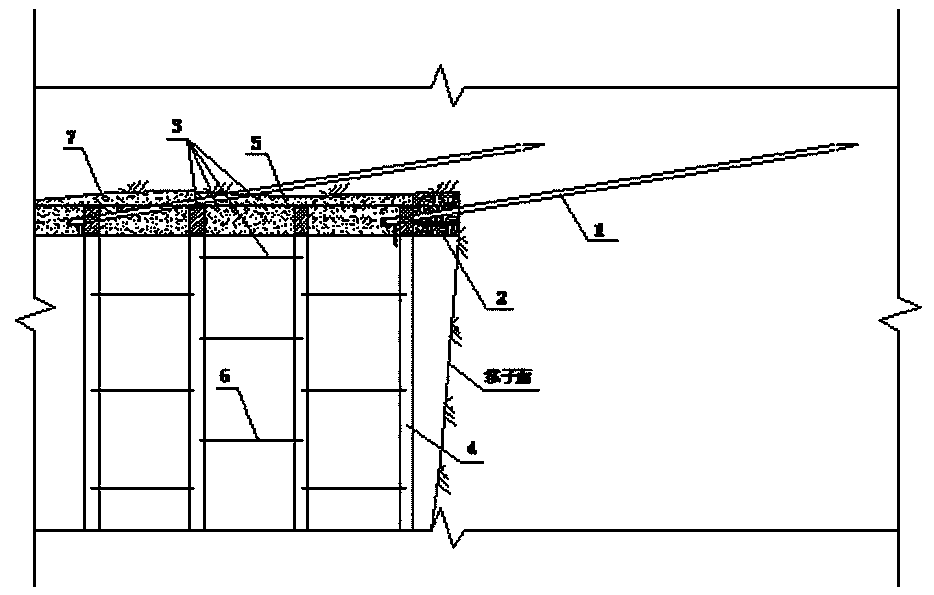

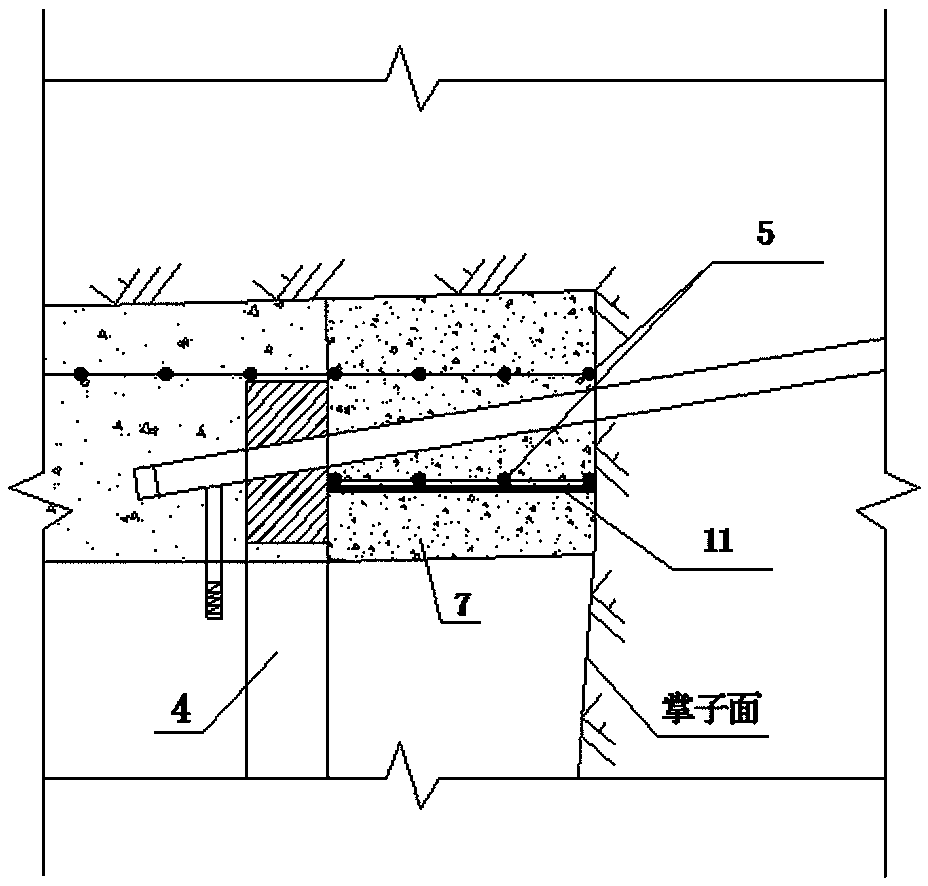

Advanced small pipe grouting structure and construction method thereof

ActiveCN109139048AGood slurry effectQuick closureUnderground chambersTunnel liningRock tunnelApplication time

The invention relates to the technical field of tunnel construction, in particular to an advanced small pipe grouting structure and a construction method thereof. According to an advanced small pipe,quick closure of a primary support can be ensured, a grout stopping wall and the primary support form an integral stress structure and are tightly attached to a tunnel face, so that the stability of the tunnel face is increased, the safety risk of the tunnel face is greatly reduced, and soft rock tunnels and special geological tunnels excavated by blasting are facilitated; and the grouting structure is simple, the application of the grout stopping wall basically does not occupy the application time of the primary support, the grout stopping wall can be applied synchronously with the primary support, the construction speed is high, rapid grouting can be realized, a great deal of time is saved and the construction progress is speeded up compared with the set of the grout stopping wall alone,and grout stopping wall can be used as a part of the primary support without dismantling after the grouting of the advanced small pipe is finished. The advanced small pipe is factory processed, and has convenient and quick installation and grouting. The grout stopping wall is of an integral structure, has good grout stopping effect, can bear large grouting pressure, and greatly ensures the grouting effect of the advanced small pipe.

Owner:CHINA RAILWAY 12TH BUREAU GRP +1

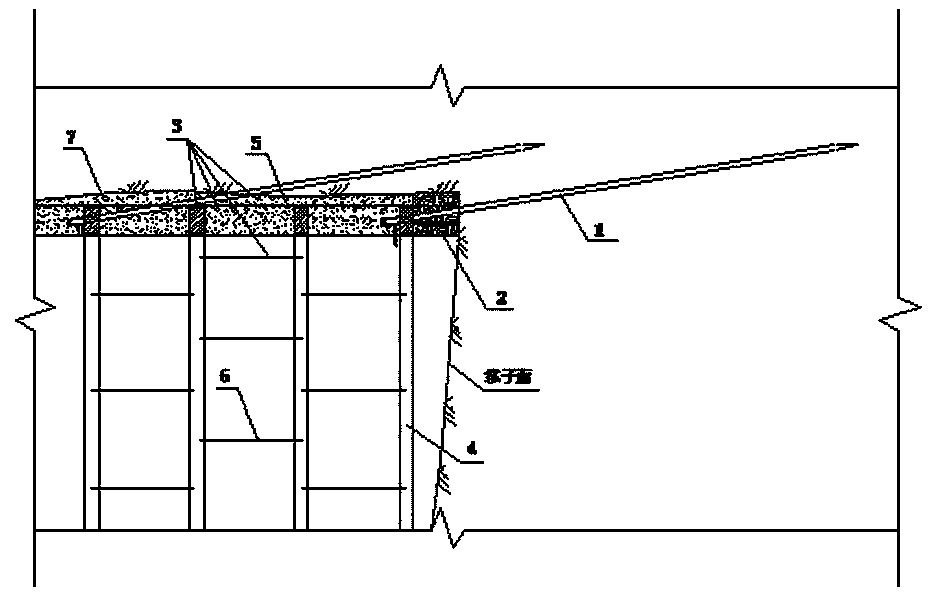

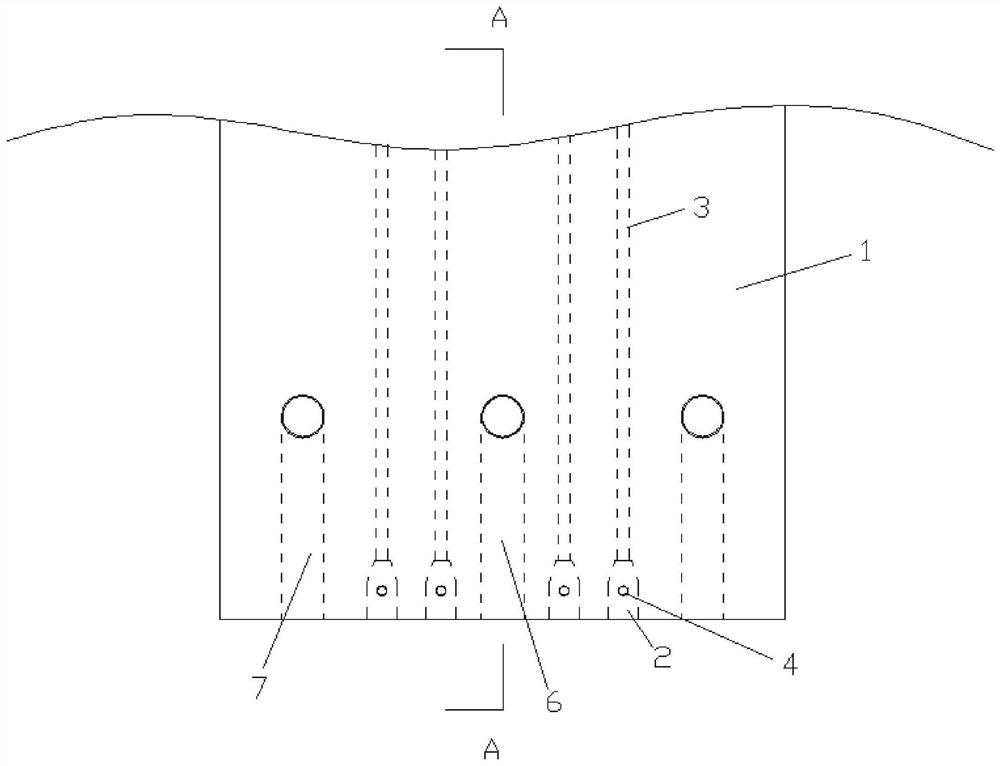

Gob-side entry narrow coal pillar advanced grouting reinforcement method

ActiveCN112096382AHigh porosityImprove bearing capacitySurveyDisloding machinesMining engineeringCoal pillar

The invention provides a gob-side entry narrow coal pillar advanced grouting reinforcement method. The method comprises the steps that before extraction of a gob-side entry upper section working face,a row of drill holes are formed in one side of an excavated upper section entry in the extending direction of a coal pillar; the drill holes are detected through a drill hole penetrometer; accordingto obtained information data of pressure and displacement in the drill holes, the compression degrees of the coal pillar at different depths and the development condition of cracks in a coal body areanalyzed, grouting reinforcement operation can be directly conducted on the part, with the large crack development, in the coal pillar, and fracturing operation is conducted on the part, with the small crack development, in the coal pillar; fracturing operation is conducted on the part, with the small crack development, in the coal pillar through an electric pulse device; the impact wave fracturing range is observed till fracturing of all the areas, with the small coal pillar cracks, in the whole upper section entry is finished; and on the basis of original anchor net supporting of the coal pillar, grouting anchor rods are placed in the drill holes to conduct grouting reinforcement on the interior of the coal pillar. According to the method, advanced reinforcement operation of the coal pillar can be effectively achieved.

Owner:CHINA UNIV OF MINING & TECH

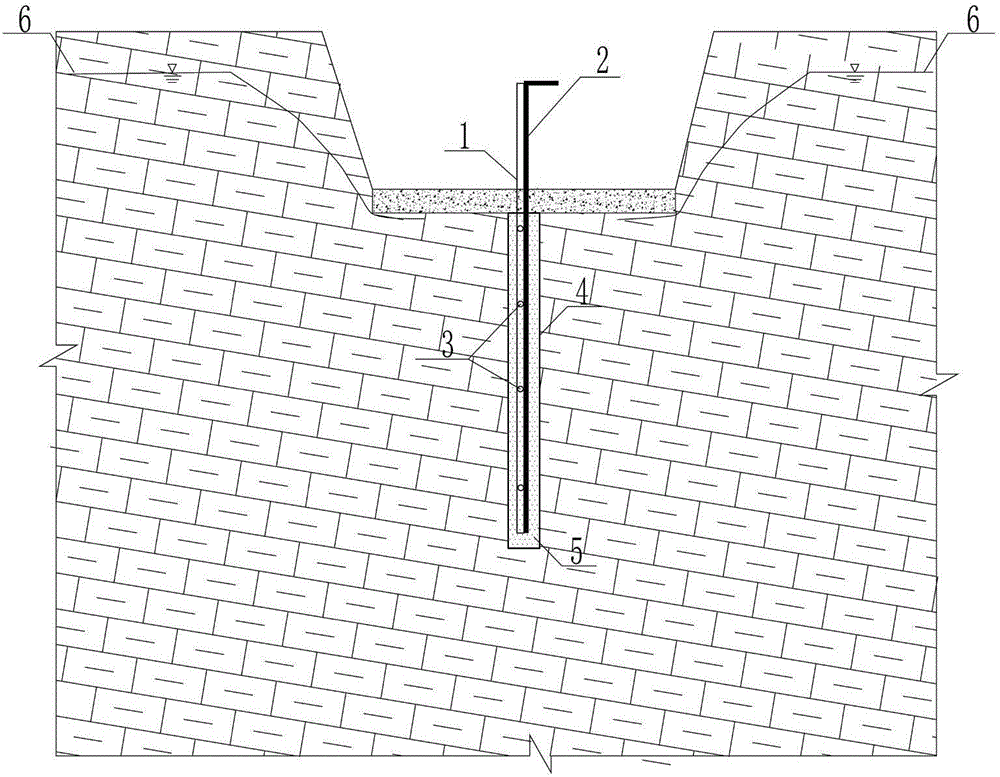

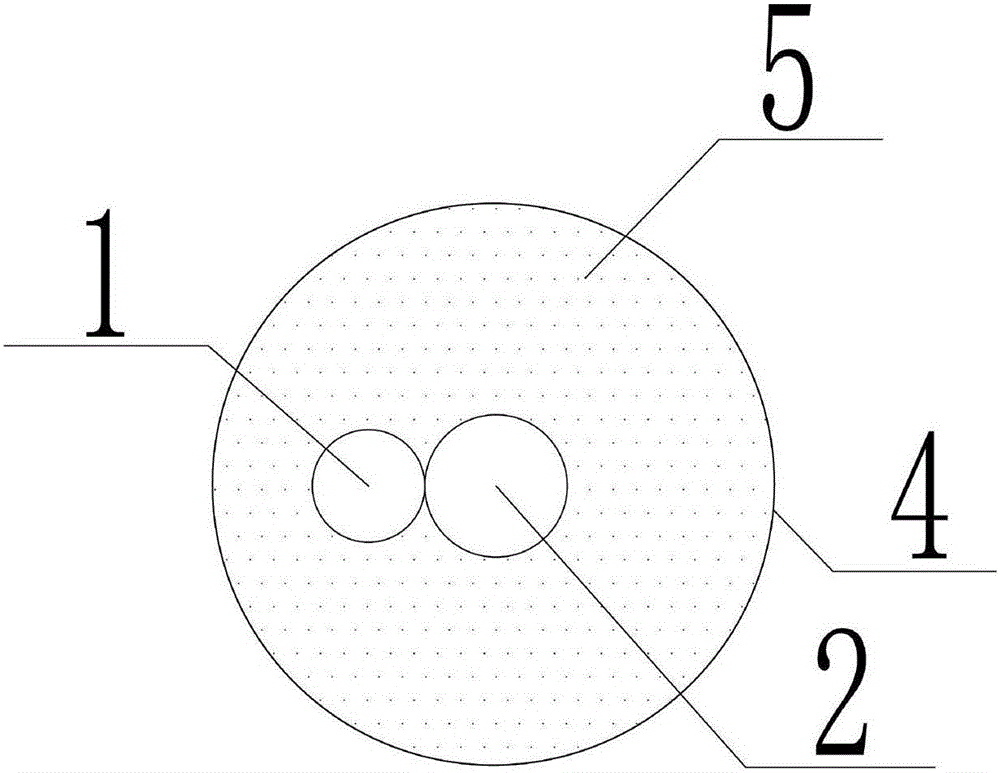

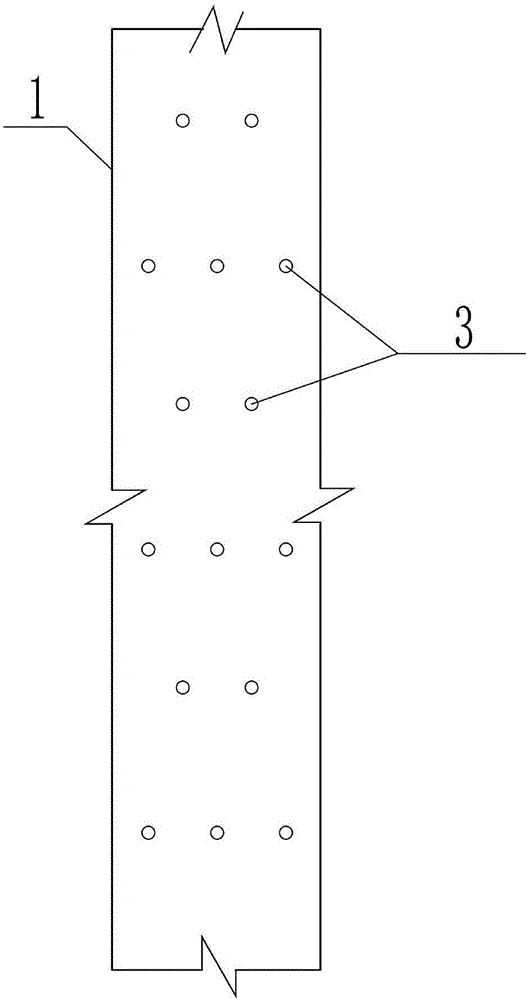

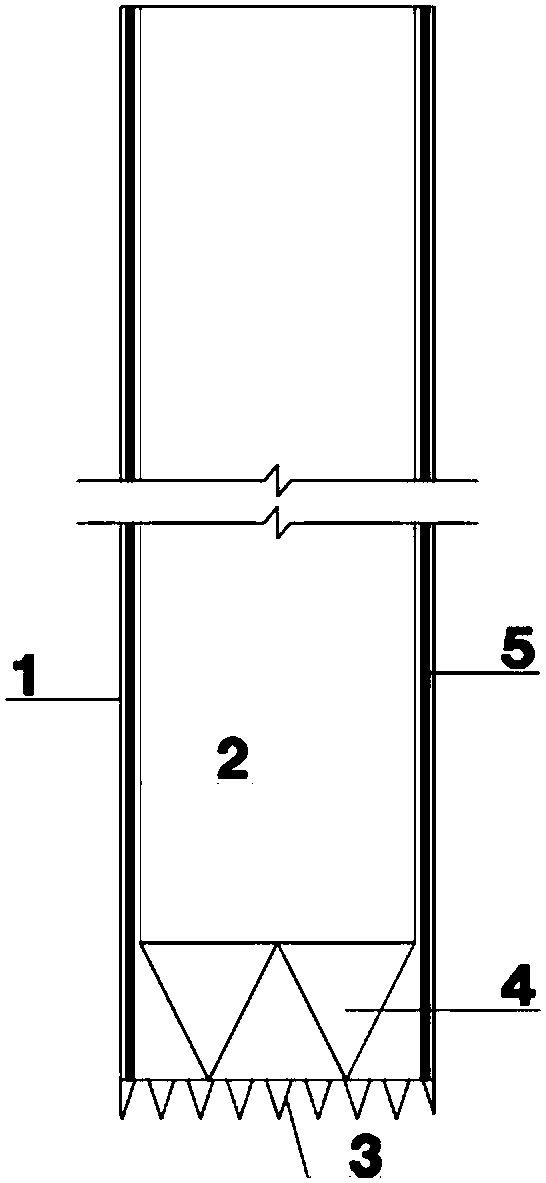

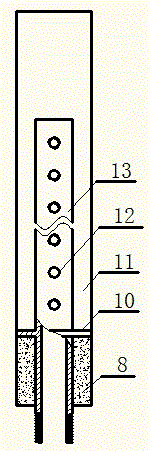

Carbonate rock area pulling-resistant anchor rod grouting and drainage device and construction method thereof

InactiveCN106555399ASolve the problem of difficult groutingGrouting pressure is smallProtective foundationBulkheads/pilesRock boltSteel tube

The invention discloses a carbonate rock area pulling-resistant anchor rod grouting and drainage device and a construction method of the carbonate rock area pulling-resistant anchor rod grouting and drainage device. The device comprises a steel pipe and an anti-floating anchor rod. The anti-floating anchor rod and the steel pipe are bound and fixed side by side and stretch into a grouting hole, and the section, stretching into the grouting hole, of the steel pipe is provided with sieve holes. The steel pipe with the sieve holes and the anti-floating anchor rod are bound, fixed and placed into the anchor rod grouting hole, and drainage and pressure relief are carried out through the sieve holes during grouting, so that grouting pressure is effectively reduced, the grouting difficulty is lowered, grouting is rapider, particularly, the secondary grouting effect is better, the problem that grouting of the anti-floating anchor rod is difficult due to the high water pressure of a carbonate rock area is effectively solved, and the carbonate rock area pulling-resistant anchor rod grouting and drainage device further has the advantages of being simple in structure, low in cost and convenient to operate.

Owner:ZHENGYE ENG & INVESTMENT INC

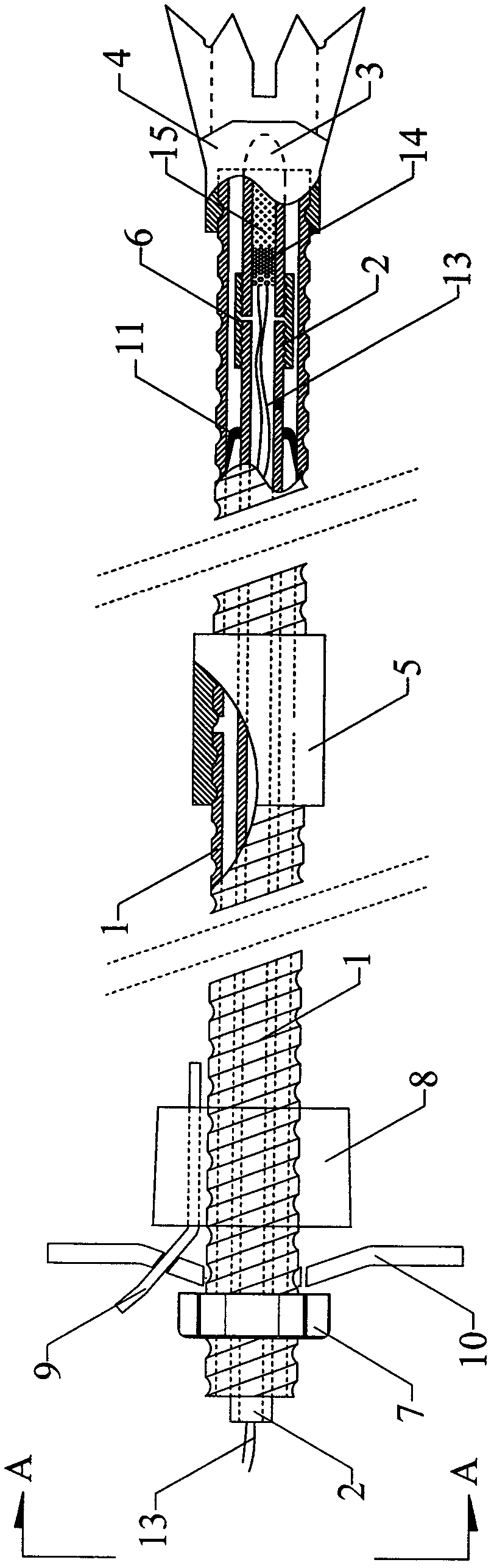

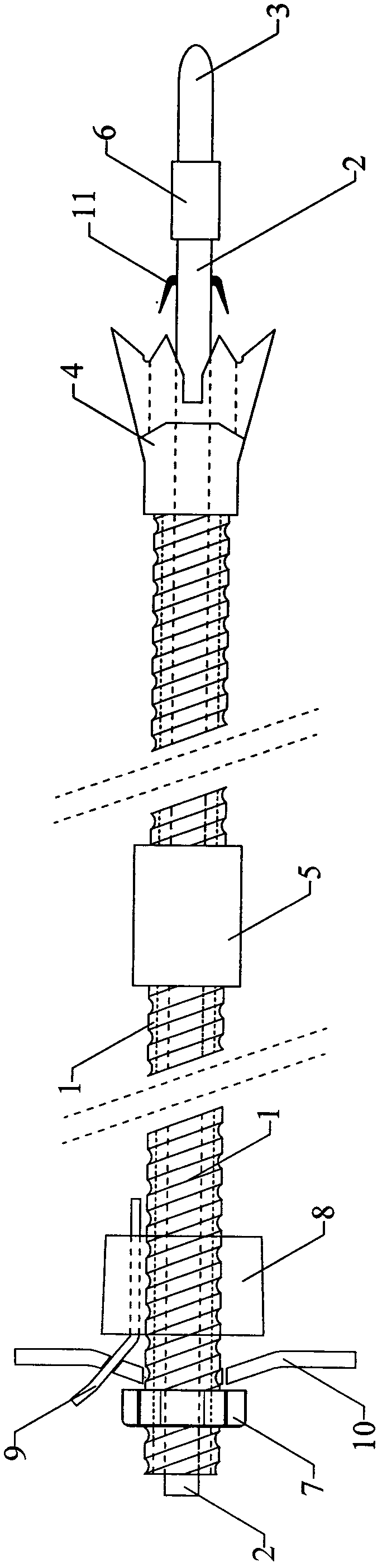

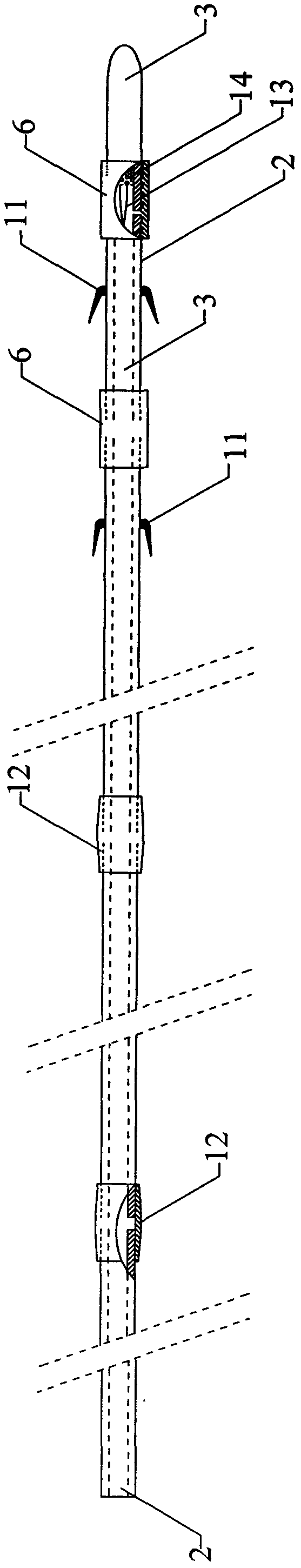

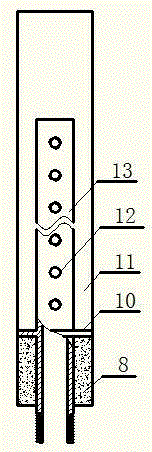

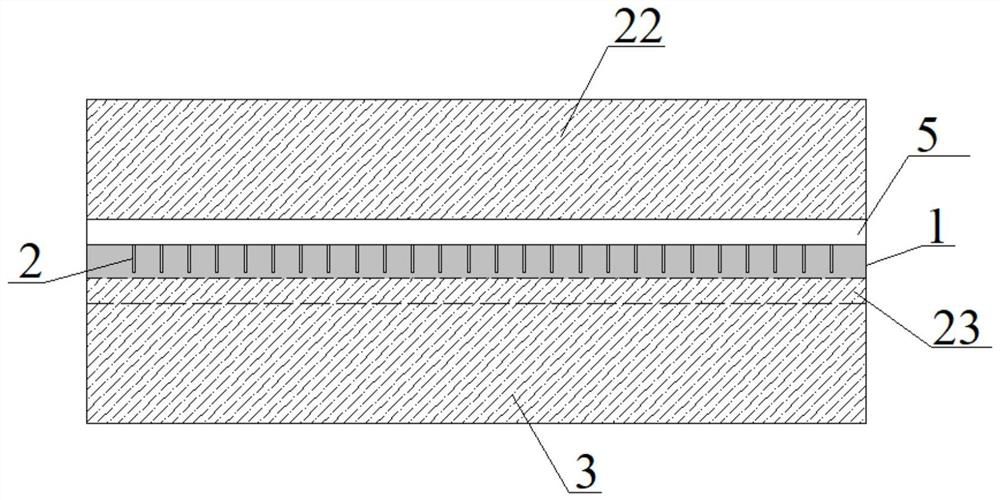

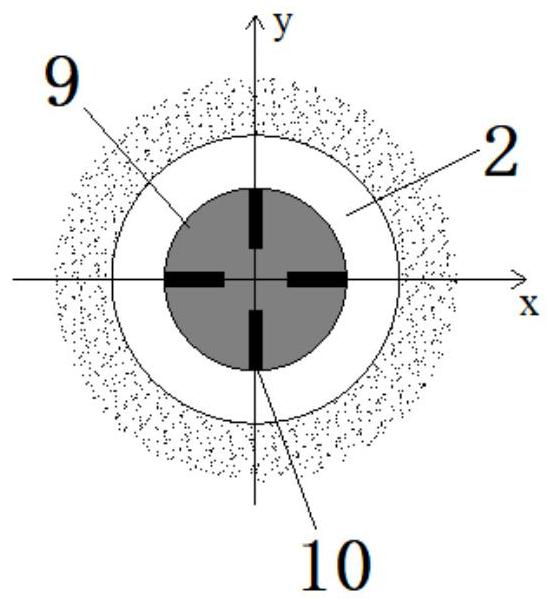

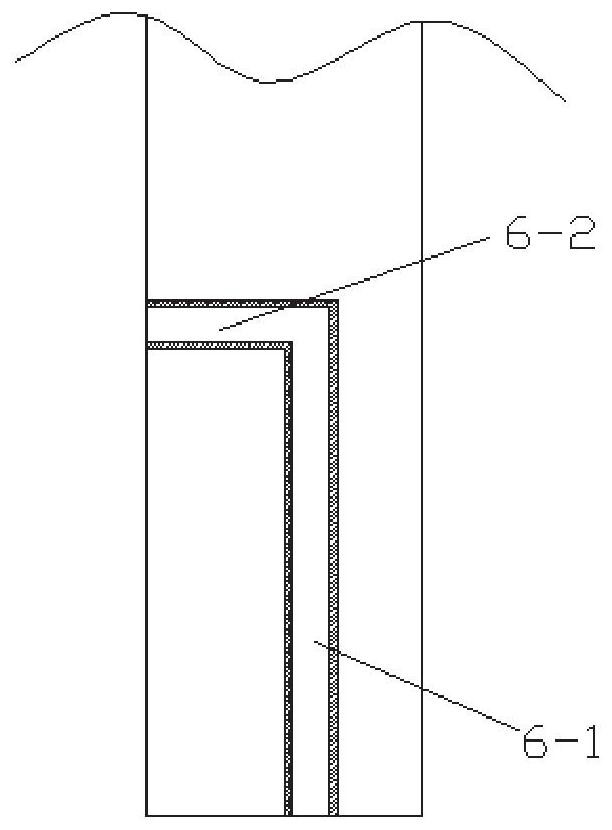

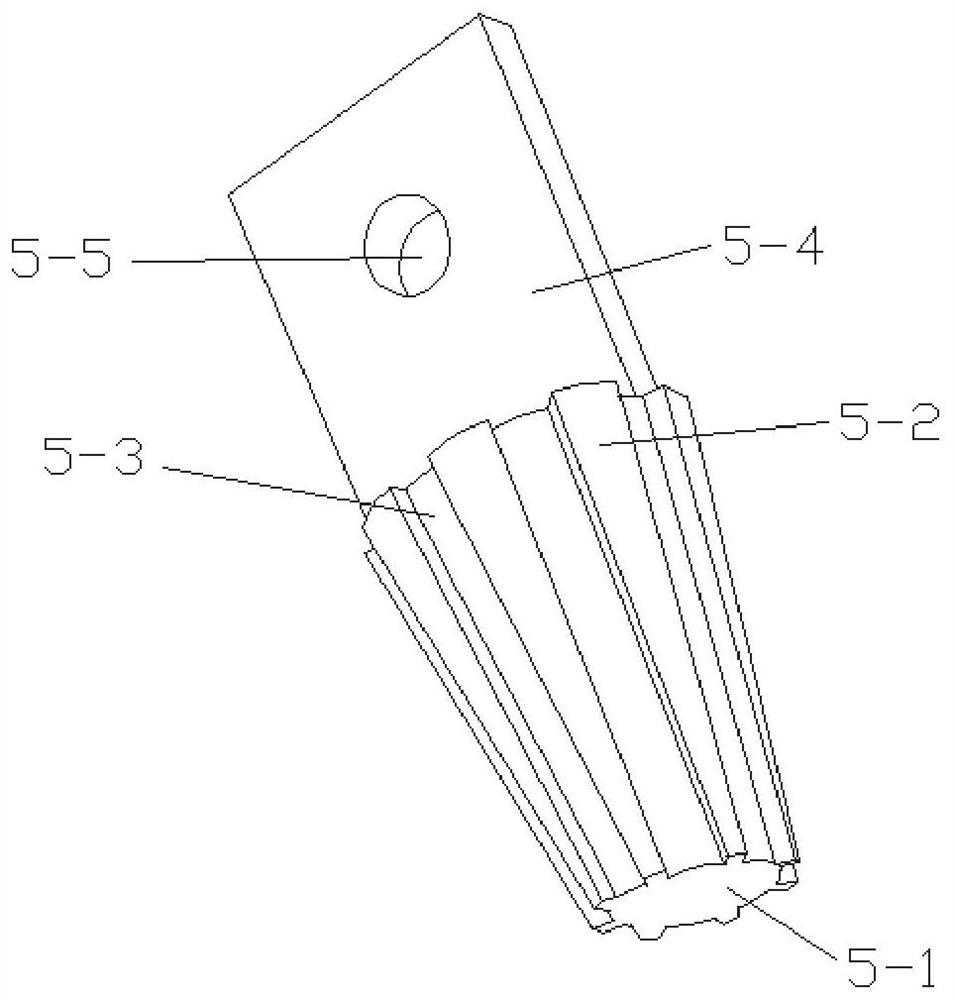

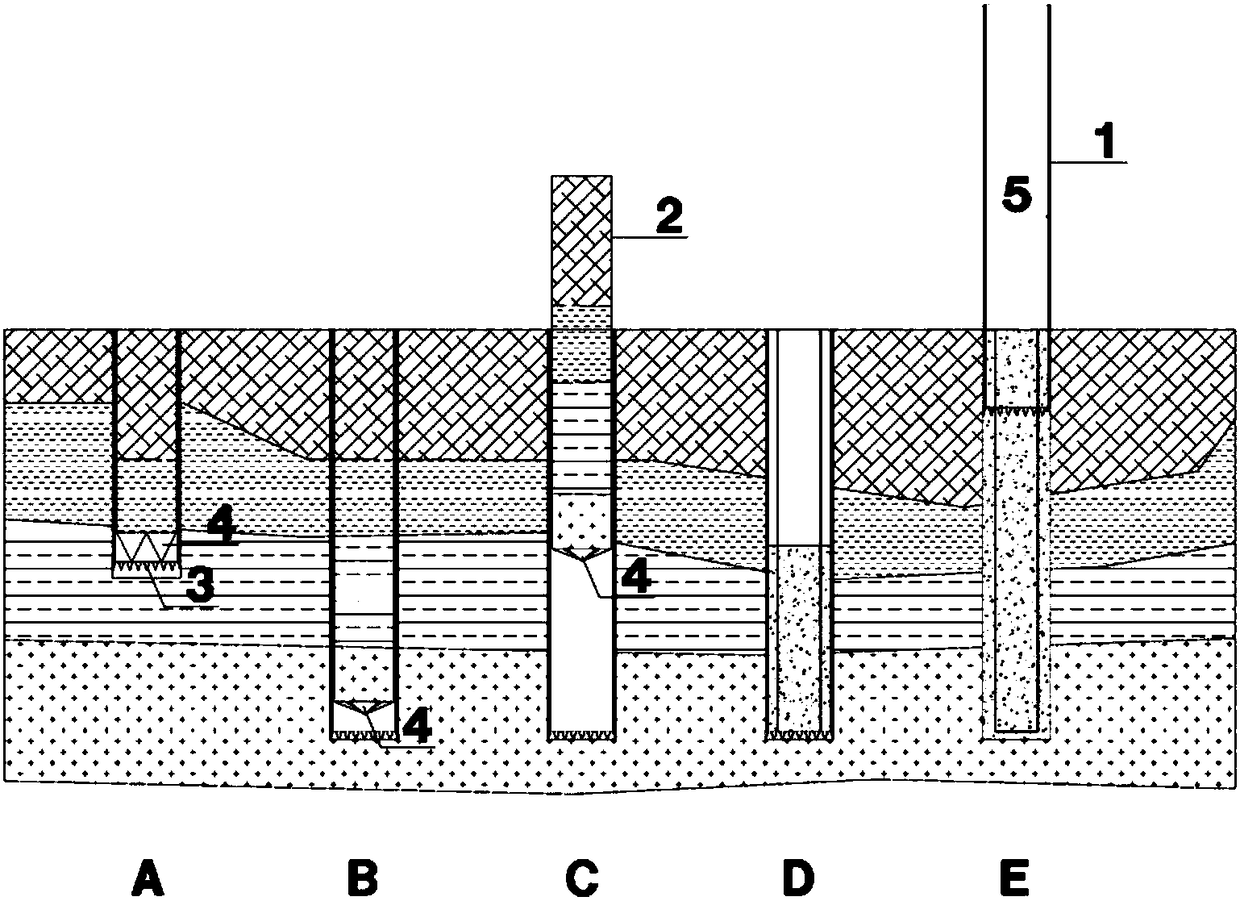

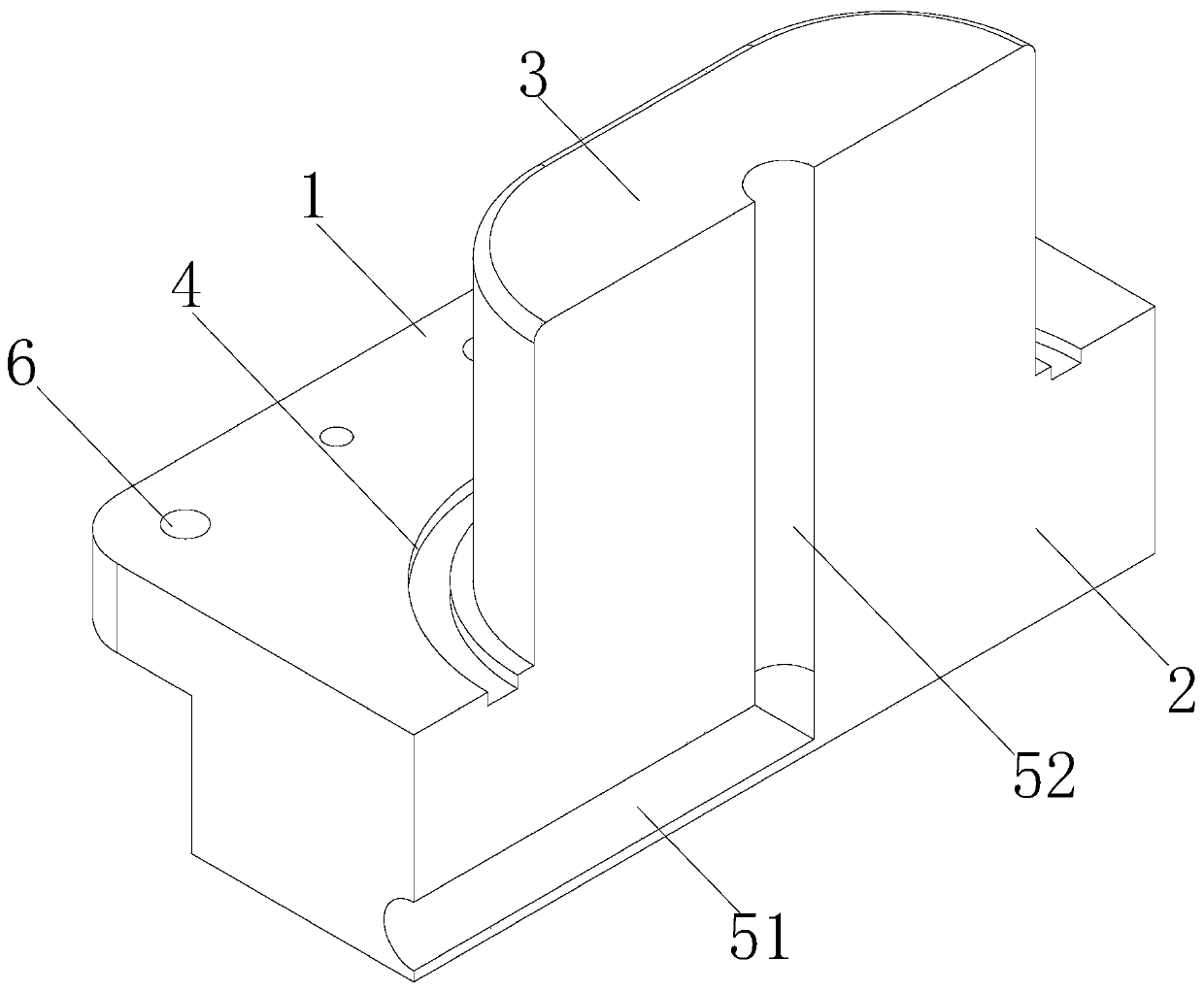

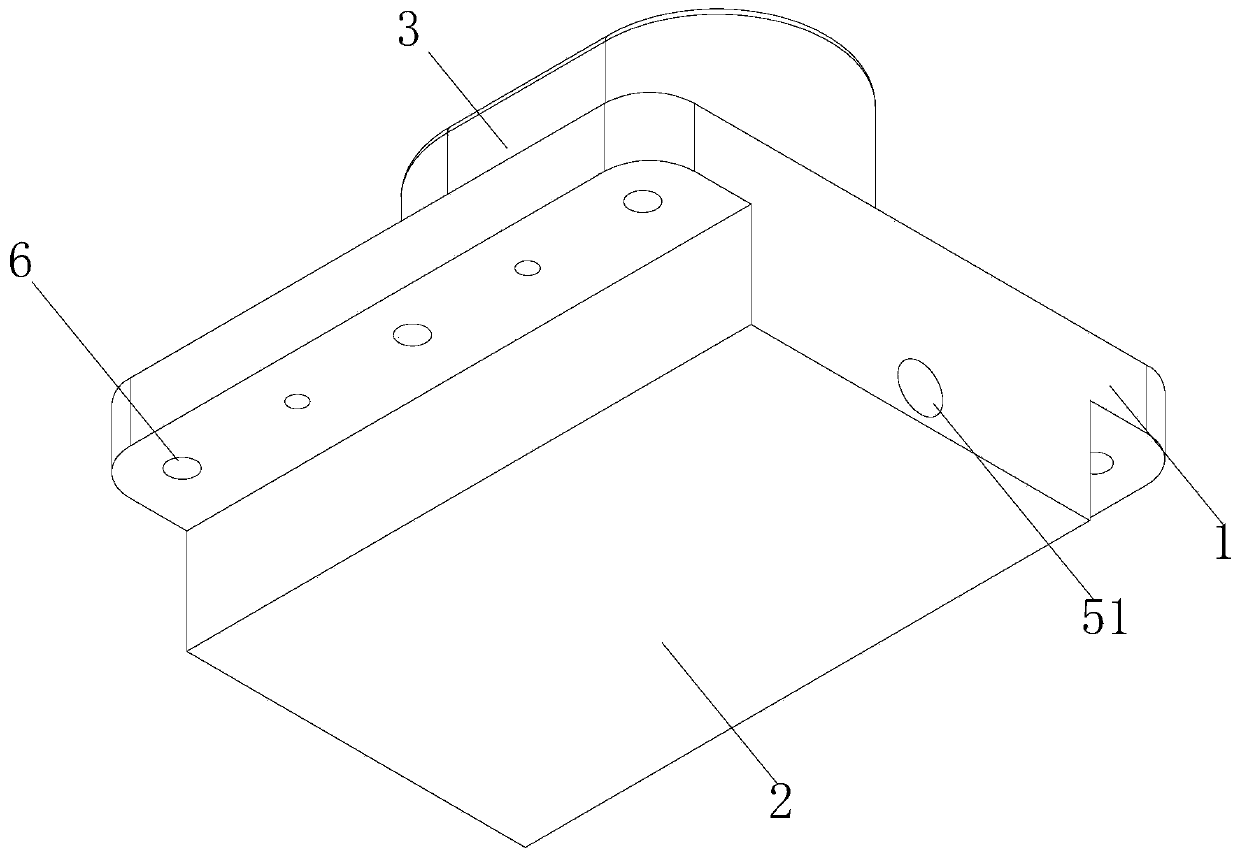

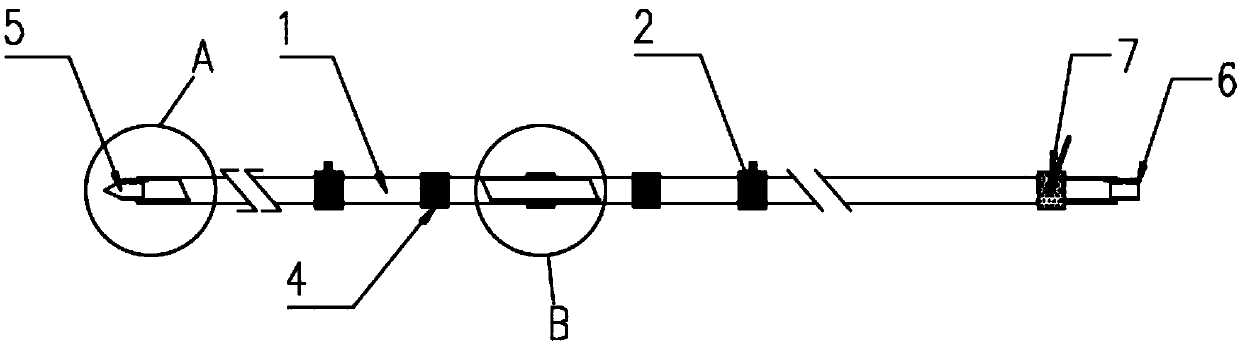

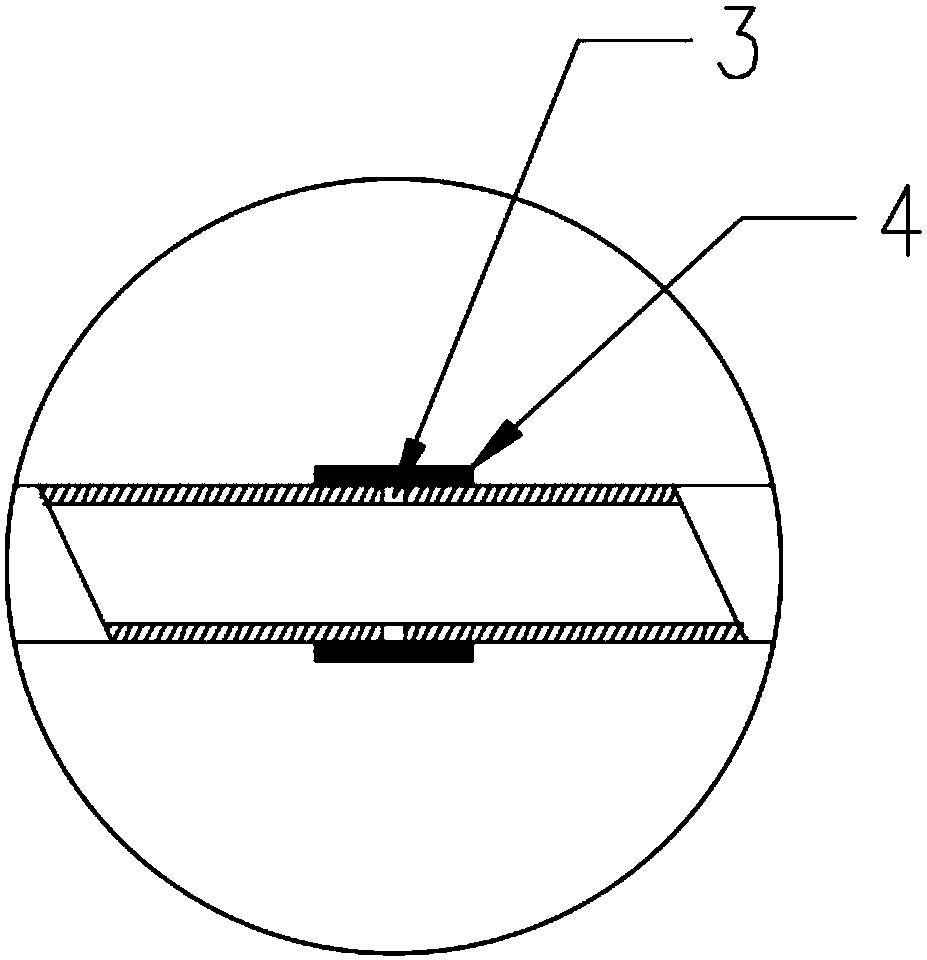

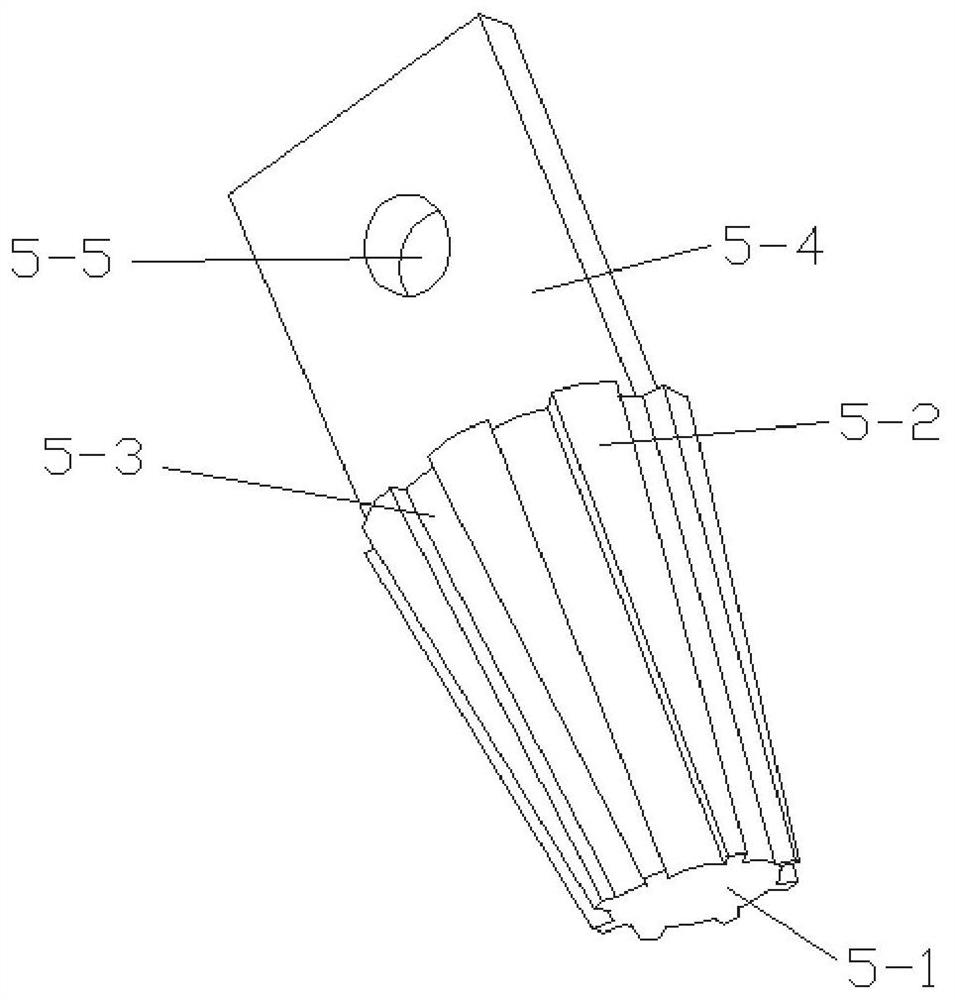

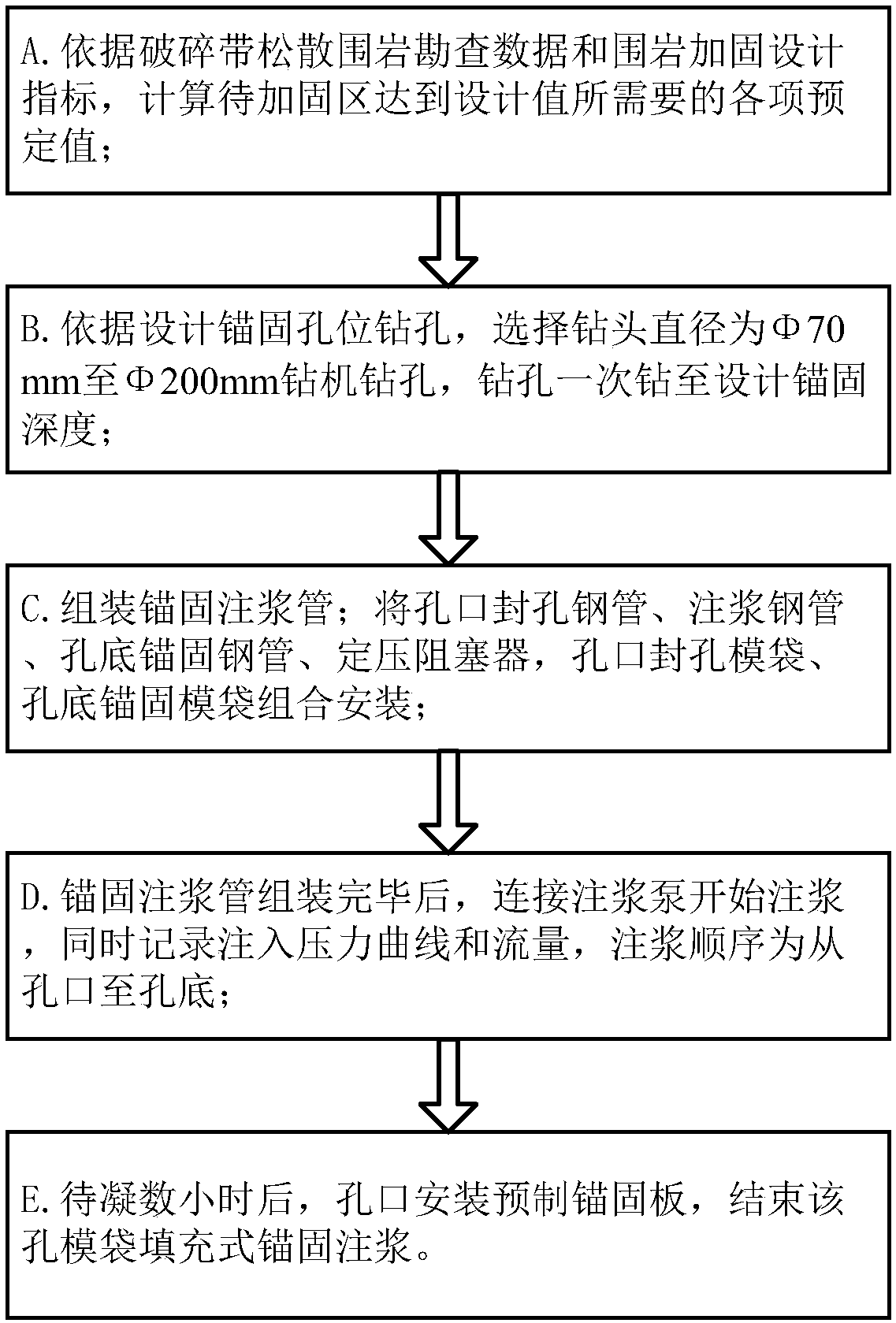

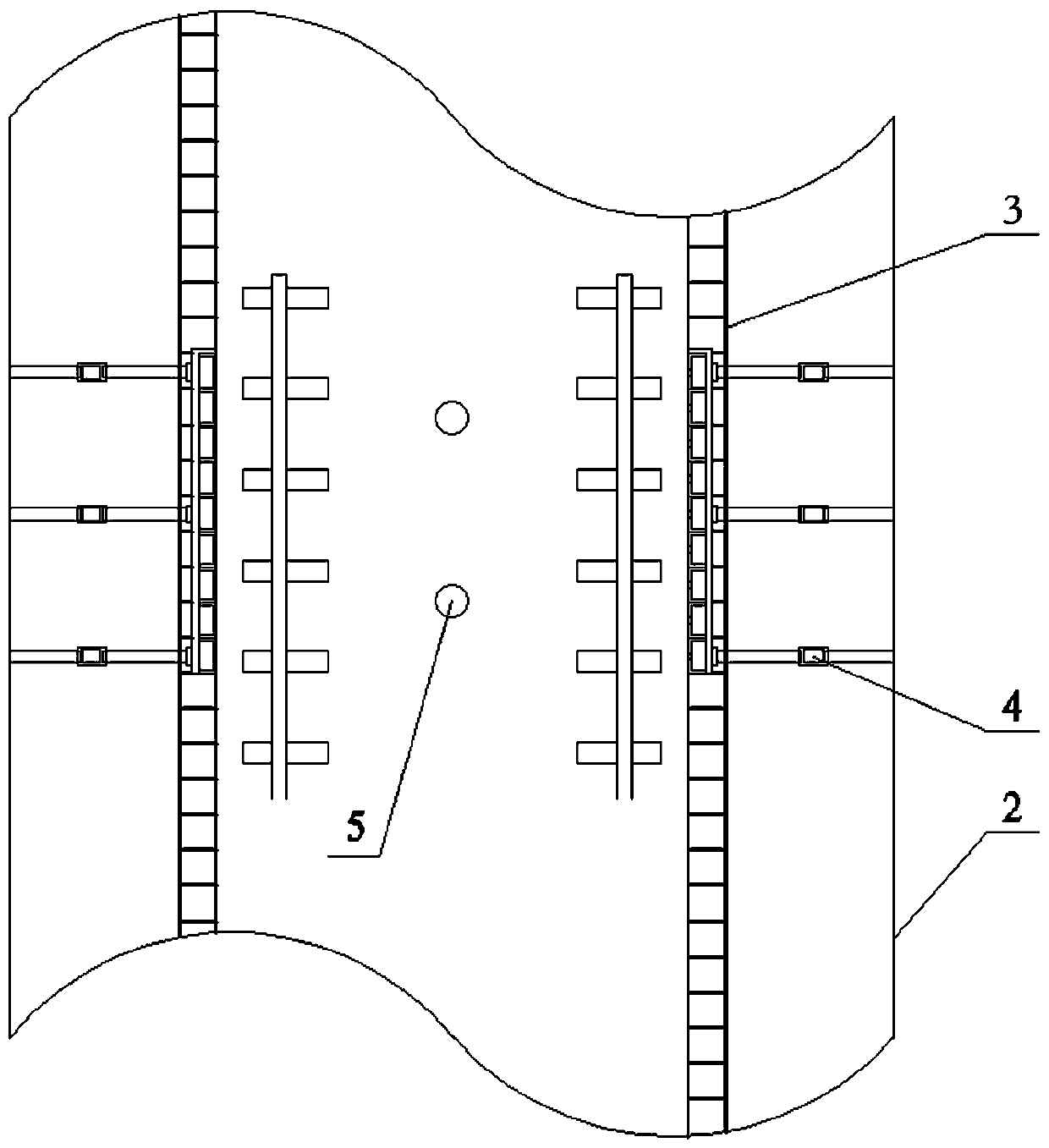

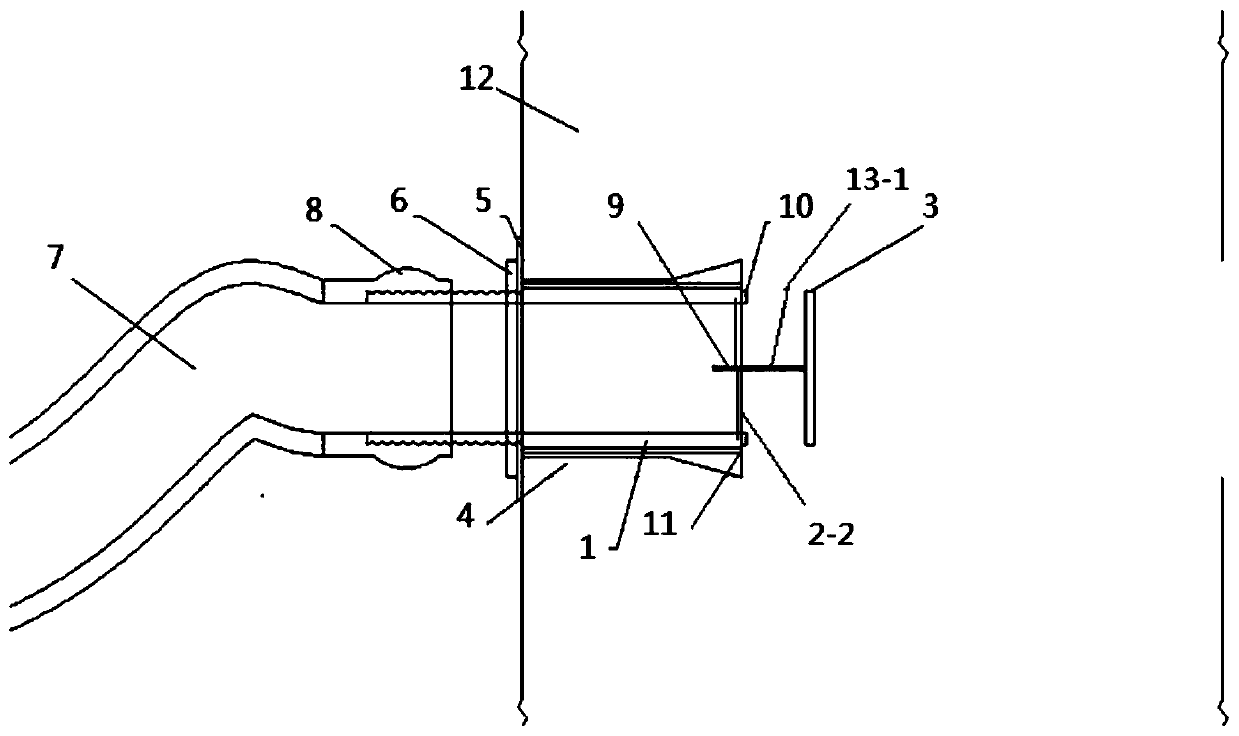

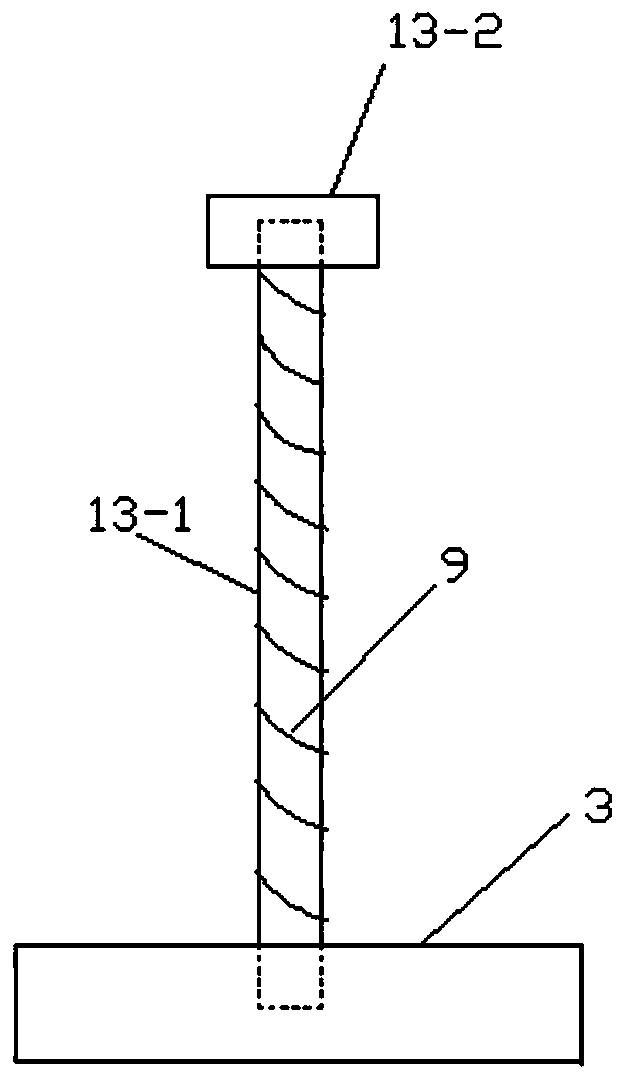

Mold-bag-filling-type anchor grouting device and method

The invention discloses a mold-bag-filling-type anchor grouting device which comprises a hole opening hole sealing steel pipe (1), wall surface patterned holes (2), a constant pressure stopper A (3),a hole opening hole sealing mold bag (4), a grouting steel pipe (5), a constant pressure stopper B (6), reinforcing ribs (7), a hole bottom anchoring steel pipe (8) and a hole bottom anchoring mold bag (9). According to the mold-bag-filling-type anchor grouting device, an anchoring rod is divided into three parts of the hole opening hole sealing steel pipe, the grouting steel pipe and the hole bottom anchoring steel pipe, the mold bags, the reinforcing ribs and the wall surface patterned holes are arranged / formed, and by combining the characteristics that the mold bags are expanded during grouting and grout leakage is not prone to occurring, hole bottom anchoring and hole opening filling closing are achieved; through the wall surface patterned holes, cement grout and solidification grout are effectively grouted into loose wall rock; and thus, the grouting pressure is effectively increased, the broken loose wall rock is quickly filled, grouting liquid is prevented from being subjected to underground water erosion, and finally the firm mold-bag-filling-type anchor rod is formed, so that the engineering quality and the technical level are comprehensively improved.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

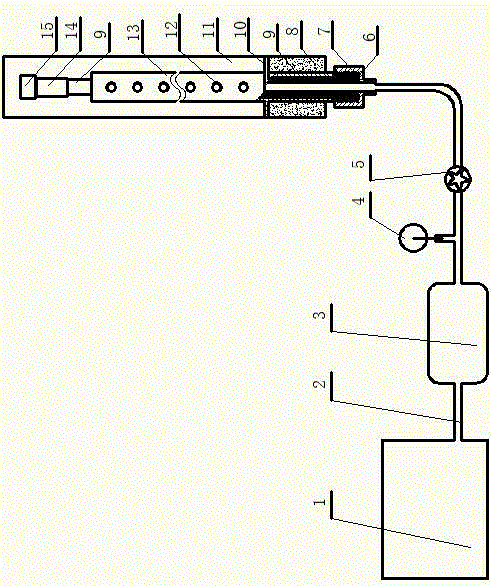

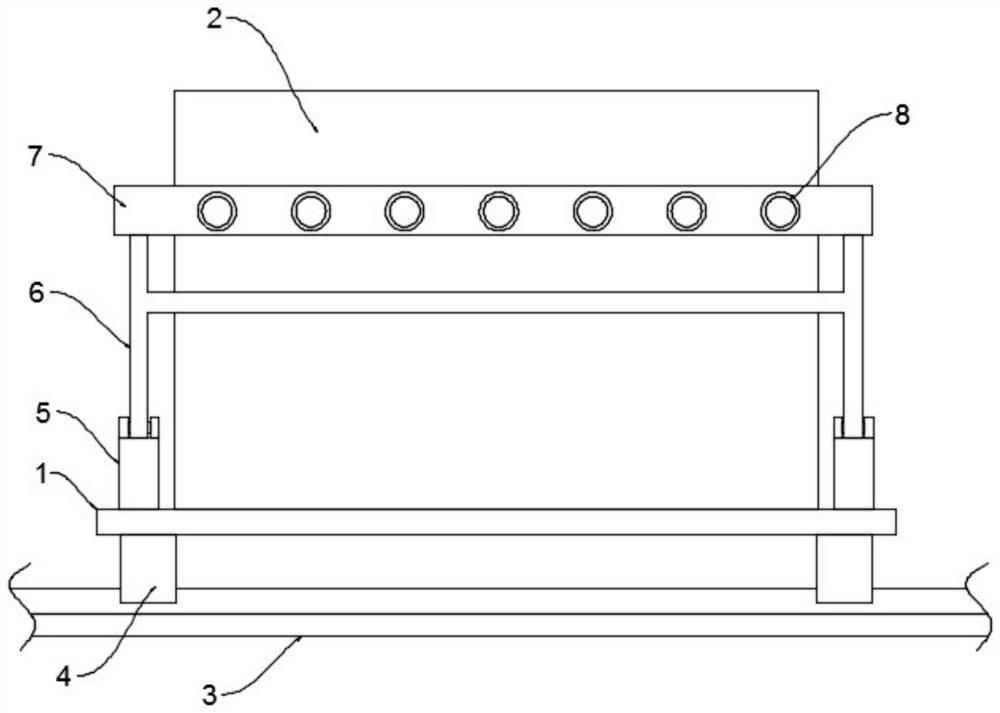

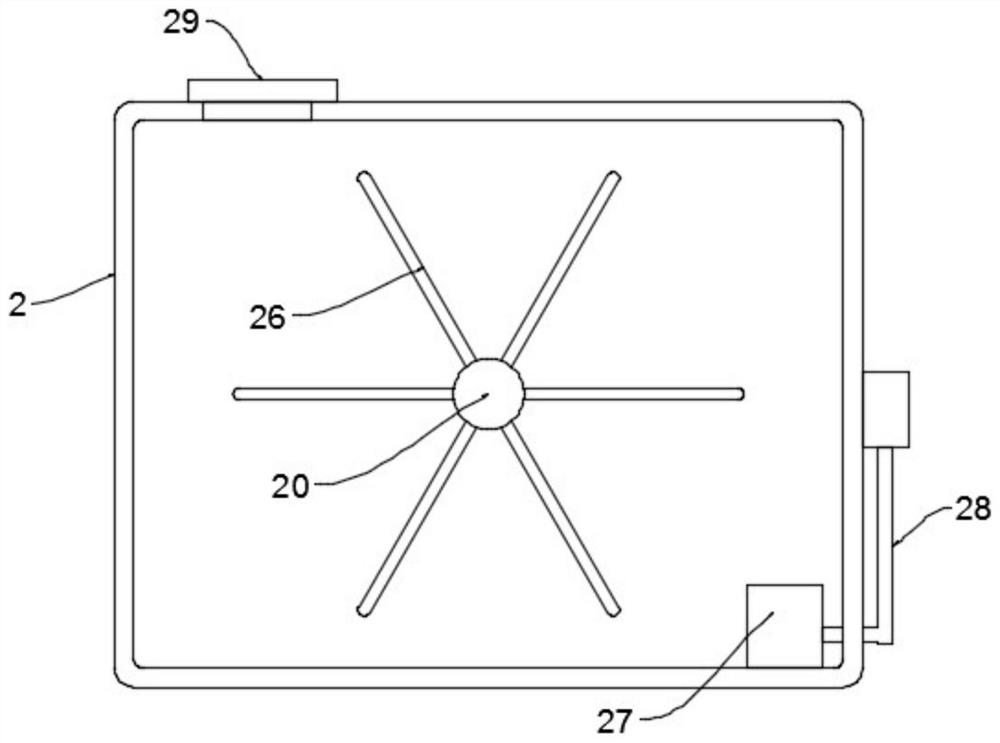

Automatically walking grouting trolley device for subway shield construction

ActiveCN111577332AFacilitate reciprocating automatic walkingConvenient groutingUnderground chambersTunnel liningGear wheelArchitectural engineering

The invention discloses an automatically walking grouting trolley device for subway shield construction. The automatically walking grouting trolley device for subway shield construction comprises a trolley rack and a grout storage tank arranged on the trolley rack; two ends of the trolley rack are provided with transverse pipes, the end of each transverse pipe is provided with a side convex body,the bottom end of each side convex body is provided with a walking slide base, the walking slide bases are slidably buckled on walking guide rails fixed on the tunnel ground, a rotating transverse shaft is arranged between the two side convex bodies, a walking driving gear is installed on the rotating transverse shaft, and the walking driving gear is engaged with a walking transverse rack arrangedon the tunnel ground; the outer wall of the grout storage tank is provided with a walking motor and a driving transverse shaft; and two sides of the trolley rack are provided with grouting mechanismsfor spraying out grout in the grout storage tank. The automatically walking grouting trolley device for subway shield construction is simple in structure, the whole trolley can conveniently walk backand forth automatically in a tunnel, rapid grouting can be achieved, operation is convenient and fast, and practicability is high.

Owner:BEIJING MUNICIPAL CONSTR +1

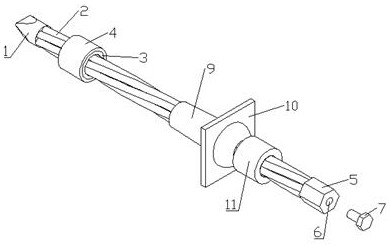

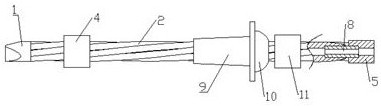

Hollow grouting mining anchor cable

The invention discloses a hollow grouting mining anchor cable. The hollow grouting mining anchor cable comprises a head steel pipe, hollow steel strands, plastic grout stopping pipes, plastic grout stopping pipe outer sleeves, hollow hexagon nuts, grouting openings, hexagon bolts, grouting pipes, grout stopping plugs, supporting plates and mining anchor cable anchorage devices, wherein a pluralityof stranded hollow steel strands are fixed to the right side of the head steel pipe; the outer sides of the hollow steel strands are sleeved with the plastic grout stopping pipes; the outer walls ofthe plastic grout stopping pipes are wrapped with the plastic grout stopping pipe outer sleeves; the hollow hexagon nuts are welded to the right ends of the hollow steel strands; the right end openings of the hollow hexagon nuts are arranged to be the grouting openings; the hexagon bolts are in threaded connection with the grouting openings; the grouting pipes are welded to the left sides of the grouting openings; and the right portions of the hollow steel strands are sleeved with the grout stopping plugs. The hollow grouting mining anchor cable has the beneficial effects of being high in strength, good in plasticity, low in relaxation value, good in straightness, high in wrapping force and integrity with resin anchoring agents and grouting liquid and the like.

Owner:枣庄市顺翔科技发展有限公司

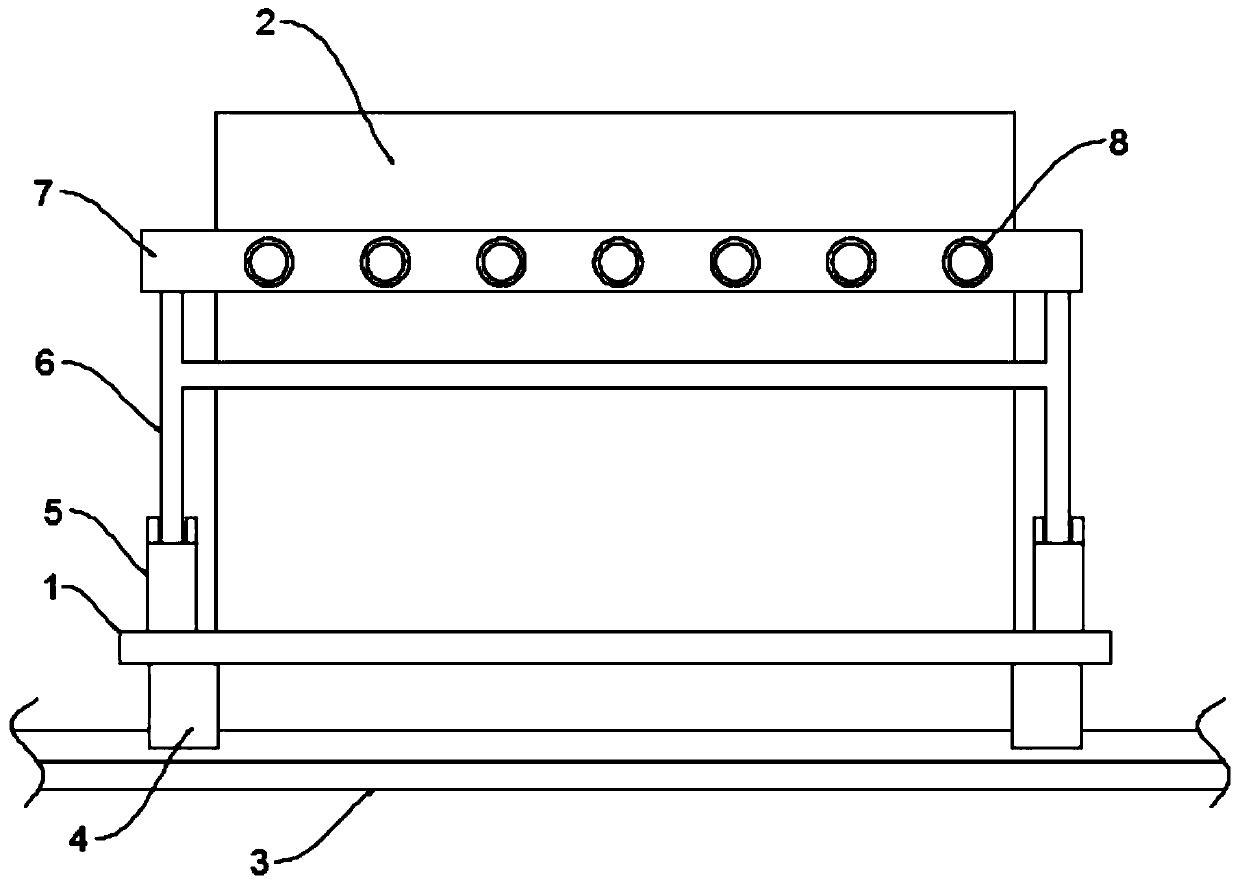

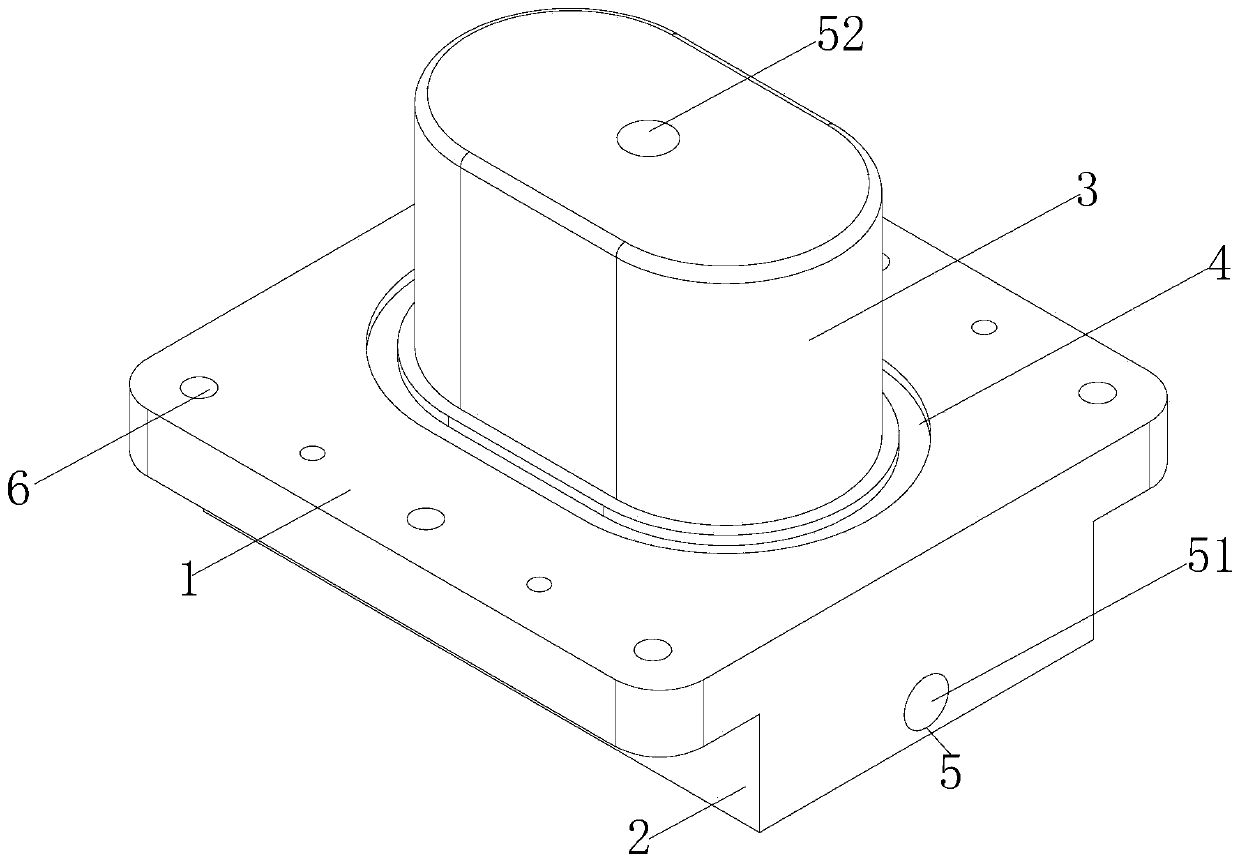

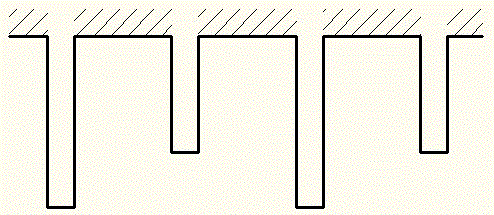

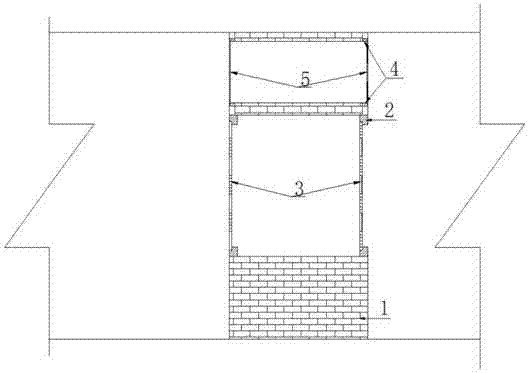

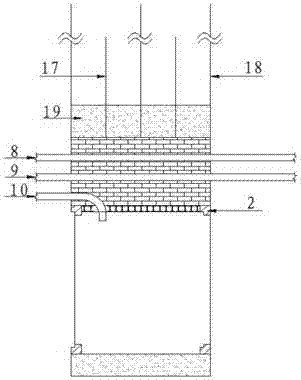

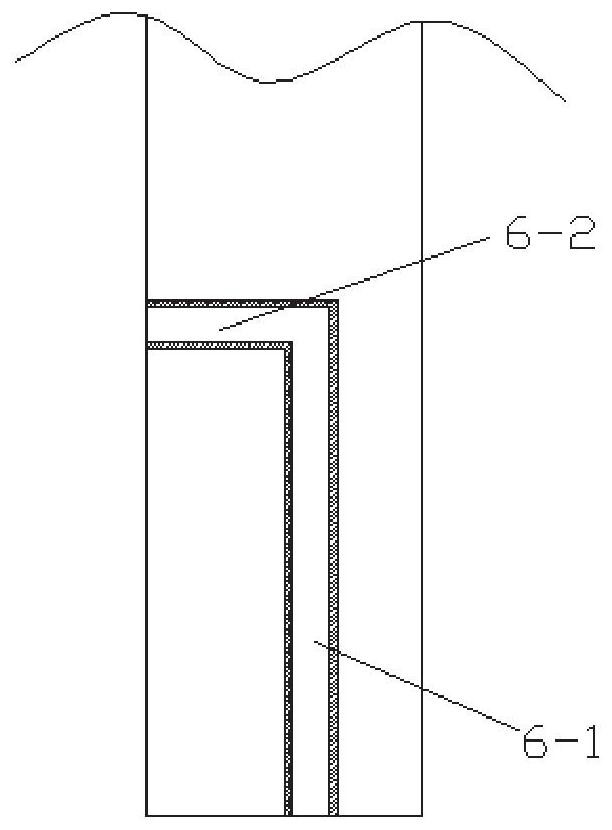

Prefabricated vertical component and sleeve grouting construction method thereof

ActiveCN112324055ARapid GroutingImprove work efficiencyBuilding reinforcementsBuilding material handlingReinforced concreteArchitectural engineering

The invention relates to a prefabricated vertical component and a sleeve grouting construction method thereof. The prefabricated vertical component comprises a component body of a reinforced concretestructure, wherein a plurality of grouting sleeves are pre-buried in the component body, a grouting pipe and a plurality of indicating pipes arranged on the two sides of the grouting pipe are furtherpre-buried in the component body, the two ends of the grouting pipe and the two ends of the indicating pipes extend to the bottom face and the side face of the component body correspondingly and can communicate with the outer space of the component body, and the height of the connecting positions of the indicating pipes and the grouting pipe and the side face of the component body is larger than the height of the top of the grouting sleeves. According to the prefabricated vertical component and the sleeve grouting construction method thereof, the construction work efficiency is high, and supplementary grouting can be conducted, so that the engineering safety is guaranteed.

Owner:山东省建筑科学研究院有限公司 +3

Preparation of a geopolymer grouting material and its method for static pressure grouting

ActiveCN106587782BReduce labor intensityLow viscosityCement productionRoads maintainenceSodium BentoniteSlag

The invention provides a method for preparing a geopolymer grouting material and a method for applying the geopolymer grouting material to static pressure grouting. Raw materials for preparing the geopolymer grouting material include steel slag, mineral slag, sodium silicate, silica fume, calcium bentonite, softened water and a composite alkali activator. The method for preparing the geopolymer grouting material comprises the steps that 1, a component A is prepared; 2, a component B is prepared; 3, a component C is prepared; and 4, the geopolymer grouting material is prepared. The method for static pressure grouting comprises the steps of 1, survey; 2, assessment; 3, pit sounding; 4, hollowing general survey; 5, deflection value check; 6, comprehensive evaluation; 7, measurement and hole arrangement; 8, drilling; 9, grouting; 10, check; 11, grouting hole sealing; and 12, recheck to complete static pressure grouting. The methods have the advantages of environmental friendliness, low viscosity, high elasticity modulus, high cohesiveness, low cost, high efficiency and high durability.

Owner:JIANGSU ZHUODIAN DRILLING & TUNNELING TECH CO LTD

Pre-explosion drilling, grouting and anchoring integrated anchor rod and construction method thereof

The invention discloses a pre-explosion drilling, grouting and anchoring integrated anchor rod and construction method thereof, and belongs to geotechnical engineering. The pre-explosion drilling, grouting and anchoring integrated anchor rod consists of a sectional type drilling anchor rod, a drill bit and a sectional type hollow grouting pipe, wherein the internal hollow grouting pipe is connected with a multi-section explosive pipe at the front end of the grouting pipe; a plurality of return stoppers are arranged on the tip of the front end of the grouting pipe, which is connected with the explosive pipe; and when the integrative anchor rod is drilled to reach a specified position, a drilling rod is taken back reversely, the internal hollow grouting pipe is pushed forwards, the return stoppers work, and then the drilling rod is stopped from being taken back. A detonating cord is connected with a detonator to detonate explosive sections, a rubber stopper provided with a slurry guide pipe (exhaust pipe) follows up on the end part of the drilling rod for sealing, and a supporting liner plate, a nut and a hollow drilling rod cooperate with one another on the end part; and the supporting liner plate, through which the detonating cord penetrates, is provided with a drill way, and one section of a pipeline penetrates through the drill way of the supporting liner plate. The pre-explosion drilling, grouting and anchoring integrated anchor rod has the advantages that: the anchor integrates drilling, grouting and anchoring and molded in one step; the integrative anchor rod is applied to reinforcement of laneways, pit shafts and side slopes, and temporary or permanent supporting in water control; and the construction method has a certain promotion value.

Owner:中煤长江基础建设有限公司

Cutting, soil taking and grouting integrated sleeve pipe

The invention relates to a cutting, soil taking and grouting integrated sleeve pipe which is composed of an outer layer pipe and an inner layer pipe. The lower portion of the outer layer pipe is provided with a tooth port which can cut soil when rotated downwards, different types of tooth ports such as cutting teeth and grinding teeth can be selected according to geological conditions, the outer layer pipe and the inner layer pipe are connected in a buckled mode and can be separated, the lower portion of the inner layer pipe is provided with a grabbing hopper which can be closed in a grabbingmode, and the inner side of the outer layer pipe is provided with grout (liquid) jet holes capable of jetting grout or water. Soil can be cut when the sleeve pipe is rotated downwards, soil can also be taken out at the same time, slag removal is not needed, then, a series of operations of grout (liquid) jetting are carried out, the construction efficiency is improved, and the integrated sleeve pipe is novel and efficient.

Owner:SHANGHAI CHENGDI CONSTR +1

Shield tail grouting liquid mixing valve

The invention belongs to the technical field of accessories of shield equipment and particularly relates to a shield tail grouting liquid mixing valve which comprises a mounting block, wherein a protruding block is fixedly mounted at the bottom of the mounting block and has a thickness of 23 cm; an embedded block is fixed at the bottom of the mounting block; a sealing groove is formed in the top of the mounting block, has a width of 5 cm and has a thickness of 2 cm; and a grouting passage is formed among the mounting block, the protruding block and the embedded block. According to the shield tail grouting liquid mixing valve, the structure of a sealing element of the existing grouting opening is improved; the protruding block and the grouting passage are additionally arranged on the basisof the original structure; after the mounting block is fixed, the embedded block is matched with the sealing groove to seal the grouting opening; due to existence of the grouting passage, a grout feeding passage and a grout discharging passage enable the grouting opening to communicate with the external world, and a pipeline directly communicates with the grout feeding passage for grouting operation, so that the step of shield tail grouting operation is simplified, fast shield tail grouting is facilitated, and the workload is reduced.

Owner:CHINA RAILWAY 14TH BUREAU GRP LARGE SHIELD ENG CO LTD

A kind of advanced small conduit grouting structure and construction method thereof

ActiveCN109139048BGood slurry effectQuick closureUnderground chambersTunnel liningArchitectural engineeringRock tunnel

The invention relates to the technical field of tunnel construction, in particular to an advanced small pipe grouting structure and a construction method thereof. According to an advanced small pipe,quick closure of a primary support can be ensured, a grout stopping wall and the primary support form an integral stress structure and are tightly attached to a tunnel face, so that the stability of the tunnel face is increased, the safety risk of the tunnel face is greatly reduced, and soft rock tunnels and special geological tunnels excavated by blasting are facilitated; and the grouting structure is simple, the application of the grout stopping wall basically does not occupy the application time of the primary support, the grout stopping wall can be applied synchronously with the primary support, the construction speed is high, rapid grouting can be realized, a great deal of time is saved and the construction progress is speeded up compared with the set of the grout stopping wall alone,and grout stopping wall can be used as a part of the primary support without dismantling after the grouting of the advanced small pipe is finished. The advanced small pipe is factory processed, and has convenient and quick installation and grouting. The grout stopping wall is of an integral structure, has good grout stopping effect, can bear large grouting pressure, and greatly ensures the grouting effect of the advanced small pipe.

Owner:CHINA RAILWAY 12TH BUREAU GRP +1

Surrounding rock high-pressure gas multi-stage pre-splitting grouting reconstruction method and reconstruction device of deep soft rock roadway

ActiveCN105156134BGood injectabilityPrevent closureUnderground chambersFluid removalHigh pressureMechanical property

Owner:CHINA UNIV OF MINING & TECH

Coal mine fireproof door wall structure and construction method thereof

PendingCN106958456ARealize the air lane track transportation of materialsReduce labor intensityMining devicesFireproof doorsCoalFire door

The invention discloses a coal mine fireproof door wall structure which comprises a ventilating roadway fireproof door wall structure and a transport roadway fireproof door wall structure. The fireproof door wall structure is treated in the mode that antiflaming wood is wrapped with antiflaming rubber. Application of the antiflaming wood greatly lowers the weight of the fireproof door wall structure. Meanwhile, a fireproof door frame structure is wrapped with the antiflaming rubber, so that a fireproof door frame and a coal transport channel door frame are completely closed after a fireproof door and a coal transport channel fireproof door are closed, and the fire retardancy of the fireproof door frame, the fireproof door, the coal transport channel door frame and the coal transport channel fireproof door are further enhanced. The problems that an existing fireproof door wall structure is high in construction labor intensity, the airtightness of the fireproof door and the fireproof door frame is poor, and the fireproof door frame is prone to deformation are effectively solved, the fireproof door can be installed on the fireproof door frame in advance, the fireproof door can be fast closed after a fire breaks out, and accordingly spreading of the disaster is fast controlled, and a good use effect is obtained.

Owner:GUIZHOU PANJIANG REFINED COAL

Full-hole one-time rapid grouting construction method

The invention discloses a full-hole one-time rapid grouting construction method. The full-hole one-time rapid grouting construction method comprises the processes of hole distribution, manufacturing of a grouting pipe, material compounding, grouting and the like. Full-hole one-time grouting is achieved, the full-hole one-time rapid grouting construction method is suitable for textures of backfillsoil, muddy soil, a riprap layer, a sand layer, a full-differentiation layer and a strong-differentiation layer, and the grouting effect is good.

Owner:CHINA RAILWAY 18TH BUREAU GRP CO LTD +1

A prefabricated vertical component and its sleeve grouting construction method

InactiveCN112324055BRapid GroutingImprove work efficiencyBuilding reinforcementsBuilding material handlingReinforced concreteArchitectural engineering

The invention relates to a prefabricated vertical component and a sleeve grouting construction method thereof. There are multiple indicator tubes on both sides of the grouting tube. The two ends of the grouting tube and the indicator tube extend to the bottom and side of the component body respectively, and can communicate with the external space of the component body. The connection between the indicator tube and the grouting tube and the side of the component body The height of the position is higher than that of the top of the grouting sleeve, the prefabricated component and the construction method of the present invention have high construction work efficiency, and can carry out supplementary grouting, thereby ensuring engineering safety.

Owner:山东省建筑科学研究院有限公司 +3

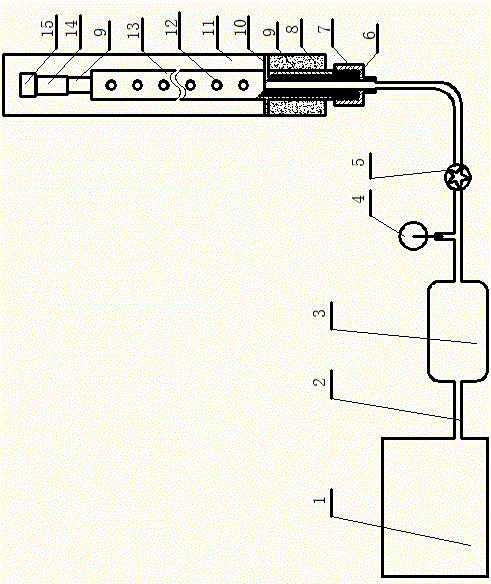

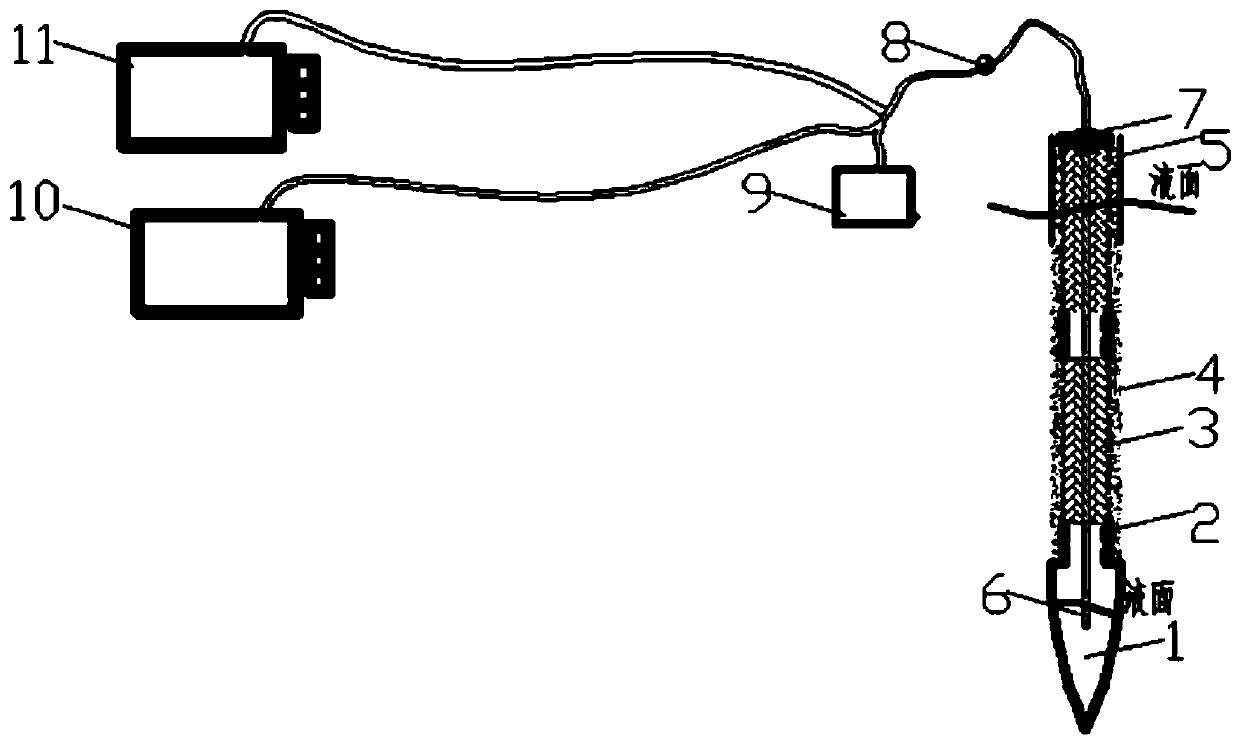

A tailings dam silting negative pressure drainage reinforcement device

ActiveCN109610434BSolve the problem of poor drainage effect of local silting and seepagePrevent dam failuresExcavationsSoil preservationTailings damExtreme weather

The invention provides a tailing dam clogging negative pressure seepage discharging reinforcement device, and belongs to the technical field of a tailing pond auxiliary device. The tailing dam clogging negative pressure seepage discharging reinforcement device comprises a water collection drill bit, a connecting threaded pipe, a metal net filtering pipe, a geotextile, a laminating film, a steam extraction pipe, a threaded clamp pipe cover, a negative pressure pump, a pressure gauge, an emergent grouting pump and a gas liquid separation container, wherein the water collection drill bit and themetal net filtering pipe are in segmented connection through the connecting threaded pipe; the metal net filtering pipe is tightly wrapped by the geotextile and is vertically pressed into tailing sand; the steam extraction pipe is put into the water collection drill bit; and the threaded clamp pipe cover and the metal net filtering pipe are connected in a sealed way for opening sealing. The tailing dam clogging negative pressure seepage discharging reinforcement device has the advantages that the problem of seepage discharging and clogging phenomena in different positions of a high-risk dam body can be effectively solved; the seepage line of the dam body is lowered; by aiming at the conditions such as extreme weather and geology, the stability of the damage body is improved through the reinforcement via internal grouting and through the reinforced surface on the ground surface by steel bars; the operation risk of the tailing dam is effectively reduced; and meanwhile, the reinforcementdevice can also be used for slope reinforcement in regions with rainfall precipitation, leaching mining and the like.

Owner:UNIV OF SCI & TECH BEIJING

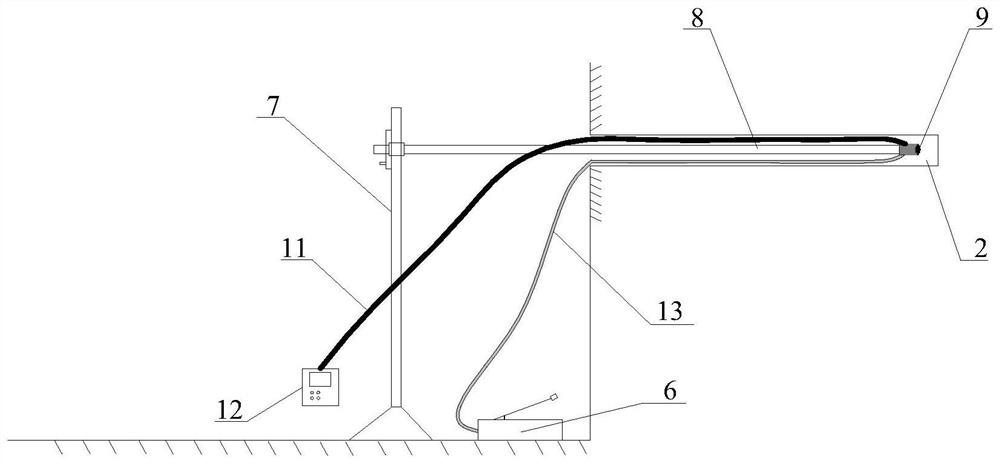

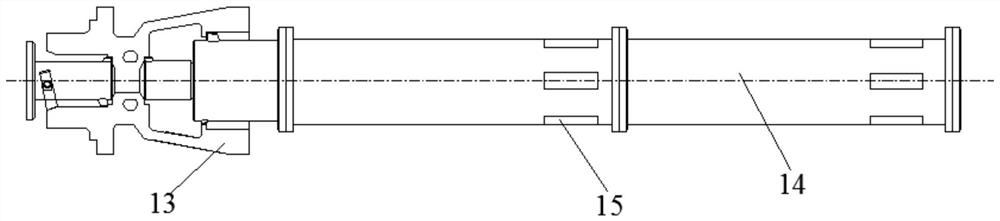

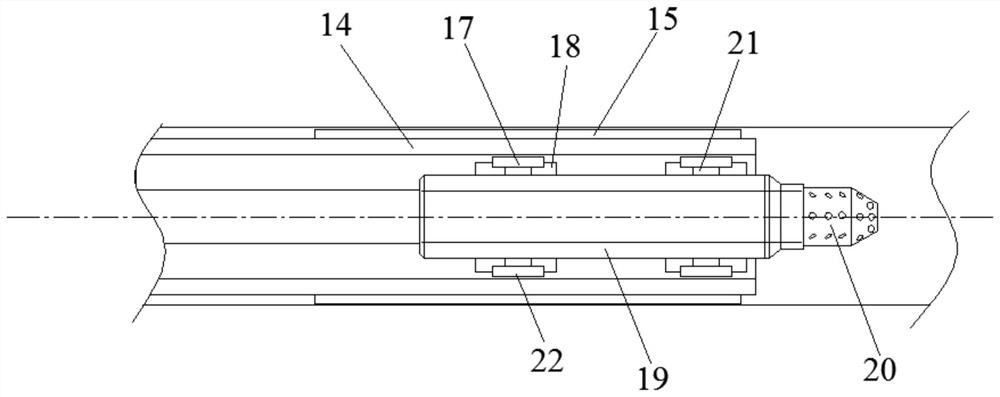

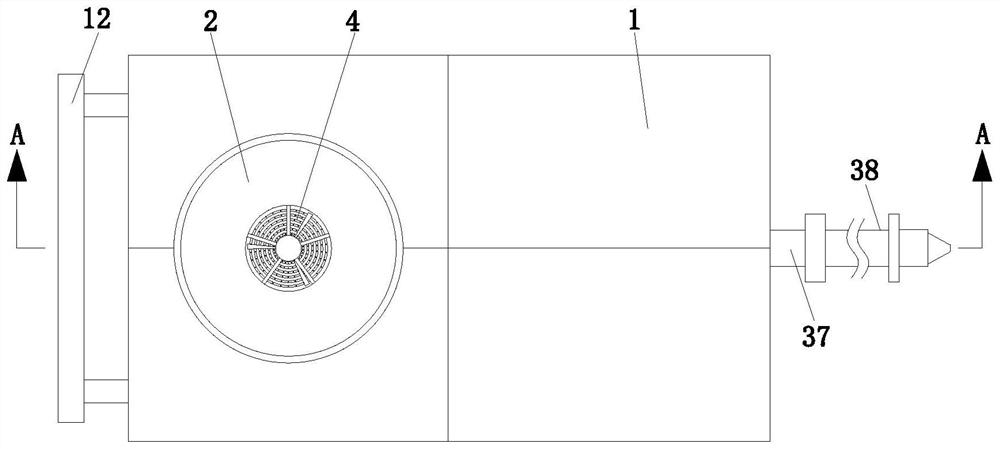

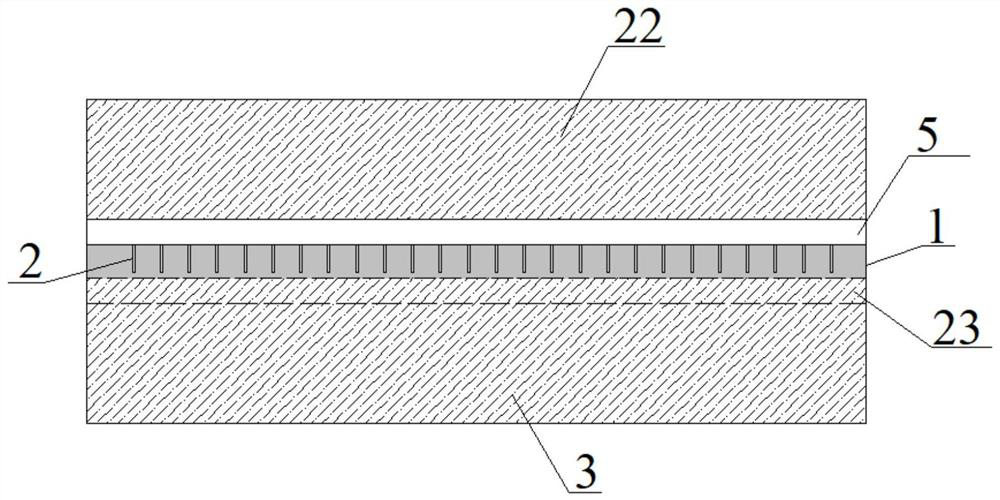

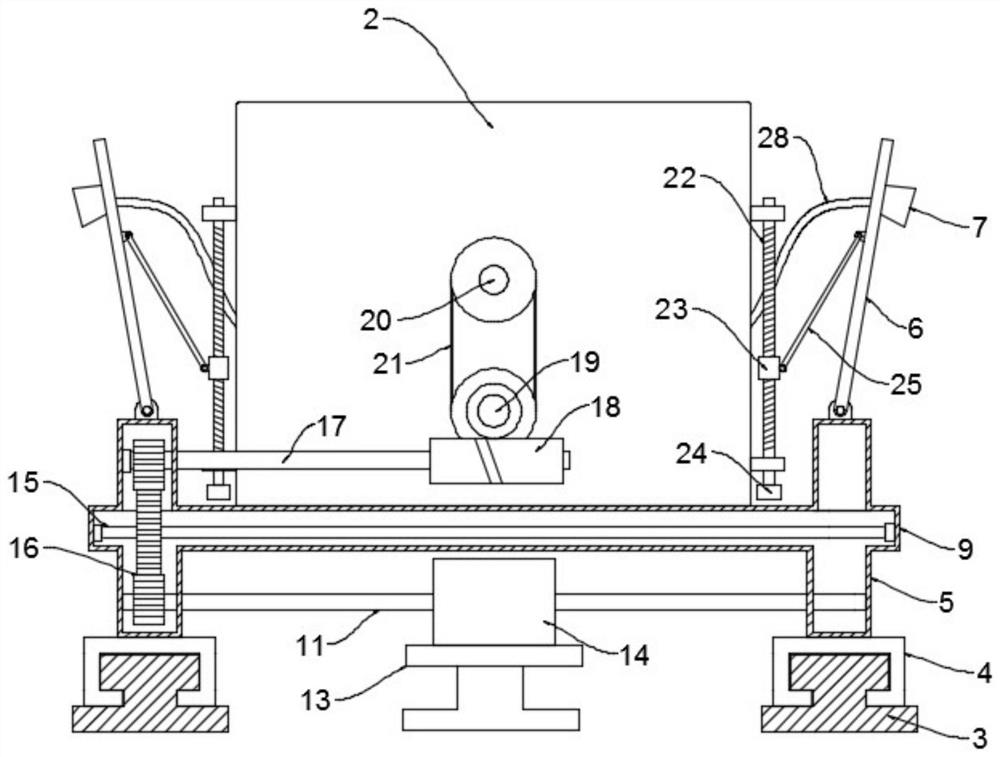

Automatic horizontal grouting device for grouting reinforcement of coal mine roof

ActiveCN112031822AGuarantee capacityGuaranteed reliabilityUnderground chambersTunnel liningStructural engineeringCoal

The invention discloses an automatic horizontal grouting device for grouting reinforcement of a coal mine roof. Grouting is conducted in a segmented mode, and the deepest grouting effect can be achieved without excessively increasing the grouting pressure; an auxiliary grouting pipe stretches into a horizontal drill hole and can be tensioned and fixed through an outer hydraulic tensioning sleeve assembly; a grouting head stretches into the auxiliary grouting pipe and can be positioned in the auxiliary grouting pipe through an inner hydraulic tensioning sleeve; and when grouting is conducted toa certain degree and the inner hydraulic tensioning sleeve slides relatively in the auxiliary grouting pipe, that the grouting process of the segment is finished is indicated, then the outer hydraulic tensioning sleeve assembly is subjected to pressure relief, the auxiliary grouting pipe is moved outwards by a certain distance, then the grouting head is fixed through the outer hydraulic tensioning sleeve assembly and the inner hydraulic tensioning sleeve assembly again, and grouting of the outer segment continues to be conducted. The grouting capacity and the grouting effect are improved, allthe segments are grouted under the roughly same grouting pressure, and the whole grouting supporting capacity and reliability are guaranteed.

Owner:北京大地高科地质勘查有限公司

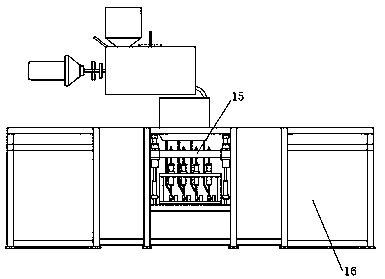

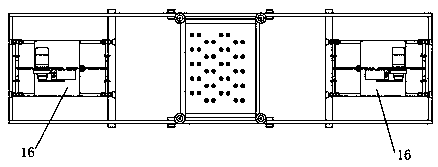

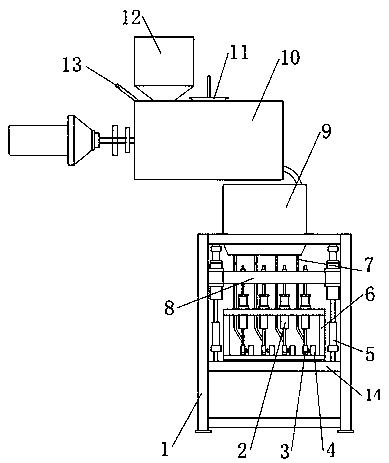

Thermal insulation brick fully automatic grouting production device

The invention relates to a thermal insulation brick fully automatic grouting production device, which includes a grouting gear, lifting gears and a conveying gear. The lifting gears are respectively installed on the two sides of the grouting gear; the grouting gear includes a main body frame, a needle drum bracket and a needle rod push rack assembly, wherein supporting seats are respectively installed on the middle part of the front end and the middle of the rear end of the main body frame; the needle bracket is installed on the upper ends of the two supporting seats, a plurality of needle drum assemblies are arranged at the upper end of the needle drum bracket, needle heads at the lower ends of the needle drum assemblies vertically penetrate through the needle drum bracket, and switchingvalves are respectively installed on the position, located on each needle drum assembly of the needle head, of the lower end of the needle drum bracket; and one sides of the switching valves are connected with a switching valve opening machine, oil cylinder assemblies are vertically installed on the supporting seats which are located on the two sides of the needle drum bracket, the upper ends of piston rods of the oil cylinders are connected with the needle rod push rack assembly, and the needle push rack assembly is connected with needle rods at the upper end of the needle drum assembly. According to the thermal insulation brick fully automatic grouting production device, grouting production can be finished quickly, accurately and fully automatic, the production efficiency is improved greatly, and the manual cost is lowered.

Owner:中山市祥兴新型墙体建材有限公司

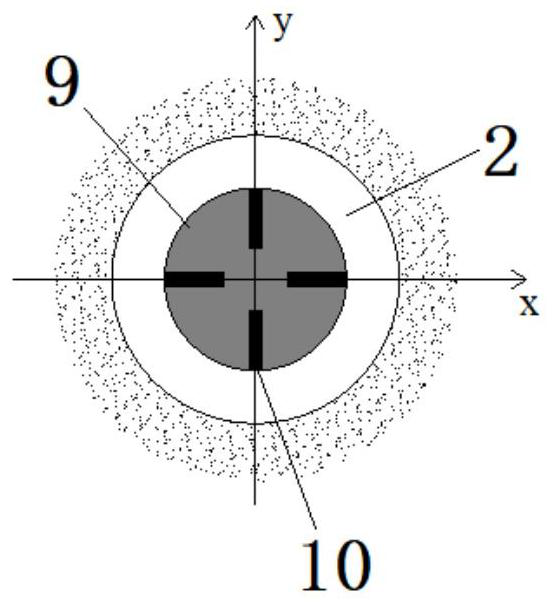

A mold bag filling type anchor grouting device and method

The invention discloses a mold-bag-filling-type anchor grouting device which comprises a hole opening hole sealing steel pipe (1), wall surface patterned holes (2), a constant pressure stopper A (3),a hole opening hole sealing mold bag (4), a grouting steel pipe (5), a constant pressure stopper B (6), reinforcing ribs (7), a hole bottom anchoring steel pipe (8) and a hole bottom anchoring mold bag (9). According to the mold-bag-filling-type anchor grouting device, an anchoring rod is divided into three parts of the hole opening hole sealing steel pipe, the grouting steel pipe and the hole bottom anchoring steel pipe, the mold bags, the reinforcing ribs and the wall surface patterned holes are arranged / formed, and by combining the characteristics that the mold bags are expanded during grouting and grout leakage is not prone to occurring, hole bottom anchoring and hole opening filling closing are achieved; through the wall surface patterned holes, cement grout and solidification grout are effectively grouted into loose wall rock; and thus, the grouting pressure is effectively increased, the broken loose wall rock is quickly filled, grouting liquid is prevented from being subjected to underground water erosion, and finally the firm mold-bag-filling-type anchor rod is formed, so that the engineering quality and the technical level are comprehensively improved.

Owner:INST OF MECHANICS CHINESE ACAD OF SCI

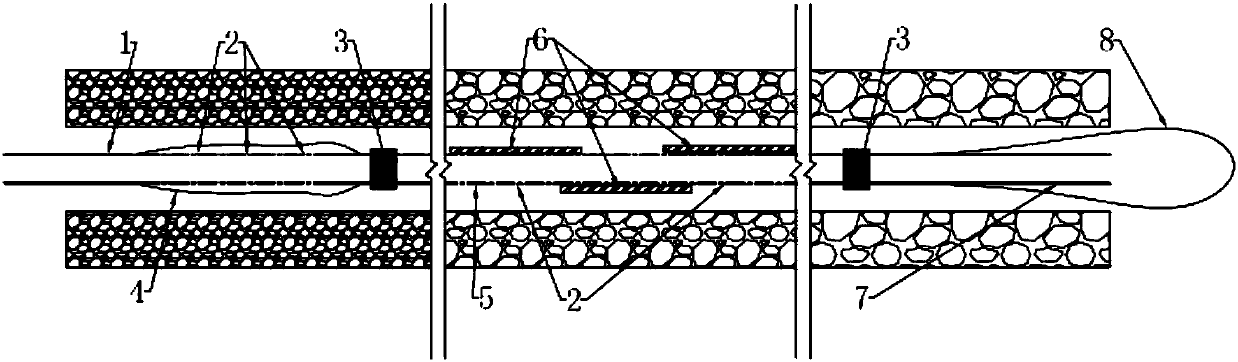

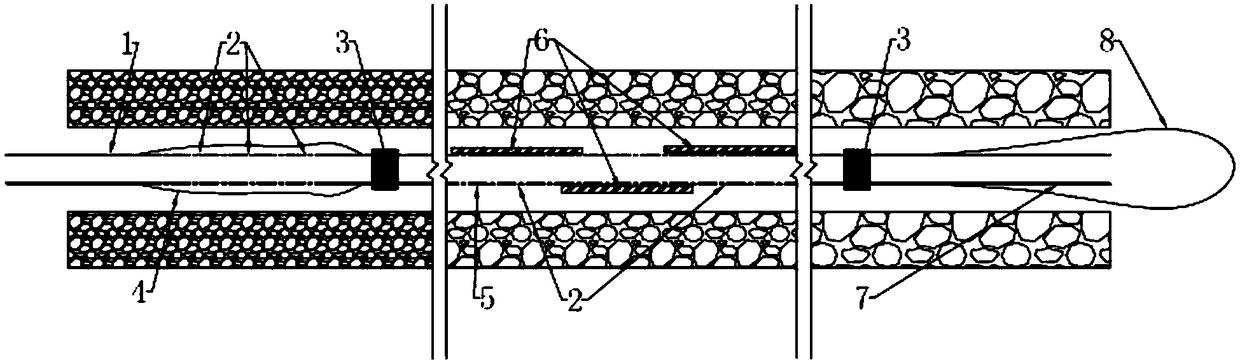

Integral ballast bed and tunnel bottom disease control method based on combined support and grouting formwork

The invention belongs to the field of settlement control of the overall ballast bed of existing long railway tunnels and the construction field of grouting reinforcement at the bottom of the tunnel. The overall ballast bed and tunnel bottom disease treatment method of support and grouting formwork adopts the construction method of first using the combined steel plate support to support the diseased section of the ballast bed, and then installing grouting formwork on both sides of the diseased section of the ballast bed to carry out disease remediation on the ballast bed and tunnel bottom . The invention organically combines the support in the early stage of disease control construction with the improvement of the grouting effect in the later stage, slows down the impact of the broken ring of the ballast bed and the bottom plate before and after the train passes, effectively fills the broken area at the bottom of the tunnel, and supports the combined steel plate to ensure The complete wrapping of the grout and the supporting steel plate achieves the purpose of quickly supporting the ballast bed in the damaged area at the bottom of the tunnel, controlling the development speed of the disease, and fast and efficient grouting to reinforce the diseased area.

Owner:CHINA RAILWAY NO 3 GRP CO LTD

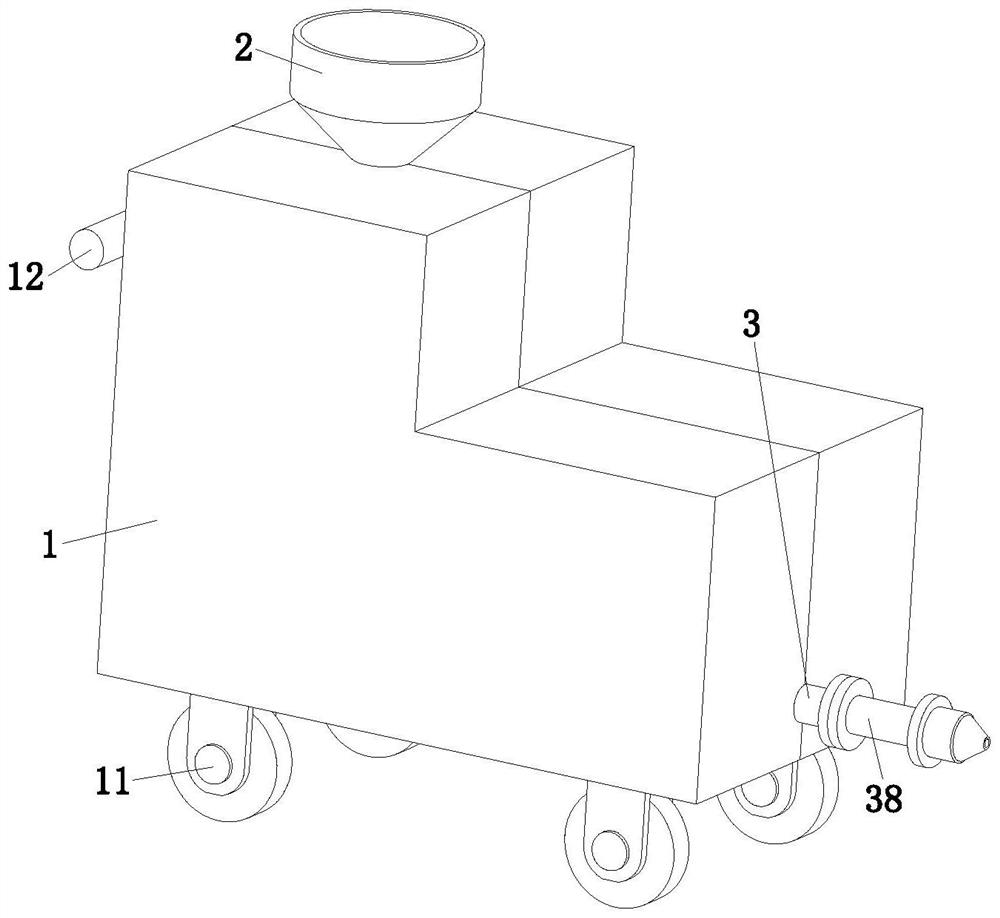

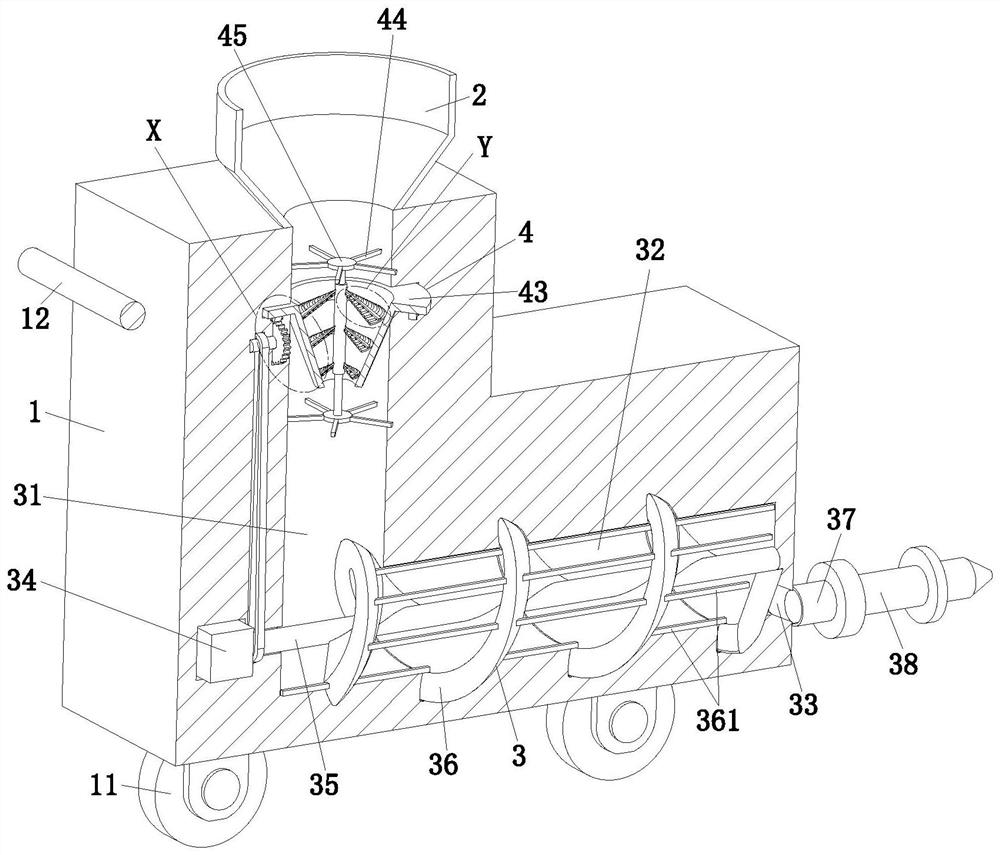

Light low-pressure grouting equipment for rapid grouting reinforcement of tunnel

ActiveCN114311299AAffect the use effectPrevent affecting the delivery efficiencyUnderground chambersDischarging apparatusSlurryMachine

The invention relates to the technical field of tunnel reinforcement, in particular to light low-pressure grouting equipment for tunnel rapid grouting reinforcement, which comprises a rack, a hopper, a conveying unit and a grinding unit, the hopper is arranged at the upper end of the rack, the conveying unit and the grinding unit are mounted in the rack, and the grinding unit is positioned above the conveying unit; an existing grouting machine has the following problems that a common grouting machine cannot remove residual slurry in the common grouting machine in time, so that the solidified slurry can form residues, and the conveying efficiency of the grouting machine is easily influenced; a traditional grouting machine cannot grind slurry, and therefore the using effect of the slurry doped with particles can be affected. According to the invention, residual slurry in the device can be scraped in time, so that the conveying efficiency of the device is prevented from being influenced by the residues; before grouting, slurry can be subjected to multi-stage grinding treatment, and therefore the situation that the using effect of the slurry is affected due to the fact that particles are left in the slurry can be avoided.

Owner:南京康泰建筑灌浆科技有限公司

Advance grouting reinforcement method for narrow coal pillars in gob-side roadway

ActiveCN112096382BHigh porosityImprove bearing capacitySurveyUnderground chambersShock waveMining engineering

A advance grouting reinforcement method for narrow coal pillars in gob-side roadways. Before mining at the working face in the upper section of the gob-side roadway, a row of drilling drills are arranged along the extension direction of the coal pillars on one side of the roadway in the upper section of the upper section that has been excavated. Borehole; use the borehole penetrometer to detect the borehole; according to the obtained pressure and displacement information in the borehole, analyze the pressure degree of the coal pillar at different depths and the development of cracks in the coal body. For the coal pillar The part with larger cracks can be directly reinforced by grouting, and the part with smaller cracks in the coal pillar can be cracked; the electric pulse device can be used to crack the part of the coal pillar with smaller cracks; observe the shock wave cracking range, until all the coal pillar cracks in the entire upper section of the roadway are cracked; on the basis of the original anchor net support of the coal pillar, grouting anchor rods are placed in the borehole to grout the inside of the coal pillar reinforcement. This method can effectively realize the advance reinforcement of coal pillars.

Owner:CHINA UNIV OF MINING & TECH

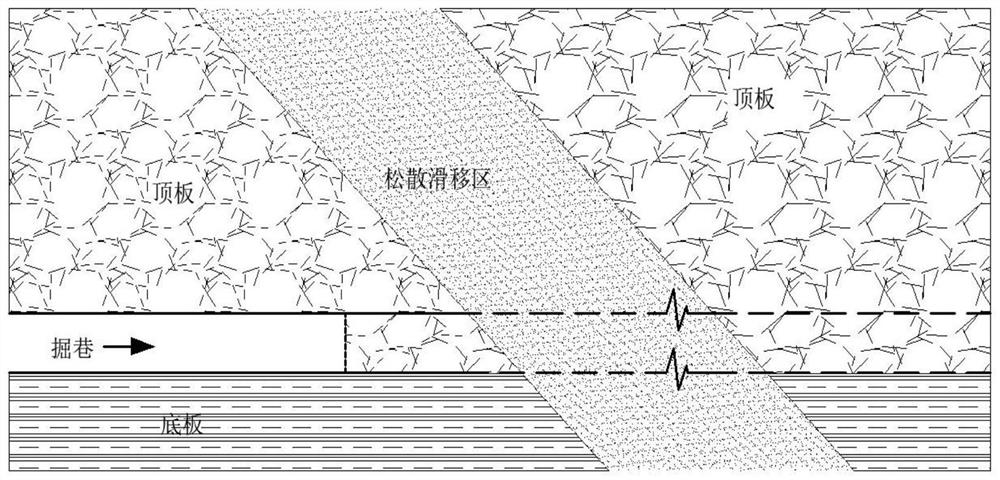

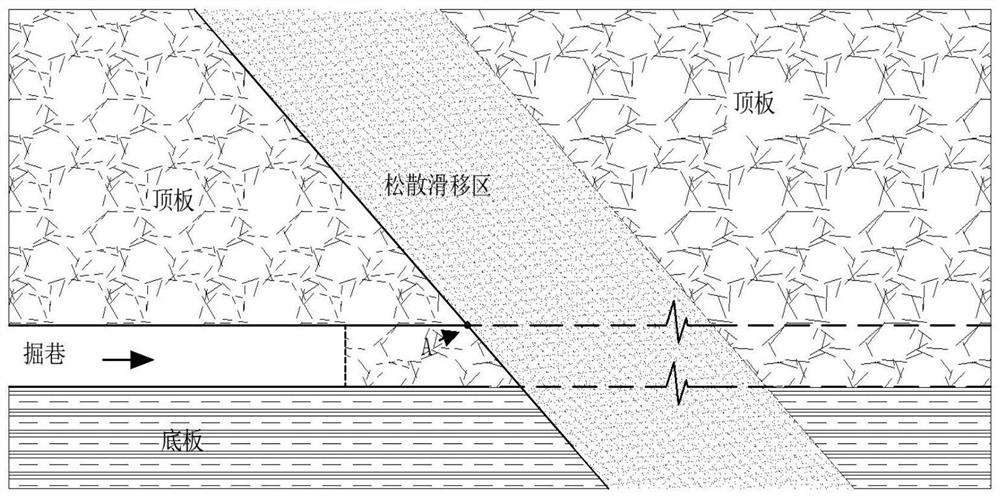

Method for grouting and fast passing of advanced dense roof protection layer in loose slippage area

PendingCN114294018AImprove the mechanical properties of rock massIncreased load carrying capacity and stabilityUnderground chambersTunnel liningDrill holeGrout

The invention discloses a method for grouting and fast passing of an advanced dense roof protection layer in a loose slippage area. The method comprises the steps that S1, the construction range and form of the loose slippage area in front of entry driving are ascertained; s2, determining the construction position of a first-round advanced dense roof protection layer; s3, advanced dense roof protection drill holes are constructed in the roadway driving roof, and I-shaped steel is installed; s4, grouting drill holes are constructed, and grouting is conducted; s5, tunneling to a roof protection position of the next cycle; and S6, the steps of roof protection and grouting are repeated till the roadway driving working face completely passes through the loose slippage area. Advanced roof protection supporting of the roadway in the loose slippage area is achieved, the problem that grout seeps into the tunneling range of the working face when the top plate of the pre-tunneled roadway of the tunneling working face is pre-grouted is solved, advanced grouting grout is controlled to be above a dense roof protection layer, and the purpose that roadway driving rapidly passes through the loose slippage area is achieved.

Owner:CHINA UNIV OF MINING & TECH

A self-propelled grouting trolley equipment for subway shield construction

ActiveCN111577332BFacilitate reciprocating automatic walkingConvenient groutingUnderground chambersTunnel liningGear wheelArchitectural engineering

The invention discloses a self-propelled grouting trolley equipment for subway shield tunneling construction, which comprises a trolley frame and a slurry storage box arranged on the trolley frame, and horizontal pipes are arranged at both ends of the trolley frame And the end of each horizontal tube is provided with a side convex body, the bottom end of the side convex body is provided with a walking slide, and the sliding seat of the walking slide is fixed on the walking guide rail fixed on the tunnel floor, and the two side convex bodies are arranged between There is a horizontal axis of rotation and a walking drive gear is installed on the horizontal axis of rotation. The driving gear is engaged with the horizontal toothed rack arranged on the ground of the tunnel. The outer wall of the slurry storage box is provided with a walking motor and a driving horizontal axis. , both sides of the vehicle platform are provided with a grouting mechanism for ejecting the grout inside the grout storage box. The invention has a simple structure, can facilitate the reciprocating automatic walking of the whole trolley in the tunnel, can realize rapid grouting, is convenient to operate and has strong practicability.

Owner:BEIJING MUNICIPAL CONSTR +1

Internal-connection-type grout-stopping plug for grouting, and grouting method

InactiveCN110241808AReduce constraintsGuarantee the quality of groutingSoil preservationSlurryEngineering

The invention discloses an internal-connection-type grout-stopping plug for grouting, and a grouting method. The internal-connection-type grout-stopping plug comprises a grout-stopping bolt, a grout-stopping cap, a connecting device and a triangular frame vertical rib; the grout-stopping bolt is of a cavity structure comprising a grout inlet end and a gout outlet end, wherein the two ends of the cavity structure communicate with each other, the cavity is used for delivering grout, the grout-stopping bolt is used for being arranged in a grouting hole, the grout inlet end is located outside the grouting hole, and the gout outlet end is located in the grouting hole; the grout-stopping cap is a thin cylinder, the diameter of the grout-stopping cap is greater than the inner diameter of the grout outlet end, the grout-stopping cap is mounted at the grout outlet end of the grout-stopping bolt, and the grout-stopping cap is opened during grouting and closed when grouting is completed; the connecting device is detachably connected with one wall surface of the grout-stopping cap and located in the cavity of the grout-stopping bolt, the triangular frame vertical rib is axially arranged in the cavity of the grout-stopping bolt and connected with the connecting device, under the effects of the pressure of grout in the cavity of the grout-stopping bolt or the pressure of the grouting hole, the triangular frame vertical rib is matched with the connecting device to drive the grout-stopping cap to be correspondingly opened or closed. By using the internal-connection-type grout-stopping plug, automatic grout stopping can be effectively achieved.

Owner:李博文

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com