Hollow grouting mining anchor cable

A hollow, mining technology, applied in mining equipment, bolt installation, earthwork drilling, etc., can solve the problems of unachievable support strength and effect, slow down grouting efficiency, affect grouting effect, etc., and simplify the construction process. , low relaxation value, good plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

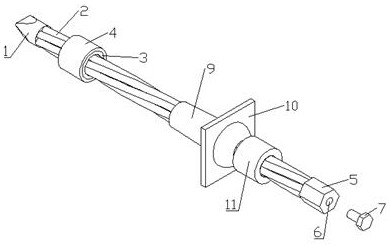

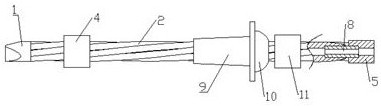

[0012] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

[0013] Such as Figure 1-2 The mine anchor cable shown has the characteristics of high strength, long anchorage length, and the ability to transmit pre-loaded tension to deep and stable rock formations.

[0014] The structural composition of the hollow steel strand is shown in the following table:

[0015]

[0016] Dimensions and mechanical properties are shown in the table below:

[0017]

[0018] 1. According to the thickness of the coal seam, different lengths of hollow grouting mine anchor cables are selected to ensure that the anchor cable penetrates into the stable rock formation not less than 1.0m.

[0019] 2. Equipment and tools required for construction: bolter, Φ32mm or Φ39mm double-wing drill bit, mixing head, tensioning jack, cement slurry mixer and cement slurry injection pump.

[0020] 3. Construction technology

[0021...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com