Internal-connection-type grout-stopping plug for grouting, and grouting method

A technology of grout stopper and connecting device, which is applied in the fields of soil protection, construction, and infrastructure engineering, etc. It can solve problems such as insufficient pressure, inability to automatically stop grout, poor apparent quality of the seal, etc., achieve quick disassembly and reduce cycle operations the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

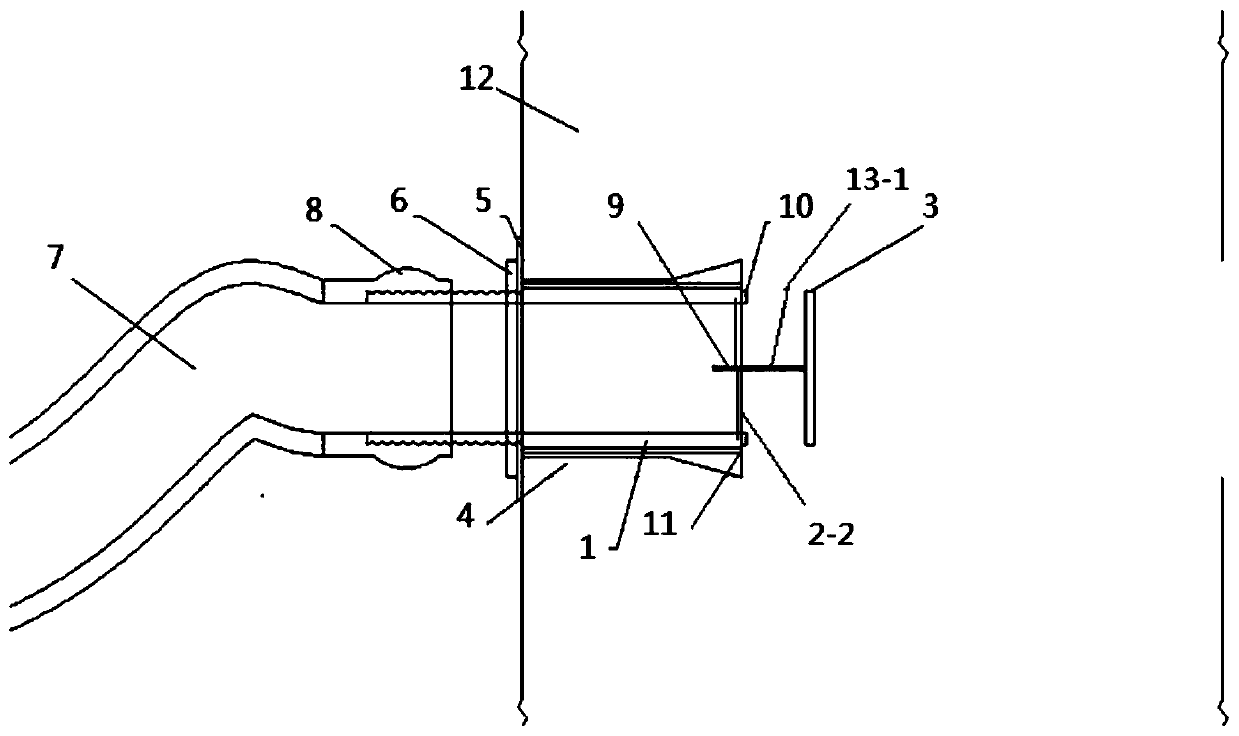

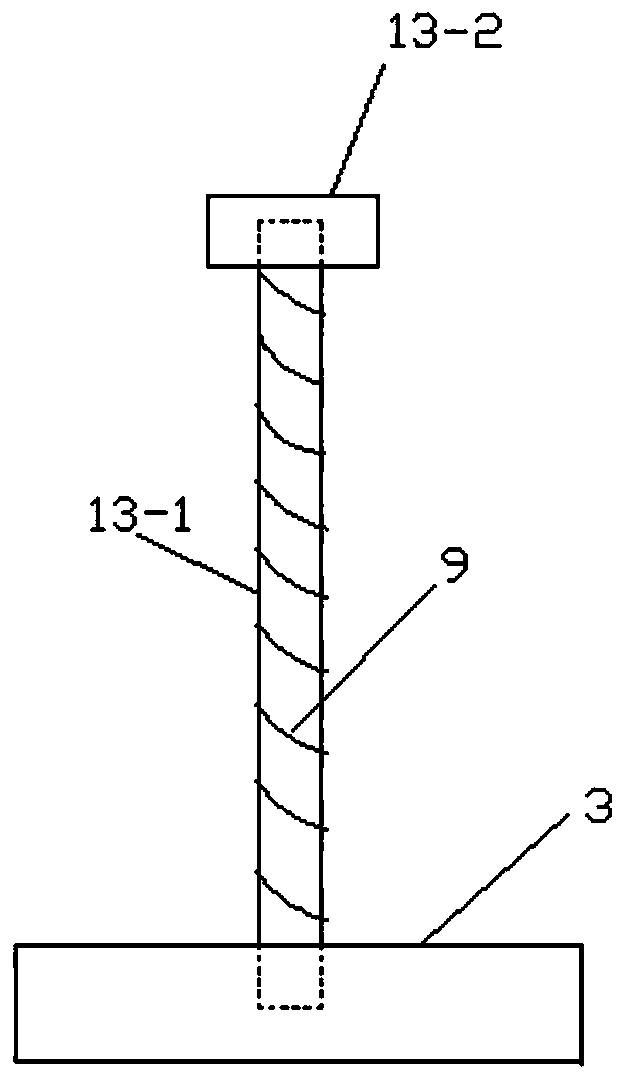

[0028] A grout stopper device for internal grouting of the present invention, such as figure 1 As shown, it includes: grout stop bolt 1, which is a cavity structure including a slurry inlet end and a slurry outlet end, and both ends are connected. Outside the grouting hole, the grouting end is located in the grouting hole; the inner diameter of the grouting bolt 1 is the same, and the outer wall of the grouting end of the grouting bolt 1 expands radially outward. On the premise that the grouting bolt 1 meets the requirement that the tear strength of the pipe wall is greater than the grouting pressure, the inner diameter can be increased as much as possible. The side wall of the slurry inlet end of the slurry stop bolt 1 is provided with an external thread.

[0029] The grout stop cap 3 is a thin cylinder with a diameter greater than the inner diameter of the grout outlet end, which fits and is installed on the grout outlet end of the grout stop bolt 1, opens during grouting, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com