Pre-explosion drilling, grouting and anchoring integrated anchor rod and construction method thereof

A technology of anchor rod construction and drilling and injection, which is applied in the fields of geotechnical engineering anchoring support and water blocking prevention, to achieve the effect of expanding the scope of grouting and increasing the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

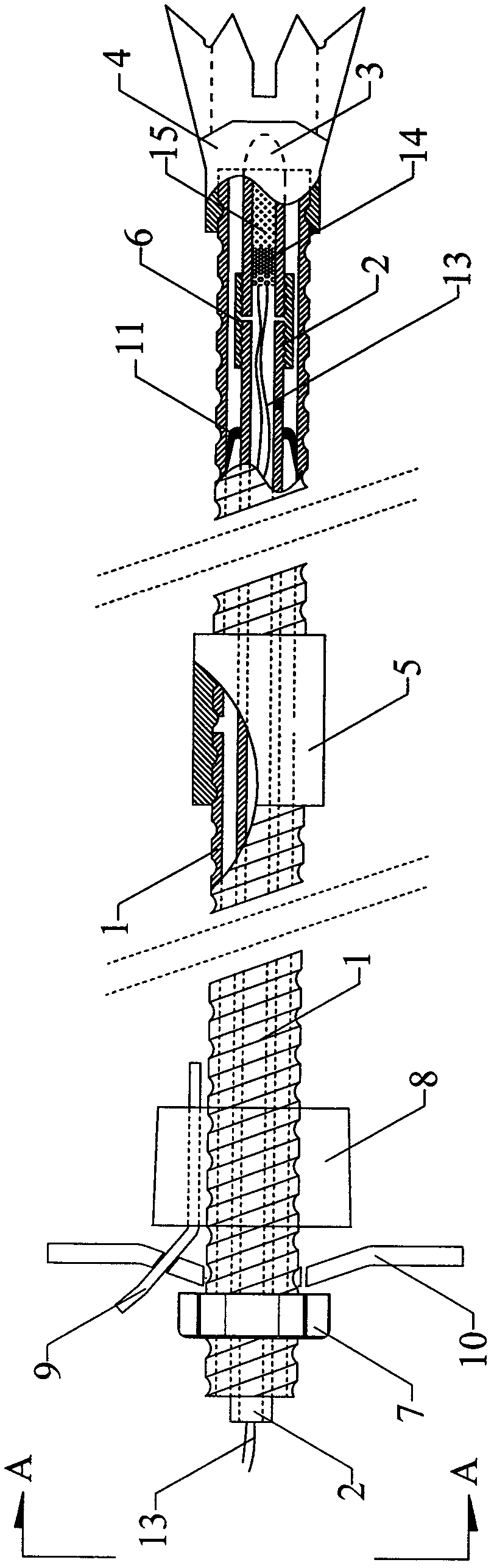

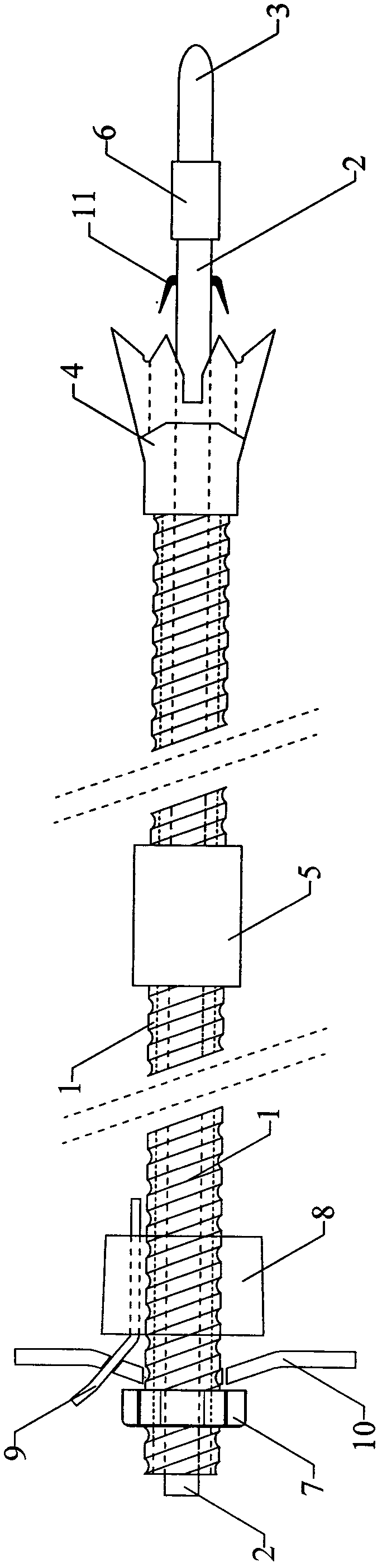

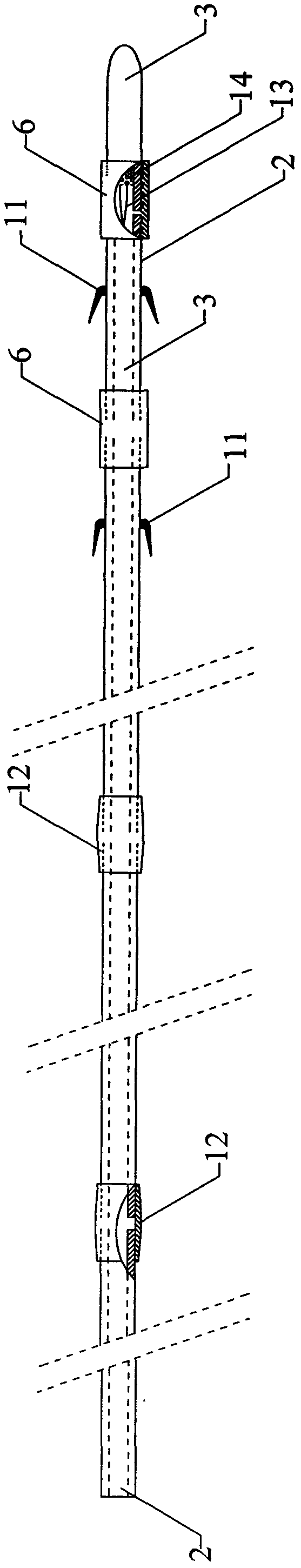

[0027] An embodiment of the present invention is described in detail below in conjunction with accompanying drawing:

[0028] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, the pre-explosion drilling and anchoring integrated anchor rod has an external hollow threaded drill rod 1, a drill bit 4 installed at the front end of the hollow threaded drill rod 1, and the hollow threaded drill rod 1 is connected by a multi-section drill rod with a threaded casing 5 The segmented hollow threaded drill pipe composed of connections; the hollow threaded drill pipe 1 and the drill bit 4 are connected by threads; the hollow threaded drill pipe 1 is equipped with a hollow grouting pipe 2 and a multi-stage explosive connected to the front end of the hollow grouting pipe 2 Pipe 3, the hollow grouting pipe 2 is a segmented grouting pipe composed of multi-section grouting pipes connected by fastening sleeves 12, and the same number of sections as the multi-section explosive p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com