Blank moving device of blowing molding machine

A technology of moving device and blow molding machine, which is applied in the field of billet moving device, and can solve the problems of manual removal of temperature, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

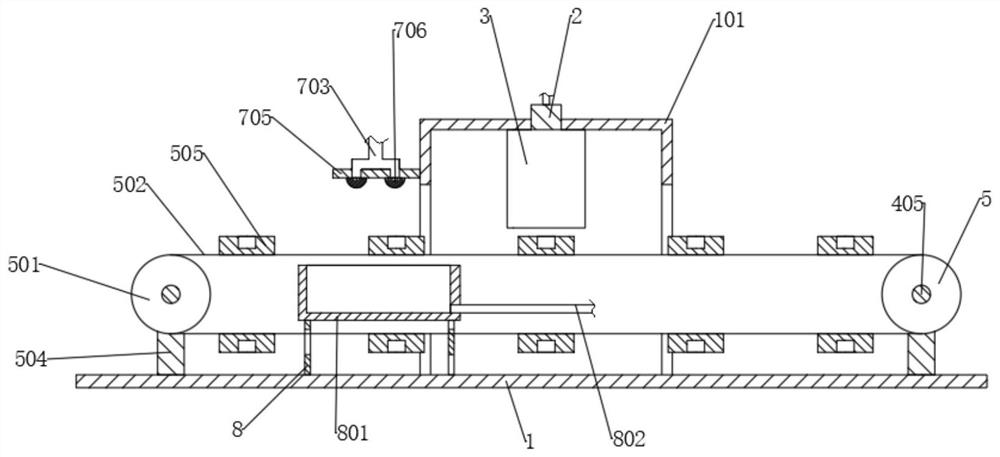

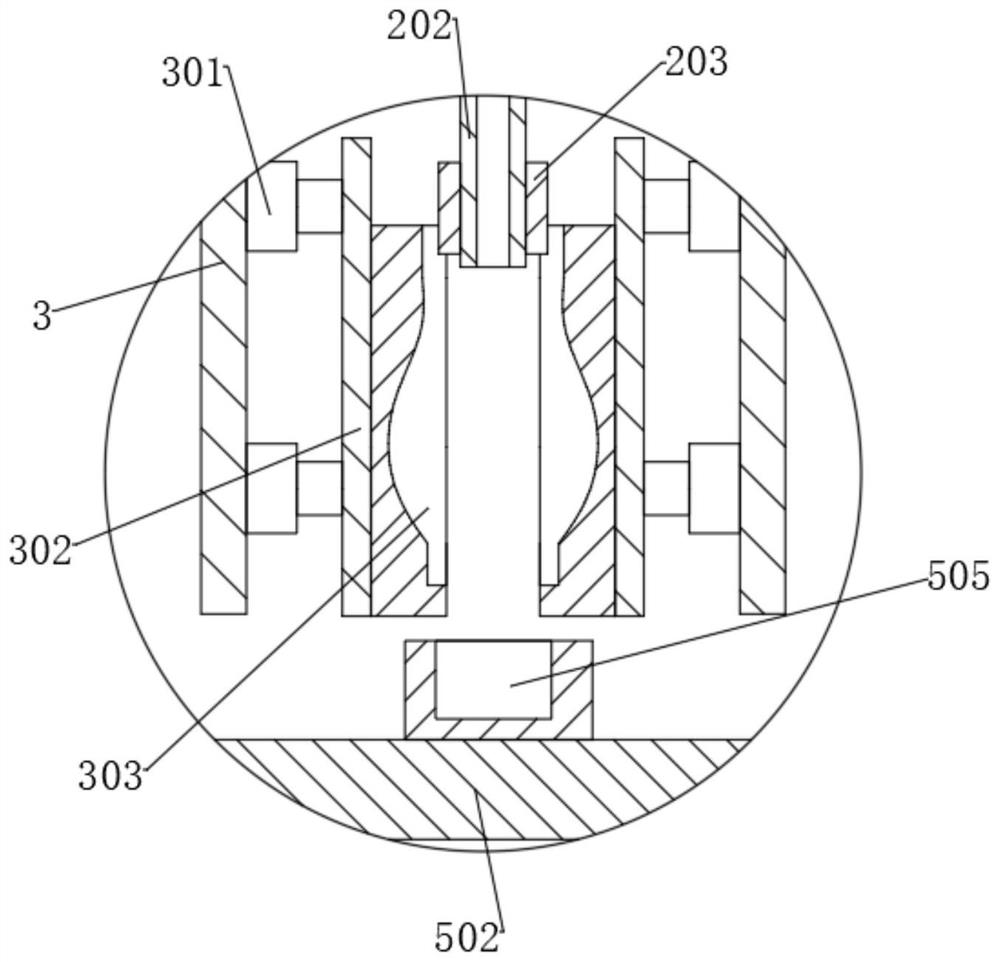

[0025] refer to Figure 1-5 , a billet moving device for a blow molding machine, comprising a bottom plate 1, a support frame 101 and a box body 102, the side wall of the box body 102 is provided with a motor 4, the output end of the motor 4 is connected to a first rotating shaft 401, and the first rotating shaft 401 The cam 402 and the first turntable 403 are respectively connected to the top, the first turntable 403 is provided with a toggle tooth 404, the side wall of the box body 102 is rotatably connected with a second rotating shaft 405, and the second rotating shaft 405 is respectively provided with a drive wheel 5 and a second rotating shaft 405. Two turntables 406, the second turntable 406 is provided with a toggle groove that cooperates with the toggle teeth 404, the base plate 1 is also provided with a driven wheel 501, a conveyor belt 502 is connected between the driving wheel 5 and the driven wheel 501, and the casing 102 A piston 604 is arranged inside, and a con...

Embodiment 2

[0035] refer to Figure 1-5, a billet moving device for a blow molding machine, comprising a bottom plate 1, a support frame 101 and a box body 102, the side wall of the box body 102 is provided with a motor 4, the output end of the motor 4 is connected to a first rotating shaft 401, and the first rotating shaft 401 The cam 402 and the first turntable 403 are respectively connected to the top, the first turntable 403 is provided with a toggle tooth 404, the side wall of the box body 102 is rotatably connected with a second rotating shaft 405, and the second rotating shaft 405 is respectively provided with a drive wheel 5 and a second rotating shaft 405. Two turntables 406, the second turntable 406 is provided with a toggle groove that cooperates with the toggle teeth 404, the base plate 1 is also provided with a driven wheel 501, a conveyor belt 502 is connected between the driving wheel 5 and the driven wheel 501, and the casing 102 A piston 604 is arranged inside, and a conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com