Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

87results about How to "Guaranteed baking quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

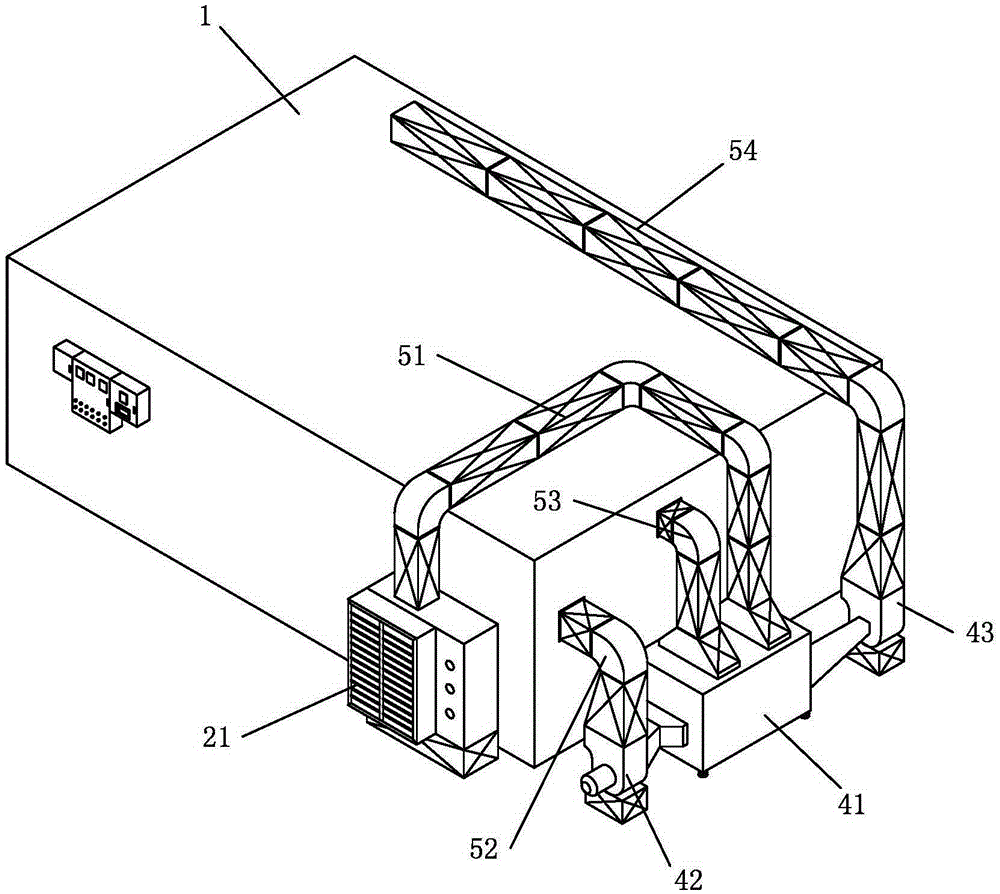

Energy-saving heat pump humidity removing drying room and control method thereof

ActiveCN103512342ASave energyControl operationDrying gas arrangementsDrying machines with local agitationCold airLow speed

The invention discloses an energy-saving heat pump humidity removing drying room and a control method of the drying room. The drying room comprises a room body, a heat pump assembly, a circulating fan assembly, a humidity removing assembly, a main control unit and a temperature and humidity sensor, wherein the humidity removing assembly comprises a heat exchanger, an air inlet fan and a humidity removing fan, and the air inlet fan and the humidity removing fan are respectively connected with an air regulator. When humidity removal is performed in the drying room, external air is turned into dry cold air through a heat pump host, the dry cold air enters the heat exchanger and is conveyed back into the room body after having non-direct-contact heat exchange with high-temperature and high-humidity air pumped out of the room body, and therefore energy is saved. The actual measured temperature and the actual measured humidity are compared with preset stage values, particularly, the preset stage values are divided into preset values in a shutting down stage and preset values in a starting stage, the starting stage is subdivided into a plurality of segments, firstly, the stage or the segment where the actual measured humidity is located is judged through the current humidity, then, according to the current temperature, the actual measured temperature is compared with the set temperature value in the stage or the segment, the humidity removing assembly is controlled to operate at low speed or to operate at full speed or to shut down, and therefore drying efficiency is improved, and energy consumption is reduced.

Owner:JIANGMEN HUAYAN AUTOMATION EQUIP +1

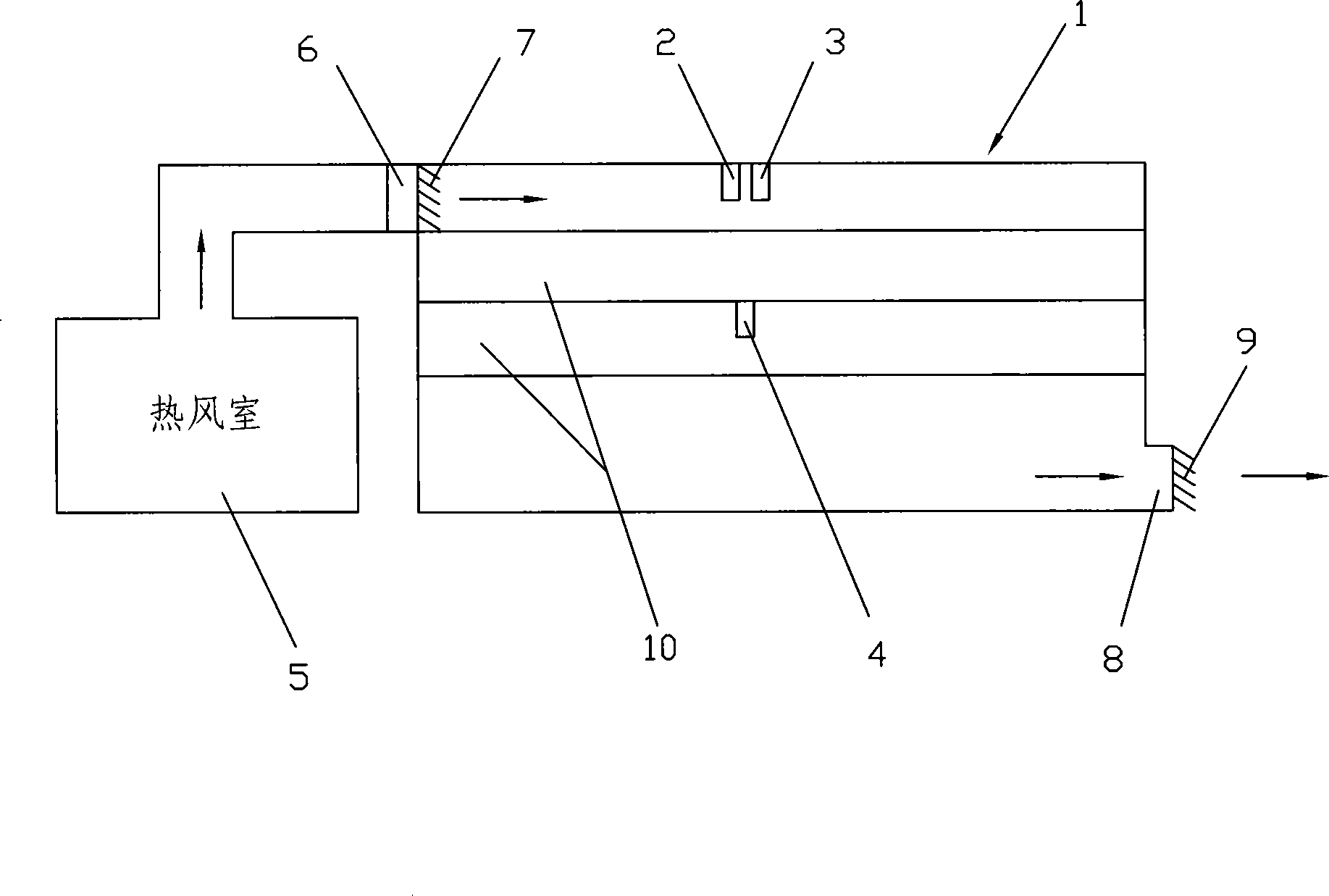

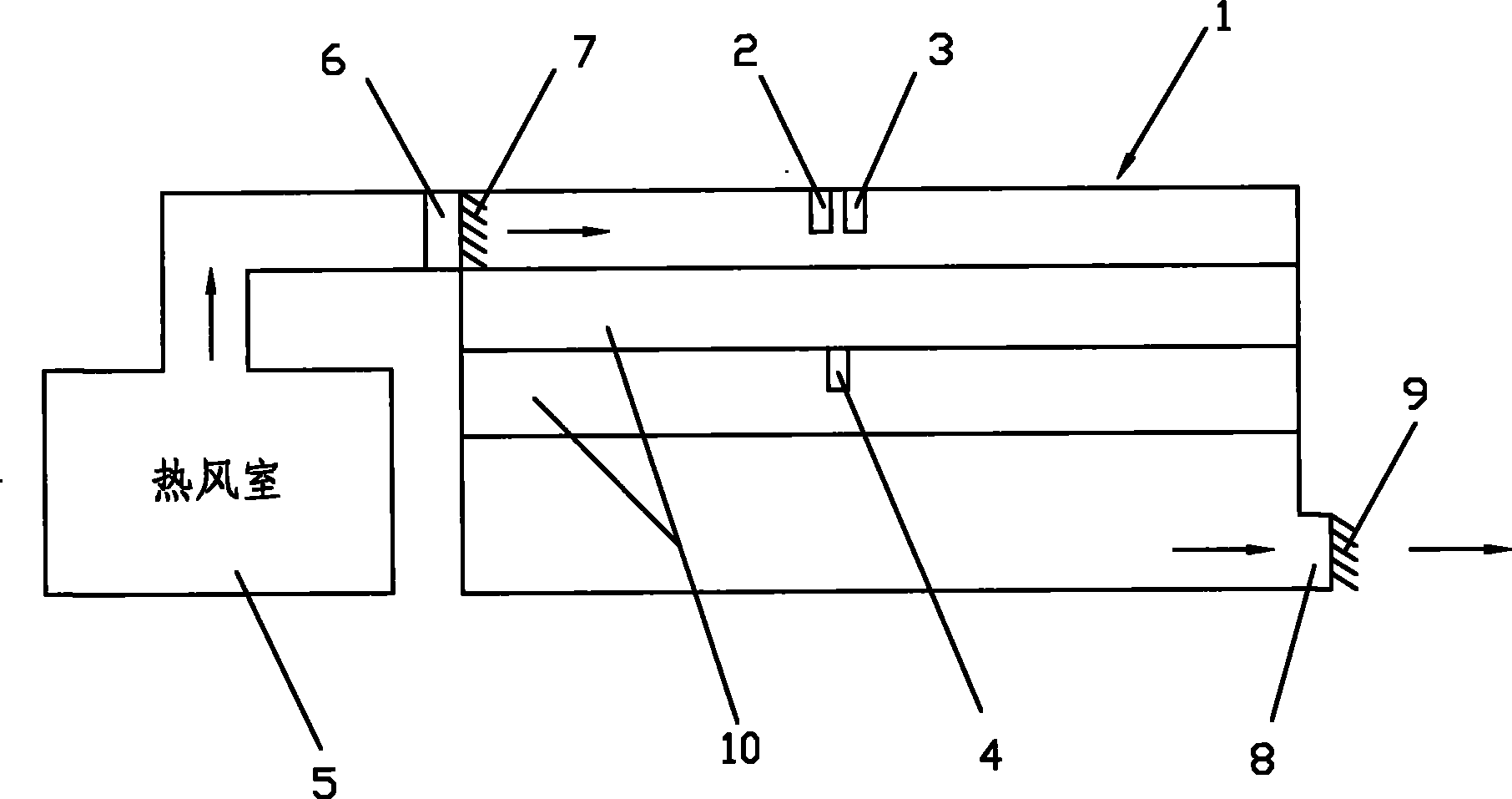

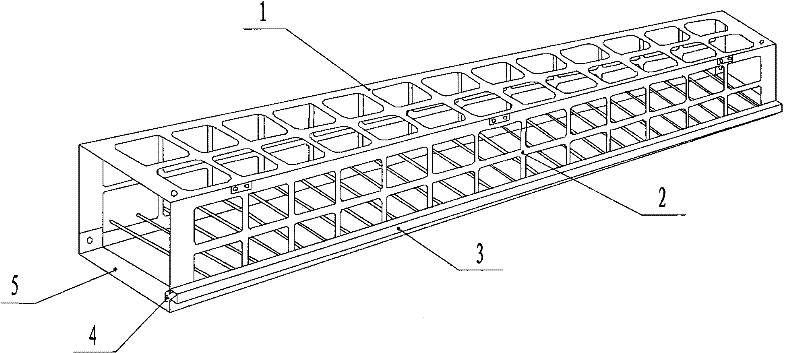

Tobacco roasting process of intensive hothouse

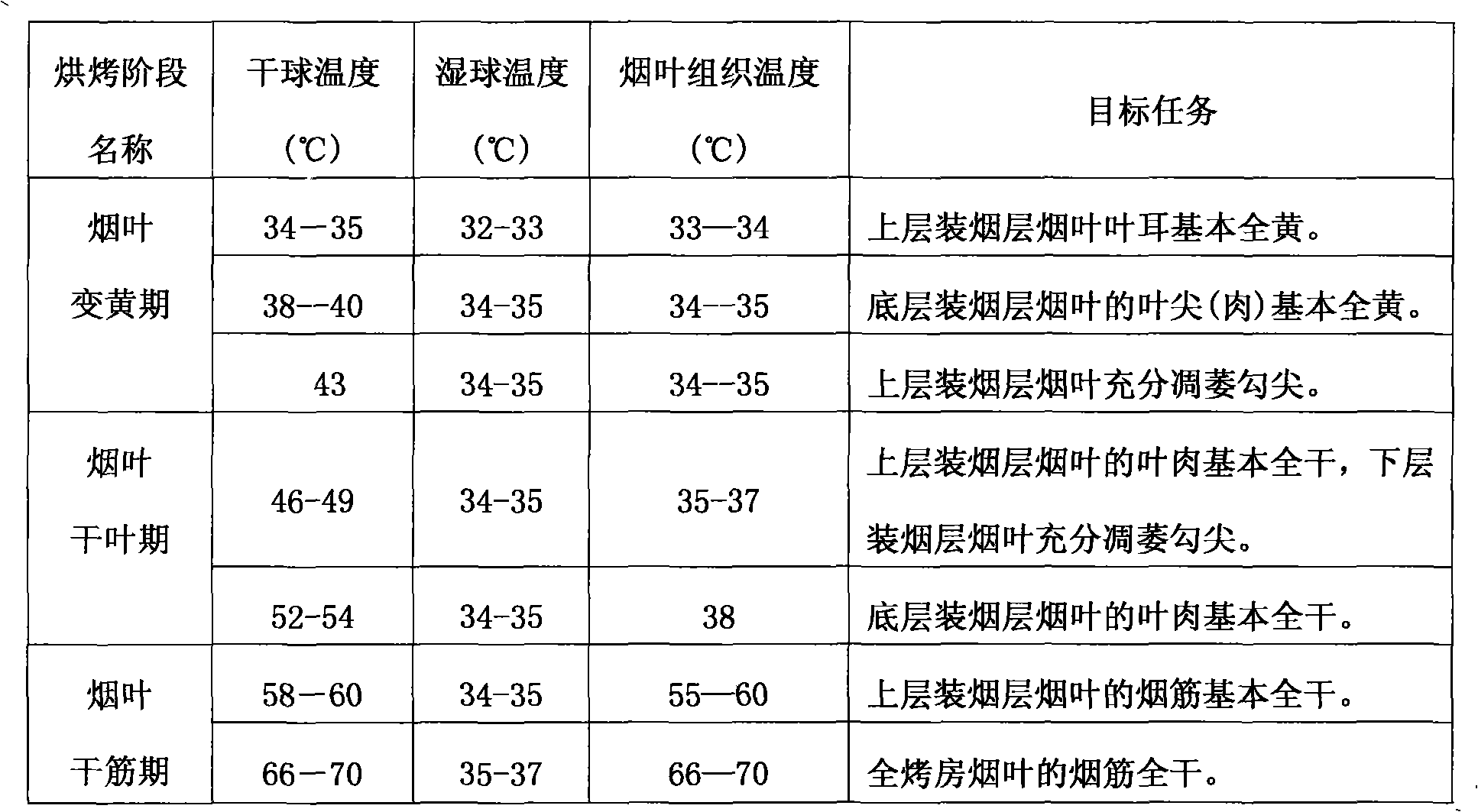

The invention discloses a tobacco curing method for intensive flue-curing barns, which comprises curing step of three stages: a yellowing stage, a leaf drying stage and a stem drying stage. The difference between the method and the conventional curing method is that a second dry bulb thermometer is arranged in a tobacco loading layer for detecting the tissue temperature of tobacco leaves besides a dry bulb thermometer and a wet bulb thermometer arranged in the curing room. Fully considering the problem of heat generated by breathing of wet tobacco tissue, the tobacco curing method can control the temperature and the humidity in the flue-curing barn as well as the tissue temperature of the tobacco leaves. Specifically, the temperature of the wet tobacco tissue in the yellowing stage must be controlled within a change range of physiological and biochemical temperature of the wet tobacco leaves, which is the key for preventing the tobacco leaves from curing bad, thus ensuring the curing quality of intensive flue-curing barns.

Owner:杨树勋

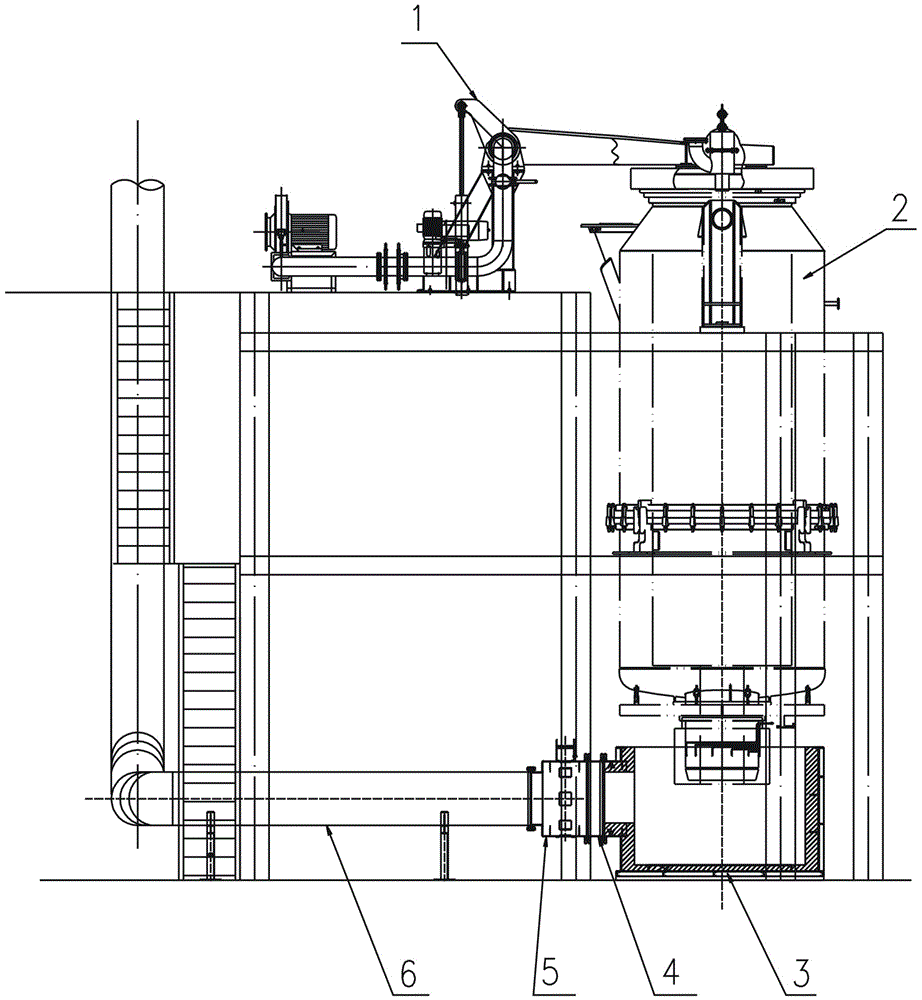

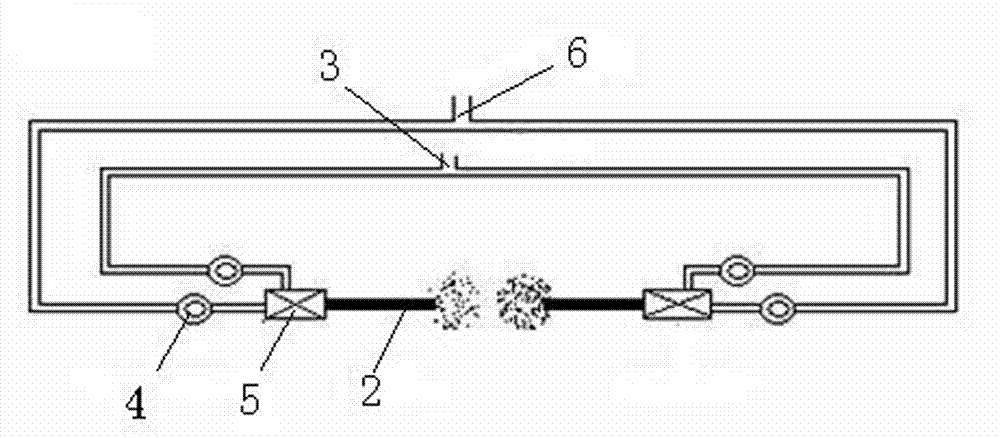

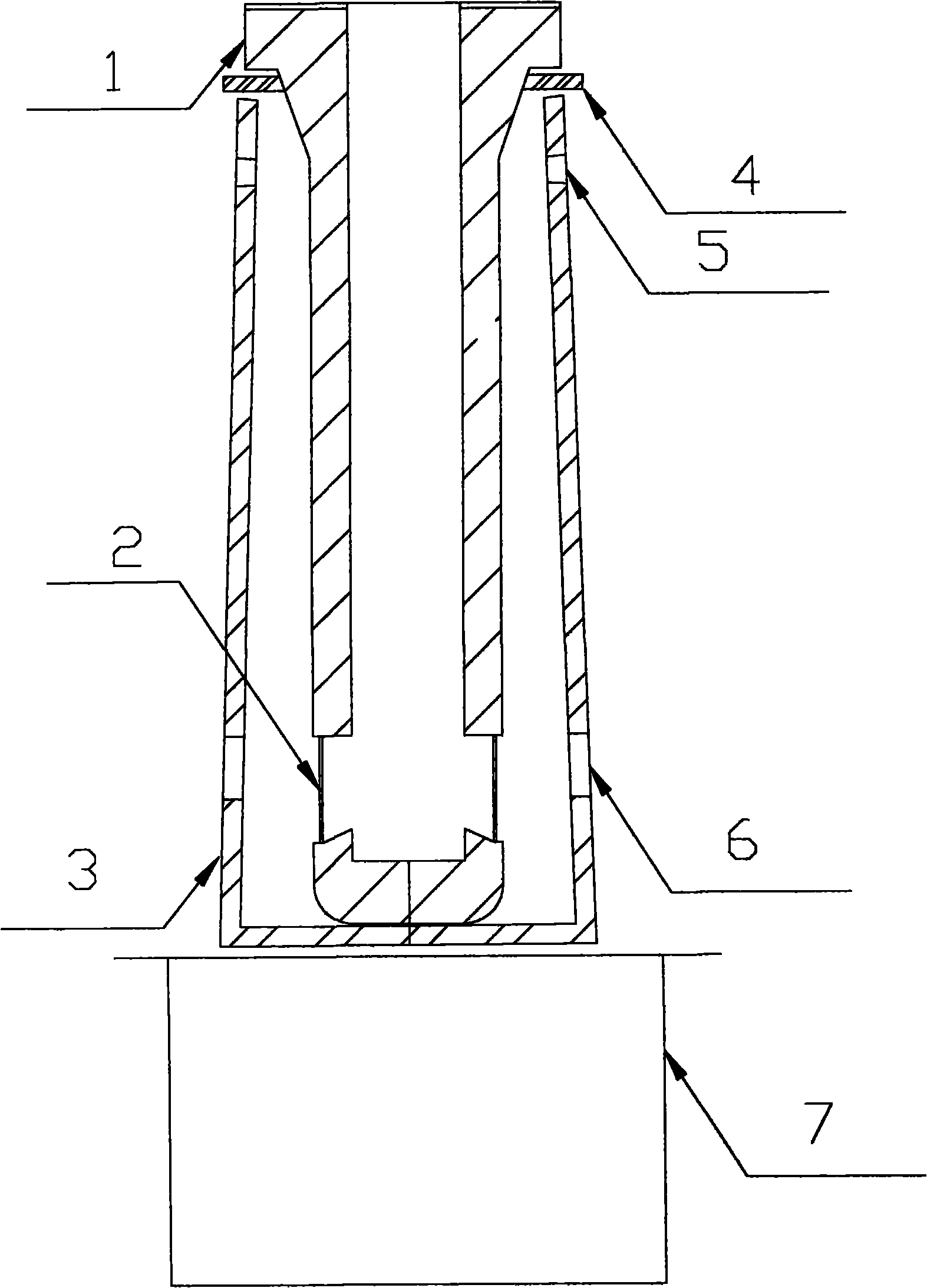

RH vacuum chamber baking system

InactiveCN102978344AControlled heatingGuaranteed baking qualityMelt-holding vesselsRetention timeProcess engineering

The invention discloses a RH vacuum chamber baking system which comprises a vacuum chamber baking device and a vacuum chamber, wherein the vacuum chamber baking device is provided with a baking cover; the baking cover is matched with the upper part of the vacuum chamber; a vacuum chamber insert tube is connected with a waste gas box; the waste gas box is provided with an exhaust port; the exhaust port of the waste heat box is connected with an air mixer through a control valve; and the air mixer is connected with a waste gas duct. By arranging the baking cover and control valve, in the vacuum chamber drying process, the opening of the control valve is reduced, the retention time of baking hot gas in the vacuum chamber is prolonged, the loss of heat is avoided maximally, and the heating of the baking waste gas on the lower part of the vacuum chamber can be effectively controlled, thereby promoting the temperature uniformity of the refractory material in the vacuum chamber; and in the vacuum chamber baking process, the control valve can be adjusted to control the flow rate of the waste gas by utilizing the draft formed by the chimney effect of the waste gas duct, thereby ensuring the baking speed and baking quality of the vacuum chamber.

Owner:WISDRI ENG & RES INC LTD

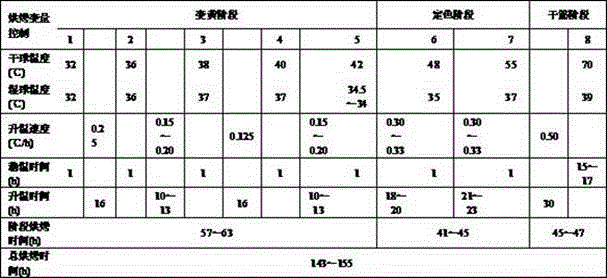

Bulk curing barn hanging rod continuous heating fragrant and soft roasting method

ActiveCN106579531AGuaranteed baking qualityImprove roast qualityTobacco preparationUsabilityEngineering

The invention provides a bulk curing barn hanging rod continuous heating fragrant and soft roasting method, and the method employs a technology of moisturizing and yellowing, slow color fixing, slow continuous heating, and temperature and humidity dynamic changing, guarantees that when the baking time of tobacco leaves at each layer in a curing barn is within a temperature and humidity range suitable for quality modulation is enough and has little difference, i.e., enabling the tobacco leaves at each layer to be yellowed fully and macromolecule materials to be fully or moderately degraded and converted into more aroma components, achieving the timely color fixing and reinforcement of quality, achieving the yellowing, fragrant roasting, soft roasting and mature roasting of tobacco leaves at each layer in the curing barn, and improving the tobacco leave baking quality and the industrial usability. The method provided by the invention is simple and clear, and is convenient for a baking person to master, set and modify.

Owner:UNIV OF SCI & TECH OF CHINA

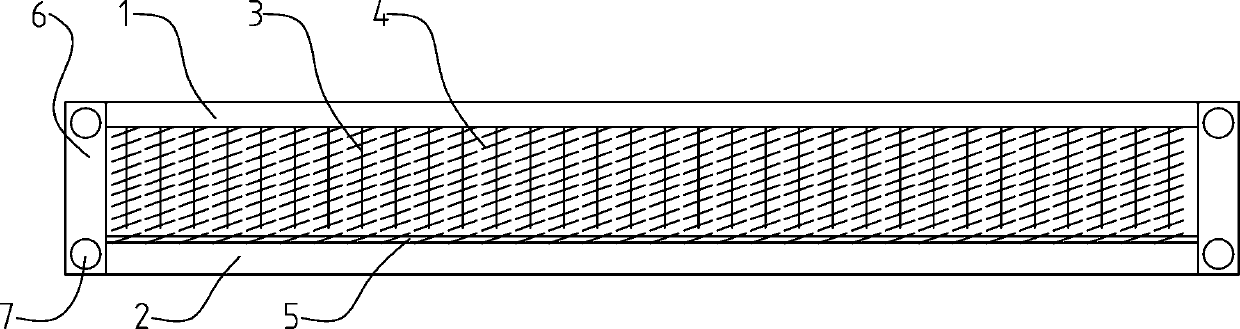

Spring tobacco clip for tobacco flue curing

InactiveCN107927888AGuaranteed baking qualityInhibit sheddingTobacco preparationFlueCuring of tobacco

The invention provides a flue-cured tobacco spring clip, which includes a first crossbeam and a second crossbeam. The first crossbeam is provided with a plurality of pins along the length direction. A spring is sleeved, one end of the spring is fixedly connected with the first beam, and the other end is a free end. Another flue-cured tobacco spring clip includes a first crossbeam and a second crossbeam, the first crossbeam and the second crossbeam are connected by a column, the first crossbeam is provided with a plurality of springs along the length direction, and the free end of the spring is provided with a pressure Frame, elastic pins are arranged in the middle of the pressure frame; two baffles along the length direction are provided on the inner side of the second beam, and a groove for accommodating the free ends of the pins is formed between the baffles, and the height of the baffles is not less than 1 / 4 of the length of the elastic pin. Through the provided spring, the pressure on the tobacco stem can be maintained all the time, and the tobacco leaves are kept smooth, thereby ensuring the roasting quality of the flue-cured tobacco. The provided spring can also prevent the tobacco leaves from falling off during the curing process.

Owner:宜昌益烟机械设备有限公司

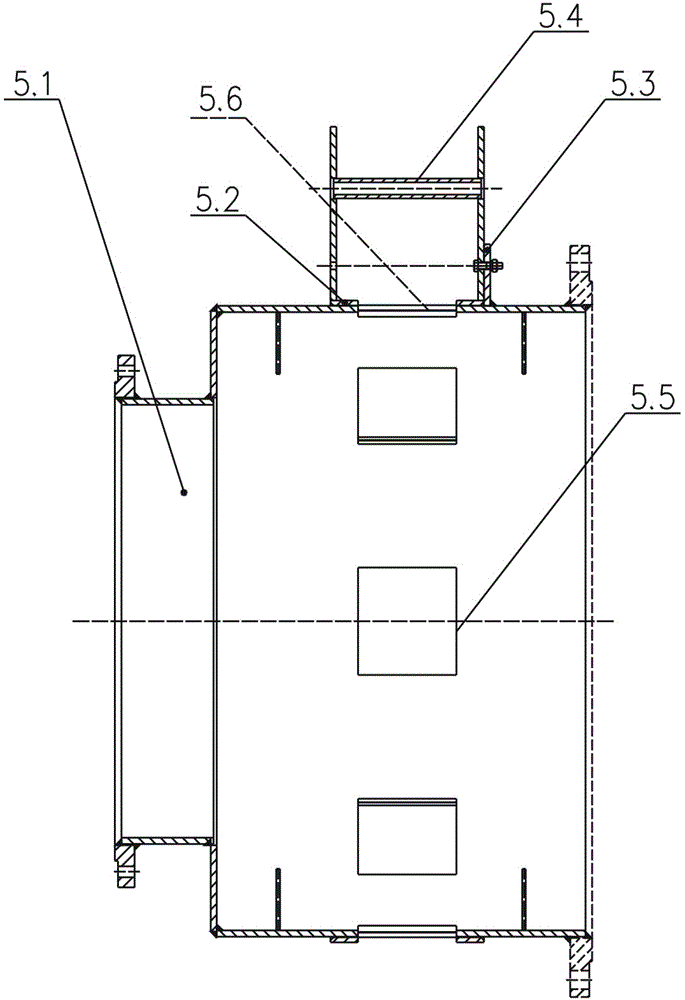

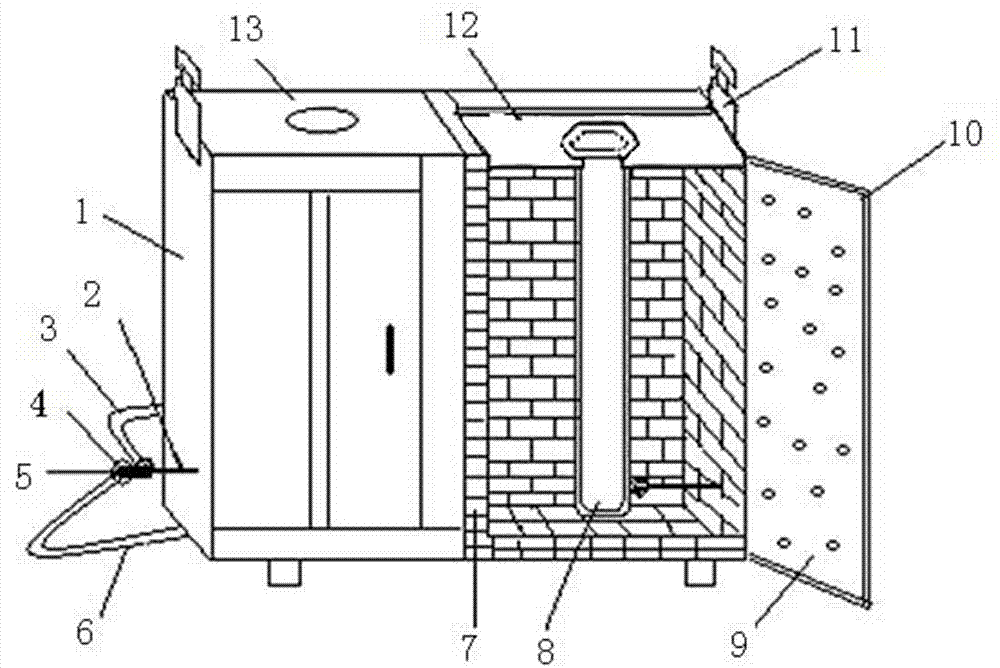

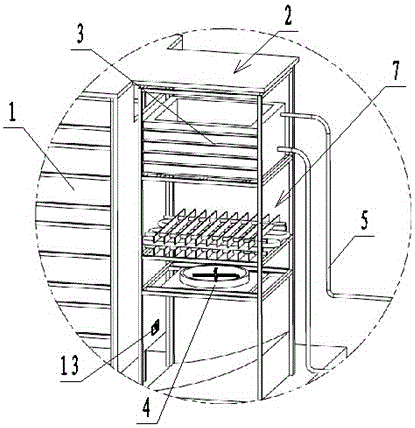

Continuous casting machine tundish submersed nozzle baking furnace

InactiveCN103878357AGuaranteed baking qualitySave on insulationMelt-holding vesselsMetallurgySpray nozzle

The invention relates to the field of metallurgical equipment, in particular to a continuous casting machine tundish submersed nozzle baking furnace. The continuous casting machine tundish submersed nozzle baking furnace comprises a furnace body, wherein two baking chambers are arranged in the furnace body, each baking chamber is provided with a spraying nozzle, each spraying nozzle is connected with a mixing valve, each mixing valve is connected with an air inlet pipe and a fuel gas inlet pipe, each air inlet pipe and each fuel gas inlet pipe are respectively provided with a control hand valve, an installation plate is arranged at the top of each baking chamber, a clamping groove is formed in each installation plate to fix a submersed nozzle, the furnace body is provided with a furnace door, a heat-preservation layer is arranged at the inner side of the furnace door, a flame retardant layer is arranged on the inner wall of each baking chamber, a heat preservation plate is formed at the top of the furnace body and provided with openings matched with the submersed nozzles, pulleys are arranged at the bottom of the furnace body, and pothooks are arranged at the top of the furnace body. The continuous casting machine tundish submersed nozzle baking furnace has the advantages of being safe to operate, capable of meeting production requirements, capable of guaranteeing baking quality and convenient to move and transport, saving energy and the like.

Owner:JIGANG GRP

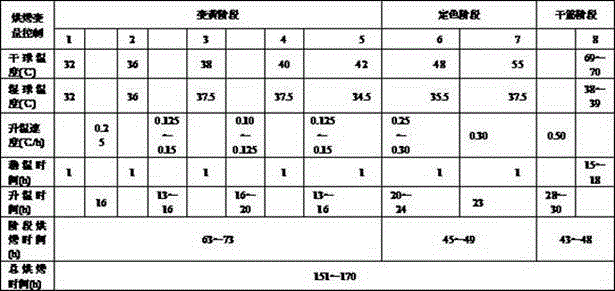

Curing method with dispersed leaf stacking type tobacco leaf loading type sustained temperature-increasing curing, fragrant curing and soft curing for bulk curing barn

ActiveCN106235371AGuaranteed baking qualityEnough time to bakeTobacco preparationTobacco processorMoisture

The invention discloses a curing method with dispersed tobacco leaf-stacking loading type sustained temperature-increasing curing, fragrant curing and soft curing for bulk curing barn. The curing method comprises the following steps of (1) adopting a dispersed tobacco leaf-stacking loading type; (2) setting and executing a dispersed tobacco leaf-stacking loading type sustained temperature-increasing curing, fragrant curing and soft curing technology of the bulk curing barn by a controller of the bulk curing barn, and curing in the air flow ascending type bulk curing barn for the dispersed tobacco leaf-stacking loading type; after yellowing period, color-fixing period and rib drying period, returning moisture, and unloading tobacco leaves. The curing method has the advantages that the curing quality of whole-curing tobacco leaves is ensured; by adopting the technique of moisture maintaining and yellowing, slow color-fixing, slow sustained temperature increasing, and dynamic change of temperature and humidity, the total content of fragrance in the cured tobacco leaves is averagely improved by 9.5%, the number of smooth tobacco leaves is averagely decreased by 38.9%, and the ratio of high-grade tobacco leaves is averagely increased by 13.6%.

Owner:ZUNYI TOBACCO OF GUIZHOU TOBACCO CORP +1

Baked tobacco upper tobacco leaf with stem cutting collecting bulk baking method and baking structure

InactiveCN110037328AImprove Harvest MaturityExtension of timeTobacco preparationCooking & bakingEngineering

The invention discloses a baked tobacco upper tobacco leaf with stem cutting collecting bulk baking method and a baking structure. When 4-6 pieces of upper tobacco leaves are fully mature, 4-6 leavesare cut and connected with stems at one time and then are directly erected and stacked on an air separation plate in an airflow falling leaf baking room for baking, which not only improves the harvesting maturity of the tobacco leaves and the time of baking and yellowing, but also coordinates the inner quality of the upper tobacco leaves, and the tobacco leaf breaking is solved in the tobacco weaving process with the stems. According to the method, since the leaves are still born on the stems, the leaves can be provided with good support during the baking process of the bulk leaf tobacco baking process with the stems, and a windward environment is formed in the airflow falling leaf baking room to promote the improvement of the baking quality of the upper tobacco leaves. The method has theadvantages of simple operation of packing tobaccos and lower baking and obvious labor saving, the smoke volume of the baking room is increased by 30-40%, there is the support of the stems, the tobaccoleaves are not easy to fall during the baking process, the ventilation and drainage environment is better, and after the upper 4-6 leaves are baked, the quality of the tobacco leaves can be significantly improved.

Owner:抚州市烟草公司宜黄分公司

Processing technology of leisure beef food with primary taste

The invention relates to the field of food processing, in particular to a processing technology of a leisure beef food with primary taste. The processing technology comprises the steps of selecting materials, dicing, cooking with clean water, dehydration, cutting into slices, subpackaging, sterilization and the like. The invention aims to provide the processing technology of the leisure beef food with primary taste. Under the condition that no artificially synthesized seasoning (essence ) or preservative is added, the leisure beef food which has the primary taste of beef, has a certain shelf life and is safe is produced.

Owner:TONGDAO YOUJIAOTOU FOOD CO LTD

Bulk curing barn leaf scrap insertion tobacco filling continuous heating roasted fragrant and roasted soft roasting method

ActiveCN106235372AGuaranteed baking qualityImprove roast qualityTobacco preparationTobacco processorMaterials science

The invention discloses a bulk curing barn leaf scrap insertion tobacco filling continuous heating roasted fragrant and roasted soft roasting method. The method includes following steps: (1), adopting a leaf scrap insertion specified mode for tobacco filling; (2), inspecting a bulk curing barn with a curing barn controller, adopting a lower air dividing partition for control on the controller in the airflow-up bulk curing barn, going through a yellowing period, a color fixing period and a stem drying period, wetting back, and unloading the tobacco, wherein the bulk curing barn is an airflow-up bulk curing barn for roasting. By the method, fragrance ingredient content of tobacco can be averagely increased by 9.3% while roasting quality of all-kang tobacco, smooth cigarette amount can be averagely reduced by 28.7%, and first-glass cigarette proportion can be averagely increased by 12.1. The roasting method is terse and concise, convenient for roasting personnel to master, set and modify and capable of increasing income of tobacco growers.

Owner:ZUNYI TOBACCO OF GUIZHOU TOBACCO CORP +1

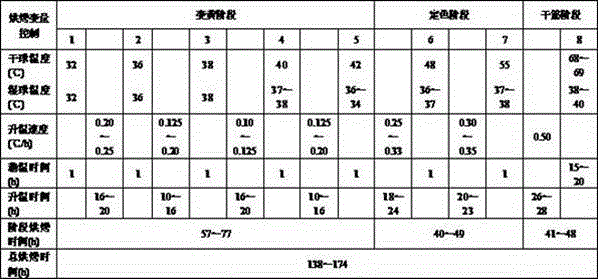

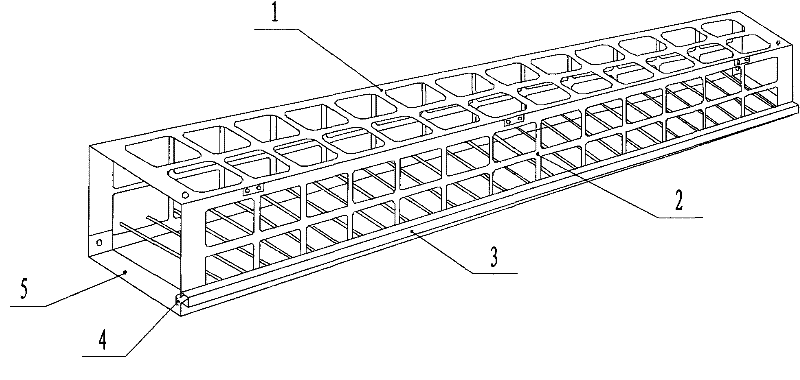

Fast cage type tobacco clamp for bulk curing barn

InactiveCN102228308AIncrease the stress pointUniform yellowingTobacco preparationEngineeringShort life

The invention provides a fast cage type tobacco clamp for a bulk curing barn. A technical scheme of the invention is as follows: a support frame is arranged on two ends of an L-shaped bracket, a movable cover is connected with the L-shaped bracket through a hinge such that the movable cover can rotate, the movable cover after folded is tightly clung on the support frame, contact pins are respectively lapped on lower edges of square holes of the L-shaped bracket and the movable cover after a tobacco fork is inserted, and the tobacco fork and the movable cover are stably clamped on the support frame by using a clip. According to the fast cage type tobacco clamp disclosed by the invention, the tobacco loading efficiency can be largely increased, links of roasting tobacco leaves and technical complexity can be reduced, the labor saving effect is remarkable, and tobacco growers can get rid of complex tobacco weaving links; in addition, the difficulties of poor roasting effect of the prior tobacco clamp and complex and short-life structure of the tobacco clamp are solved at the same time; and when the fast cage type tobacco clamp is matched with a bulk curing barn for use, the volume and the roasting capability of the bulk curing barn can be increased on the premise of ensuring the roasting quality, which is very important to expanding planting scale of each family and factory and professional roasting.

Owner:中国烟草总公司广西壮族自治区公司

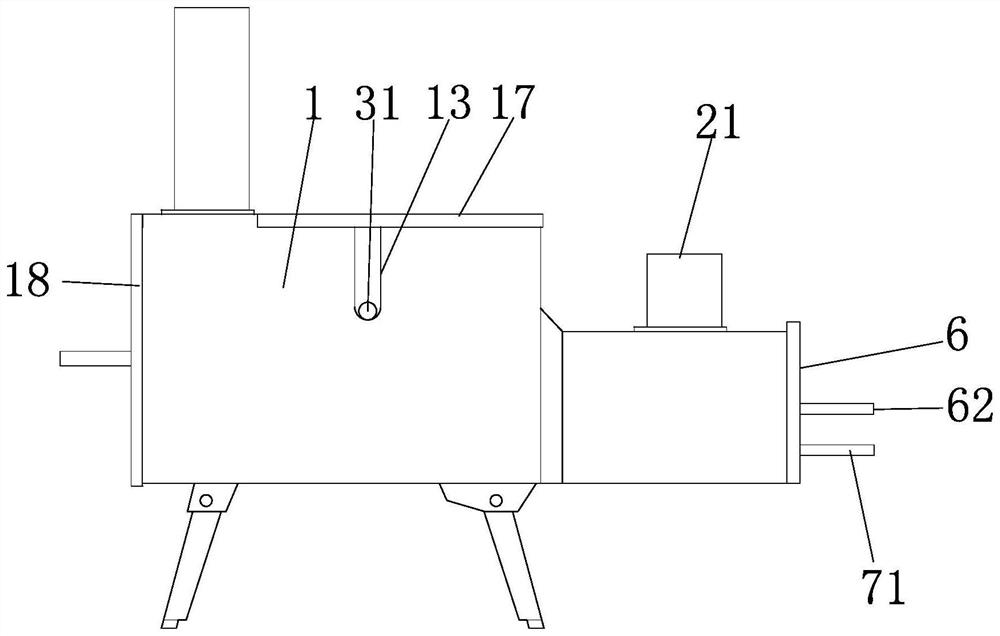

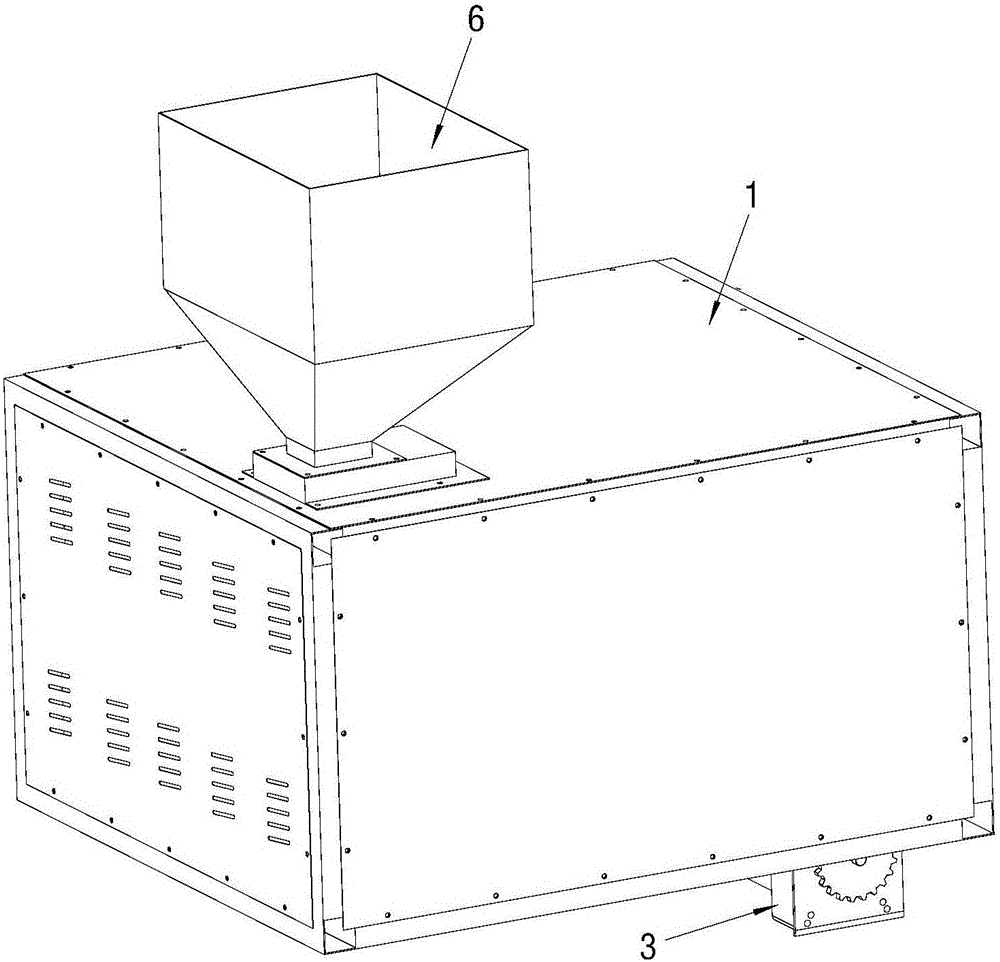

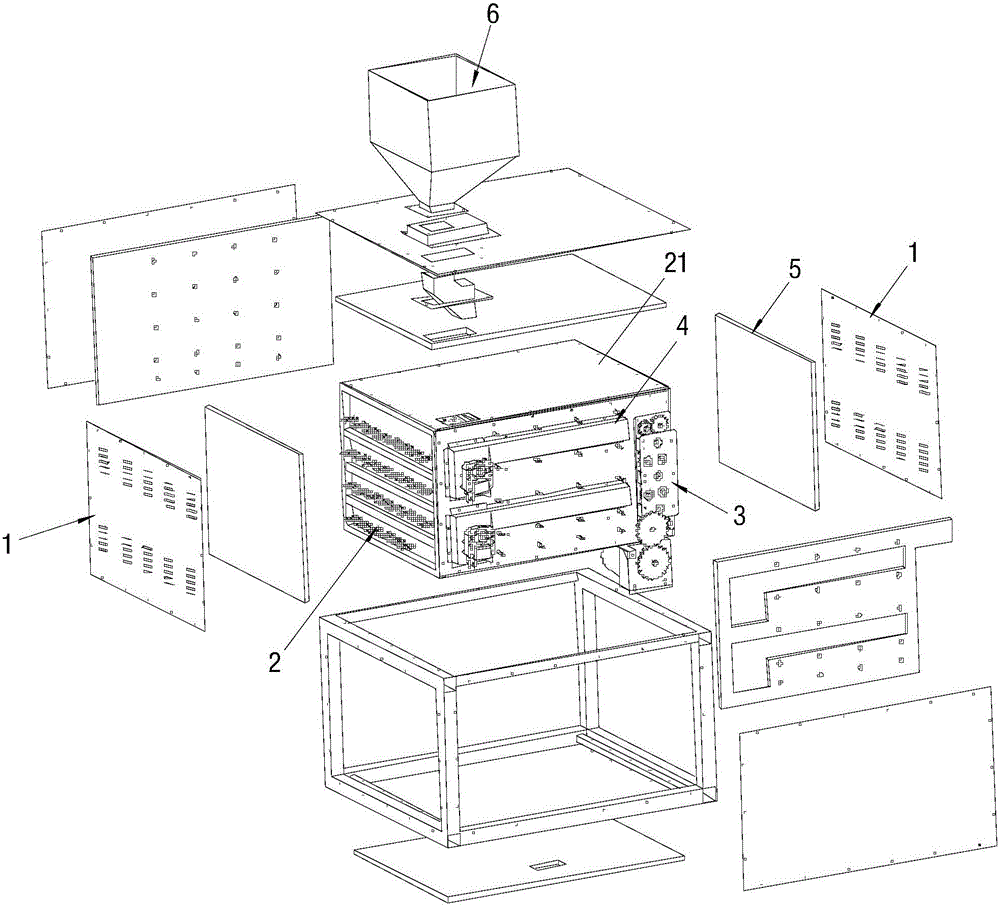

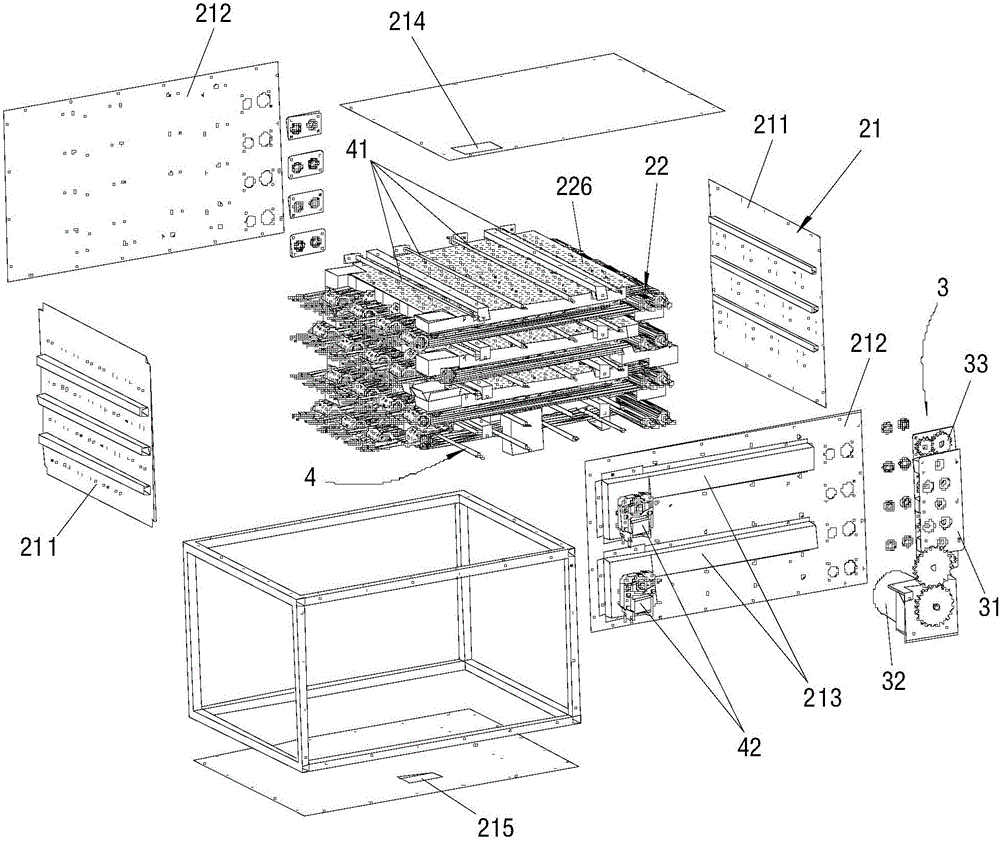

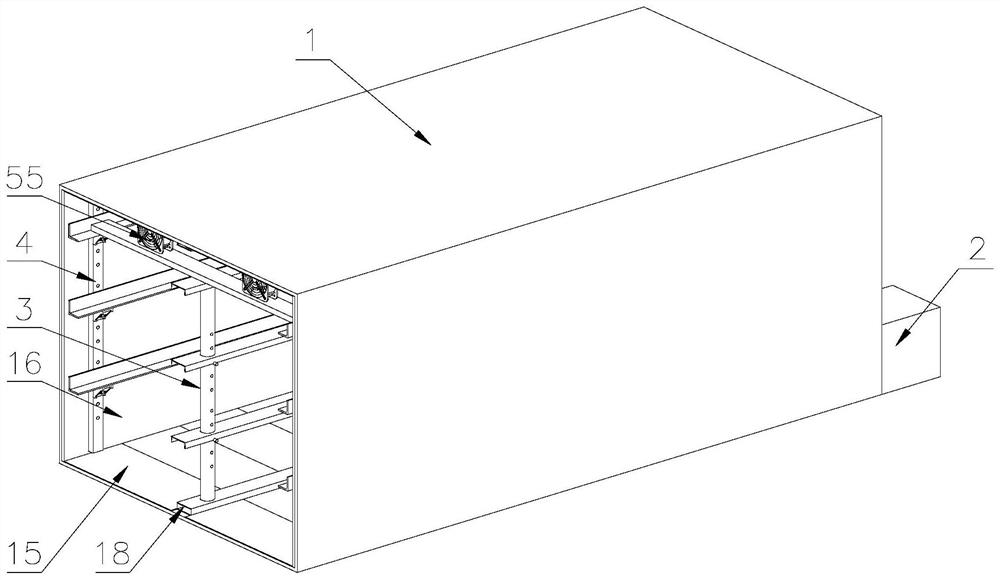

Baking device

ActiveCN106029856AReduce lossAchieve high efficiency and energy saving effectFatty-oils/fats productionFood treatmentCooking & bakingEngineering

Provided is a baking device, comprising a housing (1) and a transfer mechanism (2), a driving mechanism (3) and a baking mechanism (4) which are all arranged in the housing, wherein the baking mechanism penetrates the transfer mechanism; the transfer mechanism comprises an inner housing (2) and a plurality of transfer units (22) laminated in the inner housing at intervals and connected to the driving mechanism; the transfer paths of two adjacent transfer units are connected. The transfer unit comprises a guiding frame (225), a forward transfer element (221) and a reverse transfer element (222); the transfer directions of the forward transfer element and the reverse transfer element are opposite; and the forward transfer element and the reverse transfer element are staggered. According to the invention, the plurality of transfer units are laminated at intervals, and the transfer paths of two adjacent transfer units are connected, so that a enough long baking transfer path is realized under a certain occupation space, thereby increasing a space utilization rate, guaranteeing baking quality, and meanwhile reducing production costs.

Owner:东莞市乾道食品有限公司

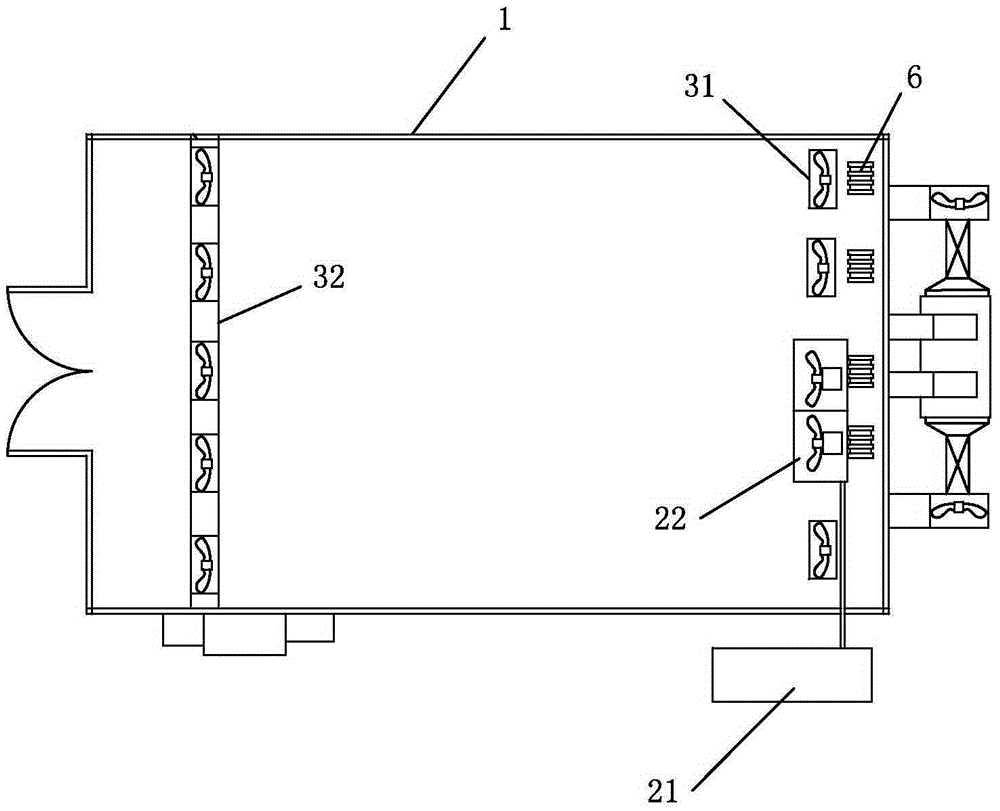

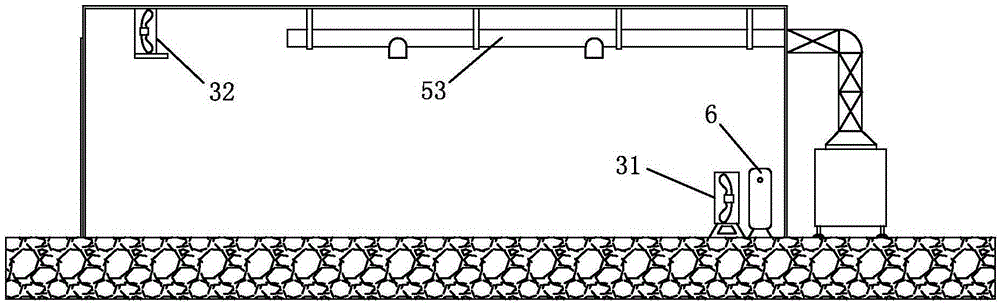

Thermal distributed tobacco curing barn

PendingCN111920075AImprove baking efficiencyImprove roast qualityTobacco preparationCold airEnvironmental engineering

The invention discloses a thermal distributed tobacco curing barn. A plurality of groups of carbon crystal plates are arranged at the bottom and the top of a curing barn body; the upper side of the back surface of the curing barn body is provided with a number of dehumidifying fans, and a cold air door is arranged on the lower side of the back surface of the curing barn body; a first tobacco hanging frame is arranged in the middle of the curing barn body, a second tobacco hanging frame is arranged on the inner walls of the two sides of the curing barn body, and a temperature sensor, a humiditysensor and the carbon crystal plates are electrically connected with a control cabinet through wires. According to the invention, a traditional hot air chamber is cancelled; the plurality of groups of carbon crystal plates are arranged at the bottom and the top of the curing barn body; heat radiation and weak convection are transmitted to the outside; heat radiation is mainly carried out throughfar infrared radiation, after the far infrared radiation is absorbed by tobacco leaves, intense molecular resonance of moisture in the tobacco leaves is caused, the molecular resonance generates heat,the temperature in the tobacco leaves is promoted to rise, the purpose of synchronously drying the moisture in the tobacco leaves and surface moisture is achieved, the tobacco leaf baking efficiencyand quality are improved, and environmental pollution is avoided.

Owner:SHANDONG LINYI TOBACCO

Processing method of dried wild fresh fishes

InactiveCN106307191AGuaranteed freshEnsure nutritionMeat/fish preservation by heatingMeat/fish preservation by coatingNutritive valuesCold air

The invention relates to a processing method of wild dried wild fresh fishes. The processing method mainly includes the following steps of raw material treating, pickling to be tasty, cold air drying, agar soaking and hot air baking, wherein during cold air drying, freshness of fresh fishes can be kept to be maximum degree when the fresh fishes are air-dried and dehydrated at the low temperature of 10-14 DEG C, and nutrients and taste are guaranteed; during hot air baking, the fresh fishes are rapidly sterilized and baked at the high temperature of 110-130 DEG C and baked and air-dried at the medium temperature of 85-95 DEG C and the medium temperature of 75-85 DEG C, the special taste is formed, and baking quality is guaranteed. The agar soaking procedure is added between the air cold drying procedure and the hot air baking procedure, in other words, the fresh fishes are soaked with an agar water solution for 30 min, and the surfaces of the fresh fishes are covered with agar; during hot air baking, it is guaranteed that nutrients of the fresh fishes are not lost, the nutritional value of the dried fishes is greatly improved, and the shelf time of the dried fishes is greatly prolonged.

Owner:三明市九龙湖生态食品有限公司

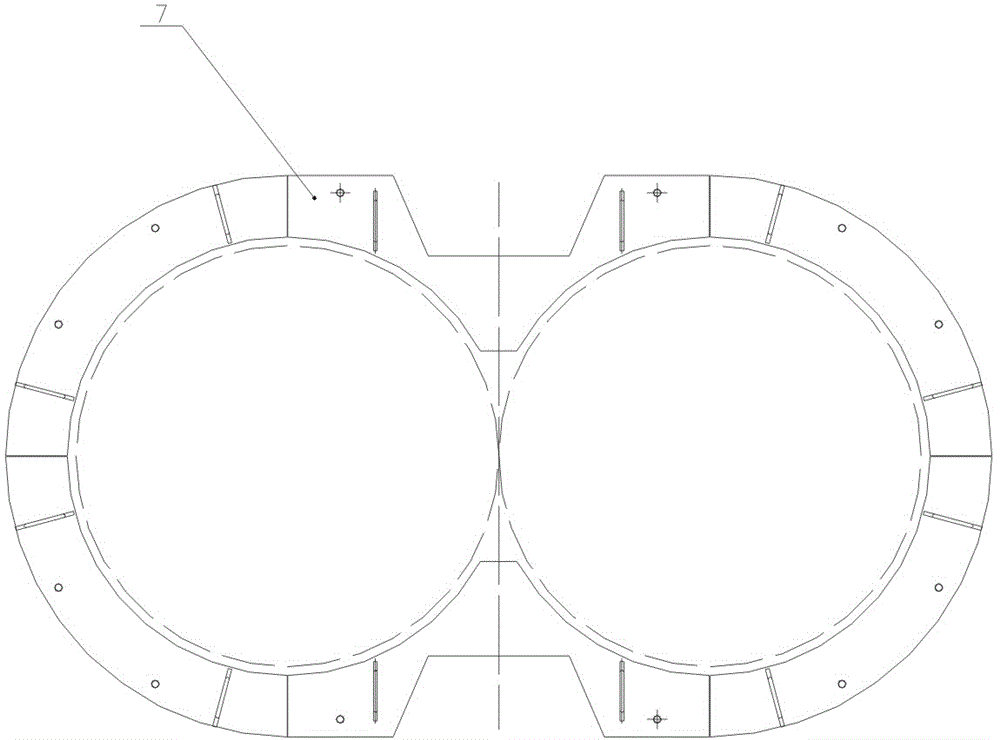

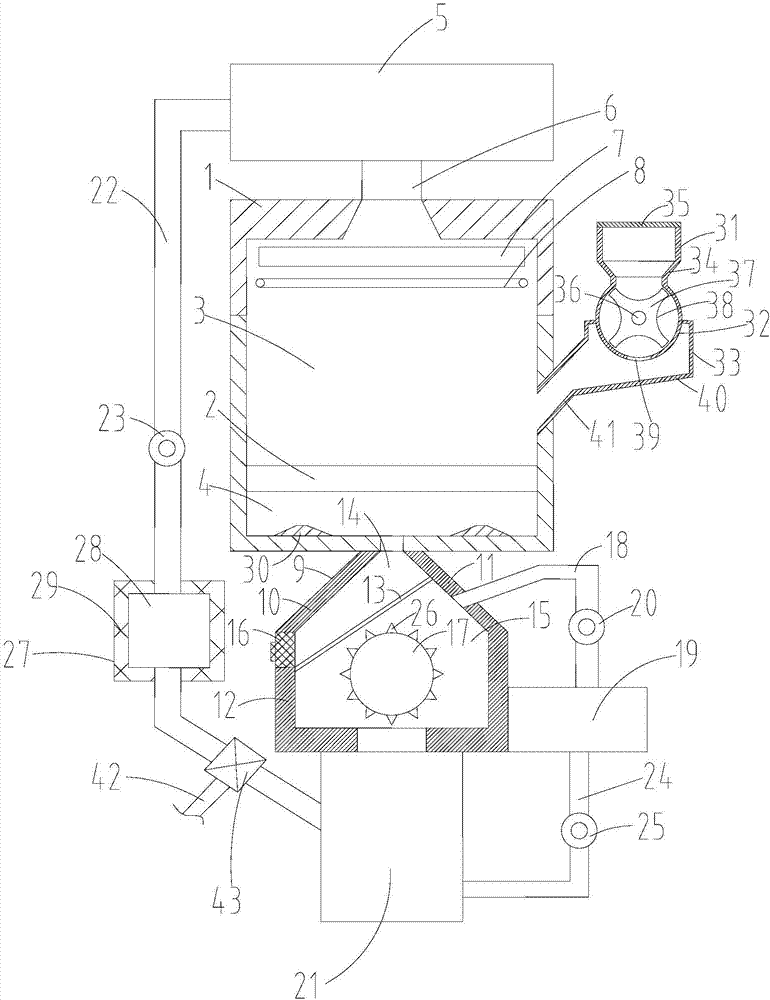

Continuous casting tundish submerged nozzle on-line roasting apparatus and roasting method

ActiveCN101879590AGuaranteed baking qualityUniform baking temperatureMelt-holding vesselsEnergy conservationMaterials science

The invention discloses a continuous casting tundish submerged nozzle on-line roasting apparatus and a roasting method, and belongs to the field of metallurgical continuous casting. The apparatus comprises a tundish roaster, an upper tundish nozzle, a nozzle quick-change mechanism, a submerged nozzle, a sealing ring, a roasting sleeve and a support frame, wherein a sealing ferrule is sleeved at the neck of the submerged nozzle, the internal diameter is in close contact with an iron cover of the submerged nozzle, the lower part of the sealing ring is provided with a roasting sleeve, the upper edge of which is in close contact with the sealing ring, and the bottom part is lifted by using the support frame. The invention has the advantages of saving a lower suction device and daily maintenance cost and reducing a large amount of cost along with simple structure. Meanwhile, the device and the method make full use of roasting heat from the tundish and save a large amount of energy medium so as to fulfill the aims of energy conservation and consumption reduction.

Owner:BEIJING SHOUGANG CO LTD

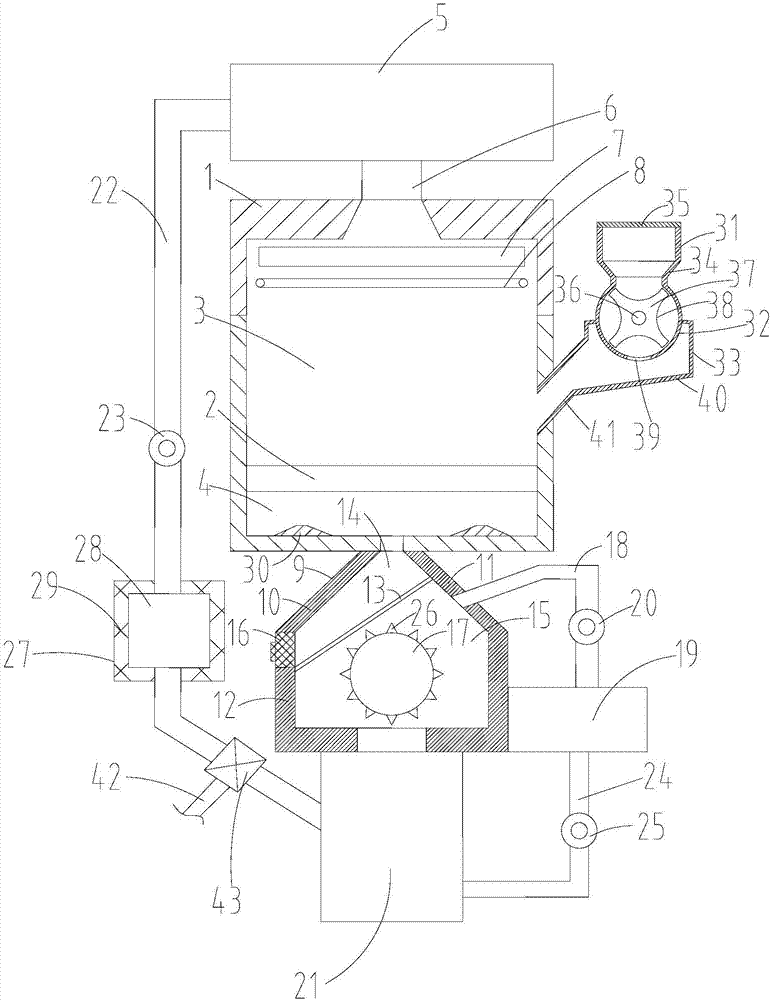

Manufacture device of apple slices

ActiveCN107114726AGuaranteed nutritional valueGuaranteed baking qualityNitrogen compoundsMetal working apparatusEngineeringManufacturing quality

The present invention discloses a manufacture device of apple slices. The manufacture device comprises a baking room. A baking machine with a hole is arranged in the baking room and divides the baking room into an upper baking room and a lower baking room. An air outlet of a nitrogen tank communicates with a top end of the upper baking room, a fan and a heating pipe are also arranged, a slice cutting machine communicates with a side wall of the upper baking room, an opening is arranged in a bottom part of the lower baking room and communicates with a washing box, a residue collecting net is inclinedly arranged in the washing box, the washing box is divided into a residue collecting chamber and a washing chamber, a water splashing wheel is arranged in the washing chamber, the washing chamber communicates with a water box via a water inlet pipe, a first water suction pump is arranged at the water inlet pipe, a separation box communicates with a bottom part of the washing chamber, one side of the separation box communicates with an air return pipe, the air return pipe communicates with the nitrogen tank, a fan is arranged at the air return pipe, the other side of the separation box communicates with the water box via a water outlet pipe, a second water suction pump is arranged at the water outlet pipe, and a filtering net is arranged at a communication place of the separation box and water outlet pipe. The manufacture device can automatically manufacture the apple slices and can ensure manufacture quality of the apple slices.

Owner:宿州速果信息科技有限公司

Continuous casting machine tundish submerged nozzle baking furnace

InactiveCN103878357BGuaranteed baking qualitySave on insulationMelt-holding vesselsMetallurgyOperation safety

The invention relates to the field of metallurgical equipment, in particular to a continuous casting machine tundish submersed nozzle baking furnace. The continuous casting machine tundish submersed nozzle baking furnace comprises a furnace body, wherein two baking chambers are arranged in the furnace body, each baking chamber is provided with a spraying nozzle, each spraying nozzle is connected with a mixing valve, each mixing valve is connected with an air inlet pipe and a fuel gas inlet pipe, each air inlet pipe and each fuel gas inlet pipe are respectively provided with a control hand valve, an installation plate is arranged at the top of each baking chamber, a clamping groove is formed in each installation plate to fix a submersed nozzle, the furnace body is provided with a furnace door, a heat-preservation layer is arranged at the inner side of the furnace door, a flame retardant layer is arranged on the inner wall of each baking chamber, a heat preservation plate is formed at the top of the furnace body and provided with openings matched with the submersed nozzles, pulleys are arranged at the bottom of the furnace body, and pothooks are arranged at the top of the furnace body. The continuous casting machine tundish submersed nozzle baking furnace has the advantages of being safe to operate, capable of meeting production requirements, capable of guaranteeing baking quality and convenient to move and transport, saving energy and the like.

Owner:JIGANG GRP

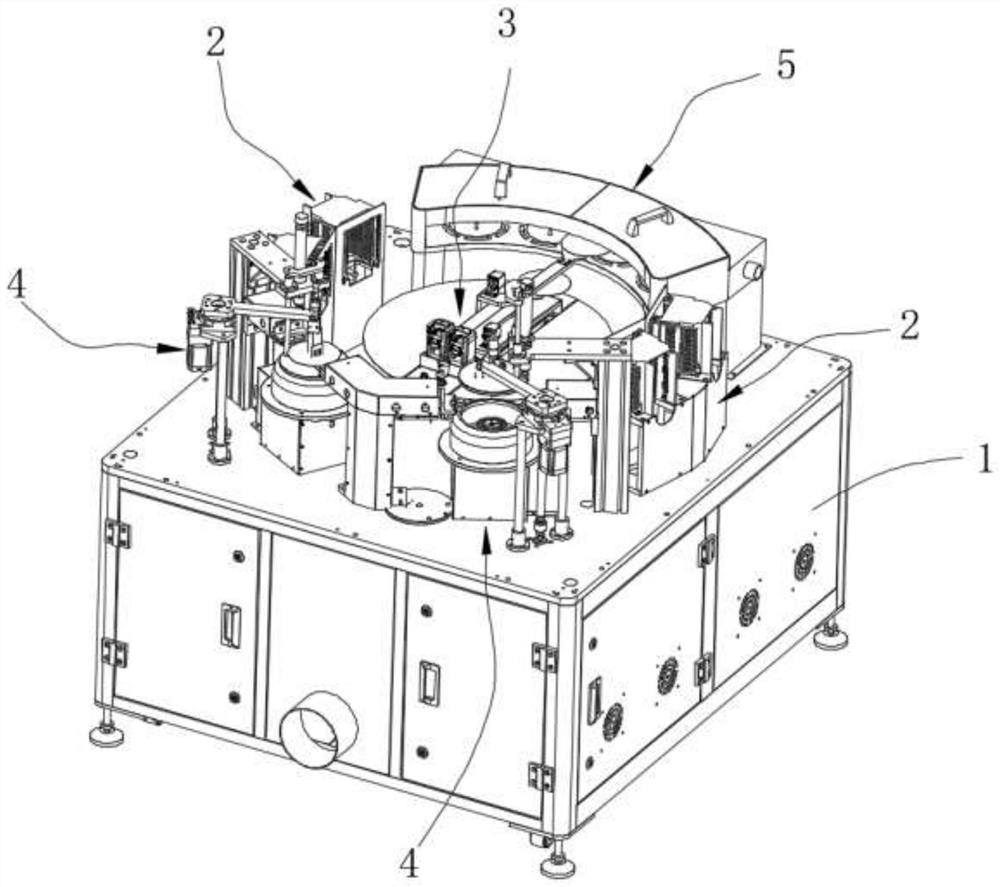

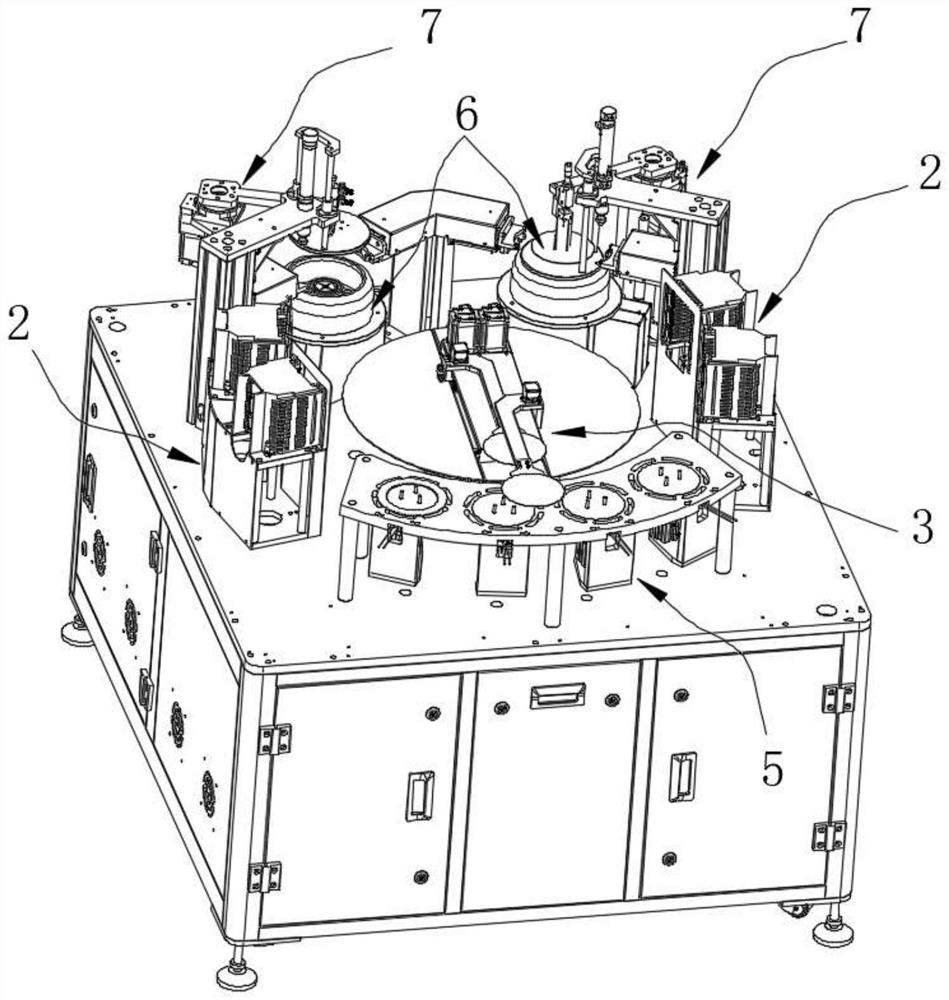

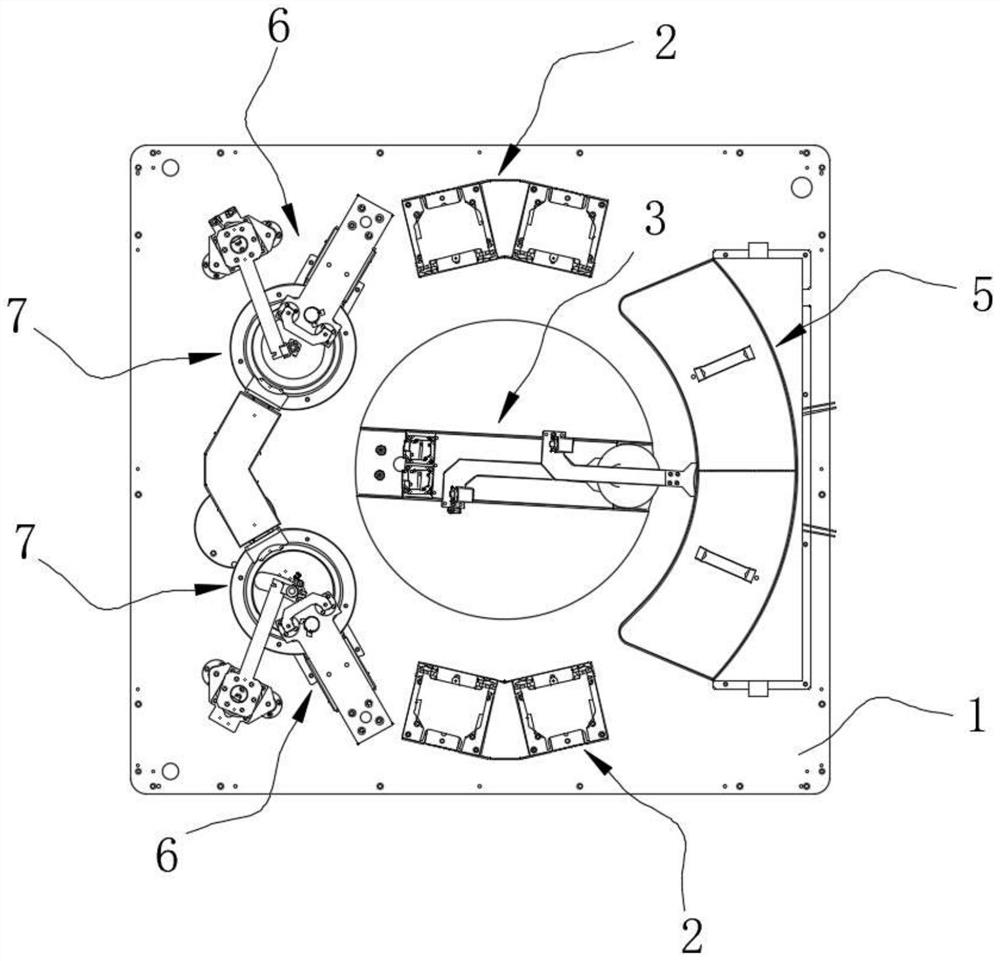

Wafer uniform glue baking machine

PendingCN114100970ARealize automatic glue applicationHigh degree of automationConveyorsPretreated surfacesWaferMechanical engineering

A wafer uniform glue baking machine disclosed by the present invention comprises a rack, the upper surface of the rack is provided with a material receiving and supplying rack, a manipulator, a uniform glue module and a baking table, the material receiving and supplying rack is used for placing a wafer, the uniform glue module comprises a gluing mechanism and a uniform glue spin-drying mechanism, the gluing mechanism is used for gluing the wafer, the uniform glue spin-drying mechanism is used for uniformly smearing glue on the wafer, and the baking table is used for baking the wafer. The baking table is used for drying the glued wafer; according to the invention, after the wafer is taken out from the material receiving and supplying frame through the manipulator, the wafer is placed on the glue uniformizing module for glue coating and uniform smearing, the wafer is transferred to the baking table after glue coating is completed, and finally the dried wafer is placed in the material receiving and supplying frame, so that automatic glue coating, glue uniformizing and baking of the wafer are realized, the automation degree of the equipment is improved, and the production efficiency is improved. According to the photoresist coating device, the coating uniformity is guaranteed, meanwhile, the thickness of the photoresist on the surface meets the requirement, then the photoresist is dried through the baking table, the baking quality is guaranteed, and the photoresist coating uniformity is further improved.

Owner:苏州康沃斯智能装备有限公司

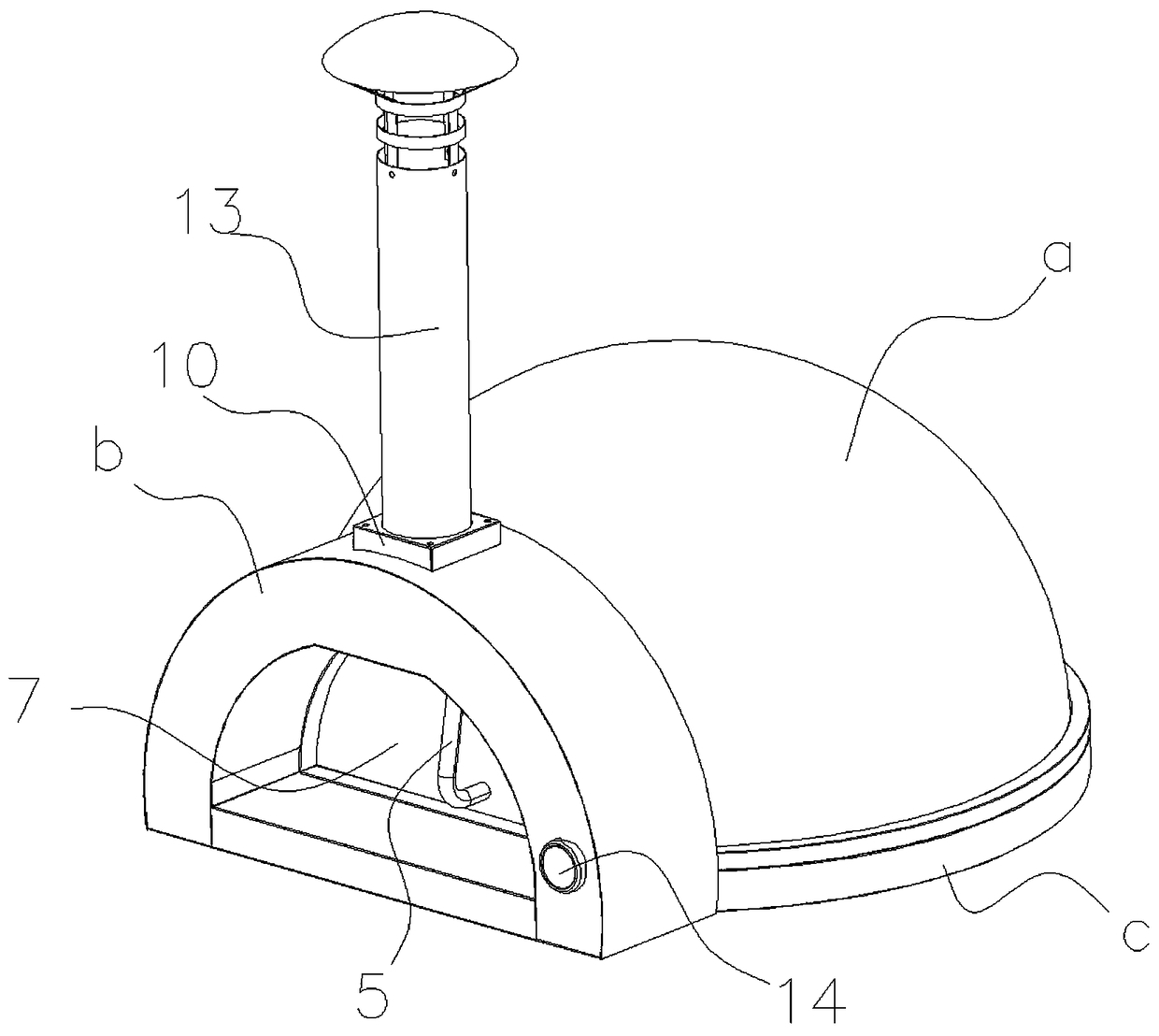

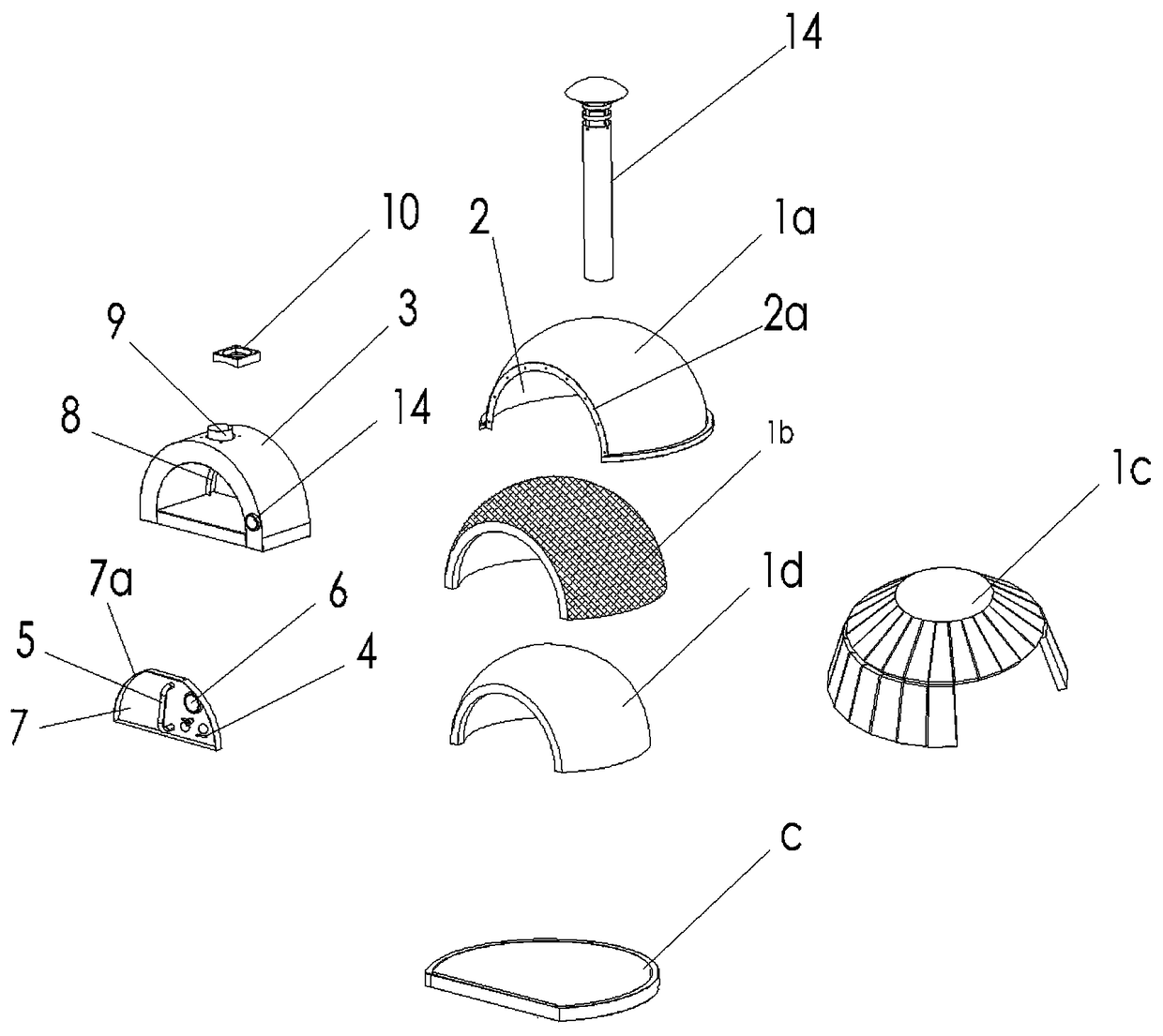

Bake oven

A bake oven is characterized in that it comprises a baking furnace section, doorway section, a chassis having a baking oven portion including a beetle-shaped housing disposed at the rear of the chassis, an arched opening at the front of a beetle-shaped shell, the beetle-like shell includes an outer metal shell, heat preservation material layer in the middle, a layer of refractory brick or clay, aleading end face of that arch-shaped open is a connecting face connected with a door portion, the door portion includes an arch-shaped door frame disposed at the front of the chassis and having a shape corresponding to the arch-shaped opening. The arch door frame body is a groove, the upper edge of the groove is connected with the connection surface of the arch opening, the groove is communicatedwith the inner cavity of the shell like a beetle, and a flue pipe communicated with the groove is connected with the top of the arch door frame. Compared with the prior art, the invention has the advantages of good heat preservation performance, easy control of baking temperature and convenience in carrying.

Owner:佛山市蹈厉金属制品有限公司

Baking method of reviving tobacco leaves of red-flower Da Jinyuan flue-cured tobacco species

ActiveCN108065447ATurn yellow fasterRaise the ratioTobacco preparationEconomic benefitsMaterials science

The invention discloses a baking method of reviving tobacco leaves of a red-flower Da Jinyuan flue-cured tobacco species. The temperature of a dry ball is adjusted to be 40-42 DEG C, the temperature of a wet ball is adjusted to be 37-38 DEG C, the leaves are sufficiently softened 6-12 hours later, the temperature of the dry ball is then adjusted to be 37-38 DEG C, the temperature of the wet ball is 35-36 DEG C, the leaves are yellowed by 80-90% 30-36 hours later, the temperature of the dry ball is adjusted to be 42 DEG C, the temperature of the wet ball is adjusted to be 35-36 DEG C, the yellow leaves are made to have blue veins and supporting strips are demounted 12-14 hours later, the temperature of the dry ball is adjusted to be 45 DEG C, the temperature of the wet ball is adjusted to be 36-37 DEG C, and the yellow leaves are made to have blue veins and tips are rolled 22-25 hours later. By means of the technical scheme, the tobacco leaves are yellowed more quickly in the baking process, and the yellowing time is shortened; the ratio of the high-grade and medium-grade tobacco leaves is increased after reviving and flue-curing, the ratio of green tobacco leaves, mixed color and messed flue-cured tobacco lamina is remarkably reduced, the economic benefits and test process of flue-cured tobacco are remarkably good, and meanwhile the baking quality of normal tobacco leaves can be ensured.

Owner:云南省烟草公司大理州公司

Process for producing spicy dried fish of fresh wild fish

InactiveCN106343401AGuaranteed freshEnsure nutritionFood ingredient as taste affecting agentMeat/fish preservation using chemicalsNutritive valuesCholesterol

The invention relates to a process for producing spicy dried fish of fresh wild fish. The process comprises the following six main steps: treating raw materials, treating the raw materials again, pickling for flavoring, airing with cold air, soaking with agar and roasting with hot air, wherein before the step of pickling for flavoring the fresh fish, the fish is soaked in cassia tea water so as to achieve the effects of removing fishy smell, clearing fire, reducing blood pressure, resisting bacteria and reducing cholesterol of fish; in the step of airing with cold air, the fresh fish can be kept fresh to the greatest degree in the process of airing and dewatering the fresh fish at the temperature of 10-14 DEG C; the step of roasting with hot air comprises the following sub-steps: rapidly sterilizing and roasting at a high temperature of 135-145 DEG C, and roasting and airing between two intermediate temperatures of 96-105 DEG C and 75-85 DEG C, so as to form unique spicy taste. Moreover, an agar soaking process is added between the steps of airing with cold air and roasting with hot air, so that an agar layer covers on the surface of the fresh fish, the nutrition of the fresh fish is not lost during roasting by hot air, the nutritive value of the dried fish is greatly improved, and the quality guarantee period is greatly prolonged.

Owner:三明市九龙湖生态食品有限公司

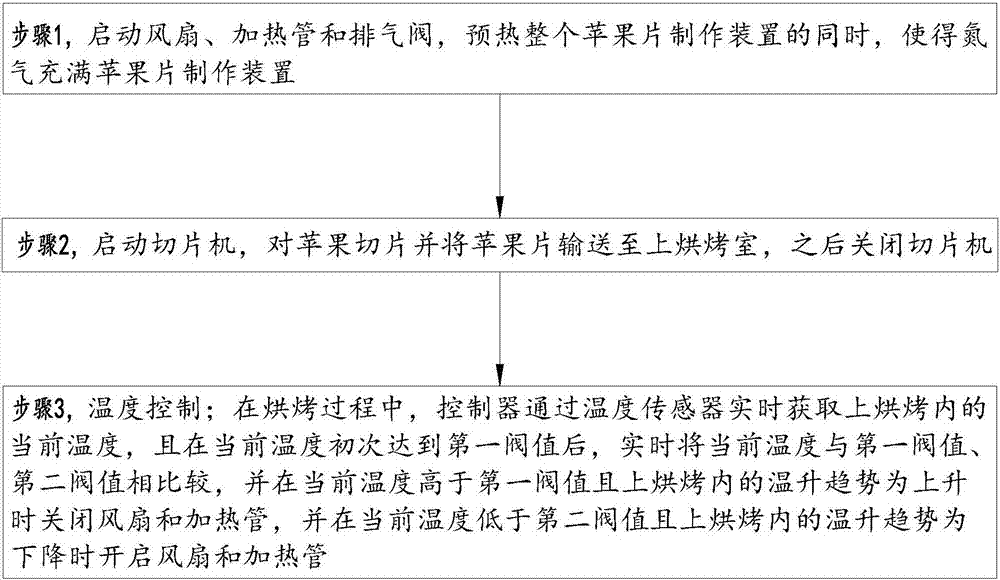

Apple slice making method

ActiveCN107410958AGuaranteed nutritional valueGuaranteed baking qualityFood scienceCooking & bakingExhaust valve

The invention discloses an apple slice making method. The apple slice making method comprises the following steps of step 1, starting a fan, a heating pipe and an exhaust valve, and preheating an entire apple slice making device, so that the apple slice making device is filled with nitrogen; step 2, starting a slicer, cutting apples to obtain the apple slices, conveying the apple slices to an upper baking chamber, and then closing the slicer; and step 3, controlling the temperature: in the baking process, acquiring the current temperature of the upper baking chamber through a temperature sensor by a controller, when the current temperature achieves a first threshold for the first time, comparing the current temperature with the first threshold and a second threshold in a real time, when the current temperature is higher than the first threshold and the temperature rise trend of the upper baking chamber rises up, closing the fan and the heating pipe, and when the current temperature is lower than the second threshold and the temperature rise trend of the upper baking chamber falls down, starting the fan and the heating pipe. According to the apple slice making method disclosed by the invention, the apple slices can be made automatically, and the making quality of the apple slices can also be guaranteed.

Owner:宿州速果信息科技有限公司

Low-temperature control process for oven baking of annular sleeve kiln

The invention discloses a low-temperature control process for oven baking of an annular sleeve kiln. Equipment such as an opening cooling fan and the like is included. A combustion chamber has ignition conditions as follows: the discharging speed is controlled to be 90 seconds; driving air pressure is adjusted to be 12-15 kpa, the revolving speed of a high temperature fan is adjusted, the negative pressure of a lower combustion chamber is controlled to be about minus 100-50 pa, and the lime cooling air volume is controlled to be 4800-5200 m<3> / h; the single air volume of a lower burner is controlled to be 140-160 m<3> / h, a gas valve is switched on, the gas flow is manually adjusted after the burner is successively ignited, the fire is controlled to be the minimum, the temperature rising condition of the lower combustion chamber is observed, and the negative pressure of the lower combustion chamber is kept to be about minus 100-50 pa constantly, and after the temperature of the lower combustion chamber tends to be stable and the temperature is maintained to be about 50-80 DEG C, the temperature rises according to a temperature rise curve. According to the control process, operation steps are clear and easy to implement, and the control difficulty of an operator in an oven baking process is effectively reduced.

Owner:NANJING MEISHAN METALLURGY DEV +1

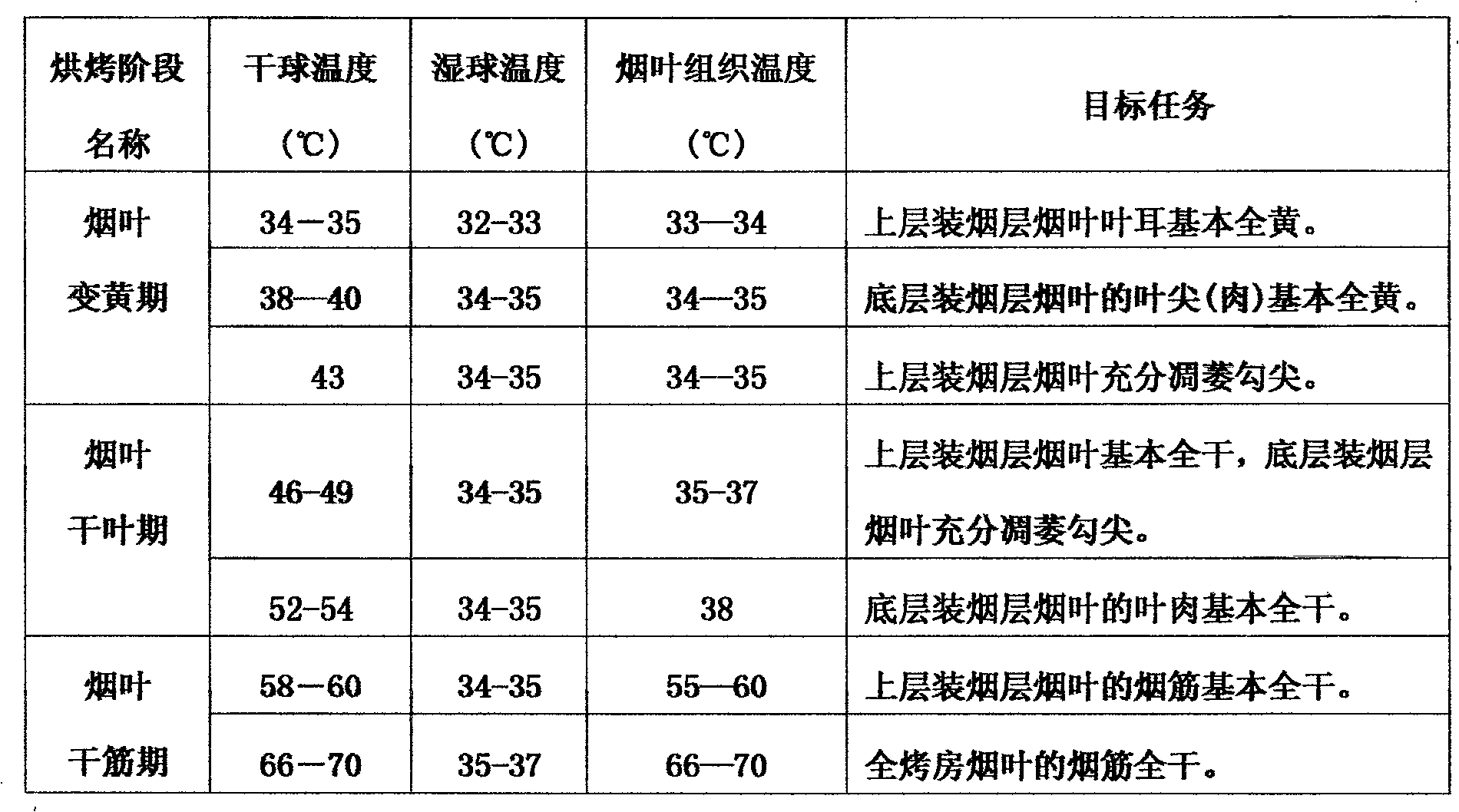

Air source heat pump type tobacco curing barn with auxiliary heat device

The invention discloses an air source heat pump type tobacco curing barn with an auxiliary heat device. The air source heat pump type tobacco curing barn comprises a tobacco containing chamber and a heating chamber arranged at one end of the tobacco containing chamber, a heat exchanger is arranged on the upper portion of an inner cavity of the heating chamber, an axial flow fan is arranged in the middle of the inner cavity of the heating chamber, the heat exchanger is connected with an air source heat pump through a pipeline, and an electric heating device is arranged between the heat exchanger (3) and the axial flow fan. According to the air source heat pump type tobacco curing barn with the auxiliary heat device, the electric heating principle is adopted, the electric heating device is additionally arranged for auxiliary heat supply based on heat supply of the air source heat pump, and the baking temperature is ensured through auxiliary heat supply of the electric heating device while the heating working efficiency of the air source heat pump is utilized, so that tobacco leaf baking failures caused by the environment temperature factor are avoided, the safe baking of tobacco leaves is guaranteed, and meanwhile the baking quality of tobacco leaves can be easily improved.

Owner:GUIZHOU UNIV

An energy-saving heat pump dehumidification drying room and its control method

ActiveCN103512342BSave energyControl operationDrying gas arrangementsDrying machines with local agitationCold airLow speed

The invention discloses an energy-saving heat pump humidity removing drying room and a control method of the drying room. The drying room comprises a room body, a heat pump assembly, a circulating fan assembly, a humidity removing assembly, a main control unit and a temperature and humidity sensor, wherein the humidity removing assembly comprises a heat exchanger, an air inlet fan and a humidity removing fan, and the air inlet fan and the humidity removing fan are respectively connected with an air regulator. When humidity removal is performed in the drying room, external air is turned into dry cold air through a heat pump host, the dry cold air enters the heat exchanger and is conveyed back into the room body after having non-direct-contact heat exchange with high-temperature and high-humidity air pumped out of the room body, and therefore energy is saved. The actual measured temperature and the actual measured humidity are compared with preset stage values, particularly, the preset stage values are divided into preset values in a shutting down stage and preset values in a starting stage, the starting stage is subdivided into a plurality of segments, firstly, the stage or the segment where the actual measured humidity is located is judged through the current humidity, then, according to the current temperature, the actual measured temperature is compared with the set temperature value in the stage or the segment, the humidity removing assembly is controlled to operate at low speed or to operate at full speed or to shut down, and therefore drying efficiency is improved, and energy consumption is reduced.

Owner:JIANGMEN HUAYAN AUTOMATION EQUIP +1

Manufacturing process of fragrant and sweet dried wild fresh fish

The invention relates to a manufacturing process of fragrant and sweet dried wild fresh fish. The manufacturing process includes the following six main steps of raw material processing, pickling to be tasty, cold air airing, agar soaking, hot air baking, honey coating and baking. During cold air airing, freshness of fresh fish can be kept to the greatest extent in the low-temperature airing dehydration process at the temperature of 10-14 DEG C; during hot air baking, the fish is fast sterilized and baked at the high temperature of 110-130 DEG C, baking and airing at the temperature of 85-95 DEG C and the temperature of 65-74 DEG C are carried out on the fish in a supplementing mode, and the process of honey coating is added between baking within the two temperature ranges, so that the dried wild fresh fish has a unique, fragrant and sweet mouthfeel, and baking quality is ensured. In addition, the process of agar soaking is added between cold air airing and hot air baking, the surface of the fresh fish is covered with an agar layer, it is ensured that nutrition of the fresh fish does not lose during hot air baking, the nutrient value of the dried fish is substantially improved, and the shelf life of the dried fish is greatly prolonged.

Owner:三明市九龙湖生态食品有限公司

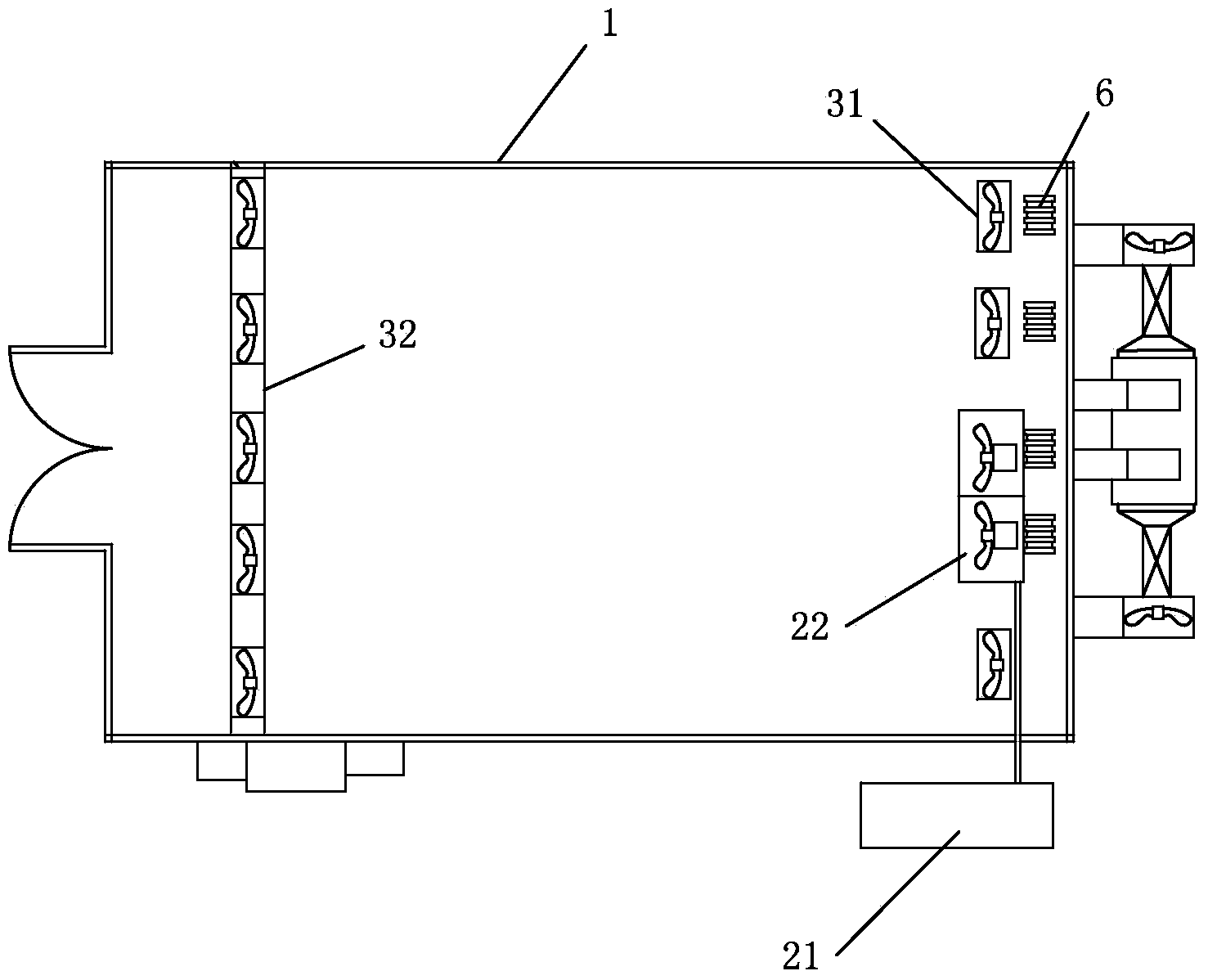

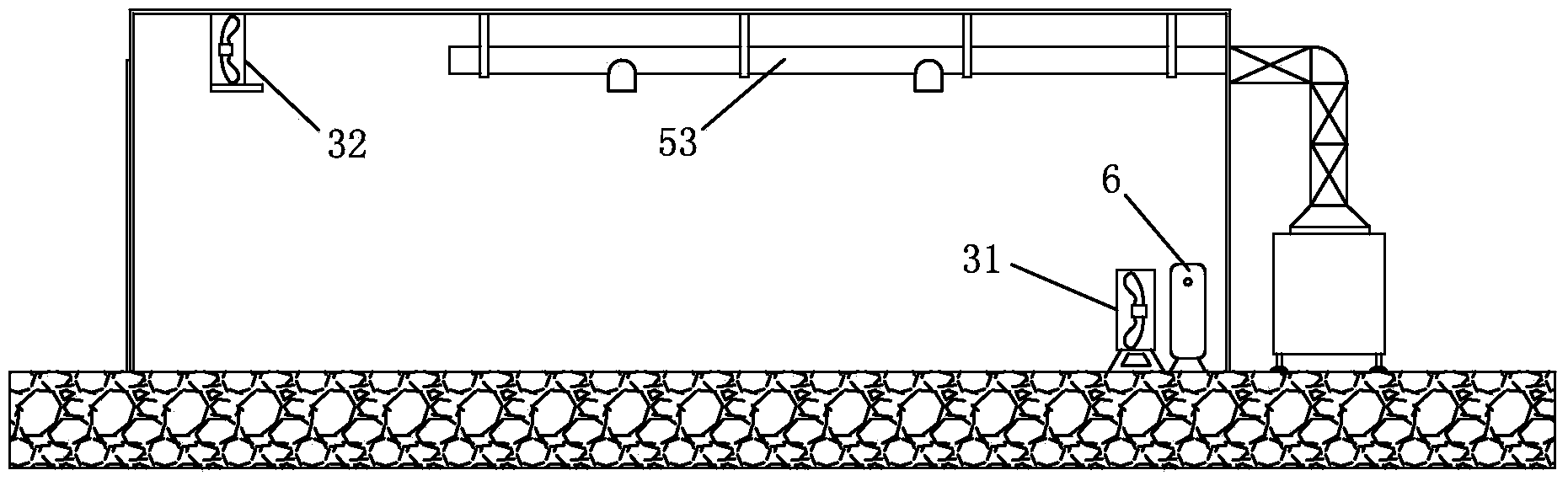

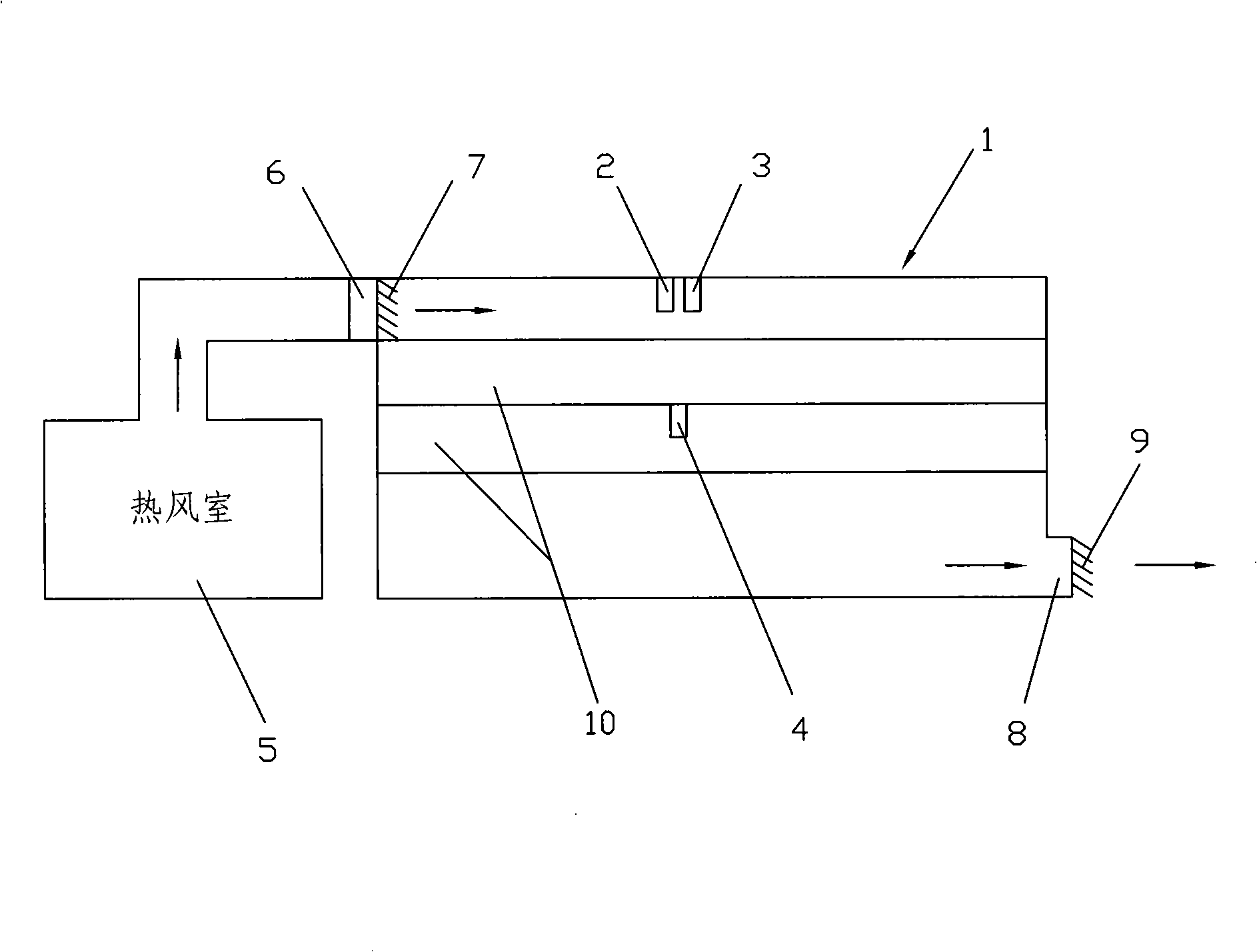

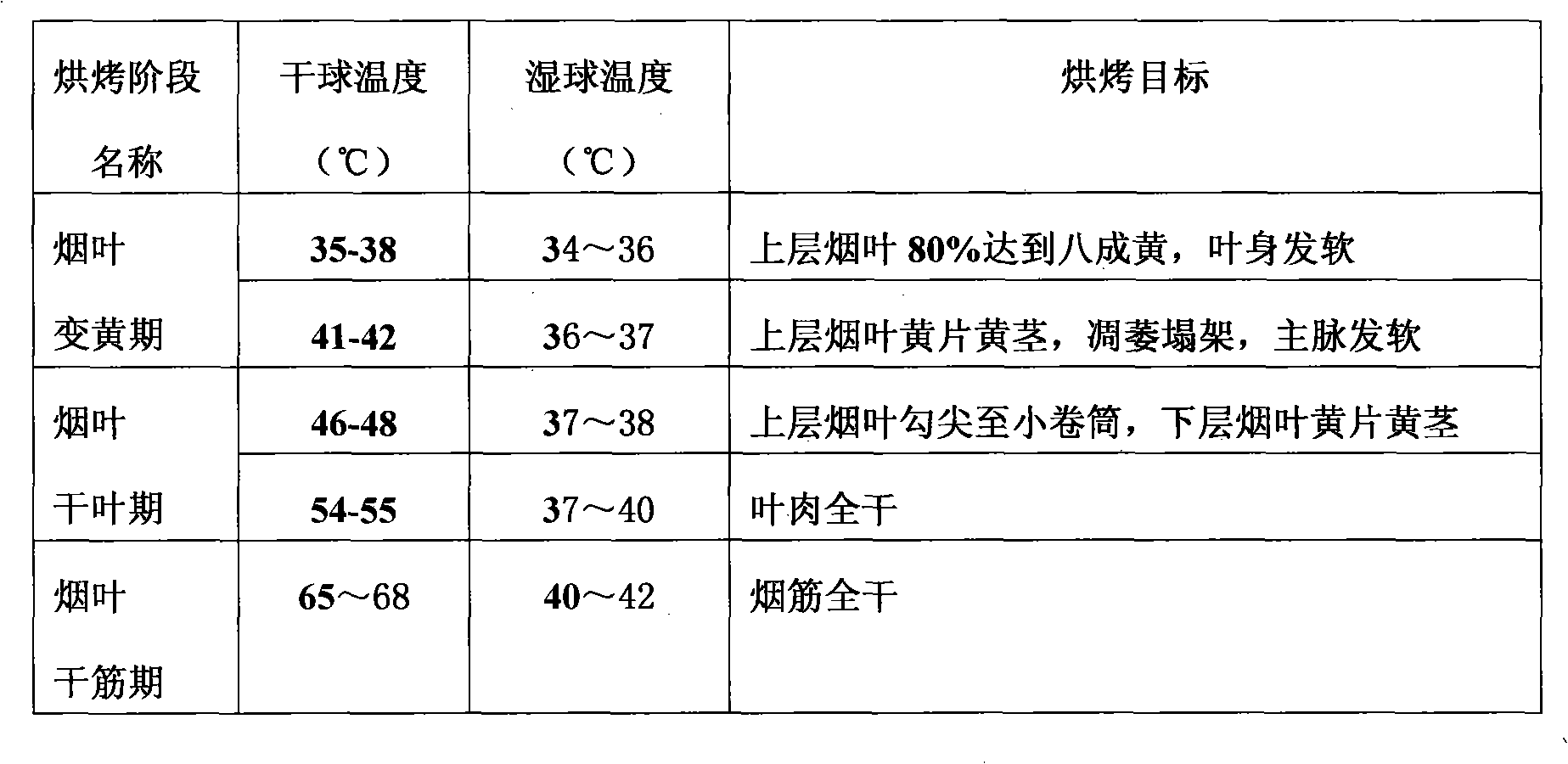

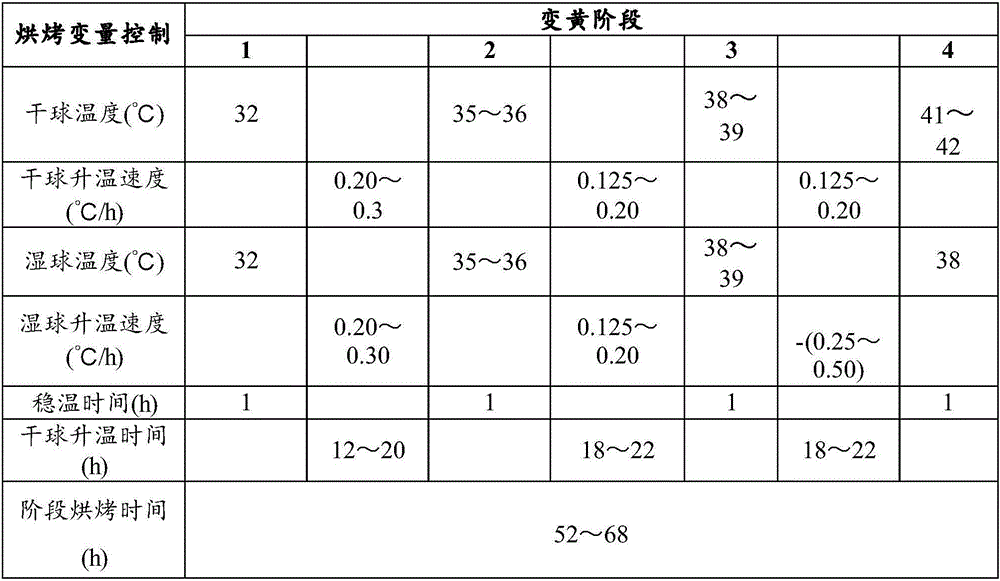

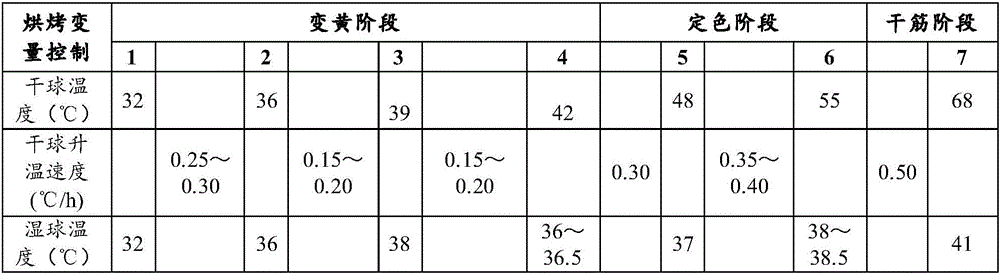

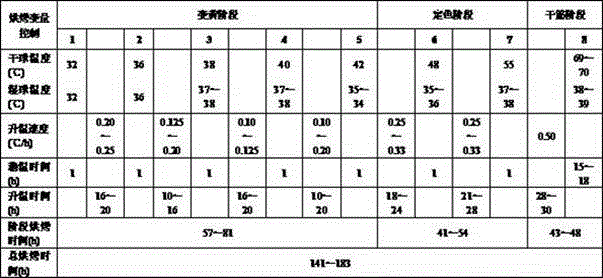

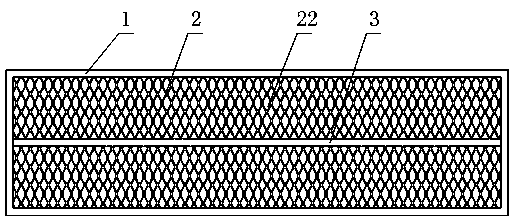

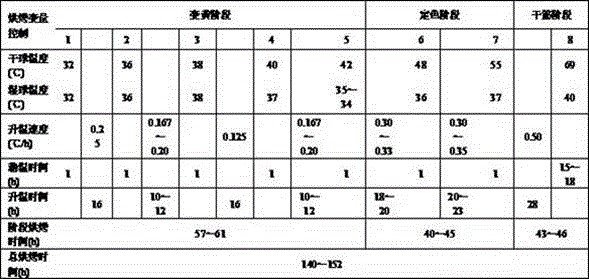

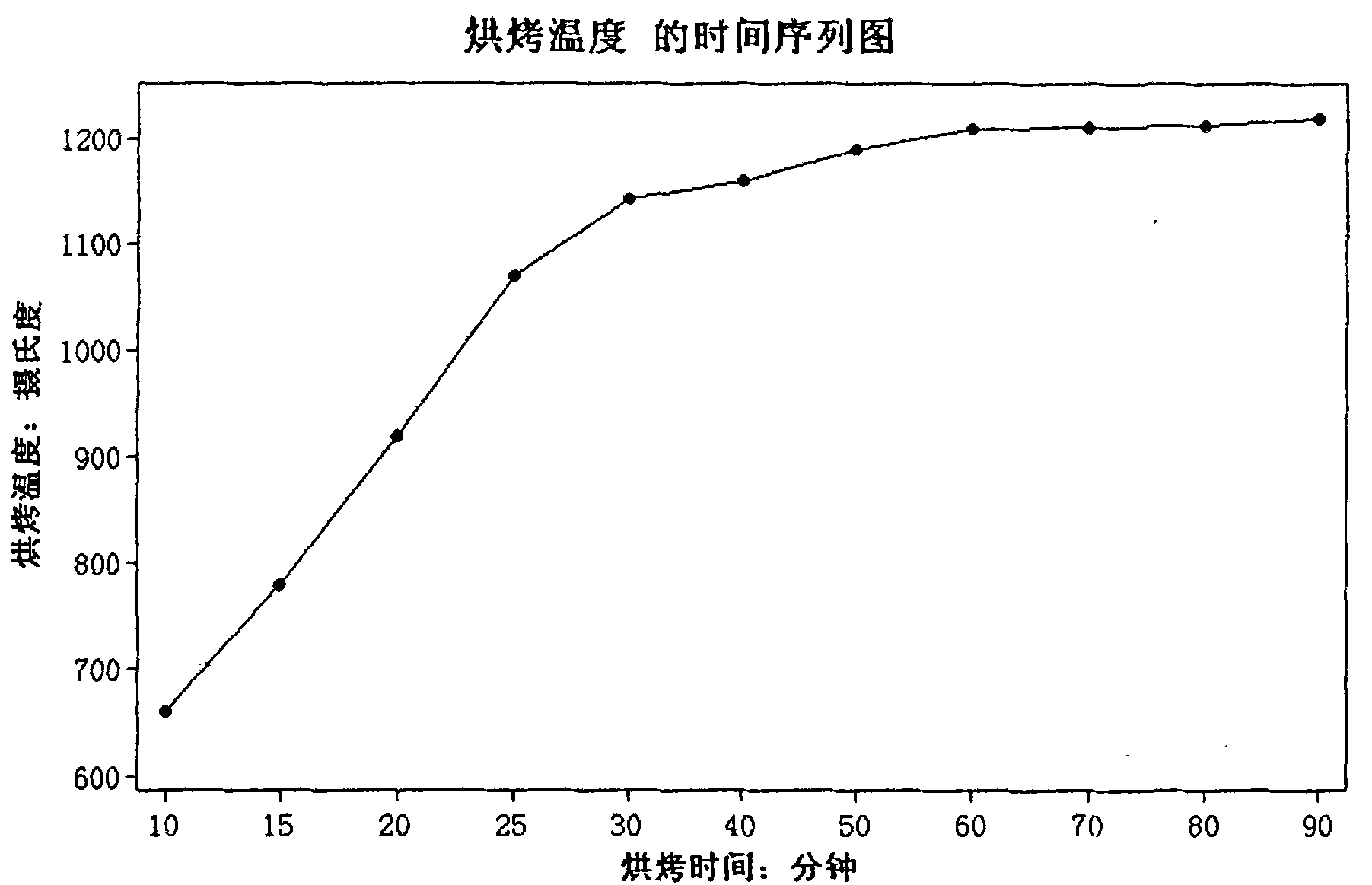

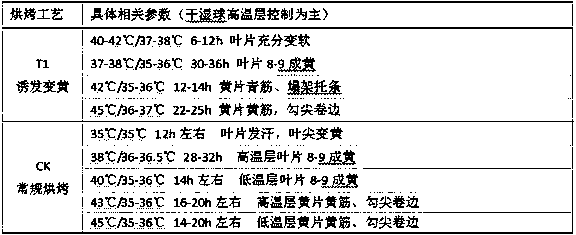

Curing method of [Honghua Dajinyuan] more-rain and low-sun-irradiation tobacco leaves

ActiveCN108095181ATurn yellow fasterShorter yellowing timeTobacco preparationEconomic benefitsEngineering

The invention discloses a curing method of [Honghua Dajinyuan] more-rain and low-sun-irradiation tobacco leaves. Conditions in a curing barn are controlled as follows in a curing process: firstly, regulating a dry-bulb temperature to 42 DEG C and a wet-bulb temperature to 38-39 DEG C, and regulating humidity for 12-20h so that the leaves are dehydrated by 25%, the tobacco leaves become soft and collapse and veins become soft; then, regulating the dry-bulb temperature to 37-38 DEG C and the wet-bulb temperature to 37-38 DEG C, preserving moisture and yellowing the leaves for 24-32h, so that theleaves are yellowed by 80-90%; regulating the dry-bulb temperature to 42 DEG C and the wet-bulb temperature to 35-36 DEG C, for 12-14h, so that blue veins of the yellow leaves appear and tips of theleaves become cuddled; and finally, regulating the dry-bulb temperature to 45 DEG C and the wet-bulb temperature to 36 DEG C, for 22-25h, so that yellow veins of the yellow leaves appear and the cuddled tips become coiled. With the application of the curing method provided by the invention, yellowing of the tobacco leaves is accelerated, yellowing time is shortened and color fixing time is shortened in the curing process, a proportion of orange smoke of the cured low-sun-irradiation tobacco leaves is increased, proportions of upper-grade and medium-grade tobacco leaves are increased, and proportions of miscellaneous-color and bad tobaccos are obviously reduced; the cured tobacco is relatively obviously good in economic benefit and test process; and meanwhile, the curing quality of normal tobacco leaves is guaranteed.

Owner:云南省烟草公司大理州公司

Multifunctional oven with automatic rotating disc

The invention discloses a multifunctional oven with an automatic rotating disc, which comprises an oven body, the rotating disc, a gridiron and a clockwork spring device, wherein a baking chamber and a combustion chamber are arranged in the oven body, the baking chamber is communicated with the combustion chamber, and the baking chamber is communicated with a smoke outlet for discharging smoke outwards; the oven body is provided with a first mounting area located on the side wall of the oven body and a second mounting area located on the bottom wall of the oven body, and the clockwork spring device is detachably mounted in the first mounting area or the second mounting area; when the clockwork spring device is detachably mounted in the first mounting area, an output shaft of the clockwork spring device extends into the baking chamber and is detachably connected with the gridiron; and when the clockwork spring device is detachably mounted in the second mounting area, an output shaft of the clockwork spring device extends into the baking chamber and is detachably connected with the rotating disc. The rotating disc or the gridiron can be driven to rotate through the clockwork spring device, so that food can be uniformly heated, the food baking efficiency and quality are effectively improved, and the food baking device has high use value.

Owner:佛山连冠科技有限公司

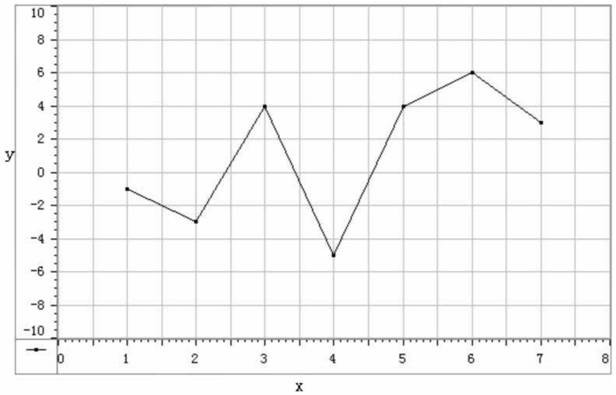

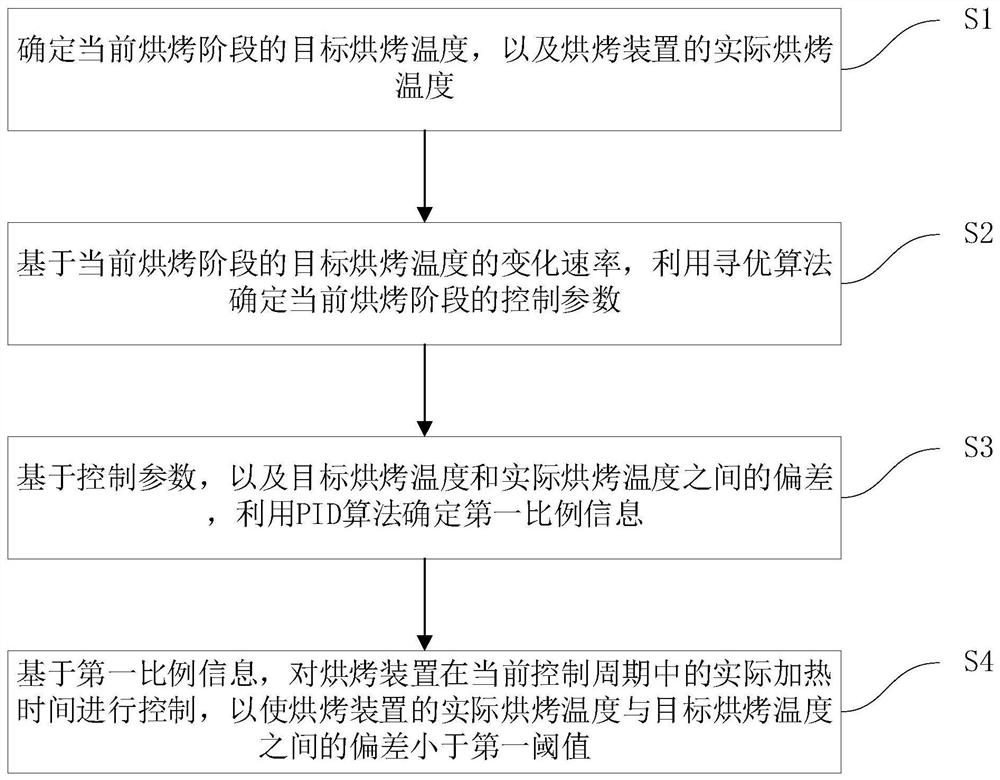

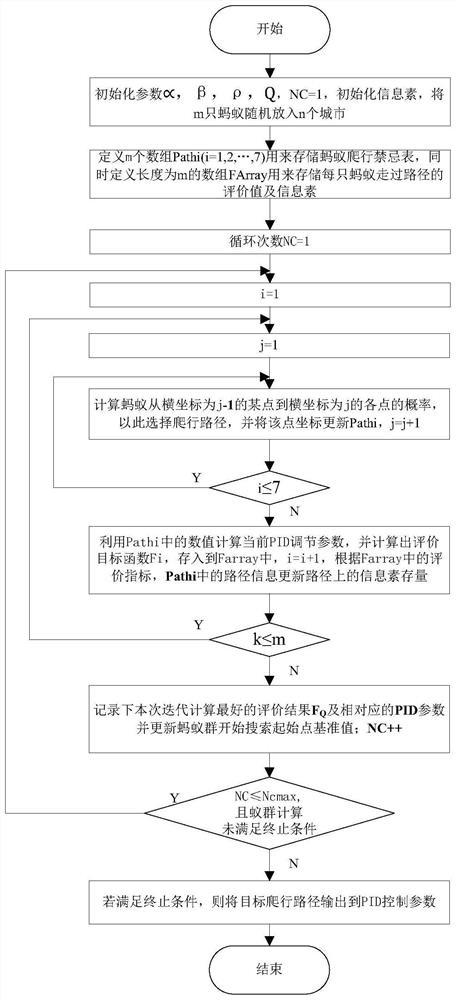

Temperature control method and device for baking device and baking system

ActiveCN113867441AGuaranteed baking qualityPrecise temperature controlFood processingTemperatue controlTemperature controlHeating time

The invention discloses a temperature control method and device for a baking device and a baking system. The method comprises the steps that the target baking temperature of the current baking stage and the actual baking temperature of the baking device are determined; based on the change rate of the target baking temperature of the current baking stage, control parameters of the current baking stage are determed by using an optimization algorithm; based on the control parameters and the deviation between the target baking temperature and the actual baking temperature, first proportion information is determined through a PID algorithm; and on the basis of the first proportion information, the actual heating time of the baking device in the current control period is controlled, so that the deviation between the actual baking temperature of the baking device and the target baking temperature is smaller than a first threshold value. The method is accurate in temperature control, high in response speed, high in stability and capable of effectively guaranteeing the baking quality of the refractory castable.

Owner:QINHUANGDAO QINYE HEAVY IND

Tobacco roasting process of intensive hothouse

The invention discloses a tobacco curing method for intensive flue-curing barns, which comprises curing step of three stages: a yellowing stage, a leaf drying stage and a stem drying stage. The difference between the method and the conventional curing method is that a second dry bulb thermometer is arranged in a tobacco loading layer for detecting the tissue temperature of tobacco leaves besides a dry bulb thermometer and a wet bulb thermometer arranged in the curing room. Fully considering the problem of heat generated by breathing of wet tobacco tissue, the tobacco curing method can controlthe temperature and the humidity in the flue-curing barn as well as the tissue temperature of the tobacco leaves. Specifically, the temperature of the wet tobacco tissue in the yellowing stage must be controlled within a change range of physiological and biochemical temperature of the wet tobacco leaves, which is the key for preventing the tobacco leaves from curing bad, thus ensuring the curing quality of intensive flue-curing barns.

Owner:杨树勋

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Curing method of [Honghua Dajinyuan] more-rain and low-sun-irradiation tobacco leaves Curing method of [Honghua Dajinyuan] more-rain and low-sun-irradiation tobacco leaves](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/935ac076-9a23-4b54-b92b-269c2aec8568/408821DEST_PATH_IMAGE004.png)

![Curing method of [Honghua Dajinyuan] more-rain and low-sun-irradiation tobacco leaves Curing method of [Honghua Dajinyuan] more-rain and low-sun-irradiation tobacco leaves](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/935ac076-9a23-4b54-b92b-269c2aec8568/567456DEST_PATH_IMAGE008.png)

![Curing method of [Honghua Dajinyuan] more-rain and low-sun-irradiation tobacco leaves Curing method of [Honghua Dajinyuan] more-rain and low-sun-irradiation tobacco leaves](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/935ac076-9a23-4b54-b92b-269c2aec8568/819576DEST_PATH_IMAGE002.png)