A self-propelled grouting trolley equipment for subway shield construction

A technology of automatic walking and subway shielding, which is applied in large fields, can solve problems such as troublesome operation, slow speed, and reduced grouting efficiency behind the wall, and achieve the effect of simple structure, fast grouting, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

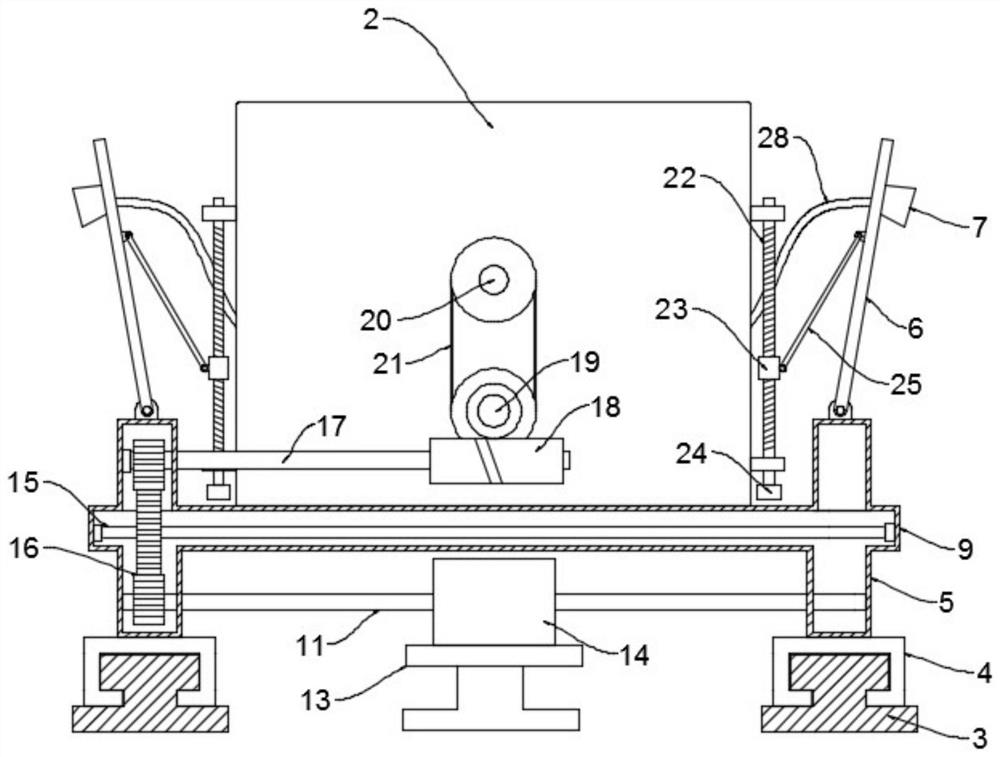

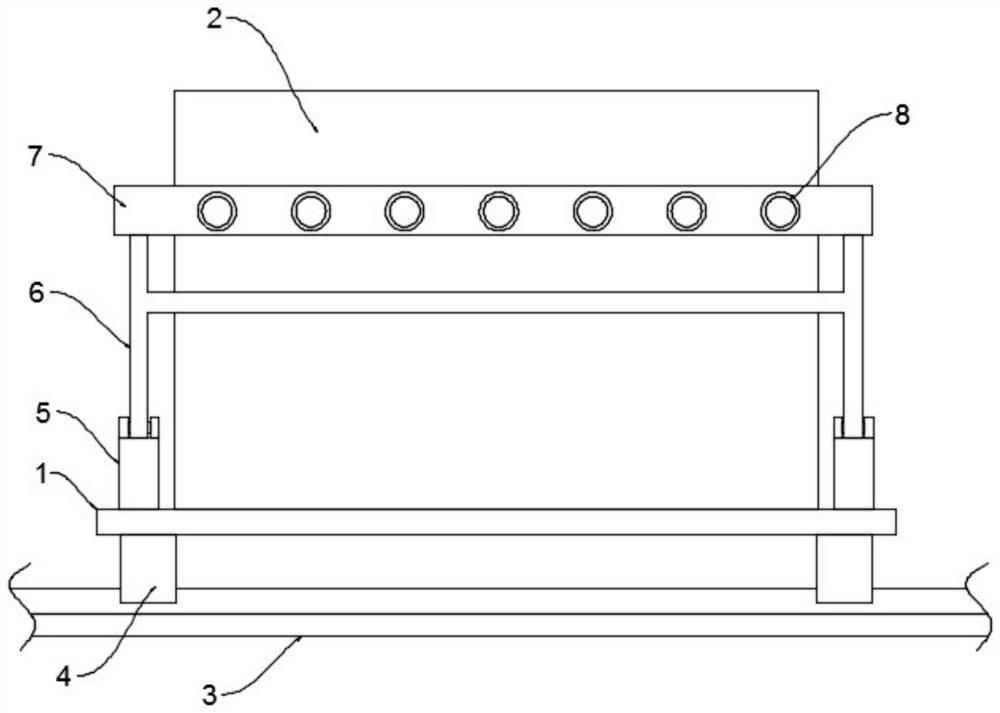

[0021] see Figure 1~3 , in an embodiment of the present invention, a self-propelled grouting trolley equipment for subway shield construction, including a trolley frame 1 and a slurry storage box 2 arranged on the trolley frame 1, the trolley frame 1 is two The ends are all provided with horizontal tubes 9 and the ends of each horizontal tube 9 are provided with side convex body 5, the bottom end of the side convex body 5 is provided with a walking slide 4 and the sliding buckle of the walking slide 4 is fixed on the tunnel ground. On the walking guide rail 3, a rotating horizontal shaft 11 is arranged between the two side convex bodies 5 and a walking driving gear 14 is installed on the rotating horizontal shaft 11. 13, and the outer wall of the slurry storage box 2 is provided with a travel motor 19 and a drive cross shaft 17, and the drive cross shaft 17 is connected to the output end of the travel motor 19 through a worm gear transmission pair 18. A transmission cross sh...

Embodiment 2

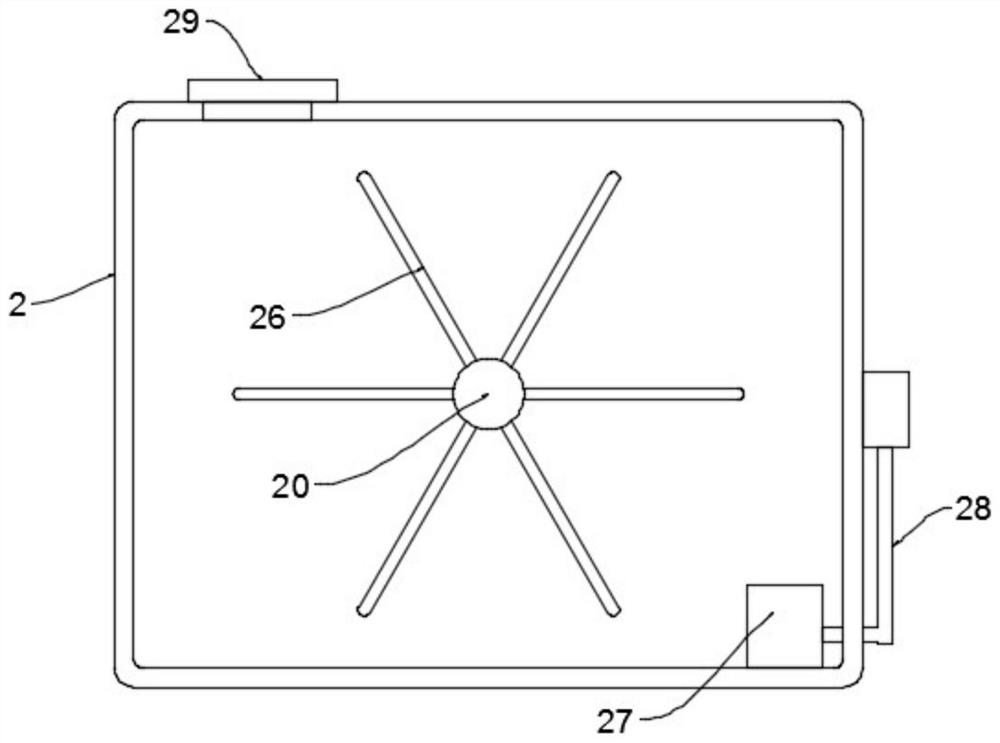

[0026] The difference between the embodiment of the present invention and embodiment 1 is that: the inside of the vehicle platform 1 is also provided with a stirring rod shaft 20 whose end is rotatably connected to the side wall, and a plurality of stirring rods 26 are arranged on the stirring rod shaft 20 One end of the stirring rod shaft 20 is connected to the output end of the travel motor 19 through the transmission unit, and the travel motor 19 can be used to drive the stirring rod shaft 20 to rotate and make the stirring rod 26 on it stir the slurry inside the slurry storage box 2 Avoid solidification or settlement; the transmission unit 21 is a belt drive or a sprocket drive.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com