Cutting, soil taking and grouting integrated sleeve pipe

A grouting and casing technology, applied in construction, infrastructure engineering and other directions, can solve problems such as single function and speed up construction efficiency, and achieve the effect of speeding up construction efficiency and fast cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

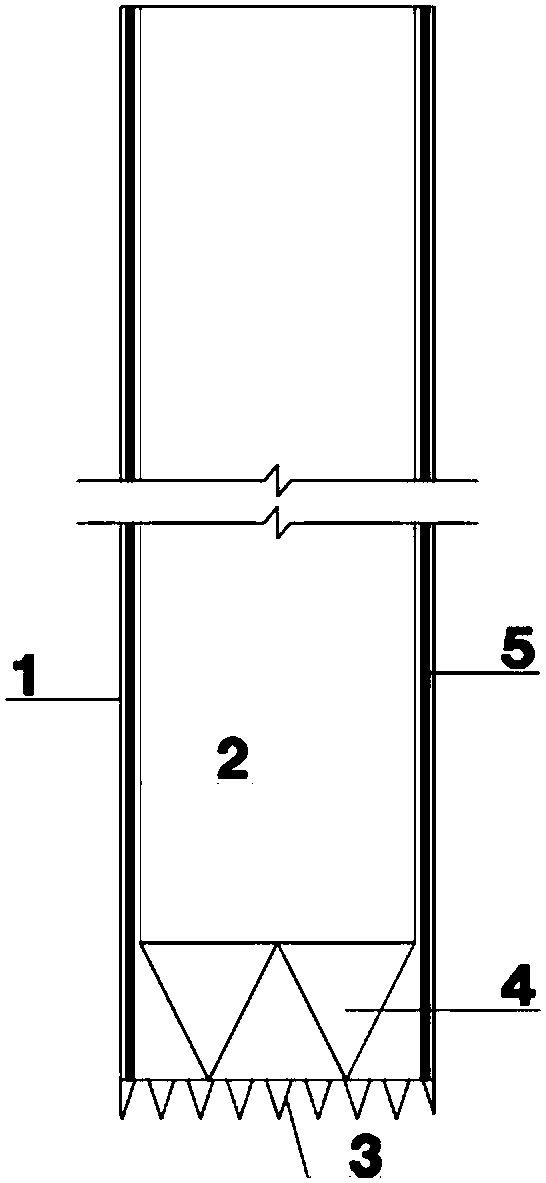

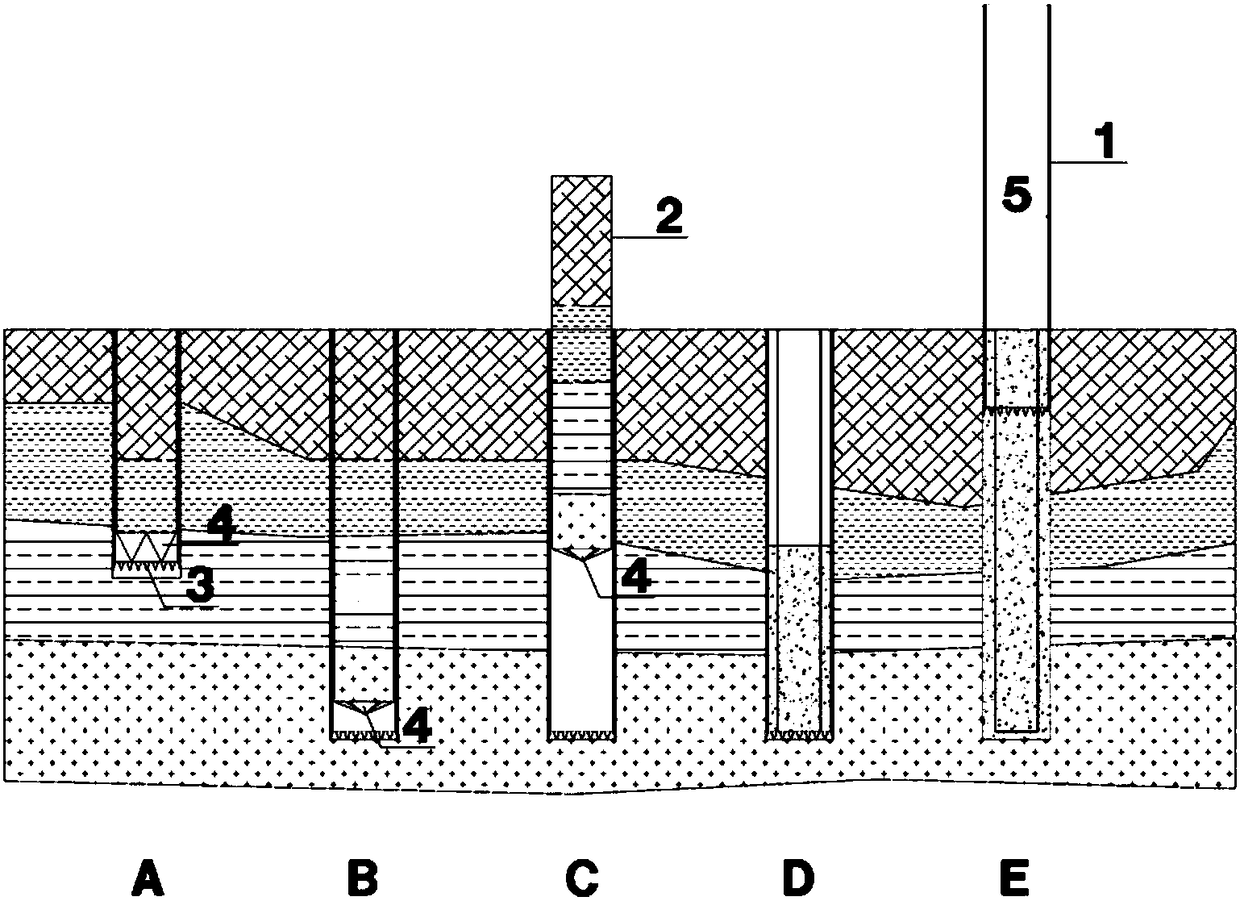

[0016] like figure 2 As shown, a cutting, soil taking and grouting integrated casing, the construction steps are as follows:

[0017] A. When the construction is turned down, the tooth mouth 3 cuts the soil,

[0018] B. After reaching the drilling depth, the grab bucket 4 is put away,

[0019] C. Lift the inner casing 2, take out the soil,

[0020] D. Carry out operations such as lowering the core material, pouring concrete, etc., or carry out spraying reinforcement through the spraying pipe hole 5,

[0021] E. After the initial setting, lift the outer layer pipe 1 to complete the construction. After the outer layer pipe 1 and the inner layer pipe 2 are locked and connected, move to the next place for construction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com