An automatic ash-cleaning oven heating equipment

A technology for automatic dust removal and heating equipment, which is applied in the fields of tobacco preparation, application, tobacco, etc. It can solve the problems of heavy workload, troublesome management, and easy obstruction of the normal operation of flue gas flow, so as to improve work efficiency and ensure the quality of baking Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to enable those skilled in the art to better understand the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

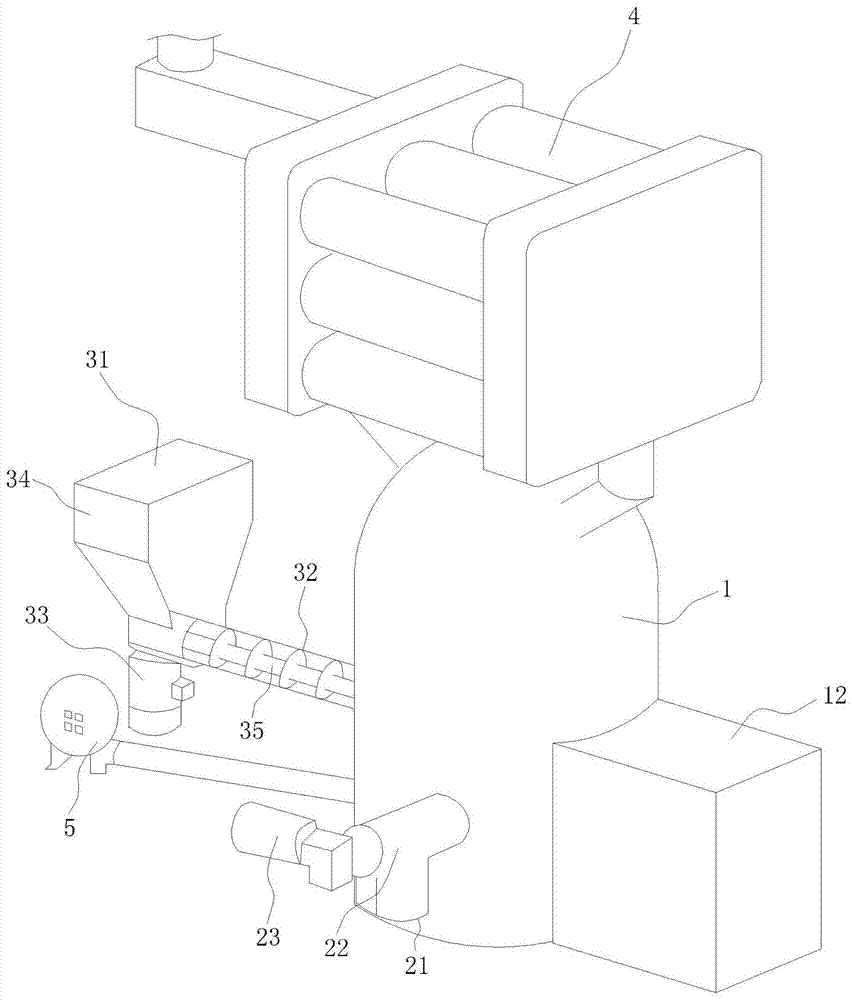

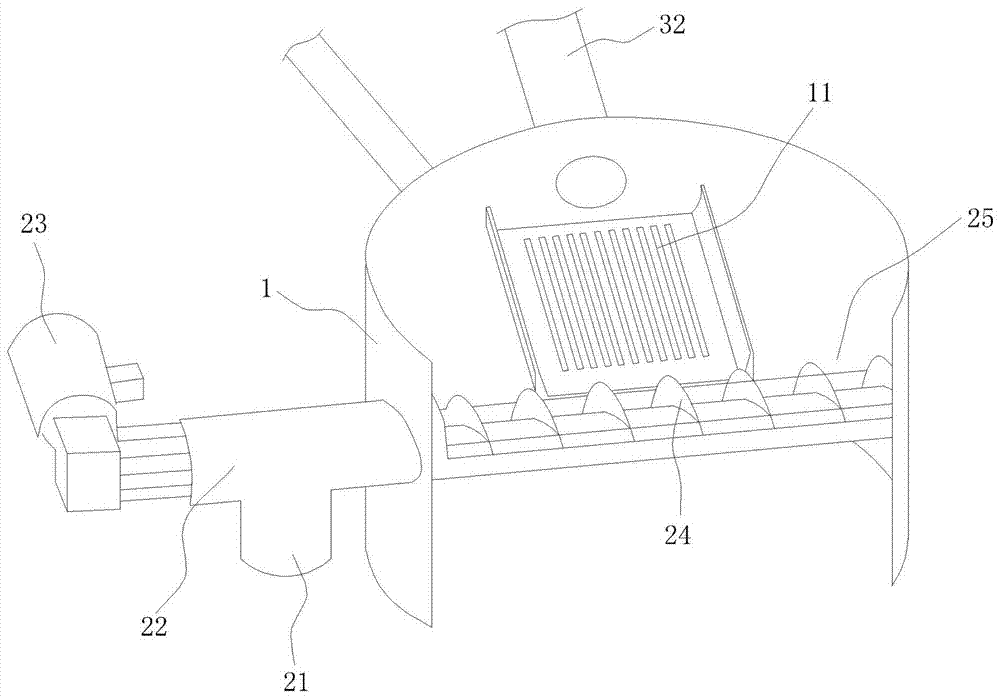

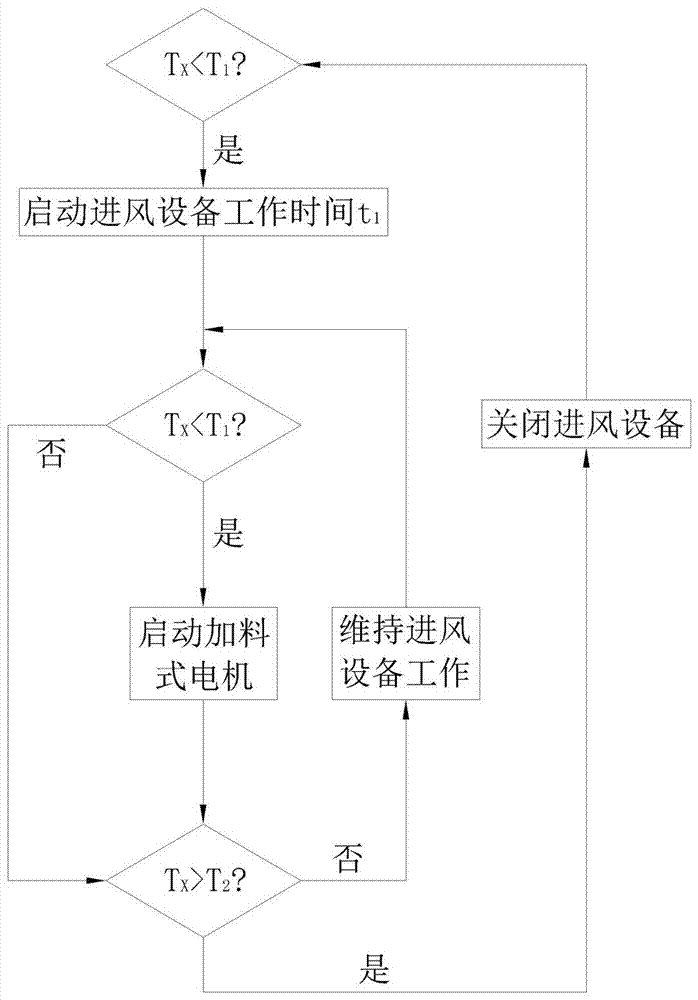

[0021] Such as figure 1 and figure 2 As shown, an automatic ash-cleaning type baking room heating equipment includes a furnace body 1 with a feed inlet 31, a slag outlet 21 and an ash outlet 12 on the outside. The upper part of the furnace body 1 is provided with a radiator 4. The furnace body 1 There is a combustion tank 11 inside, the feed port 31 communicates with the combustion tank 11 through the feeding pipe 32, and the air inlet device 5 is arranged below the feeding pipe 32, and the slag outlet 21 is connected to the combustion tank 11 through the slag outlet pipe 22. connected, the ash outlet 12 is located at the bottom side of the furnace body 1, the slag discharge direction of the combustion tank 11 is roughly perpendicular to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com