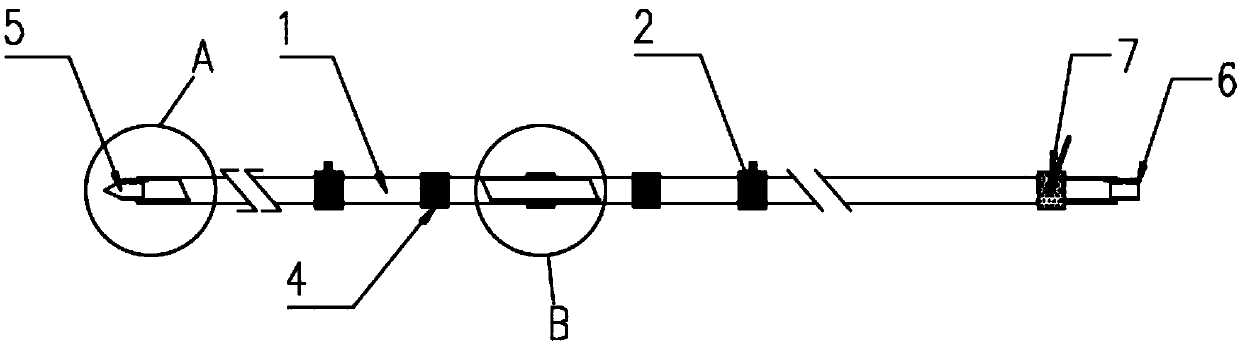

Full-hole one-time rapid grouting construction method

A construction method and grouting technology, which are used in earth-moving drilling, shaft equipment, wellbore lining, etc., can solve the problems of inappropriate operation, time-consuming grouting cycle, poor sealing of grouting wall, etc. Ideal effect, reduced thickness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

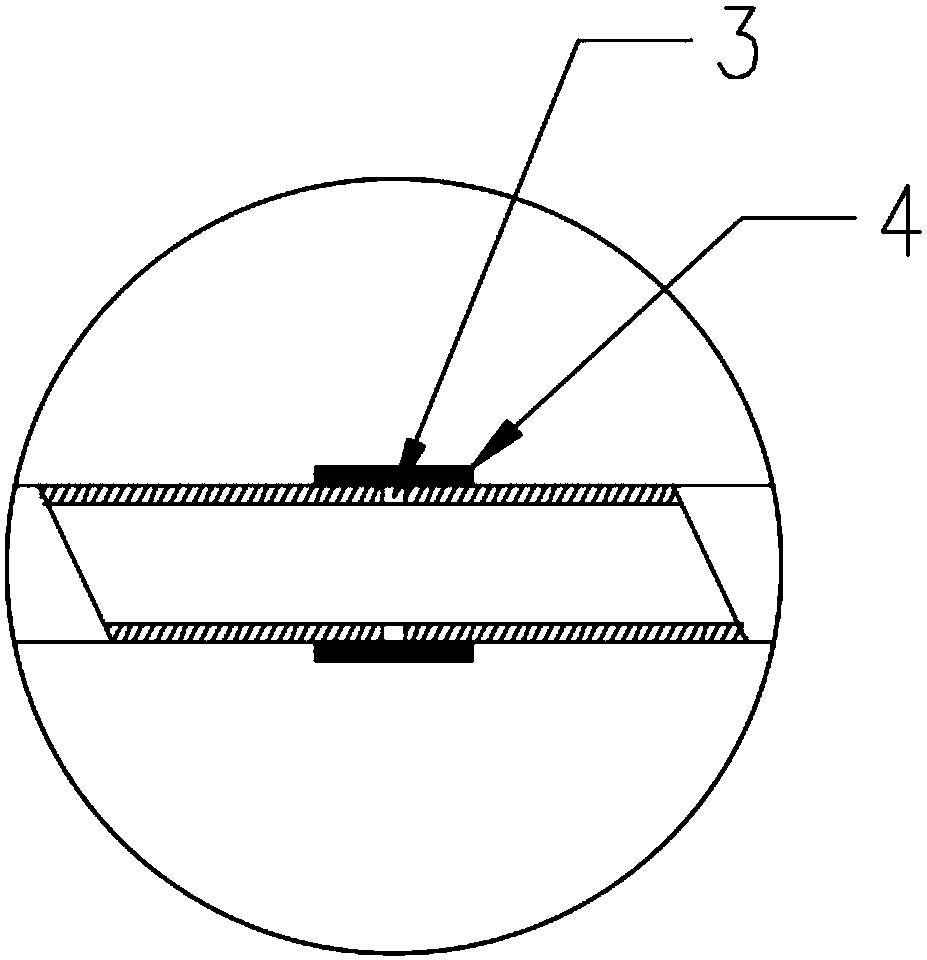

Method used

Image

Examples

Embodiment 1

[0052] The research and development is based on the curtain grouting construction of ultra-shallow buried tunnels passing through urban main roads under the condition of water-rich and weak surrounding rock near the sea;

[0053] A tunnel passes through an urban traffic artery and is close to the viaduct pier. The surface traffic flow is large and the pipelines are dense. There are more than 20 pipelines in 6 categories, and there are some unknown pipelines;

[0054] The burial depth of this lower penetration section is shallow (5.4-14.3m), and the strata in the vault area are mainly miscellaneous fill, silt, residual soil, fully weathered granite, and it is connected with sea water, so the self-stabilizing ability is poor, and the maximum daily water inflow is 1700m. 3 , the entire tunnel is below the constant water level;

[0055] The whole grouting process is as follows:

[0056] ① Hole layout: The excavation section is 58.99 square meters, and the upper half section is gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com