Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

73results about How to "Rapid cooling treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

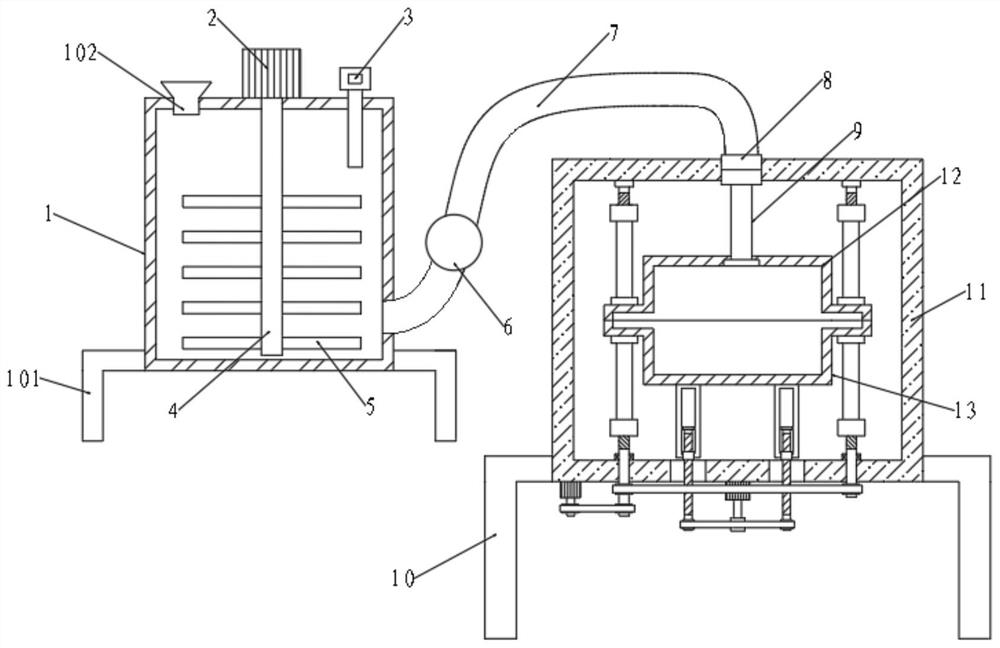

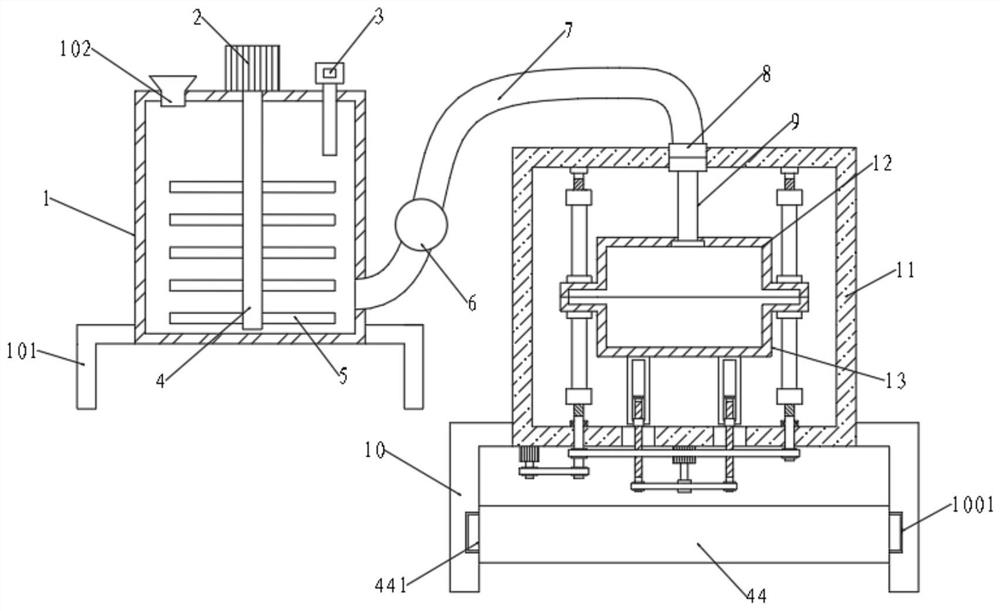

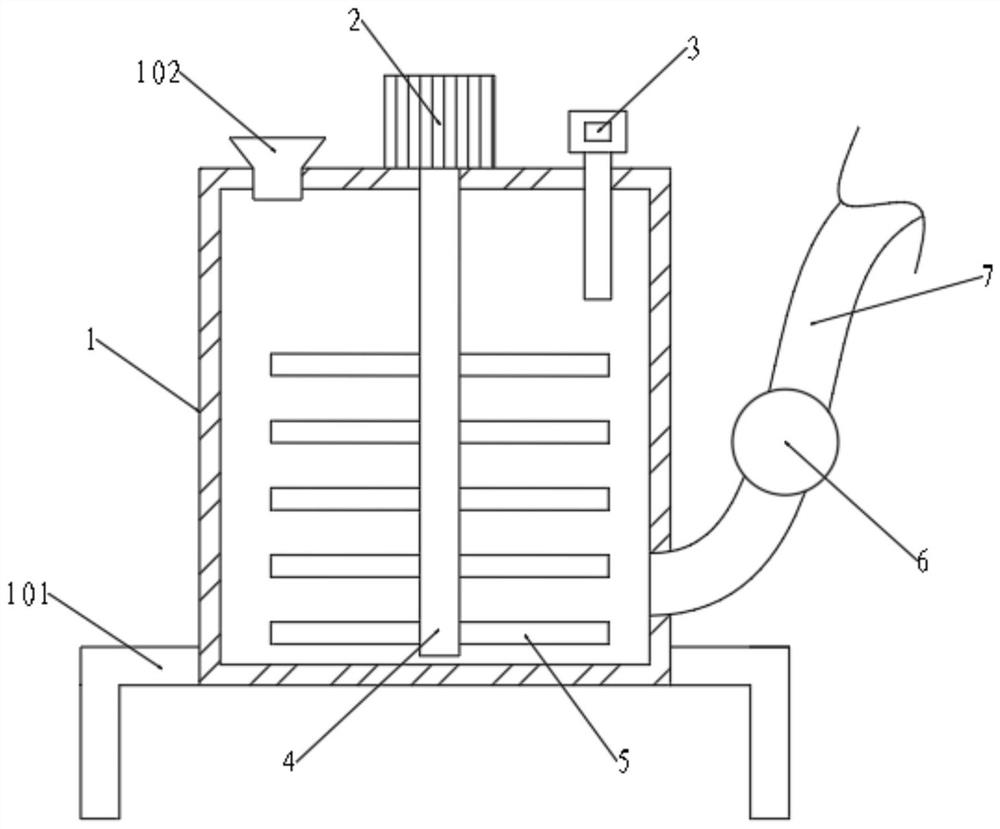

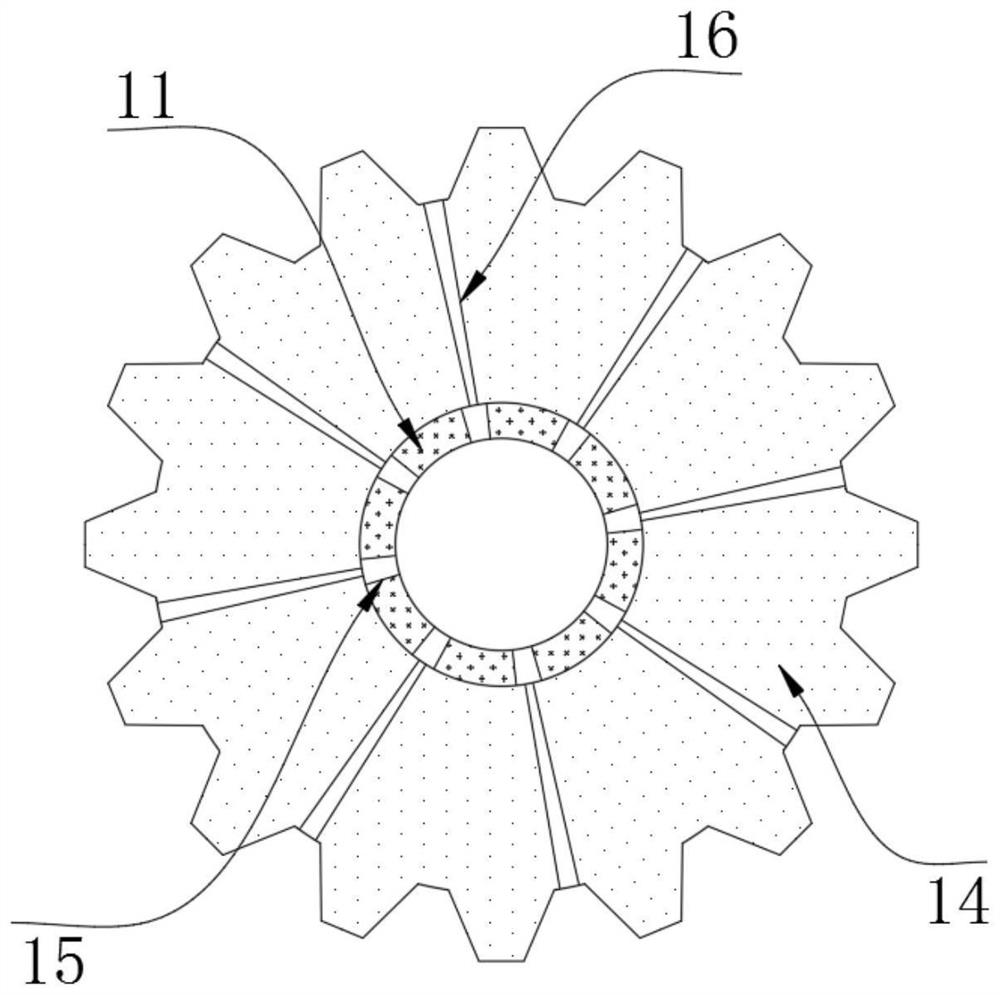

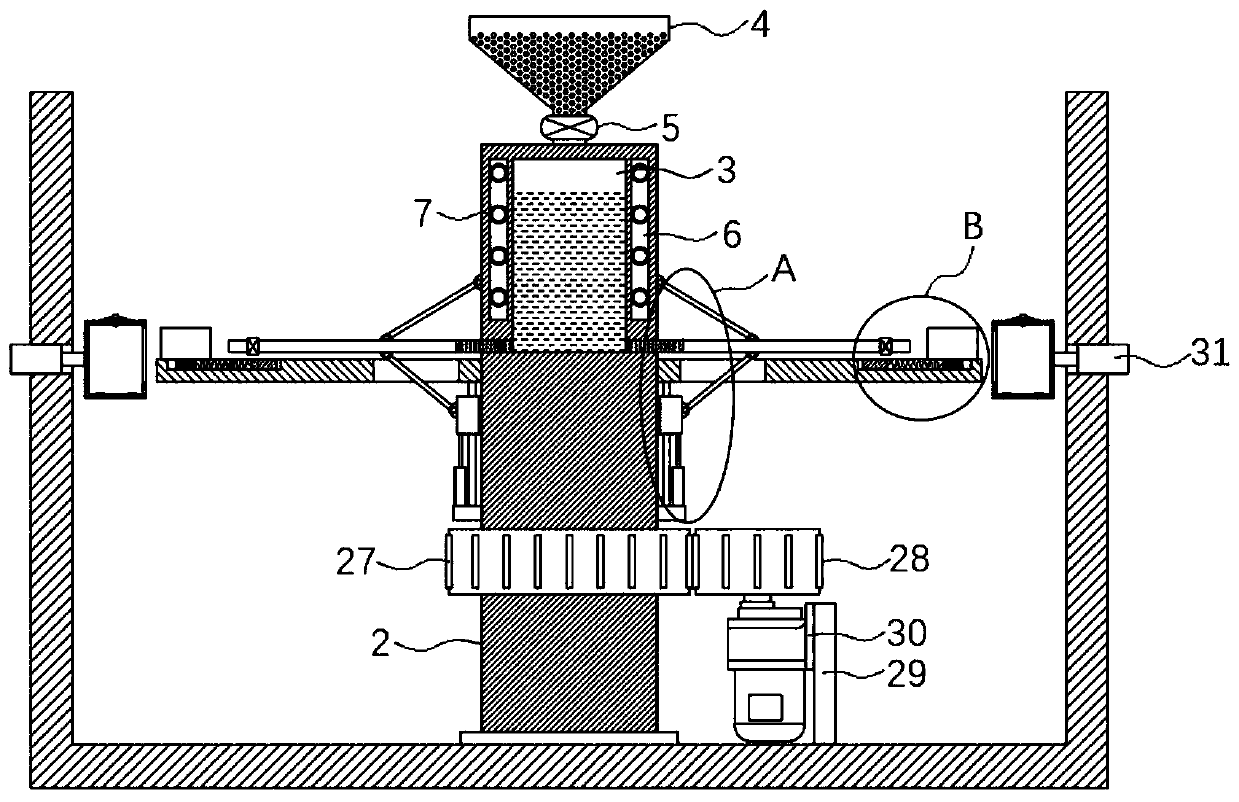

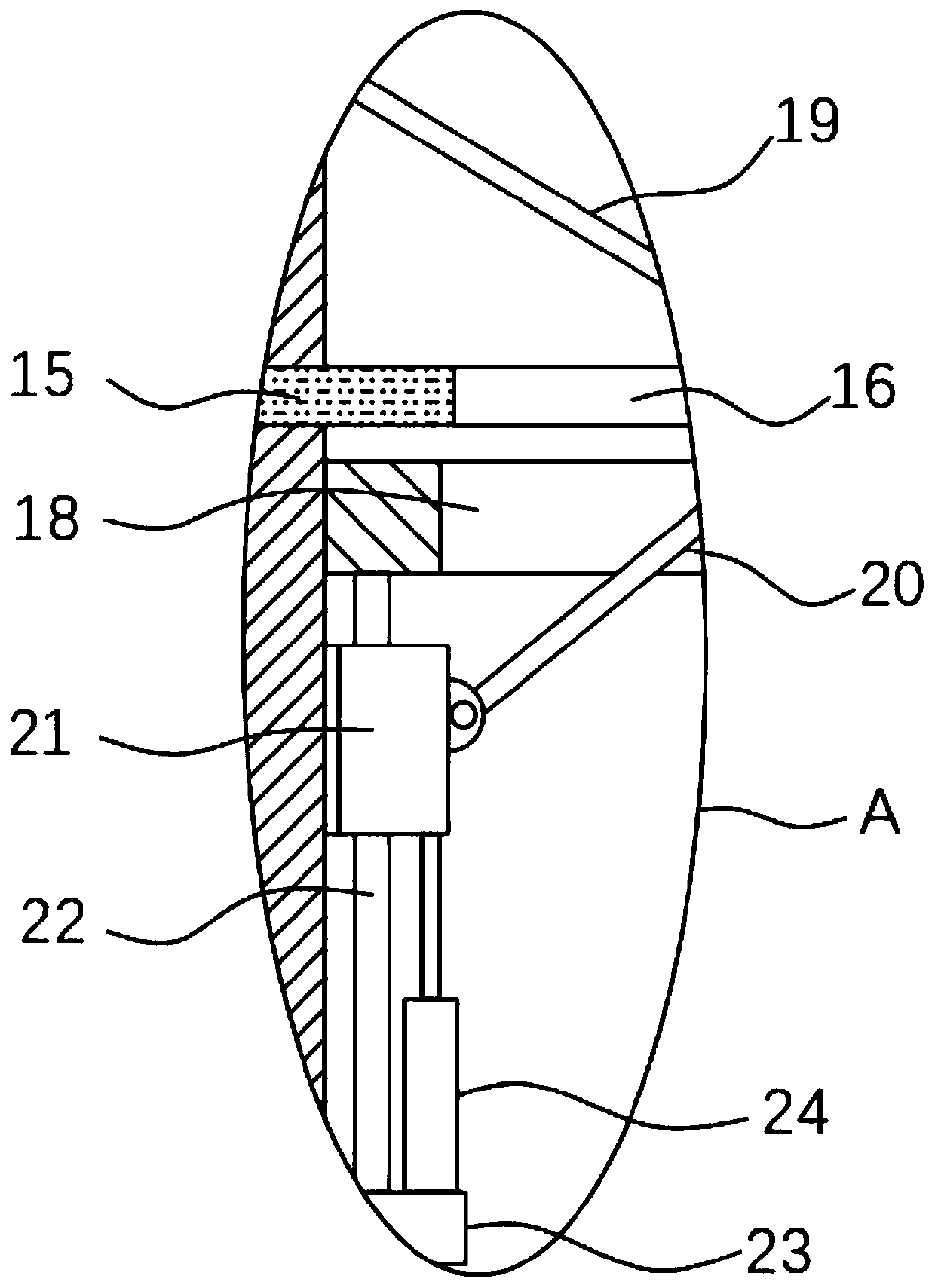

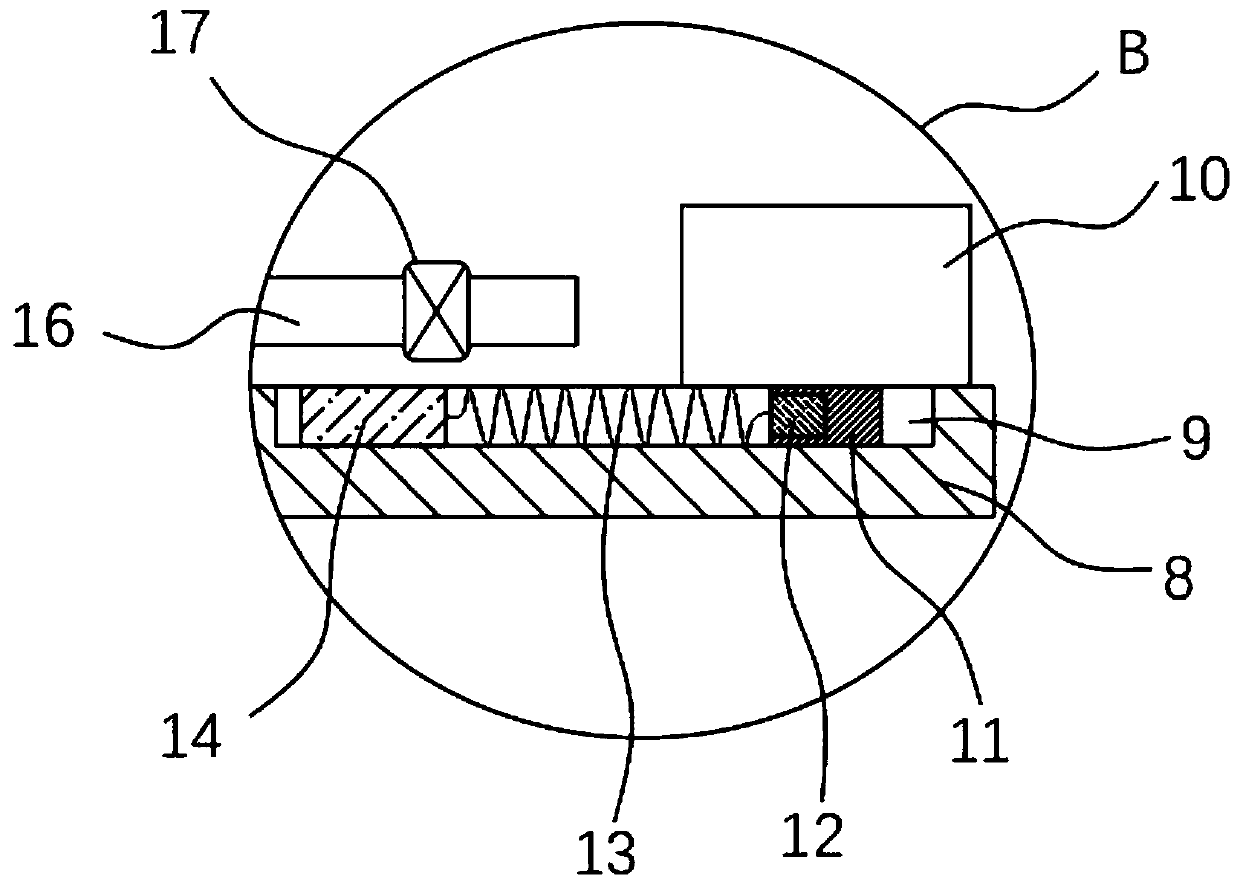

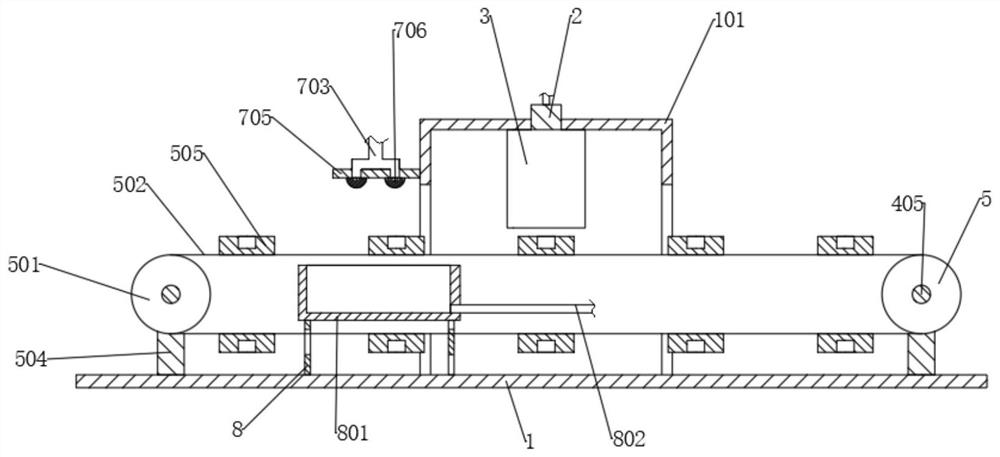

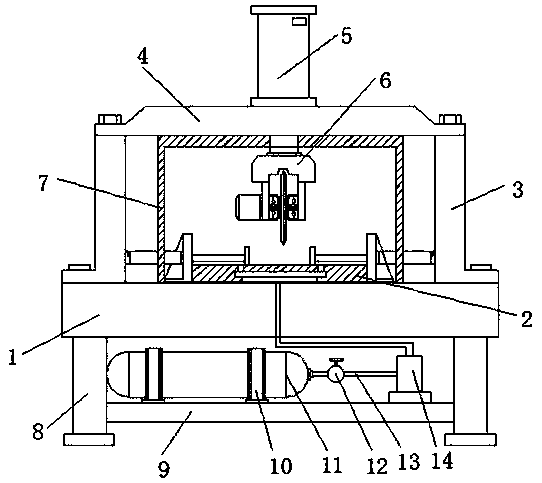

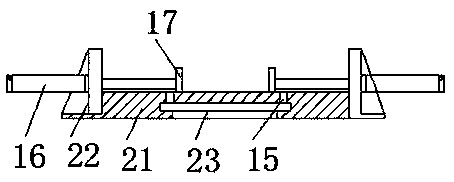

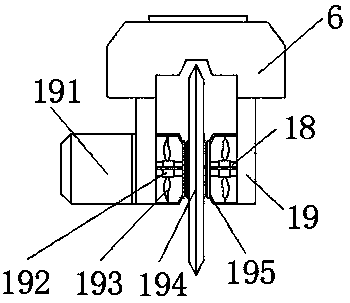

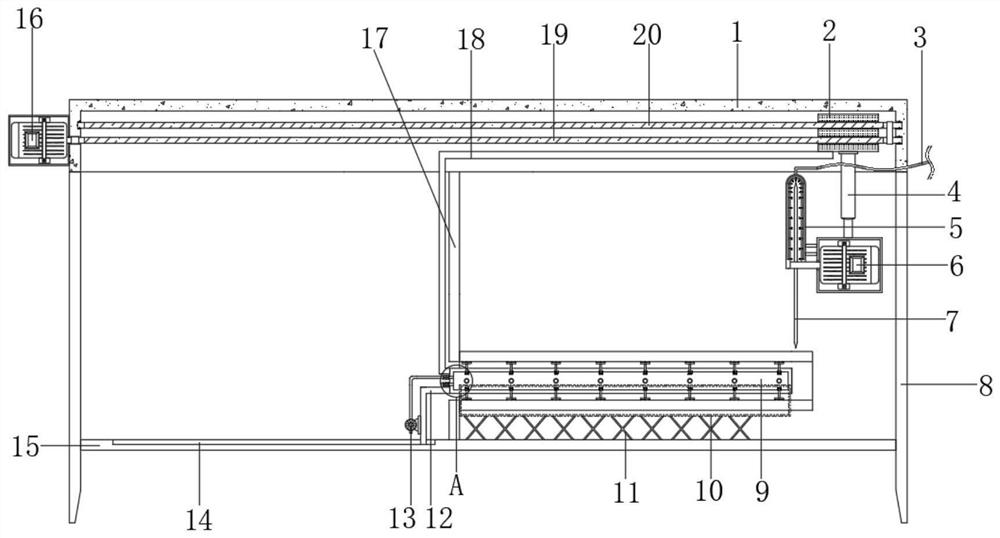

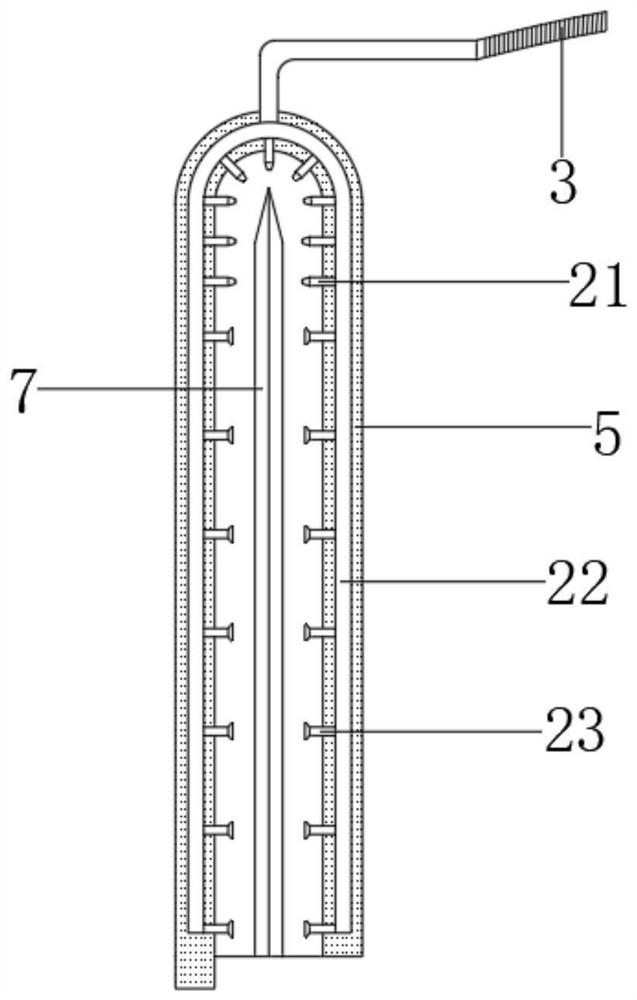

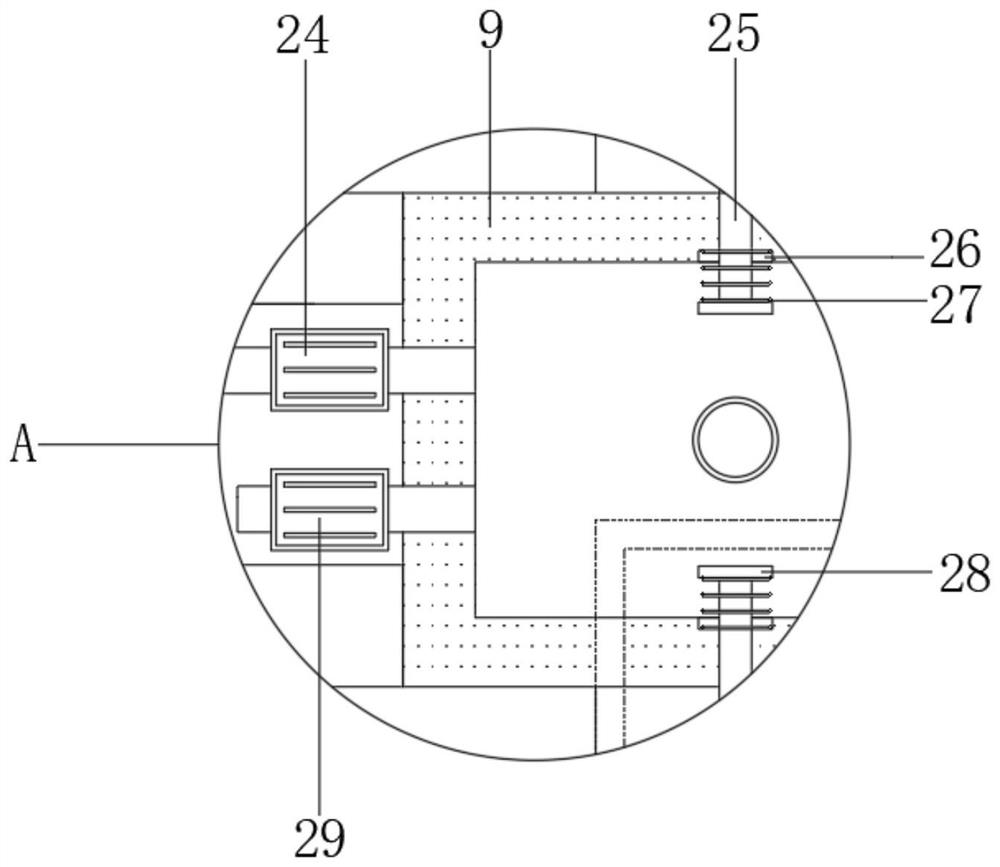

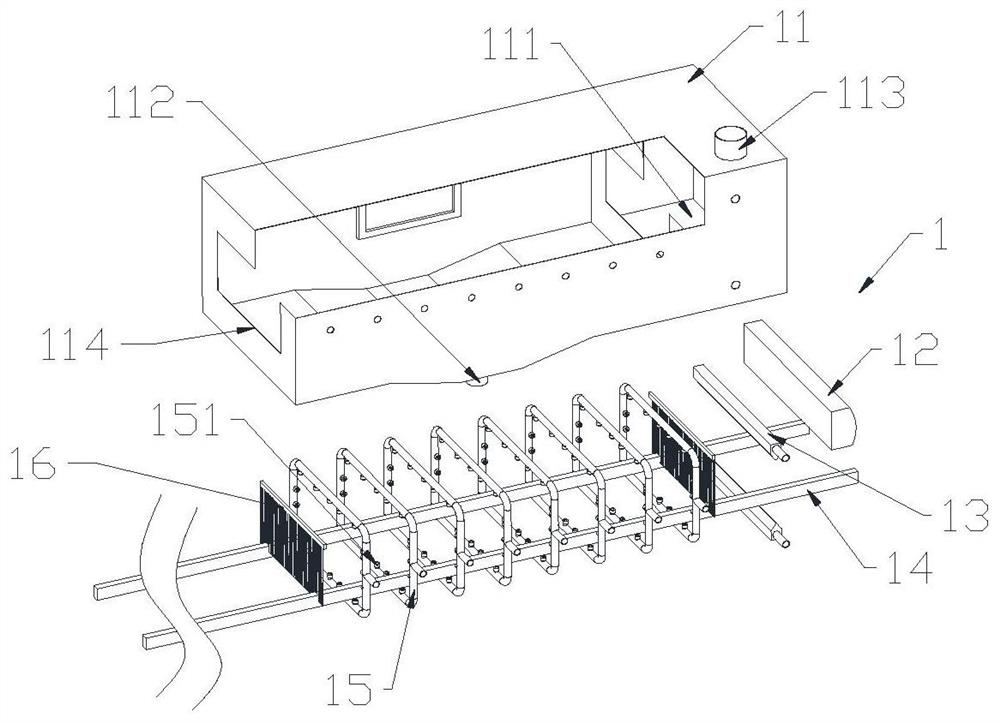

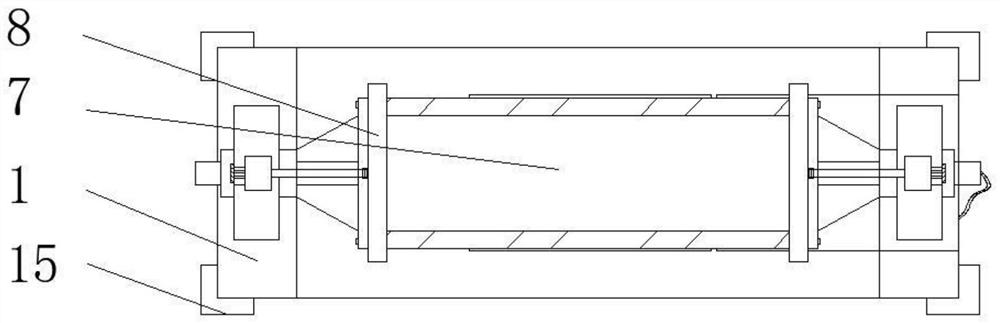

Rapid cooling and demolding device for steel casting

PendingCN113351858ARapid cooling treatmentUneven mass distributionMould handling equipmentsMolten metal conveying equipmentsElectric machineryEngineering

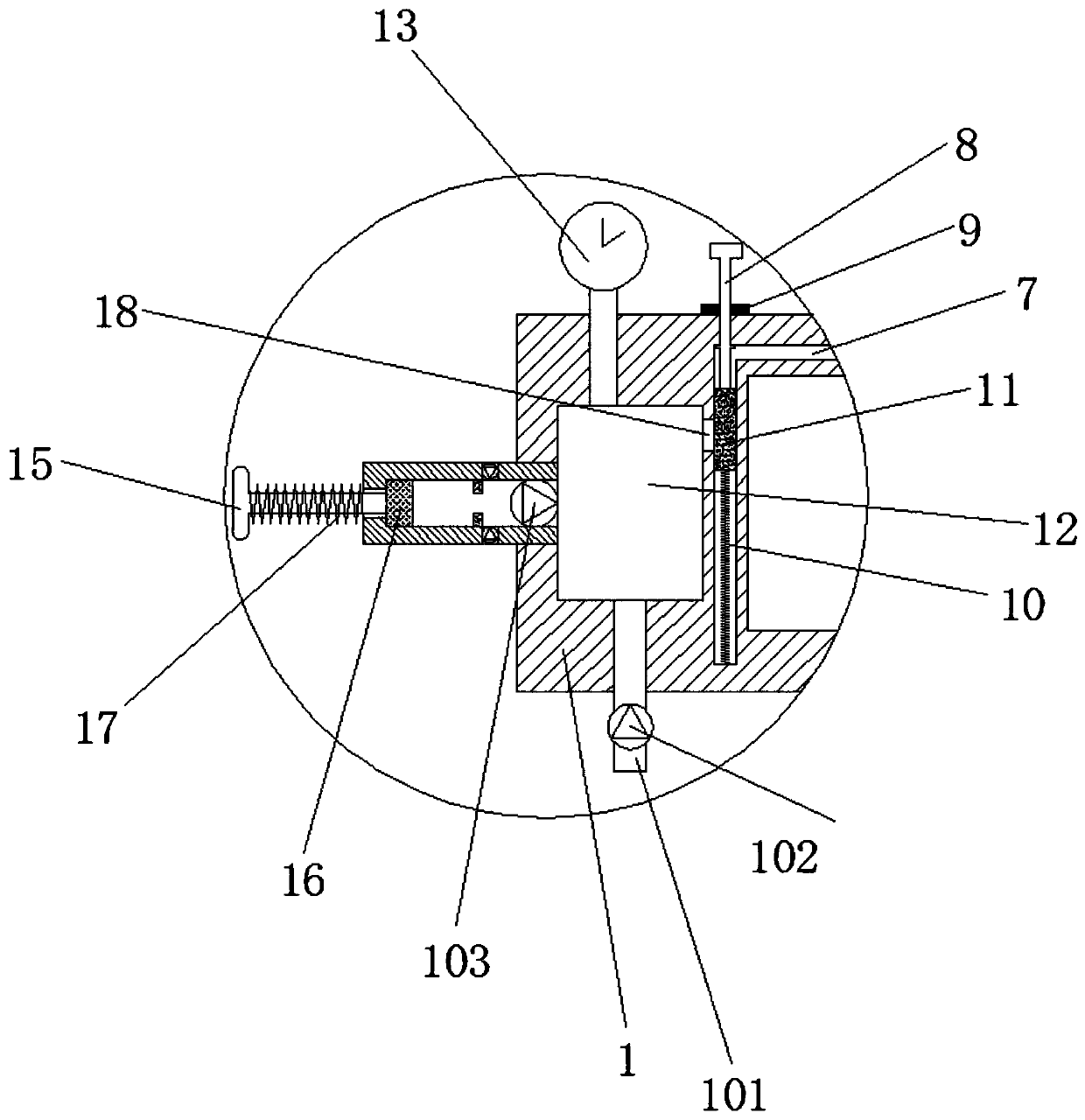

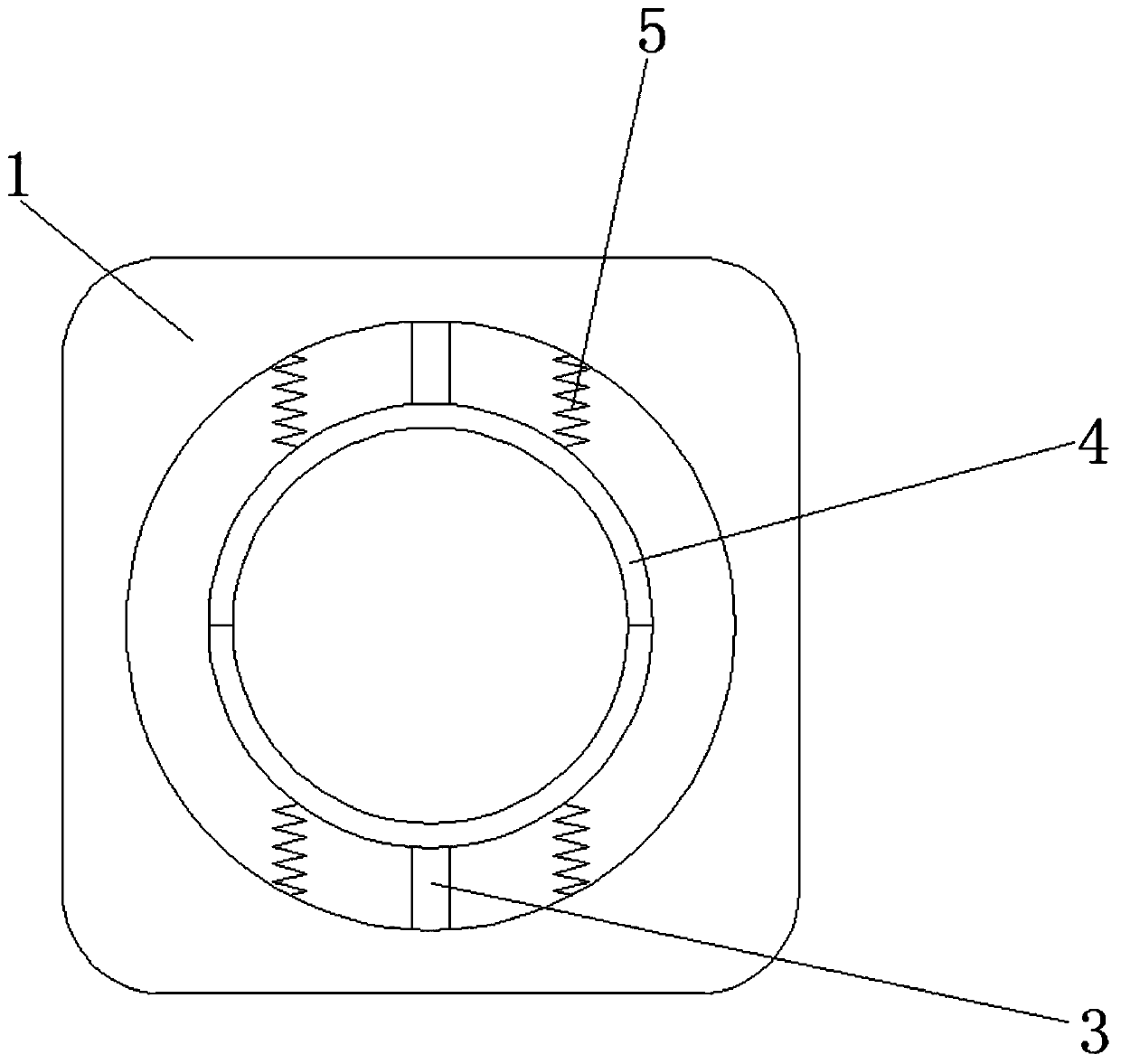

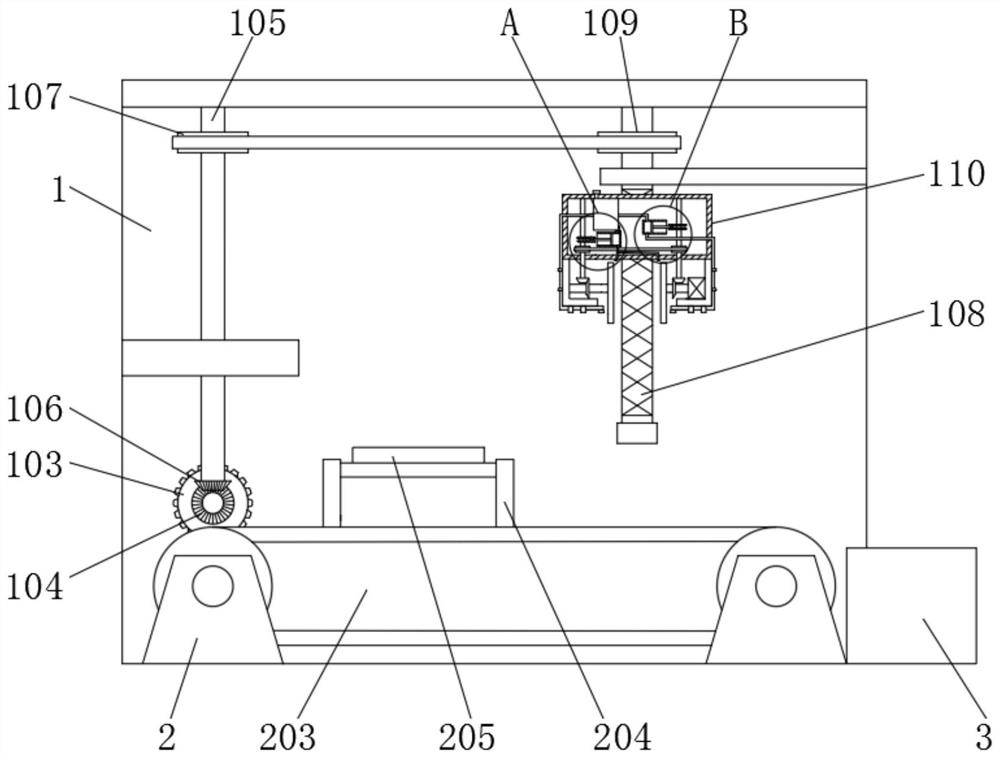

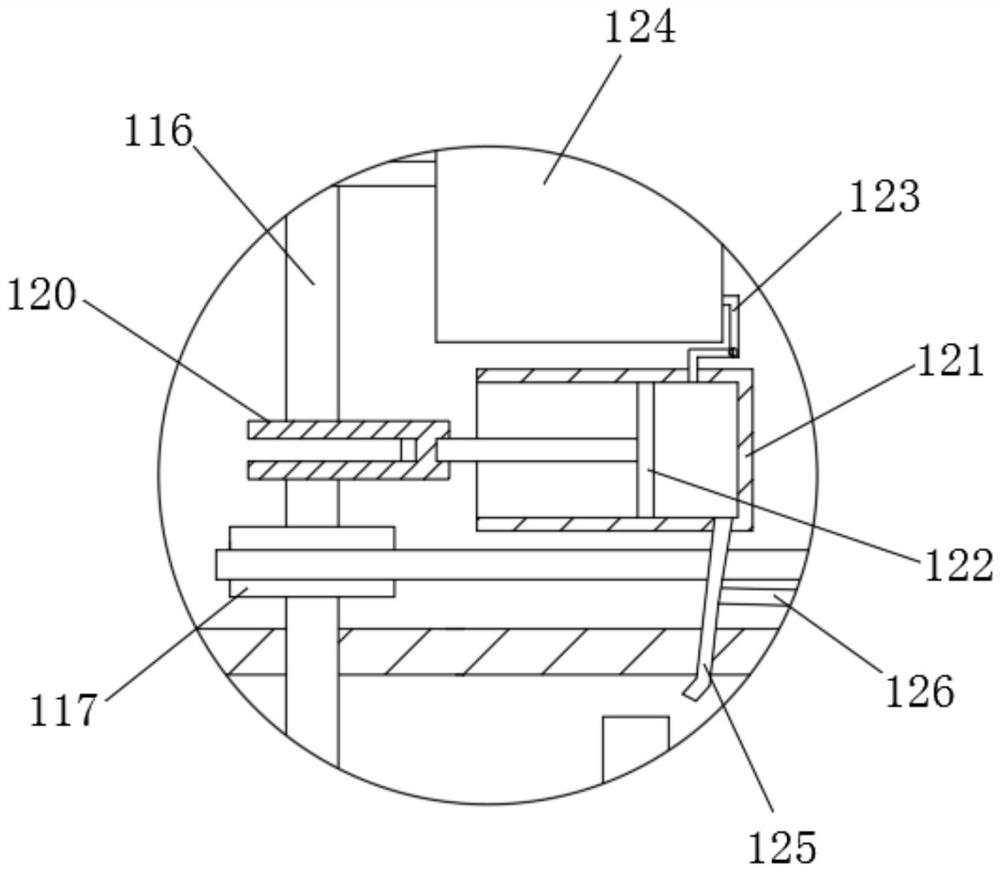

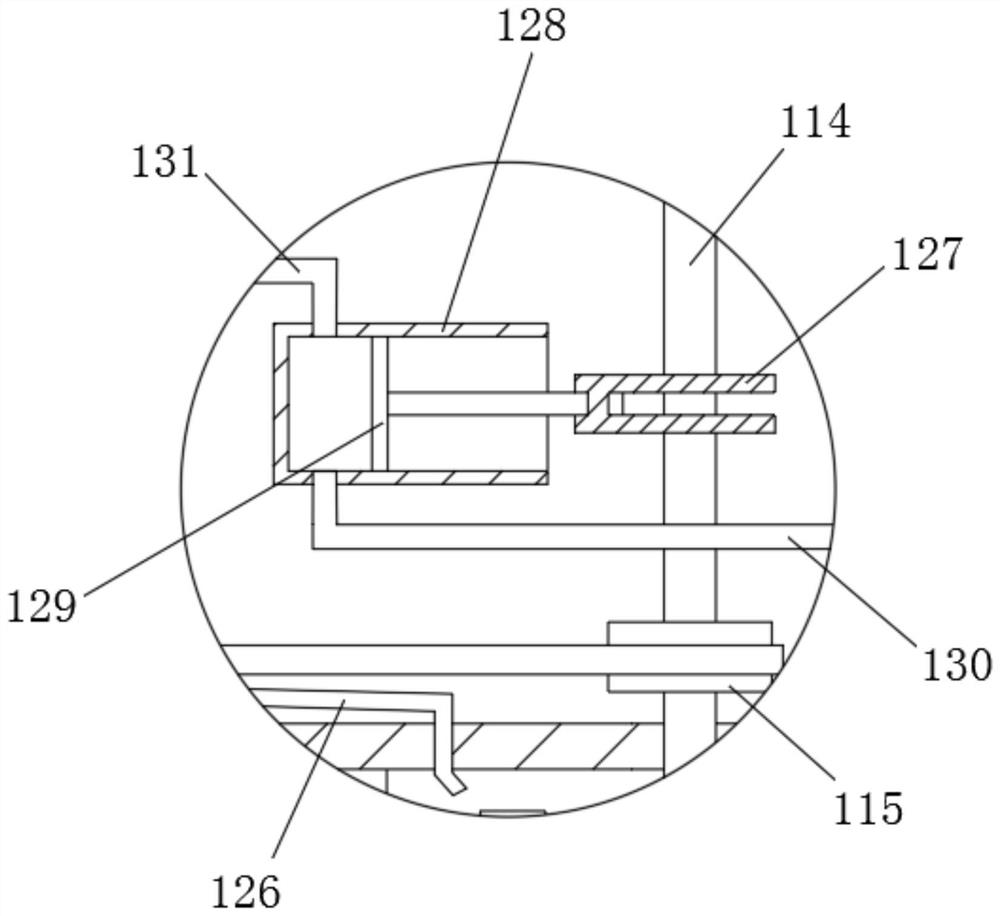

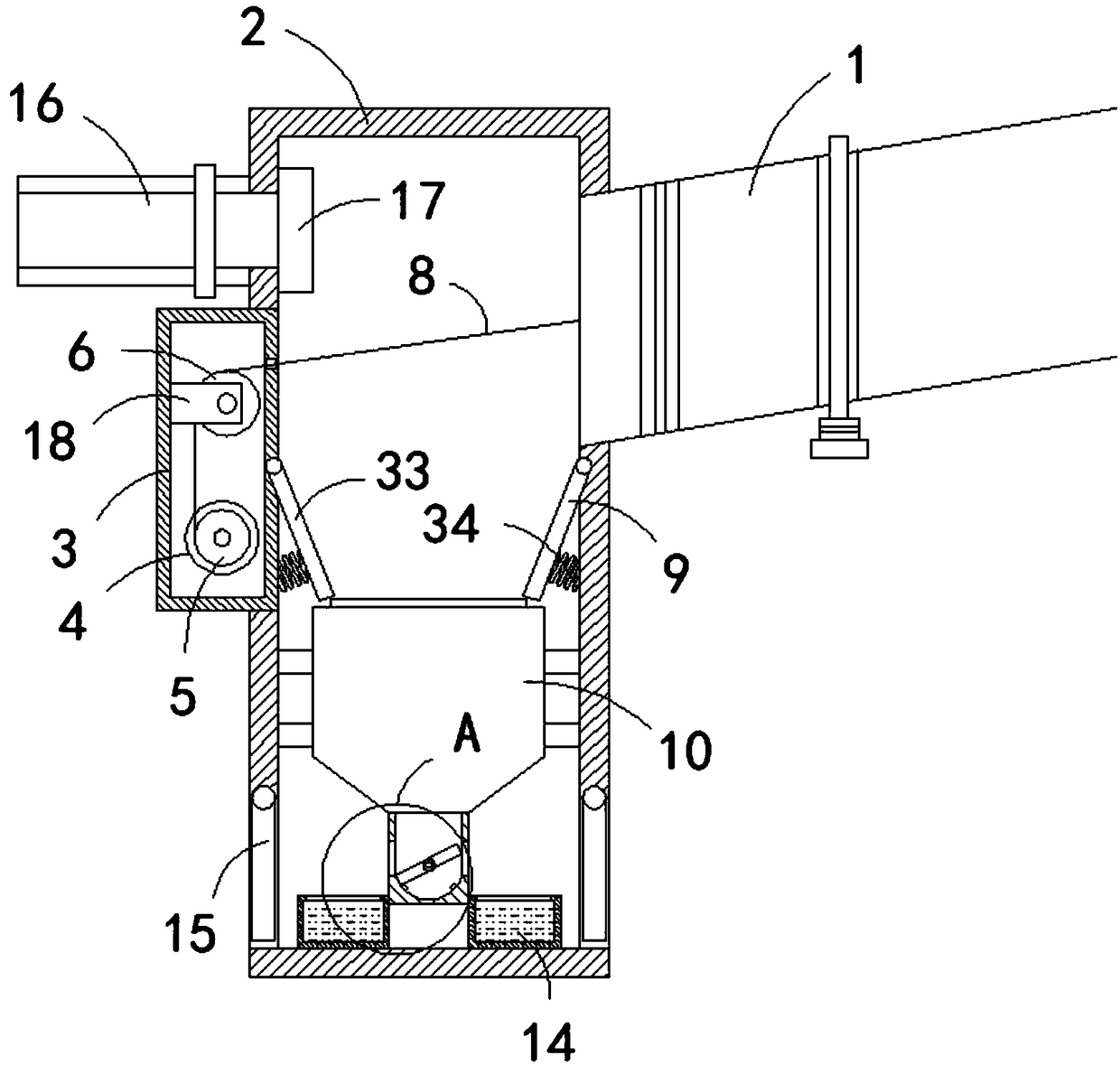

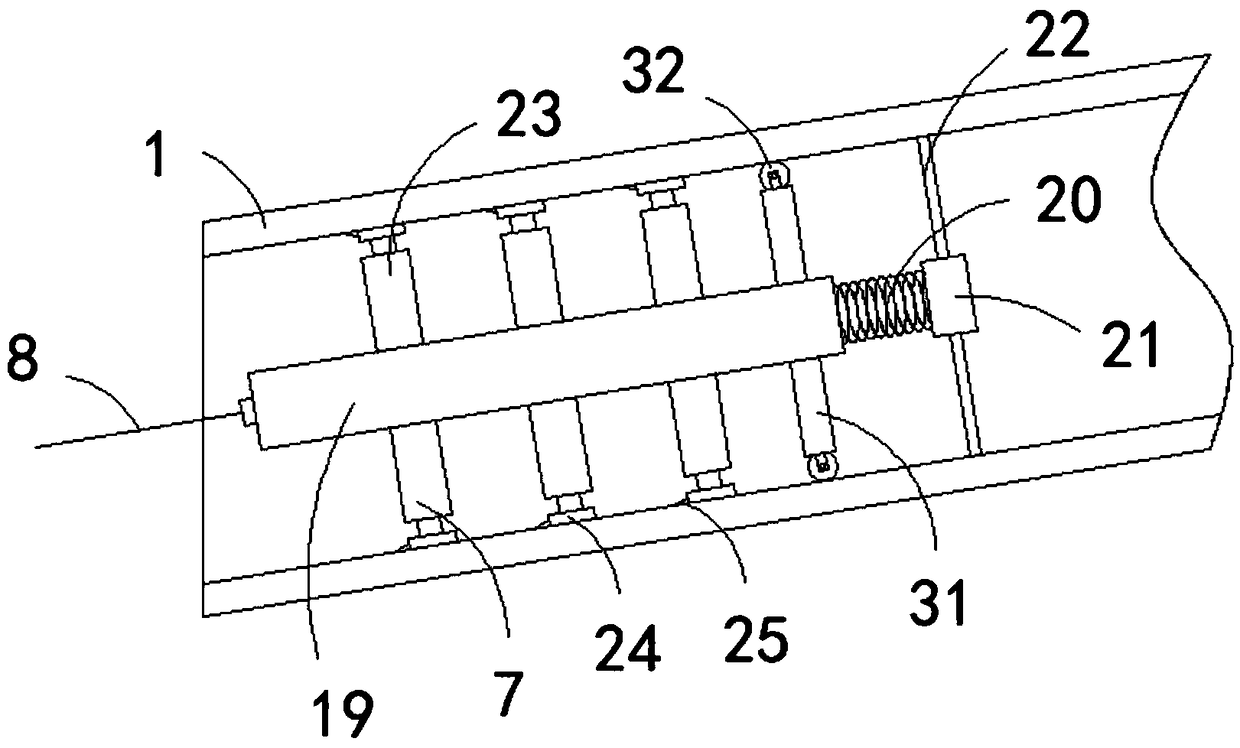

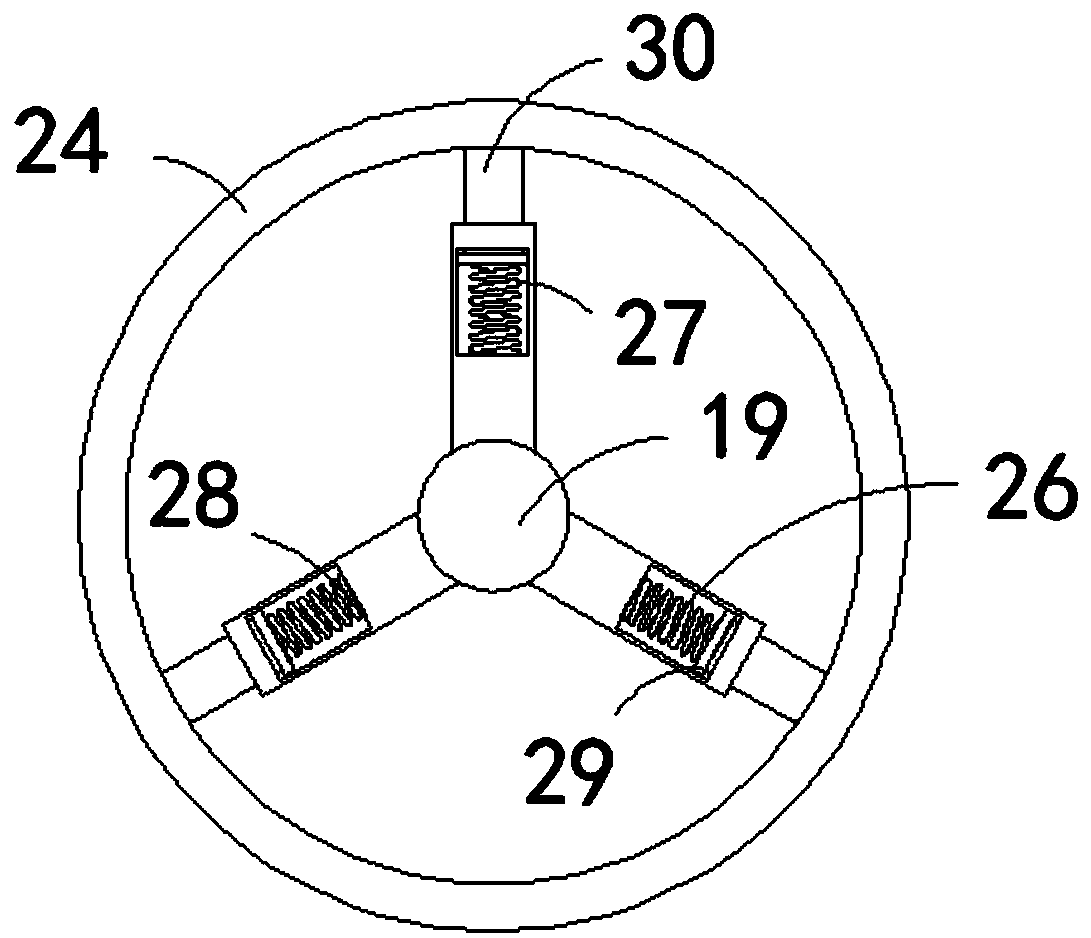

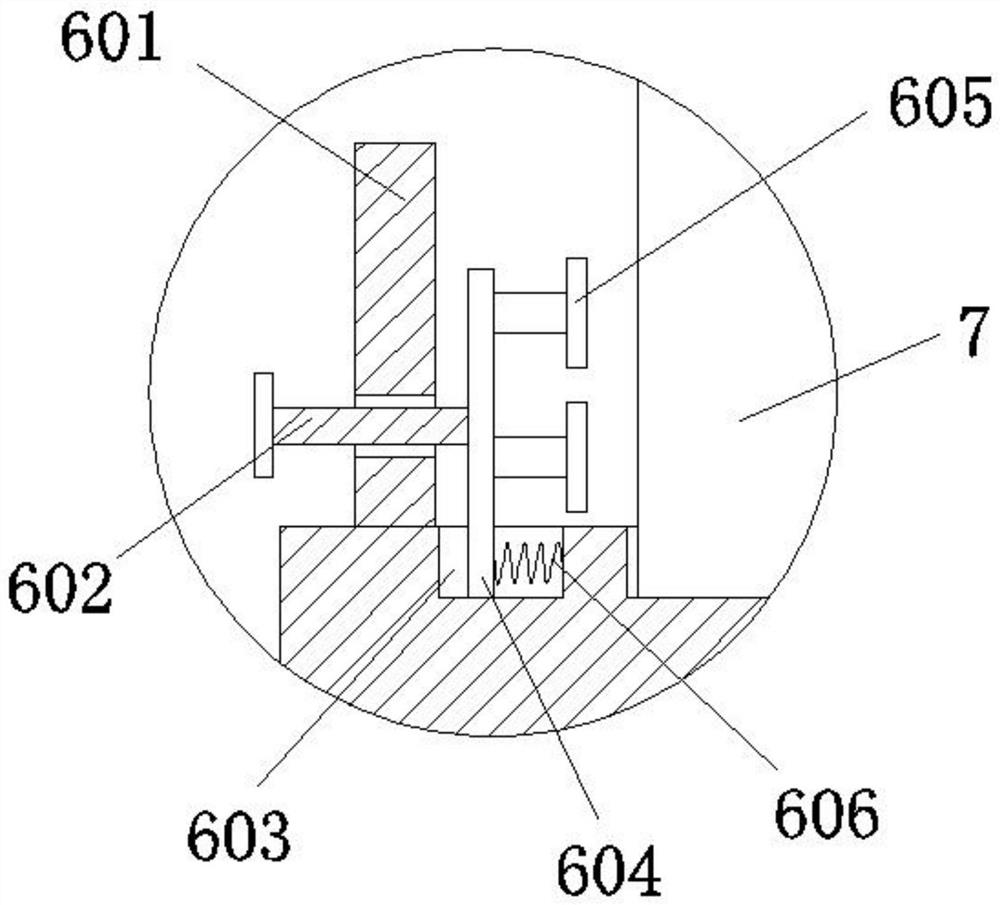

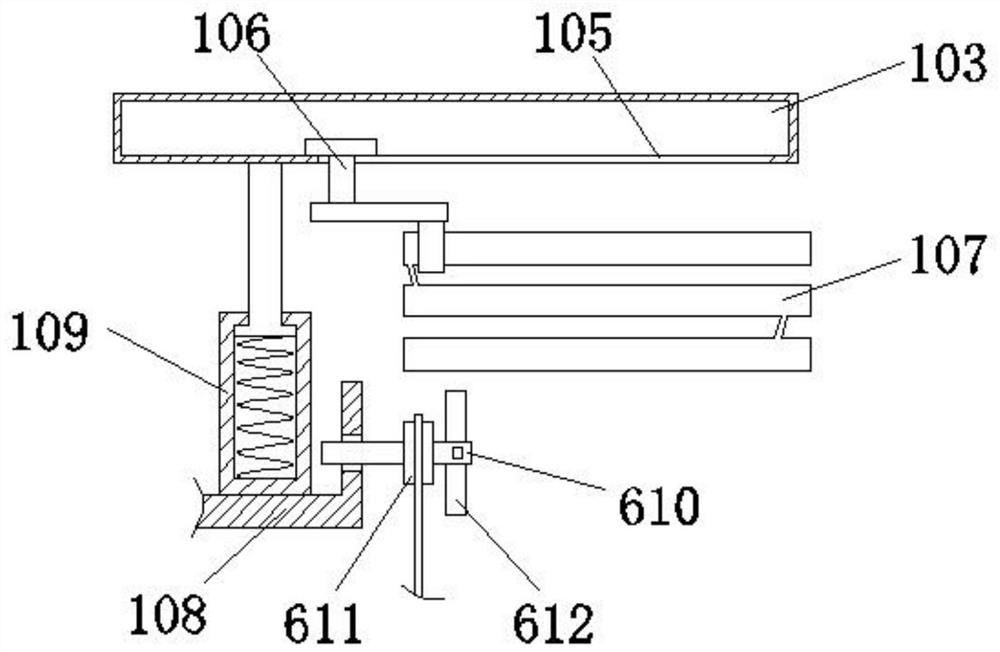

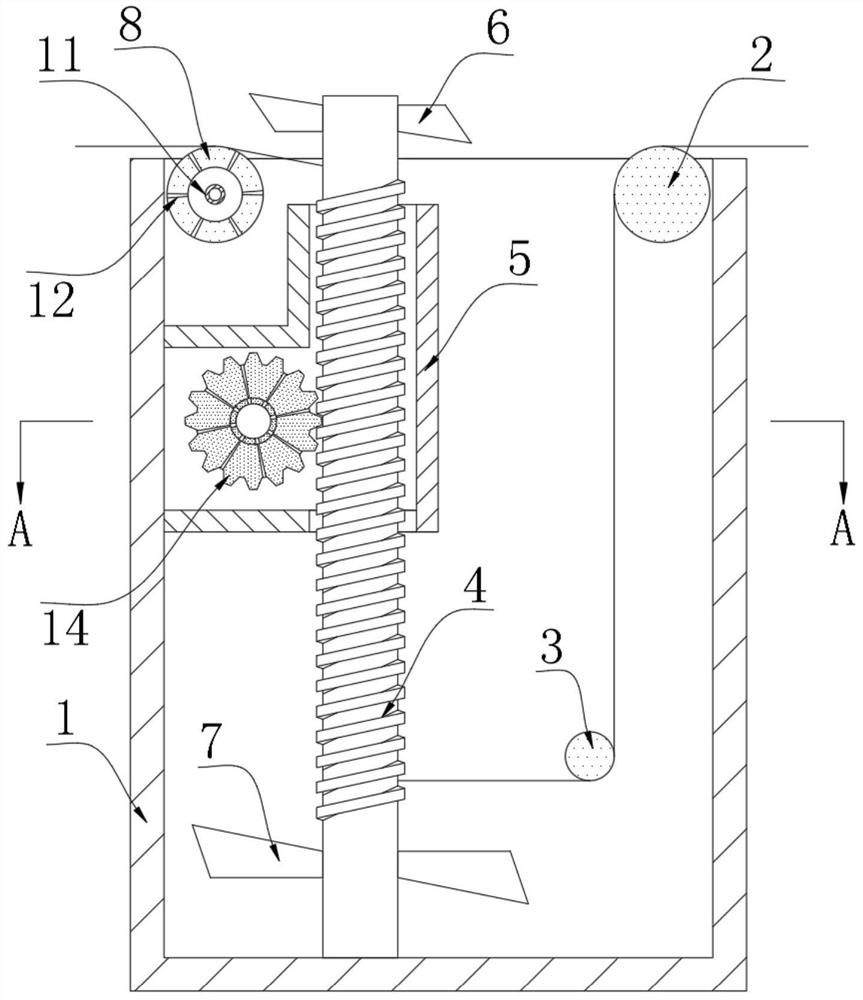

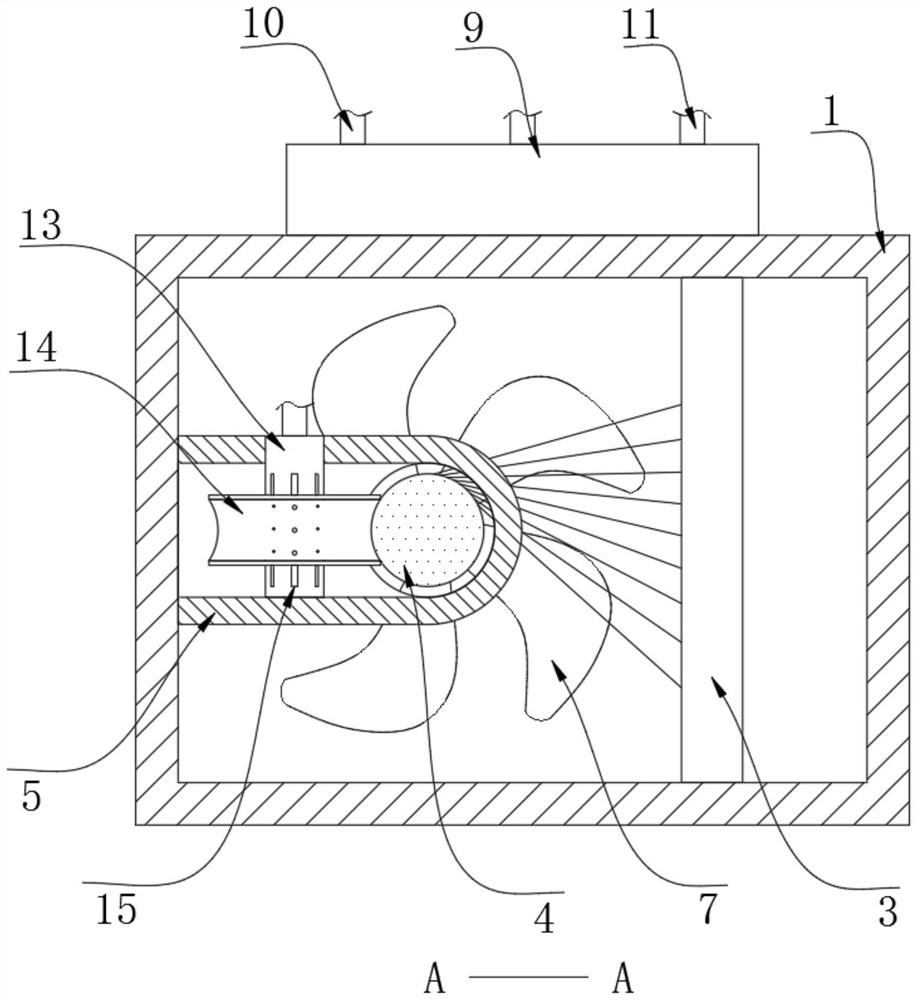

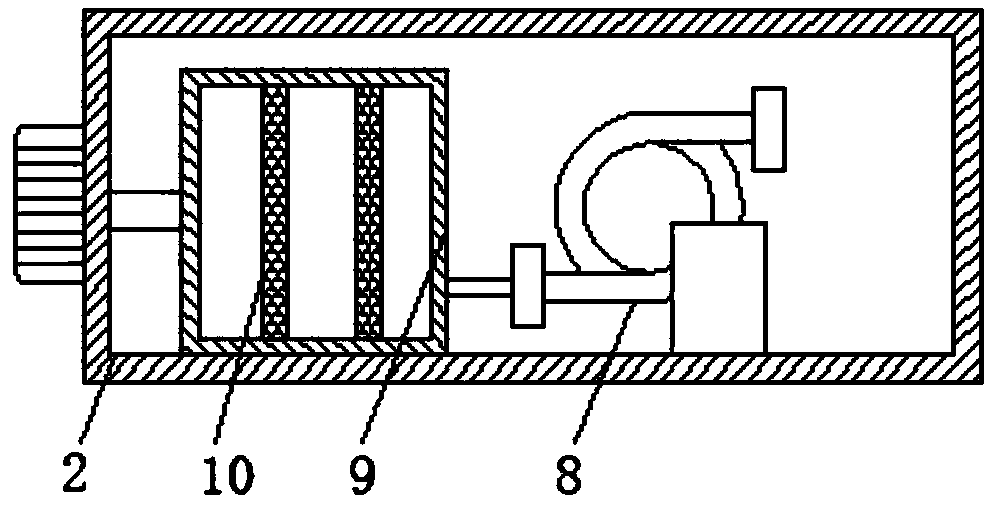

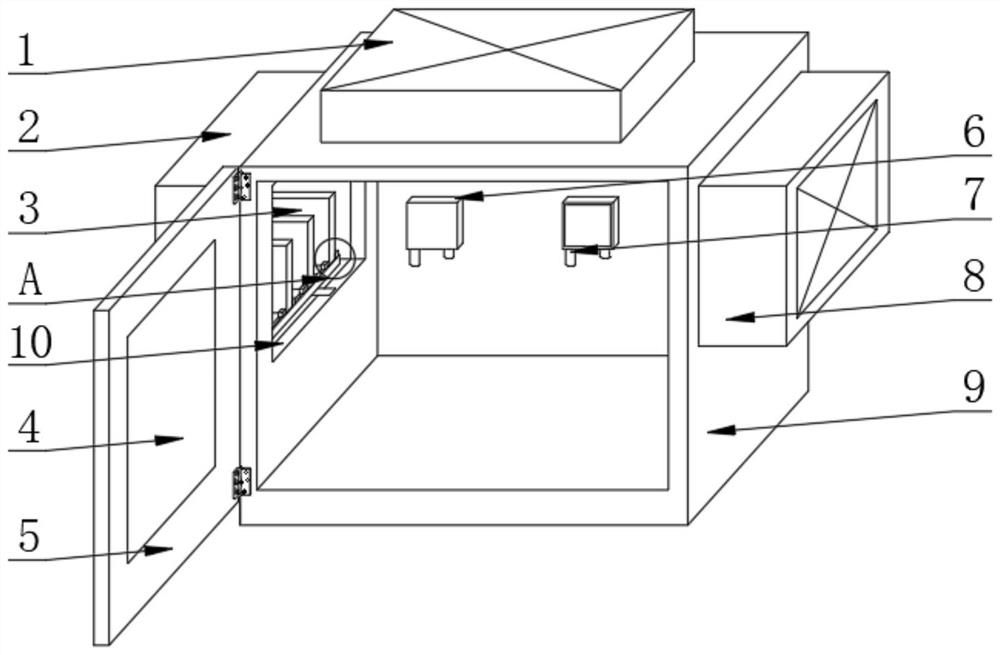

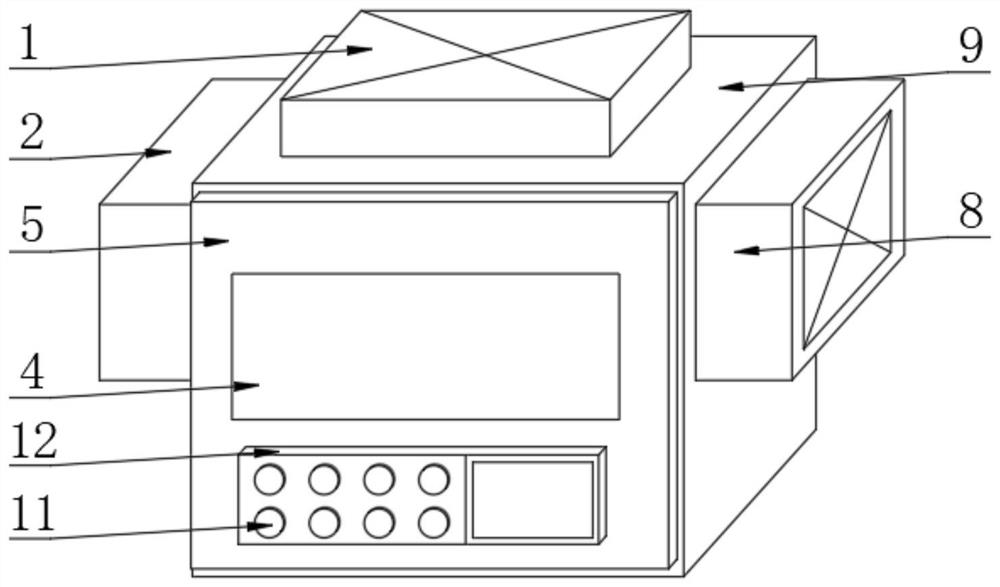

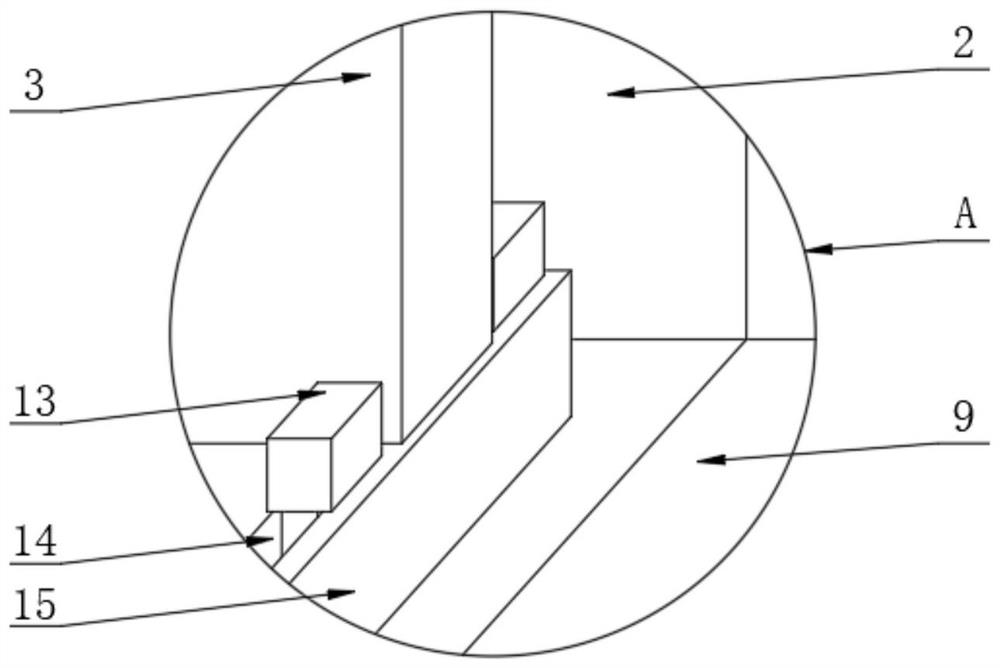

The invention relates to the technical field of steel casting demolding, in particular to a rapid cooling and demolding device for a steel casting. According to the rapid cooling and demolding device for the steel casting, a mold for producing and forming the steel casting can be well fixed through a mold fixing structure, then added molten steel can be well mixed through a stirring device, uneven mass distribution during molten steel pouring is avoided, the molten steel is well poured between molds through the effect of a pump, meanwhile, a cooling device in a cooling assembly is matched with a water suction pump and a spray head, the spray head sprays cooling liquid to the surfaces of the molds, and rapid cooling treatment on the poured molds is achieved; before demolding, the mold fixing structure is controlled to be separated from the molds, then a third motor is driven to drive a demolding assembly to pull a lower mold downwards, the lower mold is separated from the formed steel casting, and a worker opens a box door to take out the produced formed steel casting; and a water collecting tank is arranged at the bottom of a working box of the device, cooling water is specially recycled, cooling waste liquid is prevented from being discharged at will, and the environment is protected.

Owner:含山县大颉机械有限公司

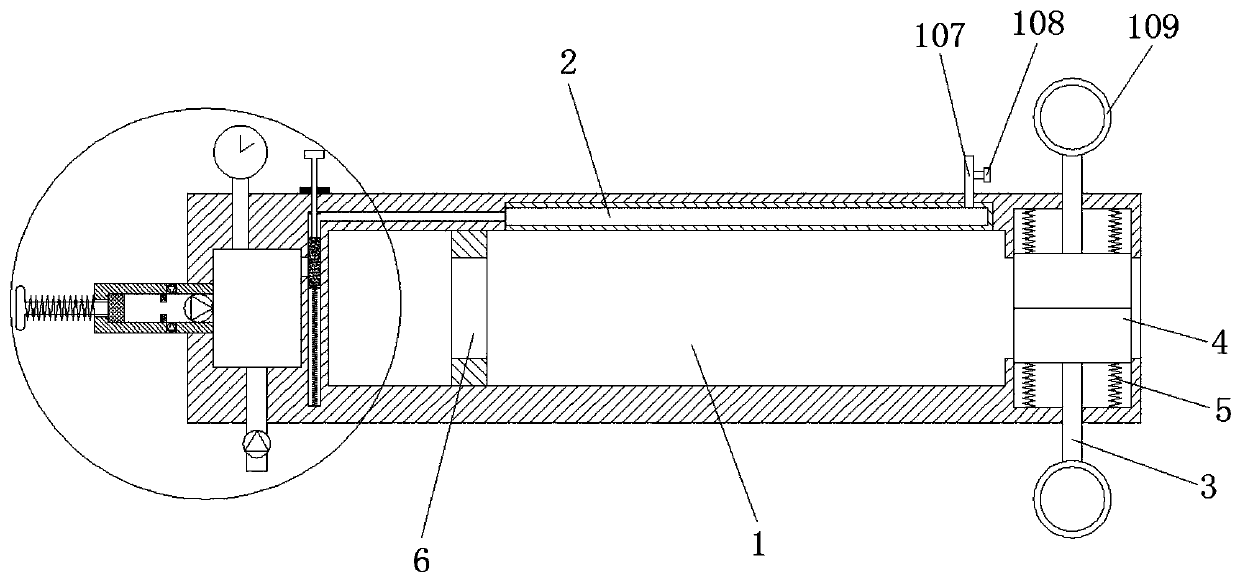

Emergency cooling device for flame burn patient

InactiveCN109758291AAvoid dischargeGood temperature conductivityTherapeutic coolingTherapeutic heatingEngineeringCopper

The invention discloses an emergency cooling device for a flame burn patient. The emergency cooling device comprises a jacket body, a copper plate, a sliding pin, a clamping plate, first springs, a supporting plate, an exhaust hole, a screw bolt, a gasket, a second spring, a rubber column, a cavity, a pressure meter, a connecting sleeve, a lifting pin, a rubber block, a third spring and a relief hole. The emergency cooling device for the flame burn patient is smart in structure, powerful in function and easy to operate. By using the device, a medical worker can quickly cool the flame burn parton a limb of the patient, it is convenient for the medical worker to subsequently treat the patient, and the treatment progress of the patient is ensured.

Owner:FOURTH MILITARY MEDICAL UNIVERSITY

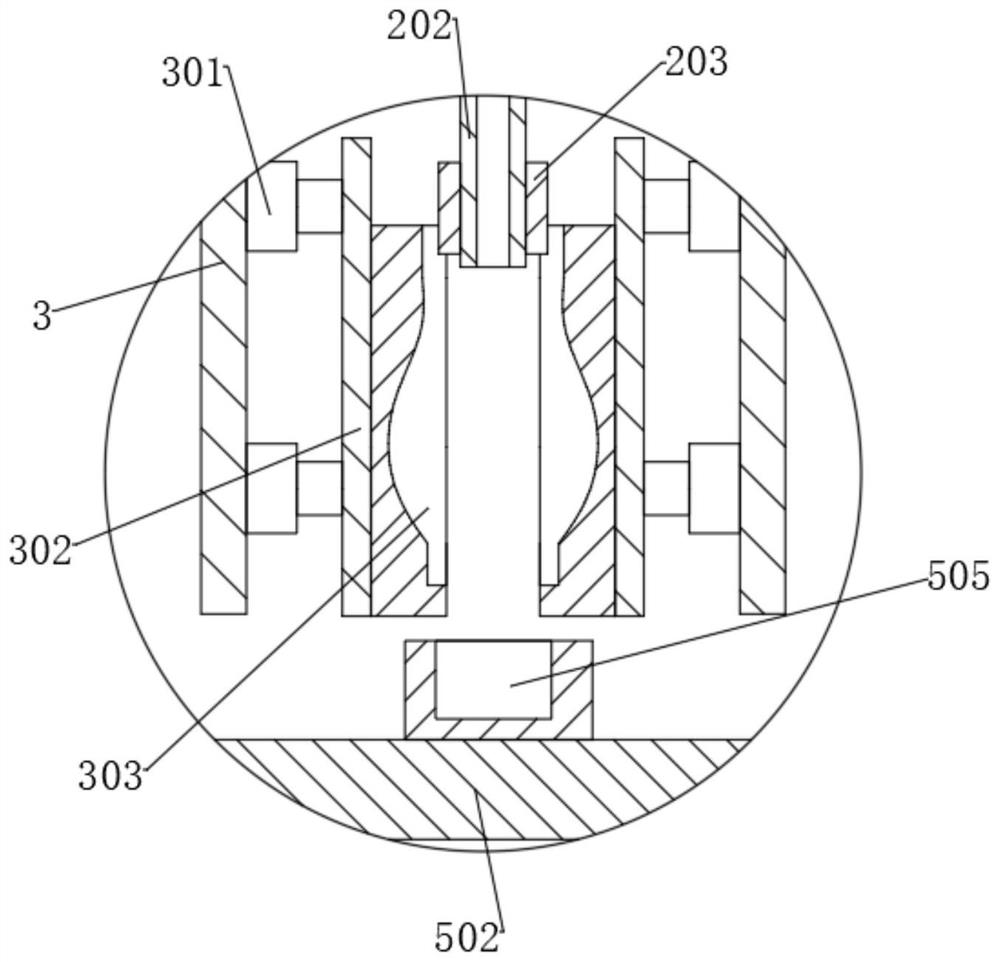

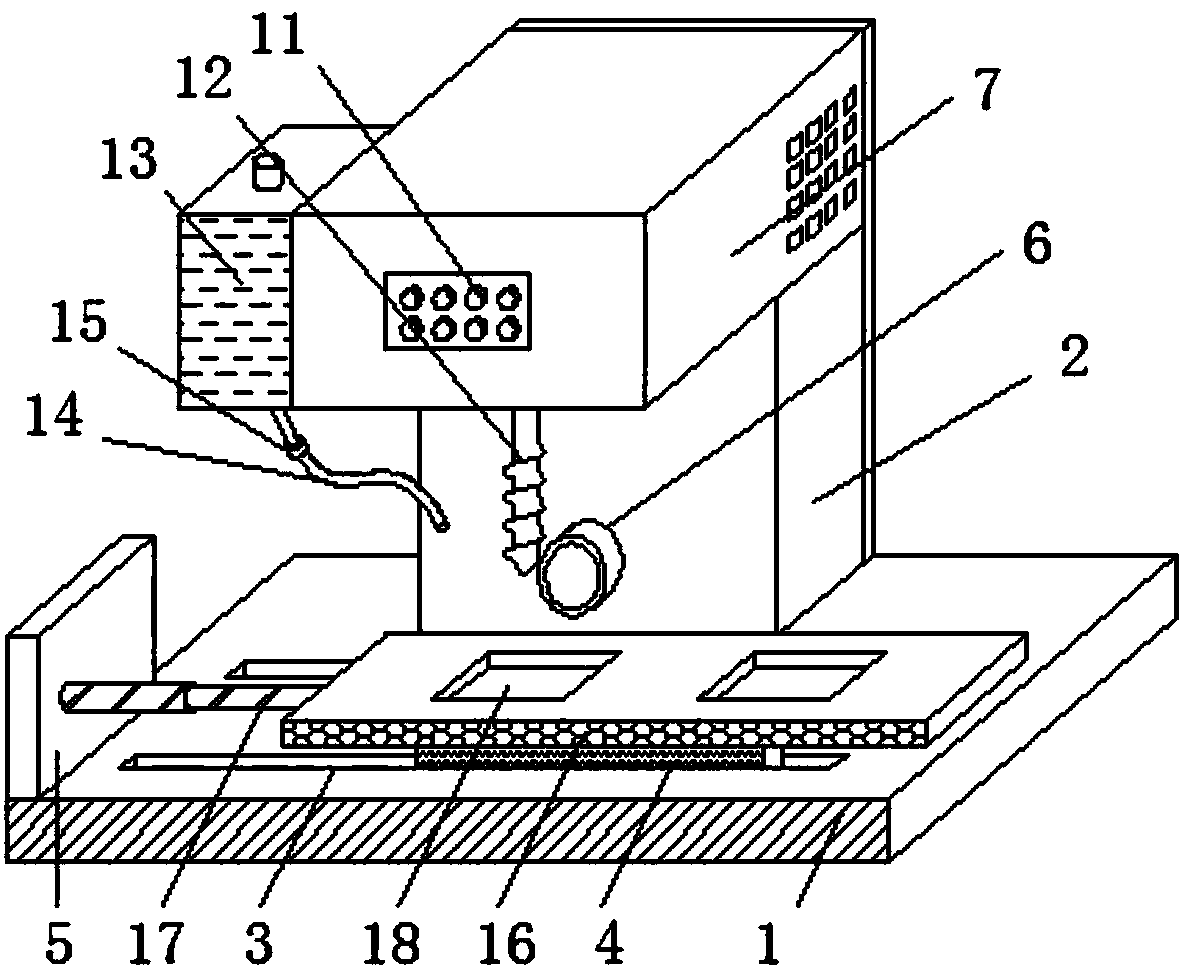

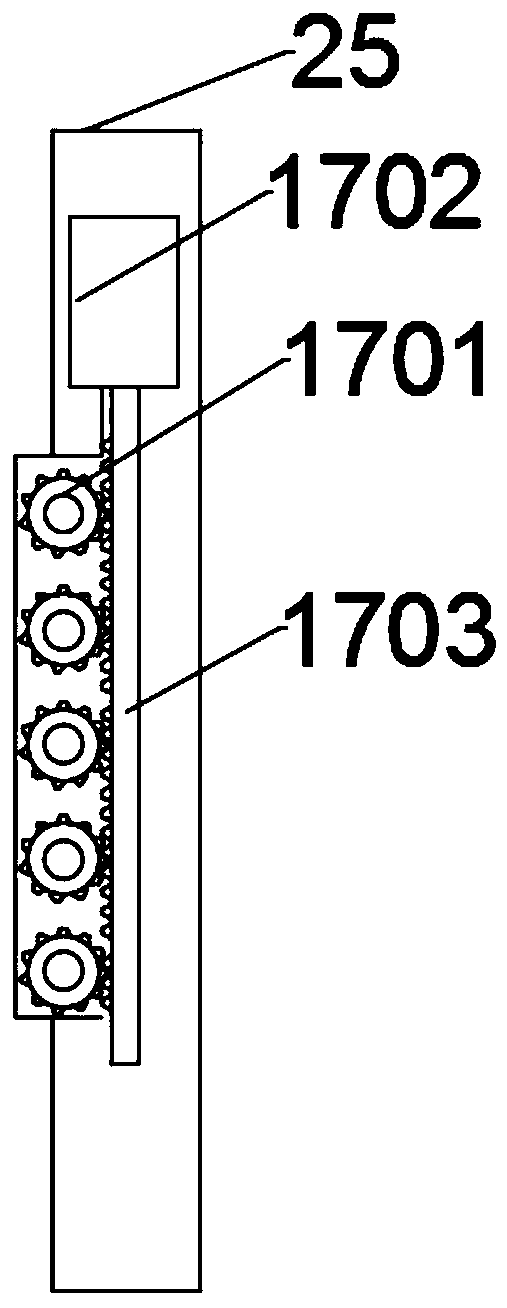

Semiconductor wafer cutting device

InactiveCN113510870AEnough timeExtended service lifeWorking accessoriesFine working devicesWaferingElectric machinery

The invention discloses a semiconductor wafer cutting device, and belongs to the technical field of semiconductors. The semiconductor wafer cutting device comprises a vertical plate, a fixing plate and a silicon body, wherein the vertical plate is fixedly connected with a first motor; an output shaft of the first motor is connected with a first bevel gear; the vertical plate is rotationally connected with a first rotating shaft; the bottom of the first rotating shaft is fixedly connected with a second bevel gear in meshed connection with the first bevel gear; the side wall of the vertical plate is rotationally connected with a reciprocating screw rod; the first rotating shaft is connected with the reciprocating screw rod through a first belt; the reciprocating screw rod is in threaded connection with a sliding box; a cutting mechanism is arranged at the bottom of the sliding box; and a second motor for driving the cutting mechanism is arranged at the bottom of the sliding box. According to the semiconductor wafer cutting device, a cutting disc can be rapidly cooled, the service life of the cutting disc is prolonged, chippings generated after cutting can be cleaned, the surface of a wafer is guaranteed to be clean, and follow-up machining is facilitated.

Owner:高彬

Kiln tail slagging preventing and slag removing device for solid hazardous waste incineration rotary kiln

The invention belongs to the technical field of rotary kiln waste incineration and slag removal, in particular to a kiln tail slagging preventing and slag removing device for a solid hazardous waste incineration rotary kiln, comprising a rotary kiln body and a casing fixedly connected at the output end of the rotary kiln body. A box is fixedly connected to the side wall, far away from the rotary kiln body, of the casing and one end of the box penetrates through the side wall of the casing and extends into the casing. The box is internally and fixedly connected with a driving motor, and a rotating roller fixedly sleeves the outer side of the driving shaft of the driving motor, and a guiding wheel is rotatably connected in the box. The rotary kiln body is equipped with a slag removing mechanism, and the outer side wall of the rotating roller is sleeved with a steel wire rope, and the other end of the steel wire rope in turn passes through the guiding wheel and the side wall of the box and is fixedly connected to the slag removing mechanism. The invention has the advantages that the residual impurities on the inner wall of the rotary kiln body can be removed and the occurrence of slagging on the inner wall of the rotary kiln body is avoided.

Owner:中节能(连云港)清洁技术发展有限公司 +1

Fermentation tank being uniform in fermentation temperature and quick in cooling

The invention discloses a fermentation tank being uniform in fermentation temperature and quick in cooling. The fermentation tank comprises an outer tank body and an inner tank body, wherein the innertank body is located in the outer tank body, and is fixedly connected with the outer tank body; a copper tube is arranged between the inner tank body and the outer tank body; a heat dissipation device is fixedly connected to the lower end of the outer tank body, and comprises a heat dissipation tank and a heat dissipation fan; the heat dissipation fan is located at the bottom of the heat dissipation tank, and is fixedly connected with the heat dissipation tank; a cold grid is fixedly connected to the upper end of the heat dissipation fan; a water tank is fixedly connected to the side wall ofthe heat dissipation tank; a circulating pump is fixedly connected to one side of the water tank, and communicates with the water tank; the cold grid communicates with the water tank through a water pipe; and one end of the copper tube communicates with the cold grid, and the other end of the copper tube communicates with the circulating pump. According to the fermentation tank being uniform in fermentation and quick in cooling disclosed by the invention, the heat dissipation device is arranged, so that quick cooling treatment can be efficiently performed on the fermentation tank by the heat dissipation device in a high-efficiency manner, so that the using of the fermentation tank is convenient, and the service life of the fermentation tank is prolonged.

Owner:江西省食品发酵研究所

Automatic workpiece welding equipment and using method thereof

InactiveCN112453770AGuaranteed stabilityEasy solderingWelding/cutting auxillary devicesAuxillary welding devicesScrew threadBevel gear

The invention relates to the technical field of welding equipment, and discloses automatic workpiece welding equipment and a using method thereof. The automatic workpiece welding equipment comprises abase, a two-way threaded rod is rotationally mounted in the base, two clamping rods are in threaded connection with the outer side of the two-way threaded rod, the bottom ends of the two clamping rods are slidably mounted on the inner wall of the bottom of the base, the top ends of the two clamping rods extend to the outer side of the base, threaded rods are rotatably mounted on the two sides ofthe top of the base, the bottom ends of the two threaded rods extend into the base, four first bevel gears are rotatably mounted in the base, and the two first bevel gears on the same side in the fourfirst bevel gears are engaged with each other. The automatic workpiece welding equipment is reasonable in design, the horizontal adjusting function can be conducted on a welding device, and thereforewelding treatment is conducted on different positions, then, through an arranged rotating wheel, a spray head can swing in a reciprocating arc shape, and therefore the cooling efficiency of workpieces is improved.

Owner:合肥华赞自动化科技有限公司

New energy automobile battery cooling device

InactiveCN112290156ARapid coolingExtended service lifeSecondary cellsCell component detailsThermodynamicsAutomotive battery

The invention discloses a new energy automobile battery heat dissipation device, and belongs to the technical field of battery heat dissipation. The new energy automobile battery cooling device comprises a box body and a battery body, a first sliding groove is formed in the inner wall of the box body, a sliding box is slidably connected into the first sliding groove, a sliding block is slidably connected to the bottom of the sliding box, a heat dissipation pipe is fixedly connected to the bottom of the sliding block, and the heat dissipation pipe is an annular pipeline; a water inlet end and awater outlet end are arranged on the heat dissipation pipe, a connecting shell is fixedly connected to the side wall of the box body, a motor is arranged in the connecting shell, a first rotating shaft is rotatably connected to the output end of the motor, a protective shell is fixedly connected to the inner wall of the box body, and a second rotating shaft matched with the first rotating shaft is rotatably connected to the interior of the protective shell; and the top of the connecting shell is fixedly connected with a cooling liquid tank. The automobile battery cooling device can quickly cool an automobile battery, avoids overheating of the battery, can effectively protect the battery, and prolongs the service life of the battery.

Owner:马春娇

Blended yarn bleaching equipment

PendingCN111705453AStable deliveryThe conveying process is smooth and there will be no confusionTextile treatment machine arrangementsLiquid/gas/vapor removal by gas jetsYarnStructural engineering

The invention discloses blended yarn bleaching equipment. The equipment comprises a treatment box, an input roller and a guide roller are rotatably connected to the inner wall of the treatment box, aworm is rotatably connected to the inner bottom of the treatment box, rotating blades are fixed to the circumferential side wall of the upper portion of the worm, stirring blades are fixed to the circumferential side wall of the lower portion of the worm, an output roller and a drying box are rotatably connected to the inner wall of the treatment box, the worm penetrates through the drying box, avortex tube is fixed to the outer wall of the treatment box, a cold outlet and a hot outlet of the vortex tube are connected with a cold flow tube and a hot flow tube respectively, and a hollow rotating shaft penetrates through the side wall of the drying box and is rotatably connected to the side wall of the drying box. The equipment has the advantages that through rotation conveying of the worm,yarns can collide with and rub bleaching liquid, the effect of contact between the yarns and the bleaching liquid is improved, the bleaching quality is further improved, through conveying of the worm, conveying in an initial state can be stably continued after preliminary winding, the circumstance that the yarns are disordered and knotted in the midway is avoided, and the yarns cannot be damagedor disordered in the bleaching and drying process.

Owner:陈勇

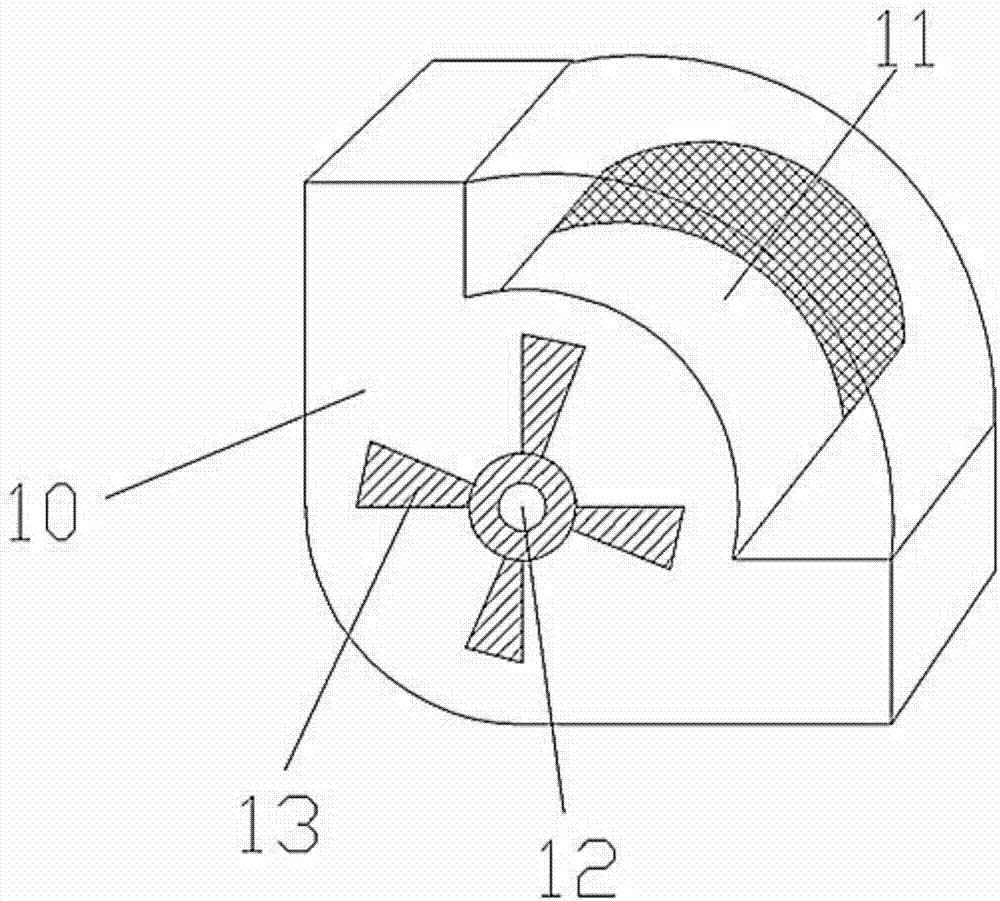

Finish machining production line for nanoscale material coating

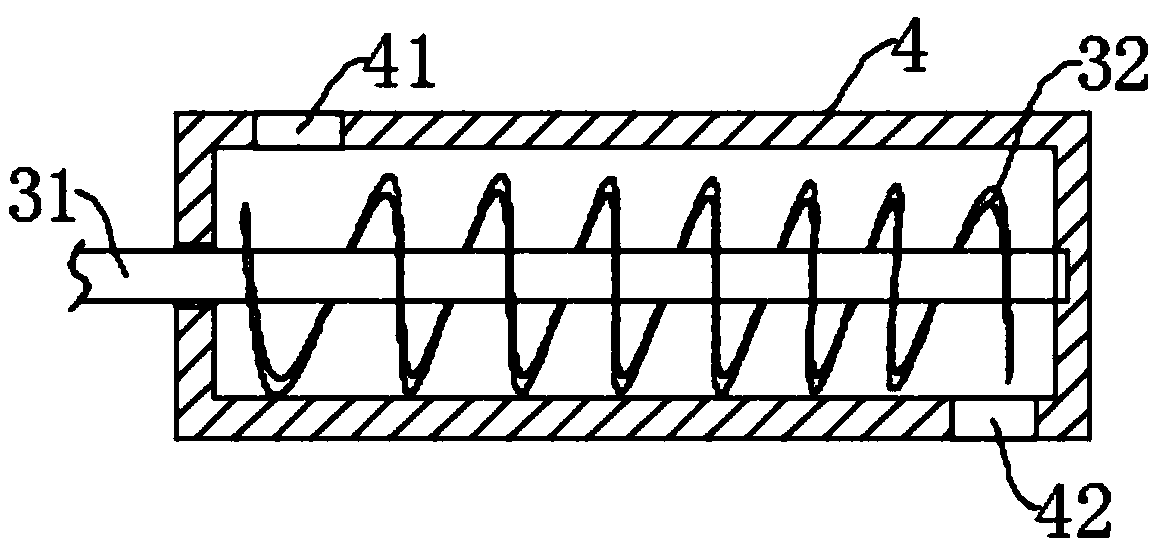

PendingCN110585972ABreak up and reunite quicklyImprove stirring efficiencyShaking/oscillating/vibrating mixersRotary stirring mixersProduction lineSlurry

A finish machining production line for a nanoscale material coating comprises a stirring kettle, a cooling box, a binder storage barrel, an active substance storage barrel and a conductive agent storage barrel; the stirring kettle comprises an inner-layer wall and an outer-layer wall, a heating cavity and a vibration cavity are formed between the inner-layer wall and the outer-layer wall, an annular heating ring is arranged in the heating cavity, and an ultrasonic generator is arranged in the vibration cavity; a second mounting base is arranged on the side wall of the stirring kettle, a firstelectric pump is mounted on the second mounting base, a material conveying pipe is arranged on the first electric pump, one end of the material conveying pipe communicates with an inner cavity of thestirring kettle, and the other end of the material conveying pipe is connected with the binder storage barrel, the active substance storage barrel and the conductive agent storage barrel; and a condensing coil pipe is arranged in the cooling box, one end of the condensing coil pipe communicates with an inner cavity of the lower end of the stirring kettle, the other end of the condensing coil pipeis connected with a second electric pump, and the output end of the second electric pump communicates with an inner cavity of the upper end of the stirring kettle through a pipeline. Therefore, slurryis ensured to be at a corresponding temperature according to process requirements, and the slurry processing quality is improved.

Owner:HIDETAKA NANO TECH CO LTD

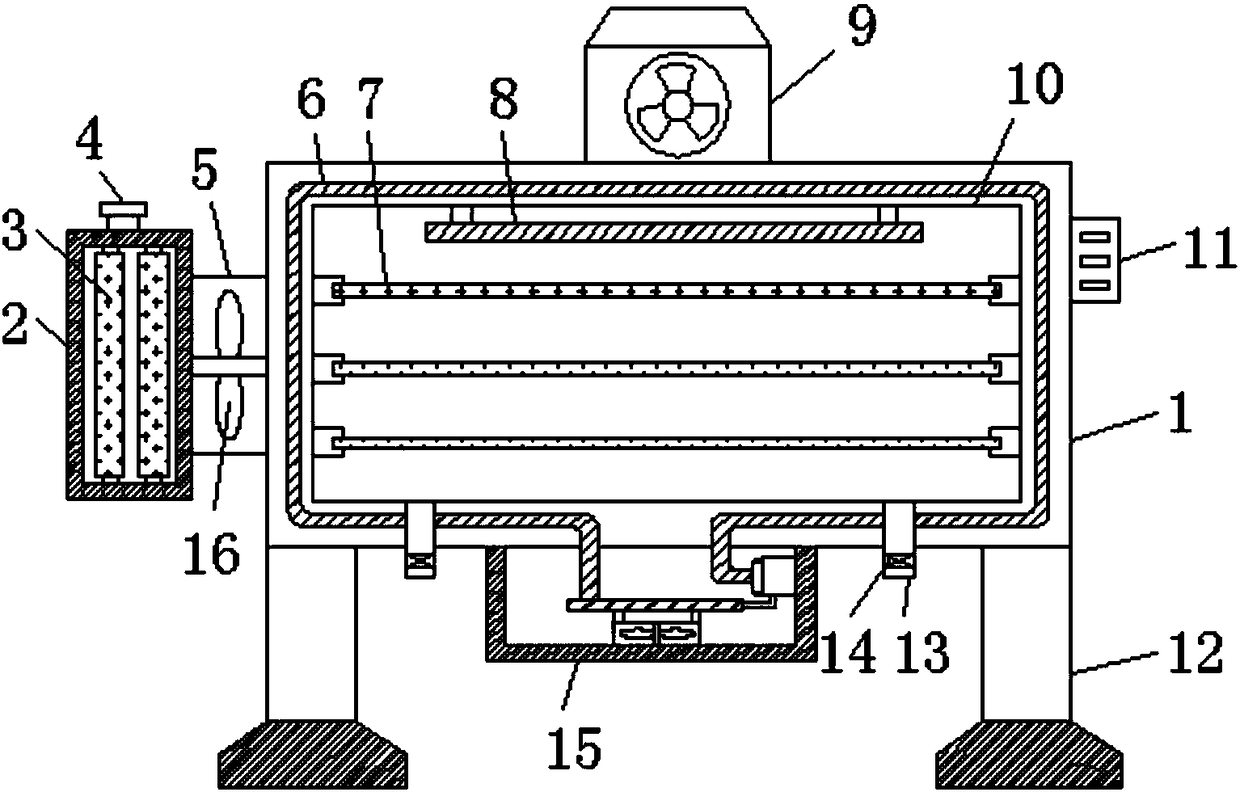

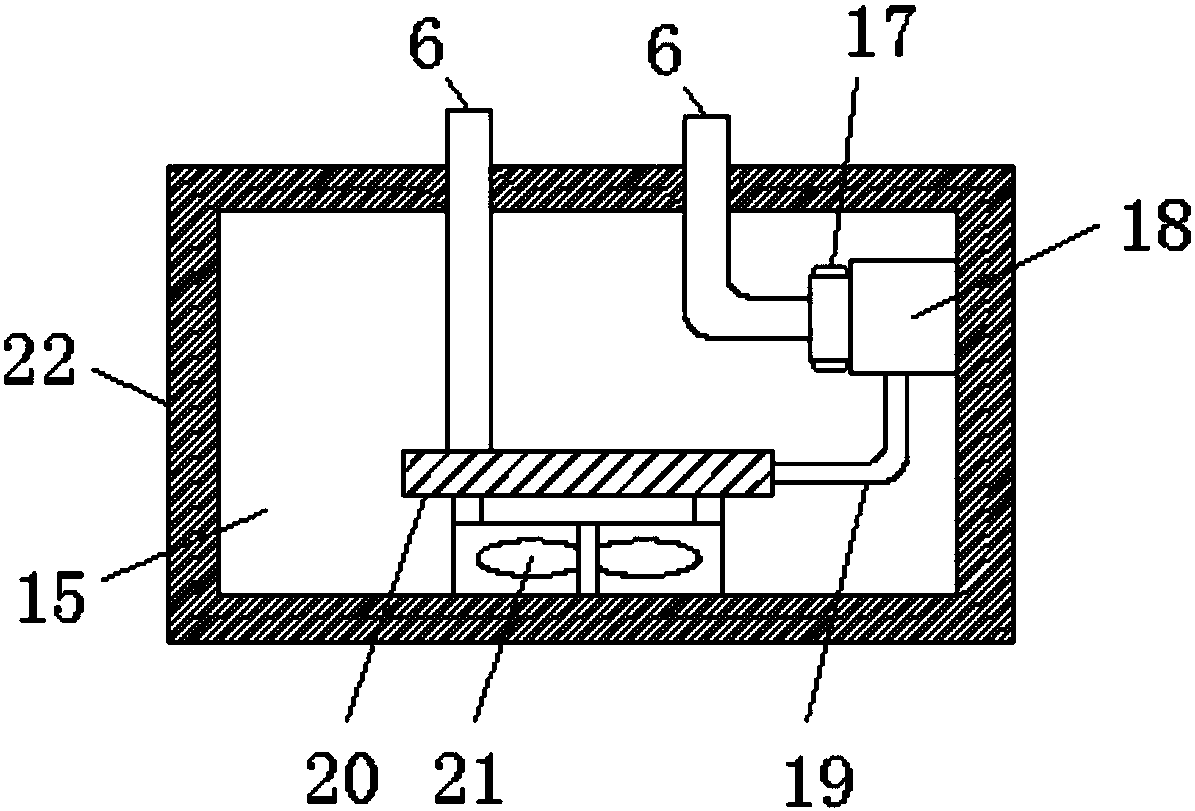

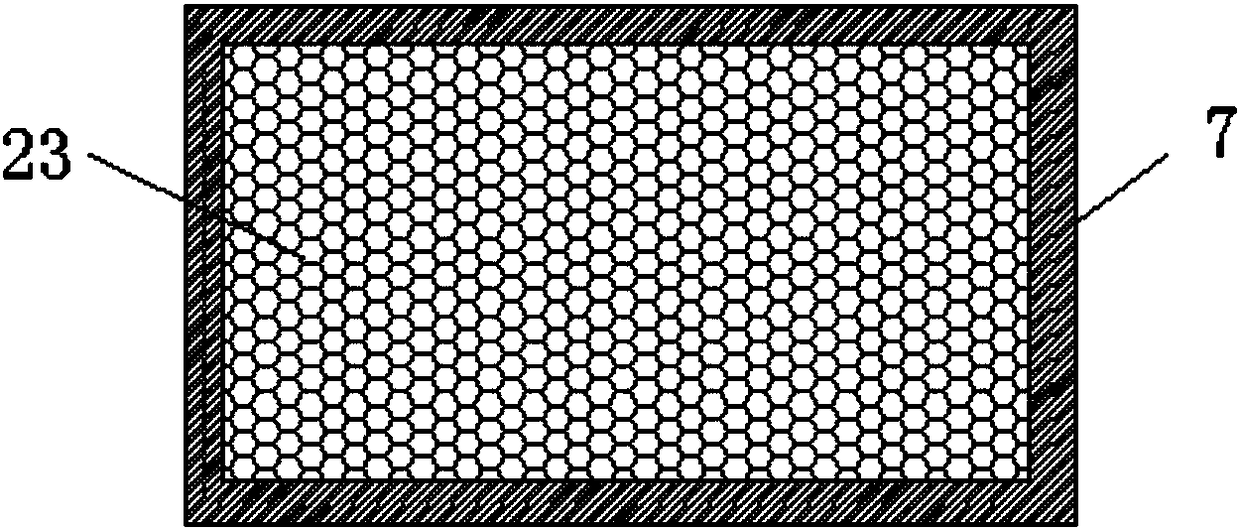

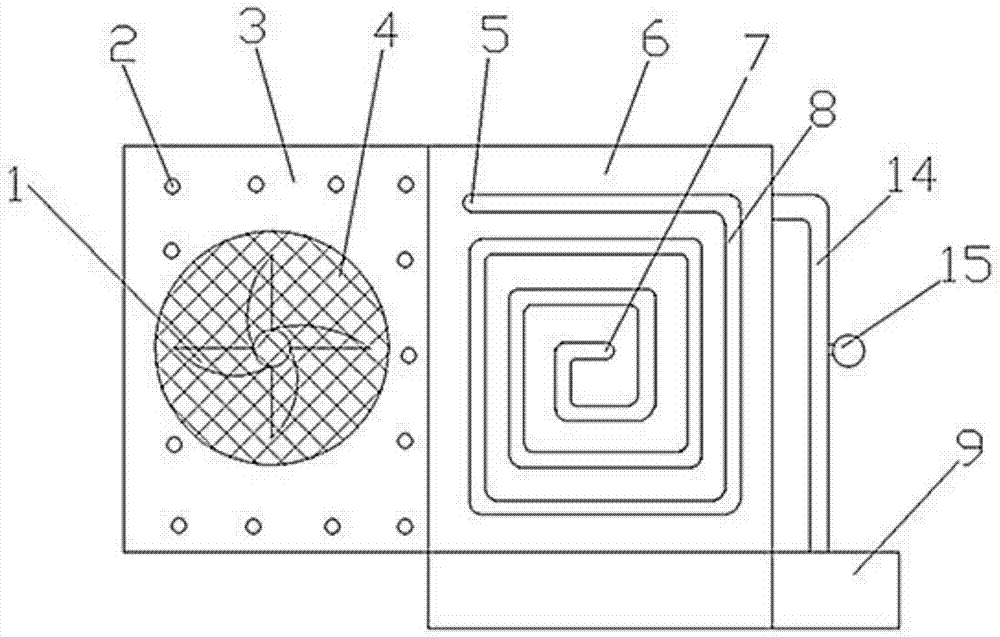

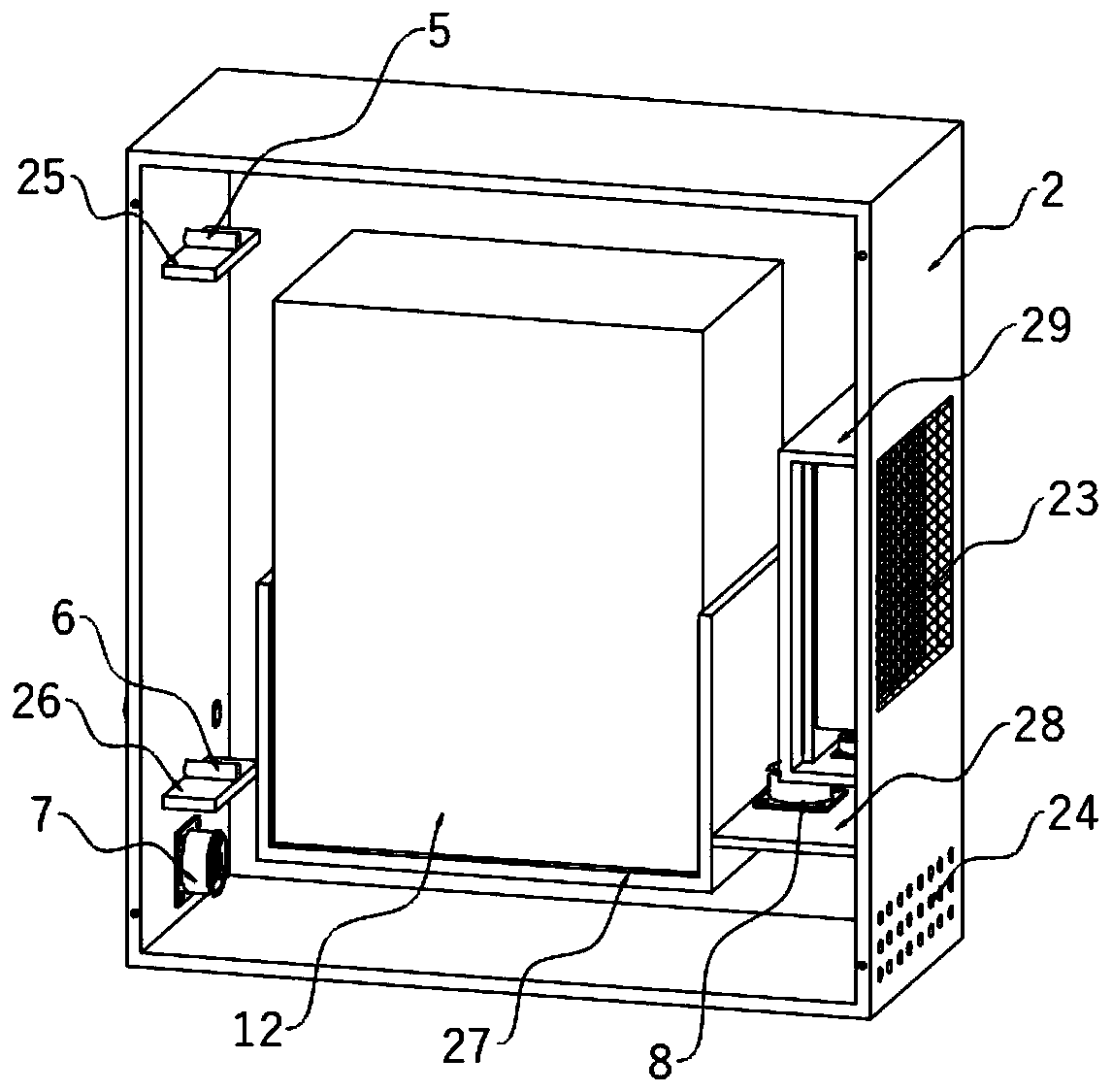

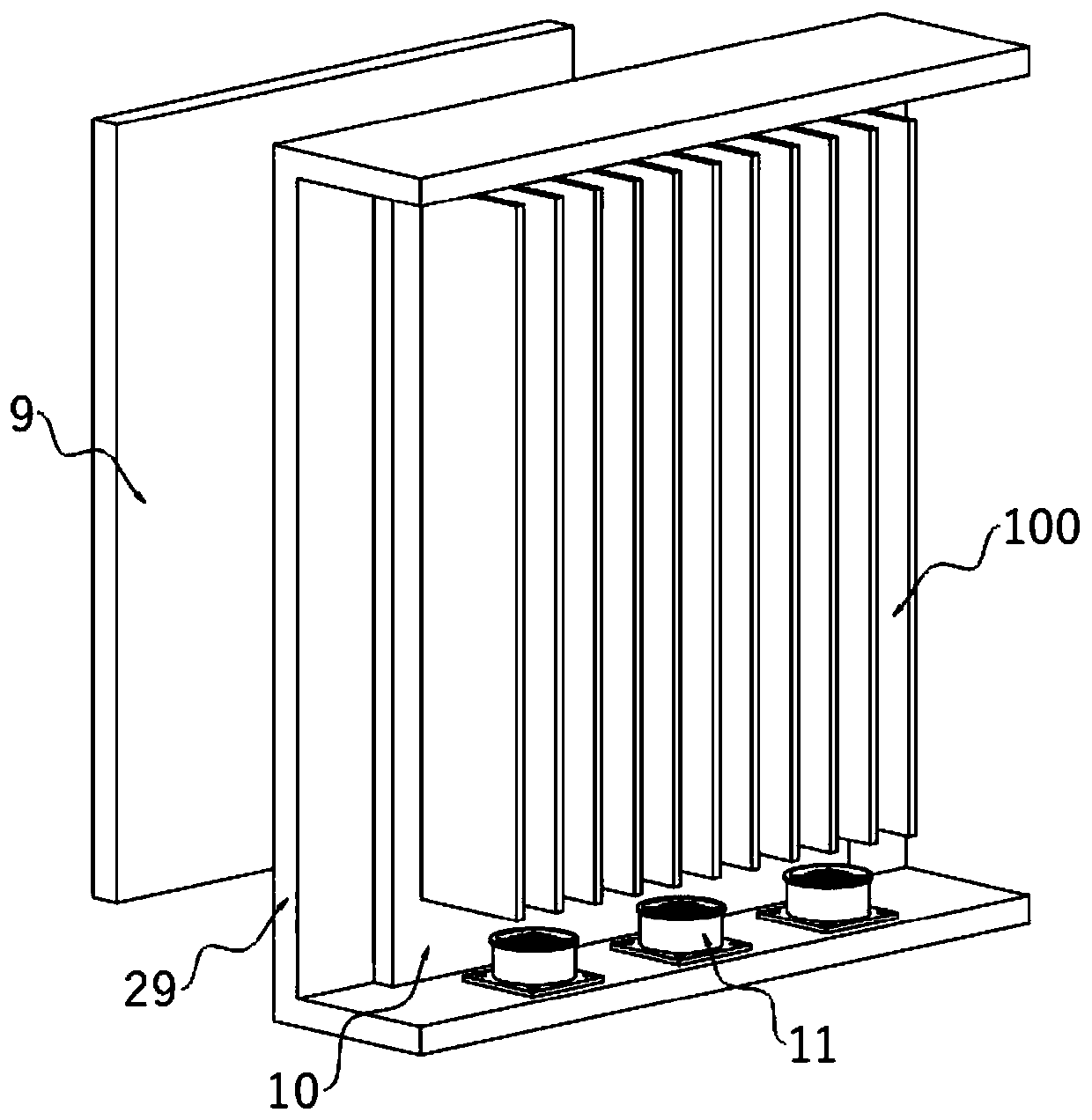

Switch cabinet capable of dual cooling

InactiveCN107508175ARapid cooling treatmentImprove efficiencySubstation/switching arrangement cooling/ventilationAgricultural engineeringAir cooling

The present invention discloses a switch cabinet capable of dual cooling. The switch cabinet comprises a heat dissipation fan, heat dissipation holes, a case cover, a net cover, a water inlet, a switch cabinet body, a water outlet, a condenser tube and a water pump. The case cover is arranged on the switch cabinet body, the heat dissipation fan is arranged on the case cover, the net cover is arranged on the heat dissipation fan, a plurality of heat dissipation holes are uniformly arranged on the case box, the condenser tube is arranged at the internal portion of the switch cabinet body, the two ends of the condenser tube are respectively connected with the water inlet and the water outlet, and the water pump is connected with the water inlet. The switch cabinet capable of dual cooling can rapidly perform cooling processing of the switch cabinet through two modes of water cooling and air cooling.

Owner:江苏叙然智能科技有限公司

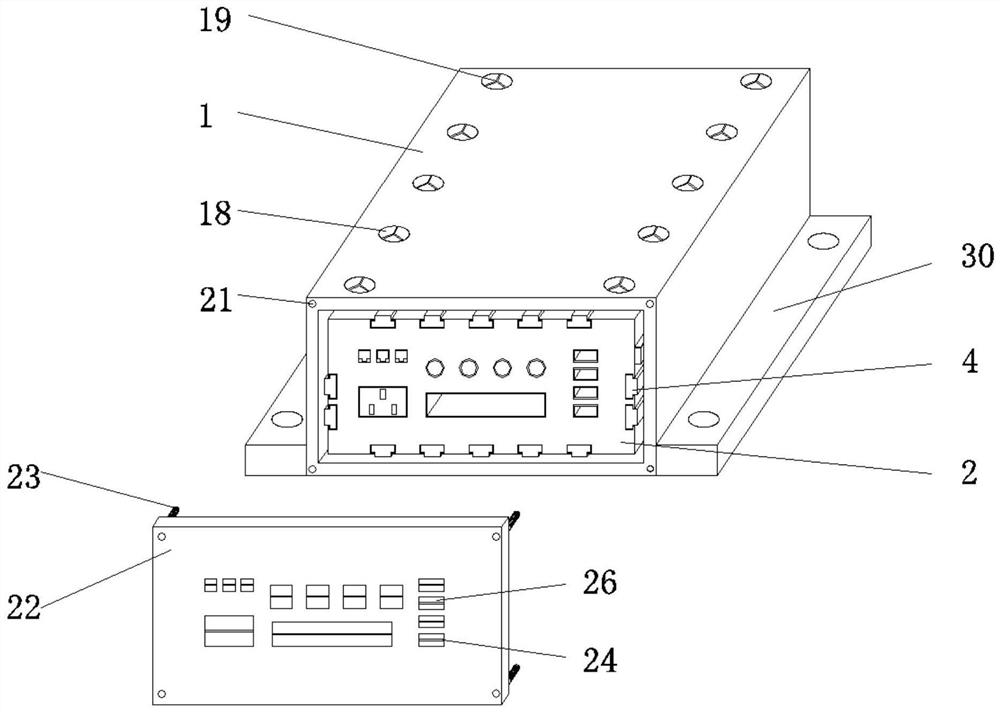

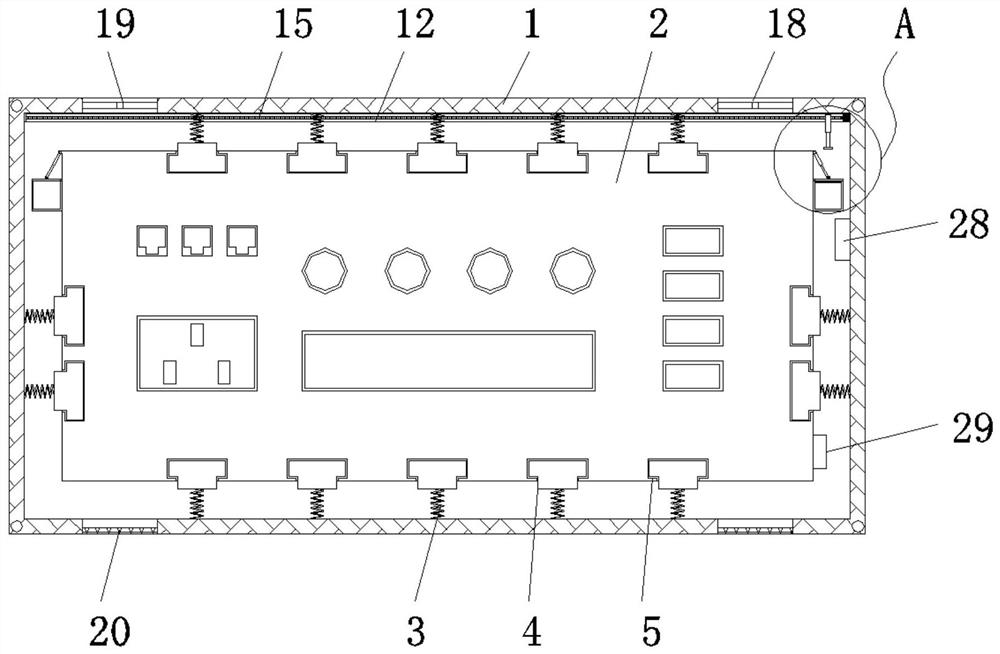

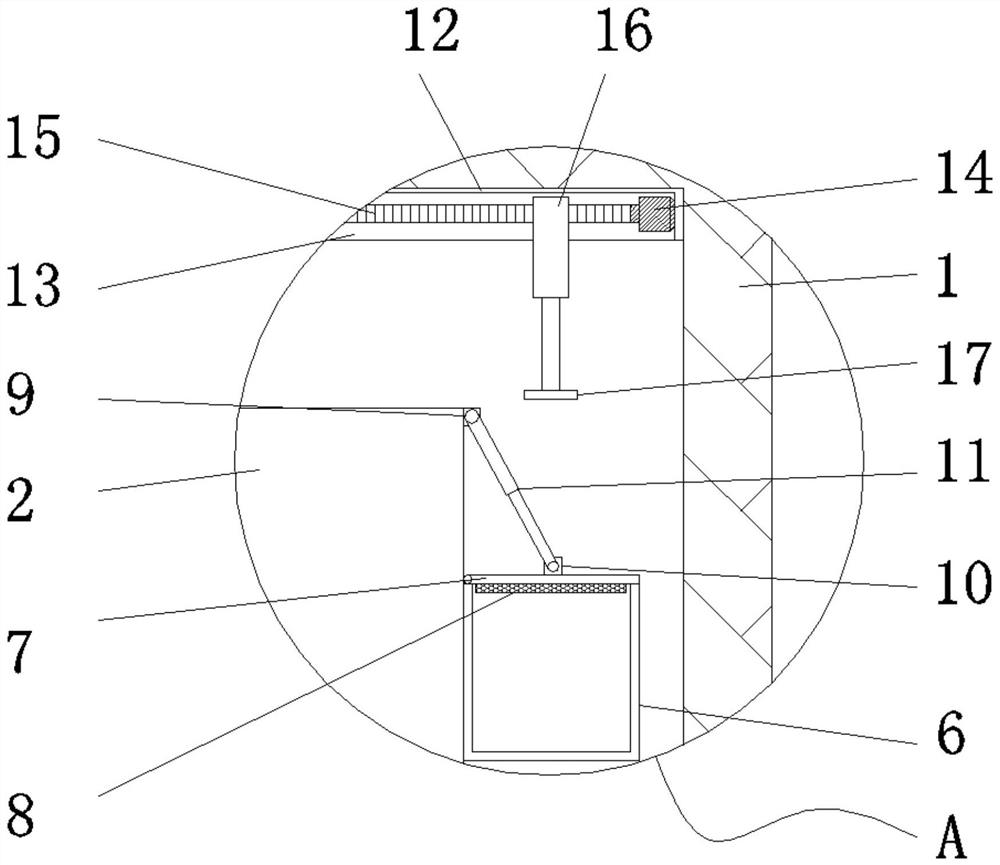

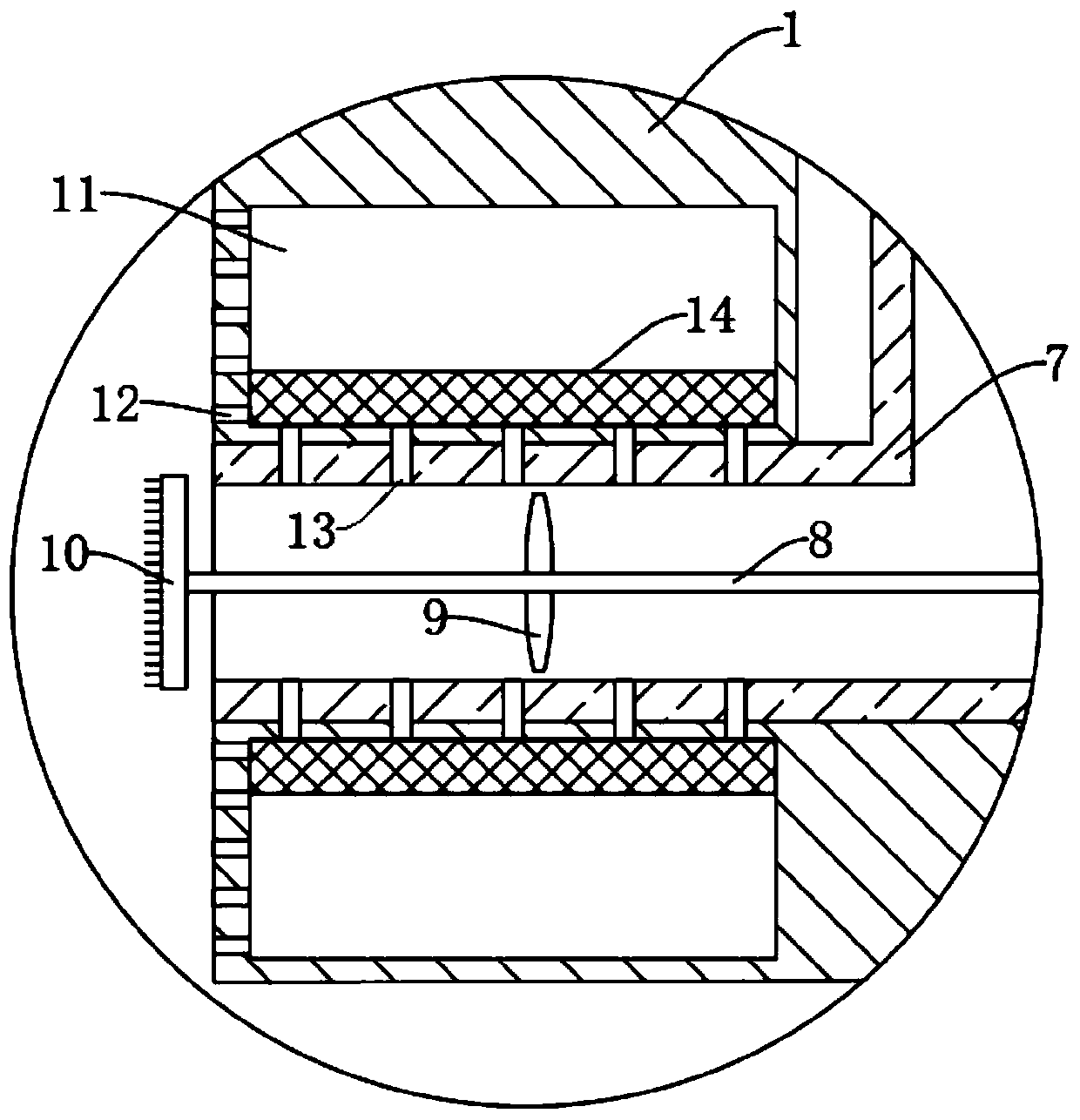

Vehicle-mounted server equipment structure

InactiveCN113721722AHigh-efficiency ventilation and exhaust effectRapid cooling treatmentCasings/cabinets/drawers detailsDigital processing power distributionIn vehicleElectric machinery

The invention relates to the technical field of vehicle-mounted servers, and discloses a vehicle-mounted server equipment structure. The vehicle-mounted server equipment structure comprises a protective shell and a main body, the protective shell is of a hollow cuboid structure with an opening in the front surface, a plurality of springs are fixedly connected to the inner side wall of the protective shell, and sliding blocks are fixedly connected to the ends, away from the protective shell, of the springs; a plurality of sliding grooves are formed in the outer side wall of the main body, the sliding blocks are located in the sliding grooves and are in sliding connection with the sliding grooves, a gap is reserved between the main body and the protective shell, the higher-efficiency ventilation and exhaust effect is achieved through a fan, a containing box is fixed to the outer side of the main body, and disinfection alcohol is contained in the containing box; and the sealing cover can be opened and closed through the first telescopic rod, the cleaning cotton and disinfection alcohol are soaked through the second telescopic rod, the motor drives the threaded rod to rotate so as to drive the second telescopic rod to move, the cleaning cotton makes contact with the main body, and rapid cooling treatment is achieved.

Owner:潘圣凯

Electric arc spraying device for machining

InactiveCN110791724AAffect the spraying effectRapid cooling treatmentMolten spray coatingCold airEngineering

The invention discloses an electric arc spraying device for machining. The electric arc spraying device comprises a spray gun body, wherein two contact tubes are mounted in the spray gun body, metal wires are arranged in the contact tubes, a vortex tube is embedded in the spray gun body, a cold air tube and a hot air tube are mounted on the upper side and the lower side of the vortex tube respectively, besides, the air outlet end of the hot air tube is located between the two metal wires, a guide tube communicating with inside of the hot air tube is fixedly connected with the lower end of thehot air tube, a rotating shaft is rotationally connected onto an inner wall of the guide tube, and multiple axial flow blades are fixedly connected with a side wall of the rotating shaft. When the spray gun performs spraying from top to bottom, the guide tube located at the lower part can guide out hot air flow, a to-be-sprayed surface of a workpiece can be subjected to preheating and warming treatment in advance, the condition that the spraying effect is affected due to temperature reduction of the workpiece in a process of waiting for spraying can be effectively prevented, a coating formed after spraying can be rapidly cooled by the cold air tube located at the upper part, and the spraying efficiency is increased.

Owner:何洋洋

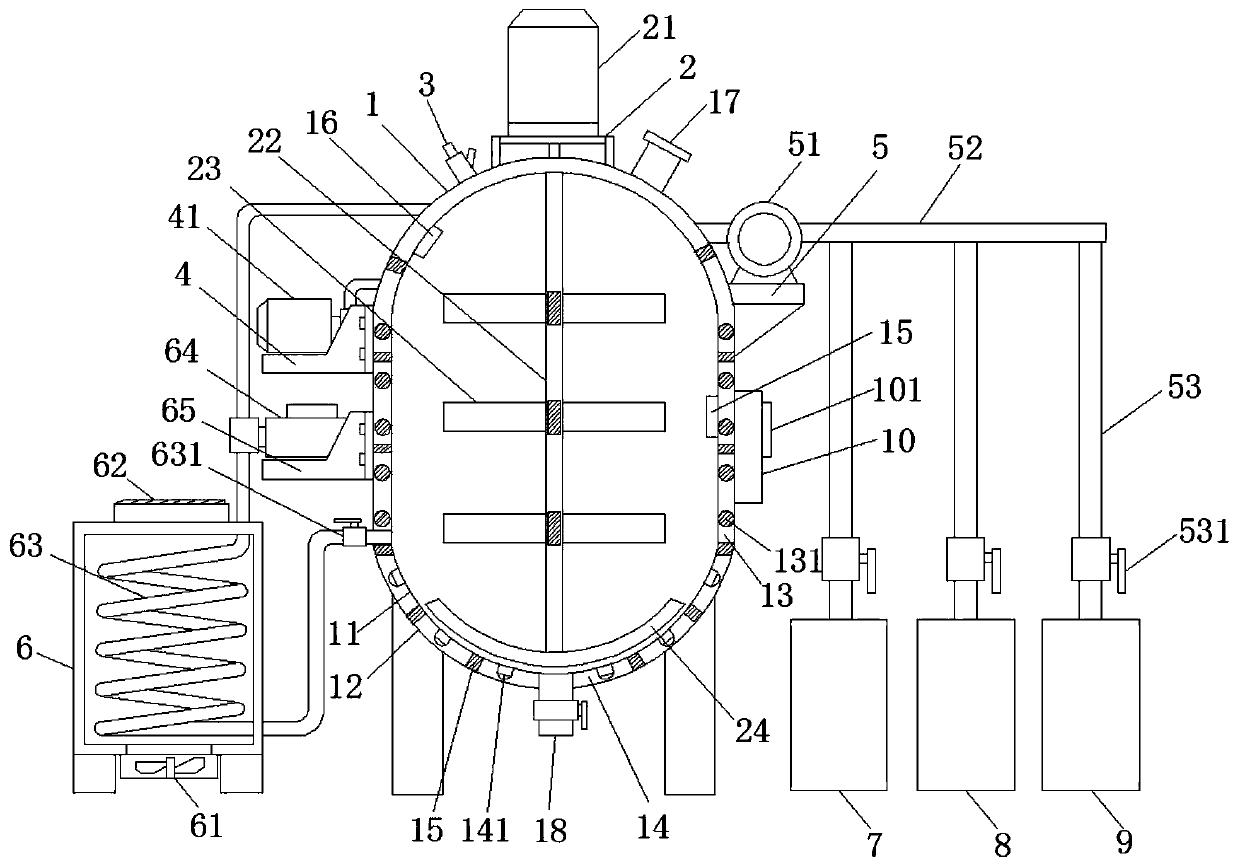

Efficient dental denture production centrifugal casting machine

ActiveCN109702166AIncrease in efficiencyImprove casting efficiencyArtificial teethDenturesTime delays

The invention discloses an efficient dental denture production centrifugal casting machine, which includes a protective cylinder with an opening on the upper side. The axis of the bottom wall in the protective cylinder is rotatably connected with a rotating cylinder body through a plane bearing, the lower end of the rotating cylinder body is provided with a driving mechanism, and the upper end ofthe rotating cylinder body is internally provided with a molten cavity; and the rotating cylinder body is provided with an annular heating cavity on the outer side of the molten cavity, an electromagnetic coil is wound on the inner wall of the heating cavity, and a feeding hopper is arranged at the upper end of the rotating cylinder body. The efficient dental denture production centrifugal castingmachine has the advantages that a solid alloy located in the molten cavity is heated and melted into a liquid alloy through the electromagnetic coil, central heating is conducted, under driving of adriving mechanism and the action of centrifugal force, a time-delay self-closing valve is opened, and in the time-delay process, the liquid alloy is thrown into an embedding ring in a casting base tocomplete casting; and one casting operation can complete casting of multiple dentures, compared with casting only one at a time in traditional techniques, the number of primary efficiency is increased, and the casting efficiency is greatly improved.

Owner:BINZHOU POLYTECHNIC

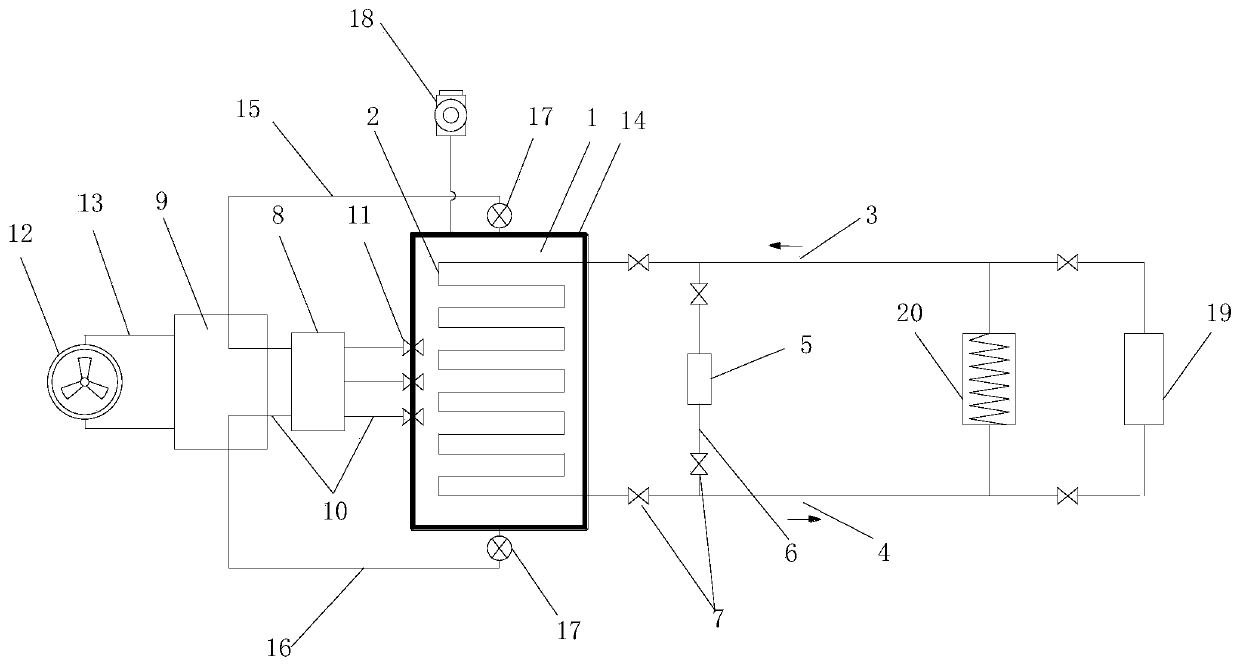

Air conditioner temperature adjustment-control unit utilizing high-pressure and low-pressure conversion

PendingCN109812901ALow boiling pointRapid cooling treatmentMechanical apparatusLighting and heating apparatusBoiling pointEngineering

The invention relates to the technical field of air conditioners, and specifically relates to an air conditioner temperature adjustment-control unit utilizing high-pressure and low-pressure conversion. The air conditioner temperature adjustment-control unit utilizing high-pressure and low-pressure conversion comprises a low-pressure bucket, a high-pressure bucket and a first heat exchanger, wherein a refrigerant water pipe is arranged in an inner cavity of the low-pressure bucket; and the refrigerant water pipe is installed in the inner cavity of the low-pressure bucket and bent in S shape. The adjustment-control unit is externally provided with a refrigerant water inlet pipe and a refrigerant water outlet pipe; a water inlet end of the refrigerant water pipe is connected with the refrigerant water inlet pipe; a water outlet end of the refrigerant water pipe is connected with the refrigerant water outlet pipe; and a plurality of water conveying pipes used for connection are arranged among the low-pressure bucket, the high-pressure bucket and the first heat exchanger. According to the air conditioner temperature adjustment-control unit utilizing high-pressure and low-pressure conversion, through system vacuumizing, the boiling point of a refrigeration solution is lowered in a vacuum environment, and the solution is vaporized and absorbs heat, so that the effect of rapid and efficient refrigeration is achieved; and energy-saving and environment-friendly overall working, and high safety are achieved.

Owner:陈国锋

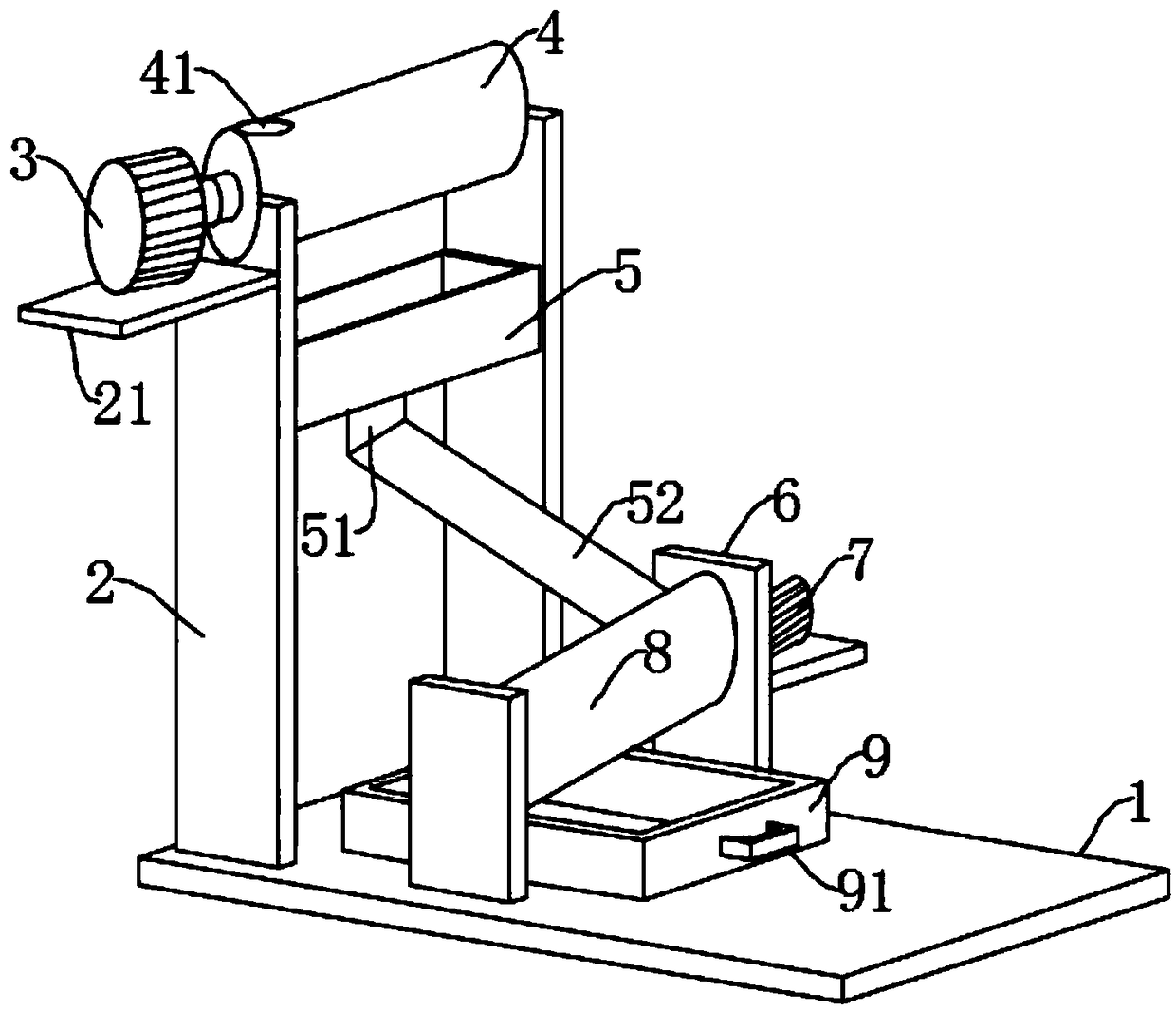

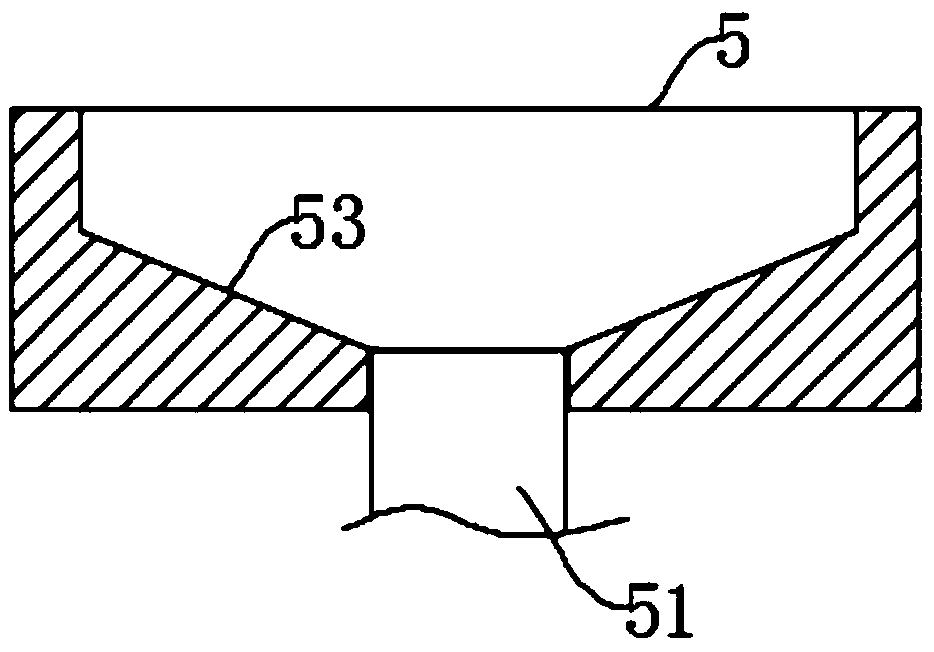

Blank moving device of blowing molding machine

The invention discloses a blank moving device of a blowing molding machine and belongs to the technical field of blowing molding machines. The blank moving device of the blowing molding machine comprises a base plate, a supporting frame and a box. A motor is arranged on the sidewall of the box. The output end of the motor is connected with a first rotary shaft. The first rotary shaft is connectedwith a cam and a first rotary disk. The first rotary disk is provided with a shifting tooth. The sidewall of the box is rotatably connected with a second rotary shaft. A driving wheel and a second rotary disk are arranged on the second rotary shaft. The second rotary disk is provided with a shifting groove matched with the shifting tooth. A driven wheel is further arranged on the base plate. A conveyor belt is connected between the driving wheel and the driven wheel. A piston is arranged in the box. The piston is connected with a connecting rod. The blank moving device is simple in structure and convenient to operate, can automatically move away blowing molded products through cooperation of the cam and the first rotary disk and can also implement rapid cooling treatment on the blowing molded products, and the working efficiency is greatly improved.

Owner:李旭燕

Feed processing device for livestock breeding

InactiveCN108741198AStir wellGood dispersionFeeding-stuffRotary stirring mixersCold airLivestock breeding

The invention discloses a feed processing device for livestock breeding. The feed processing device comprises a base; a support plate is fixedly arranged on the side wall of the upper part of one sideof a first mounting rack; a motor is fixedly arranged in the middle position of the top surface of the support plate; a stirring shaft is fixedly connected with an output shaft of the motor; spiral stirring blades are fixed on the outer wall of the stirring shaft positioned in a stirring barrel; a receiving tank is fixedly arranged on the side wall of the first mounting rack below the stirring barrel; the middle position of the bottom of the receiving tank communicates with a discharge pipe; the discharge pipe communicates with a conveying pipe; the other end of the conveying pipe communicates with the upper part of the side wall of one end of a cooling barrel; an air-conditioner is fixedly arranged in the middle position of the top surface of a bracket fixedly connected with the upper part of the outer wall of a second mounting rack; the air-conditioner communicates with a cold air pipe; the other end of the cold air pipe penetrates through the side wall of the second mounting rack and is positioned in the cooling barrel; and a collecting tank is movably placed on the top surface of the base below the cooling barrel. The feed processing device disclosed by the invention can perform quick cooling on feed to be convenient for later bagging.

Owner:东至县雨庭畜禽有限公司

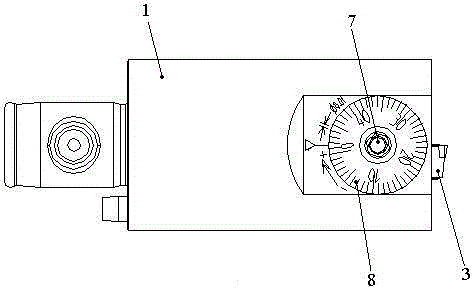

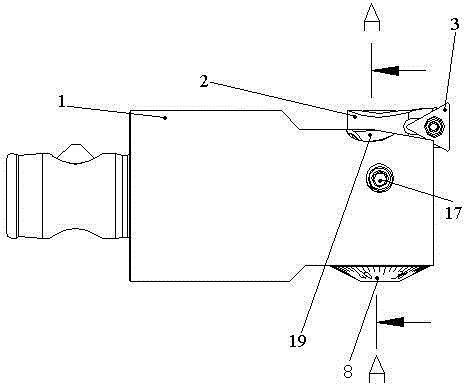

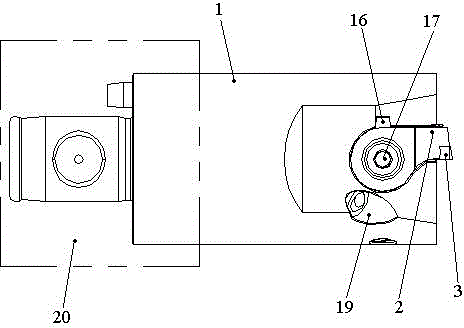

Adjustable fine boring cutter

The invention relates to an adjustable fine boring cutter. The adjustable fine boring cutter comprises a cutter body, a cutter bit and a blade. A combining hole is formed in the head of the cutter body and provided with an internal thread at one end. A positioning plate, a fine adjustment screw and a dial are arranged on the head of the cutter body, an external thread is arranged on the positioning plate and meshed with the internal thread in the combining hole, and the positioning plate and the cutter body are fixed through a bonding agent. A threaded sleeve is arranged in the combining hole, one end of the threaded sleeve is connected with a copper nut through threads, and the threaded sleeve is meshed with insection of an insection groove in the end face of the cutter bit. An axial locking nut is arranged on the outer side of the cutter bit, sequentially penetrates through the cutter bit and the threaded sleeve and fixes the cutter bit and the threaded sleeve. One end of the fine adjustment screw is connected with the dial, and the other end of the fine adjustment screw is meshed with the copper nut through threads matched accurately. The fine boring cutter is high in rigidity, strength and cutting performance, the working radius can be finely adjusted fast, the boring cutting accuracy and the working efficiency can be improved, and the service life of the fine boring cutter is ensured.

Owner:成都成林数控刀具股份有限公司

Cutting device for nonferrous metal alloy material research and application method

InactiveCN110756878AFast and accurate cooling treatmentAvoid heating upShearing machinesMaintainance and safety accessoriesMetal alloyNonferrous metal

The invention discloses a cutting device for nonferrous metal alloy material research and an application method. The cutting device comprises a cutting device main body, a cutting fixed module and a liquid nitrogen storage tank; and cutting support frames are spirally fixed in the symmetric positions on the two sides of the top of the cutting device main body. In the cutting device, the liquid nitrogen storage tank is mounted at the bottom of the cutting device main body, and can be matched with a liquid nitrogen pump and a liquid nitrogen vaporizer to spray liquid nitrogen during cutting of nonferrous metal alloy materials, so that the quick cooling of liquid nitrogen in vaporization is realized, and the oxidation of the nonferrous metal alloy materials caused by heat generated during cutting of the nonferrous metal alloy materials is prevented; air blowing fan blades are symmetrically arranged on the two sides of a cutting disc on a metal cutting head; when a rotating shaft drives the cutting disc for rotary cutting, the air blowing fan blades can be driven to rotate at the same time; and air is blown to the two sides of the cutting disc through heat dissipation by air blowing, so that the targeted blowing of the liquid nitrogen to the two sides of cutting positions of the nonferrous metal alloy materials is realized, and the cooling effect is further improved.

Owner:CHANGDE FEIERMEI CHEM TECH CO LTD

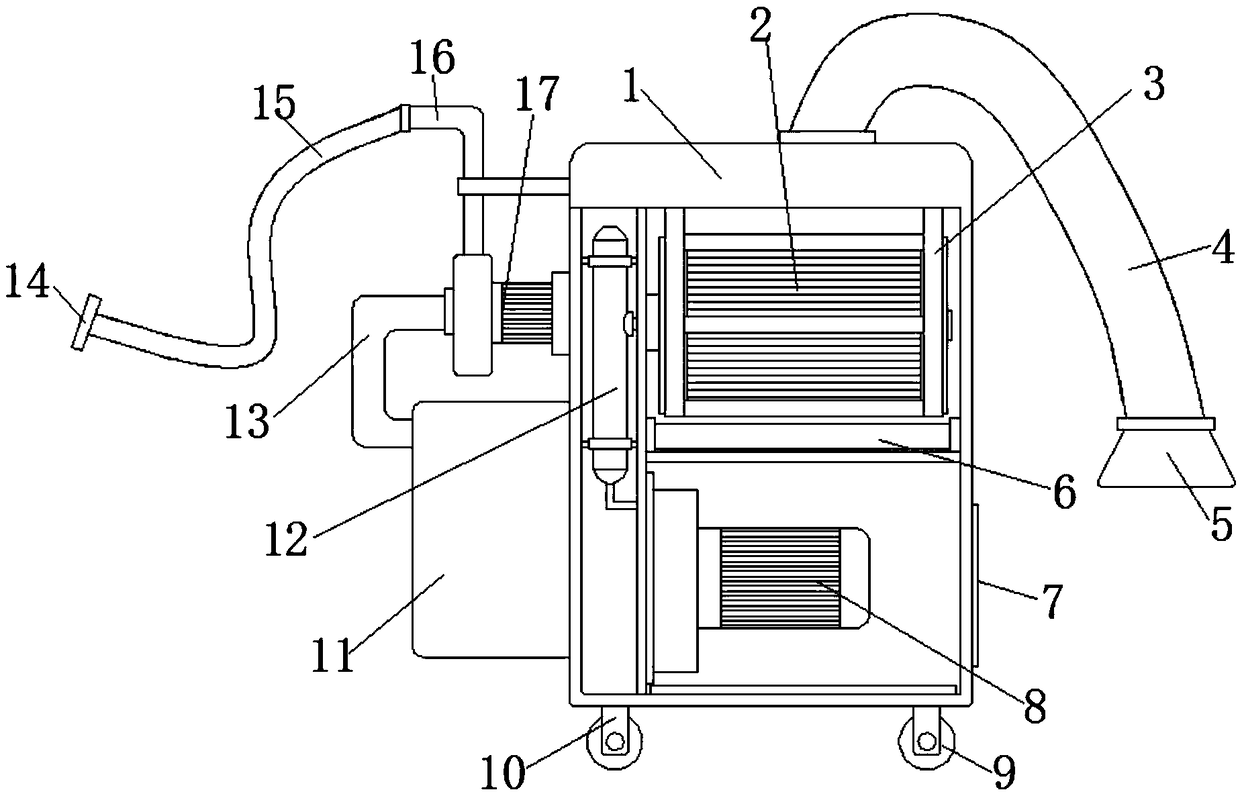

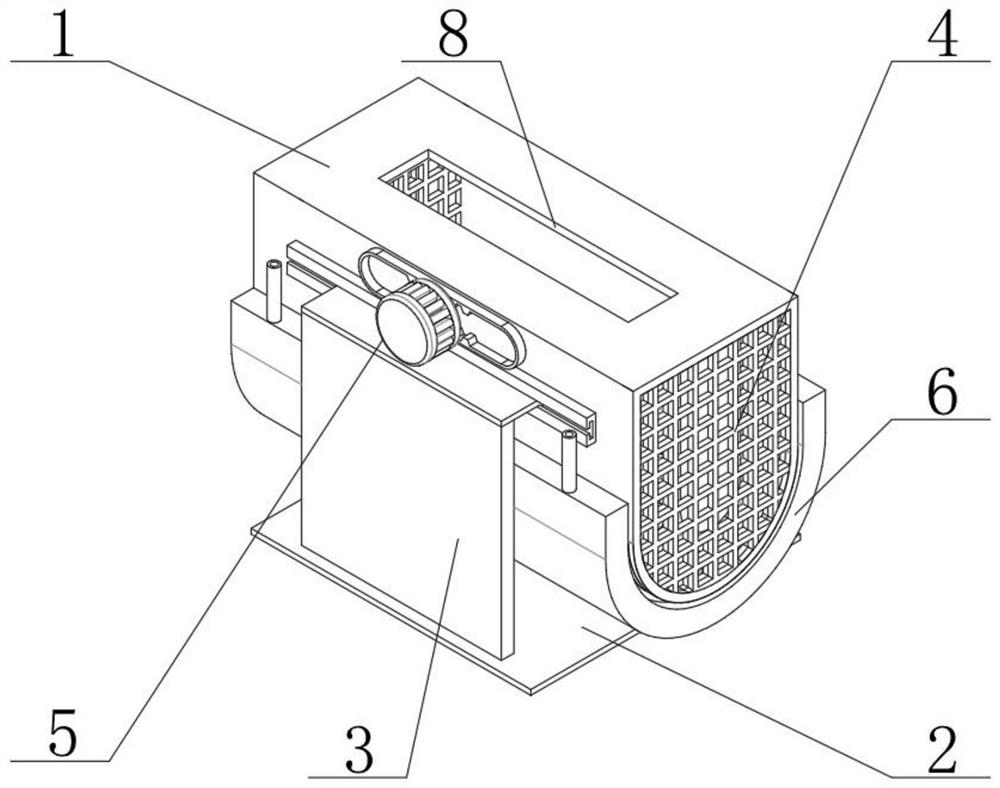

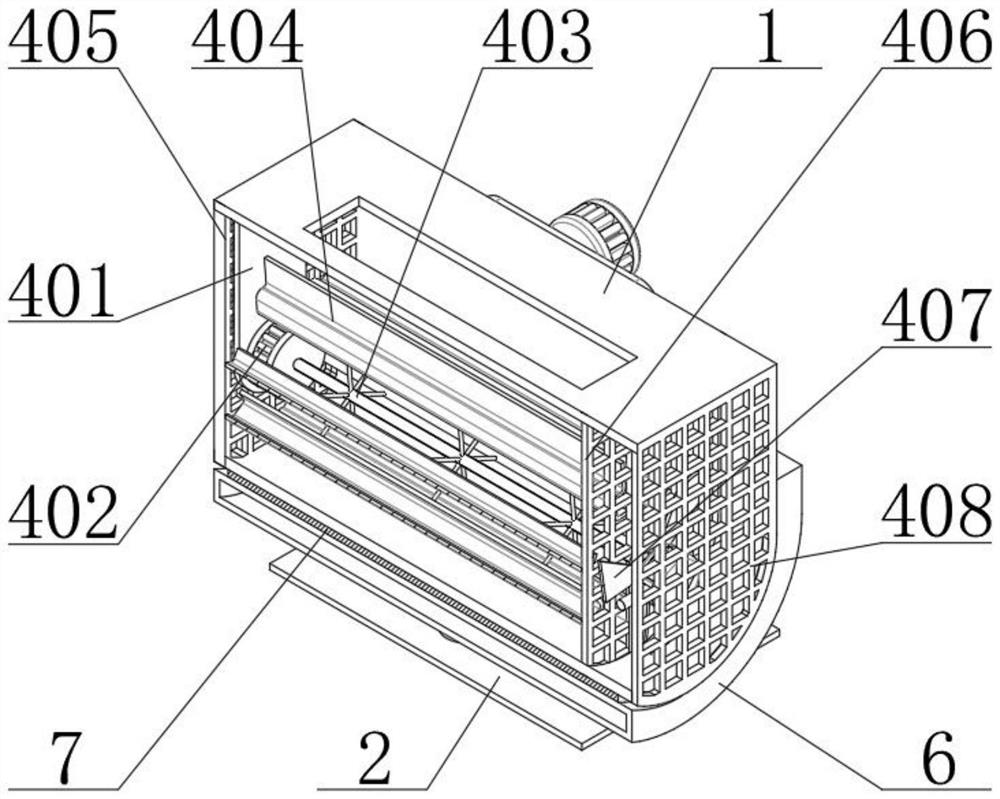

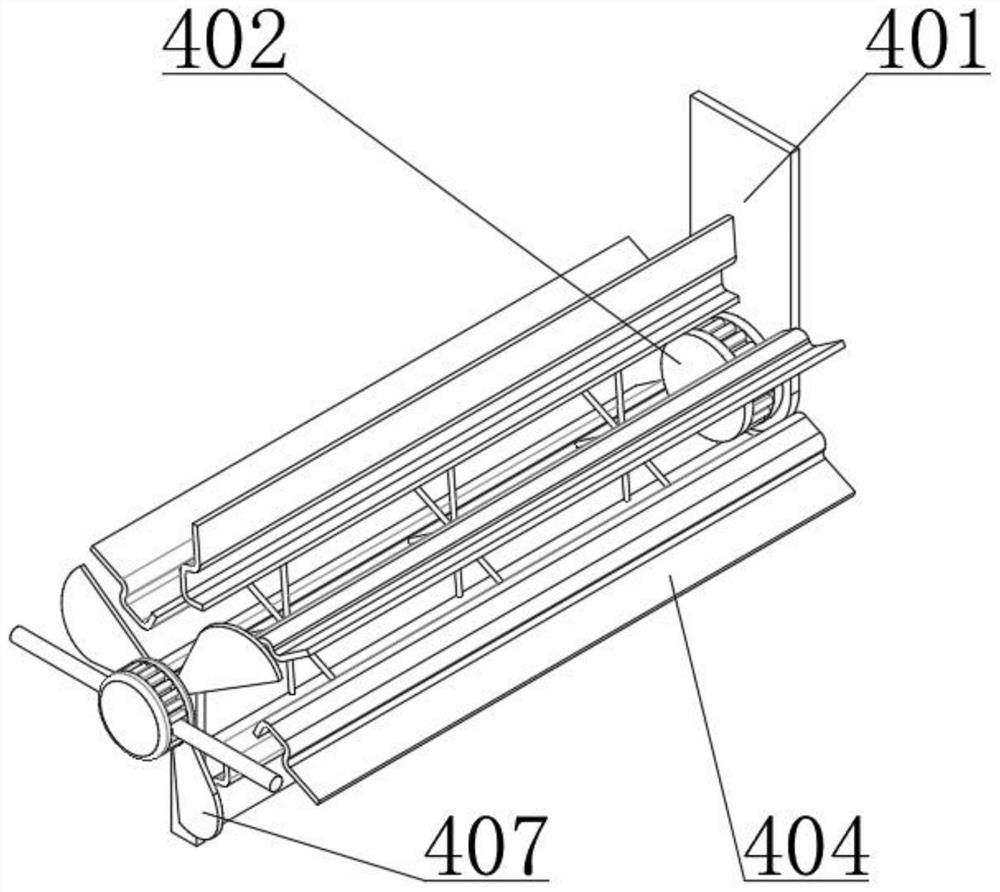

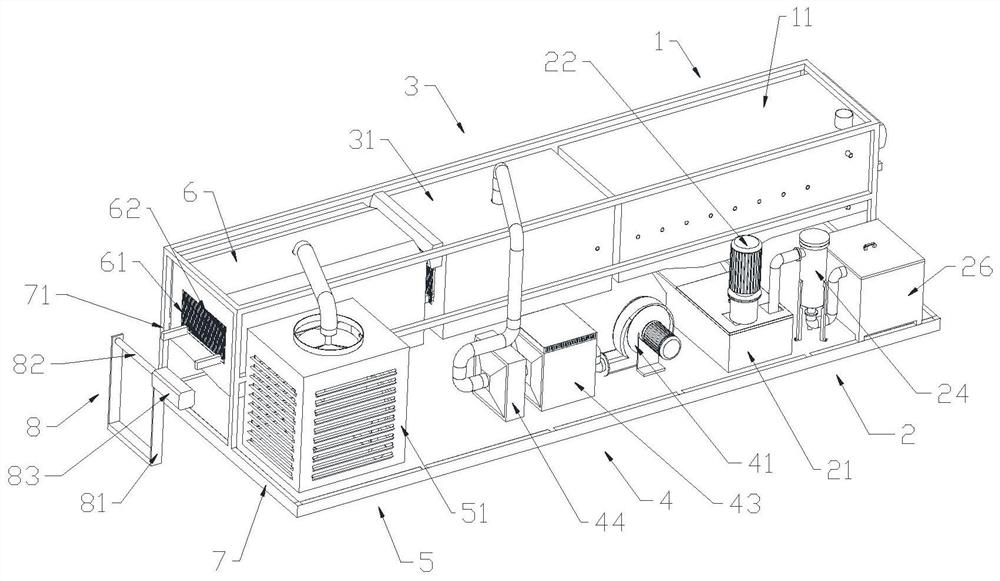

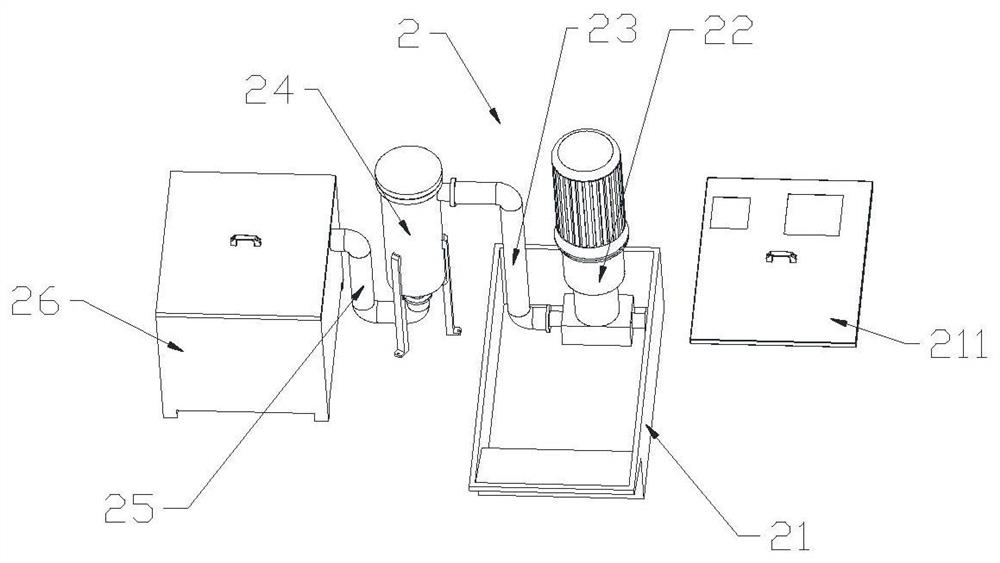

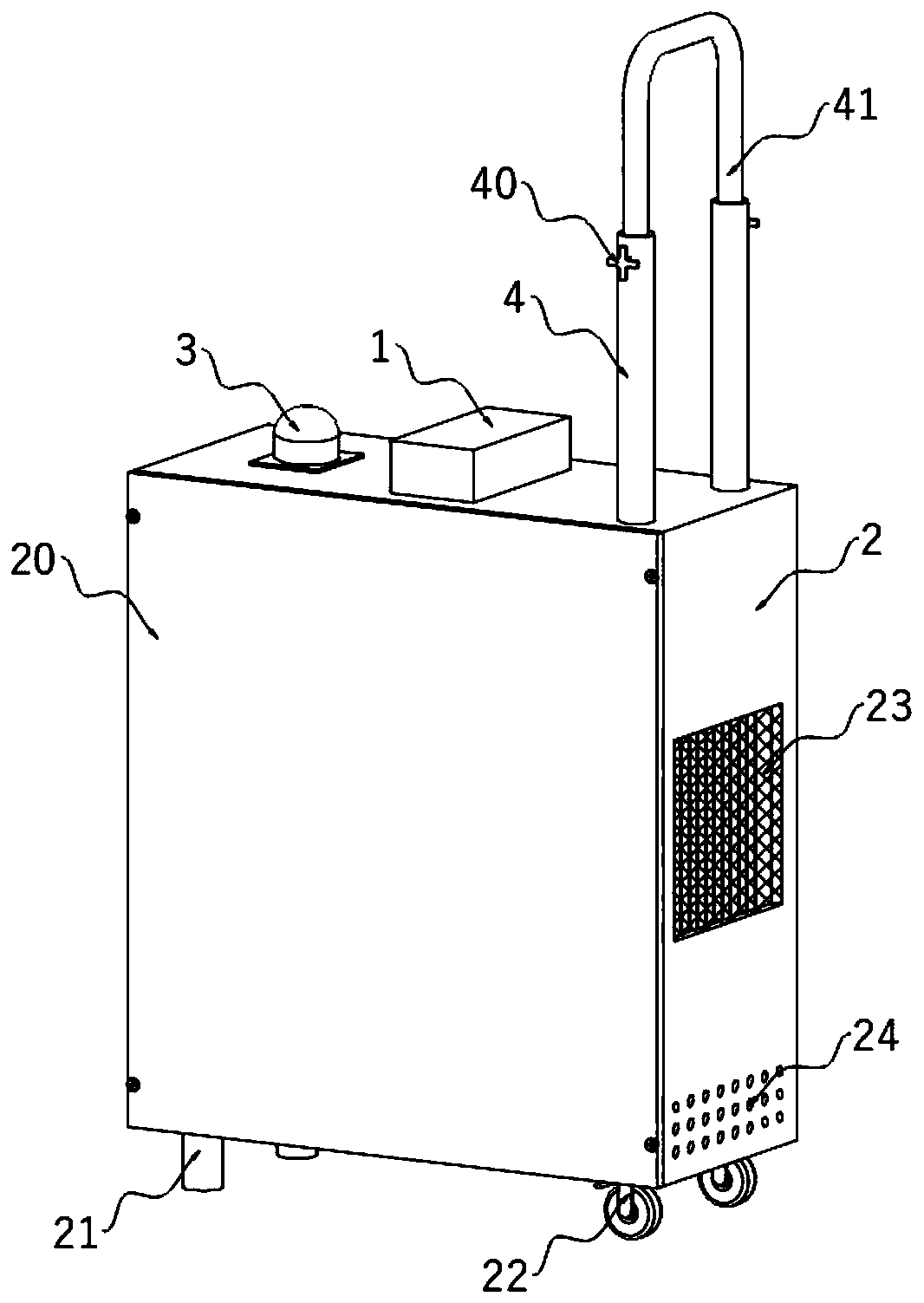

Welding smoke purifier

InactiveCN108771927AImprove functionalityRapid cooling treatmentCombination devicesGas treatmentAgricultural engineeringHigh pressure water

The invention discloses a welding smoke purifier. The welding smoke purifier comprises a purifier main body, the purifier main body has a built-in purifying filter cartridge, an air pocket assembly and a fan, the purifying filter cartridge is fixed on the inner wall of the purifier main body through a hanger, an air outlet is also provided at the lower end of the purifier main body, an air suctionarm is connected to the upper end of the purifier main body, a water tank is fixedly connected with one side of the purifier main body, a water inlet pipe is communicated to the upper end of the water tank, a high-pressure water pump is also fixedly mounted on the side wall of the water tank, the water inlet of the high-pressure water pump is connected with the water inlet pipe, the water outletof the high-pressure water pump is connected with a water outlet pipe, the water outlet pipe is fixed on one side of the purifier main body, a hose is connected to the water outlet pipe, and a nozzleis connected to the end of the hose. The welding smoke purifier solves the problem that the current small welding smoke purifier has a single function and is difficult to meet the needs of the user.

Owner:合肥炫升环保材料科技有限公司

Cutting equipment for automobile bearing production

InactiveCN112045249AFast fix processingStable supportMetal sawing devicesMetal sawing accessoriesStructural engineeringMechanical engineering

The invention belongs to the technical field of automobile bearing production, particularly relates to cutting equipment for automobile bearing production, and provides the following scheme for solving the problems that most of cutting devices for traditional bearing production are simple in structure, the fixing effect for bearing barrel material production is common, and the subsequent cutting quality is prone to being affected. The cutting equipment comprises a fixed barrel; supporting legs are vertically welded to the four corners of the outer portion of the bottom of the fixed barrel correspondingly, the opposite sides of the inner walls of the two ends of the fixed barrel are rotatably connected with a driving threaded rod and a driven threaded rod through bearings correspondingly, and one end of the driving threaded rod and one end of the driven threaded rod are connected with a same moving block through threads; and a hydraulic rod is fixed to the outer wall of the bottom of the moving block through a bolt. The cutting equipment for the automobile bearing production provided by the invention can be matched with a one-way air valve to inflate a fixed barrel tube, so that high pressure is generated in the fixed barrel tube, a sliding abutting rod and an arc-shaped abutting block abut against a barrel material, and anti-skid stripes are matched to achieve rapid fixing treatment on the barrel material.

Owner:吕旭盼

Non-standard automatic machining drilling device

InactiveCN108927540ASave placement timeImprove work efficiencyLarge fixed membersMaintainance and safety accessoriesLiquid storage tankWorkbench

The invention discloses a non-standard automatic machining drilling device comprising a base. A vertical board is fixedly installed on the upper surface of the base; a slide rail is arranged at the position, close to the front of the vertical board, of the upper surface of the base; a slide block is installed at the position, corresponding to the interior of the slide rail, of the upper surface ofthe base; a fixing board is installed at the position, close to one side of the slide rail, of the upper surface of the base; and a dust suction pipe is arranged on the front surface of the verticalboard. The structure is simple, operation is convenient, a worker can take down a drilled workpiece during drilling through sliding of a workbench and put on a new workpiece in time, the workpiece placement time is shortened, the drilling work efficiency is greatly improved, a dust filter box collects waste scraps, resources can be recycled, the utilization rate of the resources is improved, a cooling liquid storage tank can rapidly cool the workpiece and a drill bit, the service life of the drill bit is prolonged, and damage of the workpiece due to high temperature is also avoided.

Owner:芜湖若科自动化科技有限公司

Feed storage automatic temperature control system

PendingCN114013810ARealize temperature controlReduce energy consumptionContainers for heating foodContainers preventing decayEngineeringMoisture sensor

The invention discloses a feed storage automatic temperature control system. A first fan is arranged on the upper surface of a storage box, a heating chamber and a cooling chamber are mounted on the two sides of the storage box from left to right respectively, a first moving plate is slidably mounted in the heating chamber, and a heating plate is arranged on the upper surface of the first moving plate; and a second moving plate is slidably installed in the cooling chamber, a cooling plate is arranged on the upper surface of the second moving plate, a controller is installed on the front surface of the box door, and a temperature sensor and a humidity sensor are installed on the inner side of the storage box from left to right. The stability of the interior of the storage box is monitored through the temperature sensor, when the temperature is too high, the controller controls the cooling plate to conduct refrigeration through the cable, the storage chamber can be rapidly cooled, when the temperature is too low, the controller controls the heating plate to conduct heating through the cable, and the storage box can be heated. Therefore, the automatic temperature control is effectively realized.

Owner:大理州大台农台标饲料有限公司

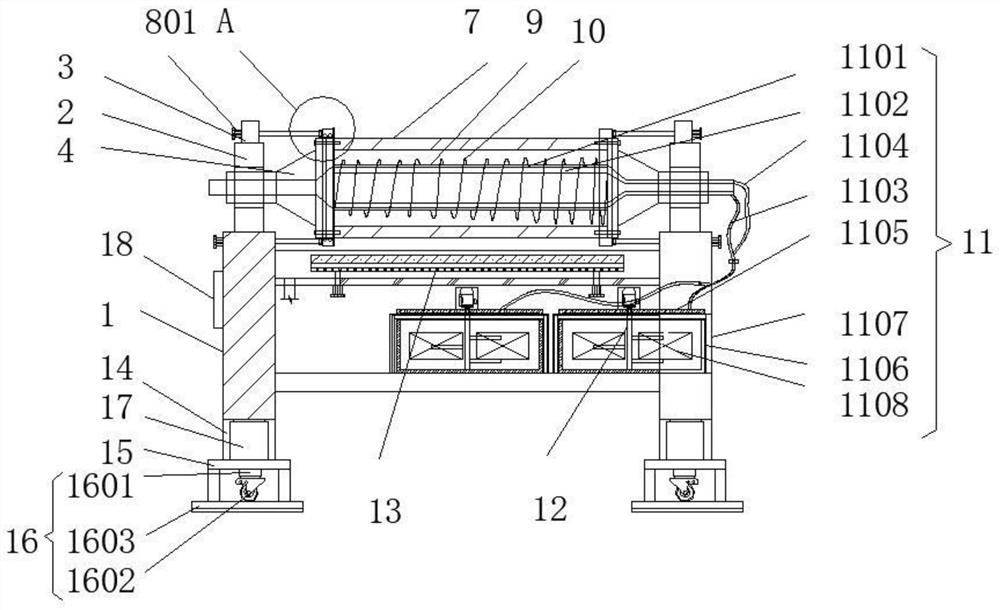

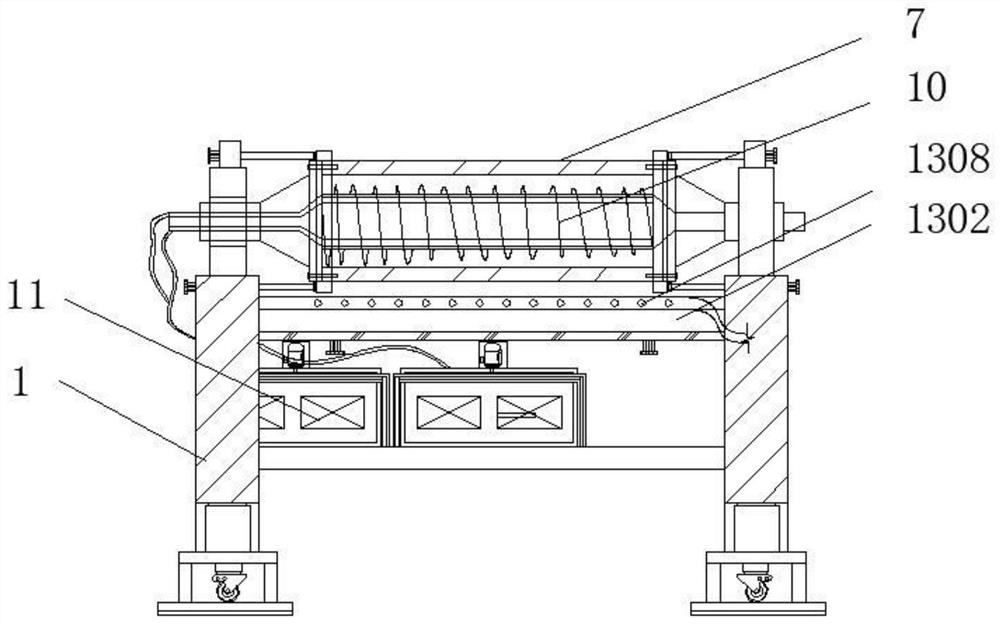

Tea frying machine

PendingCN113812470AFried evenlyImprove Flip EffectPre-extraction tea treatmentCooling/ventilation/heating modificationsElectric machineryTea leaf

The invention relates to the technical field of tea production, in particular to a tea frying machine which comprises a box body, a bottom plate, a supporting frame, a uniform tea frying device, a uniform swinging device and a cooling device, an electric heating plate is fixedly connected to the outer side of the bottom end face of the box body, a feeding port is formed in the top end face of the box body, the uniform tea frying device is installed on the inner side of the box body, the uniform tea frying device comprises a motor frame, a tea frying motor, a transmission shaft and frying plates, the motor frame is fixedly connected to the inner side of the top end face of the box body, the tea frying motor is fixedly connected to one side of the motor frame, the transmission shaft is fixedly connected to the tail end of a main shaft of the tea frying motor, the frying plates are uniformly and fixedly connected to the outer side of the transmission shaft through connecting rods, the outer sides of the frying plates are slidably connected with the box body, and a grooves are formed in the inner sides of the frying plates, so that tea leaves can be stir-fried well, a good stirring effect on the tea leaves is ensured, the tea leaves are stir-fried more uniformly, and the quality of the stir-fried tea leaves is effectively ensured.

Owner:溆浦县金香农业开发有限公司

Cleaning and drying equipment for non-woven fabric production

InactiveCN112268419AReliable structureFunctionalDrying gas arrangementsDrying chambers/containersProcess engineeringWoven fabric

The invention discloses cleaning and drying equipment for non-woven fabric production. The cleaning and drying equipment for non-woven fabric production comprises a base, wherein a waste liquid treatment assembly is arranged on the base, a hot air assembly is arranged on one side of the waste liquid treatment assembly, a cold air assembly is arranged on one side of the hot air assembly, and the hot air assembly and the cold air assembly are also fixed to the base, a bracket is arranged on the base, a cleaning assembly is arranged in the bracket, a drying box assembly is arranged at one end ofthe cleaning assembly, a cooling box is arranged at one end of the drying box assembly, the drying box assembly and the cooling box are also fixed in the bracket, and a collecting assembly is arrangedat one end of the base. The cleaning and drying equipment for non-woven fabric production is reliable in structure and practical in function. Circulating water is adopted for cleaning, so that waterresources are saved to a great extent. The cleaning cost is effectively reduced, the cleaning and drying speed is high, a cooling structure is further arranged, non-woven fabric can be rapidly cooled,and non-woven fabric deformation caused by high temperature is prevented.

Owner:黄桂荣

Moisture-proof semi-buried transformer substation and moisture-proof method thereof

ActiveCN111064080AEnhanced convectionTimely exclusionSubstation/switching arrangement cooling/ventilationEnclosed substationsTransformerEngineering

The invention discloses a moisture-proof semi-buried transformer substation and a moisture-proof method thereof. The transformer substation comprises a double-layer moisture-proof box body, a hollow box bottom and a moisture-proof box top. A moisture-proof system is arranged in the hollow box bottom. The moisture-proof system comprises an air storage convection area arranged on the upper layer ofthe hollow box bottom, and a heat collection moisture-proof area which is arranged on the lower layer of the hollow box bottom. The air storage convection area and the heat collection moisture-proof area are separated by an insulating isolation plate. A semiconductor refrigerator is mounted on the insulating isolation plate. Each side plate of the heat collection moisture-proof area is provided with a heat conduction network pipe fixedly arranged between interlayers of the double-layer moisture-proof box body. The side plate of the air storage convection area is provided with an air inlet driving mechanism. A plurality of layers of evenly-distributed breathable grids are arranged in the air storage convection area from top to bottom, and a dehumidification moisture-proof bag is laid on thesurface of each layer of breathable grids. According to the scheme, the moisture-proof function and the heat dissipation function are combined into an integrated moisture-proof mechanism; the interior and the exterior of the transformer substation box body can be effectively dried; and a damp passage of the transformer substation box body is blocked.

Owner:GUANGDONG POWER GRID CO LTD +1

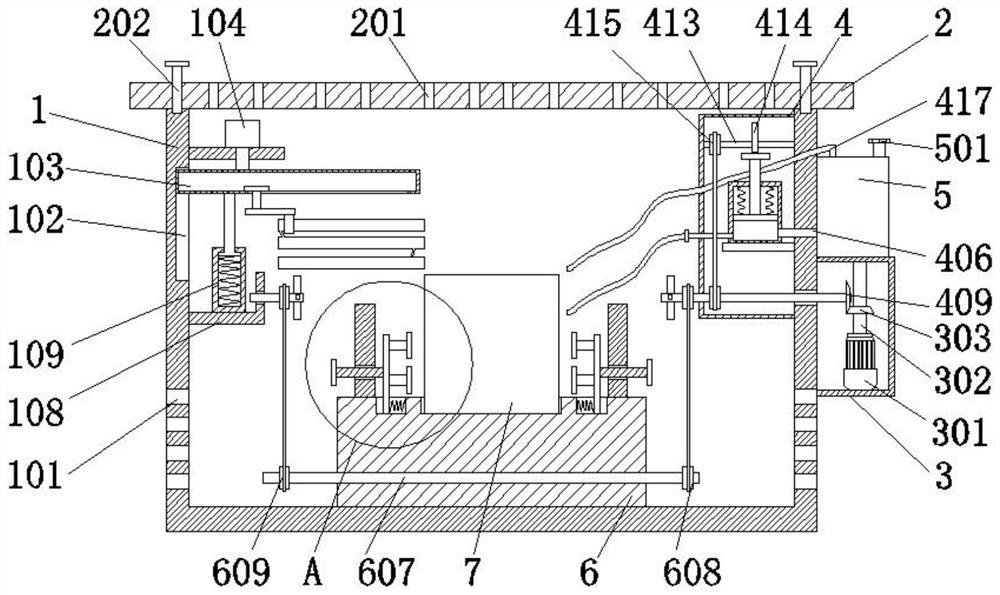

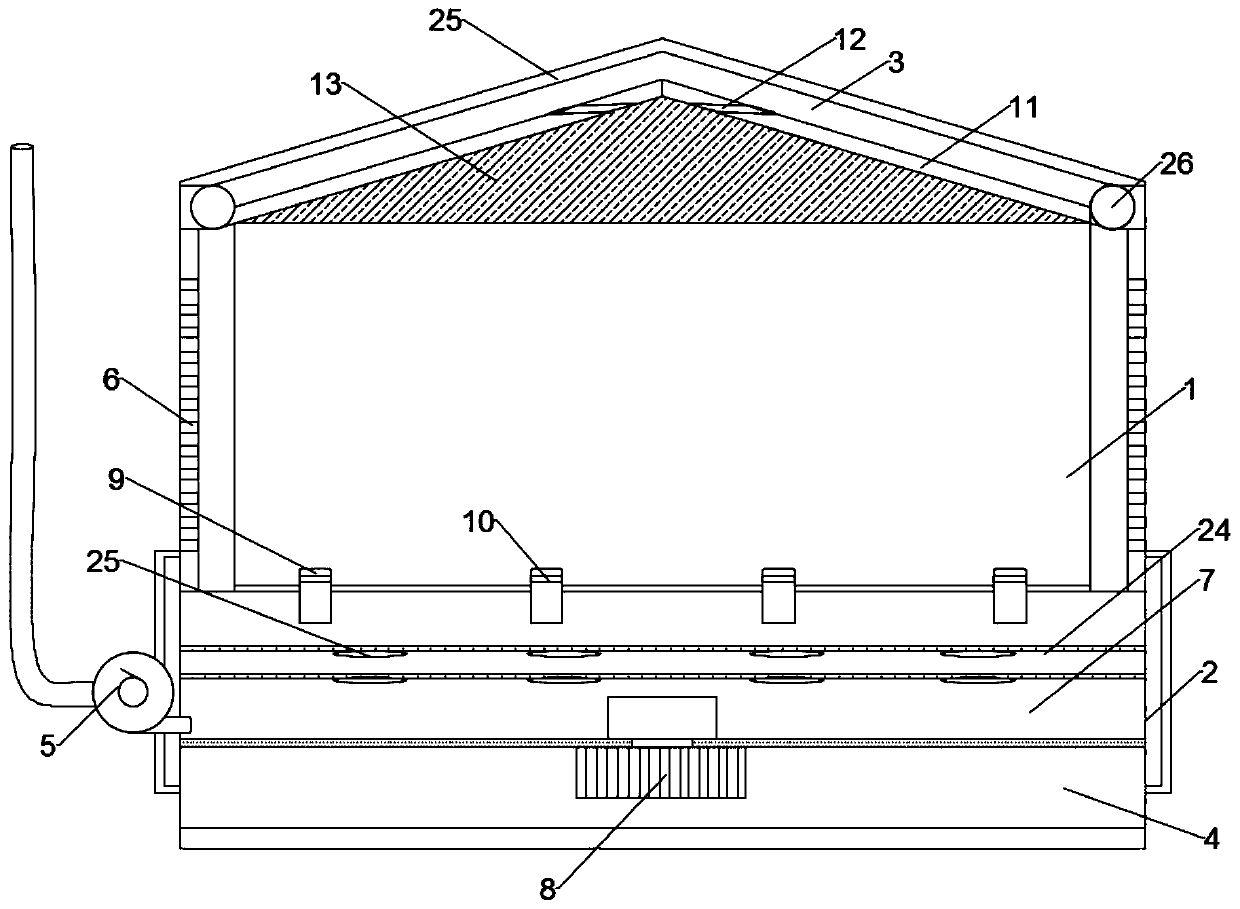

Metal heat treatment quenching system and quenching process

InactiveCN112853063AImprove continuityImprove stabilityFurnace typesProcess efficiency improvementMechanical engineeringMetal

A metal heat treatment quenching system comprises two sliding beams which are horizontally arranged in parallel, wherein the bottom of each sliding beam is mounted on the ground through two supporting beams, the opposite sides of the two transverse supporting beams are fixedly connected through a mounting strip, and the mounting strip is fixed to the ground through a mounting piece; a drive device slides on the two slide beams and moves left and right below the two slide beams in the horizontal direction, and the front side and the rear side of the drive device are fixedly connected to metal piece lifting mechanisms. According to the metal heat treatment quenching system disclosed by the invention, the drive device, the metal piece lifting mechanism, the heating device and the quenching device are arranged, the metal piece lifting mechanism adjusts the height of a metal piece, and the drive device can drive the metal piece to transversely move left and right, so that the metal pieces can be conducted more rapidly and continuously in each step, and the machining continuity, stability and flexibility of the whole system are improved.

Owner:江能军

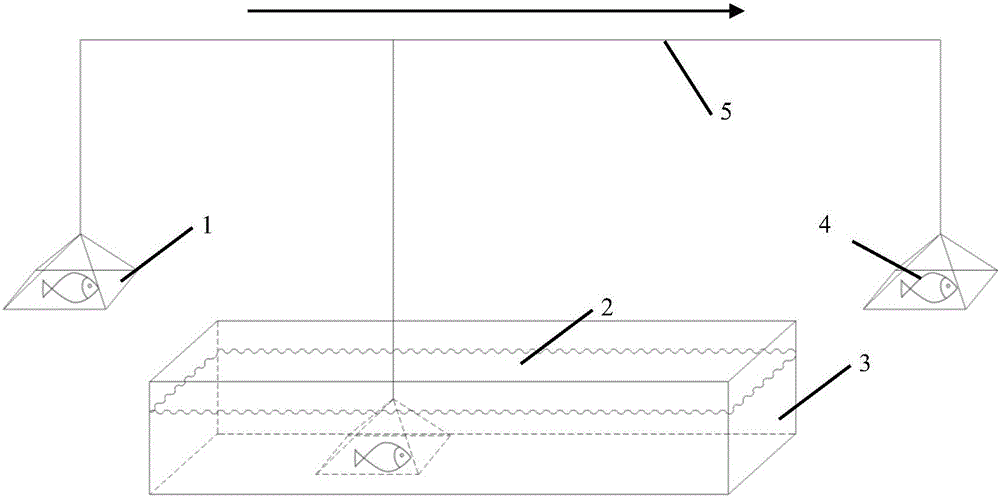

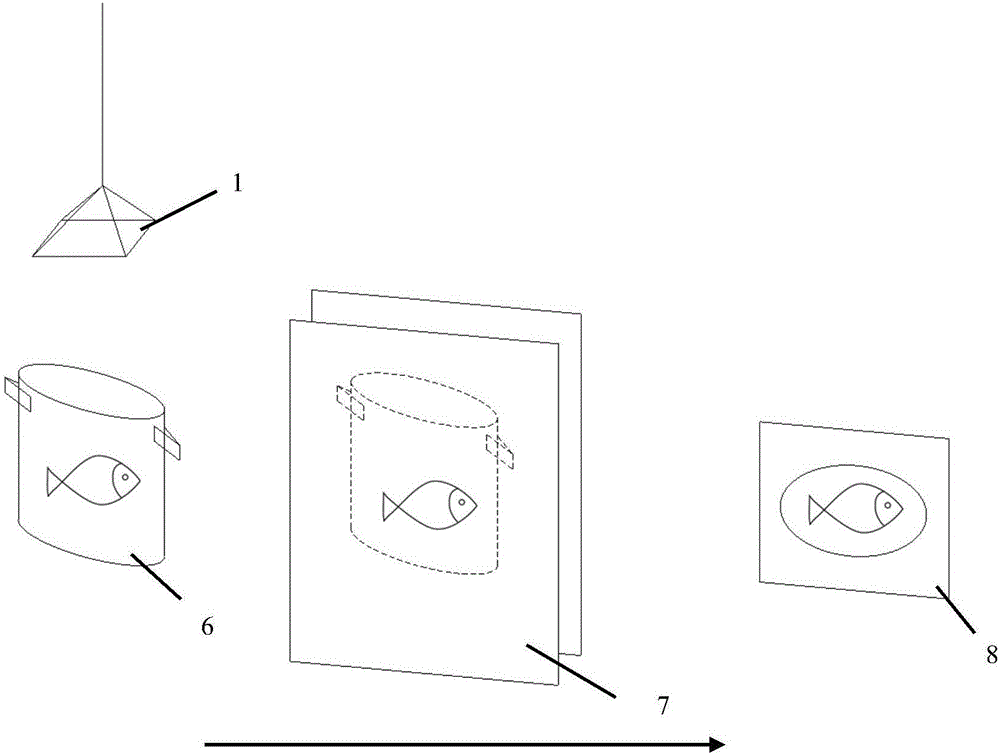

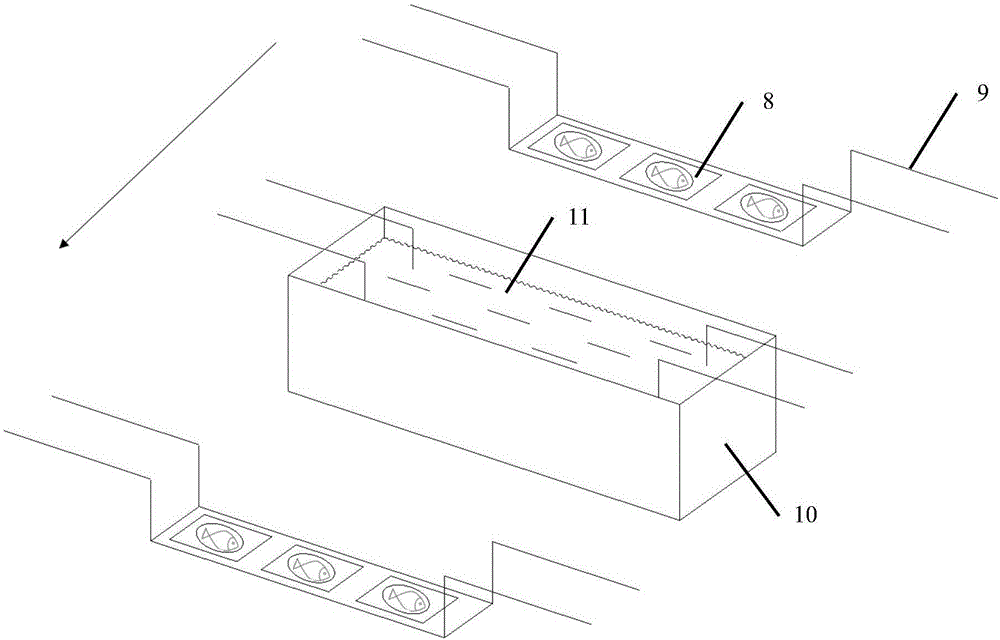

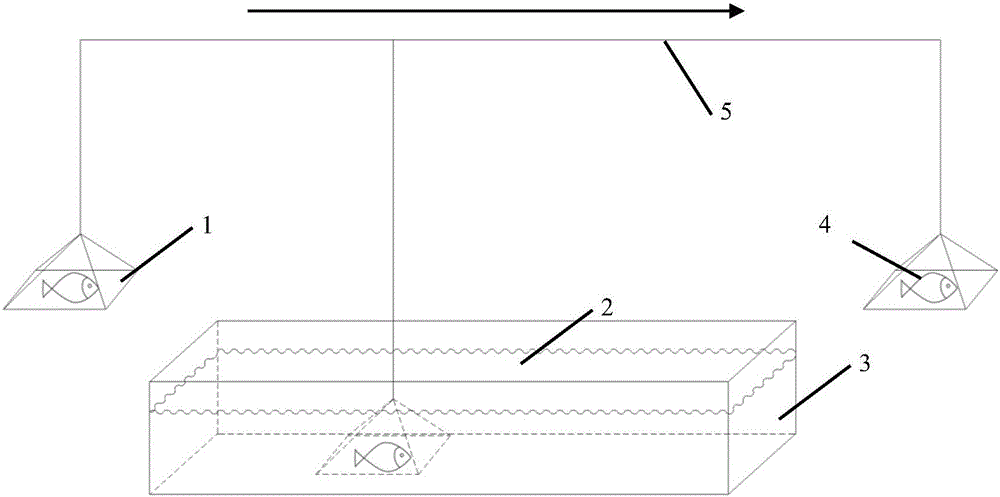

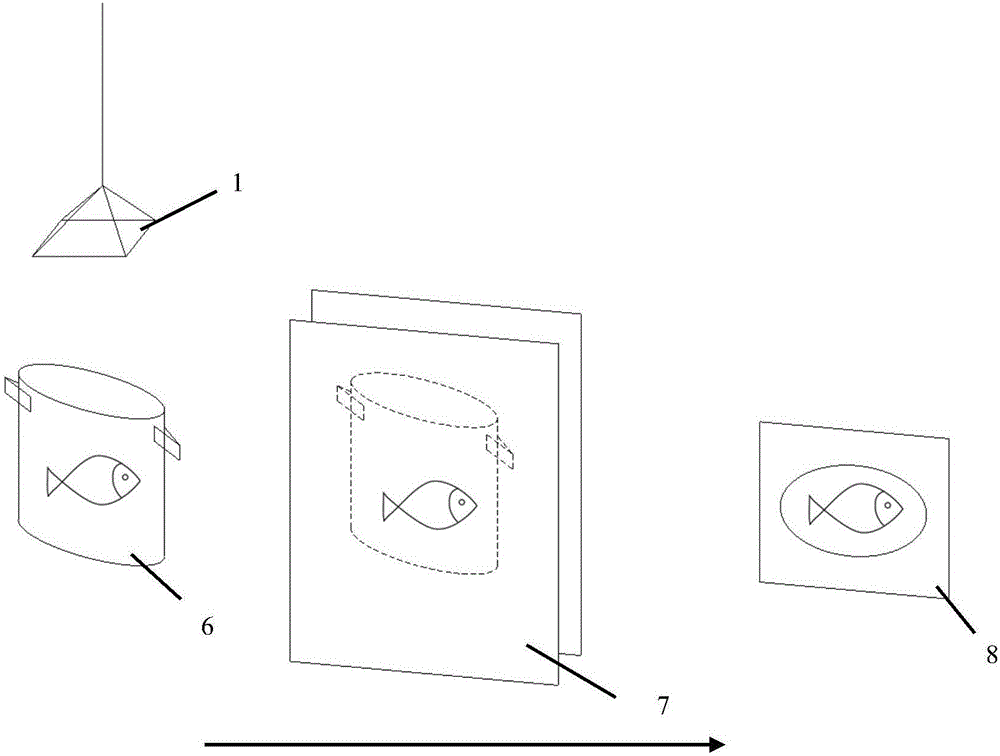

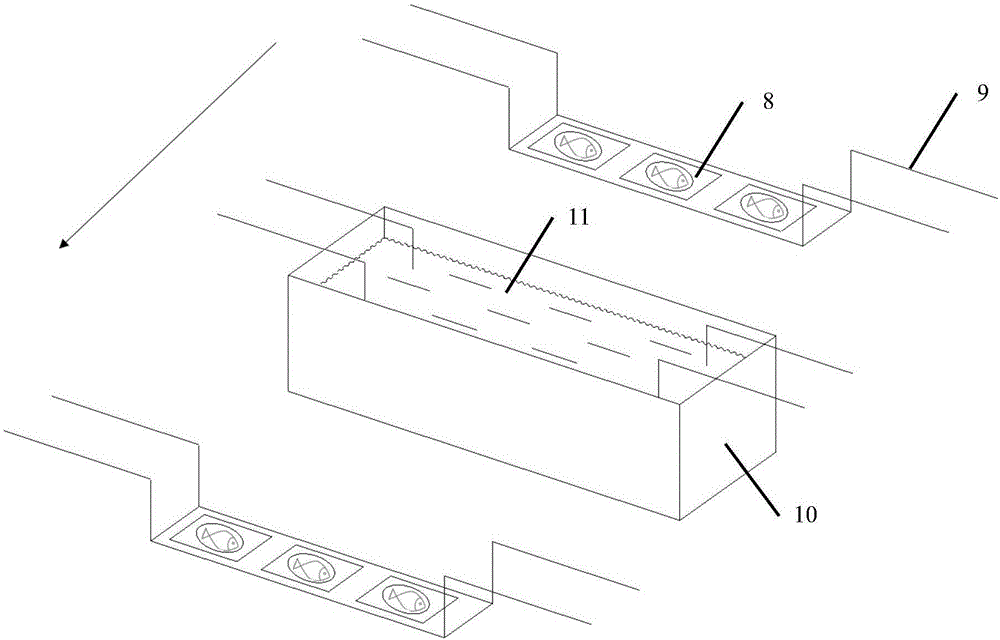

Low-temperature freezing fresh preservation method and system for aquatic products

ActiveCN106234561ARapid cooling treatmentFree from Ice CrystalsMeat/fish preservation by freezing/coolingPackaging under special atmospheric conditionsOxidation stateAquatic product

The invention discloses a low-temperature freezing fresh preservation method and low-temperature freezing fresh preservation system for aquatic products. The fresh preservation method comprises the following steps that 1, anti-oxidation treatment is conducted on the aquatic products through an anti-oxidation solution for 2 minutes to 10 minutes; 2, vacuum packaging is conducted on the aquatic products subjected to anti-oxidation treatment; 3, low-temperature refrigeration treatment is conducted on the vacuum-packaged aquatic products through low-temperature active liquid, wherein the temperature of the low-temperature active liquid ranges from minus 45 DEG C to minus 35 DEG C, and the refrigeration treatment time ranges from 10 minutes to 30 minutes. According to the automated low-temperature freezing fresh preservation system for the aquatic products, the aquatic products can be in an anti-oxidation state in a low-temperature storage environment, and it is guaranteed that the quality of the aquatic products is not affected in the storage process.

Owner:国俊伍

Method and system for low-temperature freezing and fresh-keeping of aquatic products

ActiveCN106234561BRapid cooling treatmentFree from Ice CrystalsMeat/fish preservation by freezing/coolingPackaging under special atmospheric conditionsOxidation stateAquatic product

The invention discloses a low-temperature freezing fresh preservation method and low-temperature freezing fresh preservation system for aquatic products. The fresh preservation method comprises the following steps that 1, anti-oxidation treatment is conducted on the aquatic products through an anti-oxidation solution for 2 minutes to 10 minutes; 2, vacuum packaging is conducted on the aquatic products subjected to anti-oxidation treatment; 3, low-temperature refrigeration treatment is conducted on the vacuum-packaged aquatic products through low-temperature active liquid, wherein the temperature of the low-temperature active liquid ranges from minus 45 DEG C to minus 35 DEG C, and the refrigeration treatment time ranges from 10 minutes to 30 minutes. According to the automated low-temperature freezing fresh preservation system for the aquatic products, the aquatic products can be in an anti-oxidation state in a low-temperature storage environment, and it is guaranteed that the quality of the aquatic products is not affected in the storage process.

Owner:国俊伍

Microgrid fault recognition device accessed to power system

InactiveCN111554849AAvoid displacementAvoid damageSecondary cellsElectrical testingMicrogridElectric power system

The invention relates to the technical field of fault identification devices, in particular to a microgrid fault recognition device accessed to a power system. The device comprises a box body; a firsttemperature sensor is arranged at the left side of the inner wall of the box body and close to the top; a second temperature sensor is arranged on the left side of the inner wall of the box body andclose to the bottom; a U-shaped mounting plate with a rightward opening is arranged in the middle of the right side of the inner wall of the box body; a semiconductor chilling plate is arranged on theside face of a vertical plate of the U-shaped mounting plate; a mounting box is arranged in the middle of the top of the box body; a lithium battery and a single-chip microcomputer are arranged in the mounting box; and an early warning lamp is arranged at the top of the box body and close to the left edge. According to the microgrid fault recognition device accessed to the power system, temperature in the box body can be detected through the first temperature sensor and the second temperature sensor, and a user can be reminded that the temperature in the box body is too high through the earlywarning lamp, so that work of a storage battery pack is stopped in time, and fault maintenance is carried out on the storage battery pack.

Owner:HXXN ELECTRICITY

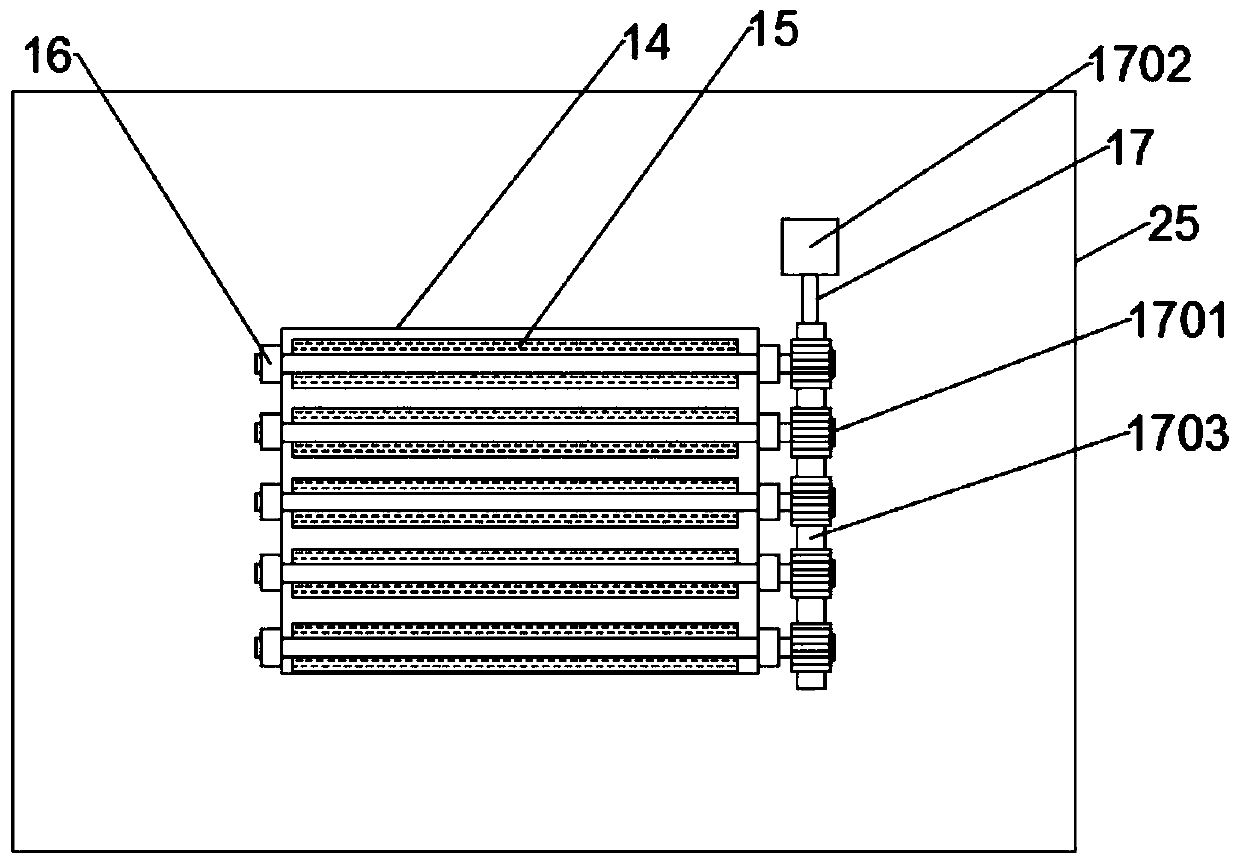

Electromagnetic heating roller capable of accurately positioning

InactiveCN113099567AGuarantee processing qualityGuaranteed cooling qualityInduction heating apparatusPhysicsMachine material

The invention discloses an electromagnetic heating roller capable of accurately positioning. The electromagnetic heating roller comprises bases, limiting assemblies, a winding inner roller, a hollow supporting rod and a control box, first supporting plates are fixed to the upper sides of the bases, fixing blocks are fixed to the upper sides of the first supporting plates, meanwhile, supporting rods are rotationally connected into the fixing blocks, and flanges are fixed to the supporting rods. The flanges are in threaded connection with an outer roller through bolts, a cleaning assembly is fixed between the bases and located on the lower side of the outer roller, a limiting assembly is used for accurately limiting materials and fixed to the upper sides of the supporting rods, the winding inner roller is located in the outer roller, and a stirring assembly is fixed to a cooling assembly. A hollow base is fixed to the lower side of the hollow supporting rod. The electromagnetic heating roller capable of being accurately positioned has the advantages that a machining material can be accurately positioned, the interior of the electromagnetic heating roller can be rapidly cooled, the surface of the electromagnetic heating roller can be automatically cleaned, and the whole device can be driven to move.

Owner:南通盛邦制辊有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com