Kiln tail slagging preventing and slag removing device for solid hazardous waste incineration rotary kiln

A rotary kiln and anti-slagging technology, applied in the direction of incinerator, combustion method, combustion type, etc., can solve the problems of destroying the stability of the incineration system, reducing the combustion efficiency of the rotary kiln, and reducing the temperature, so as to achieve enhanced strength, extended life, The effect of increasing the rate of slag discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following examples are for illustrative purposes only and are not intended to limit the scope of the invention.

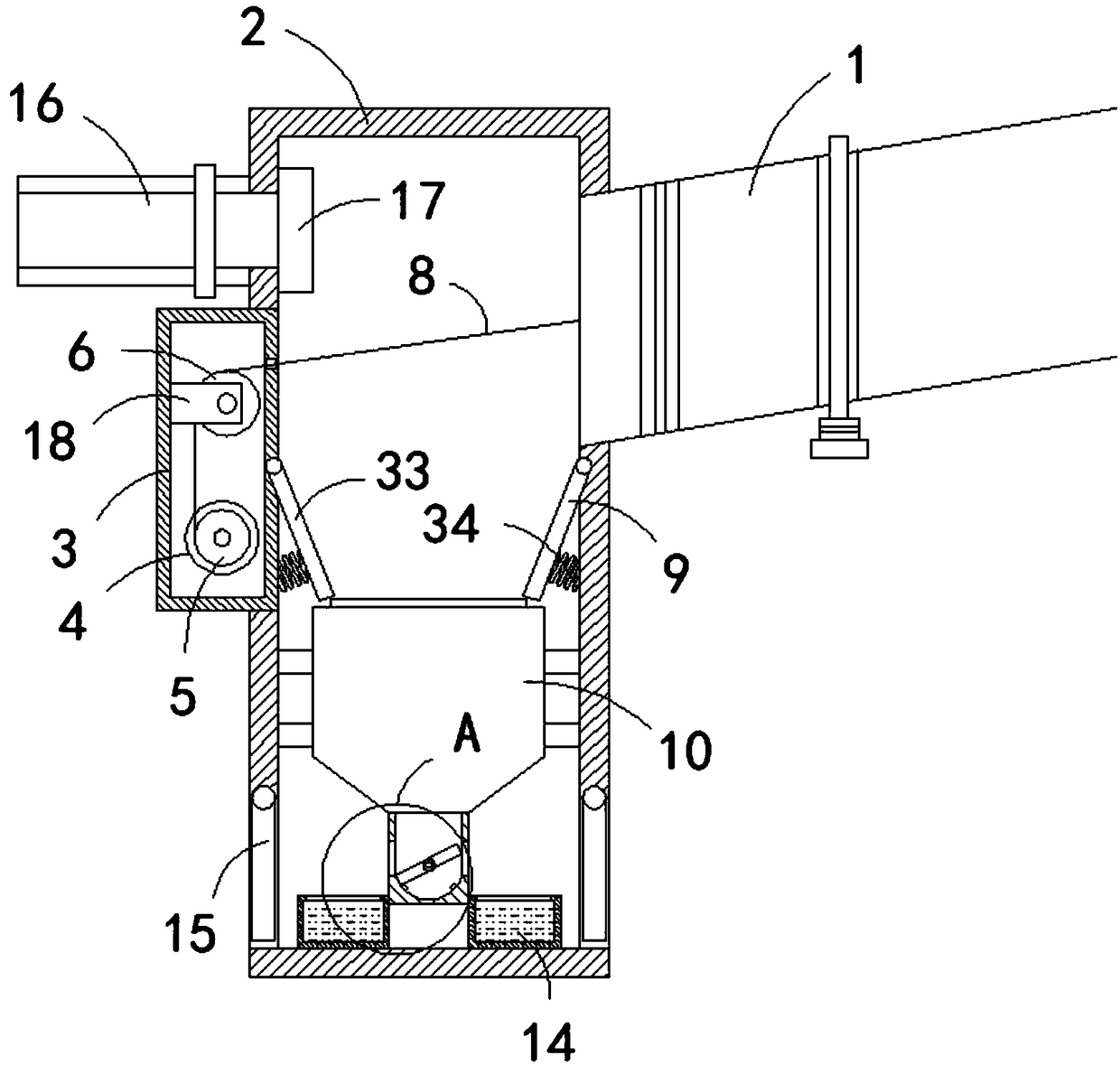

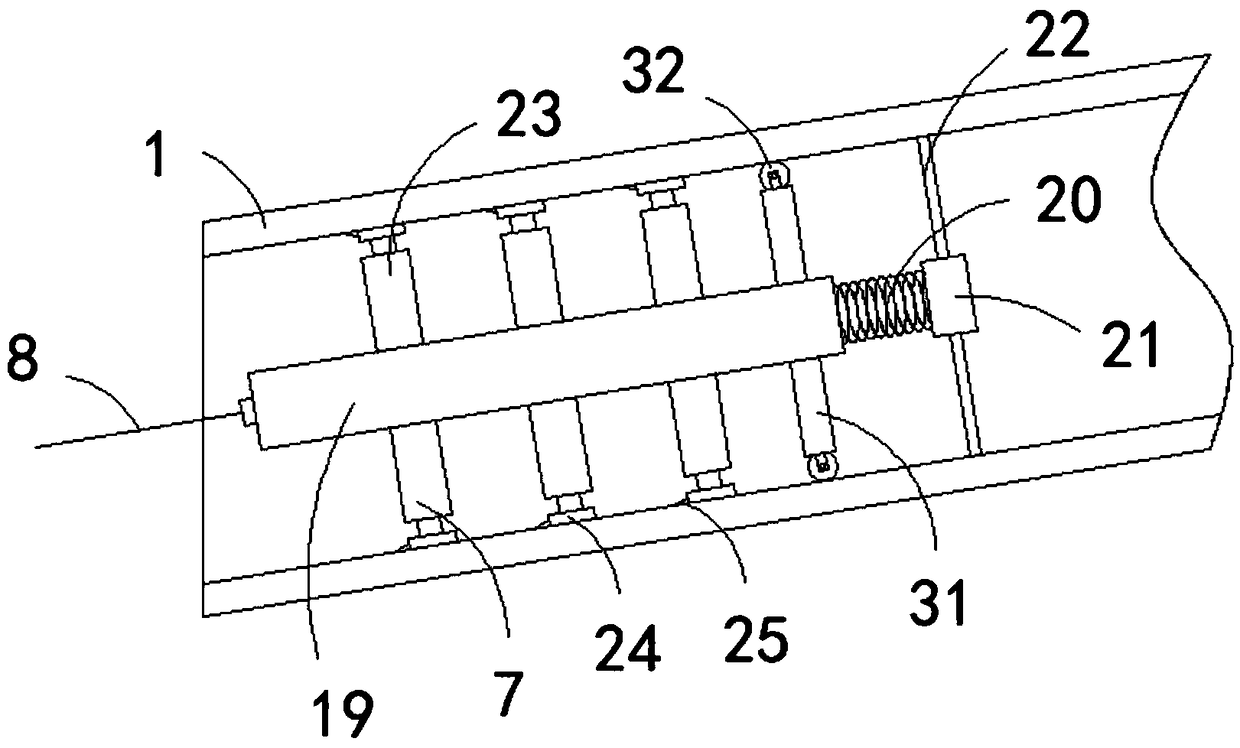

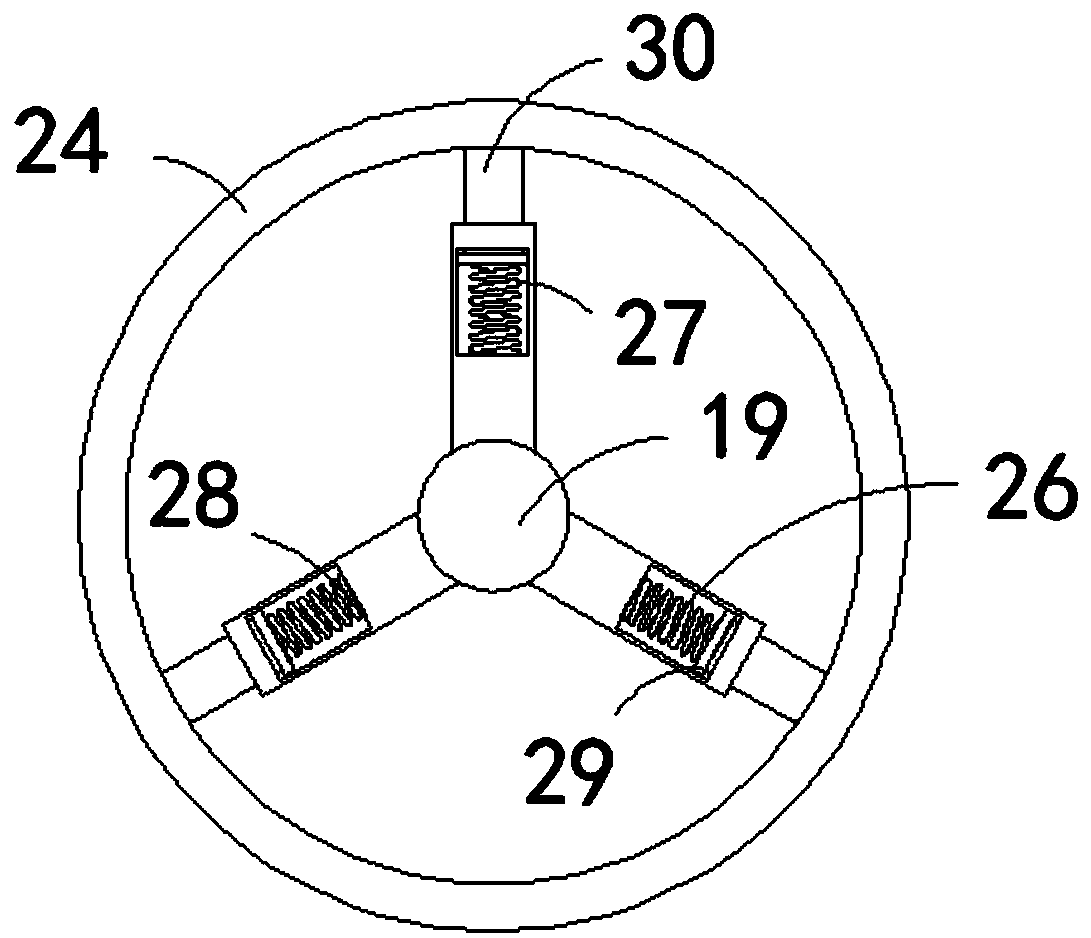

[0022] Such as Figure 1-4 As shown, a kiln tail anti-slagging and slagging device for a solid hazardous waste incineration rotary kiln includes a rotary kiln body 1 and a shell 2 fixedly connected to the output end of the rotary kiln body 1, and the side of the shell 2 away from the rotary kiln body 1 A box body 3 is fixedly connected to the wall, and one end of the box body 3 penetrates the side wall of the casing 2 and extends into the casing 2. A drive motor 4 is fixedly connected to the inside of the box body 3, and the outer side of the drive shaft of the drive motor 4 is fixed. Connected with a rotating roller 5, the casing 3 is rotatably connected with a guide wheel 6. Specifically, the inner wall of the casing 3 is fixedly connected with a U-shaped piece 18, and the guide wheel 6 is rotatably connected in the notch of the U-shaped piece 18, whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com