Shift control mechanism of transmission

A technology of operating mechanisms and transmissions, applied to mechanical equipment, components with teeth, belts/chains/gears, etc., can solve the problems of complex structure, expensive cost, poor fault tolerance, etc., and achieve simple assembly, simple type, and improved guarantee Effects of Capability and Reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

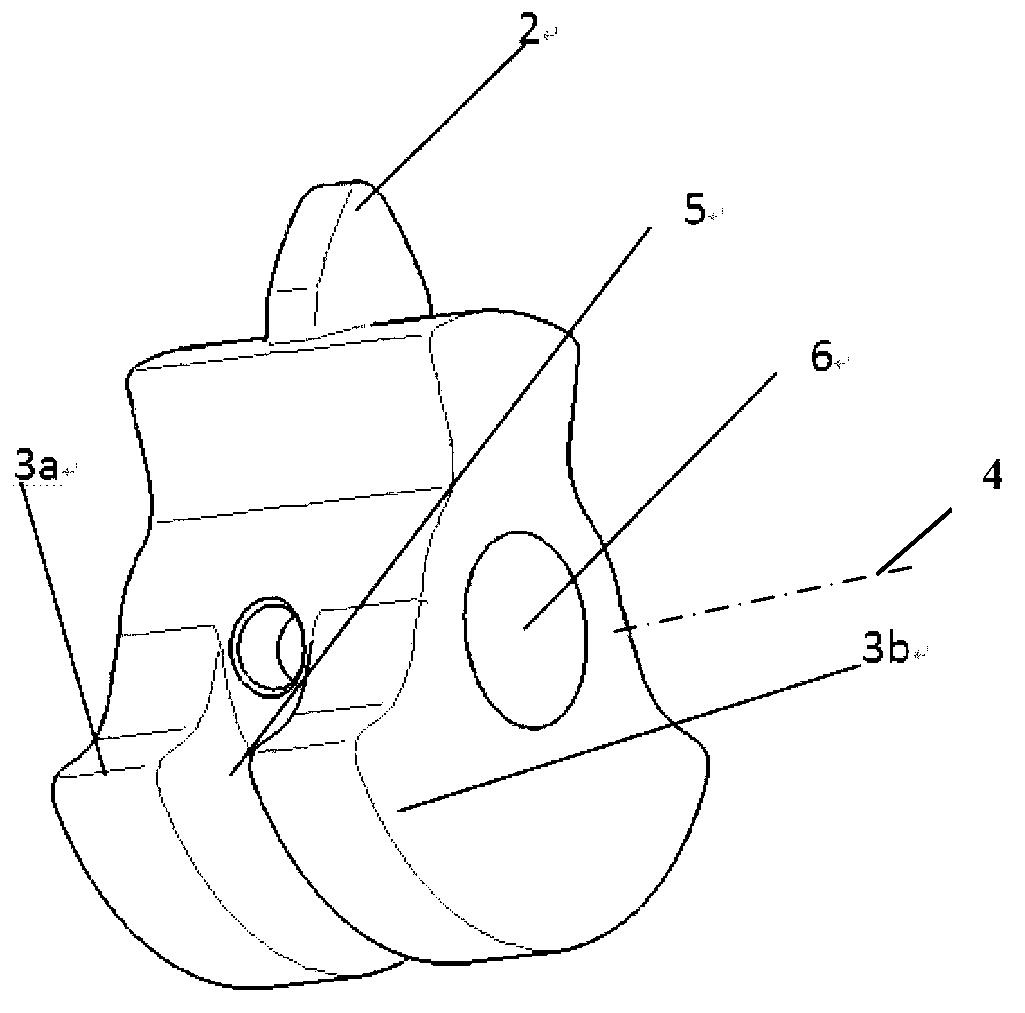

[0026] The following structural drawings further illustrate the present invention.

[0027] see figure 1 , figure 2 , image 3 and Figure 4 , a transmission shift operating mechanism, including the first shift rod 11, the second shift rod 12, the third shift rod 13 and the fourth shift rod 18 which are arranged on the transmission housing and are parallel in space; A first shift fork 15 and a first shift fork 10 are fitted to the middle and upper part of the first shift lever 11, and a second shift fork 16 and a second shift fork 16 are fitted to the middle and lower part of the second shift lever 12. Two gear shift forks 8, the bottom of the third gear shift rod 13 and the fourth gear shift rod 18 cooperate with the third gear shift fork 7 respectively, and the middle and upper parts of the fourth gear shift rod 18 are matched with The third shift fork 17; Its structural characteristics are:

[0028] A shift block 4 is made of shift finger 2 and shift cam 3, and the ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com