Cutting equipment for automobile bearing production

A technology for automobile bearings and cutting equipment, applied in metal sawing equipment, metal processing equipment, support and other directions, can solve problems such as general fixing effect, and achieve the effect of ensuring support effect, rapid cooling treatment, and improving structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

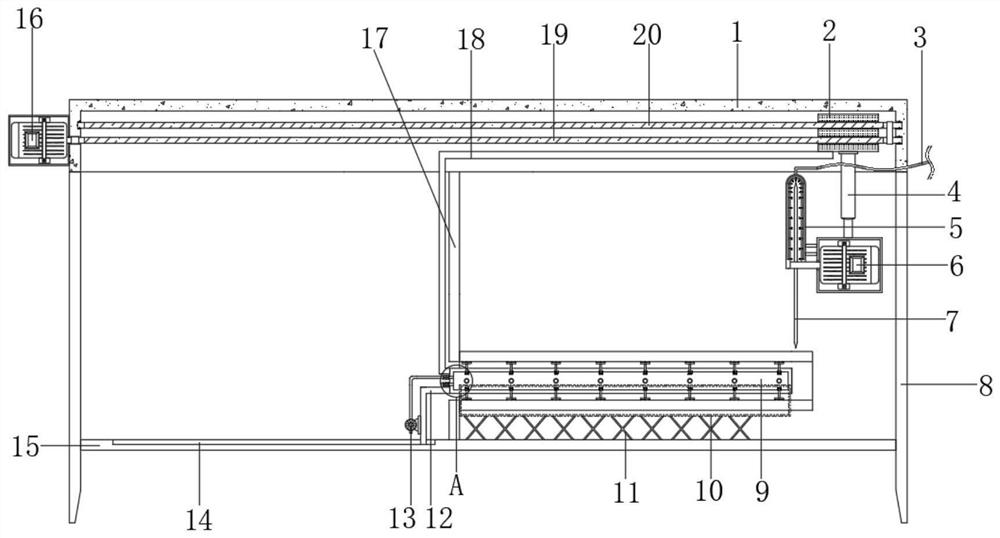

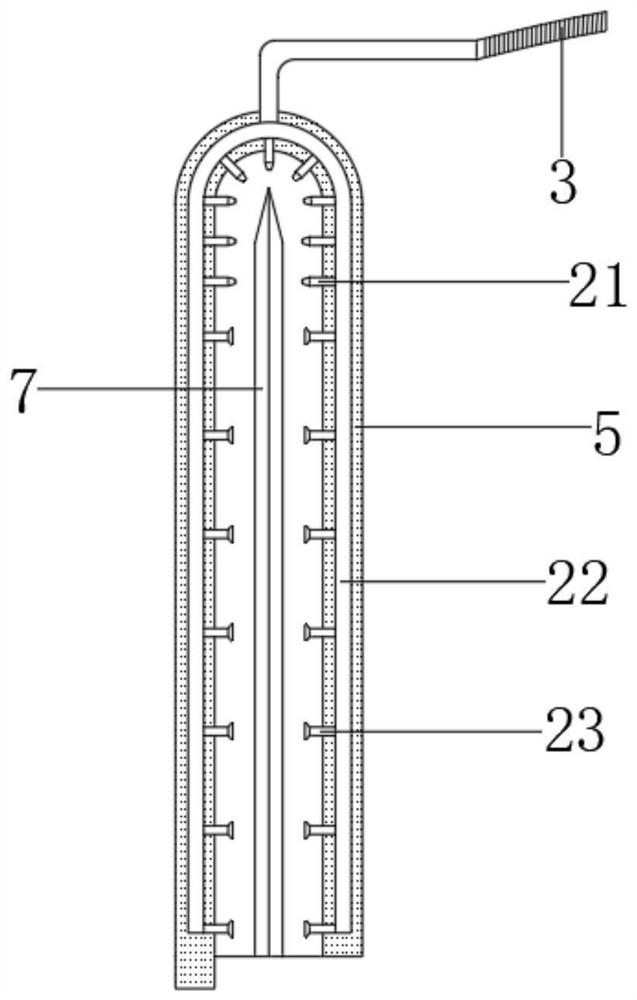

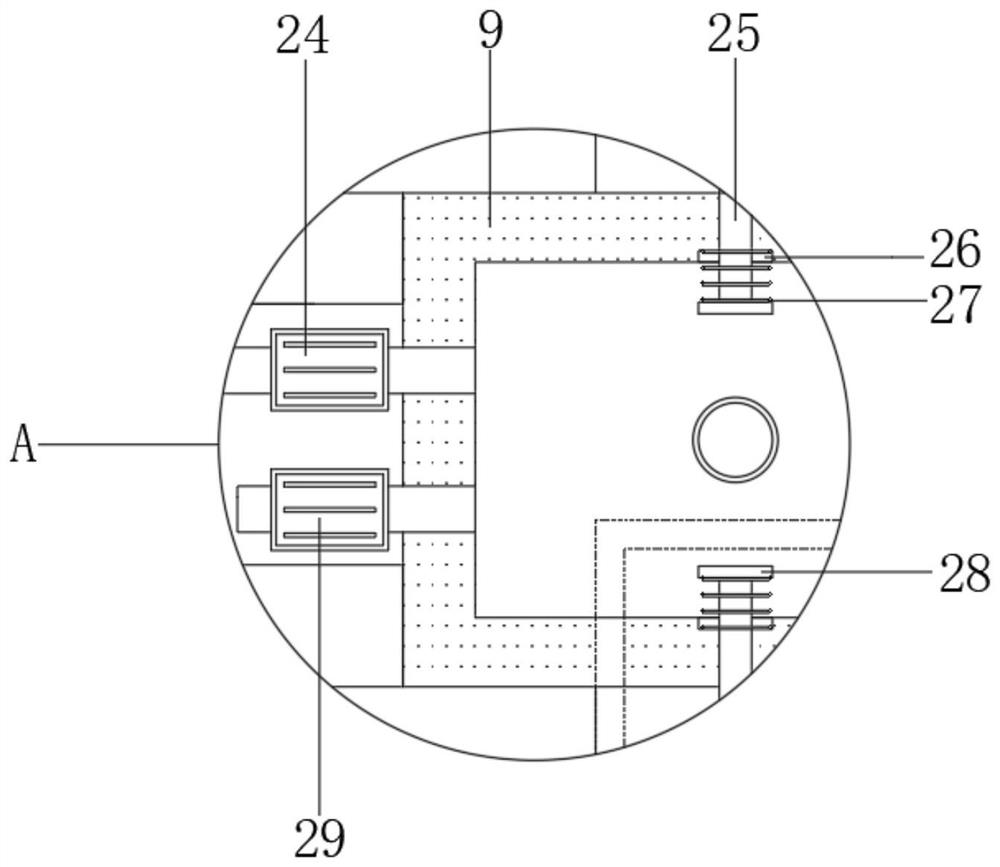

[0030] refer to Figure 1-5 , a kind of cutting equipment for the production of automobile bearings, comprising a fixed cylinder 1, the four outer corners of the bottom of the fixed cylinder 1 are vertically welded with support legs 8, and the opposite sides of the inner walls of the two ends of the fixed cylinder 1 are respectively connected with driving threaded rods through bearing rotation 19 and the driven threaded rod 20, and one end of the driven threaded rod 19 and the driven threaded rod 20 is threadedly connected with the same moving block 2, the bottom outer wall of the moving block 2 is fixed with a hydraulic rod 4 by bolts, and the hydraulic rod 4 The end of the extension rod is fixed with an installation box by bolts, and the inside of the installation box is fixed with a rotary motor 6 by bolts, and the output shaft of the rotary motor 6 is keyed to a cutting tooth 7, and one side of the installation box is fixedly installed with a cover covering the cutting toot...

Embodiment 2

[0041] refer to Figure 5 , a cutting device for the production of automobile bearings. Compared with Embodiment 1, this embodiment further includes that both sides of the inner bottom of the bracket 10 are welded with y-shaped struts 34 .

[0042] When the present invention is used: the setting of the y-shaped struts 34 is used to effectively improve the structural strength of the bracket 10 and ensure the supporting effect of the bracket 10, so as to achieve the purpose of ensuring the smooth progress of the cutting operation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com