Mold-bag-filling-type anchor grouting device and method

A grouting device and filling technology, which is used in earth-moving drilling, bolt installation, mining equipment and other directions, can solve problems such as the decline of anchoring quality, low strength of tunnel surrounding rock, loss, etc., so as to increase grouting pressure and improve engineering. The effect of quality and technical level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

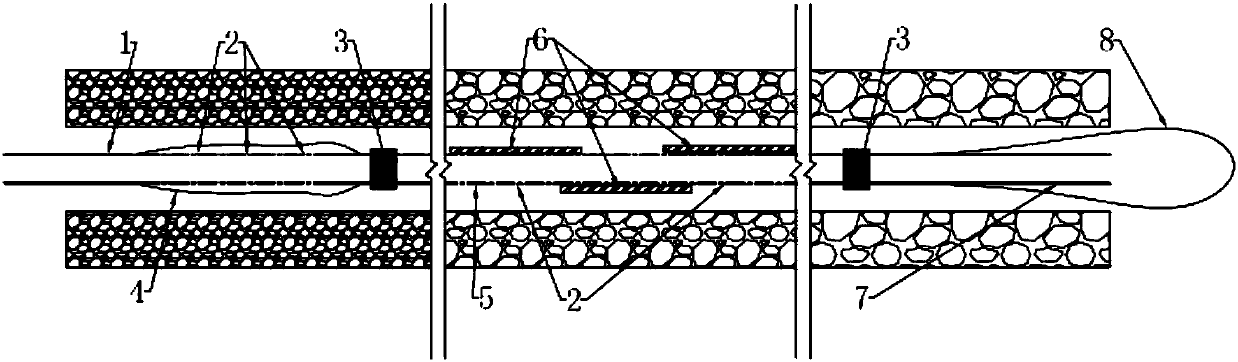

[0028] Embodiment 1: see figure 1 , a mold bag filling type anchor grouting device, comprising: orifice sealing steel pipe 1, wall eyelet 2, constant pressure occluder A3, orifice sealing mold bag 4, grouting steel pipe 5, constant pressure occluder B6, Reinforcing rib 7, hole bottom anchor steel pipe 8, hole bottom anchor mold bag 9;

[0029] The orifice sealing steel pipe 1, the grouting steel pipe 5, and the hole bottom anchoring steel pipe 7 are seamless steel pipes, which are fixedly connected, and each connection part is inserted into the constant pressure blocker 2;

[0030] The length of the orifice sealing steel pipe 1 is consistent with the depth of the orifice sealing area, and is used to inject pure cement slurry into the orifice sealing mold bag 4 through the wall eyelet 2;

[0031] The wall eyelets 2 are arranged around the orifice sealing steel pipe 1 for injecting pure cement slurry into the orifice sealing mold bag 4; the wall eyelets 2 are arranged on the gr...

Embodiment 2

[0039] Example 2: see figure 2 , 2. a kind of mold bag filling type anchoring grouting method, uses a kind of mold bag filling type anchoring grouting device described in embodiment 1, comprises the following steps:

[0040] A. According to the exploration data of the loose surrounding rock in the broken zone and the surrounding rock reinforcement design index, calculate the size of the hole sealing die bag, the anchoring grouting drilling depth, the anchoring die bag size at the bottom of the hole, the injection The size of the reinforcement rib of the slurry pipe, the number of drilling holes and the spacing of the drilling holes;

[0041] B. Drill holes according to the designed anchor hole position, select a drill with a diameter of Φ70mm to Φ200mm to drill the hole, and drill the hole once to the designed anchor depth;

[0042] C. Assemble the anchoring grouting pipe; first connect the orifice sealing steel pipe, the grouting steel pipe and the anchoring steel pipe at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com