Automatic horizontal grouting device for grouting reinforcement of coal mine roof

A grouting reinforcement and grouting technology, which is applied to mining equipment, shaft equipment, shaft lining, etc., can solve problems such as poor grouting conditions, increased costs, and limited improvement in grouting effects, and achieves improved grouting capacity and Grouting effect, guaranteed ability and reliability, guaranteed uniformity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

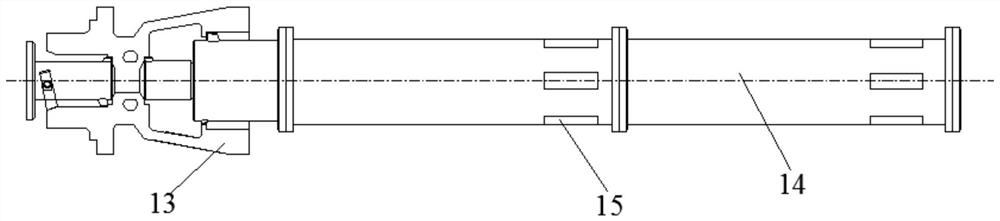

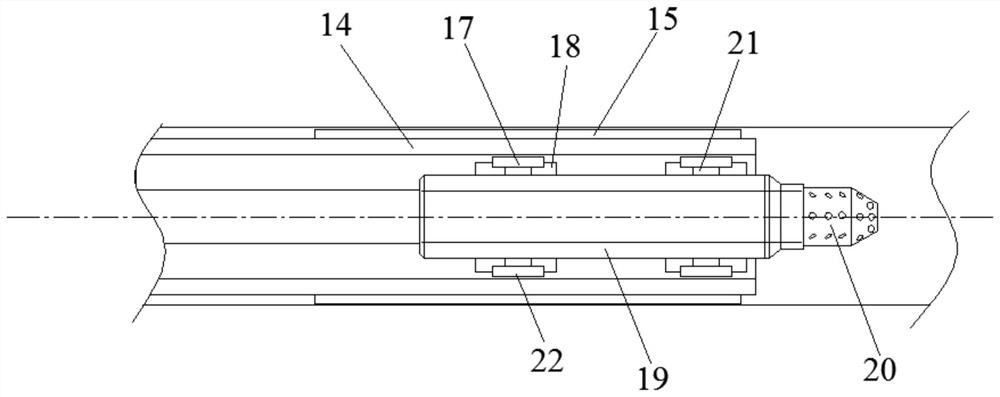

[0020] see Figure 1~3 , in an embodiment of the present invention, an automatic horizontal grouting equipment for coal mine roof grouting reinforcement, which includes a slurry mixing mechanism, a grouting pump 8, an automatic clamping grouting connection mechanism, a grouting head 19, an auxiliary Grouting pipe 14 and hydraulic controller, the slurrying and mixing mechanism can realize slurrying and slurrying for the slurry to be injected, and one end of the grouting pump 8 is connected with the output end of the slurrying and mixing mechanism , the output end of the grouting pump 8 is connected to the automatic clamping grouting connection mechanism through a grouting pipe 9, characterized in that the automatic clamping grouting connection mechanism can realize the auxiliary grouting pipe 14 The end clamping connection of the automatic clamping grouting connection mechanism is also connected with the grouting head 19 through the grouting connection pipe, the auxiliary grout...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com