Coal mine fireproof door wall structure and construction method thereof

A technology for fire doors and firewalls, which is applied to fire doors, door leaves, windows/doors, etc. It can solve problems such as easy deformation of fire door frames, poor airtightness between fire doors and fire door frames, and high labor intensity in the construction of fire door and wall structures. The effect of air lane track transporting materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

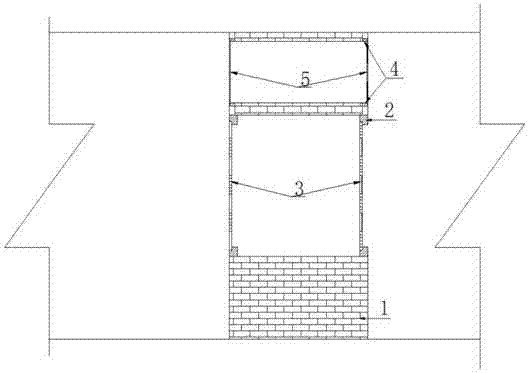

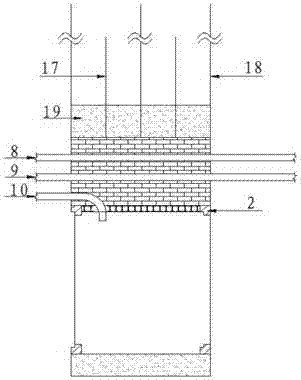

[0046] Embodiment 1: A coal mine fireproof door wall structure, which includes a wind lane fireproof door wall structure and a transport lane fireproof door wall structure.

[0047] Further, the fireproof door wall structure of the transportation lane includes: firewall 1, fireproof door frame 2, fireproof door 3, coal transportation channel door frame 4, coal transportation channel fire door 5, hinge 6, coal transportation channel slurry pipe 7, detection hole 8. Measure hole 9, grouting hole 10, water inlet pipe 11, air pressure pipe 12, nitrogen injection pipe 13, gas extraction pipe 14, drainage pipe 15, cable pipe 16, anchor rod 17, anchor cable 18, pouring layer 19 .

[0048] Further, the fireproof door wall structure of the wind lane includes: firewall 1, fireproof door frame 2, fireproof door 3, hinge 6, detection hole 8, measure hole 9, grouting hole 10, water inlet pipe 11, air pressure pipe 12, injection hole Nitrogen pipe 13, gas drainage pipe 14, drainage pipe 15...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com